Sell 3d printers

How to Sell Your 3D Printer (Used & New) – Where to Sell It – 3D Printerly

Selling your 3D printer can be tough but there are some strategies that you can use to sell your used 3D printer. This article will help you figure out the places where you can sell your 3D printer as well as how to sell it.

To sell your 3D printer, you can try to sell it locally to places such as a community college, an engineering organization, or try and pitch it to another hobbyist. Many people choose to sell their 3D printers online in general marketplaces like eBay and Gumtree, as well as Facebook and even forums.

There is more information that you’ll want to know about selling your 3D printer so keep on reading to find out.

Where to Sell Your 3D Printer

Selling your used 3D printer can be an easy thing to do if you check out the right places both online and in physical stores. Here is a list of places where you can sell your used 3D printer which I have compiled for you.

1. General Market Place Websites

You can check out general marketplace sites such as eBay, Gumtree, and Craigslist (choose your location). This is a great platform to sell your old 3D printer as you get the opportunity to display your printer to a vast audience.

You would still have to ship the printer depending on the arrangement. They can either pick it up in person if they are willing to travel or you pack it up and send it out to them.

However, you should get enough information about the terms and conditions of the platform you choose as they have different policies. Some of them take commissions off sales and you should factor that in.

For instance, you will not be able to sell on eBay if you don’t have a verified address or if your country or region is not among the listed countries.

Another thing is, once you make a sale, you pay eBay about 9% of the selling price and you also pay a fee for listing your item which is a fixed-price listing fee.

Unlike eBay, you can list your used 3D printer for free on Gumtree so you can keep the full sale price. If you choose to, they offer paid options that let you increase your visibility to potential buyers.

Craigslist gives the chance of keeping the full sale price as there are no extra charges either for listing or making a sale. You can just make a post with the 3D printer details and wait for engagement or responses.

The general marketplace websites are proven and effective places to sell your items as many users are known to have successfully sold their old 3D printers there.

Do keep in mind that people will try to make you offers so have a price range in mind when you go to sell your machine. Maybe you can throw in some accessories like filament and spare nozzles for negotiating power.

Remember to keep safe when using these online marketplaces if you are meeting people in person.

2. 3D Printing Forums

Even though 3D printing forums are commonly used as platforms where users connect and share their 3D printing experiences, you can also sell your 3D printer on these platforms.

Here, you can get your old 3D printers right in front of the right community that may need it. You have a higher chance of selling it off since this is a gathering of actual users who are more involved in 3D printing and creation.

However, you may not be able to upload photos or post ads on some 3D printing forums as these actions may be restricted. You may also have to message people on the forum by sending them a direct message which may be time-consuming.

You can take advantage of the forums to both connect and cart off your used 3D printer.

3. Facebook Market Place

The Facebook marketplace is another platform where you can sell your used 3D printer. A user mentioned how they sold their Prusa 3D printer without hassle on a Prusa Facebook group.

You can also contact local businesses on Facebook that rent out used 3D printers to sell yours since they are always looking for units to buy. Another user recalled how they sold a PrintrBot 3D printer in no time by simply pinging them up.

You can have immediate results on Facebook as you have access to an unlimited number of users and 3D printers available for sale.

A Facebook group by Vincent Puthoff with about 11,000 members called 3D Printers Buy Sell Trade connects 3D printer buyers and sellers. All you have to do is join the group and post your 3D printer with a price and description and wait for responses.

How to Sell Your 3D Printer

Your used 3D printer may not look so new or may be a bit worn out but there are certain procedures that are needed if you want to sell your used 3D printer. The first thing you want to do is to get your printer in a good shape since it is fairly used.

You also want to make sure that it is well functioning as buyers may want to test it out before offering to buy it.

After ensuring that it is in a good state, you can try to box it up either in a new unlabeled box or the box or package that came with the printer if it is still in a good and presentable state. This is so it can be easily sent out for delivery if your buyer is not in your region or country.

This is so it can be easily sent out for delivery if your buyer is not in your region or country.

This is also where you ensure that you pack all the parts that came with your printer if they are still available or in a good shape. There are some 3D printers that come with extra screws and parts so may want to pack up all of that too.

Then find a good platform from one of the marketplaces listed above where you can easily list your printer for sale. As mentioned earlier, you should ensure to check out the policies and terms of the marketplace before making your choice.

A user suggested returning your 3D printer to the place you bought it from and that way you can have your money back for the printer. Most companies also have warranties and you may be able to take it back if you are still within the given timeframe if there are issues.

You can also decide to join various 3D printing groups on social media where you can put up your printer for sale.

Is Owning a 3D Printer Illegal?

No, it is absolutely legal to own a 3D printer. There are no laws against owning a 3D printer in all countries of the world including countries like China, Iran, North, South Korea, and many others where one can be tempted to think that it is illegal.

There are no laws against owning a 3D printer in all countries of the world including countries like China, Iran, North, South Korea, and many others where one can be tempted to think that it is illegal.

3D printers have proven to be very useful to society and even in the medical space as they are used in printing prosthetics so they may not be easily written off.

It is also not voluntary to get a license to own or use a 3D printer.

You may only have to be careful with the models you 3D print as there are laws surrounding this especially when they are models that are owned by a licensed 3D printing company or registered works of private individuals.

How To Sell a Used 3D Printer (5 Best Places) – Printing It 3D

Gadgets and devices like cameras, laptops, and gaming consoles continuously evolve, with manufacturers endlessly churning out updates and better versions. The same goes for 3D printers. So if you want to sell your current 3D printer because you’re eyeing to upgrade to a better model or because of any other reason, it helps to know the best places to sell it.

You can sell a used 3D printer online or offline. To sell it online, you need to post or list it on trading websites, forums, or social media platforms. The five best places to sell a used 3D printer online are:

- Craigslist

- eBay

- Facebook (groups or marketplace)

- 3D printing forums

Read on as we talk about all the best places to sell your used 3D printer in more detail. You can also sell it in places other than on online platforms. I will also share with you some tips on how you can put your 3D printer up for sale.

1. Craigslist

Craigslist is a popular classified advertisements website where many people buy and sell all sorts of stuff. The site has dedicated sections for jobs, services, housing, gigs, items wanted, and items for sale, among many others. Initially based in the U.S., Craigslist now has a presence in many other countries. Some cities and regions also have their own Craigslist sites.

Some cities and regions also have their own Craigslist sites.

Craigslist is relatively a breeze to use and navigate, and listing items is easy and quick. The platform makes selling easy, too, even if we’re talking about large and high-value items. And because its regional audience creates a local community, you can sell your 3D printer to someone within your area. That means you no longer have to add shipping costs to your item.

2. eBay

eBay started out as a site where sellers can trade or auction off rare and hard-to-find items, and buyers purchase or bid on these items. It later became a global marketplace where people could buy and sell almost anything.

If your used 3D printer is now a hard-to-find model and you know many people are looking for them, you would want to sell it to the highest bidder. You can also find a potential buyer to purchase it immediately.

3. Reddit

Reddit is more than just a social media platform and discussion site. It’s also a web content rating and social news aggregation website. One cool thing about Reddit is that it has “Subreddits,” specific online communities within the site dedicated to a particular topic or interest. You can sell your used 3D printer in certain Subreddits.

One cool thing about Reddit is that it has “Subreddits,” specific online communities within the site dedicated to a particular topic or interest. You can sell your used 3D printer in certain Subreddits.

However, be careful when posting about your item in a Subreddit because not all of them allow direct for-sale threads. For instance, while there’s a Subreddit for 3D printing hobbyists and enthusiasts of all skill levels, you’re not allowed to create a thread offering your used 3D printer. You can try to sell it through an appropriate comment in such Subreddits, but you need to be very careful that your comment doesn’t turn into or qualify as spam.

As such, you’ll have to look for the Subreddits that were made for buy and sell or trading, such as Hardware Swap and Deals Reddit.

4. Facebook Groups or Marketplace

One of the best things about Facebook is that you have access to groups and marketplaces where you can sell pre-loved items. One of these places is the 3D Printers Buy Sell Trade group.

Ask to join such groups, and then you can post an ad for your used 3D printer so other members can see it and send you private messages or comment on your post if they’re interested. There are also more localized groups and marketplaces that cater to your area, making it easier for you to sell your printer.

This option is really great if Facebook is your social media platform of choice and you’re always on it. This way, you no longer have to log into and check other sites just to see if somebody is inquiring about your listing.

Of course, there’s always our email for this kind of notification, but if you get tons of emails every day, especially from work, it can add to the clutter.

5. 3D Printing Forums

If you belong to 3D printing forums and communities, you can try listing your used 3D printer in the marketplace section. Or, if there’s no specific section for trading, try making a thread directly, provided that the forum allows for-sale posts.

The good thing about this particular option is that the people in these forums are interested in 3D printing and familiar with the materials and equipment.

You could sign up with 3D Print Board, which has a wealth of information about the 3D printing industry. This forum has over 60,000 members, with thousands of users being online at any given time. It has a General 3D Printing Marketplace section, where members are allowed to buy, sell, or trade 3D printers, printer parts, filament, and other related merchandise.

Other forums you can check out include 3D Printers Forum and 3D Print Forums.

Other Options for Selling a Used 3D Printer Online

If you’re on various social media platforms and have a lot of friends or social media contacts who are into crafts or making models and prototypes, it’s also a good idea to offer it to them first.

For example, you can take a photo and post it on your wall, timeline, or page on Facebook or Instagram. You can even Tweet about it. It’s always a nice thought that your beloved printer that has served you well goes to someone who’ll take good care of it.

There are also classified ads websites with more local scopes that allow you to look into such sites for the city, state, or country you’re in. For instance, there’s Gumtree in the UK, which is also available in Australia, South Africa, Poland, Germany, and Italy.

For instance, there’s Gumtree in the UK, which is also available in Australia, South Africa, Poland, Germany, and Italy.

You can also try 3D printing websites that allow you to list your used 3D printer, like 3D Printer Boom. Or sites that allow you to trade machines, equipment, and computer parts like Machine Seeker.

Where To Sell a Used 3D Printer Offline

The best place to sell your used 3D printer depends on what type of printer it is. According to users on Quora, if you’re talking about a hobbyist or enthusiast printer, or even a cheaper and small-scale industrial one, you can sell it online, such as through Craigslist or Facebook marketplace. This way, you and your buyer don’t have to worry about logistics or delivery.

However, if it’s a professional or heavy-duty industrial 3D printer, the best option is to sell it to a local community college. You can also look for architecture firms or art and design schools in your area and send them a message or set an appointment to visit and show them what you’re offering. You might also know of a local business that would benefit from having such equipment.

You might also know of a local business that would benefit from having such equipment.

Challenges of Selling a Used 3D Printer

Some people on Quora advise against selling a used hobby-level 3D printer online if you expect good value out of it. You’d be lucky to get a third of the original value of your printer if it’s in excellent condition and you haven’t used it too much.

Moreover, 3D printers at this level move fast, and people can get this type of machinery cheap from China. As such, if you sell an old 3D printer to earn money for whatever reason, you can get far more from actually printing 3D objects with it.

Selling a used 3D printer also has other challenges, especially when potential buyers are kind of wary or cautious. For one, unlike a used car, a used 3D printer won’t allow the new buyer to get a comprehensive record of its service history, including how extensively it has been used and for what purpose. So buyers can only trust your word, and it better matches the printer’s general working condition when they use it.

A potential buyer might also hesitate to buy it without knowing for sure that the printer isn’t yet close to the end of its product cycle. Will they be able to get firmware updates? What happens if they would need to get spare parts?

Another thing that could make selling a used 3D printer difficult for you is if the manufacturer’s warranty period has elapsed. If that’s the case, it’s another chip off the price tag.

Tips on How To Sell a Used 3D Printer

Here are some tips on how to successfully sell your used 3D printer:

Provide 3D Printer Information and Specs

It’s good practice for buyers to do some research before purchasing any gadget or equipment. So make it easy for potential buyers to do that by providing relevant information and the specs for the exact 3D printer model you’re selling. This way, your post or listing will serve as a one-stop-shop for them, and they wouldn’t need to search and look it up. You can also provide links to user reviews about the printer.

Aside from the model specs, you also need to provide truthful information regarding your use of the printer and its history. It includes when you bought it or how old the printer is, how much you have used it, the kind of maintenance and repair work it has received, the issues you’ve encountered while printing, and why you’re selling it.

This way, you’ll give any potential buyer an insight into the printer’s general condition and an idea of what to expect even before they actually see or use the item. You would also let interested buyers determine whether the price you’re asking is fair and reasonable.

Allow Interested Buyers To Inspect Your 3D Printer

It helps to indicate in your post or listing that you’re open to having potential buyers check your used 3D printer. This would prove to them that you’re selling a used product in good faith.

Besides, it’s also another good practice for buyers to inspect and test a 3D printer, especially if we’re talking about a professional- or industrial-level unit that still costs hundreds or thousands of dollars even if used.

Facilitate the Inspection

When the potential buyer is there to check your used 3D printer, you should facilitate the inspection. Do it in a step-by-step manner and encourage the buyer to take their own inspection notes. Ideally, here’s how it should go:

- Show them the print head. Demonstrate how the print head can be moved easily by hand with the power turned off.

- Show them the frame. It should still be sturdy and must not have any prior damage.

- Print a quick test object. Make sure to print using a fast speed setting to highlight any mechanical issues or lack thereof. And when the print is done, use a pair of calipers and verify if the quality is good and the size is accurate.

- Try to change the filament. This is to show the buyers that there are no problems like stripped filament.

- Let the buyers check the heated bed’s temperature. This way, you’ll show them that the heat is distributed evenly.

- Talk the buyers through the printer’s history. That should include the maintenance works done and the upgrades.

Tell Potential Buyers What They Can Expect Post-Sale

Tell them the truth if the buyer asks whether you can offer troubleshooting support even after the sale. If you can, let them know the best way to contact you and the extent of support or advice you can give. If you can’t, give recommendations on who to call. You may want to provide them with the name and contact number of your maintenance and repair company.

Key Takeaways

Many online buy-and-sell or trading platforms allow you to put up used and pre-loved items for sale. People looking for bargains and specific pre-loved items purposely check out these sites, so you have a good chance of selling your 3D printer to whoever needs it.

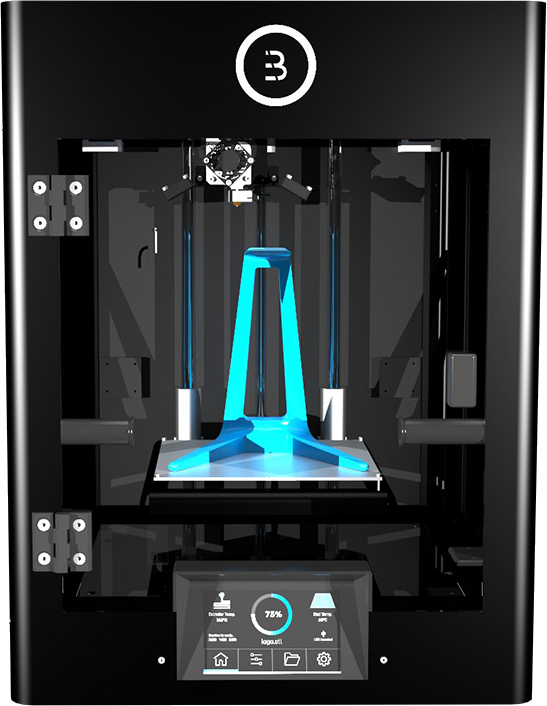

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer additive machines produce objects from high-strength thermoplastics and are designed for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts automotive, shipbuilding and oil and gas industries

Creation of objects of exterior and interior design and design products for construction, production of facing materials

Production of functional prototypes for R&D and design bureaus in mechanical engineering, shipbuilding and aircraft construction

Production of large-sized wax or burnt master models for metal casting and metallurgy or trolleys)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

3D printer Discovery 3D Printer 2021

Compact solution for 3D printing of large-sized products

Read more

3D printer Super Discovery Compact 9000

Learn more

Super Discovery 3D Printer Hybrid

Advantages of granule and filament printing in one machine

More details

Super Discovery 3D Printer 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer Workstation 3D Printer

3D large format printer combination: unique 2 in 1 combination and milling systems

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is elastic, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling a part after printing

Accelerate the creation of new products thanks to the dual extrusion system

Repair and replacement of products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of irregularities

Case Studies

FDM Airbus Spare Parts 3D Printing

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low thermal expansion coefficient.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

The solid statue is printed and is 1. 87 m high and 45 kg in weight.

87 m high and 45 kg in weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.

A prototype of a modular toilet has been printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Ventilation grill printed 59 x 89 x 4. 5 cm and weight 3500 g.

5 cm and weight 3500 g.

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlayer adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

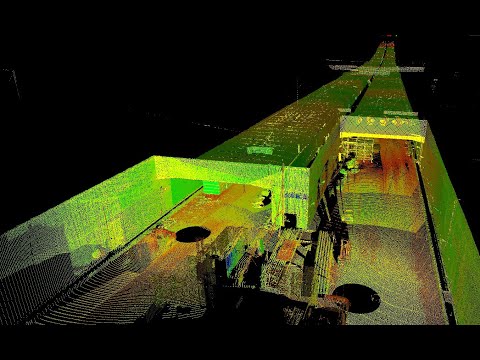

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for this class of equipment

Training on how to use 3D printers

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The whole structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The whole structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process. If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

This is often not necessary as the product is not visible.

full name *

Company *

E-mail *

Telephone *

Message

A small guide for choosing a 3D printer for beginners / Sudo Null IT News0726 ”, at the end of which the author asks to answer a few questions.

I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats. In this article there will be no advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y in any case”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

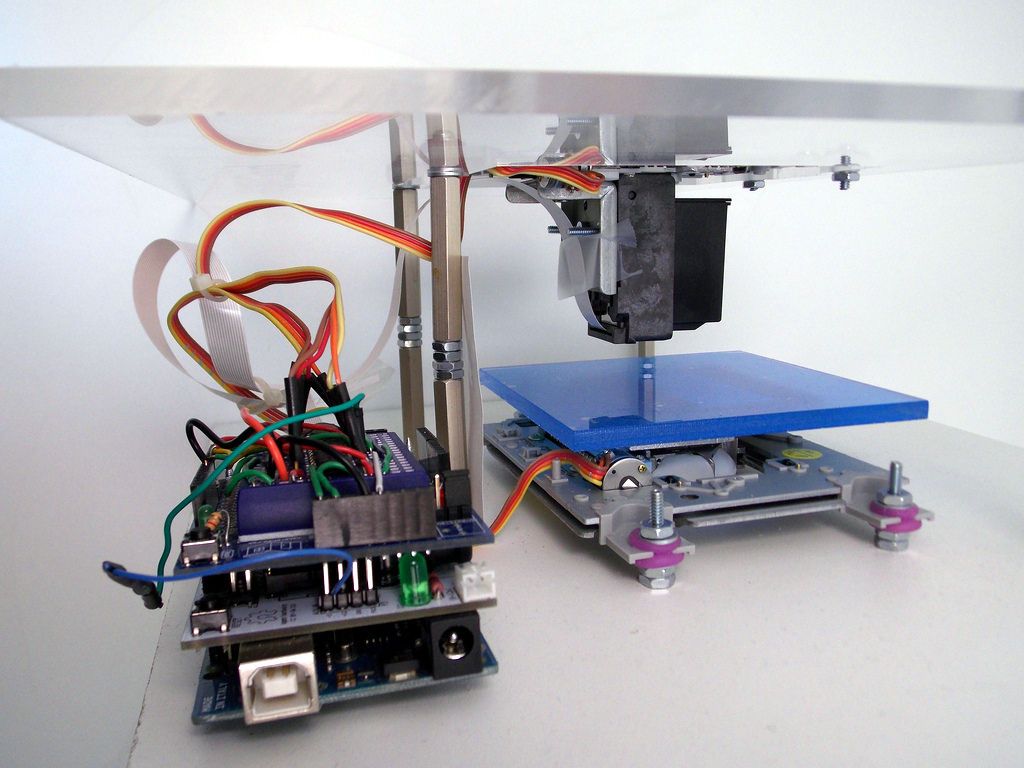

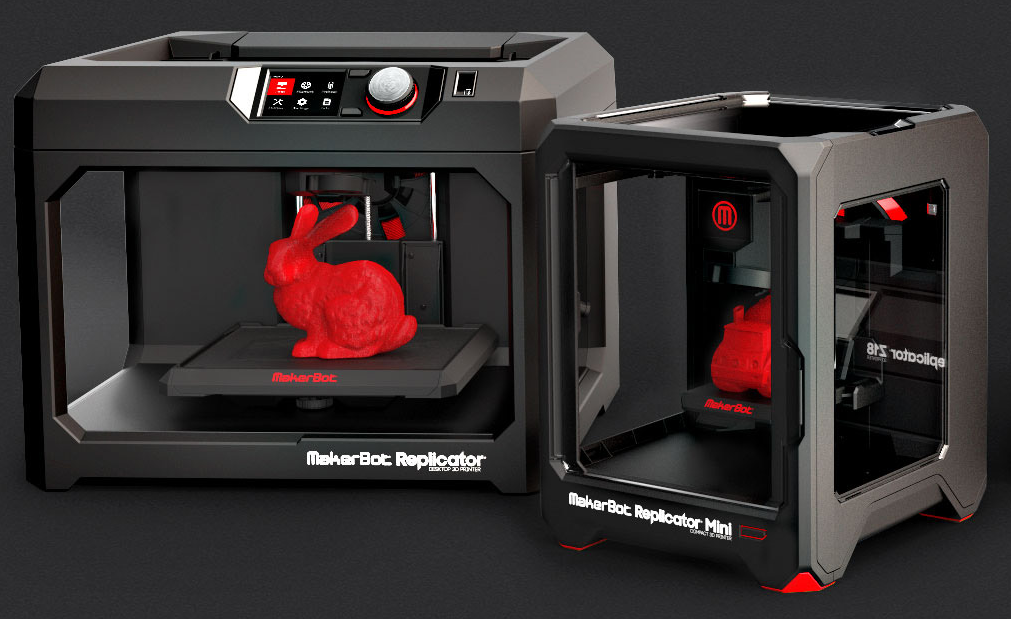

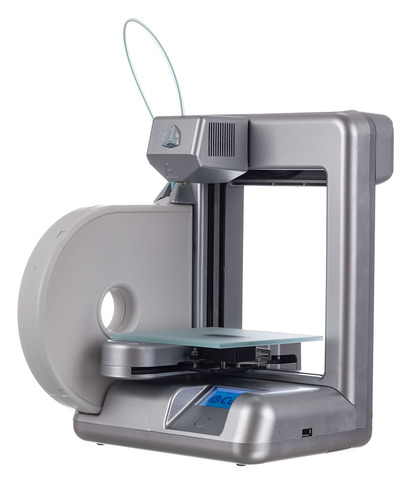

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

Photo from the personal archive There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti-covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti-covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusing, which is fed in the form of a rod and SLA (LCD) - printing with a photo-curing polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

To be honest, I almost never did SLA printing and I still don’t have an LCD printer in my home zoo (but it may appear soon), so I will mainly talk about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

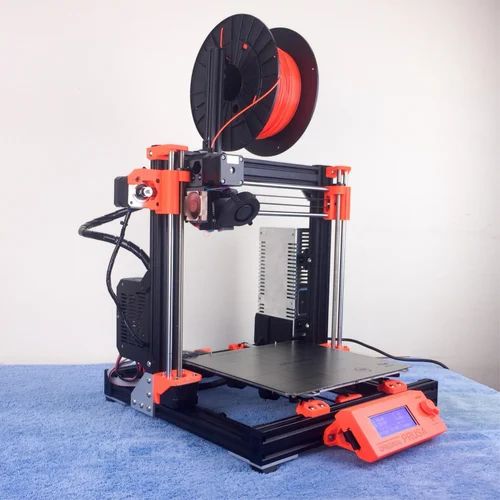

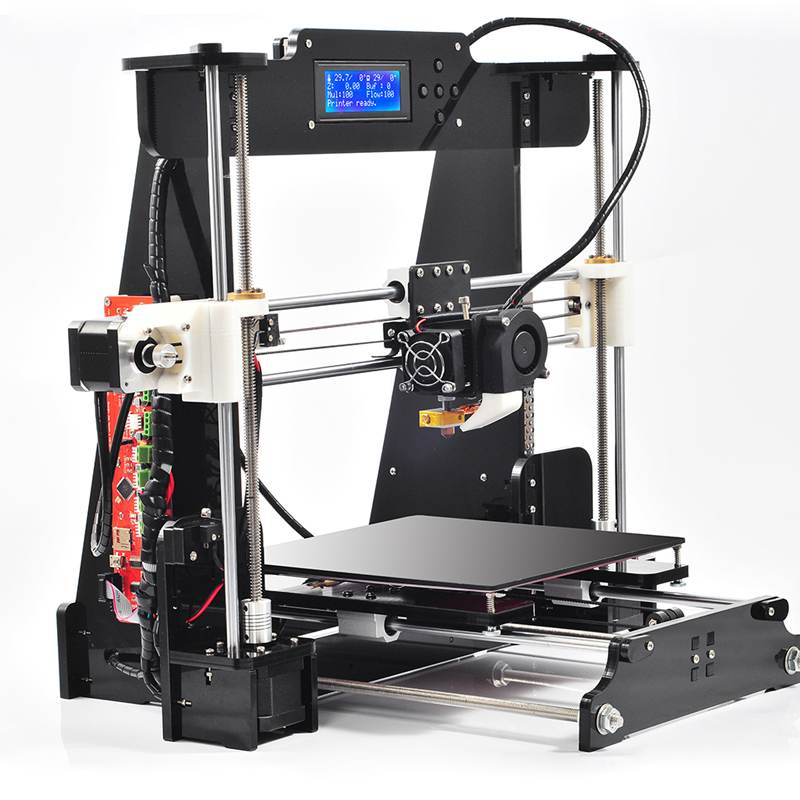

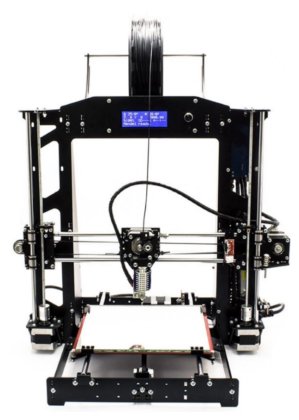

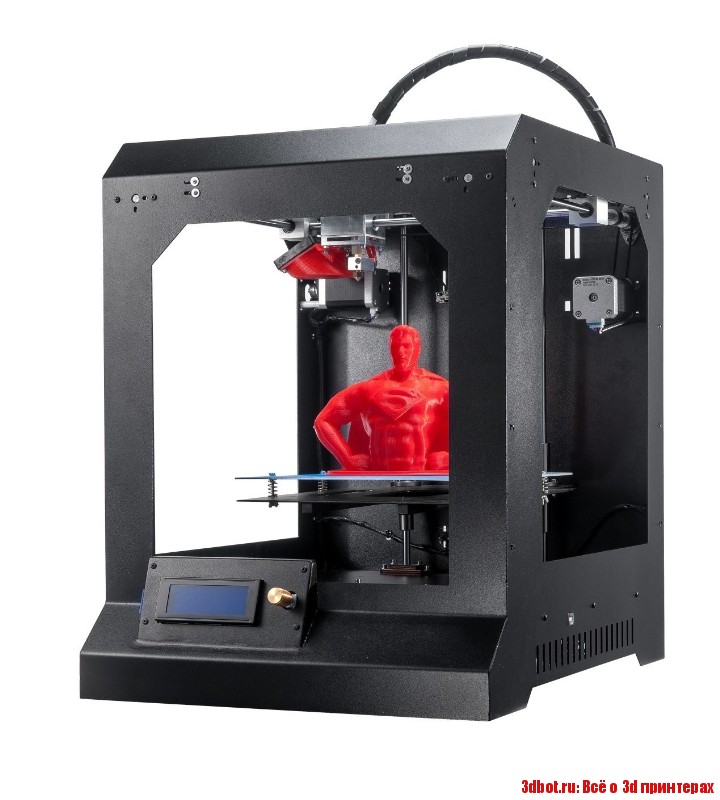

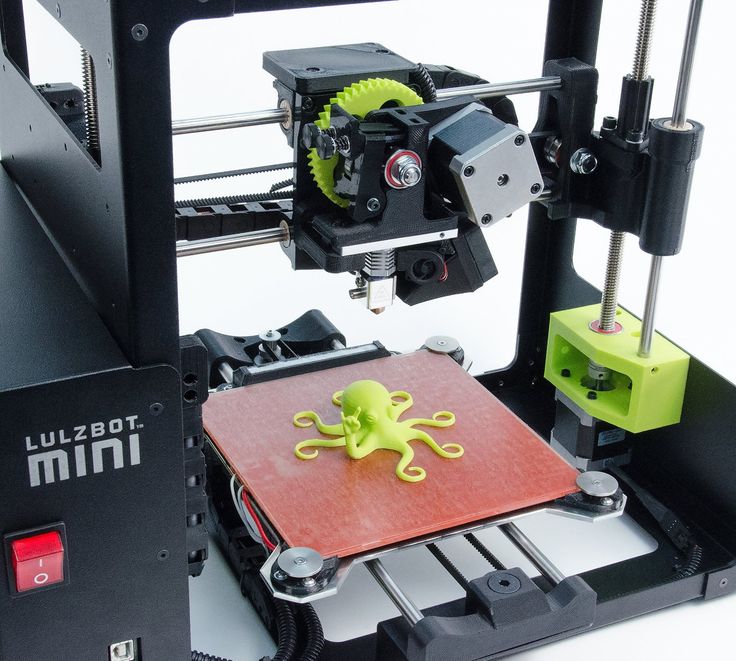

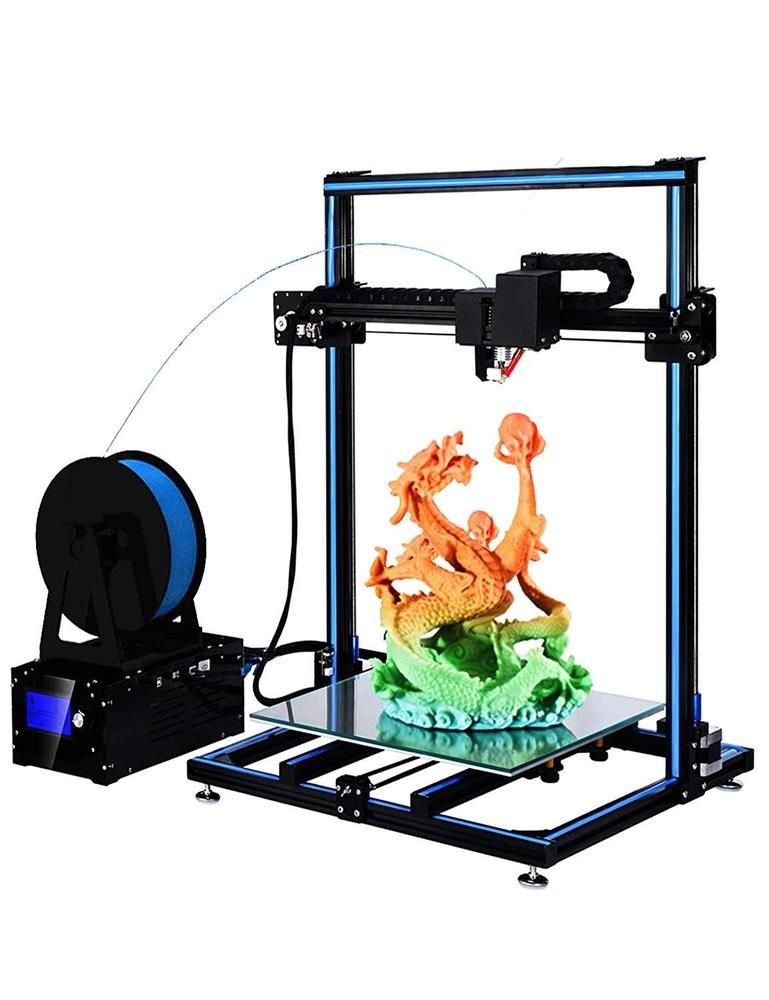

Drygostables - printers with a table movable horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

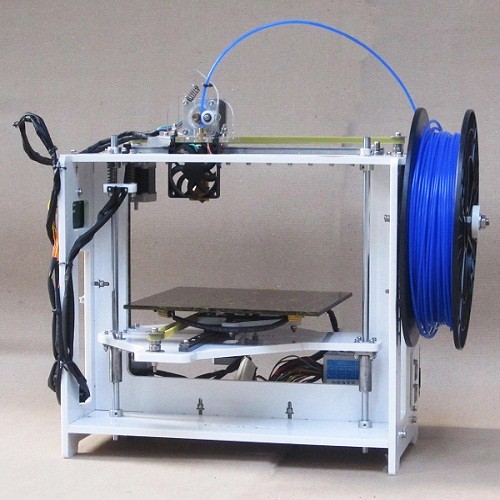

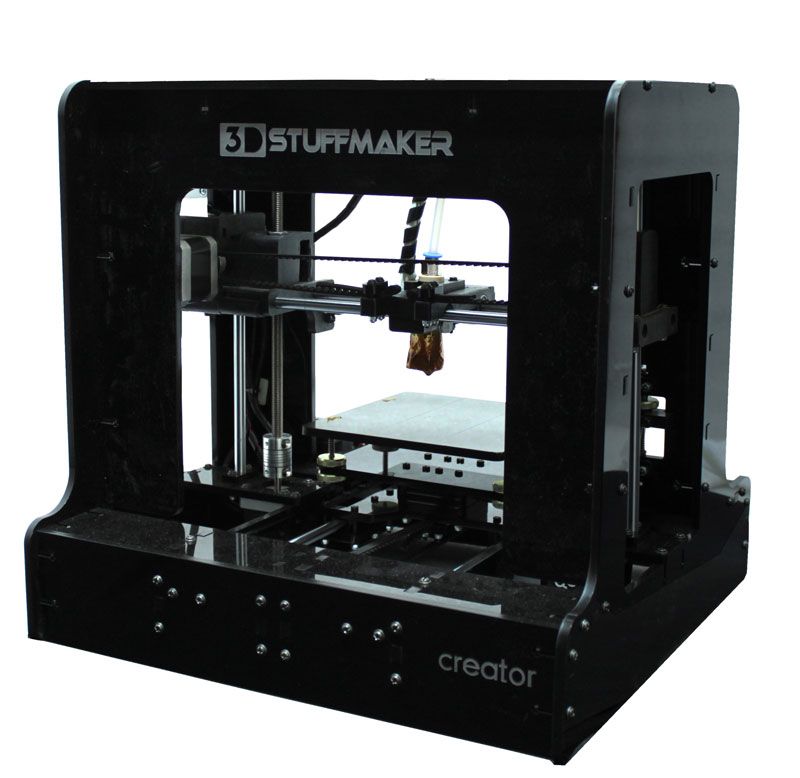

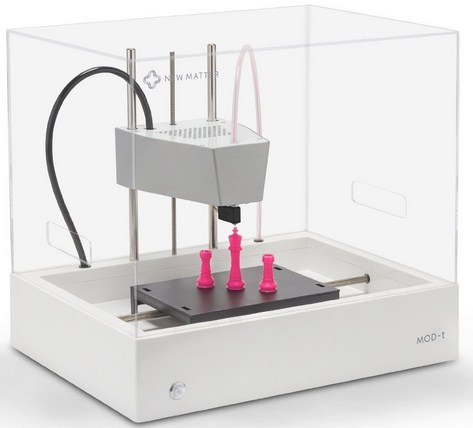

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

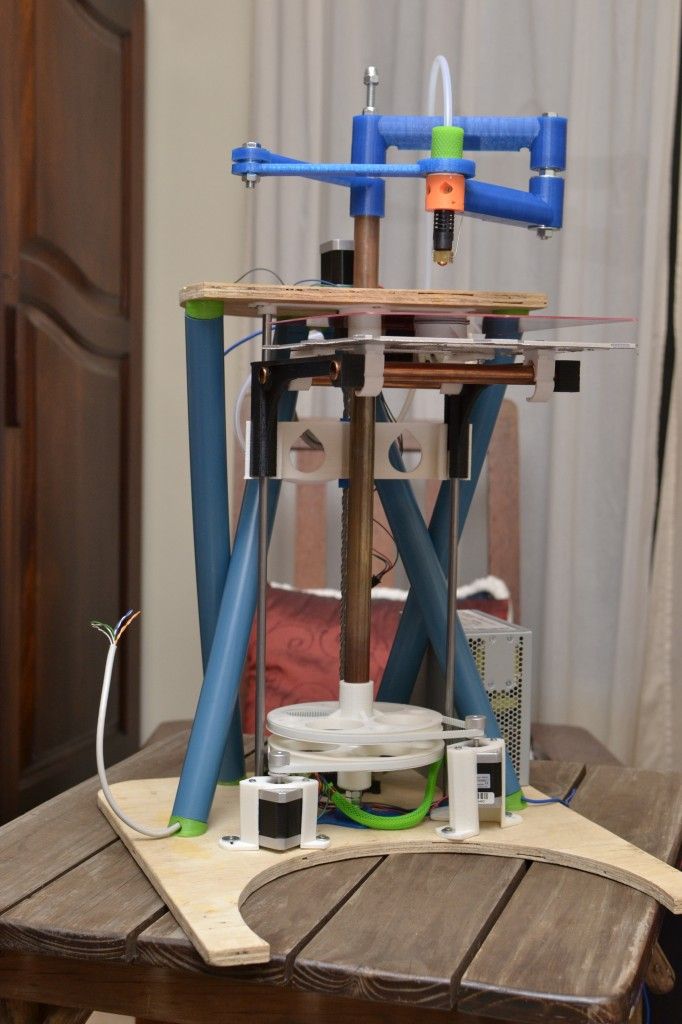

Typical cubes Delta - printers with the so-called delta kinematics, when the print head, using a system of rods, is attached to carriages that move along vertical guides. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites. Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation.

-

The downsides include the quality of the components/assembly and the need to refine these printers to obtain acceptable print quality/speed.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The pluses include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers.

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them. When assembling, direct hands are required.

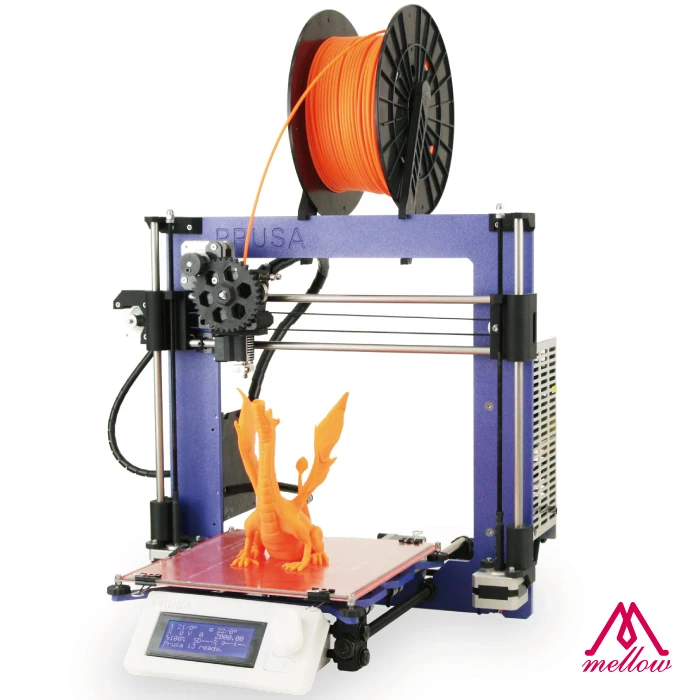

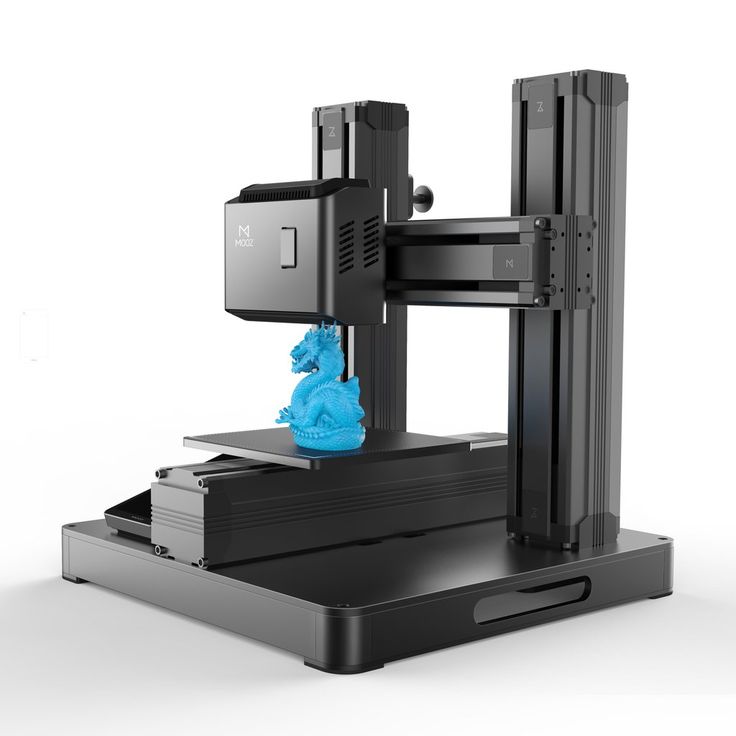

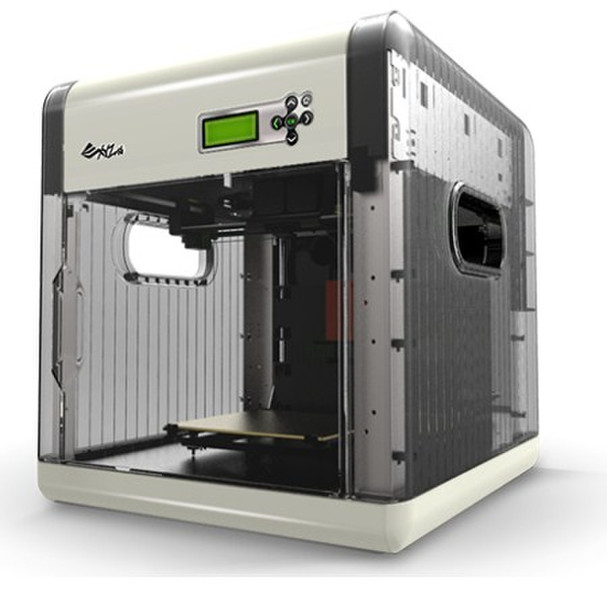

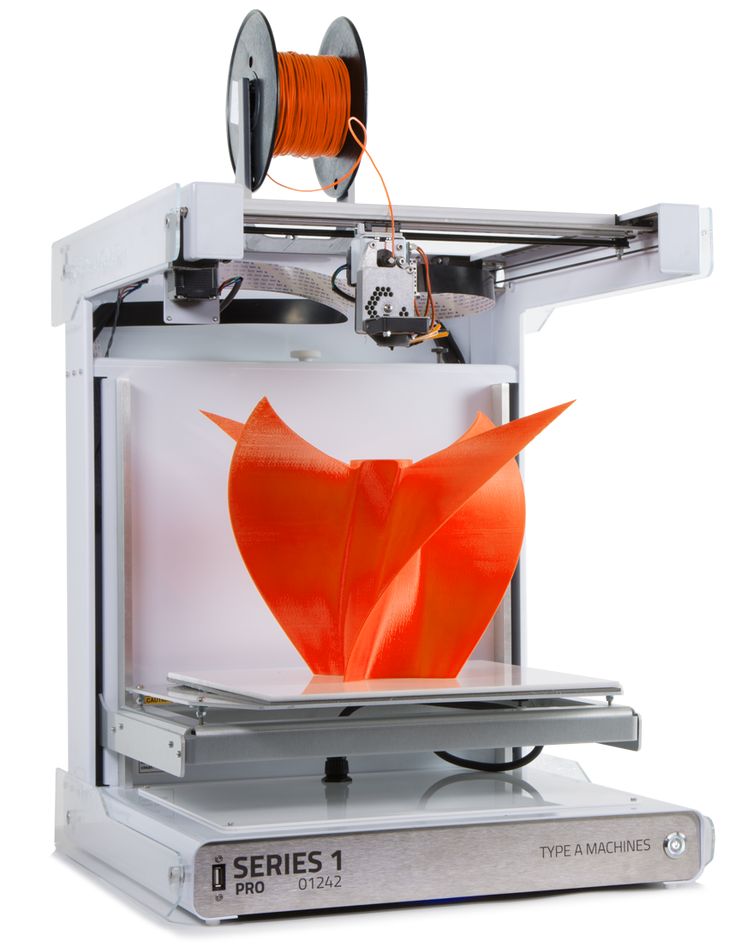

Factory Printers (Semi-Professional domestic or American/European manufacturers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box. In addition, you get operational reliability and warranty support from the manufacturer.

-

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for ourselves, our beloved. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze a few typical situations:

I want to do something for myself and my family - if you do not plan to print products from engineering plastics that can withstand decent loads and temperatures - a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail.

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see which printers are used in prototyping competitions in your area. Take the same one. May be used.

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

There is no money at all, but I want to print, I will collect it myself from scratch - it will turn out better and cheaper than the Chinese. Oddly enough, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat this as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

Firstly, on the rigidity of the structure - the accuracy and speed of printing depend on it. It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

-

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying.

-

Third - the presence of a heated table and ease of modification to a closed case. Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

-

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

-

In the sixth, seventh, etc. - there are many nuances in the design of printers. If something is unclear, feel free to ask the community.

In any case, if you are going to buy or have already bought a 3D printer, start learning some 3D editor.