Carnegie mellon 3d printing

FabLab

- Tech Spark facilities

- Equipment access

- Policies

- Safety policies

- Room and equipment reservation policy

- Storage policy

- Machine shop

- Machining services

- Machine shop access

- Welding

- Shop calendar

- Contacts

- Wood shop

- ANSYS High Bay

- PCB Lab

- Additional rooms

- Equipment list

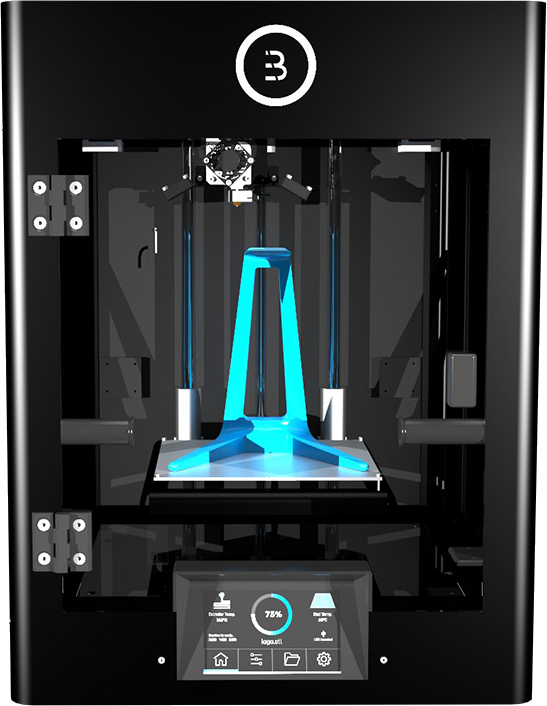

The FabLab is available to anyone associated with Carnegie Mellon University. However, certain trainings are required to use the laser cutters. 3D printers are available for open access but require a job submission through our service program. Uasge of the laser cutters requires the completion of 24-105 or 24-104.

Undergraduate/graduate training

Using laser cutters requires the completion of:

- 24-105: Intro to Laser Cutting & Engraving (1 unit)

or

- 24-104: Intro to Modern Making (MINI) (3 units)

Open lab/part creation process

- You must have completed training to access laser cutters.

- Open lab is offered in between class. (No open lab during 24-105/104).

- Full-time staff workers are always available for consultation/support.

- Students must clean up work area and return all tooling when done. (Those who do not comply will be suspended from the lab.)

FabLab service process

The FabLab is actively involved in the fabrication of custom print/laser cut parts for educational, personal, and research projects. Our experienced staff can advise you on the feasibility and cost associated with any project.

Our experienced staff can advise you on the feasibility and cost associated with any project.

- Contact Ryan Bates or Jen Hitchcock to set up an FBS account (if you don’t have one) or if you have questions.

- Accept invite and submit your request through FBS, our job submission site.

- Be prepared with Oracle #/pay alias, solid part files, dxf, quantity specs, material, etc.

- A student worker or staff member will contact you when your parts are complete.

Please note:

- Material must be provided for laser cut parts.

- You will be charged for 3D print filament expenses.

- $0.50 / gram (Dremel, Form)

- $1.25 / gram (F170, Elite)

Advanced 3-D bioprinting

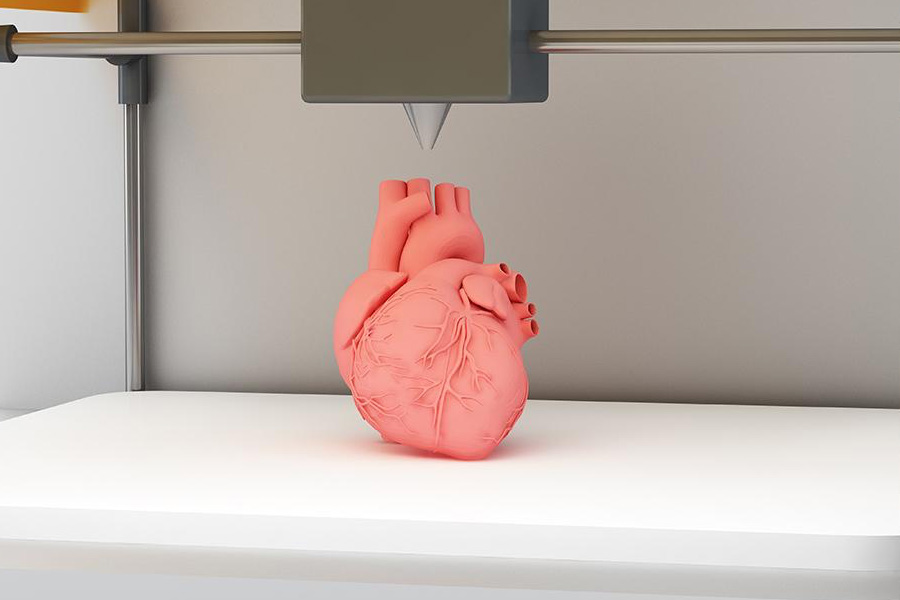

Carnegie Mellon researchers are developing advanced, 3-D “bioprinters” that are able to print soft biomaterials and cells within three-dimensional tissue constructs or even whole organs.

Advanced bioprinters and printing techniques

The number of patients on an organ transplant waiting list highly outnumbers the amount of organs available, leading to thousands of organ failure deaths each year. Carnegie Mellon researchers are developing advanced "bioprinters" -- 3-D printers that are able to print soft biomaterials that may someday lead to the printing of organ parts, or even whole organs, that are compatible with the human body.

Carnegie Mellon researchers are developing advanced "bioprinters" -- 3-D printers that are able to print soft biomaterials that may someday lead to the printing of organ parts, or even whole organs, that are compatible with the human body.

Publications:

- Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels

- 3D bioprinting from the micrometer to millimeter length scales: Size does matter

- 3D Printing PDMS Elastomer in a Hydrophilic Support Bath via Freeform Reversible Embedding

Organ-specific bioprinting bioinks

All tissue-forming cells require direct binding to extracellular matrix (ECM). The ECM “scaffold” provides a 3D matrix for spatial organization of the cells and three forms of ECM-to-cell communication. First, ECM structural constituents bind to cell surface integrins and other ECM receptors, which enable cell attachment while also acting as signaling molecules. Second, peptide/protein hormones and their modifiers are immobilized within the ECM and signal cells via their own cell surface receptors. Third, extracellular vesicles (EVs), immobilized within the ECM, deliver a wide variety of cargo constituents to signal cells, including miRNA, growth factors, cytokines, transcription factors, enzymes and lipids. Carnegie Mellon University researchers are thus developing custom, printable ECM bioinks that contain cell binding ECM molecules, growth factors, and, EVs that can be printed into organ constructs. Where applicable, these bioinks are being customized for the type of organ or tissue being developed.

Second, peptide/protein hormones and their modifiers are immobilized within the ECM and signal cells via their own cell surface receptors. Third, extracellular vesicles (EVs), immobilized within the ECM, deliver a wide variety of cargo constituents to signal cells, including miRNA, growth factors, cytokines, transcription factors, enzymes and lipids. Carnegie Mellon University researchers are thus developing custom, printable ECM bioinks that contain cell binding ECM molecules, growth factors, and, EVs that can be printed into organ constructs. Where applicable, these bioinks are being customized for the type of organ or tissue being developed.

Publications:

- Engineered spatial patterns of FGF-2 immobilized on fibrin direct cell organization

- Dose-dependent cell growth in response to concentration modulated patterns of FGF-2 printed on fibrin

- Spatially directed guidance of stem cell population migration by immobilized patterns of growth factors

- Inkjet printing of growth factor concentration gradients and combinatorial arrays immobilized on biologicallyrelevant substrates

- Microenvironments engineered by inkjet bioprinting spatially direct adult stem cells toward muscle- and bone-like subpopulations

- Inkjet-based biopatterning of bone morphogenetic protein-2 to spatially control calvarial bone formation

- Engineering spatial control of multiple differentiation fates within a stem cell population

- Precise control of osteogenesis for craniofacial defect repair: the role of direct osteoprogenitor contact in BMP-2-based bioprinting

- Inkjet-based biopatterning of SDF-1beta augments BMP-2-induced repair of critical size calvarial bone defects in mice

- Transforming growth factor beta 1 augments calvarial defect healing and promotes suture regeneration

Explore Other Research Topics

- Bioengineered hearts

- Bioengineered lungs

- Enabling technologies

- Research areas

- Three-dimensional tissue constructs

Scientists from Disney Research and Carnegie Mellon University built a 3D printer to print teddy bears

Archive

Subscribe to the author

Subscribe

Don't want

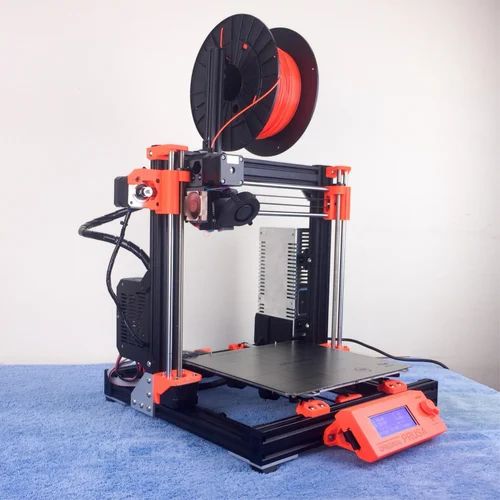

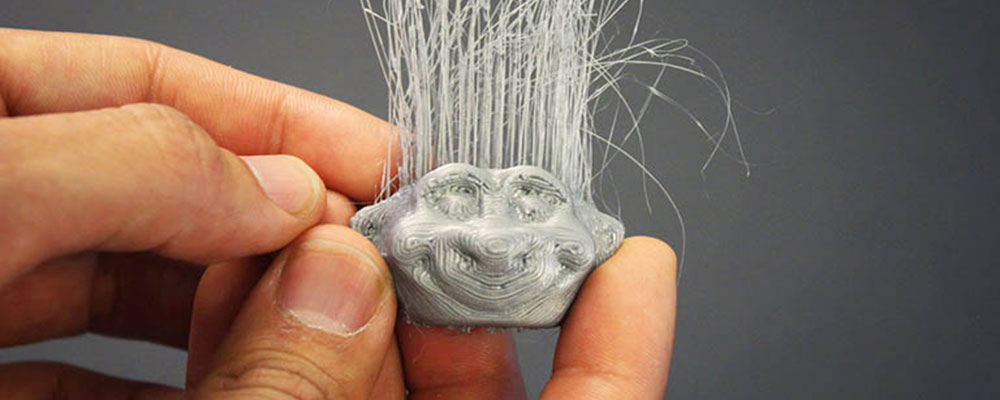

Disney Research Lab with Professor Scott Hudson Institute for Human Interaction and Interaction Computer Science at Carnegie Mellon University has assembled a new type of 3D printer that turns wool yarn into knits that could very well be soft interactive toys.

3D printer, developed by researchers at Carnegie Mellon University and Disney Research Labs, shapes yarn into a desired shape and uses a needle to sew the yarn onto felt felt. Scott Hudson, a professor at Carnegie Mellon University's Institute for Human-Computer Interaction who developed the knitting printer with support from Disney Research, said the products look like they're hand-knitted.

Hudson's research paper Printing Teddy Bears: A 3D Printing Technique for Soft Interactive Products states that this "printer combines the undoubted advantages of additive manufacturing (including rapid prototyping of physical objects and support for high-level customization and layout) with a new kind of material . This material is a loose felt, on which yarn fibers are connected with a needle, forming layers of the product. As a result, according to the indicated three-dimensional models, geometric shapes are obtained, however, unlike plastic ones, these are soft and flexible, somewhat reminiscent of hand-knitted products. This created a whole new category of tactile knitwear, and gave researchers the opportunity to experiment with a new kind of material in interactive devices.”

This created a whole new category of tactile knitwear, and gave researchers the opportunity to experiment with a new kind of material in interactive devices.”

“I really think this material can be used to create nice textiles,” says Hudson. “We have been able to expand the choice of materials for 3D printing and open up new production possibilities.”

This printer can print garments, accessories such as scarves, hats, and even teddy bears. It can also be used to make so-called "soft robots".

The Hudson device works in a similar way to deposition modeling, the most common printing method on inexpensive 3D printers. Only here the print head releases yarn instead of melted plastic. The printer can print products directly from digital models on a computer. A notched felting needle inserted into the printer head pierces the yarn again and again, pulling out individual fibers from it and tying it to the lower layers. As a result, the fibers become entangled and the layers are joined together.

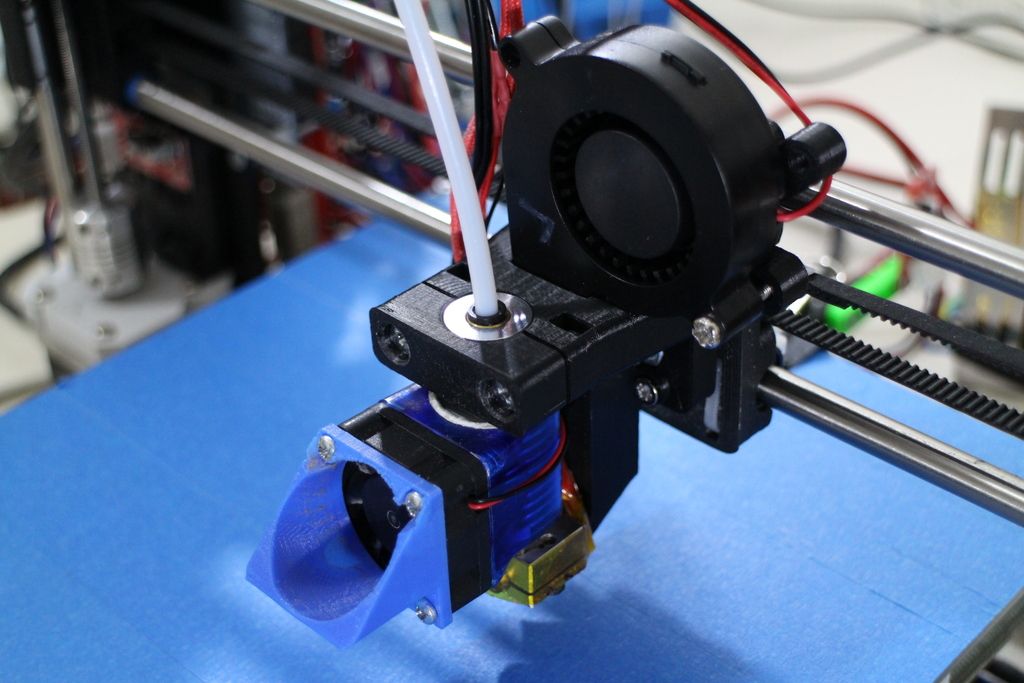

Printhead with felting needle. The dark base is laser-cut acrylic, while the white parts are 3D printed on a

3D printer Hudson said the printer can't achieve the same accuracy as other 3D printers because the yarn is much thicker than the plastic layers. obtained as a result of layer-by-layer deposition. In addition, the yarn is not as strong as ordinary fabric, so if soft products are attached to a hard object, a layer of nylon mesh fabric should be used in the process. This will avoid tearing the material at the connection point.

Hudson demonstrated a technique for joining soft and hard materials by controlling the strength of soft products and using electronic components.

Partially printed hand with embedded elements. The photo shows a black nylon mesh tube (left) with a yellow wire threaded through it. It is circled around a bolt that is attached to the (white) assembly below it. The assembly consists of a metal nut, nylon mesh to cushion pressure on the attachment point, and 3D printed sealing material

Currently only textiles can be printed on this printer, so the conceived product may require manual assembly. However, Hudson said that it is possible to design a printer that prints products from both fabric and plastic.

However, Hudson said that it is possible to design a printer that prints products from both fabric and plastic.

“Some researchers are trying to find ways to use mixed materials in 3D printing,” he says. “Today this is one of the most interesting tasks.”

Hudson will talk about its knitting printer at the Human Factors in Computer Systems Conferencewill in Toronto on April 28th.

Watch the video below to understand how the knitting printer works and understand what it can be used for:

Article prepared for 3DToday.ru

7

Subscribe to the author

Subscribe

Don't want

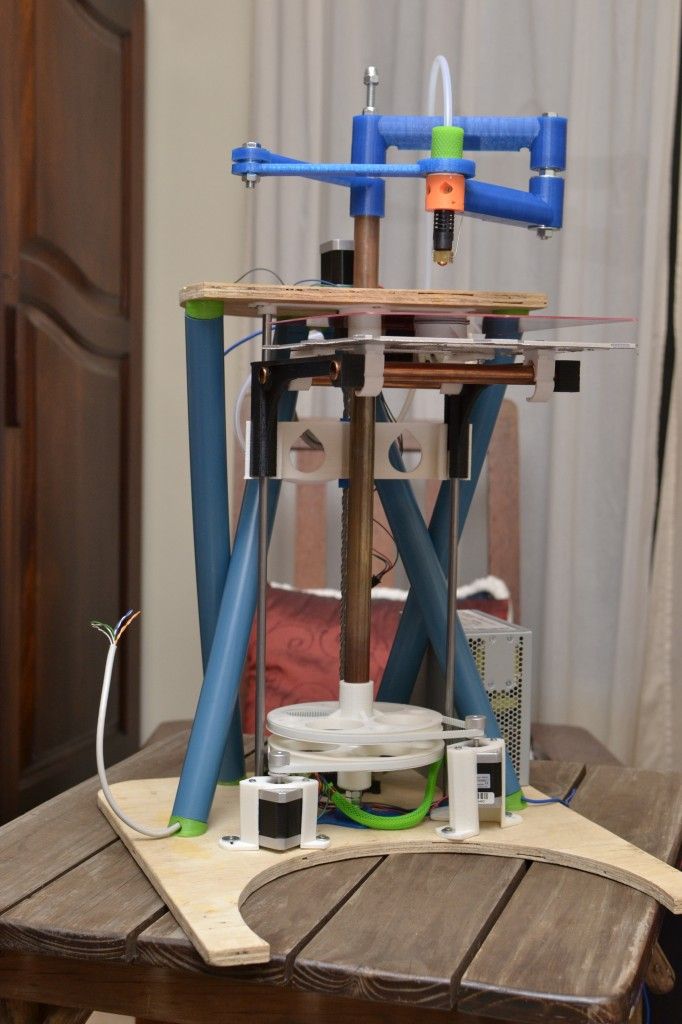

Volgograd schoolboy Mikhail Kozenko joined the ranks of 3D-makers by designing his own 3D-...

Read more

6

Subscribe to the author

Subscribe

Don't want

One of the newest developments in 3D printing devices has been the advent of extruders. No, it's not...

No, it's not...

Read more

four

Subscribe to the author

Subscribe

Don't want

One of the most promising and least developed areas of 3D printing is bioprinting. Whole a...

Read more

Ordinary 3D printers adapted to print arteries

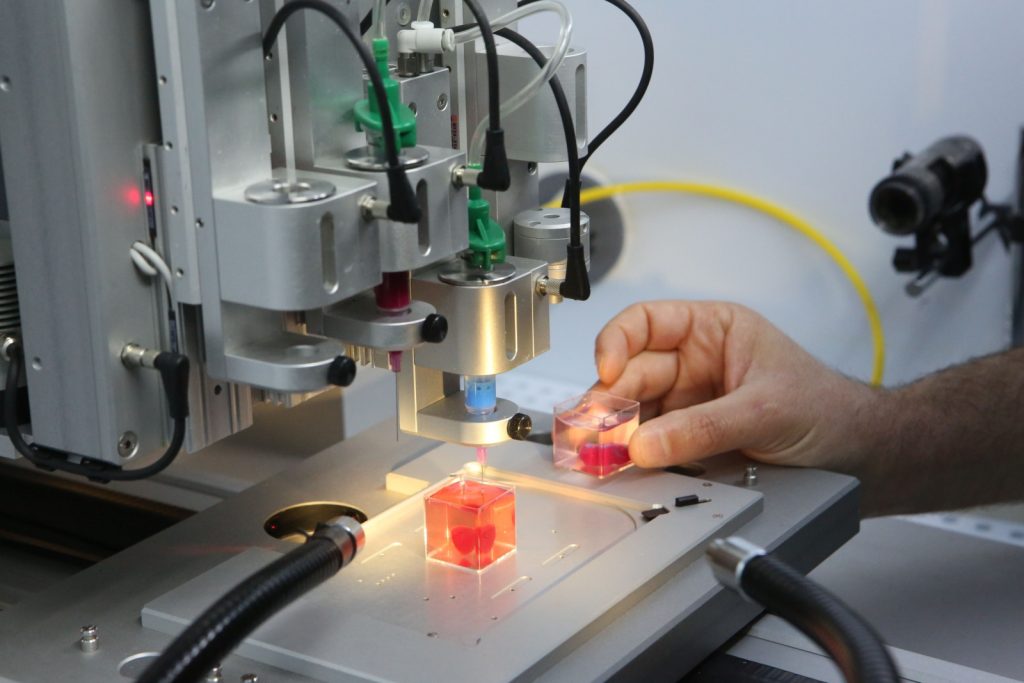

A group of researchers from the USA printed artificial analogues of coronary and femoral vessels, heart and other complex biological structures. To do this, they came up with a new gel-in-gel printing method. Work published in Science Advances , The press release is available on the Carnegie Mellon University website.

Traditional 3D printing allows you to create objects from plastic or metal. However, to create biological structures such as the heart or blood vessels, soft biocompatible materials. The main problem of creating non-rigid objects lies in the very principle of 3D printing: when applying the next layer, it is necessary that the previous one serve as the basis for it. However, ideally suited for medical applications, collagen, fibrin and other jelly-like materials, when trying to "print" them, simply settle under their own weight.

However, ideally suited for medical applications, collagen, fibrin and other jelly-like materials, when trying to "print" them, simply settle under their own weight.

Researchers have found a way around this problem by using as a matrix for printing another gel based on gelatin microparticles. Scientists selected biocompatible material with low mechanical resistance, so that the “needle” of the printer can move freely along it, but it remains dense enough to prevent already printed layers from spreading. To achieve the necessary parameters, scientists subjected ordinary gelatin jelly to processing in a blender and centrifuge, obtaining in this way a gel with particles of a certain size.

Printed with proteins or gel-like polysaccharides, such as alginic acid. As a template, the authors used detailed 3D images vessels or heart, obtained using the method of magnetic resonance imaging. The experiments were carried out in a sterile atmosphere, the gelatin base gel was placed in a Petri dish fixed on the table. The "needle" of the printer was injected into gelatin and printed with material that flowed from its spout. In the process of printing gelation of the polysaccharide in gelatin occurred.

The experiments were carried out in a sterile atmosphere, the gelatin base gel was placed in a Petri dish fixed on the table. The "needle" of the printer was injected into gelatin and printed with material that flowed from its spout. In the process of printing gelation of the polysaccharide in gelatin occurred.

Printed at a temperature of 4 to 22°C so that the gel base does not melt. At the end the temperature was raised to 37°C, which made it easy to remove gelatin matrix. This temperature is non-destructive not only for printed objects, but also for living cells that can be included in the printed mixture.

Scientists were able to not only create a new method for creating complex biological structures, but also significantly reduce the cost of its cost. Seal biological objects is not a novelty, but earlier 3D printers of a special structures that are very expensive. The authors of this work succeeded adapt ordinary 3D printers for this purpose, the cost of which is 100 times less.