3D print sale

3d Printing - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Related to 3d printing

- 3d printed

- 3d printing service

- 3d printing files

- custom 3d printing

- 3d printer

- 3d wall art

3d Printing - Etsy UK

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevance, and the amount sellers pay per click. Learn more. )

Related to 3d printing

- 3d printed

Page not found - Plastic for 3D printing in Yekaterinburg

Nothing found at this address. Use the search or see the links below.

Use the search or see the links below.

Search:

Discounts

-

ABS plastic SEM 1.75mm White 900g

1190 RUB Add to cart1 pc. in stock

ABS plastic SEM 1.75mm White 900g

ABS plastic for 3D printers with a diameter of 1.75 mm from the domestic manufacturer SEM. Designed for the manufacture of parts for housings, various designs, kitchen products, as well as medical supplies. Printed products can be used in water, for example in the manufacture of parts for sanitary ware or aquariums. The material is suitable for various FDM 3D printers.

1190 RUB

-

Sale!

ABS plastic SEM 1.75mm Bronze metallic 900g

1190 RUB Add to cart1 pc. in stock

ABS plastic SEM 1.

75mm Bronze metallic 900gr

75mm Bronze metallic 900gr ABS plastic for 3D printers with a diameter of 1.75 mm from the domestic manufacturer SEM. Designed for the manufacture of parts for housings, various designs, kitchen products, as well as medical supplies. Printed products can be used in water, for example in the manufacture of parts for sanitary ware or aquariums. The material is suitable for various FDM 3D printers.

1190 RUB

Featured Products

-

3D printer adhesive 250 ml The 3D “Click” New

499 RUB Add to cart24 pcs. in stock

3D printer adhesive 250 ml The 3D “Click” New

Adhesive for FDM printing. Perfectly solves the problems of poor adhesion of plastic to the table. How to use: before printing, apply the glue solution to the fabric and wipe the surface of the table of the heated platform with it.

For easy removal of the product from the table, after printing, wait for the work surface to cool down to 30°C. Ingredients: isopropyl alcohol, P-complex, water, fragrance. Ingredients: isopropyl alcohol, P-complex, water, fragrance.

For easy removal of the product from the table, after printing, wait for the work surface to cool down to 30°C. Ingredients: isopropyl alcohol, P-complex, water, fragrance. Ingredients: isopropyl alcohol, P-complex, water, fragrance. 499 RUB

-

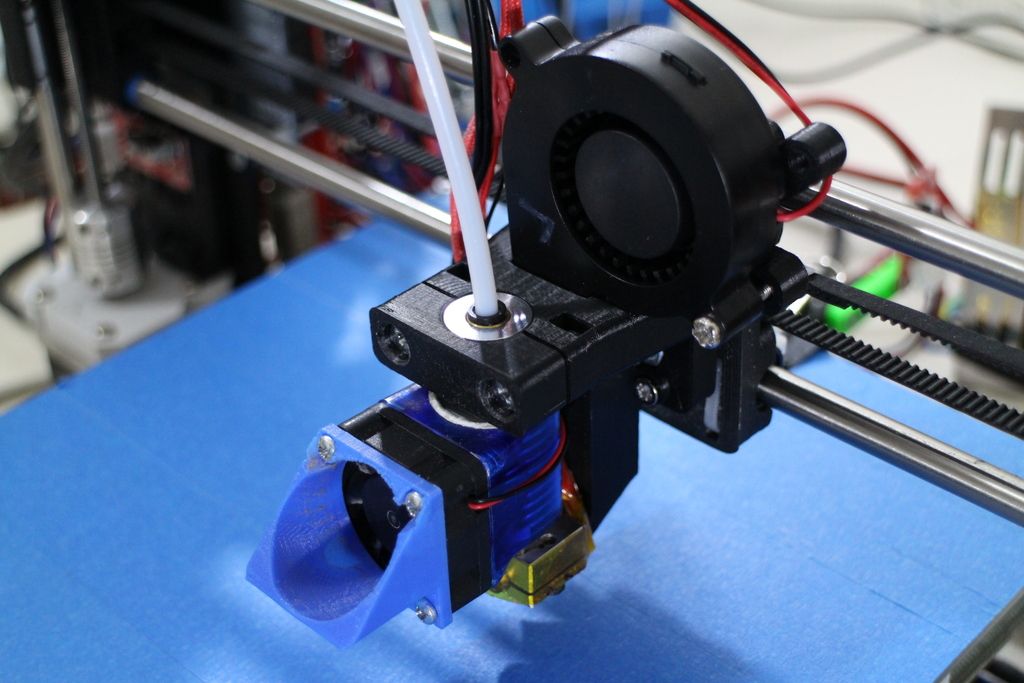

Nozzle brass 0.4mm MK8 for plastic 1.75mm 5APlus

40 ₽ Add to cart5 pcs. in stock

Nozzle brass 0.4mm MK8 for plastic 1.75mm 5APlus

Brass, size: 13 mm x 6 mm. Thread diameter: 1.75 mm. Thread diameter: 6 mm. Nozzle outlet diameter: 0.4mm

Suitable for 3D printers with MK8 type hot end: Anet A6, Anet A8, Creality CR-10, Ender-3, Ender 5, Ender 5 plus, etc.

40 ₽

-

Nozzle brass 0.4mm V6 for plastic 1.75mm 5APlus

40 ₽ Add to cart13 pcs. in stock

Nozzle brass 0.4mm V6 for plastic 1.75mm 5APlus

Brass, size: 12.

5 mm x 7 mm. Thread diameter: 1.75 mm. Thread diameter: 6 mm. Nozzle outlet diameter: 0.4 mm.

5 mm x 7 mm. Thread diameter: 1.75 mm. Thread diameter: 6 mm. Nozzle outlet diameter: 0.4 mm. Suitable for v5/V6 type 3D printers: Anycubic i3 Mega, Mega-S, 4MAX PRO, Kossel, Predator, Chiron

40 ₽

-

PETG plastic FDplast 1.75 White Guard 1000gr

1399 RUB Add to cart1 pc. in stock

PETG plastic FDplast 1.75 White Guard 1000gr

PETG plastic is based on a modified polyethylene terephthalate, which is ideal for a 3D printer and the further creation of three-dimensional three-dimensional models suitable for the production of car parts, architectural objects, models of human body organs.

1399 RUB

3D printing in cinema - how technology has changed the film industry!

For the creators of entertaining science fiction films, there has always been a problem of the real embodiment of the most daring author's ideas. Many fascinating plots did not become masterpieces of world cinema due to weak and unrealistic effects that caused laughter from the audience and criticism from professionals. It seemed that in our era of digital technologies, when any scenes and fantastic attributes can be reproduced using computer graphics, the problems of filling any fantasy film with colorful spectacular details will become a thing of the past. However, screen masters have become convinced that not everything can be created with a graphic image, and therefore directors are still looking for ways to realistically convey the incredible appearance of the intended characters and create amazing objects of the fictional world. The graphics help to reproduce the overall environment in an incomparable way, but the human eye cannot be deceived and close-ups are often impossible to make believable using the style of a computer game. And then 3D printing came to the aid of directors and cameramen, thanks to the possibilities of which make-up artists and effects specialists today create unimaginable screen images.

Many fascinating plots did not become masterpieces of world cinema due to weak and unrealistic effects that caused laughter from the audience and criticism from professionals. It seemed that in our era of digital technologies, when any scenes and fantastic attributes can be reproduced using computer graphics, the problems of filling any fantasy film with colorful spectacular details will become a thing of the past. However, screen masters have become convinced that not everything can be created with a graphic image, and therefore directors are still looking for ways to realistically convey the incredible appearance of the intended characters and create amazing objects of the fictional world. The graphics help to reproduce the overall environment in an incomparable way, but the human eye cannot be deceived and close-ups are often impossible to make believable using the style of a computer game. And then 3D printing came to the aid of directors and cameramen, thanks to the possibilities of which make-up artists and effects specialists today create unimaginable screen images.

Where and how did the 3D printer work?

A quarter of a century ago, it was hard to imagine that technological and scientific progress would so significantly change the technologies for preparing props for the film industry. Even in such a cult film of 1997 as "Men in Black", which was replete with alien guests, the process of creating unprecedented characters consisted in hand-molding from clay, familiar to the "kitchen" of the cinema. Not a single worthwhile spectacular scenario could do without the work of experienced craftsmen. The manual production of unique layouts and details for effects was time consuming and costly. And at the same time, there were always risks that the created images would not be able to fully convey what was intended. But 3D printing has changed everything, without which it is now difficult to imagine the process of modern film production.

Fans of Stranger Things may not know that it was the 3D printer that was used to create objects for the scariest scenes. The task of the authors was to accurately reproduce the atmosphere of the 80s, and to achieve their goals, the creators used a kind of hybrid method, combining the possibilities of graphic editing and 3D printing. As a result, we can say that both technologies perfectly complement each other. From simple sketches of the monster, with which the authors turned to the special effects studio, the creators came to a realistic embodiment on the screen not only of the character himself, but also completely reproduced the whole bewitching inverted world. A striking example of technological interaction is the Demogorgon model, which was created by a 3D printer, but the mouth mucus appeared with the help of graphics, and the fire was brought up for real. As a result, the viewer is completely immersed in believable footage, and the series has been in the top of the best films since the first season.

The task of the authors was to accurately reproduce the atmosphere of the 80s, and to achieve their goals, the creators used a kind of hybrid method, combining the possibilities of graphic editing and 3D printing. As a result, we can say that both technologies perfectly complement each other. From simple sketches of the monster, with which the authors turned to the special effects studio, the creators came to a realistic embodiment on the screen not only of the character himself, but also completely reproduced the whole bewitching inverted world. A striking example of technological interaction is the Demogorgon model, which was created by a 3D printer, but the mouth mucus appeared with the help of graphics, and the fire was brought up for real. As a result, the viewer is completely immersed in believable footage, and the series has been in the top of the best films since the first season.

New technologies could not ignore the mastodon of Hollywood fiction, the recognized master and creator of space worlds Ridley Scott. The 2020 series Raised by Wolves, produced by HBO Max, required the director to think outside the box when it comes to screening another sci-fi story in which androids are busy creating a new population of people on a desert planet. Almost all the components and elements of the new world were reproduced by 3D printing. It was only thanks to the technological acceleration of behind-the-scenes production of props and furnishings that the famous director's production team was able to keep up with the tight schedule of working in the challenging conditions of South Africa. Each episode took 2-3 weeks to prepare and shoot. During this time, sketches were prepared, layouts were designed, final details were agreed. Everything happened with the direct participation of the art director of the picture Yako Snaiman and Ridley Scott himself.

The 2020 series Raised by Wolves, produced by HBO Max, required the director to think outside the box when it comes to screening another sci-fi story in which androids are busy creating a new population of people on a desert planet. Almost all the components and elements of the new world were reproduced by 3D printing. It was only thanks to the technological acceleration of behind-the-scenes production of props and furnishings that the famous director's production team was able to keep up with the tight schedule of working in the challenging conditions of South Africa. Each episode took 2-3 weeks to prepare and shoot. During this time, sketches were prepared, layouts were designed, final details were agreed. Everything happened with the direct participation of the art director of the picture Yako Snaiman and Ridley Scott himself.

The most difficult thing was to create the main character of the film - android. This required a head scan of the actress. Next, a transparent polymer copy was printed through which the liquid could be seen. Metal parts were highlighted in chrome, and the containers were filled with water with a common food coloring that mimics yellow acid. Small details of the severed head, muscles, skull were created by the Zbrush program. Many elements were printed separately and assembled together. When installing the details on the actor's head, it was possible to achieve a real feeling that an artificially created person was in front of the audience. If not for the possibilities of 3D printing, no previous technical tricks and skill of design technicians would have allowed the series team to meet the allotted time and give the characters such a realistic look.

Metal parts were highlighted in chrome, and the containers were filled with water with a common food coloring that mimics yellow acid. Small details of the severed head, muscles, skull were created by the Zbrush program. Many elements were printed separately and assembled together. When installing the details on the actor's head, it was possible to achieve a real feeling that an artificially created person was in front of the audience. If not for the possibilities of 3D printing, no previous technical tricks and skill of design technicians would have allowed the series team to meet the allotted time and give the characters such a realistic look.

Most of all, the creators of the Marvel Universe know about the indispensability and practicality of 3D printers. Not a single studio film is complete today without the use of 3D printing technology. Only such fast and precise production is able to provide the film sets with the necessary props. Russell Bobbitt, who is in charge of this direction at Marvel Studios, says that everything that we see on the screen in the hands of the Avengers, on their costumes and in the setting, is created only through printer printing. Without it, such an unthinkable number of objects and details simply would not have been physically possible to recreate. Thor's hammer and Captain America's shield, Iron Man's reactors and hundreds of other elements of a fictional space future - all this became possible only thanks to the latest technologies. Russell remembers first encountering 3D printing on the set of Star Trek in 2009.1999, where director and producer J.J. Abrams introduced him to new technology.

Without it, such an unthinkable number of objects and details simply would not have been physically possible to recreate. Thor's hammer and Captain America's shield, Iron Man's reactors and hundreds of other elements of a fictional space future - all this became possible only thanks to the latest technologies. Russell remembers first encountering 3D printing on the set of Star Trek in 2009.1999, where director and producer J.J. Abrams introduced him to new technology.

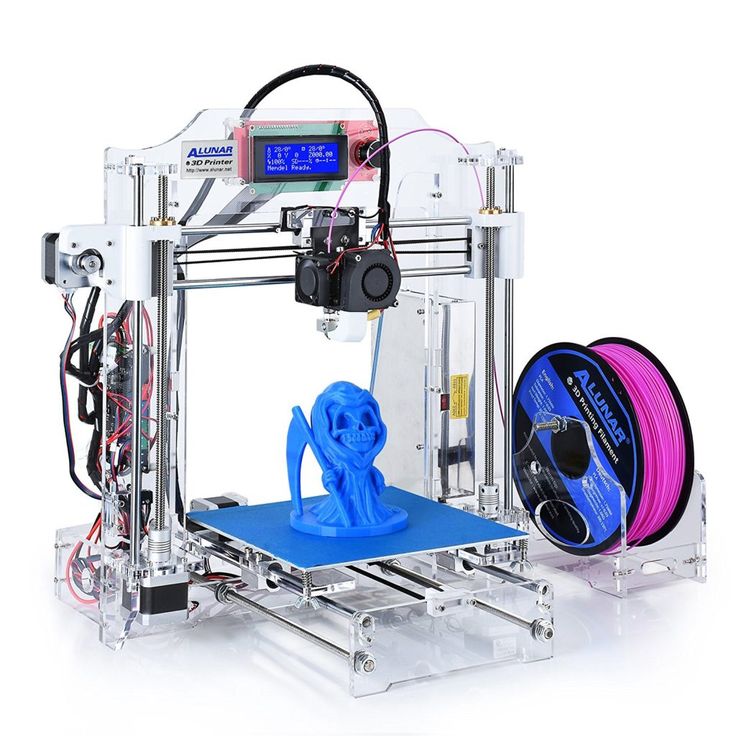

The first 3D printer that Bobbitt himself used cost an insane $150,000. Today, these technologies have become much more accessible. And most importantly - cost-effective. At a time when the financial success of films and series has become directly dependent on the speed of the filming process, when it is necessary to shoot not just spectacular science fiction, but entire series of space battles and sci-fi everyday life in the shortest possible time, only 3D printing provides the film industry with the necessary amount of stage props.