Seemecnc 3d printer

Downloads – SeeMeCNC

Starting June 2021, new guides are found here

Documents & Instructions

User guides prior to June 2021 are here:

Click here to go to our User Guides

Cura Slicing Software User Guide

The Cura slicing software is our recommended choice. Our slicing profiles have been perfected and perform excellent with the filament we sell.

Click here to go to our User Guides

Artemis

User Guides

Rostock MAX v3.2

User Guides

Hotend & Upgrade Assembly Instructions

User Guides

Delta Calibration Wizard

Use this wizard is for use with RAMBo controlled SeeMeCNC Delta printers. These includee RostockMAX v1, v2, v3, Orion, Eris, and h3 printer models.

Click here to go to the Delta Calibration Wizard page

Rostock MAX v3

Assembly and setup guides for v3 only. See above for v3.2

Rostock MAX v3 DIY Kit Assembly Instruction Manual

Rostock MAX v3 RTP User Manual

Probing GCODE

RostockMAX v3 Firmware

h3 DIY Hacker Delta

h3 Assembly Manual

ERIS Delta

ERIS User Manual

Eris Firmware Update Instructions

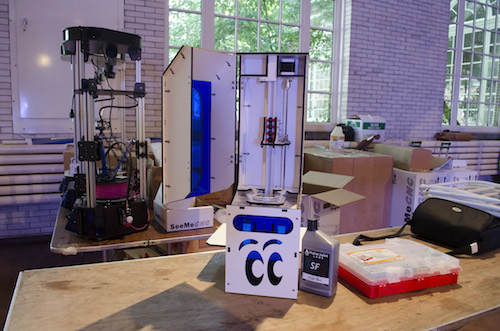

ORION DELTA

ORION Users Manual For Current ModelsThis is the complete User Manual for the Orion Delta 3D Printer that came with the firmware version 0.91. To verify this, simply look at the LCD screen when it powers on and it will display the machines firmware information

ORION Users Manual For machines with 0. 83 Firmware

83 FirmwareThis is the complete User Manual for the Orion Delta 3D Printer that came with the firmware version 0.83. To verify this, simply look at the LCD screen when it powers on and it will display the machines firmware information

ORION Delta Firmware Calibration Gcode FilesThese two files are handy for calibrating your ORION DELTA. The first one named ORIONTOWERS will help you set your three tower endstop screws so you have a level table. The second file named ORIONHRADJUST is for adjusting any delta offset (concave/convex) movement if you modify or adjust your machine. It is specifically written to work best with the newest (091 or newer) firmware for the ORION DELTA. If you are using an older version, you can either update your firmware, or you will have to modify the firmware settings and re-upload for versions previous to 091.

Rostock MAX v2

We recommend the follow deviations from this guide

- Page 5 link error.

Click Here for RAMBO WinDrivers

Click Here for RAMBO WinDrivers - Use our recommended latest Cura slicing software setup for SE300 hotends Click Here for the setup guide

Building and Assembling Guide

Rostock MAX v2 Assembly Guide 4th Edition *

* corrections:

- page 139 click here for the new link for v2 original calibration

User Manual for operation and general setup (factory assembled machines start here)

Rostock MAX v2 Users Manual

Older versions for reference can be found below:

Rostock MAX v2 3rd Edition Manual for kits shipped between appx. 06/2015 and 10/2015

Rostock MAX v2 2nd Edition Manual for kits shipped between appx. 02/2015 and 06/2015

Rostock MAX v2 1st Edition Manual for kits shipped between appx. 03/2014 and 02/2015

Rostock MAX v2 Firmware

Rostock MAX v1 (kits shipped

BEFORE appx. 2/22/2014)

2/22/2014)We're often asked for help when someone buys one of these original kits assembled by the original buyer. SeeMeCNC will always provide help, but realize we will only direct you back the these original assembly instructions. We are not able to teach basic wiring, soldering, electrical troubleshooting. These are all basic skills and subject matter you can search on the web. :)

The RostockMAX v1 printer kits would have been assembled by the original purchaser. SeeMeCNC did not manufacture fully assembled printers at the time these printers were sold, we only sold a parts kits. So these machines would have been wired and built by the original buyer. As such, you should carefully review all connections and wiring. Review there are genuine SeeMeCNC factory parts used on the machine (reference the manual) or you could risk fire or damage to personal property or death.

Rostock MAX v1 Assembly/Users Manual

The complete Assembly Manual and users manual for the Rostock MAX DIY 3D Printer Kit

Rostock MAX Firmware

Here's a link to the firmware for the Rostock MAX

SeeMeCNC Open Source Files

Open Source Files

MatterControl User Manual

Here's a guide to get you started with our printers and MatterControl software.

Mattercontrol User Manual

The below links are for our SeeMeCNC specific versions of MatterControl. Use MatterControl to store your stl files, create your gcode and manage your prints all in one software.

GETTING STARTED GUIDE FOR MATTERCONTROL

MatterControl Pre configured Slicing Profiles

These settings are pre-configured for great starting prints with MatterControl software.

MatterControl Orion

MatterControl Rostock MAX

RAMBo USB Driver for Windows, including Windows 8 (Will require manually installing this driver)

Linux and Mac use CDC the interface and have the hardware driver built in already

Slic3r Pre configured Settings

These older profiles were proven to be good starting points for use with slic3r on stock 3D Printers. They were taken directly from our own setups at the shop, the only thing you may need to alter is the machine tab to set it to your machine size.

PLA Profile

ABS Profile

T-GLASE Profile

More... Online User Guides

Other Guides Online

Featured Products

View

View

View

View

See-Me-CNC - Orion Delta Printer | Adafruit Desktop 3D Printer Buyers Guide

See-Me-CNC - Orion Delta Printer

Save Subscribe

Please sign in to subscribe to this guide.

You will be redirected back to this guide once you sign in, and can then subscribe to this guide.

Download Profiles

CURA Orion Delta Profiles

Our preferred software for slicing parts is CURA from Ultimaker. Below is our profiles for CURA slicer settings. You can import the .ini file by using the “Open Profile…” option in the File menu.

Download Orion CURA Profile

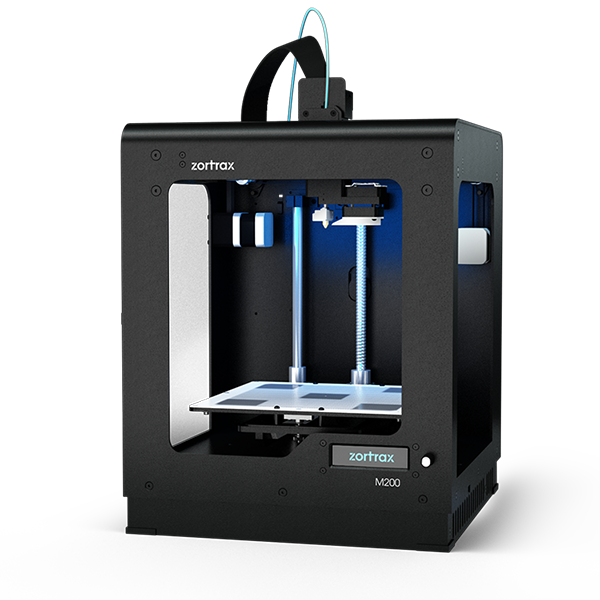

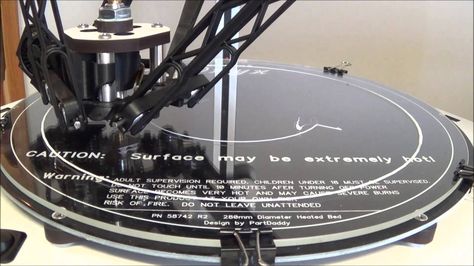

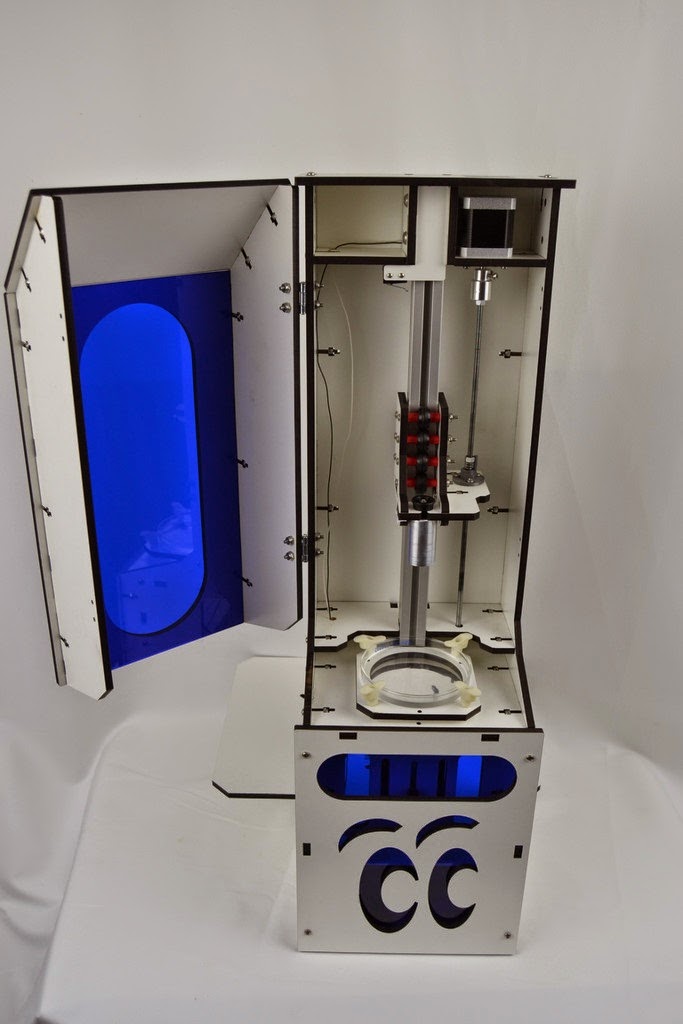

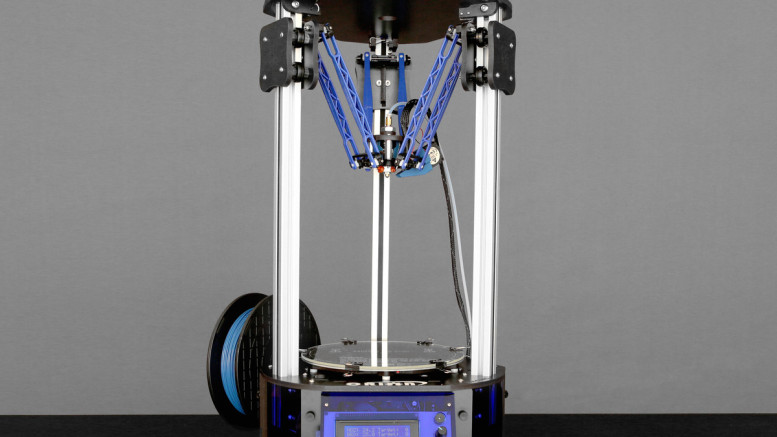

The ORION™ Delta 3D Printer is an exciting and attractive new 3D printer from the folks at SeeMe CNC that's designed to print ABS, PLA, and other materials from the very beginning. There's no need to refine or do anything to your printer - so you really have a ton more options for material than you usually do with an unmodified 3D printer.

There's no need to refine or do anything to your printer - so you really have a ton more options for material than you usually do with an unmodified 3D printer.

There's also an up-front LCD panel so you can see your printing status and an on-board SD card to store up to 4GB of files. The printer runs with high speed positioning (up to 300mm/s) with high precision at 50 micron accuracy.

This printer doesn't require much set up or configuration and you can basically start printing right out of the box. Comes with a 0.5mm nozzle and includes a 1lb spool of PLA filament. And if you need more, we carry a wide variety of filament here.

For the technical specs, accessories, and other details for the latest model version we are shipping, please visit the product page here.

- Excellent resolution for small prints at 100 microns

-

The small foot print is very welcoming in cramped spaces, enclosing it for printing in ABS will also save on space.

-

The drive gear is on the back, so it’s also more faster due to less weight on the extruder.

- Great value for a pre-assembled Delta with professionally manufactured parts such as injection molded Delta arms and Universal Joint brackets.

- Aluminum extrusions provide sturdy vertical tracks for the carriages.

- Print completely untethered with an onboard LCD interface allowing for printing from SD card *and* printer calibration.

- It is really fun watching this delta printing!

- Adjusting the endstop trigger screws at the top of each carriage is crucial to good printing, but time consuming to dial in accurately. It's worth doing this carefully!

- If the carriages are not tightened appropriately to the tracks, backlash can produce radial deformation, more difficult to identify and troubleshoot than backlash on a Cartesian machine. Adjust the "eccentric cams" to dial in the right grip on the rails, and you are back in business!

- Many of the best prints we have seen with these printers are using custom configurations for Cura, MatterSlice, or Simply3D rather than the original Slic3R profiles -- reach out to the active See-Me-CNC community and support resources for the latest slicing suggestions.

(They will be sharing more resources for us to link to here as well!)

(They will be sharing more resources for us to link to here as well!)

Who's the Machine For?

- Educators and students.

- Shop-owners, hackerspaces, and entrepreneurs looking to mesmerize onlookers.

- Those looking to print tall narrow objects such as 3D portraits.

- 3D Hobbyists eager to try a Delta -- who have been scared off by high price tag and steep learning curve of earlier Delta kits.

Bottom Line

Easy to setup and operate -- and half the cost of many of the Delta printers available on the market -- the Orion is the first Delta suitable for first-time 3D printing hobbyists, teachers and students. Expert users who spend extra effort dialing in this machine and building their own custom slicing profiles using tools such as Cura and Simplify3D will raise the baseline of the print quality from good up to excellent.

Printrbot Models

This guide was first published on Jul 31, 2014. It was last updated on Jul 31, 2014.

This page (See-Me-CNC - Orion Delta Printer) was last updated on Nov 09, 2014.

Text editor powered by tinymce.

Review-review on the Stratex 500 3D printer from 3diy

Hello everyone! I bought a Stratex 500 3D printer (previously called the Stratex L700) from 3diy, and I want to bring to your attention a review-review on this product from a domestic manufacturer, since on the Internet neither YouTube nor even the manufacturer's website has any review or recall on it, there is not even exact specifications (complete set, dimensions, weight, etc.).

The first thing I noticed and what confused me after unpacking is the absence of a filament end sensor, although it is present on other printers of this manufacturer at a price 2-3 times cheaper, when asked why it is not there, the 3diy manager has a clear answer could not give. This thing is inexpensive and I do not understand its absence.

https://youtube.com/shorts/Qj7JP0s25UI

Then I confused the wire from the cooler, lying directly on the rail, later I fixed it with a clamp to another wire and so far it seems to be holding on, although I have not even printed on this printer yet).

When the head is in the far right corner, the Teflon tube breaks in several places and I think it is unlikely that printing is possible there, when moving along the Y axis, the cable channel rubs against a wall painted with rough powder paint, which will be erased earlier - paint or cable channel is still unknown.

https://youtube.com/shorts/R5I1UnEkzPM

When turned on, you can immediately pay attention to the roaring single-board cooling fan (by the way, Raspberry Pi4B), apparently, the cheapest and at the same time high-speed fan is installed here. But the strangest thing is not even the noise, but the meaning of installing it here, since it is eventually closely closed by a lid, leaving a gap of a couple of millimeters, which is not enough for the passage of air flows, which prevented the electrician from arranging differently - it is not clear, there is plenty of space here. You can immediately pay attention to the cable management and garbage, apparently left by the collector.

https://youtube.com/shorts/iv8USgXAWxc

Next, let's move on to the printer workspace. It was supplied with glass measuring 530x530x5 mm, although the dimensions of the aluminum table plate are 520x520x3 mm, as a result, during installation, it protrudes from the edge of the plate by 5 mm on all four sides and actually rests against the walls of the printer case (!!!), on which there is still and the screws are screwed on, I think everyone understands what will happen to the glass if the table is lowered lower).

https://youtube.com/shorts/pqGLNXO7JFo

The printer is equipped with glass clamps, calculated but the total thickness of the plate-glass cake is 7mm, but the thickness of the complete glass is 5mm, the plate thickness is 3mm, total 8mm, so these clamps cannot be installed with this glass either. Moreover, these clamps cannot be used normally even with 4mm thick glass, since silicone heating of the table is glued to the underside of the plate almost right next to the edge (5mm), they can only be installed vice versa with the wide side up, which is also wrong because in this case they can hit the nozzle.

https://youtube.com/shorts/ZKeuABQHxZE

There are just under-twisted screws, which in principle is not surprising.

And here is the untwisted optical sensor of the Y axis, the nuts were just screwed on:

https://youtube.com/shorts/sV06hUjOpk4

fastenings 30 cm, rails 80 cm long are held on 4 screws), rails along the X and Y axes are fastened with screws 1 through 3 (rails 60 cm long are held on 5 screws). It is worth noting that all rails are HIWIN, along the X axis - 12mm, along the Y and Z axes - 15mm.

Next, we try to reset the head along the axes, and pay attention to the noise and resonances when moving along the X or Y axis separately (the Y axis is noticeably stronger), while moving diagonally, the printer does not hum or resonate. Initially, when zeroing, the printer was parked propping up the nozzle and the entire head by 1-2 mm on the table. Technical support initially tried to explain this by saying that it was most likely that something went wrong during transportation by the transport company (although I don’t understand what could go wrong here, because the table couldn’t go up from shaking, only fall down, the head with the beam couldn’t fall either) , in the end it turned out that this printer was simply not configured, more precisely, the Z offset was set incorrectly, in connection with which the table propped up its head. At the same time, technical support assures that at first they printed test samples, everything was fine, but before sending they changed the firmware and without checking it they sent it to me, and when I asked about noises and resonances, they answered me that it should be so, “this is not a music center” . It is also worth paying attention to the very tight movement along the axes, especially along the X axis, in order to push your head somewhere you need to make a huge effort, initially it was even scary to break something, everything seemed to be sitting there tightly (unfortunately I don’t have hand scales and measure the force that needs to be applied to move the head along the X axis or the beam along the Y axis, I can’t yet, maybe I’ll measure it later).

At the same time, technical support assures that at first they printed test samples, everything was fine, but before sending they changed the firmware and without checking it they sent it to me, and when I asked about noises and resonances, they answered me that it should be so, “this is not a music center” . It is also worth paying attention to the very tight movement along the axes, especially along the X axis, in order to push your head somewhere you need to make a huge effort, initially it was even scary to break something, everything seemed to be sitting there tightly (unfortunately I don’t have hand scales and measure the force that needs to be applied to move the head along the X axis or the beam along the Y axis, I can’t yet, maybe I’ll measure it later).

https://youtube.com/shorts/9FSkIcKX6zI

During the correspondence with technical support, as compensation for the crookedly assembled printer, I was asked to send plastic for printing, but why should I, it’s still unclear whether it will print at all, so I refused, I ordered such an expensive printer, hoping for quality and sane technical support, and all that technical support can do is offer plastic.

As a result, the print area seems to be large (500x500x700), but I won’t be able to print dimensional details on it, since it’s impossible to turn it on at night, the neighbors will complain, and I myself most likely won’t be able to fall asleep with such noise even in another room for two doors, moreover, the question is whether I can print on it at least during the day, whether the neighbors complain about the noise and that I set up a factory in the apartment)) In general, most likely it will have to be completely sorted out, change all the fans and the layout of the electrics, fix it normally and lubricate the rails (they are completely dry, the X-axis rails in places with traces of either corrosion or something else), at the same time transfer it to the Clipper, since it is on Marlin with Octoprint, perhaps the resonances will become less, or their influence on the print quality with InputShaping will become smaller.

In general, there is an opinion that this is an extremely crude, structurally unfinished product, although 3diy managers claim that they have sold a lot of printers of this model, but I think that this, in principle, cannot be sold, especially for such money. Perhaps in the future I will supplement the review with a new article, since I just unpacked this 3D printer and did not print anything on it and did not even fill it with plastic. That's all for now)

Perhaps in the future I will supplement the review with a new article, since I just unpacked this 3D printer and did not print anything on it and did not even fill it with plastic. That's all for now)

How Volgograd united the owners of 3D printers throughout the country to help the military in the NWO | v1.ru

All newsVolgograd man surrendered child porn seller to investigation

50 servicemen of the Russian Armed Forces released from Ukrainian captivity: news around the special operation on December 1

“Even a kindergarten and a school are freezing”: a military town near Volgograd was left without heat

Ended up in the base of the dead: traffic police officers stopped a man and reported that he had died - according to documents

“Everything for 100”: how an entrepreneur lost hundreds of thousands selling sweatshirts on Wildberries

“I'll shoot you! You won’t live until tomorrow”: a dog-catcher who beat a girl with a pipe in Volgograd threatened to kill her

Stably serious: doctors told about the condition of a pedestrian who was hit by a policeman near Volgograd corporal woman

Authorities are handing out multimillion-dollar contracts to private traders to feed patients in hospitals in Volgograd and the region

“He was a man of victory”: in Volgograd, orders were handed over to the families of seven soldiers and officers who died in Ukraine video

“Why am I worse?”: a pensioner with cancer is relocated from an emergency house to a problematic one, and her neighbors are moved to new buildings

Potemkin village or a new way? Experts on what is behind the rapid Chineseization of the automotive industry

“She works as a manager”: the parents of a child who died in a car explosion dealt with gas equipment

My husband's ear can't hear, his eyes can't see, but he was mobilized. Wife's hand is taken away, and she doesn't know how to live without him

Wife's hand is taken away, and she doesn't know how to live without him

In Volgograd, the Order of Courage is handed over to relatives of seven killed in a special operation in Ukraine

“No one knew that the boy was in the car. We could have saved him”: everything we know about the car explosion in Volgograd

“I don’t eat sugar and bread”: we asked our readers what and how they save money — here are their tips

A street video surveillance camera filmed the moment of a car explosion in a residential area of Volgograd

“A man broke his arm and burned his face”: eyewitnesses told about a car explosion in Volgograd

“There is not even a “pop””: look at how the emergency services called the tragedy in Volgograd and law enforcement agencies

"Strong smell for safety": all about the gas that killed a three-year-old boy in Volgograd

"People almost don't shop." Economists told who in Russia will increase salaries next year0003

There was a loud bang and sparks flew: the moment of the explosion in Novokomarovo in Volgograd was caught on video

A criminal case was initiated in Volgograd on the fact of a car explosion in which a three-year-old child died

Is it forbidden to write about a special operation in Russia? We study the order of the FSB, which came into force on December 1

Everything burned to the ground there: a video from the site of a car explosion in Volgograd appeared

A child died, an adult was in the hospital: details of a car explosion in Volgograd

Terrible car explosion in Volgograd. Child died, father in critical condition

Child died, father in critical condition

Salary up to 150,000: defense plants lure workers away with huge earnings — who and whom is looking for

“An adult with a child sat in it”: a car exploded in a residential area of Volgograd — video

What, again? ! The first region of Russia proposed to return to masks - and it's not just about covid

What awaits us in December: the communal apartment was unscheduled, but it was allowed to make hammams and saunas in apartments

VKontakte does not work, YouTube does not open: social networks began to fail in Russia

“We did not give up”: the court changed the verdict in the case of the death of five Volgograd basketball players communal disaster in Volgograd

Senators do not consider Ukrainian captivity as a reason not to pay child support: news around the special operation for November 30

All news

Vladimir started printing turnstiles for the military right at home

Photo: Aleksey Volkhonsky

Share

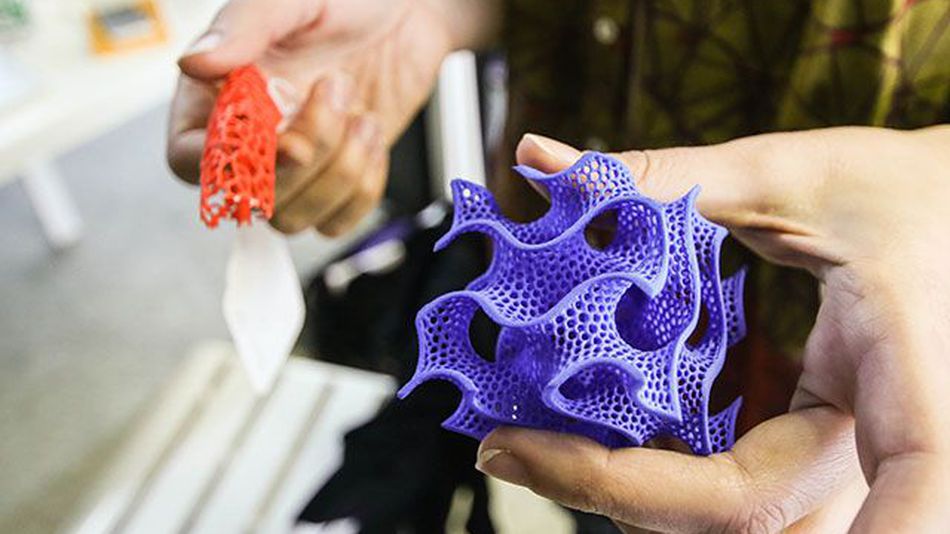

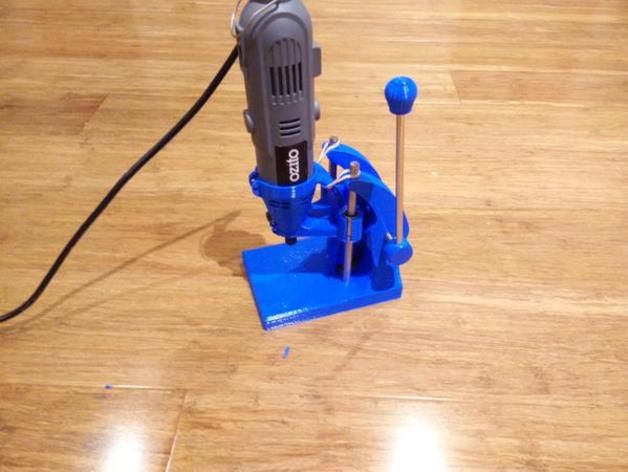

Women from different cities of Russia knit hats and scarves, sew balaclavas and sweatshirts for the military engaged in a special military operation; children from all over the country write letters of support to the military; and enthusiasts and inventors from Volgograd united craftsmen, adapting 3D printing to the needs of the military. We tell how Volgograd made Russia "printed".

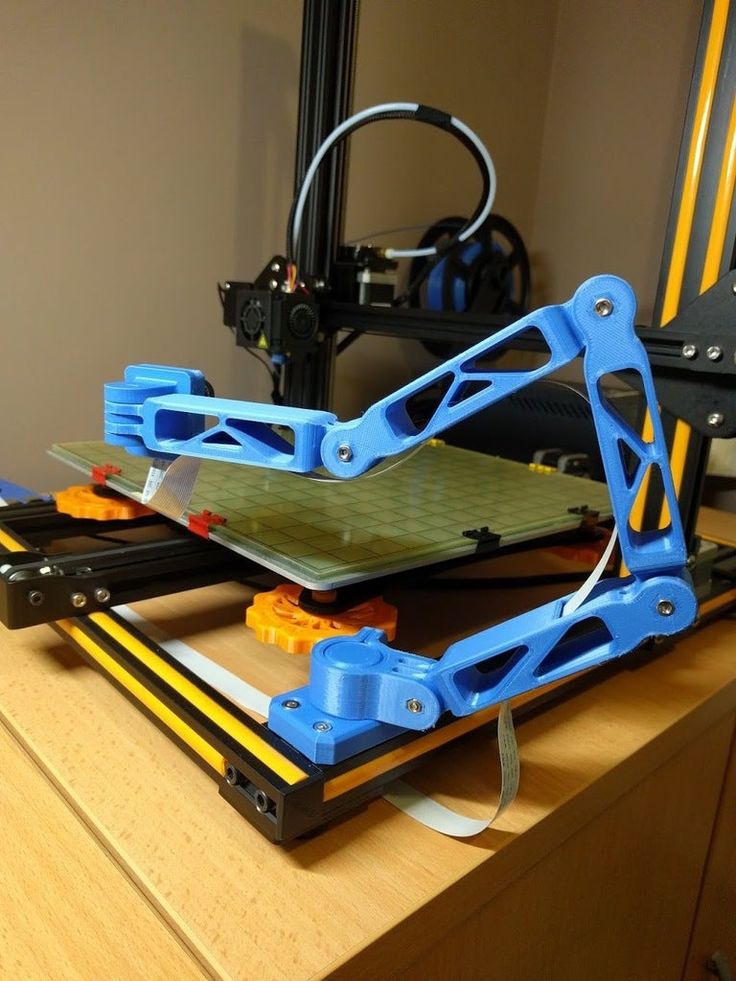

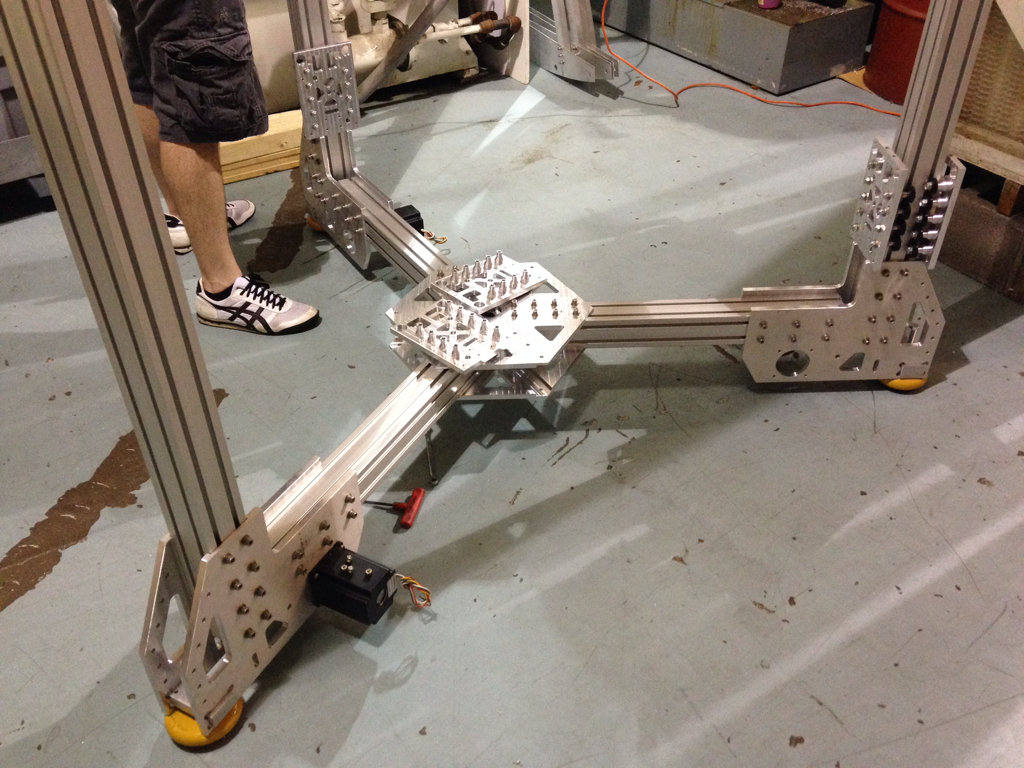

Vladimir Slobodenyuk is one of the Volgograd residents involved in the production, assembly and shipment of turnstiles. He is an ordinary guy who has a couple of 3D printers at home and some free time. And he proposed the idea of printing turnstiles for the needs of doctors and military personnel. Hundreds of Russians who own newfangled technology supported the idea.

“During the coronavirus pandemic, communities of people with 3D printers were already uniting to help healthcare workers,” recalls Vladimir. - Then many printed masks on printers, helped to do some necessary things with the help of printing, and it worked. This year, in the process of communicating with doctors on the front line, it became clear: we need to help those who are now defending our country. This is how the community “For Life” appeared.

This year, in the process of communicating with doctors on the front line, it became clear: we need to help those who are now defending our country. This is how the community “For Life” appeared.

Then, according to Vladimir, through a joint brainstorming session that brought together the military, doctors, and printer owners, they found that very useful and extremely necessary little thing that everyone could do.

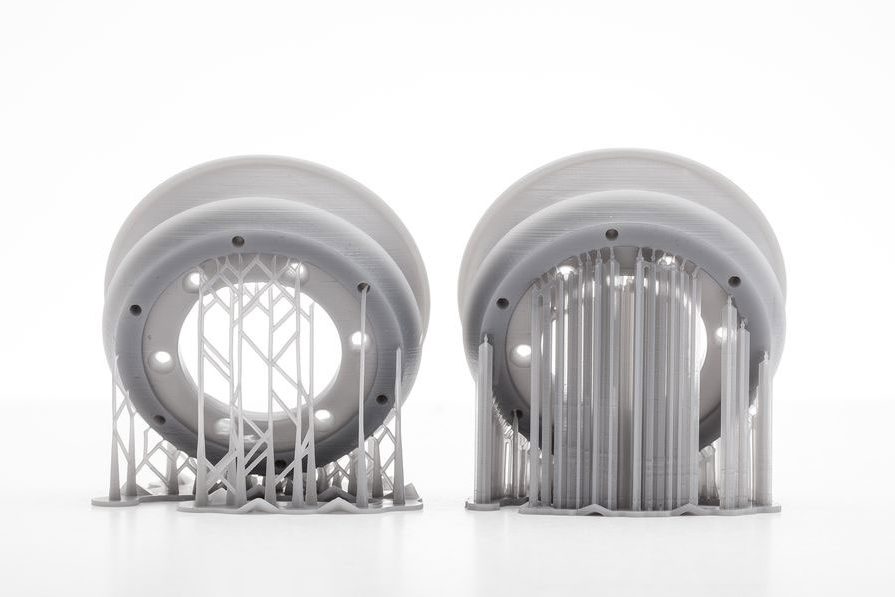

— We consulted for a long time, thinking about how we can also help. As a result, doctors and the military said that there was a problem with consumables, in particular, there were not enough hemostatic tourniquets and tourniquets,” says Vladimir. - They are necessary both for learning and for the ability to apply this skill if necessary. We decided to try to make it ourselves. We reviewed the design of already existing similar devices, available ready-made 3D models, noted weaknesses and strengths, a concept was formed, and we began to try. More and more they tried to use printed parts, tried different manufacturing options, changed plastics, used a freezer, tested for twisting and breaking. All in order to be able to produce the same part with the most identical characteristics in completely different regions of Russia.

All in order to be able to produce the same part with the most identical characteristics in completely different regions of Russia.

Hemostatic tourniquet - a device for pulling a limb and stopping blood flow. According to experts, this is a modern analogue of a medical tourniquet, the simplest surgical instrument for clamping blood vessels. The turnstile can be used on any limb (even the head) - it works by squeezing. At the same time, tourniquets are actively used in field medicine.

Components for turnstiles are printed by owners of 3D printers from all over Russia

Photo: ZaHealth/ telegram

Share

According to the craftsmen, it was important for them that the turnstile was of high quality and could withstand any, even the most unrealistic loads.

“We were faced with the task of making such a device, having learned to use it, the wounded person will be able to help himself,” Volgograd residents said. “We wanted the device to be as simple and easy to use as possible. We started making hemostatic tourniquets ourselves. Parts were printed by people from various cities of Russia: from Murmansk to Volgograd and Novosibirsk. In order to maintain the same quality, we decided that all printed parts are sent to us - in Volgograd, here each part is already checked and, if necessary, replaced. We have several verification and testing systems.

“We wanted the device to be as simple and easy to use as possible. We started making hemostatic tourniquets ourselves. Parts were printed by people from various cities of Russia: from Murmansk to Volgograd and Novosibirsk. In order to maintain the same quality, we decided that all printed parts are sent to us - in Volgograd, here each part is already checked and, if necessary, replaced. We have several verification and testing systems.

Each turnstile takes about five hours of work

Photo: Alexey Volkhonsky

Share

Turnstiles are tested for flexibility, for the ability to bend in different directions without cracks or breakage, plastic must be pliable and elastic.

“We freeze them, then we check again how the product reacts to cold, many details are rejected during the checks,” Volgograd residents say. - We remove everything that does not fit our criteria, because we do not want the turnstile to break in the hands of a fighter, for example.

By the way, at the same time, the fighters themselves arranged a test drive for the turnstiles, the military checked the flexibility on a birch tree, wrapping the device around a tree trunk.

— The whole family really takes part in the assembly process, — the townspeople say. - Children help someone to collect, grandfathers or grandmothers, husbands and wives help someone. Do you understand what is the most valuable thing in these turnstiles? It is made with love and care. There, in the NVO zone, the fighters, receiving it, feel the warmth that some Masha from Murmansk put into it.

Companies share their capacities and also print turnstiles

Photo: ZaHealth/ telegram

Share

— In fact, there are a lot of details, one print takes 5 hours, and it still takes time to prepare fittings, assembly and laying. Approximately as much of the most valuable resource is invested in each product, - says Vladimir. Therefore, we are always happy to receive any help. Someone came in their free time and assembled a dozen turnstiles, while someone has a 3D printer at home and would like to participate in the manufacture of parts. Our entire community is made up of such caring people who want to at least somehow help the military.

Therefore, we are always happy to receive any help. Someone came in their free time and assembled a dozen turnstiles, while someone has a 3D printer at home and would like to participate in the manufacture of parts. Our entire community is made up of such caring people who want to at least somehow help the military.

Volgograd residents were also supported by Russian entrepreneurs.

news from the story

Subscribe to important news about the special operation in Ukraine

— Many business representatives really help us a lot. Someone makes good discounts for us, someone helps with fittings, and someone, having learned that 15 turnstiles are obtained from a kilogram plastic coil, transfers money for the purchase of plastic,” Vladimir said. — Some companies that have 3D printers in production provide part of their capacities for the manufacture of turnstiles, this is a very big support for us. More and more people learn about the project "For Life" and actively participate in it, people express their thoughts on how to improve certain production processes, and help in modeling.