Meaning of 3d printing

What is 3D Printing? - Technology Definition and Types

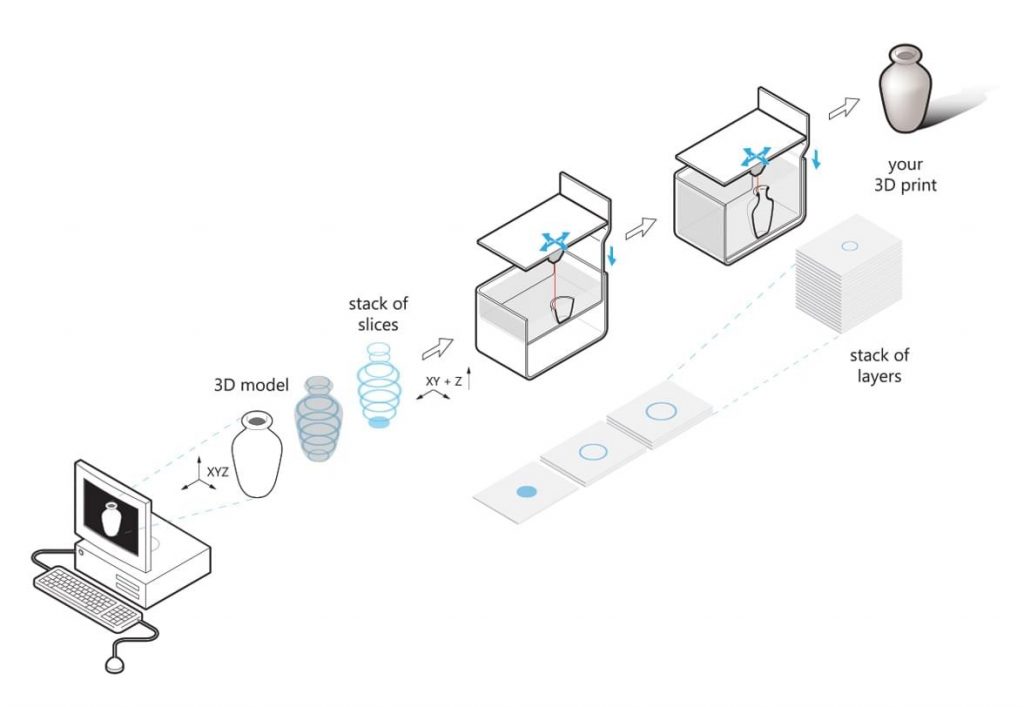

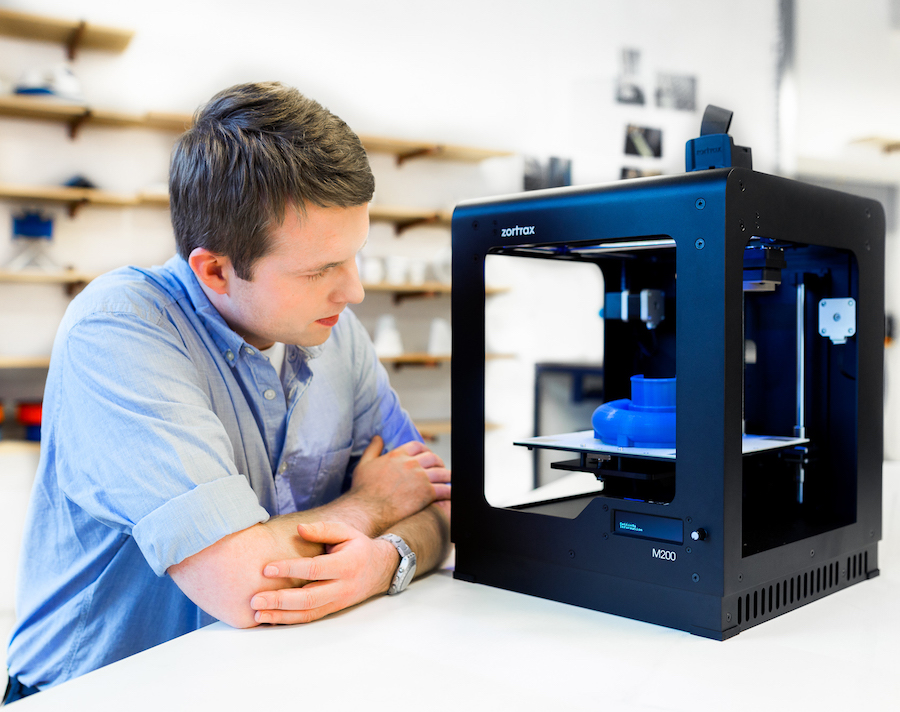

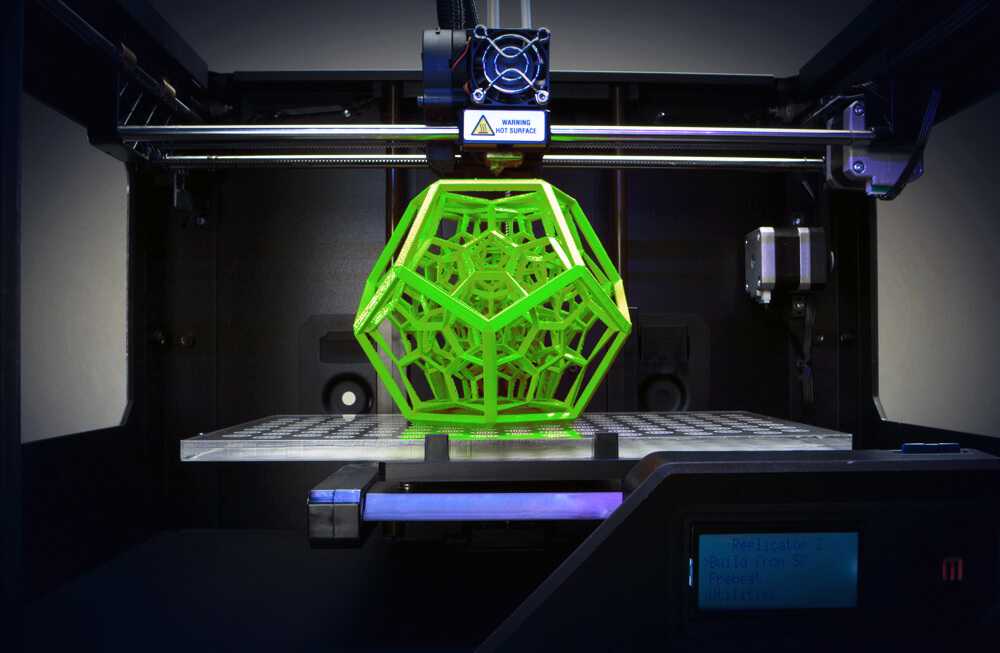

3D printing, also known as additive manufacturing, is a method of creating a three dimensional object layer-by-layer using a computer created design.

3D printing is an additive process whereby layers of material are built up to create a 3D part. This is the opposite of subtractive manufacturing processes, where a final design is cut from a larger block of material. As a result, 3D printing creates less material wastage.

This article is one of a series of TWI frequently asked questions (FAQs).

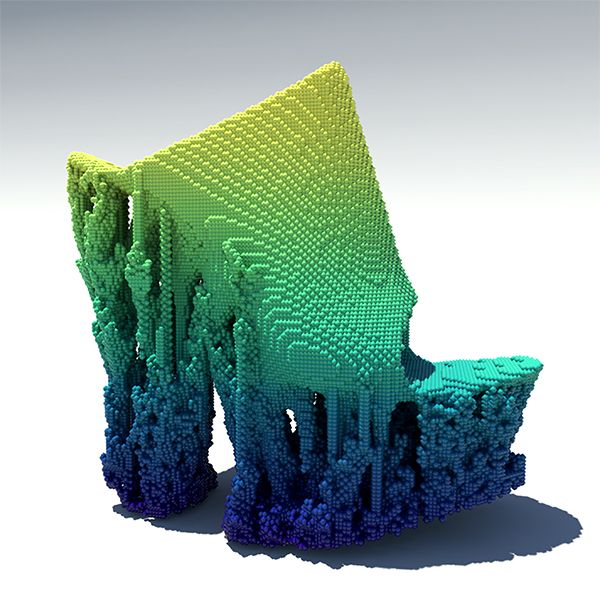

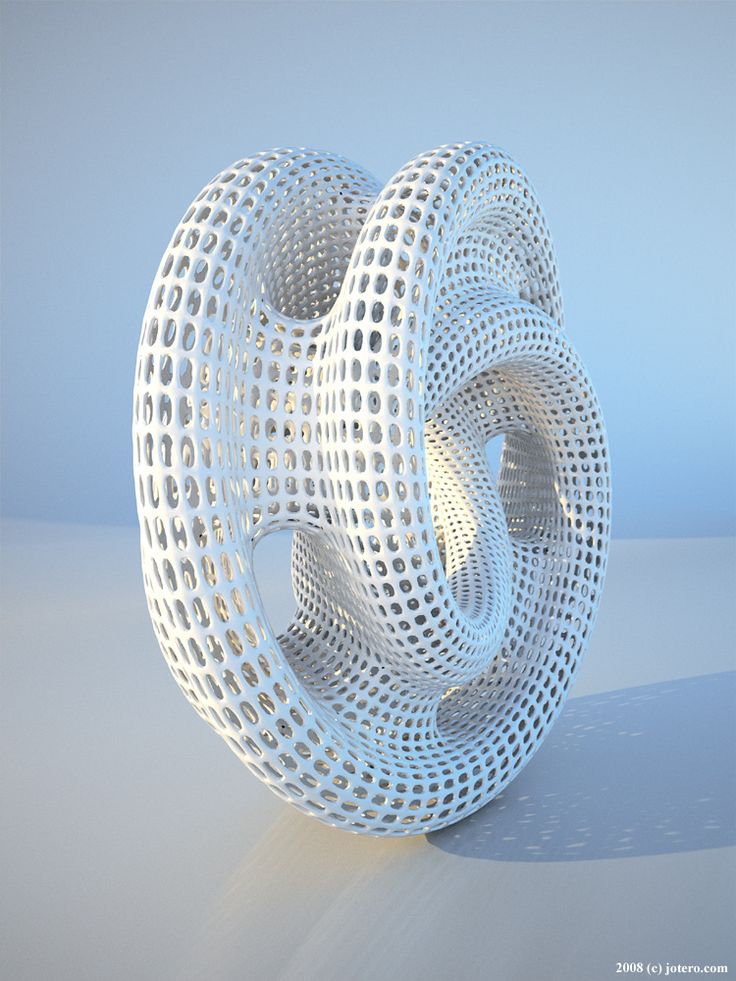

3D printing is also perfectly suited to the creation of complex, bespoke items, making it ideal for rapid prototyping.

Contents

- What materials can be used?

- History

- Technologies

- Process types

- How long does it take?

- Advantages and disadvantages

- What is an STL file?

- Industries

- Services

- FAQs

TWI

TWI is an Industrial Membership based organisation. TWI's experts can provide your company with an extension to your own resources. Our experts are dedicated to helping industry improve safety, quality, efficiency and profitability in all aspects of materials joining technology. Industrial Membership of TWI currently extends to over 600 companies worldwide, embracing all industrial sectors.

You can find out more by contacting us, below:

There are a variety of 3D printing materials, including thermoplastics such as acrylonitrile butadiene styrene (ABS), metals (including powders), resins and ceramics.

Who Invented 3D Printing?

The earliest 3D printing manufacturing equipment was developed by Hideo Kodama of the Nagoya Municipal Industrial Research Institute, when he invented two additive methods for fabricating 3D models.

When was 3D Printing Invented?

Building on Ralf Baker's work in the 1920s for making decorative articles (patent US423647A), Hideo Kodama's early work in laser cured resin rapid prototyping was completed in 1981. His invention was expanded upon over the next three decades, with the introduction of stereolithography in 1984. Chuck Hull of 3D Systems invented the first 3D printer in 1987, which used the stereolithography process. This was followed by developments such as selective laser sintering and selective laser melting, among others. Other expensive 3D printing systems were developed in the 1990s-2000s, although the cost of these dropped dramatically when the patents expired in 2009, opening up the technology for more users.

There are three broad types of 3D printing technology; sintering, melting, and stereolithography.

- Sintering is a technology where the material is heated, but not to the point of melting, to create high resolution items.

Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering.

Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering. - Melting methods of 3D printing include powder bed fusion, electron beam melting and direct energy deposition, these use lasers, electric arcs or electron beams to print objects by melting the materials together at high temperatures.

- Stereolithography utilises photopolymerization to create parts. This technology uses the correct light source to interact with the material in a selective manner to cure and solidify a cross section of the object in thin layers.

Types of 3D printing

3D printing, also known as additive manufacturing, processes have been categorised into seven groups by ISO/ASTM 52900 additive manufacturing - general principles - terminology. All forms of 3D printing fall into one of the following types:

- Binder Jetting

- Direct Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- VAT Polymerization

Binder Jetting

Binder jetting deposits a thin layer of powered material, for example metal, polymer sand or ceramic, onto the build platform, after which drops of adhesive are deposited by a print head to bind the particles together. This builds the part layer by layer and once this is complete post processing may be necessary to finish the build. As examples of post processing, metal parts may be thermally sintered or infiltrated with a low melting point metal such as bronze, while full-colour polymer or ceramic parts may be saturated with cyanoacrylate adhesive.

This builds the part layer by layer and once this is complete post processing may be necessary to finish the build. As examples of post processing, metal parts may be thermally sintered or infiltrated with a low melting point metal such as bronze, while full-colour polymer or ceramic parts may be saturated with cyanoacrylate adhesive.

Binder jetting can be used for a variety of applications including 3D metal printing, full colour prototypes and large scale ceramic moulds.

Direct Energy Deposition

Direct energy depositioning uses focussed thermal energy such as an electric arc, laser or electron beam to fuse wire or powder feedstock as it is deposited. The process is traversed horizontally to build a layer, and layers are stacked vertically to create a part.

This process can be used with a variety of materials, including metals, ceramics and polymers.

Material Extrusion

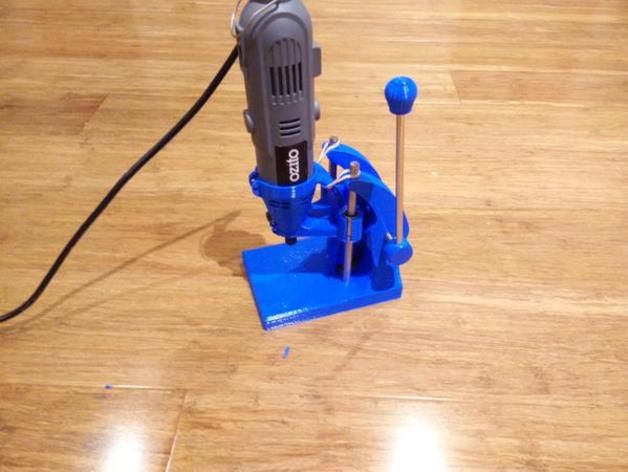

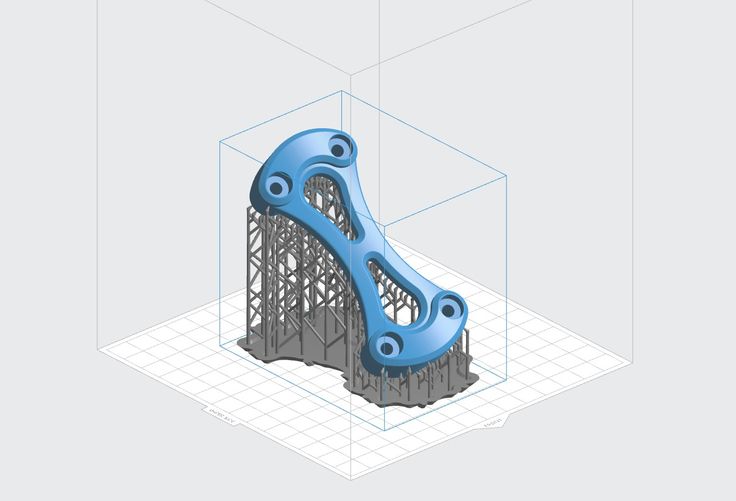

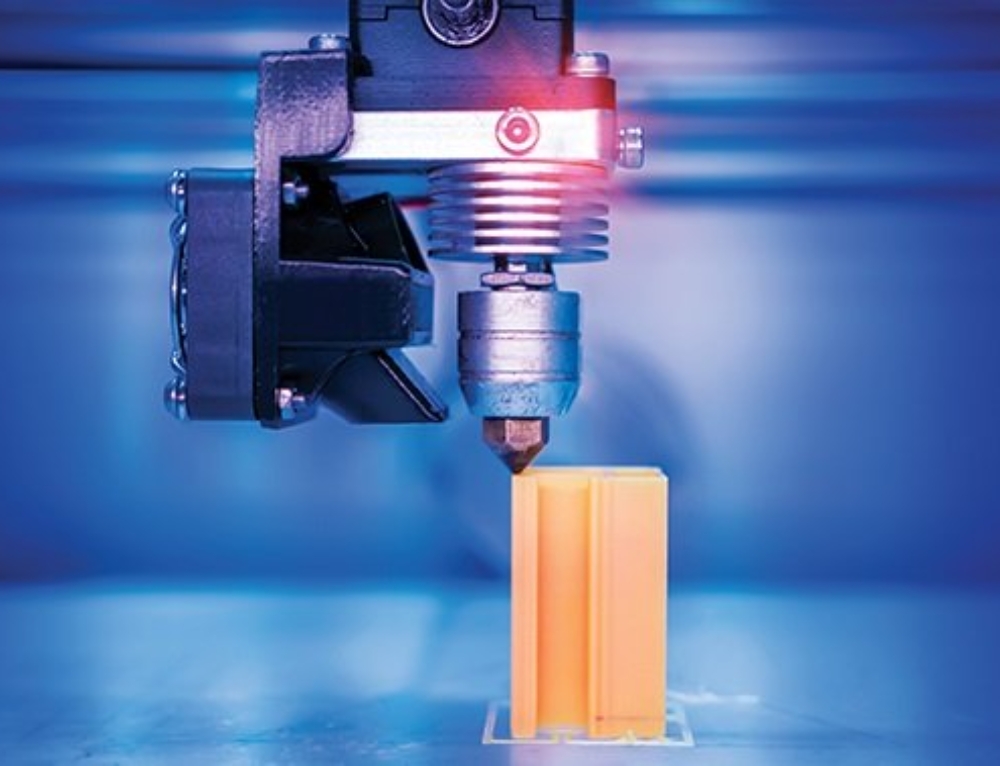

Material extrusion or fused deposition modelling (FDM) uses a spool of filament which is fed to an extrusion head with a heated nozzle.![]() The extrusion head heats, softens and lays down the heated material at set locations, where it cools to create a layer of material, the build platform then moves down ready for the next layer.

The extrusion head heats, softens and lays down the heated material at set locations, where it cools to create a layer of material, the build platform then moves down ready for the next layer.

This process is cost-effective and has short lead times but also has a low dimensional accuracy and often requires post processing to create a smooth finish. This process also tends to create anisotropic parts, meaning that they are weaker in one direction and therefore unsuitable for critical applications.

Material Jetting

Material jetting works in a similar manner to inkjet printing except, rather than laying down ink on a page, this process deposits layers of liquid material from one or more print heads. The layers are then cured before the process begins again for the next layer. Material jetting requires the use of support structures but these can be made from a water-soluble material that can be washed away once the build is complete.

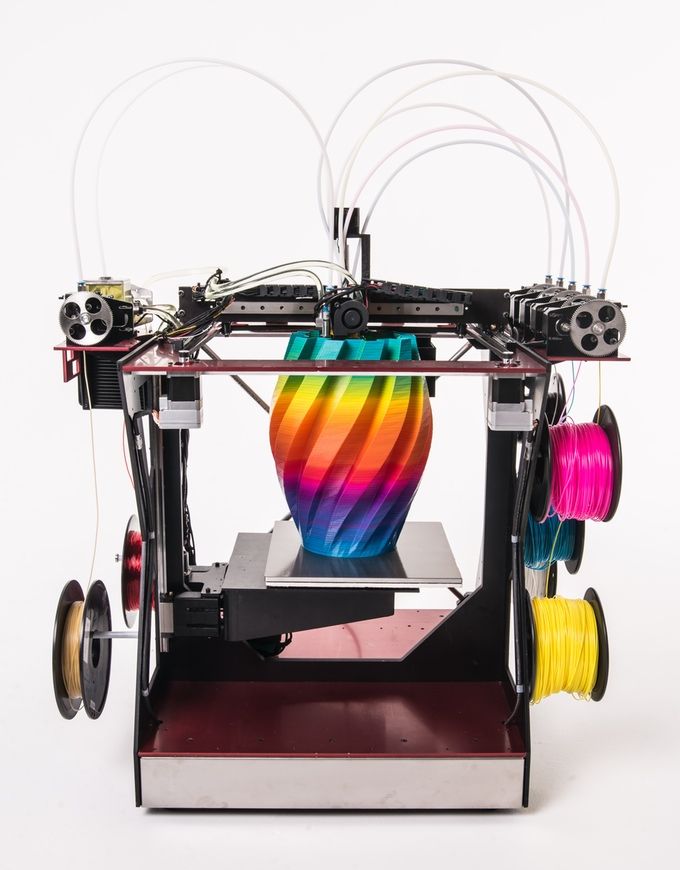

A precise process, material jetting is one of the most expensive 3D printing methods, and the parts tend to be brittle and will degrade over time. However, this process allows for the creation of full-colour parts in a variety of materials.

However, this process allows for the creation of full-colour parts in a variety of materials.

Powder Bed Fusion

Powder bed fusion (PBF) is a process in which thermal energy (such as a laser or electron beam) selectively fuses areas of a powder bed to form layer, and layers are built upon each other to create a part. One thing to note is that PBF covers both sintering and melting processes. The basic method of operation of all powder bed systems is the same: a recoating blade or roller deposits a thin layer of the powder onto the build platform, the powder bed surface is then scanned with a heat source which selectively heats the particles to bind them together. Once a layer or cross-section has been scanned by the heat source, the platform moves down to allow the process to begin again on the next layer. The final result is a volume containing one or more fused parts surrounded by unaffected powder. When the build is complete, the bed is fully raised to allow the parts to be removed from the unaffected powder and any required post processing to begin.

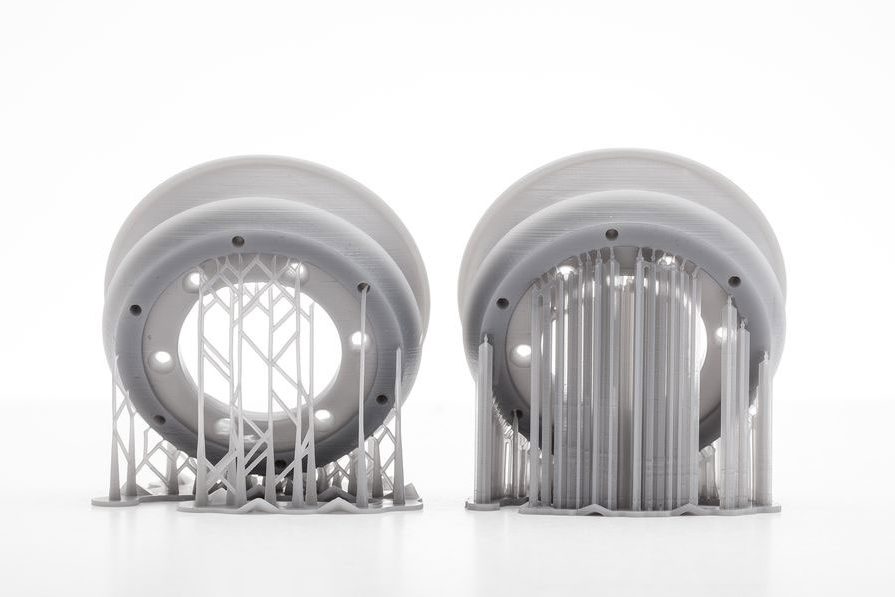

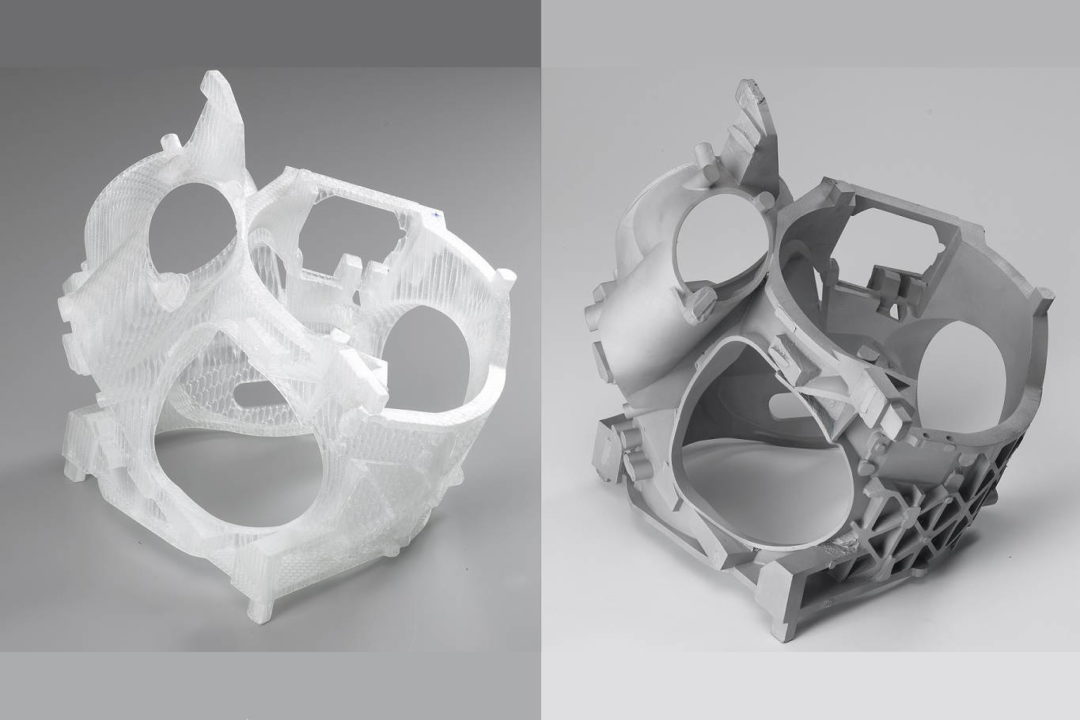

Selective laser sintering (SLS) is often used for manufacture of polymer parts and is good for prototypes or functional parts due to the properties produced, while the lack of support structures (the powder bed acts as a support) allows for the creation of pieces with complex geometries. The parts produced may have a grainy surface and inner porosity, meaning there is often a need for post processing.

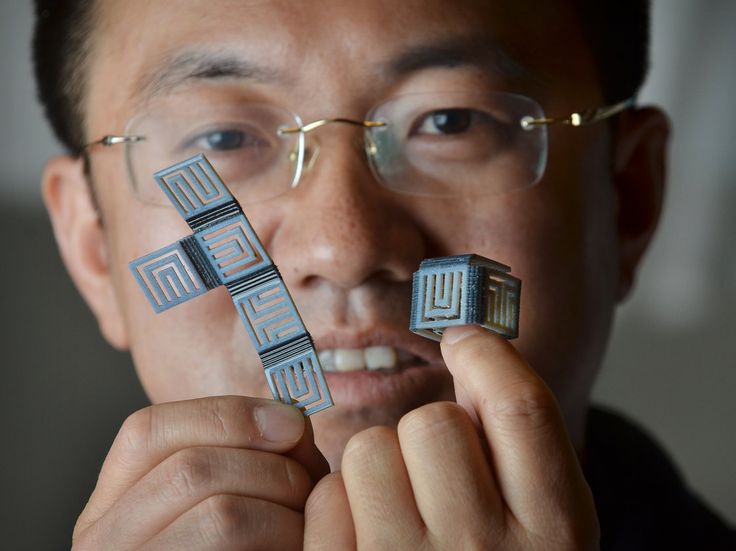

Direct metal laser sintering (DMLS), selective laser melting (SLM) and electron beam powder bed fusion (EBPBF) are similar to SLS, except these processes create parts from metal, using a laser to bond powder particles together layer-by-layer. While SLM fully melts the metal particles, DMLS only heats them to the point of fusion whereby they join on a molecular level. Both SLM and DMLS require support structures due to the high heat inputs required by the process. These support structures are then removed in post processing ether manually or via CNC machining. Finally, the parts may be thermally treated to remove residual stresses.

Both DMLS and SLM produce parts with excellent physical properties - often stronger than the conventional metal itself, and good surface finishes. They can be used with metal superalloys and sometimes ceramics which are difficult to process by other means. However, these processes can be expensive and the size of the produced parts is limited by the volume of the 3D printing system used.

Sheet Lamination

Sheet lamination can be split into two different technologies, laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). LOM uses alternate layers of material and adhesive to create items with visual and aesthetic appeal, while UAM joins thin sheets of metal via ultrasonic welding. UAM is a low temperature, low energy process that can be used with aluminium, stainless steel and titanium.

VAT Photopolymerization

VAT photopolymerization can be broken down into two techniques; stereolithography (SLA) and digital light processing (DLP). These processes both create parts layer-by-layer through the use of a light to selectively cure liquid resin in a vat. SLA uses a single point laser or UV source for the curing process, while DLP flashes a single image of each full layer onto the surface of the vat. Parts need to be cleaned of excess resin after printing and then exposed to a light source to improve the strength of the pieces. Any support structures will also need to be removed and additional post-processing can be used to create a higher quality finish.

These processes both create parts layer-by-layer through the use of a light to selectively cure liquid resin in a vat. SLA uses a single point laser or UV source for the curing process, while DLP flashes a single image of each full layer onto the surface of the vat. Parts need to be cleaned of excess resin after printing and then exposed to a light source to improve the strength of the pieces. Any support structures will also need to be removed and additional post-processing can be used to create a higher quality finish.

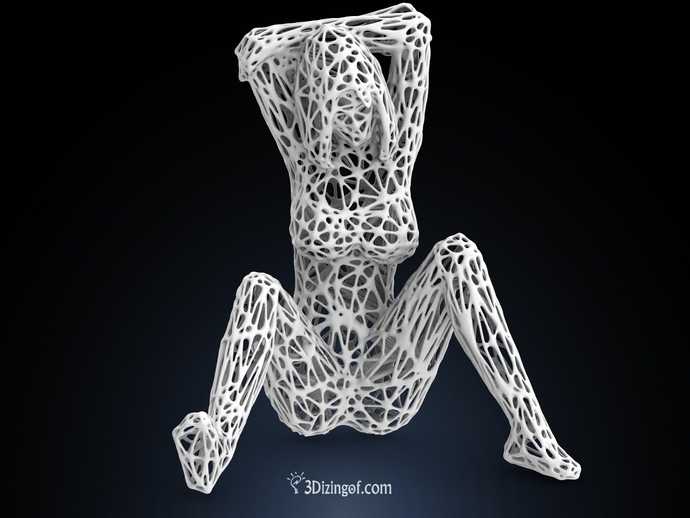

Ideal for parts with a high level of dimensional accuracy, these processes can create intricate details with a smooth finish, making them perfect for prototype production. However, as the parts are more brittle than fused deposition modelling (FDM) they are less suited to functional prototypes. Also, these parts are not suitable for outdoor use as the colour and mechanical properties may degrade when exposed to UV light from the sun. The required support structures can also leave blemishes that need post processing to remove.

The printing time depends on a number of factors, including the size of the part and the settings used for printing. The quality of the finished part is also important when determining printing time as higher quality items take longer to produce. 3D printing can take anything from a few minutes to several hours or days - speed, resolution and the volume of material are all important factors here.

The advantages of 3D printing include:

- Bespoke, cost-effective creation of complex geometries:

This technology allows for the easy creation of bespoke geometric parts where added complexity comes at no extra cost. In some instances, 3D printing is cheaper than subtractive production methods as no extra material is used. - Affordable start-up costs:

Since no moulds are required, the costs associated with this manufacturing process are relatively low. The cost of a part is directly related to the amount of material used, the time taken to build the part and any post processing that may be required.

The cost of a part is directly related to the amount of material used, the time taken to build the part and any post processing that may be required. - Completely customisable:

Because the process is based upon computer aided designs (CAD), any product alterations are easy to make without impacting the manufacturing cost. - Ideal for rapid prototyping:

Because the technology allows for small batches and in-house production, this process is ideal for prototyping, which means that products can be created faster than with more traditional manufacturing techniques, and without the reliance on external supply chains. - Allows for the creation of parts with specific properties:

Although plastics and metals are the most common materials used in 3D printing, there is also scope for creating parts from specially tailored materials with desired properties. So, for example, parts can be created with high heat resistance, water repellency or higher strengths for specific applications.

The disadvantages of 3D printing include:

- Can have a lower strength than with traditional manufacture:

While some parts, such as those made from metal, have excellent mechanical properties, many other 3D printed parts are more brittle than those created by traditional manufacturing techniques. This is because the parts are built up layer-by-layer, which reduces the strength by between 10 and 50%. - Increased cost at high volume:

Large production runs are more expensive with 3D printing as economies of scale do not impact this process as they do with other traditional methods. Estimates suggest that when making a direct comparison for identical parts, 3D printing is less cost effective than CNC machining or injection moulding in excess of 100 units, provided the parts can be manufactured by conventional means. - Limitations in accuracy:

The accuracy of a printed part depends on the type of machine and/or process used. Some desktop printers have lower tolerances than other printers, meaning that the final parts may slightly differ from the designs. While this can be fixed with post-processing, it must be considered that 3D printed parts may not always be exact.

Some desktop printers have lower tolerances than other printers, meaning that the final parts may slightly differ from the designs. While this can be fixed with post-processing, it must be considered that 3D printed parts may not always be exact. - Post-processing requirements:

Most 3D printed parts require some form of post-processing. This may be sanding or smoothing to create a required finish, the removal of support struts which allow the materials to be built up into the designated shape, heat treatment to achieve specific material properties or final machining.

An STL file is a simple, portable format used by computer aided design (CAD) systems to define the solid geometry for 3D printable parts. An STL file provides the input information for 3D printing by modelling the surfaces of the object as triangles that share edges and vertices with other neighbouring triangles for the build platform. The resolution of the STL file impacts the quality of the 3D printed parts - if the file resolution is too high the triangle may overlap, if it is too low the model will have gaps, making it unprintable. Many 3D printers require an STL file to print from, however these files can be created in most CAD programs.

Many 3D printers require an STL file to print from, however these files can be created in most CAD programs.

Due to the versatility of the process, 3D printing has applications across a range of industries, for example:

Aerospace

3D printing is used across the aerospace (and astrospace) industry due to the ability to create light, yet geometrically complex parts, such as blisks. Rather than building a part from several components, 3D printing allows for an item to be created as one whole component, reducing lead times and material wastage.

Automotive

The automotive industry has embraced 3D printing due to the inherent weight and cost reductions. It also allows for rapid prototyping of new or bespoke parts for test or small-scale manufacture. So, for example, if a particular part is no longer available, it can be produced as part of a small, bespoke run, including the manufacture of spare parts. Alternatively, items or fixtures can be printed overnight and are ready for testing ahead of a larger manufacturing run.

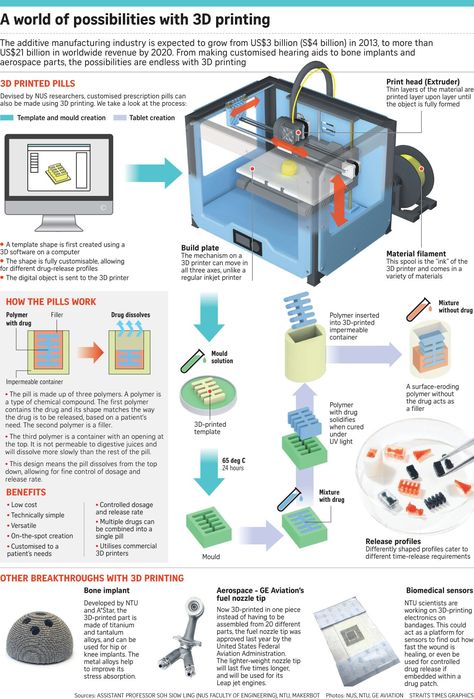

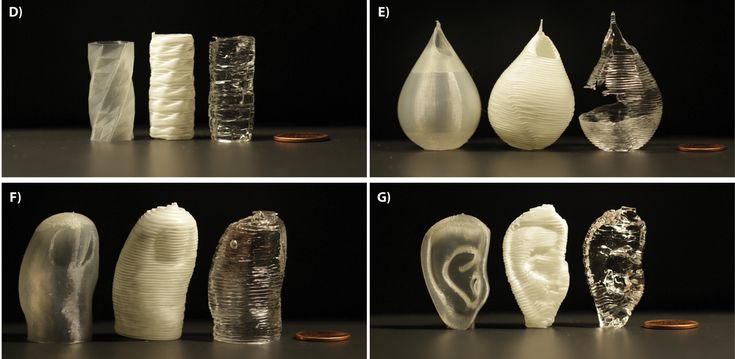

Medical

The medical sector has found uses for 3D printing in the creation of made-to-measure implants and devices. For example, hearing aids can be created quickly from a digital file that is matched to a scan of the patient's body. 3D printing can also dramatically reduce costs and production times.

Rail

The rail industry has found a number of applications for 3D printing, including the creation of customised parts, such as arm rests for drivers and housing covers for train couplings. Bespoke parts are just one application for the rail industry, which has also used the process to repair worn rails.

Robotics

The speed of manufacture, design freedom, and ease of design customisation make 3D printing perfectly suited to the robotics industry. This includes work to create bespoke exoskeletons and agile robots with improved agility and efficiency.

TWI has one of the most definitive ranges of 3D Printing services, including selective laser melting, laser deposition, wire and arc additive manufacturing, wire and electron beam additive manufacturing and EB powder bed fusion small-scale prototyping, and more.

Additive Manufacturing

TWI provides companies with support covering every aspect of metal additive manufacturing (AM), from simple feasibility and fabrication projects to full adoption and integration of metal AM systems.

Laser Metal Deposition

TWI has been developing LMD technology for the last ten years. For full details of our capabilities in this area, and to find out more about the process and the benefits it can bring to your business.

Selective Laser Melting

TWI has been developing selective laser melting technology for the last decade. Find out full details of our capabilities in this area and the benefits it can bring to your business.

Can 3D Printing be used for Mass Production?

While there have been great advances in 3D printing, it still struggles to match other manufacturing techniques for high volume production. Techniques such as injection moulding allow for much faster mass production of parts.

Where is 3D Printing Heading in the Future?

As 3D printing technology continues to improve it could democratise the manufacture of goods. With printers becoming faster, they will be able to work on larger scale production projects, while lowering the cost of 3D printing will help its use spread outside of industrial uses and into homes, schools and other settings.

Which 3D Printing Material is most Flexible?

Thermoplastic polyurethane (TPU) is commonly deemed to be the most flexible material available to the 3D printing industry. TPU possesses bendable and stretchy characteristics that many other filaments do not have.

Which 3D Printing Material is the Strongest?

Polycarbonate is seen as the strongest 3D printing material, with a tensile strength of 9,800 psi, compared to nylon, for example, with just 7,000 psi.

Why is 3D Printing Important?

3D printing is important for the many benefits it brings. It allows users to produce items that have geometries which are difficult or impossible for traditional methods to produce. It also allows users with a limited experience to edit designs and create bespoke, customised parts. On-demand 3D printing also saves on tooling costs and provides an advanced time-to-market. 3D printing is important for industries such as aerospace, where it can create lightweight yet complex parts, offering weight saving, the associated fuel reductions and a better environmental impact as a result. It is also important for the creation of prototypes that can advance industry.

It also allows users with a limited experience to edit designs and create bespoke, customised parts. On-demand 3D printing also saves on tooling costs and provides an advanced time-to-market. 3D printing is important for industries such as aerospace, where it can create lightweight yet complex parts, offering weight saving, the associated fuel reductions and a better environmental impact as a result. It is also important for the creation of prototypes that can advance industry.

Will 3D Printing Replace Traditional Manufacturing?

3D printing has the capability to disrupt traditional manufacturing through the democratisation of production along with the production of moulds, tools and other bespoke parts. However, challenges around mass production mean that 3D printing is unlikely to replace traditional manufacturing where high volume production of comparatively simple parts is required.

Are 3D Printing Fumes Dangerous?

3D printing fumes can be dangerous to your health as the process produces toxic filament fumes. These emissions are produced as the plastic filaments are melted to create the product layer-by-layer. However, correct procedures such as ensuring sufficient ventilation or using extractors can solve this issue.

These emissions are produced as the plastic filaments are melted to create the product layer-by-layer. However, correct procedures such as ensuring sufficient ventilation or using extractors can solve this issue.

Related Frequently Asked Question (FAQs)

What are the Pros and Cons of 3D Printing?

The demand is growing due to some of the revolutionary benefits that it can provide. Like almost all technologies it has its own drawbacks that need considering.

How Long Does 3D Printing Take?

There are several factors that determine the time it takes to 3D print a part. These include the size, height, complexity and the printing technology used.

Can 3D Printing Use Metal?

Yes, it is possible to 3D print items from metal. There are several types of process which fall under the heading of metal additive manufacturing.

What is Additive Manufacturing?

Additive manufacturing (AM) is a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.

3D Printing Definition

By

Adam Hayes

Full Bio

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master's in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

Learn about our editorial policies

Updated November 29, 2021

Reviewed by

Khadija Khartit

Reviewed by Khadija Khartit

Full Bio

Khadija Khartit is a strategy, investment, and funding expert, and an educator of fintech and strategic finance in top universities..jpg) She has been an investor, entrepreneur, and advisor for more than 25 years. She is a FINRA Series 7, 63, and 66 license holder.

She has been an investor, entrepreneur, and advisor for more than 25 years. She is a FINRA Series 7, 63, and 66 license holder.

Learn about our Financial Review Board

Fact checked by

Vikki Velasquez

Fact checked by Vikki Velasquez

Full Bio

Vikki Velasquez is a researcher and writer who has managed, coordinated, and directed various community and nonprofit organizations. She has conducted in-depth research on social and economic issues and has also revised and edited educational materials for the Greater Richmond area.

Learn about our editorial policies

What Is 3D Printing?

Three-dimensional (3D) printing is an additive manufacturing process that creates a physical object from a digital design. The process works by laying down thin layers of material in the form of liquid or powdered plastic, metal or cement, and then fusing the layers together.

Key Takeaways

- Three-dimensional (3D) printing is an additive manufacturing process in which a physical object is created from a digital design by printing thin layers of material and then fusing them together.

- Some industries, such as hearing aids manufacturers, airline manufacturers, and car manufacturers, use 3D printing to create prototypes and mass produce their products using custom scans.

- While it is currently too slow to be used in mass production, 3D printing technology is still evolving and has the potential to massively disrupt both the manufacturing logistics and inventory management industries.

Understanding 3D Printing

Since it was introduced, 3D printing technology has already increased manufacturing productivity. In the long-term, it has the potential to massively disrupt both the manufacturing, logistics, and inventory management industries, especially if it can be successfully incorporated into mass production processes.

Currently, 3D printing speeds are too slow to be used in mass production. However, the technology has been used to reduce the lead time in the development of prototypes of parts and devices, and the tooling needed to make them. This is hugely beneficial to small-scale manufacturers because it reduces their costs and the time to market, that is, the amount of time from a product being conceived until its being available for sale.

3D printing can create intricate and complex shapes using less material than subtractive manufacturing processes, such as drilling, welding, injection molding, and other processes. Making prototypes faster, easier, and cheaper allows for more innovation, experimentation, and product-based startups.

Industrial Uses

Car and aircraft manufacturers have taken the lead in 3D manufacturing, using the technology to transform unibody and fuselage design and production, and powertrain design and production. Boeing is using 3D-printed titanium parts in the construction of its 787 Dreamliner airliner.![]() In 2017, General Electric created a helicopter engine with 16 parts instead of 900–an indication of how big an impact 3D printing could potentially have on supply chains.

In 2017, General Electric created a helicopter engine with 16 parts instead of 900–an indication of how big an impact 3D printing could potentially have on supply chains.

In medical sciences, 3D printing is being used to customize implants. In the future, organs and body parts may be created using 3D printing techniques. In the fashion world, Nike, Adidas, and New Balance are using 3D printing to create their shoes. In the construction industry, companies around the world are making breakthroughs in 3D printing of the materials need to build homes. Using layers of concrete, homes can be built in 24 hours, which are stronger than regular cinder blocks and cost a fraction of the price.

In the manufacturing of hearing aids, 3D printing is now customary. The use of 3D printing accelerates the process of manufacturing and enables manufacturers to make custom hearing aids. Audiologists can use 3D scanners to create a custom prototype using reference points from the scan. Manufacturers can feed the scan into a 3D printing machine and after fine-tuning the materials and the ear shapes, print the entire hearing aids.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

Norsk Titanium. "Norsk Titanium to Deliver the World’s First FAA-Approved, 3D-Printed, Structural Titanium Components to Boeing." Accessed Aug. 23, 2021.

General Electric. "An Epiphany Of Disruption: GE Additive Chief Explains How 3D Printing Will Upend Manufacturing." Accessed Aug. 23, 2021.

Nike. "Nike Flyprint is the First Performance 3D Printed Textile Upper." Accessed Aug. 23, 2021.

Adidas. "4DFWD: Data-Driven 3D Printed Performance Technology Designed to Move You Forward." Accessed Aug.23, 2021.

New Balance.

"New Balance Launches a Premium 3D Printing Platform." Accessed Aug. 23, 2021.

"New Balance Launches a Premium 3D Printing Platform." Accessed Aug. 23, 2021.Sonova. "3D Printing Technology for Improved Hearing." Accessed Aug. 23, 2021.

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

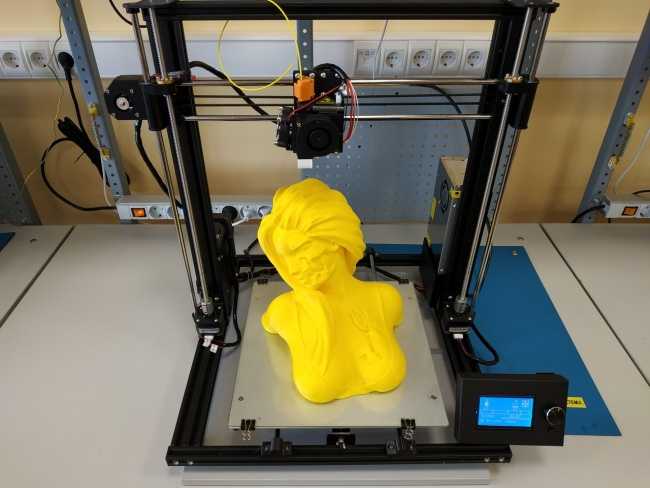

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to the 3D printer;

- 3D model reproduced.

Objects are reproduced gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Different 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

- Laser stereolithography (SLA) .

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; - Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

As you may have guessed by now, 3D printing is extremely versatile. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We also want to remind you about the possibility to order 3D printing, 3D scanning, 3D modeling services or purchase of related equipment and consumables with delivery throughout Ukraine in 3DDevice. If you have any questions, please contact us at one of the phone numbers listed here. We look forward to collaborating!

Back to main page

3D printing for dummies or "what is a 3D printer?"

- 1 3D printing term

- 2 3D printing methods

- 2.1 Extrusion printing

- 2.2 Melting, sintering or gluing

- 2.3 Stereolithography

- 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

- 3.1 Consumables

- 3.2 Extruder

- 3.3 Working platform

- 3.4 Positioners

- 3.5 Control

- 3.6 Varieties of FDM printers

- 4 Laser stereolithography (SLA)

- 4.

1 Lasers and projectors

1 Lasers and projectors - 4.2 Cuvette and resin

- 4.3 Varieties of Stereolithography Printers

The term 3D printing

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

3D printing techniques

There are many 3D printing technologies, and even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

However, you can try to divide technologies into main areas:

Extrusion printing

This includes techniques such as deposition fusion (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

This model of James Bond's Aston Martin was successfully printed on a Voxeljet SLS printer and blown up just as successfully during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Lamination

3D printers using lamination technology (LOM)

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut along the contours of the digital model using a laser or blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

Fused deposition modeling (FDM) and laser stereolithography (SLA) have become the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

Fused Deposition Printing (FDM)

FDM is perhaps the simplest and most affordable 3D construction method, which is the reason for its high popularity.

High demand for FDM printers is driving device and consumable prices down rapidly, along with technology advances towards ease of use and improved reliability.

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze.

One has only to remember that thermoplastics serve as a connecting element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly.

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The hot end is used to heat and melt the thread fed by the puller. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

PrintBox3D One FDM Extruder

To prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

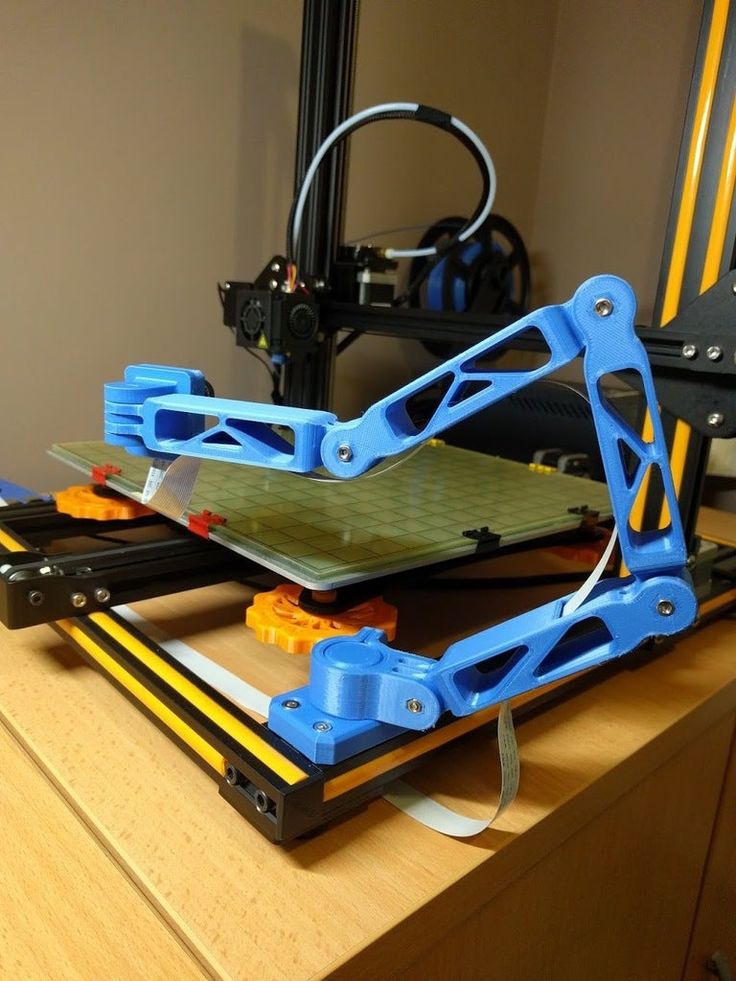

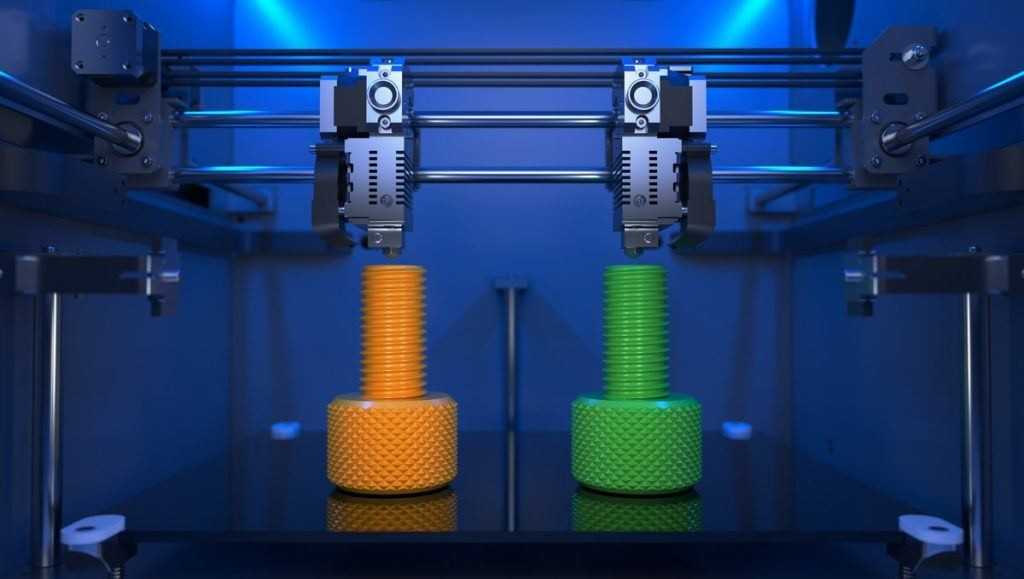

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single print head. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

Finished model with PVA supports (white) before and after washing

In such cases, the very water-soluble polyvinyl alcohol (PVA) comes in handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can be simply dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders.

Work platform

Heated platform covered with removable glass work table

Models are built on a special platform, often equipped with heating elements. Preheating is required for a wide range of plastics, including the popular ABS, which are subject to a high degree of shrinkage when cooled. The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

Heating is not recommended for some materials. A typical example is PLA plastic, which requires a fairly long time to harden. Heating PLA can lead to deformation of the lower layers under the weight of the upper ones. When working with PLA, measures are usually taken not to heat up, but to cool the model. Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Calibration screw for work platform covered with blue masking tape

The platform needs to be calibrated before printing to ensure that the nozzle does not hit the applied layers and move too far causing air-to-air printing resulting in plastic vermicelli. The calibration process can be either manual or automatic. In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

As a rule, platforms are equipped with an additional element - a removable table. This design simplifies the cleaning of the working surface and facilitates the removal of the finished model. Stages are made from various materials, including aluminum, acrylic, glass, etc. The choice of material for the manufacture of the stage depends on the presence of heating and consumables for which the printer is optimized.

For a better adhesion of the first layer of the model to the surface of the table, additional tools are often used, including polyimide film, glue and even hairspray! But the most popular tool is inexpensive, but effective masking tape. Some manufacturers make perforated tables that hold the model well but are difficult to clean. In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

Positioning mechanisms

Operation of positioning mechanisms

Of course, the print head must move relative to the working platform, and unlike conventional office printers, positioning must be done not in two, but in three planes, including height adjustment.

Positioning pattern may vary. The simplest and most common option involves mounting the print head on perpendicular guides driven by stepper motors and providing positioning along the X and Y axes.

Vertical positioning is carried out by moving the working platform.

On the other hand, it is possible to move the extruder in one plane and the platforms in two.

SeemeCNC ORION Delta Printer

One option that is gaining popularity is the delta coordinate system.

Such devices are called "delta robots" in the industry.

In delta printers, the print head is suspended on three manipulators, each of which moves along a vertical rail.

The synchronous symmetrical movement of the manipulators allows you to change the height of the extruder above the platform, and the asymmetric movement causes the head to move in the horizontal plane.

A variant of this system is the reverse delta design, where the extruder is fixed to the ceiling of the working chamber, and the platform moves on three support arms.

Delta printers have a cylindrical build area, and their design makes it easy to increase the height of the working area with minimal design changes by extending the rails.

In the end, everything depends on the decision of the designers, but the fundamental principle does not change.

Control

Typical Arduino-based controller with add-on modules

FDM printer operation, including nozzle and platform temperature, filament feed rate, and stepper motors for positioning the extruder, is controlled by fairly simple electronic controllers. Most controllers are based on the Arduino platform, which has an open architecture.

The programming language used by printers is called G-code (G-Code) and consists of a list of commands executed in turn by the 3D printer systems. G-code is compiled by programs called "slicers" - standard 3D printer software that combines some of the features of graphics editors with the ability to set print options through a graphical interface. The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

Some companies make printers that require proprietary software.

Program code for printing is generated using slicers

As an example, we can mention Cube printers from 3D Systems. There are companies that offer proprietary software but allow third-party software, as is the case with the latest generation of MakerBot 3D printers.

Slicers are not intended for 3D design per se. This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

Finally, 3D printers can be used in conjunction with 3D scanners to automate the process of digitizing objects. Many of these devices are designed specifically to work with 3D printers. Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

MakerBot Replicator 5th Generation FDM Printer with built-in control module on the top of the frame

The user interface of a 3D printer can consist of a simple USB port for connecting to a personal computer. In such cases, the device is actually controlled by the slicer.

The disadvantage of this simplification is a rather high probability of printing failure when the computer freezes or slows down.

A more advanced option includes an internal memory or memory card interface to make the process standalone.

These models are equipped with control modules that allow you to adjust many print parameters (such as print speed or extrusion temperature). The module may include a small LCD display or even a mini-tablet.

Varieties of FDM printers

Stratasys Fortus 360mc professional FDM printer that allows printing with nylon

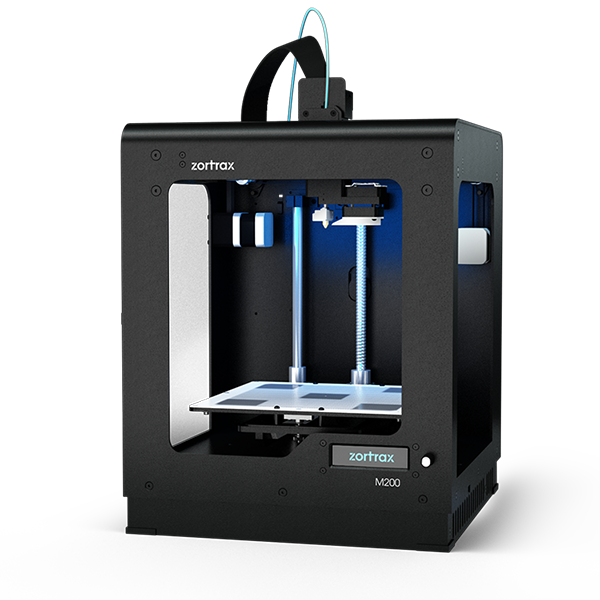

FDM printers are very, very diverse, ranging from the simplest home-made RepRap printers to industrial installations capable of printing large-sized objects.

Stratasys, founded by Scott Crump, the inventor of FDM technology, is a leader in the production of industrial installations.

You can build the simplest FDM printers yourself. Such devices are called RepRap, where "Rep" indicates the possibility of "replication", that is, self-reproduction.

RepRap printers can be used to print custom made plastic parts.

Controller, rails, belts, motors and other components can be easily purchased separately.

Of course, assembling such a device on your own requires serious technical and even engineering skills.

Some manufacturers make it easy by selling DIY kits, but these kits still require a good understanding of the technology.

A variant of the popular late 3rd generation Prusa RepRap printer

If you like to make things with your own hands, then RepRap printers will pleasantly please you with the price: the average cost of the popular early generation Prusa Mendel design is about $500 in a complete set.

And, despite their "do-it-yourself nature", RepRap printers are quite capable of producing models with quality at the level of expensive branded counterparts.

Ordinary users who do not want to delve into the intricacies of the process, but require only a convenient device for household use, can purchase a ready-made FDM printer.

Many companies are focusing on the development of the consumer market segment, offering 3D printers for sale that are ready to print "straight out of the box" and do not require serious computer skills.

3D Systems Cube consumer 3D printer

The most famous example of a consumer 3D printer is the 3D Systems Cube.

While it doesn't boast a huge build area, ultra-fast print speeds, or superb build quality, it's easy to use, affordable, and safe: This printer has received the necessary certification to be used even by children.

Mankati FDM printer demonstration: http://youtu. be/51rypJIK4y0

be/51rypJIK4y0

Laser Stereolithography (SLA)

Stereolithographic 3D printers are widely used in dental prosthetics

Stereolithographic printers are the second most popular and widespread after FDM printers.

These units deliver exceptional print quality.

The resolution of some SLA printers is measured in a matter of microns - it is not surprising that these devices quickly won the love of jewelers and dentists.

The software side of laser stereolithography is almost identical to FDM printing, so we will not repeat ourselves and will only touch on the distinctive features of the technology.

Lasers and projectors

Projector illumination of a photopolymer model using the Kudo3D Titan DLP printer as an example

The cost of stereolithography printers is rapidly declining, due to growing competition due to high demand and the use of new technologies that reduce the cost of construction.

Although the technology is generically referred to as "laser" stereolithography, most recent developments use UV LED projectors for the most part.

Projectors are cheaper and more reliable than lasers, do not require the use of delicate mirrors to deflect the laser beam, and have higher performance. The latter is explained by the fact that the contour of the whole layer is illuminated as a whole, and not sequentially, point by point, as is the case with laser options. This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

Cuvette and resin

Photopolymer resin is poured into a cuvette

A photopolymer resin that looks like epoxy is used as consumables for stereolithographic printers. Resins can have a variety of characteristics, but they all share one key feature for 3D printing applications: these materials harden when exposed to ultraviolet light. Hence, in fact, the name "photopolymer".

Hence, in fact, the name "photopolymer".

When polymerized, resins can have a wide variety of physical characteristics. Some resins are like rubber, others are hard plastics like ABS. You can choose different colors and degrees of transparency. The main disadvantage of resins and SLA printing in general is the cost of consumables, which significantly exceeds the cost of thermoplastics.

On the other hand, stereolithography printers are mainly used by jewelers and dentists who do not need to build large parts but appreciate the savings from fast and accurate prototyping. Thus, SLA printers and consumables pay for themselves very quickly.

An example of a model printed on a 3D laser stereolithography printer

Resin is poured into a cuvette, which can be equipped with a lowering platform. In this case, the printer uses a leveling device to flatten the thin layer of resin covering the platform just prior to irradiation. As the model is being made, the platform, together with the finished layers, is “embedded” in the resin. Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Some SLA and DLP printers work in an "inverted" scheme: the model is not immersed in the consumable, but "pulled" out of it, while the laser or projector is placed under the cuvette, and not above it. This approach eliminates the need to level the surface after each exposure, but requires the use of a cuvette made of a material transparent to ultraviolet light, such as quartz glass.

The accuracy of stereolithographic printers is extremely high. For comparison, the standard for vertical resolution for FDM printers is considered to be 100 microns, and some variants of SLA printers allow you to apply layers as thin as 15 microns. But this is not the limit. The problem, rather, is not so much in the accuracy of lasers, but in the speed of the process: the higher the resolution, the lower the print speed. The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

Video from CES 2013 showing Formlabs Form1 stereolithography 3D printer in action: http://youtu.be/IjaUasw64VE

Stereolithography Printer Options

Formlabs Form1 Desktop Stereolithography Printer

As with FDM printers, SLA printers come in a wide range in terms of size, features and cost. Professional installations can cost tens if not hundreds of thousands of dollars and weigh a couple of tons, but the rapid development of desktop SLA and DLP printers is gradually reducing the cost of equipment without compromising print quality.

Models such as the Titan 1 promise to make stereolithographic 3D printing affordable for small businesses and even home use at prices in the region of $1,000.