Sculptify david 3d printer

Introducing David – Sculptify

Prototype shown.

The Next Step in 3D Printing.

David is a next-generation desktop 3D printer that can create with a rapidly

expanding library of pelletized materials.

Watch David in action.

FLEX Technology

Industry-inspired technology, on your desktop.

Fused Layer Extrusion (FLEX) technology allows users to print directly with

pelletized materials - this means vastly more material options than many

current 3D printers, at a significantly reduced cost.

At its core, FLEX is inspired by proven technology from the plastics industry,

but with new features and innovations that make it great for personal printing.

Here are a few of the materials that Sculptify

is currently testing and optimizing:

ABS

Acrylonitrile butadiene styrene

Hard plastic commonly used in plastic car components and household items.

HDPE

High-density polyethylene

Semi-hard and durable plastic, used in milk jugs and plastic bags.

PLA

Polylactide

Hard plastic, biodegradable, made from renewable resources. The standard in 3D printing.

EVA

Ethylene vinyl acetate

Soft silicone-like material often used in shoes and sportswear.

Nylon

Hard and durable material that is often used in low-friction applications like bearings.

TPU

Thermoplastic polyurethane

Rubber-like material that is often used in shoes and mobile device cases.

HIPS

High impact polystyrene

Semi-hard and durable plastic used in disposable utensils and containers.

PC

Polycarbonate

Very hard plastic that is typically transparent. Often used in safety glasses and DVDs.

Often used in safety glasses and DVDs.

Wood composites

Earthy look and finish, often used in synthetic decking

And we are just getting started.

Features

Engineered to perform, built to last.

David features both groundbreaking technology and commercial-grade components,

all specifically designed to provide versatility, precision, and consistency.

In short, David is a 3D printer you’ll be proud to own.

Under the hood

Only precision components can make precision prints. Using high-quality, high-tolerance parts allows David to print smoothly, quietly, and accurately. A unique lead screw design allows for excellent print resolution and consistency. Using a steep-threaded lead screw system provides a great balance between speed, precision, and durability.

Watch the close-up video.

Built to compete with the best.

David is designed to offer not only new technology, but also great performance

and reliability. David includes additional features that add industrial-grade capability.

Removable heated bed.

David's removable aluminum print surface is extremely durable and resistant to warping. It can also be heated to 200°C, for added capability.

Watch the print platform video.

Assembled in America.

Designed, engineered, and proudly assembled in central Ohio.

Specifications

Printing Technology

FLEX: Fused Layer Extrusion

Build Volume

20w x 22d x 18.5h cm

(7.8in x 8.6in x 7.3in)

8140 cubic centimeters

(496 cubic inches)

Build Surface

Auto-leveling

Heated Aluminum

Temperature: 200°C

(392°F)

Hopper Capacity

. 56kg of PLA pellets

56kg of PLA pellets

(1.25lbs)

Extruder Max Temperature

330°C

(626°F)

Layer Resolution

100 microns for PLA

(varies for other materials)

Print Speed

10‐150mm/s

Positioning Precision

XY axis: 8 micron or better

Z axis: 3 micron or better

Stepper Motors

1.8° Step angle with

minimum 1/16 micro-stepping

Nozzle Diameter

0.3mm, 0.4mm, 0.5mm

all included

Construction

Aircraft aluminum

Polycarbonate windows

Weight

29 kg

(64 lbs)

Product Dimensions

53.8w x 50.2d x 62h cm

(21.2w x 19.8w x 24.4h in)

Connectivity

USB

Prototype specifications shown. Subject to change without notice.

Subject to change without notice.

Prototype model shown. Production model may change without notice.

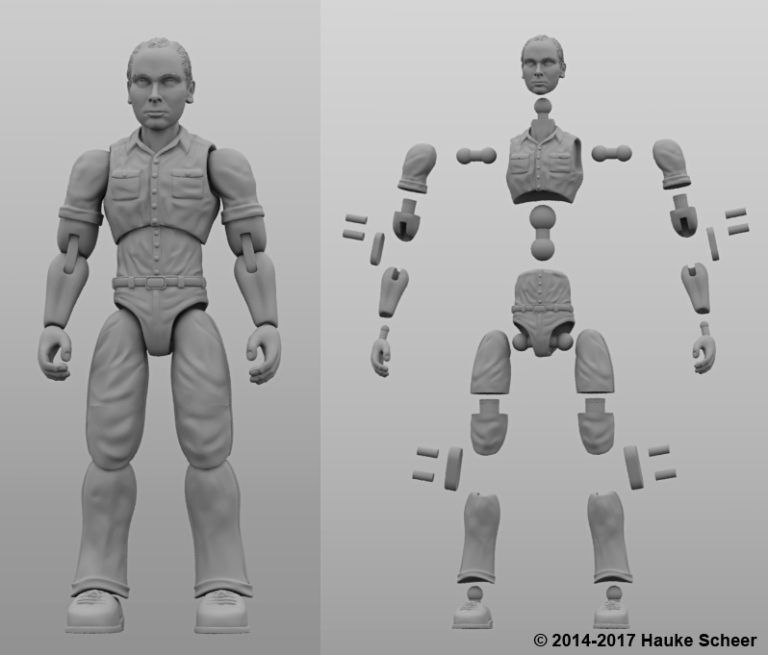

Sculptify Announces 'David', Their New 3D Printer, Capable of Printing With Pellets of Filament - 3DPrint.com

One of the most expensive aspects of running a 3D printer, day-in and day-out, is the cost of printing materials. Spools of filament run between $20 and $50 per kilogram, and this can add up very quickly.

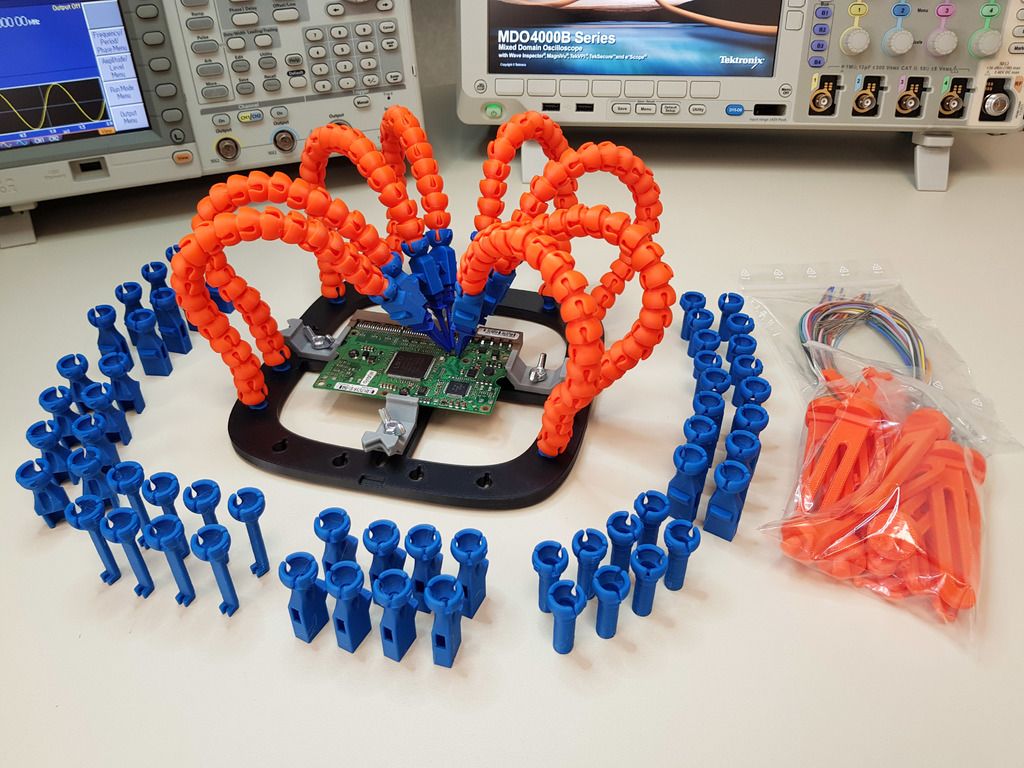

Back in May, we broke a story about a company called Sculptify, that was planning on releasing a 3D printer capable of printing directly from pelletized filament. Rather than requiring expensive spools of filament to print with, this printer utilizes a special ‘FLEX’ (Fused Layer Extrusion) systems that allows it to take simple raw materials (pellets of plastic), melt it down and 3D print the objects you desire.

The Sculptify David 3D Printer

Today, Sculptify provided more details, as well as photographs to 3DPrint.com. This innovative new 3D printer has a name; The David 3D Printer. Not only is it able to print using this so called FLEX technology, but it also features commercial-grade components, which have been designed to provide versatility, accuracy, and speed. It also comes stocked with an easy loading system and removable print platform.

Not only is it able to print using this so called FLEX technology, but it also features commercial-grade components, which have been designed to provide versatility, accuracy, and speed. It also comes stocked with an easy loading system and removable print platform.

“David is an incredibly versatile device, that can be used by both consumers and prosumers alike,” said Slade Simpson, Sculptify Co-Founder and CEO. “Sculptify believes that for 3D printing to reach its fullest potential, printers need to be able to serve hundreds of different purposes. We think that FLEX technology is the next logical step in making this possible.”

Using the FLEX technology doesn’t only save users of the ‘David’ money, but it also permits users to print with many unique materials. One of these materials is thermoplastic polyurethane (TPU), which allows for the printing of flexible, bendable, and super durable objects. It is traditionally found in shoes, athletic gear, and smartphone cases. Some other uses of TPU include tool grips, RC tires, and flexible fabrics.

Some other uses of TPU include tool grips, RC tires, and flexible fabrics.

Pellets of Material

“We think that FLEX printing is going to open the door to hundreds of new applications in both the consumer and commercial sectors because of the unique, and growing material library — we are venturing into a new realm of 3D printing,” stated Todd Linthicum, President and Co-Founder.

Previously if someone wanted to 3D print objects using pellets of plastic or other materials, they would have to purchase a separate filament extruder, which would be used to create spools of filament. Those spools would then need to be fed into a 3D printer in order to print with. The David 3D printer allows users who wish to save money by printing directly from pellets of material, to simply feed the pellets into the machine and begin printing.

“David provides customers with the freedom to choose from an extensive selection of materials — which range from hard and durable to soft and flexible.

By eliminating the dependence on filament, Sculptify can offer exotic materials and composites never before used in 3D printing,” said Luke Daniel, Director of Business Development.

So why in the world is this printer named “David”? The name came from a famous sculpture by Michelangelo. “It’s one of the most recognized works of art in the world, and reminds us that with the right tools, anything is possible,” explained Slade Simpson. “We have poured our hearts and souls into this printer for the past year and a half, and we are really excited to get it into people’s hands.”

Sculptify plans on launching a Kickstarter campaign for the David 3D Printer in the near future, although no date has yet been set.

What do you think? Would you consider purchasing a printer like the David, to 3D print directly from pellets of material? Discuss in the David 3D Printer forum thread on 3DPB.com

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: david • david 3d printer • pellet filament • pellets • sculptify

Please enable JavaScript to view the comments powered by Disqus.

3D printers and 3D pens

HOW DO 3D pens AND 3D PRINTERS WORK AND WHAT DO YOU NEED?

Define. Devise. discovery.

“Maybe you guys are not mature yet. But your kids will love it.”

“Wow!” - you will say when you find out that 3D printers are actively used in medicine. At the moment, scientists are already able to make some organs. The simplest ones (ears, nose, face) can be printed, while the complex ones (heart, liver, kidneys) are still in development. Is this not the future? nine0005

Technologies in the 21st century are developing rapidly, you will not have time to get up from the couch, as something new will come out. Now you will not surprise anyone with the abbreviation "3D", but not everyone knows that the First Department of Computer Graphics was opened back in the 1960s by Ivan Sutherland and David Evans at the University of Utah. Sutherland created the program that was the prototype of all modern 3D editors and CAD systems - Sketchpad.

Sutherland created the program that was the prototype of all modern 3D editors and CAD systems - Sketchpad.

(Ivan Sutherland and David Evans)

Today you can watch movies in 3D at home on your 8K TV, although until recently 3D was only available in cinemas.

3D technologies have taken over the world and penetrated into the most diverse areas: 3D image, 3D model, 3D printer and even 3D pens. We will dwell on the last two points in more detail. What do you know about 3D printers and pens? Nothing? We didn’t know anything either, but we figured it out and are ready to share it with you. ISI media center is online! Go! nine0005

3D pens - SIMPLE AND COMPLEX

3D pen is something you never dreamed of as a child. This is what modern children beg from their parents in the same way as you once begged for an ordinary kinder.

Where did it come from? In 2012, inventors Peter Dilworth, Daniel Cowan and Maxwell Baugh invented a prototype 3D pen. The 3d pen they created in one day was tested, and it took about 14 hours to create the first 3d object. Realizing that 14 hours is long enough, they improved their prototype and brought 3Doodler to the market. nine0005

(photo by Peter Dilworth and Maxwell Baugh)

What is it for? For creativity, for developing activities with children, for correcting models printed on a 3D printer, and even for minor household repairs of plastic items.

How does it work? The main material is PLA and ABS plastic: the first is made from natural products, the second is made from petroleum.

What are 3D pens? Cold and hot. The first ones are painted with photopolymers, fast-hardening resins. The latter use a coil with polymer alloys, which, when melted, acquire the desired shape. nine0005

nine0005

Designation 3 D - handle

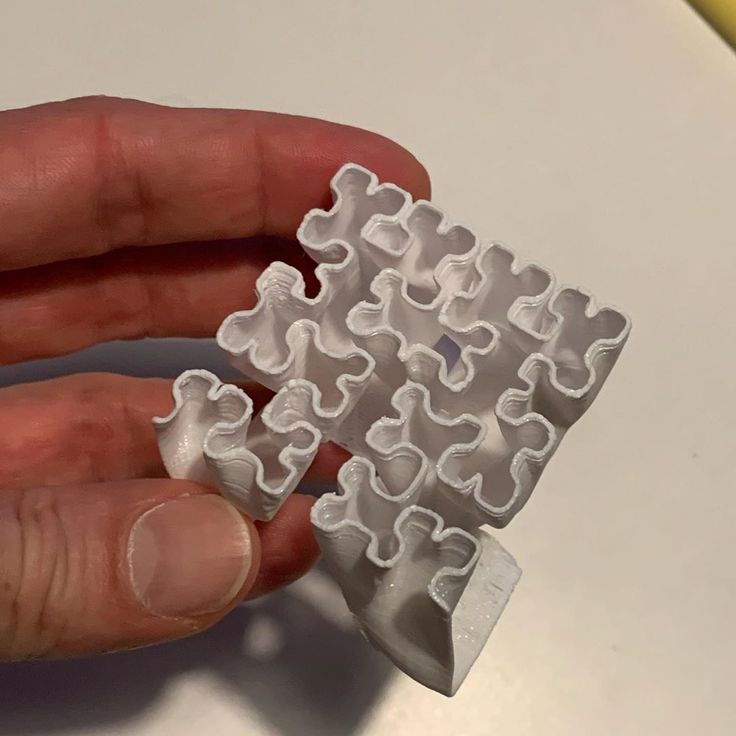

To begin with, 3D pens aren't as powerful as you might think. You won't be able to print organs or build houses with them, although the prospect is good. 3D pens are designed to create various shapes of all sizes and colors. They can be used to make small figurines for games, small decorations, and even parts of cosplay costumes!

3D pens have a wide range of 3D pens for every taste:

1. 3D-pen MyRiwell Pen without display is one of the most inexpensive pens that can be a great tool for a creative person or a great gift for a child.

The pen allows you to draw separate parts of the figure on a plane with ABS plastic, and then combine them into three-dimensional objects. Also, any 3D pen can be used as a glue gun to hold together small parts in various miniature hand-made assemblies.

2. MyRiwell RP100B 3D pen with LCD display is the next step in the development of Myriwell Pen.

This pen differs from the younger model by the presence of a display showing the mode and the ability to draw not only ABS, but also PLA. Working with PLA provides a wide field for creativity in decorating various objects with three-dimensional patterns; this plastic adheres especially well to fabric.

3. Creopop Pen Creopop is the first 3D pen to feature photopolymerization technology. nine0005

There are no heating elements and the material coming out of it is not at high temperature, which eliminates the possibility of burns and inhalation of evaporating plastic. Plastic polymerizes under the influence of ultraviolet radiation. A cartridge with a liquid polymer is inserted into the pen - no more filament threads sticking out of the 3D pen will hinder your movements in a fit of creativity. This model does not have any wires at all. Due to the absence of heat in the working process of this 3D pen, its power consumption is low enough to operate from the built-in battery. The properties of the materials used allow you to get an impressive result. nine0007

This model does not have any wires at all. Due to the absence of heat in the working process of this 3D pen, its power consumption is low enough to operate from the built-in battery. The properties of the materials used allow you to get an impressive result. nine0007

3D pens are not as simple as they seem at first glance. This is not a tool for entertainment, but is a way to express 's creativity and create amazing new things. If you have never tried to create something with a 3D pen, be sure to correct yourself! We are sure you will like it!

It's time to move on to

3D PRINTERS

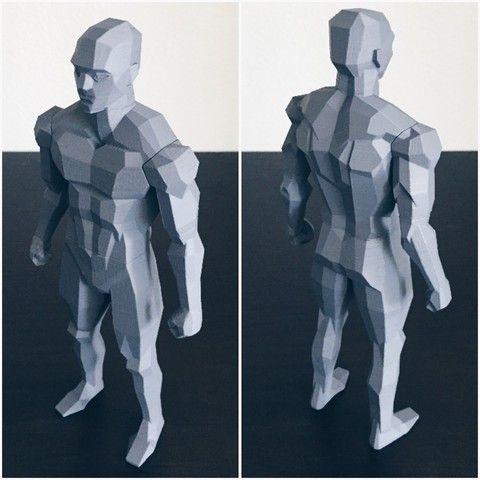

New generations of 3D printers are released every year, specialists use them to create everything that is enough for imagination, for example, various parts for cars, medical devices, build residential buildings printed on printer, and even recreate human organs! nine0005

And what is this miracle machine? 3D printer - external computer device, which is nothing more than a machine tool with numerical control (CNC), designed to quickly produce prototypes of products designed on a PC by layer-by-layer printing.

The concept of 3D printing was invented in the 1970s, but the first experiments in this field date back to 1981. A patent application for rapid prototyping technology was filed by Dr. Kodama in Japan on May 1980 years. He was the first to describe a method of creating an object using layering, creating an apparatus for stereolithography. Ironically, Dr. Kodama was unable to register the patent because he did not provide a full description of the patent.

(Dr. Kodam)

In 1986, the first stereolithography device (SLA) patent was issued. This patent belonged to Charles Hull, who invented the SLA machine in 1983.

(Charles Hull)

Will you FDM me? And if "SLA"?

Two old 3D printer technologies.

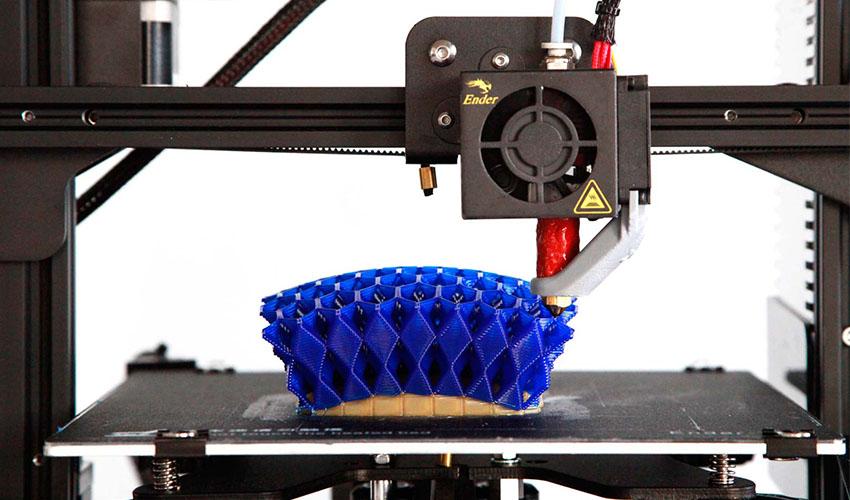

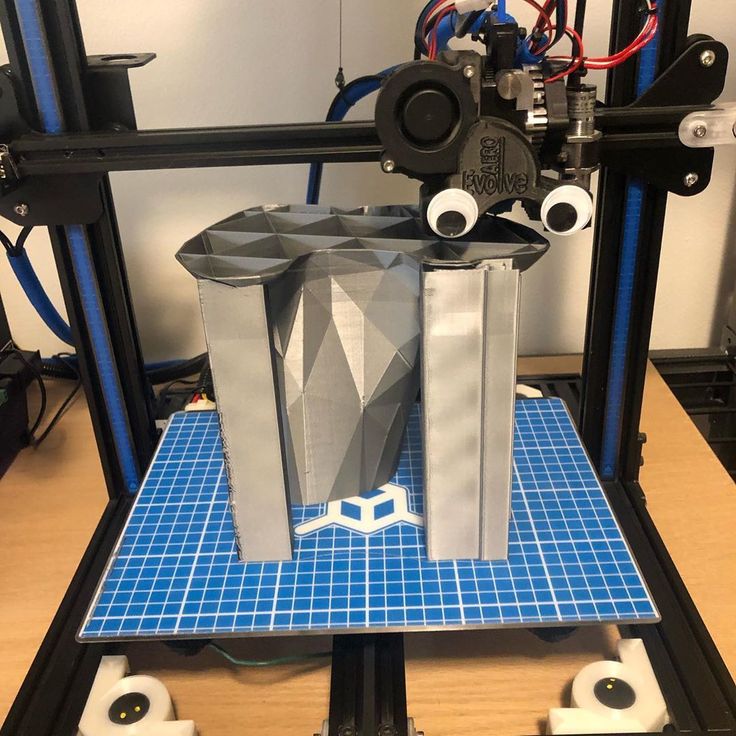

“Difficult” is what many people think about how 3D printers work. In fact, the printing process is quite simple. There are two main technologies: FDM and SLA. Only threads and resin are needed to work.

(filament and resin printers)

The first use of thermoplastic threads is called FDM. The technology lies in the fact that a person inserts a thread into the upper part of the printer (extruder), it becomes soft and flexible. The thread is held on by a structure that moves it in the right direction. It turns out that the user's task is only to drive in the code that must be written in advance, and put the thread. The 3D printer will take care of the rest of the work.

In the second case (SLA), the magic of resin occurs, but not wood, but complex, polymeric. First you need to pour the resin into the container, then enter the code and that's it. The laser will make the figure, after which it will be necessary to wash the resulting figure and let it cool with ultraviolet light. Ready! nine0005

Ready! nine0005

(FDM 3D printer, reel of material and a couple of 3D prints)

The house that… It's hard to believe, but the house printed on the printer is real. In it you can safely spend time, move, live and work. The site presents 10 real buildings printed on a printer.

Mechanical engineering. The use of 3D printing in the technological process solves many problems. The product can be made cheaper and many times faster. Now creating complex parts is not a problem. You draw the model you need, set the code and the product is ready. The human factor is minimized, all the work is done by the machine. A 3D printer is no longer a luxury, it is a complete tool for any production process. nine0005

Theater and cinema are also on point: a 3D printer can create anything!

How can printers and art be related? At first we did not understand either, but then we learned that the connection could be the most direct. We invite you to watch the interview that we managed to record with Evgeny Umanets.

We invite you to watch the interview that we managed to record with Evgeny Umanets.

“I am an architect, a creative person, and I constantly use 3D printers in my work!”

As it turns out, 3D pens and printers is unusual and very exciting devices with which you can create almost anything. Of course, this cannot be fully compared with the work of a true artist, but experimenting and innovating in art is great! Thanks to new technologies, we are moving into the future at a very fast pace. Everything new and incomprehensible is not always boring and complicated. We did not understand how a 3D printer works, but when we started to understand, we found out that this is one of the most interesting and promising things in the modern world. nine0007 We hope that this material was interesting and you liked it. Never be afraid to learn new things, everything is accessible and easy.

Follow our news, we have more to tell!

3D Printer Capabilities: 2-Story House, Millimeter David Statue and Vegan Steak

3D Printer Applications are extensive and often used for unusual purposes, often such situations remain behind the scenes. But not at this time. In this article, we have collected interesting cases of 3d printing applications that will not leave you indifferent. nine0007

But not at this time. In this article, we have collected interesting cases of 3d printing applications that will not leave you indifferent. nine0007

Will 3D printers replace construction workers? Europe's largest 3D printed house

appears in BelgiumExperts have long predicted that 3D printers will revolutionize the construction industry, making home building cheaper, faster and greener. However, the implementation of this idea is slower than expected, because 3D technologies for creating fully functional houses have not yet been sufficiently considered. This perception may change after the opening of the world's first two-story house, printed in a single copy, in Antwerp, Belgium. nine0005

“What makes this house so unique is that we printed it on a stationary 3D concrete printer” said Emiel Ascione, Project Manager at Kamp C, the construction company that led the venture. “Other houses that have been printed around the world have only one floor. In many cases, the components were factory printed and assembled on site. However, we printed the entire shell of the building in-house” .

However, we printed the entire shell of the building in-house” .

Photos of the house:

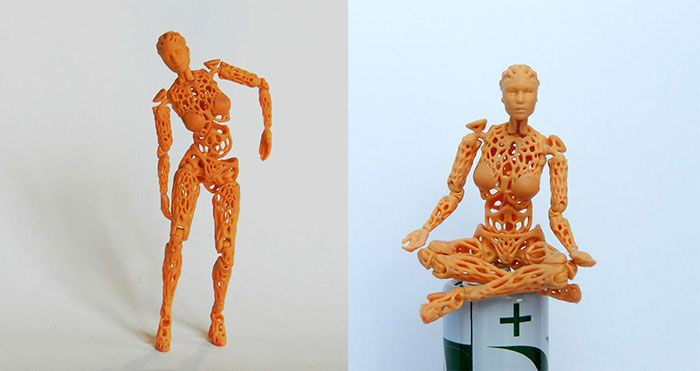

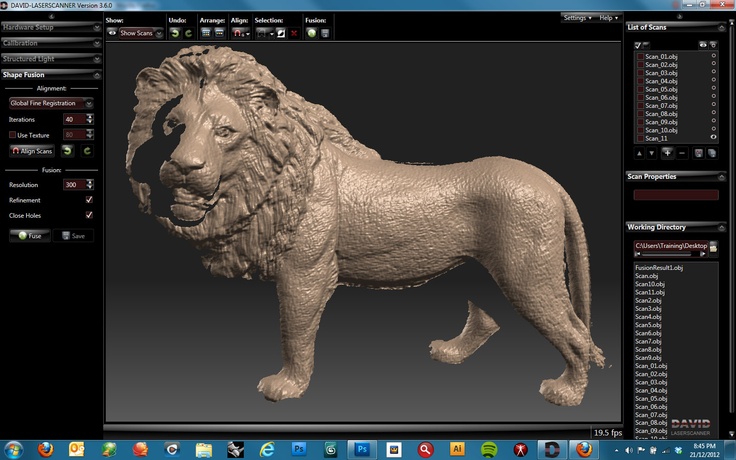

Micro Angelo? Michelangelo's David statue 1 mm high

3D printing has made a name for itself in many industries, so there's no need to brag anymore, but some people just can't help it. Case in point: this is a millimeter-sized statue of Michelangelo's famous "David", printed in copper using a newly developed technique. The aptly named "Tiny David" was created by Exaddon, a subsidiary of Cytosurge. Its width is only a fraction of a millimeter, and its weight is two micrograms. It was created using an Exaddon "CERES" 3D printer, which emits a stream of ionized liquid copper at a rate of just a femtoliter per second, forming a rigid structure with micrometer-sized elements. David took about 12 hours to print, although something simpler in structure could probably have been done much faster. nine0007

nine0007

Anyway, the level of detail is amazing. Although it is obviously impossible to recreate all the nuances of Michelangelo's masterpiece, even small textures like hair and muscle tone are reproduced quite well. No finishing or support legs required.

Of course, we can create much smaller structures at the nanometer level using advanced lithography techniques, but this is a complex and sensitive process that must be carefully designed by experts. nine0005

“This is more than just a copy and scaled-down model of Michelangelo's David,” said Exaddon's Giorgio Ercolano on the company's blog. “Our deep understanding of the printing process has led to a new way of processing a 3D computer model of a statue and then converting it into machine code. This object was cut from an open source CAD file and then sent directly to the printer. This slicing method opens up a whole new way to print designs with the CERES additive micromanufacturing system.” nine0221

3D printed steak was indistinguishable from the original:

Israeli startup Redefined Meat has unveiled the world's first plant-based alternative steak and announced that market trials will begin at select high-end restaurants later this year.