3D printing casting molds

Introduction to Metal Casting and Ways to Combine 3D Printing With Casting Workflows

Metal casting is an age-old metalworking process in which molten metal cools and solidifies in a mold to form metal parts. Despite its ancient roots, metal casting is still one of the most popular processes for companies looking to produce metal parts.

This article will cover what metal casting is, how it works, and walks you through the most common metal casting processes and the benefits manufacturers can attain by combining modern digital tools like 3D printing with traditional casting workflows.

White Paper

Get design guidelines for creating 3D printed patterns, walk through the step-by-step direct investment casting process, and explore guidelines for indirect investment casting and sand casting.

Download the White Paper

Metal casting step-by-step from the original design through final casting.

Since the advent of metal casting, the methods have evolved and varied. Its core techniques, however, have remained constant. Here is a general step-by-step process for metal casting:

Ring patterns 3D printed in Castable Wax 40 Resin.

In order to begin the metal casting process, a manufacturer first must develop a representation of the desired pattern. This pattern is essential in designing the mold used for the cast. It is traditionally made from wood, foam, plastic, or wax and ensures that the mold accurately produces the finished metal part. Today, 3D printing is also a common method to produce patterns, which allows designers to create accurate patterns directly from digital CAD software tools.

A pattern is not an exact replica of the desired part. It has additional elements that make the casting process possible, including gates that allow molten metal to flow at a steady rate and vents for gas to escape. Additionally, patterns are also larger than the parts they represent to account for the shrinkage that occurs during cooling.

When the casting piece is hollow, the manufacturer also creates a core of sand or metal to shape the internal form. This core gets removed upon completion of the casting.

This core gets removed upon completion of the casting.

The next step is creating a casting mold, which can be either reusable (non-expendable) or non-reusable (expendable). Non-reusable molds are usually made out of sand, plaster, wax, or by 3D printing, and just as the name suggests, they get destroyed in the casting process. Reusable molds are made out of metal and other durable materials and can be reused for multiple casting cycles.

Ceramic shells after burnout and 3D printed patterns in Clear Resin.

Molten pewter poured into a High Temp Resin 3D printed mold for metal casting.

During this step, the metal gets heated in a furnace until it melts. Depending on the application, manufacturers can use a variety of different metals, with the most commonly cast metals being iron, aluminum, aluminum alloy, steel, copper, and zinc, as well as precious metals like gold and silver. Once the metal melts, the manufacturer pours it into the mold cavity and allows it to cool and solidify.

Metal casting post-production.

Once the metal cools down and solidifies, the parts get removed from the mold. Depending on the mold type, this can be done by vibrations in a shakeout process, washing away the investment material, or by ejector pins. Then, excess material, such as vents, gates, and feeders, are removed from the parts. Finally, the parts get filed, grated, machined, or sandblasted to smooth the surface and reach the final shape requirements.

Though all metal casting techniques share the same core process, there are various methods better suited for different applications. Some of the most common methods include die casting, investment casting, and sand casting.

Die casting uses a steel mold and high pressure. (Source: buhlergroup.com)

Die casting is a metal casting process in which a manufacturer pushes molten metal into a steel mold cavity at a high pressure to quickly produce metal parts. In die casting, the manufacturer fixes two halves of a die or reusable mold together and uses a nozzle to inject pressurized molten metal into the die. When the metal cools, the die opens, and ejector pins push out the cast.

When the metal cools, the die opens, and ejector pins push out the cast.

The two most common die casting processes are hot-chamber and cold-chamber casting. While the specifics of these processes vary, there are several shared characteristics of the die casting process as a whole.

Hot-chamber die casting is the most common of the two main die casting processes. Hot-chamber die casting machines have a built-in furnace to heat the metal within the machine. Once the metal reaches a molten state, the machine lowers a cylindrical chamber into the molten metal. The gooseneck shape of the metal injection system allows the chamber to quickly fill itself, and then push the material into the mold with air pressure or a piston.

Immersing the injection mechanism to fill it allows for rapid and streamlined mold injection in this casting process. Because the chamber is subject to direct heat from the molten metal, however, hot-chamber die casting systems are at risk for corrosion, making them a less viable option for metals with high melting points. Instead, it is better suited for materials with low melting points and high fluidity, like lead, magnesium, zinc, and copper.

Instead, it is better suited for materials with low melting points and high fluidity, like lead, magnesium, zinc, and copper.

By contrast, the cold-chamber die casting process works more slowly to avoid corrosion. With this method, a foundry worker ladles molten metal into the injection system. A piston then pushes the metal into the mold.

This process limits the corrosion that is more common in hot-chamber die casting. It is an ideal option for metals with high melting points, like aluminum and aluminum alloy.

The die casting process is rapid and produces highly detailed parts. It is ideal for the production of high volumes of complex parts and can also produce strong parts with smooth surface finishes. Die casting’s capacity to produce a high volume of parts makes it a crucial process in the automotive and aerospace industries.

As die casting tooling and equipment are expensive, this process is not cost-effective for smaller production runs. In addition, the malleability of metals used in the process can impact the complexity of the product.

Cast parts from SLA patterns printed in Clear Resin on a Formlabs 3D printer.

Investment casting, also known as lost-wax casting, is a process that uses wax, slurry, and molds to produce complex parts. It is one of the oldest metal casting techniques but is still valued for its ability to create precise metal parts with intricate shapes.

This process is still widely used for producing jewelry, dentistry, and art. Its industrial form, investment casting, is a common way to create precision metal parts in engineering and manufacturing.

Investment casting patterns are typically made out of wax or 3D printed polymers. The patterns are assembled into a tree-like structure and dipped into a slurry of silica, or put into a flask and surrounded by the liquid investment plaster. After the investment material dries, the flask is placed upside down into a kiln, which melts the pattern, leaving a negative cavity in the shape of the original model. Metal is melted and then poured, using gravity or vacuum pressure to pull the metal into the cavity. The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish.

The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish.

Sprue trees with cast rings.

Investment casting is a versatile process. It allows manufacturers to produce accurate and repeatable parts out of nearly any metal available for casting and complicated shapes that would be difficult or impossible with other casting methods. Casted parts also have excellent surface qualities and low tolerances, with minimal surface finishing or machining required.

These features make investment casting ideal for complex parts in automotive, aerospace, and industrial applications, medical tools, dental implants, as well as fine jewelry and art.

Investment casting is a complex and labor-intensive process. It requires specialized equipment, costly refractories and binders, as well many manual operations to make a mold. It can be difficult to cast parts that require cores and the process is better suited to small parts.

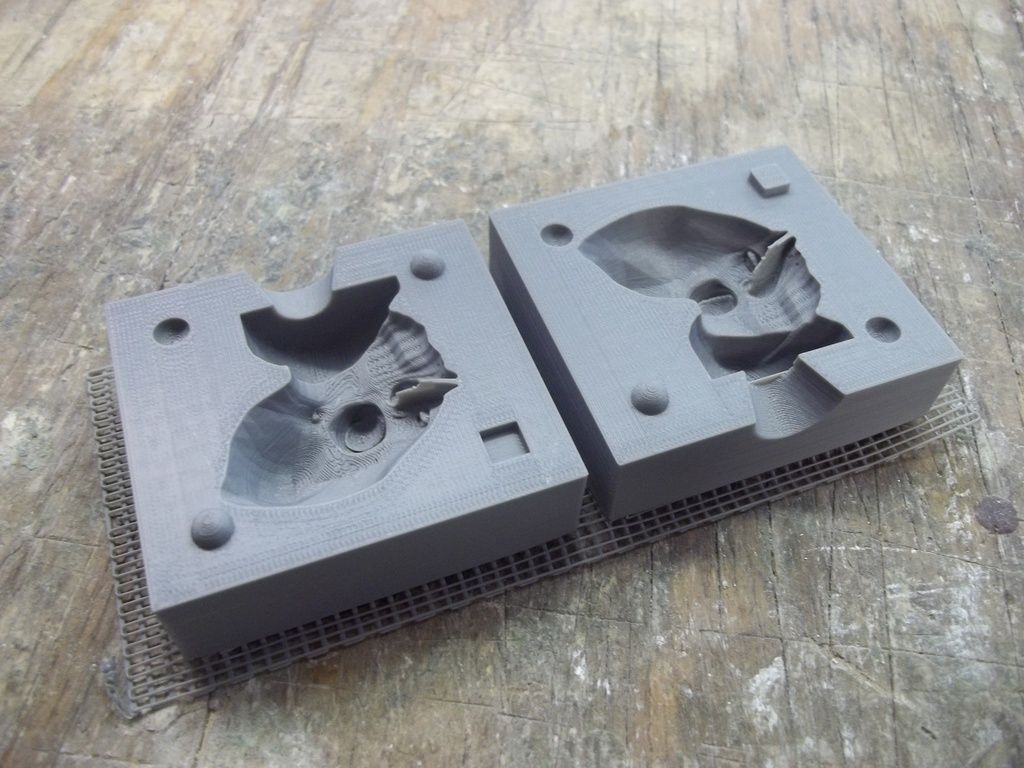

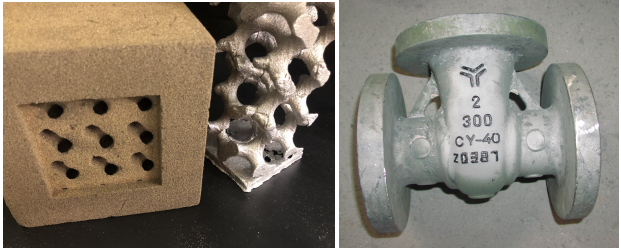

One half of a sand casting mold.

Sand casting is a metal casting method that was first in use 3,000 years ago but remains the most widely used casting method to this day. This process allows manufacturers to cast metal without relying on machining.

In the sand casting process, the manufacturer first creates a foundry pattern, or replica of the casting, most commonly from wood or plastic. The pattern is oversized to allow for shrinkage. Parts with features on one side only require an open-faced mold. For parts with multiple detailed surfaces, the manufacturer separates the foundry pattern into two mold boxes to form a closed cavity mold. The top half is called a cope and the bottom a drag.

Once the manufacturer creates the pattern, they tightly pack sand around the pattern. Then, they add sprues and gates to ensure that the molten metal flows smoothly through the mold cavity. The manufacturer removes the pattern then clamps the two halves of the sand mold together. Once the metal melts to a molten state, it is poured into the mold and left to cool. From here, the sand mold is removed using vibrations or high-pressure water. Finally, the manufacturer refines the part by removing sprues and gates, and polishing the cast metal part.

From here, the sand mold is removed using vibrations or high-pressure water. Finally, the manufacturer refines the part by removing sprues and gates, and polishing the cast metal part.

Sand casting is an adaptable process that functions outside the limitations of machinery. Because of this, it can create complex parts of virtually any size. Sand is inexpensive and plentiful, which lowers the setup cost and makes modifications possible. It is the only practical or economical way to produce very large castings. The lead time of sand casting is also short, making it a viable process for short production runs.

Sand casting’s versatility makes it a manufacturing option across a wide array of industries. It can produce medical equipment, automobile parts, electronic equipment, gas tanks, and engine blocks, and more.

Sand casting creates highly porous, textured metals. The shrinkage and rough surface finish also lower the dimensional accuracy of parts. This results in a low-strength final product that requires time-consuming post-processing to achieve a higher quality finish.

In order to choose the right industrial metal casting process, several factors must be considered. We’ve created this comparison table to help you compare die casting, investment casting, and sand casting in terms of types of metals, production volume, costs, production time, part complexity, and for which industries they are generally used.

| Die Casting | Investment Casting | Sand Casting | |

|---|---|---|---|

| Compatible metals | Aluminum, copper, lead, magnesium, zinc | Most metals | Most metals |

| Production volume | High volume | Low to high volume | One-off to medium volume |

| Unit costs | Low | Moderate to high | Moderate |

| Tooling costs | High | Moderate | Low |

| Cycle time | Rapid | Long | Moderate |

| Industries | Automotive, aerospace, consumer products, furniture, power tools | Automotive, aerospace, jewelry, medicine, dentistry, art | Automotive, aerospace, industrial equipment, electronics, consumer products |

3D printed jewelry ring pattern and cast metal part.

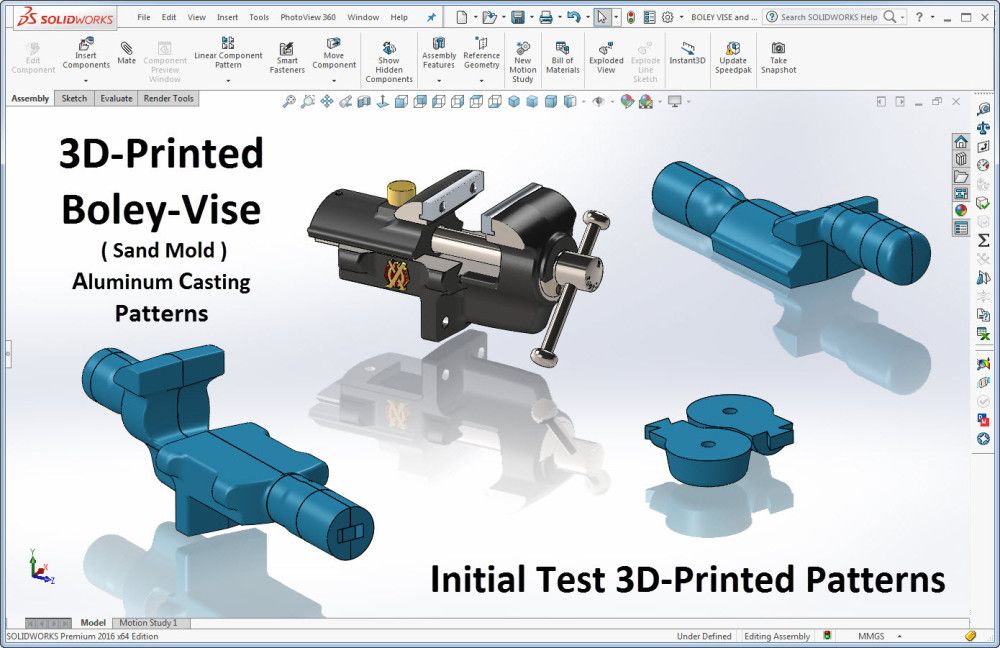

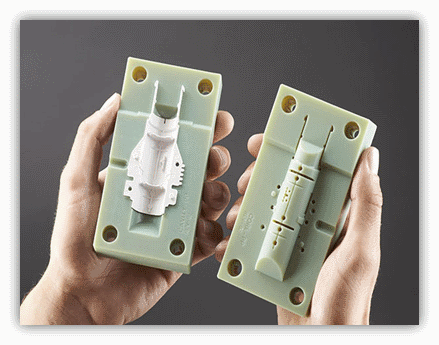

Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3D printing by combining castings processes like indirect investment casting, direct investment casting, pewter casting, and sand casting with 3D printed patterns or casting metal into 3D printed molds. Cast metal parts using 3D printed rapid tooling can be produced in a fraction of the time invested in traditional casting and at a significantly lower cost than metal 3D printing.

Stereolithography (SLA) 3D printers offer high precision and a broad material library that is well-suited for casting workflows and can produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Webinar

In this webinar, we will look at how desktop stereolithography (SLA) 3D printers are being used to directly print patterns, how to work with SLA patterns for investment casting, and how the benefits of generative design are increasing the demand for printed patterns.

Watch the Webinar Now

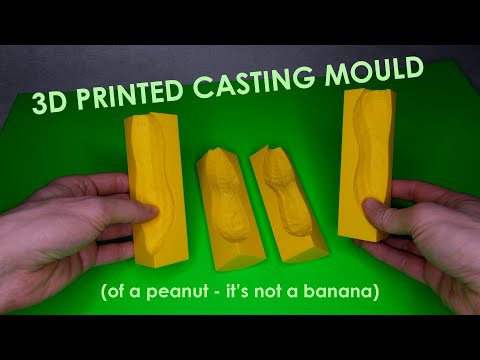

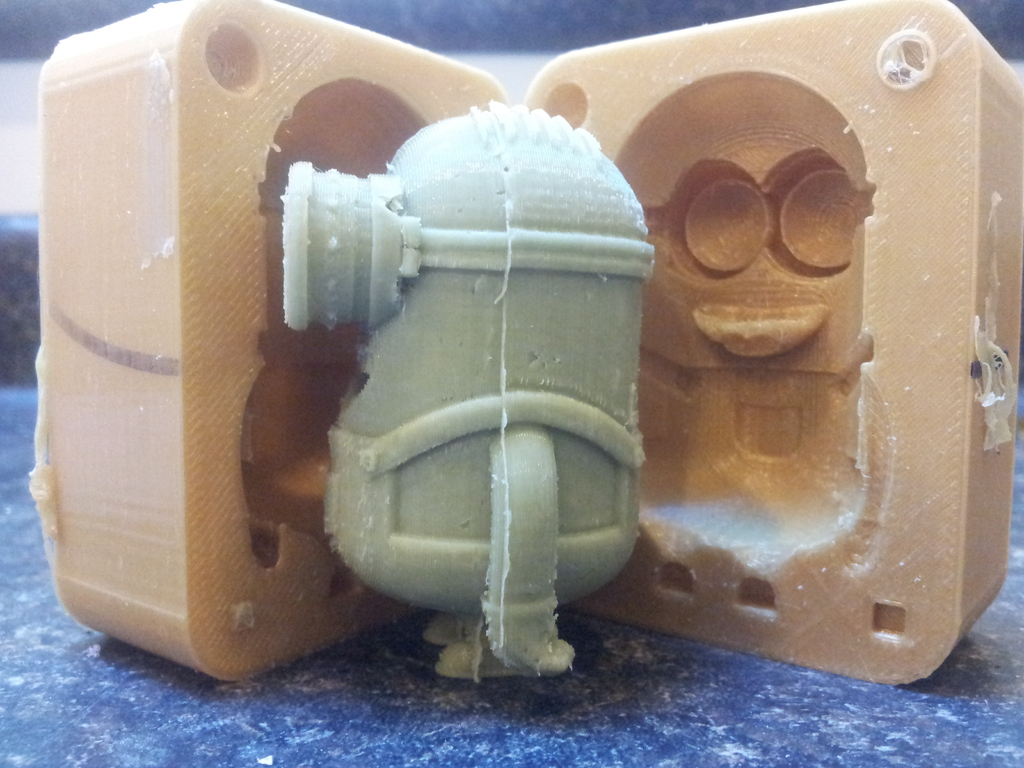

A 3D printed mold in Clear Resin for wax injection.

The process of making patterns from molds or tooling is referred to as indirect investment casting because it requires creating molds for producing the patterns in addition to final investment molds.

Rigid molds for wax (often referred to as tools) are commonly fabricated by machining aluminum or steel. Machined metal molds cost thousands of dollars to produce and take weeks of machining and polishing work before first shots can be run and pattern parts evaluated within a casting process.

With 3D printing, manufacturers can directly 3D print the mold for their pattern using materials like High Temp Resin or Rigid 10K Resin, resins with high-temperature resistance. For an optimal surface finish of molded parts, treat the interior surfaces of the mold by sanding and polishing for a smooth look, or bead blasting if a uniform matte look is desired. To ensure the final cast parts are dimensionally accurate, compensate for shrinkage by scaling up the printed mold. The exact shrinkage of the wax and the casting process can be obtained from supplier specifications.

The exact shrinkage of the wax and the casting process can be obtained from supplier specifications.

3D printed molds for metal casting shorten the time between concept and first tests to a matter of days because manufacturers can directly print the tooling necessary for running and evaluating parts.

While molded pieces must follow design rules for moldability (e.g., no undercuts, draft is beneficial, etc.), you can achieve increased pattern complexity by using assembly jigs to combine multiple components into a single structure.

White Paper

Download our white paper to learn about six moldmaking processes that are possible with an in-house SLA 3D printer, including injection molding, vacuum forming, silicone molding, and more.

Download the White Paper

3D printed jewelry patterns and metal casted rings.

Direct investment casting is a version of investment casting where the process moves directly from pattern creation to surrounding the pattern with investment material. It is ideal for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs.

It is ideal for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs.

Traditionally, patterns for direct investment casting are carved by hand or machined if the part is a one-off or expected to be only a handful of units. With 3D printing, however, manufacturers can directly print the patterns, removing the design and time constraints common in other processes.

With 3D printing, engineers, designers, and jewelers can direct 3D print patterns in order to achieve shorter lead times and geometric freedom that exceeds the design for manufacturability constraints of molding processes. Formlabs developed a range of castable materials suitable for direct investment casting, in particular for the jewelry industry.

White Paper

The way jewelers work is changing, and castable photopolymer resins are leading the way. In this guide, learn how to cast fine jewelry pieces 3D printed on Formlabs printers.

In this guide, learn how to cast fine jewelry pieces 3D printed on Formlabs printers.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Grey Resin printed pattern and finished aluminum casting from an open-faced sand mold.

Similar to investment casting, 3D printing can be used to create patterns for sand casting.

In comparison to traditional materials like wood, 3D printing allows manufacturers to create complex shapes and go straight from digital design to casting.

Metal Miniatures made with pewter casting and 3D printing.

Pewter is a malleable metal alloy with a low melting point that can be used for making fully metal objects for decorative applications such as detailed metal miniatures, jewelry, scale models, and replicas of antiques.

With recent developments in temperature-resistant 3D printing materials, like High Temp Resin for Formlabs SLA 3D printers, it’s now possible to 3D print molds for direct pewter casting.

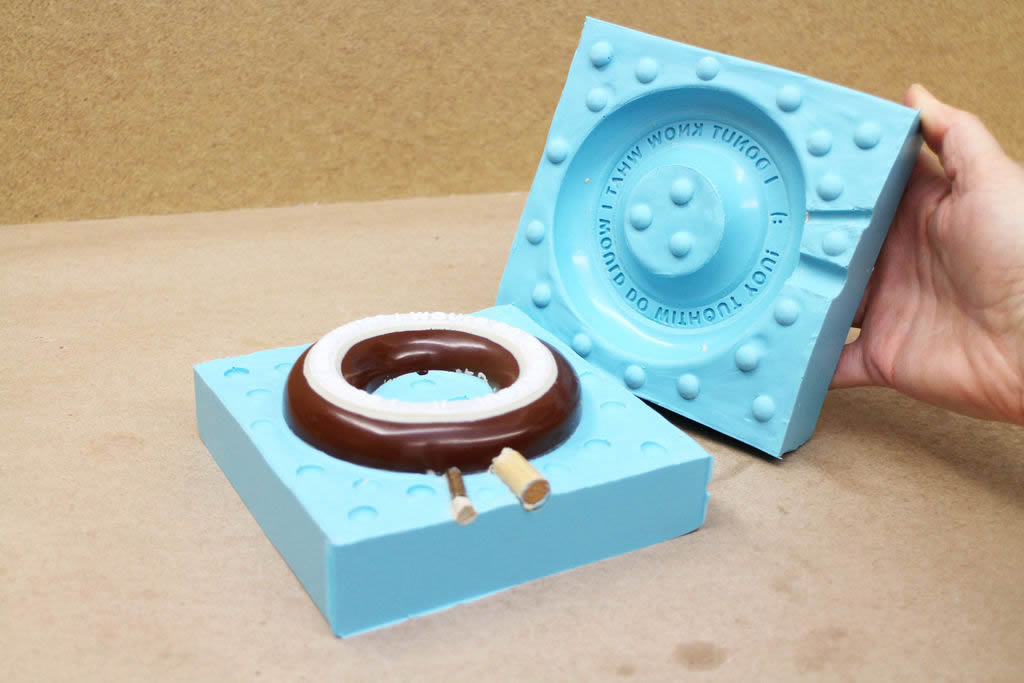

There are two options for mold designs: a sacrificial or pull-apart mold. In a sacrificial mold, there is a shell designed to be broken apart in the process. Pull-apart molds function with separate halves so the mold can be reused.

Compared to directly printing metal, the casting pewter in 3D printed molds offers significantly better detail and surface finish at a small fraction of the cost. Compared to wax casting, directly 3D printing a mold has fewer steps and requires less manual effort, while preserving the most possible detail.

Webinar

Watch our webinar to learn how moldmaking using 3D printed masters and reusable or sacrificial molds can allow you to produce parts in porcelain, precious and non-precious metals, silicone and biocompatible flexible materials, and more.

Watch the Webinar Now

Jewelry investment casting process with 3D printed patterns.

Businesses looking to boost design freedom or cut costs and lead times have a strong solution in metal casting with 3D printing.

Certain types of complex metal castings, such as large shapes with cross-sections and pieces with multiple cores, are difficult to create using traditional metal casting methods. 3D printing allows manufacturers to produce these complex designs. For example, jewelers can create intricate and custom designs that might be impossible without a 3D printed pattern.

3D printing also eliminates reliance on multiple machines or service providers to create parts. Instead, companies just need a digital file, a 3D printer, and printing material. This can cut costs and waste, as all the material used goes into the final product.

Finally, the combination of 3D printing with metal casting can cut costs and lead time. Rather than waiting weeks for expensive tooling before being able to cast a final product, a 3D printer can create a pattern or mold in hours.

Rather than waiting weeks for expensive tooling before being able to cast a final product, a 3D printer can create a pattern or mold in hours.

Metal casting combined with 3D printing help companies quickly and efficiently create metal parts. With a Formlabs SLA 3D printer, you can expedite the metal casting process and cut costs along the way.

Learn more about the Form 3 desktop SLA 3D printer and request a free sample part to evaluate the quality firsthand.

See the Form 3Request a Free Sample Part

Ultimate Guide to Silicone Molding for 3D Printing (Part 1)

Download the full Guide

as a PDF!

The simple post-processing techniques presented in this guide are an excellent way for professionals to create low-cost silicone molds, threaded inserts for enclosures, vacuum formed parts, and more.

Silicone molding is a powerful production method that, when combined with 3D printing, can allow you to make several copies of one product. You can also create a product in a material that is not supported by your 3D printer.

You can also create a product in a material that is not supported by your 3D printer.

In this How To, we will show you some of the best practices associated with creating silicone molds around 3D printed parts.

Working time will vary depending on a number of factors. Creating a mold around our 3D printed part took us about 1.5 hours. Casting into our mold took about 15 minutes.

Supplies

3D printed mold box, hardware, vents & keys (read on for more info).

Master (the print you are molding)

Silicone

Resin and dye

Mixing cups

Mixing sticks

Mold release spray

Hot glue or cyanoacrylate glue

Funnel

Ex acto knife

Rubber bands, tape, or straps

Gloves

Respiratory mask

Eye protection

Need some of these products? We've curated an Amazon wish list for you.

Step 1: Choose a file to cast a mold around

Obtain a file that you would like to either make several of, or create in a material not supported by your printer.

We chose the cap to a perfume bottle to understand what the process would look like for a product development team attempting to produce several concept models of a prototype.

The next step is to create your mold box. This is the structure that will hold the silicone in place around your part when pouring. Your master will need to be suspended in this structure.

You can create mold boxes from:

Foam core board

Legos

3D printing

We chose to design and print ours as this method has a few benefits. Designing and 3D printing mold boxes allows you to:

Print in pour holes and vents

Easily calculate the volume of our mold

Create boxes that perfectly fit the parts you plan to create a mold of

Re-use mold boxes to create multiple molds

While 3D printing your mold box isn’t necessary, it provides you with a reusable customizable mold box that the other methods cannot produce.

Step 3: Prepare and Print

Because the silicone molding process is not very demanding on the 3D printed mold box or master, you can select standard print settings.

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

Supplies Used:

3D printed mold box, 3D printed master, Cyanoacrylate glue, Mold release spray, Vents & Keys

A: Spray your mold box, master, vents, and keys with mold release.

B: Choose points across model to glue vents

C: With our 3D printed mold box we were able to glue our master directly onto the pour hole during preparation.

D: Spray again with mold release for good measure

You can suspend your master using popsicle sticks, skewers, or 3D printed rods glued to the surface of the master in an inconspicuous place. The holes left in their place after your mold has cured will aid in resin flow through the mold.

Step 5: Open Bottles of Silicone (Parts A and B) and Stir Thoroughly

Supplies Used: Silicone (Part A & B), Mixing Sticks

As silicone comes in two parts, it needs to be mixed both individually and once combined with its hardener.

Mix slowly using separate mixing sticks.

Supplies Used: Measuring cups

A: Determine the volume of silicone needed to fill your mold

B: Measure desired amount of silicone and hardener separately in two measuring cups.

We calculated our mold volume by filling our 3D printed mold box with water and pouring the water into a measuring cup to find exact volume.

For two part molds like the one shown, you only need to mix enough silicone to fill half of the volume of your mold.

Once you have measured each part, combine the two parts into one mixing cup and stir slowly with a mixing tool.

Be cautious not to stir in air bubbles. Be sure to scrape the sides of the cup to mix in all material.

Once your parts are thoroughly mixed the curing process will begin.

TIP

Read instructions on your silicone for “pot-life”. This is how long you have to work with the silicone before it cures.

Supplies Used: Mixed silicone, prepared mold box and master

Pour silicone into the first half of your mold box.

When pouring, pour slowly into one corner of the mold box and allow the silicone to run to other parts of the mold box as it fills.

Stop when the silicone reaches the top of the first half of your mold box.

Once you have poured your silicone place small keys into the silicone. These will create negative spaces and allow the mold halves to fit together once poured. We will remove them before pouring the second half of our mold.

Depending on what type of silicone you are using it can take anywhere from 75 minutes to overnight to cure.

Temperature and humidity will affect curing times, so we recommend this process be done in a room temperature environment.

Step 10: Attach and Prepare Mold Part Two

Supplies Used: Mold box part two, hardware (nuts & bolts)

Once our mold has set, we will prepare to pour the second half of our mold.

A: Remove the keys you inserted in step 9.

B: Attach and secure second half of mold box.

C: Spray with mold release

Next, repeat steps 5-9 and create the second half of your mold using the methods mentioned above.

Step 12: Let Cure

Supplies Used: Pliers or Ex-Acto knife

Once both halves of your mold have cured you are ready to remove them from the mold box and begin using them to recreate parts.

A. Remove the hardware

B: Remove the mold from the mold box and open.

C: Remove the master and vents.

Supplies Used: Cured mold, mold release spray, rubber bands

Next, you will need to reassemble your mold.

A: Ensure that all parts of your mold are correctly aligned, and plug any holes created by vents.

B: Secure mold pieces using rubber bands, straps, or tape.

Tip

Another great application for 3D printing would be to design and print a box to hold the mold together when pouring resin, or modify the mold box we used to serve the same purpose.

TIP:

If your vents leave holes in areas where resin can spill out during the pour, they will need to be plugged.

Supplies Used: Resin (Part A & B), measuring cups, measuring sticks, dye.

Just as with silicone you will need to measure each part of the mixture taking into account the volume needed to create a part.

If you have made several molds, you can mix a larger quantity of resin and pour several molds at once.

Add dye to the part of the resin mixture specified in the instructions.

Step 16: Mix Resin

Combine both parts of the resin mixture and mix thoroughly being sure not to stir in air bubbles.

TIP:

Resins typically have a shorter “pot-life” than silicone meaning they will cure faster.

Step 17: Pour Resin

Supplies: Funnel

Once mixed, pour immediately into the opening of your mold using a funnel.

Pour slowly as not to overfill and spill resin.

Any resin that remains in the mixing cup will harden, but can typically be removed afterwards.

Step 18: Let Cure

Once poured, allow the resin to cure for the appropriate amount of time.

Supplies Used: Pliers

Once your resin has cured, you can open the mold and remove your cast part.

Any resin that escaped through seams or voids and cured is called “flash”. Flash will need to be removed from the part through post processing.

Below, you can see that we were able to recreate our perfume bottle cap in several different colors and opacities using silicone molding.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Silicone Molding Part II

Vacuum Forming

Sanding

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Powered by MakerBot Learning.

3D printers in the foundry

Supplier of 3D equipment since 2010

+7 495 646-15-33

3D-scanners 3D-printer-printering services

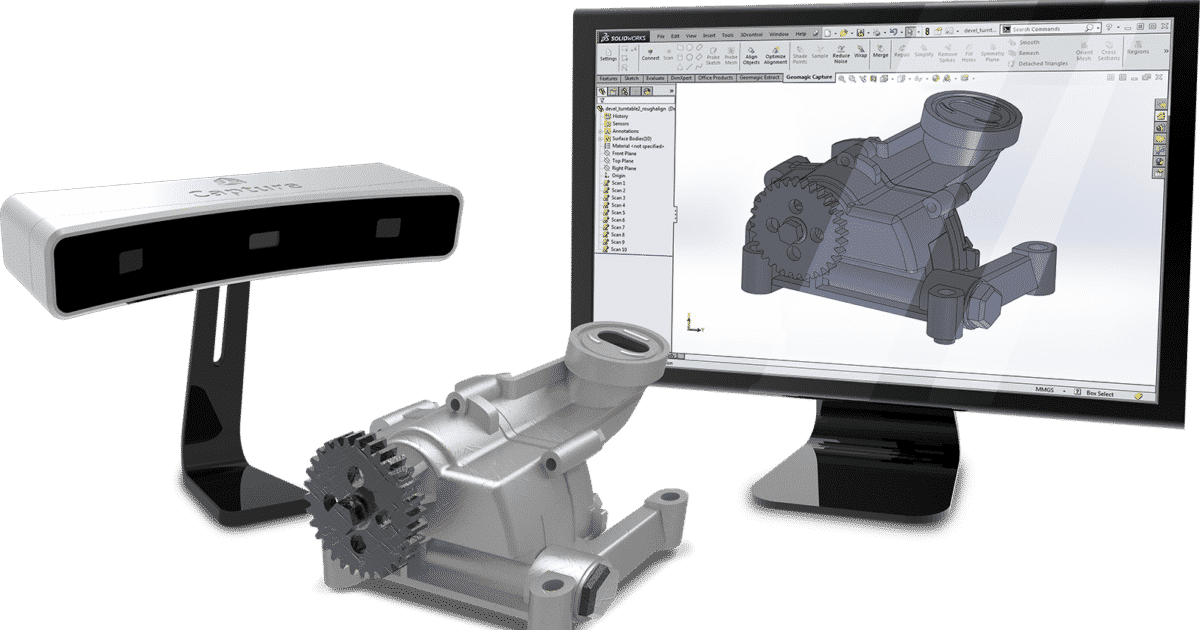

On the Project-Squaps-Peculsia Service-Service 3D 9000. makes it possible to print master models for the manufacture of molds based on CAD files. The time to create a master model on a 3D printer is much less than the time to produce a casting sample using traditional methods. nine0003

makes it possible to print master models for the manufacture of molds based on CAD files. The time to create a master model on a 3D printer is much less than the time to produce a casting sample using traditional methods. nine0003

- Bessions of traditional casting

- Advantages of 3D printing

- Choosing 3D printer

- Bessions of traditional casting

- Advantages 3D printing

- selection include 3D modeling and production of a master model using milling finishing, manual labor or other types of machining. All these methods are quite laborious and have obvious disadvantages:

- long lead time,

- high cost,

- Error probability due to factor,

- is not too high precision.

Special features, such as embossed markings on flat and conical parts of the product, are very difficult to achieve with these methods.

The situation is the same with the wooden master models.

To obtain a mold, they are covered with a special mixture of betonite and sand, due to which the method is called "casting into the ground." Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product. nine0003

To obtain a mold, they are covered with a special mixture of betonite and sand, due to which the method is called "casting into the ground." Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product. nine0003 Disadvantages of traditional casting

Familiar mold making techniques include 3D modeling and making a master model using milling, manual labor, or other types of machining. All these methods are quite laborious and have obvious disadvantages:

- long production time,

- high cost,

- Error probability due to factor,

- is not too high precision.

Special features, such as embossed markings on flat and conical parts of the product, are very difficult to obtain with these methods.

The situation is the same with the wooden master models. To obtain a mold, they are covered with a special mixture of betonite and sand, due to which the method is called "casting into the ground.

" Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product.

" Such an operation requires a huge amount of labor and time, and most importantly, it is quite expensive and does not provide the required accuracy of the finished product. 3D printing and molding: why it pays off

3D printing speeds up the mold creation cycle many times over. It takes only a few hours to produce a high-precision master model using a 3D printer (as opposed to long and painstaking manual work). In addition, the master can be sure that he will receive a product that matches the digital model by 100%.

3D printing allows you to make casting master models from different materials

Wax. This material produces blanks for creating molds with a melting point of about 60 degrees, smooth surfaces and excellent detail. 3D stencils are most widely used in industry, dentistry, and jewelry. nine0003

3D printing and injection molding: Why it pays off

3D printing speeds up the mold creation cycle many times over.

It takes only a few hours to produce a high-precision master model using a 3D printer (as opposed to long and painstaking manual work). In addition, the master can be sure that he will receive a product that matches the digital model by 100%.

It takes only a few hours to produce a high-precision master model using a 3D printer (as opposed to long and painstaking manual work). In addition, the master can be sure that he will receive a product that matches the digital model by 100%. 3D printing allows you to make casting master models from different materials

Wax. nine0074 This material produces blanks for creating molds with a melting point of about 60 degrees, smooth surfaces and excellent detail. 3D stencils are most widely used in industry, dentistry, and jewelry.

3D Wax Printers >>

Photopolymer. Burnout master models (burnout temperature from 600 degrees) with an ash content of 0.01% are created from this material, as well as high-precision samples for creating silicone molds. nine0003

3D Wax Printers >>

Photopolymer. Burnout master models (burnout temperature from 600 degrees) with an ash content of 0.01% are created from this material, as well as high-precision samples for creating silicone molds.

Resin burnout

3D printed silicone mold

Resin burnout

3D printed silicone mold

In addition, when using a 3D printer for foundry production in Moscow and other cities of Russia, it became possible to refine the master model in a new way. Under the complex geometric design, grooves are made on the mold, into which the missing pieces of durable material made using 3D printing are glued. The use of this technology significantly reduces labor costs for manual refinement, and also reduces the time for preparing the mold for casting.

Before starting production, 3D prototyping can optimize the working steps of the casting process. For example, after trial tests of injection molds, you can check the parts made in them and correct the molds without any difficulties, without creating a new model equipment every time. nine0003

Creating a mold on a 3D printer guarantees

- fast prototyping of parts from drawings or 3D file data.

- the ability to print molds of any complexity.

- ease, convenience, cleanliness and low cost of mold creation.

In addition, when using a 3D printer for foundry production in Moscow and other cities of Russia, it became possible to refine the master model in a new way. Under the complex geometric design, grooves are made on the mold, into which the missing pieces of durable material made using 3D printing are glued. The use of this technology significantly reduces labor costs for manual refinement, and also reduces the time for preparing the mold for casting. nine0003

Before starting production, 3D prototyping can optimize the working steps of the casting process. For example, after trial tests of injection molds, you can check the parts made in them and correct the molds without any difficulties, without creating a new model equipment every time.

-

-

- 3D printing of a mold allows rapid production of part prototypes from drawings or 3D file data.

- the ability to print molds of any complexity. nine0016

- ease, convenience, cleanliness and low cost of mold creation.

How the process of casting on the burned workshops

How is the process of casting on the burned mastermodes

Choosing a founder 3D printer

Uniontech RSPRO 600

9000Flashforge Waxjet 400000 9000 9000 9000 9000 W

UnionTech RSpro 600

Flashforge WaxJet 400

3D Systems ProJet 2500 W

- +7 495 646-15-33

2010–2022, Globatek JSC. All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

3D PRINTING OF SAND FORMS AND METAL CASTING RODS - SMARTPRINT

[qode_advanced_tabs][qode_advanced_tab tab_title="Voxeljet Binder Jetting Technology"]

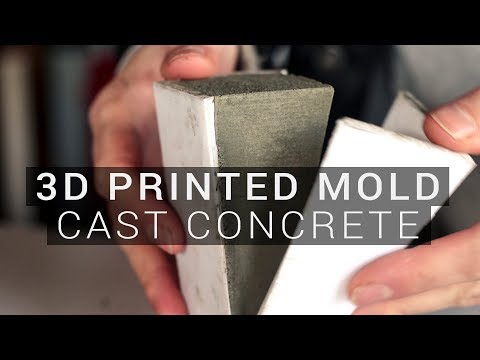

We use voxeljet 3D printers to efficiently and economically produce sand molds and cores for metal casting without tooling.

This innovative process offers the foundry industry a cost effective solution for rapid and flexible production of prototypes, spare parts and small to medium series.

The use of standard casting materials such as silicate or special sands and appropriate binders ensures optimum casting results. nine0003

OUR 3D PRINTING PROCESS

Binder Jetting is a 3D printing process where powder material is deposited in layers on a build platform and then selectively bonded according to CAD data.

BENEFITS OF 3D PRINTED SAND FORMS AND RODS:

- Freedom of geometry and design:

Due to layered sand bonding, complex cores can be simplified and shapes, including undercuts, can be created in one piece without tooling. nine0003

- Cost efficiency :

Especially for prototypes, individual parts and small series, additive manufacturing of sand molds pays off.

Since no tooling is required for 3D printing, the cost of making it is also eliminated.

Since no tooling is required for 3D printing, the cost of making it is also eliminated. - Part reduction:

In additive manufacturing, complex parts can be combined using 3D printing to reduce the number of shapes required. Thanks to digital mold design, the gating system can be built into the mold for fast casting. nine0003

- Flexibility and time saving:

Get your forms when you need them. Our service makes it possible. Once cleaned, the molds can be used directly for metal casting.

- Hybrid:

Use our technology in conjunction with your production processes by printing complex sand cores and combining them with your usual shapes.

- Risk reduction:

Minor changes to the workpiece quickly cause unplanned costs and a large waste of time. With 3D printing, you can digitally tailor your shape and print it at minimal cost.

Learn more

- 3D printing of a mold allows rapid production of part prototypes from drawings or 3D file data.

-