3D printer z corporation

Zcorp 3D Printer Review 2022

3.9

See Price

Although manufacturer ZCorporation no longer exists, the company’s range of printers stays a reference in the annals of 3D printing history for bringing full-color printing to the forefront of 3D possibilities.

Among the shining lights of this revolutionary series of printers is the ZCorp Z450 and today we’ll focus on this very model to determine how well it stacks up to trials and tribulations of time. Let’s jump in and find out what this 3D printer has to offer.

| Printing Area | 203 mm x 254 mm x 203 |

| Layer Resolution | 90 – 100 microns |

| Supported Filament | ZP130 Powder and ZB59 Binder |

| Printing Technology | 3DP/ZPrinting/ColorJet Printing |

| Resolution | 300 x 450 dpi |

Table of ContentsShow

Design & Features

Visually, the ZCorp Z450 isn’t the most appealing and is very much a product of tech production of the early 2010s with a rather uninspiring grey scheme covering the entire unit only interrupted by a questionably stylish orange near the control panel.

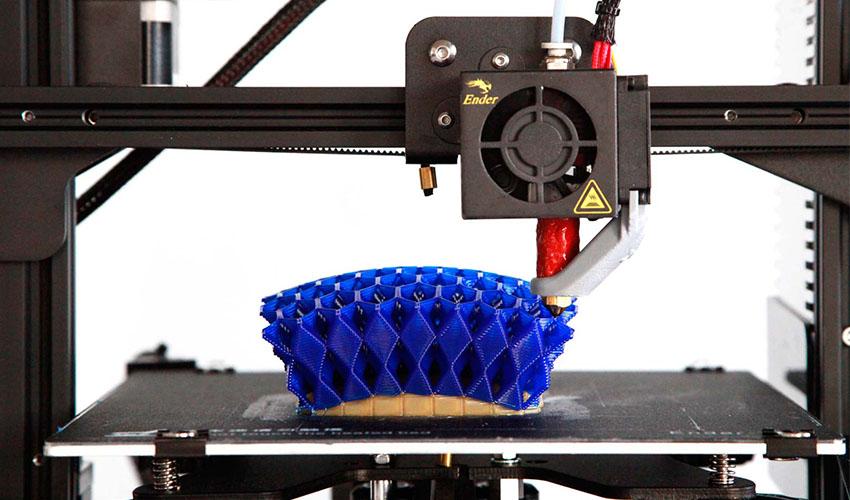

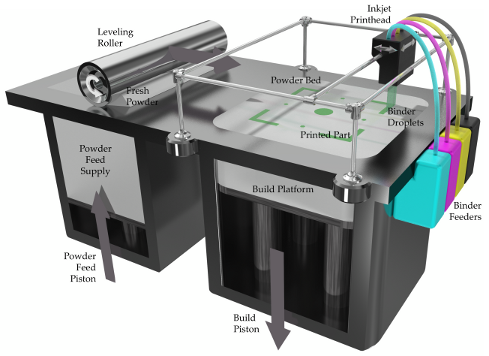

Rather than relying on Fused Deposition Modelling, the Zcorp Z450 is based on a patented additive manufacturing technology known as 3DP, ZPrinting, or ColorJet Printing depending on who you ask.

The basic tenet of the process involves a print head – very similar to that found in traditional inkjet printers – selectively laying down a liquid binding material on a thin layer of powder causing it to solidify into a specific shape and design. The main upside of the technology is a near limitless use of color because the inkjet selectively colors the binder from a range of 180,000 individual shades before applying it to the powder.

When the shape has been etched into the powder, the print bed lowers down ushering in a fresh layer of powder spread thanks to a roller for the process to repeat itself. Add up all these layers, dust off any extra powder, and you get a full-color 3D model. The results can include graded color fades, intricate patterns, and near lifelike color renditions.

The innards of the printer are divided into two chambers one for building and one for fine-powder removal. Nearing the end of the build process the first chamber runs a cursory powder removal cycle that removes the bulk of the excess powder. When the model is dry, it is moved to the second chamber where a stronger, deeper removal process cleans off any remaining powder.

The build area of the Z450 totals in at 203 mm x 254 mm x 203 for an entirely respectable surface area that is in line with similarly sized printers, but doesn’t set any records. A happy middle ground if you will. It can print up to 23 mm per hour with a layer resolution range of 90 to 100 microns and a print resolution of 300 x 450 dpi.

In what is undoubtedly the most significant negative of the Z450, the printer is only compatible with ZP130 Powder and ZB59 Binder materials. In itself, this isn’t an issue as there are many printers on the market with proprietary material limitations. The problem here is that buying the powder and binder is a bit like finding a needle in a haystack. Vendors are out there, but they charge a pretty penny for the materials.

Vendors are out there, but they charge a pretty penny for the materials.

An LCD controlled by a wheel knob sits on the front of the printer providing an array of functions ranging from de-powdering, status details, and platform raising controls. Connectivity is assured via Ethernet.

The printer runs alongside the ZPrint software that acts as both a slicer and interface to communicate with the printer. It can read STL, VRML, PLY, 3DS, ZPR file types and is compatible up to Windows 7 or older. The software isn’t innately shoddy but does show its age with an absence of functions and tinkering options we’ve come to expect from modern slicing software.

Assembly & Unpacking

Due to its 193 kg total weight and 122 cm x 79 cm x 140 cm dimensions, the Z450 falls into the crate shipped printer category, and this is precisely how the model was delivered when it was still being manufactured and how we took custody of it second hand.

The printer comes fully assembled other than fitting a new printhead and replacing the binder/powder cartridges. Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Printing

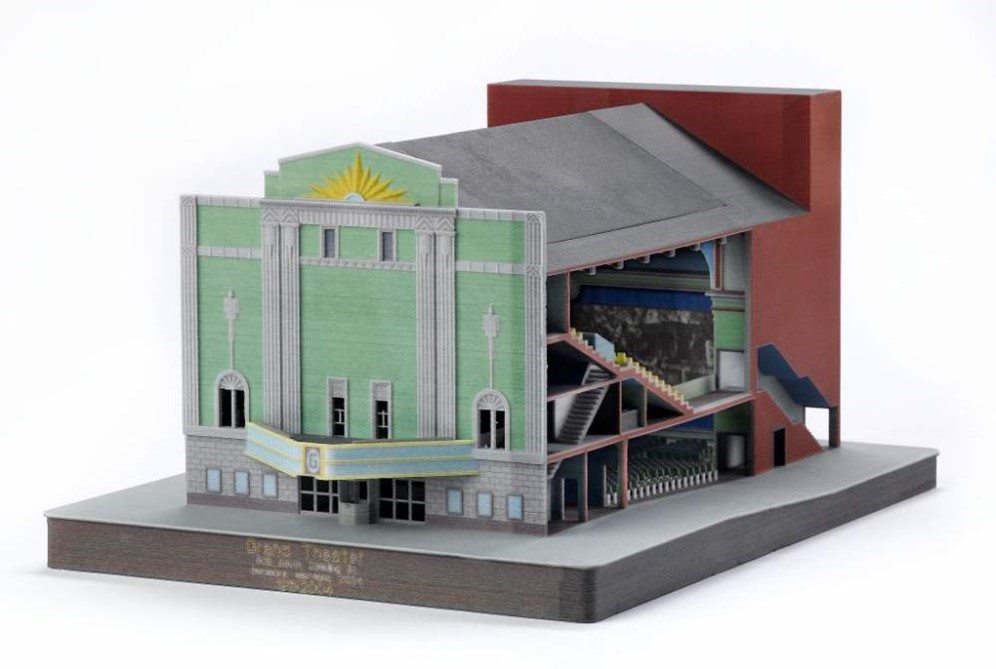

The Z450 produces high-quality prints with an eye-watering range of colors that put standard FDM 3D printers to shame. The printing process is also extremely streamlined due to the arrangement of the chambers and their various dry, vacuum, and print functions. The printer is also very waste conscious and automatically reuses excess powder. The added vacuum nozzle also works admirably for manual powder clearing.

Where this printer truly shines is in the speed of the printing process. In what is near enough twice the rate of traditional 3D printers, the Z450 is the fast prototypers dream with the ability to produce conceptual parts very quickly.

The models look and feel amazing, but there is a certain frangibility to them that is absent in PLA or ABS models for example. There’s a distinct sense that beyond being a visual representation of an idea or model, the prints from the Z450 won’t fare well being handled for practical uses or mechanical purposes, even as a functional proof of concept.

Support

In light of 3D Systems taking over Z Corporation and manufacturing of the Z450 long since abandoned, official support is unavailable. Any warranties for new units have long since expired with the chances of obtaining one is confined to merchants and auction sites flogging the printer second hand. These vendors may offer other warranties so check before committing to a purchase.

It is, however, possible to successfully hew through successive Google search pages to find advice and tips for using the Z450. Among these are niche communities of users who vow by the Z450 for all their printing needs. The difficulty lies in tracking them down.

The user manual is also a great source of information for troubleshooting problems and maintenance guidelines.

Verdict

In our eyes, the Zcorp Z450 is geared towards fast prototyping for design concepts, architectural models, form-and-fit prototypes, and demonstration pieces. Within these spheres, the Z450 performs admirably, but the questionable reliability of the end product with a propensity for being unduly brittles means practical uses are out of the picture.

Equally, a hobbyist who wants reliable models for either ornamental purposes will find use in the Z450 but venture even slightly into application based printing, and this model falls short.

The real allure of the Zcorp 3D printer is that it is possible to pick one up for a fraction of the retail price (approximately around $40,000 at its peak price). We are talking less than a $1000, if not less.

A hobbyist who wants a printer with powder/binder-based technology to add to their workshop should strongly consider the Z450 for its reliability and low cost.

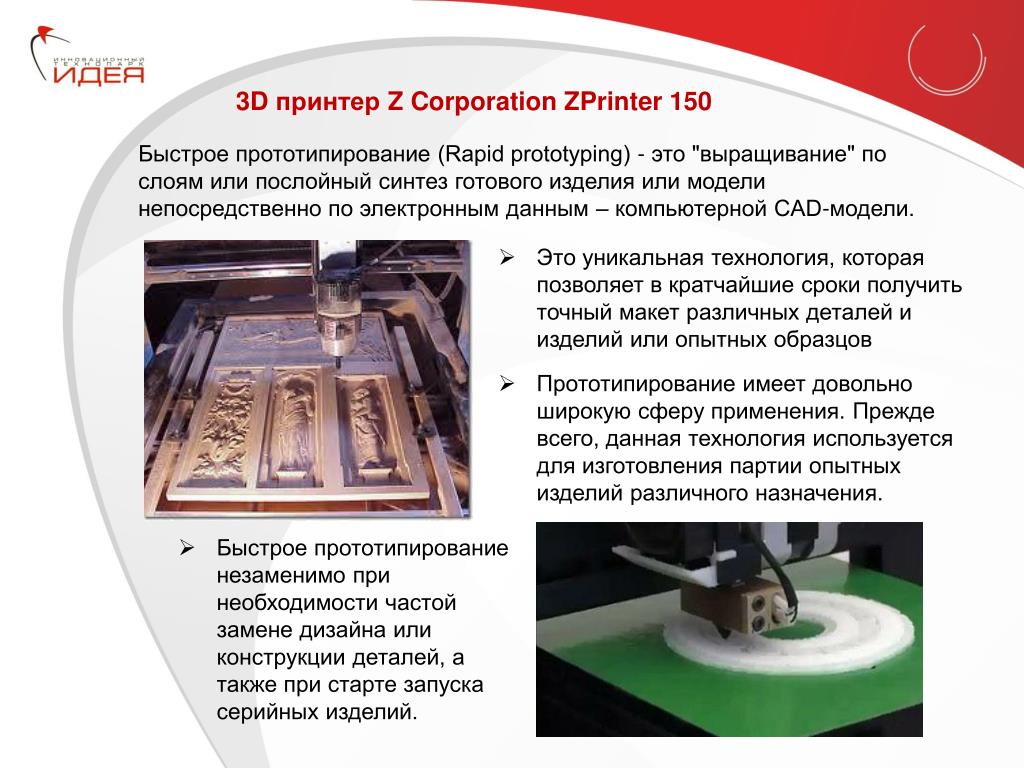

Z Corp. Introduces Two Value-Priced 3D Printers Starting at Just $14,900

BURLINGTON, Mass., USA - Z Corporation today continued its quest to make 3D printing available to every designer, engineer, architect and student with the introduction of affordable, commercial-class 3D printers.

The ZPrinter® 150 (monochrome, $14,900) and ZPrinter® 250 (multicolor, $24,900) have a small physical footprint ideal for the classroom, department, or small business. Unlike low-end 3D printers, the new ZPrinter 150 and ZPrinter 250: are easy to use out of the box; build 3D models with five times the resolution; and have the industry's lowest operating cost (lowest cost per model).

Unlike low-end 3D printers, the new ZPrinter 150 and ZPrinter 250: are easy to use out of the box; build 3D models with five times the resolution; and have the industry's lowest operating cost (lowest cost per model).

In addition to being affordable to purchase and use, the new ZPrinters print five to 10 times faster than other 3D printing technologies, with the unique ability to print multiple, stacked models simultaneously. This dramatic throughput advantage enables ZPrinters to support entire classrooms or departments at their busiest times.

The ZPrinter 250 and other color ZPrinters are the only ones capable of simultaneously printing in multiple colors. Color 3D printing enables designers and students to better evaluate the look, feel and style of designs by enhancing 3D models with graphics, logos, text, labels, and design comments.

ZPrinter 150/250 specifications include:

- Resolution: 300 x 450 dpi

- Minimum Feature Size: 0.016 inches (0.4 mm)

- Vertical Build Speed: 0.

8 inch/hour (20 mm/hour)

8 inch/hour (20 mm/hour) - Build Size: 9.3 x 7.3 x 5 inches (236 x 185 x 127 mm)

Both new ZPrinters incorporate automation features first offered in the midrange ZPrinter 450, including automatic setup, automatic powder loading, and self-monitoring of materials and print status. At home in any office or classroom, they are clean, quiet and free of any hazardous waste.

"The price of ZPrinting is coming down to enable broader adoption by mainstream users," said Z Corporation CEO John Kawola. "We're driving that revolution with new machines offering new levels of value. Though smaller in scale than the rest of our line, these ZPrinters deliver trademark Z Corp. speed, quality, and affordability."

Pricing, Availability

The ZPrinter 150 and ZPrinter 250 are available now through Z Corporation's worldwide reseller network. Manufacturer's Suggested Retail Price in the USA is $14,900 USD and $24,900 USD respectively, ex works (options, shipping, local taxes, and duties not included. International pricing will vary - please consult your local Z Corporation reseller.).

International pricing will vary - please consult your local Z Corporation reseller.).

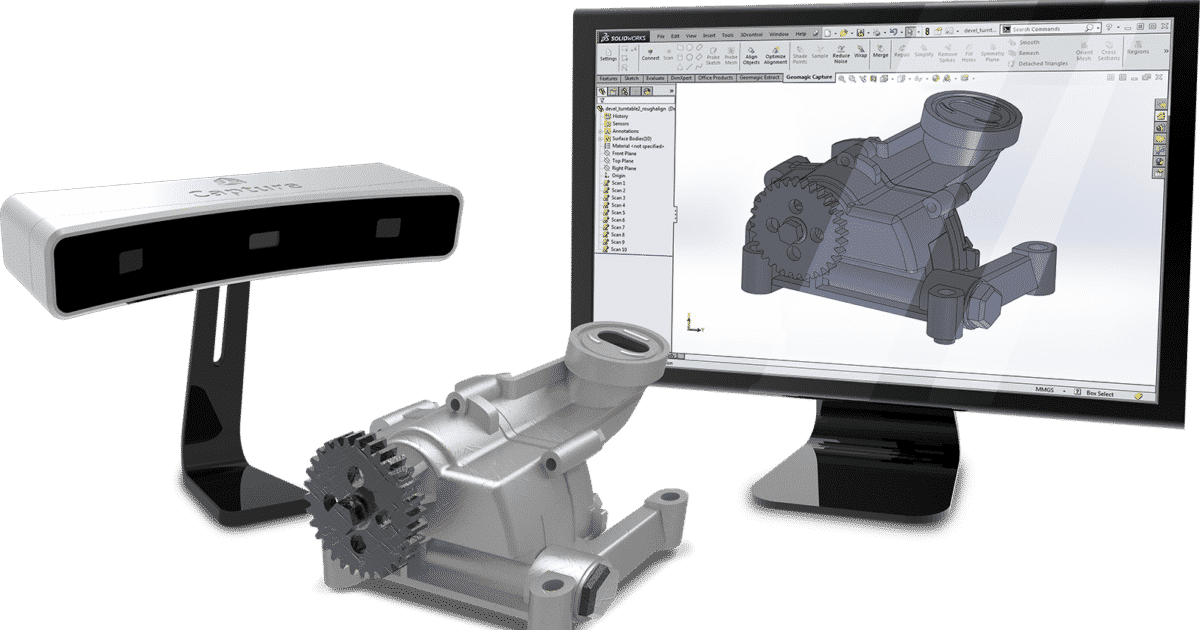

About Z Corporation

Z Corporation 3D technologies help product designers, engineers and architects create the right designs the first time. Professionals use ZPrinter 3D printers, ZBuilder rapid prototyping machines and ZScanner® 3D laser scanners to compress the design cycle, generate new concepts, communicate clearly, foster collaboration, and reduce errors. These solutions span the entire 3D CAD/BIM design process from concept through design verification.

# # #

|

|

Z Corporation 3D printers

ASCON and Cybercom Ltd. , the official representative of Z Corporation in Russia, tested the rapid prototyping technology and confirmed the correct operation of the hardware and software system built on the basis of the KOMPAS-3D system http://kompas .ru/ and 3D printer Z Corporation. nine0041

, the official representative of Z Corporation in Russia, tested the rapid prototyping technology and confirmed the correct operation of the hardware and software system built on the basis of the KOMPAS-3D system http://kompas .ru/ and 3D printer Z Corporation. nine0041

Z Corporation 3D printers work in the same way as a conventional inkjet printer. The main difference is that instead of applying ink from the print head to the next sheet of paper in a 3D printer, the binder is applied through the print head to the next thin (about 0.1 mm) layer of powder, creating one section of the object. In those places where the binder was applied, the powder hardens. The next section is "glued" to the previous one, and so on, until a fully solid body is formed. After the end of the 3D printer, the product is removed from the powder mass. Where no binder has been applied, the powder remains crumbly and can be reused. nine0040

.. nine0041

.. nine0041  A three-dimensional model is created 5-10 times faster than using other known technologies, and none of these solutions provides such a low cost of work. nine0041

A three-dimensional model is created 5-10 times faster than using other known technologies, and none of these solutions provides such a low cost of work. nine0041  It is suitable for a wide range of applications, from industrial design, architectural design and functional prototyping, to applications in medicine, education and the arts. nine0041

It is suitable for a wide range of applications, from industrial design, architectural design and functional prototyping, to applications in medicine, education and the arts. nine0041  nine0041

nine0041  nine0041

nine0041  It features high speed and performance. It can print one or several models at once. nine0041

It features high speed and performance. It can print one or several models at once. nine0041  nine0041

nine0041  nine0041

nine0041  By adjusting the desired mode for each task, the system allows you to significantly save the cost of creating each model. nine0041

By adjusting the desired mode for each task, the system allows you to significantly save the cost of creating each model. nine0041