3D print universe

3D Printing the Universe - Perkins School for the Blind

Despite our very limited abilities to travel to distant objects in outer space that can be thousands of light years — if not millions or billions of light years away from Earth — astronomers, computer scientists, and other specialists have been developing 3D models of the stars with data from NASA’s Chandra X-ray Observatory, the Hubble Space telescope and other telescopes. The 3D modeling and printing of objects in our Universe offer unique tools to understanding scientific data.

Scientists at the Chandra X-ray Observatory Center have worked with students from the National Federation of the Blind YouthSlam summer program to improve the 3D prints. The materials were then further tested and piloted with programs through UNESCO, the International Astronomical Union, NASA centers & additional communities of people who are blind or low vision.

Best Practices for 3D Prints

The best practices recommended included:

- Size: bigger = better, larger 3D print size allows more detail to be handled tactilely (about 6-8” minimum, up to 12” if feasible)

- Resolution: smoother = better, improved information processing and better information gleaning

- Quality: stronger = better, always reinforce joints, jets, or weak areas, for detailed handling

- Access: Cut whole models of objects in half when feasible; can reattach sliced parts with internal magnets

- Quantity: more models and more content were desired.

- Universal design: these approaches help more users everywhere!

All of the 3D printable files are available free online at http://chandra.si.edu/3dprint and http://chandra.si.edu/tactile.

Available 3D Kits

We also offer two kits of the 3D prints by special request to Kim Arcand (free, but with limited availability). The Touchable Universe kit contains five 3D prints created from NASA data including three models from Chandra: Supernova remnant Cassiopeia A (which also uses NASA infrared and ground-based optical data), Supernova 1987a, and the double star system and nova V745 SCO; as well as two models from Hubble and other data: Eta Carina, a bright star system, and the star-formation region known commonly as the Pillars of Creation.

Touchable Universe Kit

Here’s what you’ll find inside:

- Five 3D prints:

- Supernova remnant Cassiopeia A

- Supernova 1987a

- Double Star System and Nova V745 SCO

- Eta Carina

- Pillars of Creation (also known as the Eagle Nebula).

- Audio files with descriptions for each of the 5 3D-printed objects included.

- A tactile and Braille poster series mounted on still styrene that cover science topics of eruptions, shadows, wind, erosion, outflows, seeding and spirals.

- Audio files of the text from the Braille panels.

Image 1: Touchable Kit

Mini Stars Kit

Our smaller Mini Stars Kit explores three examples of stellar objects in our own cosmic backyard, the Milky Way galaxy, that we can feel in 3D through the mapping of direct observations in the sky. The set includes a region of star birth (M16/Pillars), a mature star system (Eta Carinae), and an exploded star that left behind a dense core (Crab Nebula).

Mini Tour

Take a mini tour of our 3D printable Universe with some of these examples of our 3D prints:

Supernova 1987A

On February 23, 1987, astronomers noticed a new source of light in the Large Magellanic Cloud, a small satellite galaxy of the Milky Way. Scientists realized that this new beacon was, in fact, an explosion caused by the death of a massive star. It was a supernova, and became known as Supernova 1987A, or SN87A for short. This 3D print maps the SN87A supernova remnant at its current observed age of 30 years. The blast wave from the supernova has crashed into a pre-existing ring of gas, throwing blobs of this gas upwards and downwards.

Scientists realized that this new beacon was, in fact, an explosion caused by the death of a massive star. It was a supernova, and became known as Supernova 1987A, or SN87A for short. This 3D print maps the SN87A supernova remnant at its current observed age of 30 years. The blast wave from the supernova has crashed into a pre-existing ring of gas, throwing blobs of this gas upwards and downwards.

Cassiopeia A

The Cassiopeia A supernova remnant was created when a massive star ran out of fuel and exploded, hurtling its outer layers into space at millions of miles per hour. The 3D model maps its two main features: a spherical component in the outer parts of the remnant and a flattened (disk-like) one in the inner region. The spherical piece reveals the outer layer of the star that exploded and drove a spherical blast wave into gas surrounding the star. The flattened component consists of the inner layers of the star. High-velocity jets of this material are shooting out from the explosion in multiple directions.

Image 2: A 3D printed model of Cassiopeia A, cut in half.

Pillars of Creation (M16)

M16, also called the Pillars of Creation, is a nearby star-forming region. The Pillars, which are sometimes called elephant trunks due to their shape, are an example of the column-like shapes that develop in giant clouds of gas and dust that are the birthplaces of new stars. This 3D model depicts details about the orientation of the Pillars in space, mostly that the Pillars actually consist of several distinct pieces on either side of a star cluster. In this model, note that the relative distance between the pillars is not to scale.

Eta Carinae

In the middle of the 19th century, the massive binary system Eta Carinae underwent an eruption that ejected at least 10 times the sun’s mass and made it the second-brightest star in the sky. As a part of this event, which astronomers call the Great Eruption, the gaseous shell formed a twin-lobed dust-filled cloud known as the Homunculus Nebula, which is now about 10 trillion kilometers long and continues to expand at more than 2. 1 million kilometers per hour. This 3D print of the Homunculus Nebula reveals protrusions, trenches, holes and irregularities in the gaseous material.

1 million kilometers per hour. This 3D print of the Homunculus Nebula reveals protrusions, trenches, holes and irregularities in the gaseous material.

Click to download 3D Model files here:

Tactile Universe

By Kimberly Arcand

SHARE THIS ARTICLE

Universe best 3D printer files・Cults

Stargate Particle Magnum Pistol Prop Cosplay

€4

Marvel Moon Knight floating Egyptian Scarab of Ammit

Free

Ngc 7496 galaxy 3D software analysis

€2.50

Steven universe keychains

€1. 36

36

Zombie Musclor

€2

The Evil Horde Stand Masters of the Universe

€4.99

Hyper3D - Shuri - Black Panther

€24

Hyper3D - Black Adam

€24

UFO beam Planter

€4.72

SORCERESS THRONE FILMATION MODEL (Origins figure)

€6.12

Omni-Man

€1

PINK DIAMOND GEM BATH BOMB SOLID SOAP MOLD

€1.89

SKELETOR Head 2 with movable jaw for MOTU replacement

€4.33

SKELETOR Head 1 with movable jaw for MOTU replacement

€4.33

Steven Universe Amethyst 3D model

€4. 72

72

BLUE DIAMOND GEM BATH BOMB SOLID SOAP MOLD

€1.89

AG CARINAE 3D software analysis

€2.50

YELLOW DIAMOND GEM BATH BOMB SOLID SOAP MOLD

€1.89

Symbol OM wall Art openwork

€1.87

NGC 4676 Galaxy 3D software analysis

€2.50

Hanging UFO Home decor

€4.72

Trap Jaw bust Motu

€26.40

KAYO TATARUS HE-MAN NEW ADVENTURES

€4

ROSE QUARTZ GEM BATH BOMB SOLID SOAP MOLD

€1.41

MR. T Bobble Head

€2.83

Sora Bulq Freescan

Free

The Child PEZ Style Topper

Free

JASPER GEM BATH BOMB SOLID SOAP MOLD

€1. 41

41

Skeletor Masters of the Universe MOTU

€4.72

astronaut on the moon

€2.86

warrior explorer

€3.21

HEMAN HEAD FOR ORIGINS 2.0

€4.72

Model Rocket

€1.23

Mego Style Robin Shoes

€0.94

Star Wars Ewok God Chair

Free

x6 Gods of Destruction Universe dragon ball super

€70

dragon ball super oregano team universe 9

€7

dragon ball super maji kayo universe 3

€7

dragon ball super Hyssop universe 9

€7

dragon ball super bergamo universe 9

€7

CRYSTAL GEMS PERIDOT BATH BOMB SOLID SOAP MOLD

€1. 41

41

CRYSTAL GEMS LAPIS LAZULI BATH BOMB SOLID SOAP MOLD

€1.41

MOVIE TEELA

€3.58

James Webb Mirror

Free

QUEEN MARLENA

€4.72

Mister Universe

€10 -10% €9

WASHU HAKUBI CHAN - TENCHI MUYO UNIVERSE - Hi-Poly STL 3D print model

€5.65

Articulated MOATY style monster

€9.20

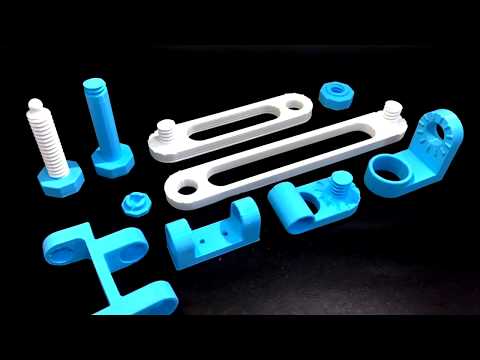

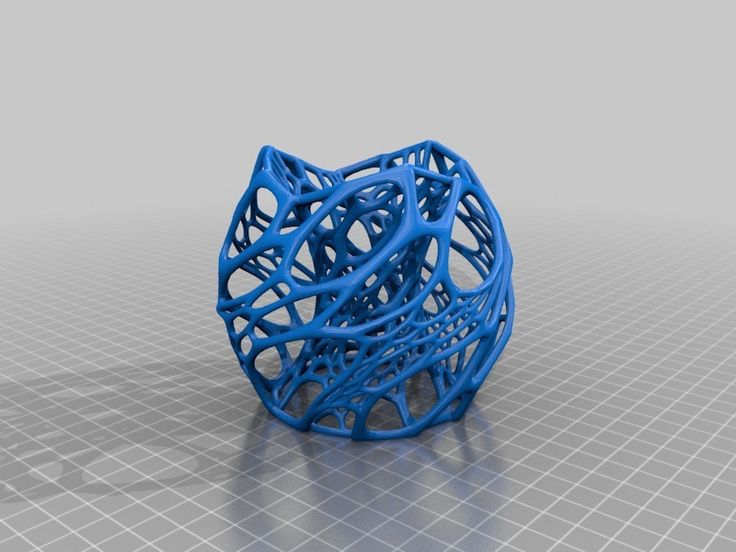

Thingiverse Service - Universe for 3d Printing / Sudo Null IT News

When it comes to 3D printers and 3D printing, the following questions usually arise:

- Why do use 3D printing at all, what can be useful and interesting done with it?

- With the help of what programs, preferably free, can create a 3D model ?

These questions can be answered using the 3D models catalog service - Thingiverse .

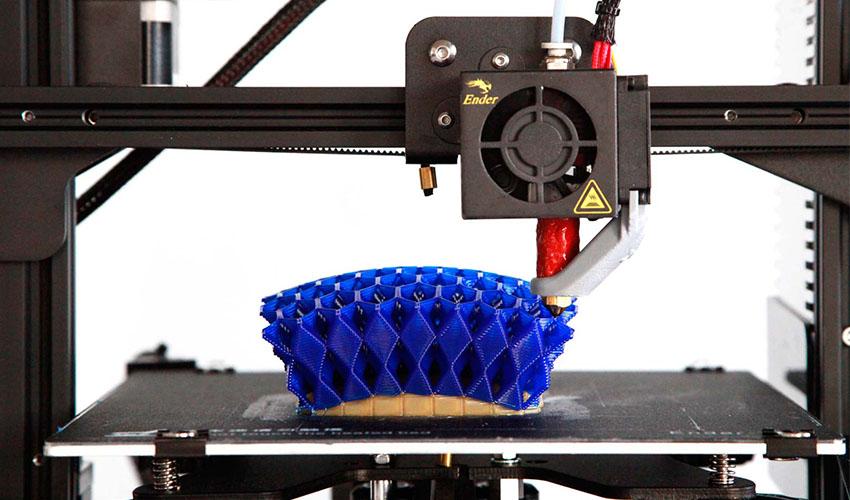

This post will do a small review of 3d models from Thingiverse (grouped by the programs with which they were created). As an example, the header provides a 3D printed construction kit created with 123D Design . More details about this constructor, and other examples of 3d models from Sketchup , OpenSCAD , Blender3d , FreeCAD - under the cut.

At the beginning, a little about the service itself, and the specifics associated with 3D printing. nine0003

Thingiverse is a free service opened in 2008, developed and maintained by MakerBot (which in turn creates and sells well-known 3D printers), anyone can register on this service and upload a 3D model for download. A key feature of the service is that all uploaded models are published under a Creative Commons license, which means that you can freely and freely download and just as freely modify.

The generally recognized format for 3D printing is STL (short for STereoLithography), this format contains only the shape of the object, without color, texture information, in fact it is a surface made up of triangles. It is in this format that you need to export 3D models if you plan to print them on a 3D printer. nine0003

It is in this format that you need to export 3D models if you plan to print them on a 3D printer. nine0003

Let's start the review of 3D programs.

123D Design

AutoDesk is seriously entering the 3D printing market - it provides a good service for preparing 3D models, in particular, you can download the 123D Design program for free. Available for PC and Mac.

Pixil Bits

The 3D printed Pixil Bits constructor consists of several elements, on the basis of which you can assemble a variety of shapes:

Hidden text

Hidden text

Hidden text

All files can be downloaded here, source code is also provided for editing in 123D Designer.

Birds mobile

Want to make sitting and spinning birds? (good example for basic math :))

Here is Joseph's "Birds Mobile" project.

The assembly process and final result can be viewed here.

Here's what you need to print:

Hidden text

And of course different arrangements are possible:

Hidden text

The original 123D Design files can be downloaded from the project page.

Sketchup3d

Perhaps one of the most famous programs will be Sketchup3d, originally developed under the wing of Google, but later transferred by the search giant to Trimpble.

Pluses — user-friendly interface for work, scripting in Ruby. Cons - not open-source, version only for Windows and Mac. nine0003

Mini Sumo Robot

3d printed platform for mini sumo robot, contains frame and

blade.

Assembly process

Files for 3D printing and original Sketchup files can be downloaded here.

3D Logo or name

Want to print a logo or name?

Here is the How To Make A 3D Logo Or Name project, where you can download instructions on how to do it in Sketchup. nine0003

Marblevator

The Marblevator project is an example of a "railway" using 3D printed rails and an iron ball.

Assembly instructions, and here you can download all the elements and original files in Sketchup.

OpenSCAD

OpenSCAD is a free open-source, cross-platform program for creating 3D models using a special modeling language.

You can create graphic primitives, merge, subtract, clone, and so on. To get the object you want. And after - export it to STL (recently there was a small tutorial on OpenSCAD on Habré)

Case for glasses

Need a glasses case? You can download and print from here.

The original format in OpenSCAD - that is, you can edit it to fit your glasses.

Animal bowl

Is your cat's bowl still unsigned?

This is easy to fix with 3D printing. In the files section, the original OpenSCAD file for customization (scad extension) is provided.

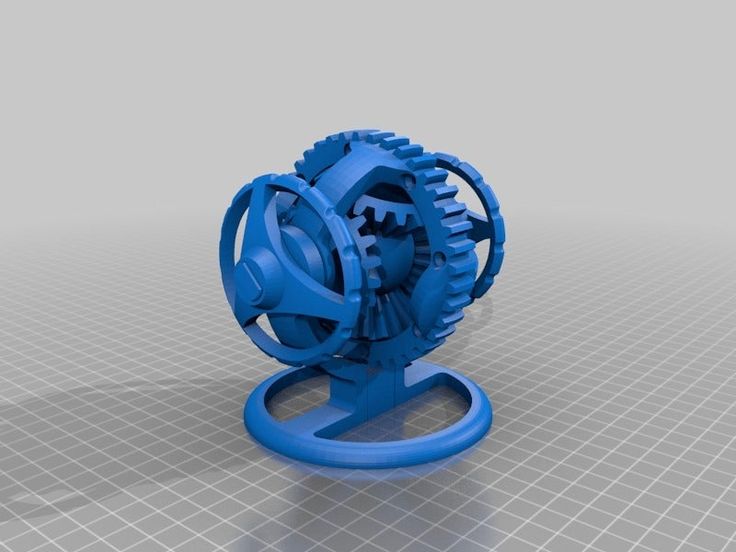

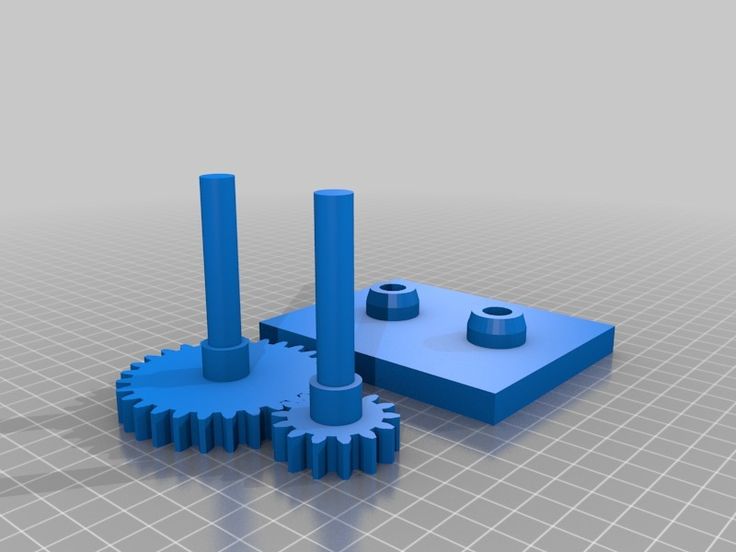

Reducer

Want to print mechanics? Please - Tiny Planetary Gears Set project.

All parts of the mechanism can be downloaded here, and here is a link to the archive with all OpenSCAD original files.

Gears

If you need to print a variety of gears, you can look at this project: Public Domain Involute Parameterized Gears, which contains OpenSCAD files for creating 3d models of various gears.

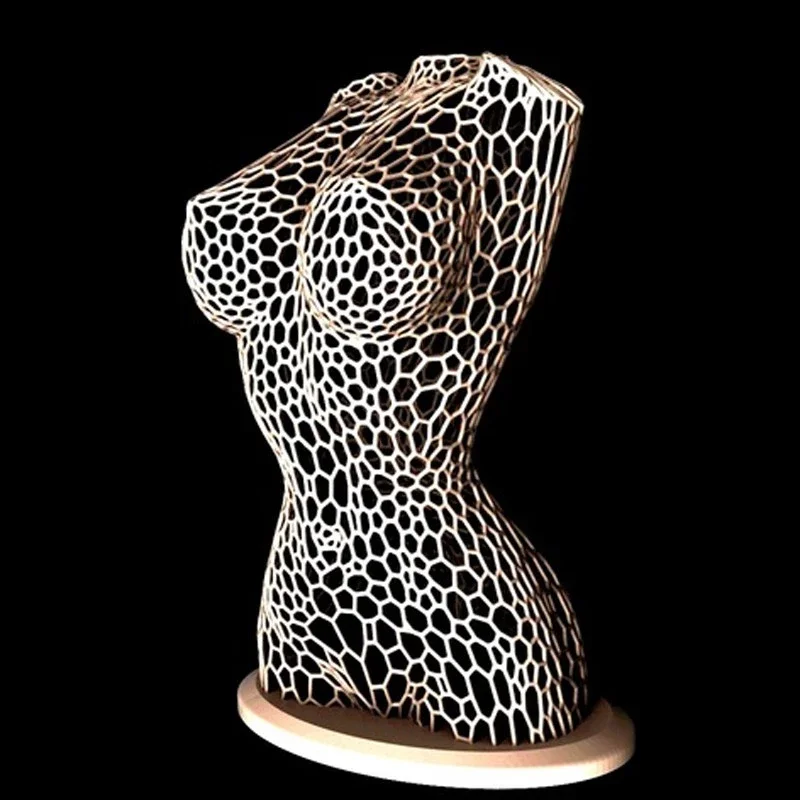

Blender

Blender3d is a free open source 3D modeling program (supports Python scripting)

Singing Dragon

One of the popular models on Thingiverse, the Adalinda: The Singing Serpent project, is made with Blender3d.

The author who created the model - specially optimized it for 3D printing - there is no need for "support" supporting elements, the whole model is printed as is.

Master Yoda

The fairly popular Yoda Figure model was created using Blender, or rather “assembled” from several models.

Based on the information from the original article, for its "preparation" were taken:

1. Yoda's head bust (from thingiverse)

Hidden text

2. Yoda's body from google sketchup gallery.

Hidden text

Airplane

Skewer Fighter Jet (F-86 Saber) aircraft model project, with the ability to download the Blender source file. nine0003

The author of macouno can see many other models created based on Blender3d, in particular:

Keyboard support

Sometimes the keyboard lifters break, you can download and print: Computer Keyboard Riser

FreeCAD

FreeCAD is a lesser known program, but interesting enough as it is positioned as a professional CAD system, completely free and open-source. Full Python scripting is supported. nine0003

Full Python scripting is supported. nine0003

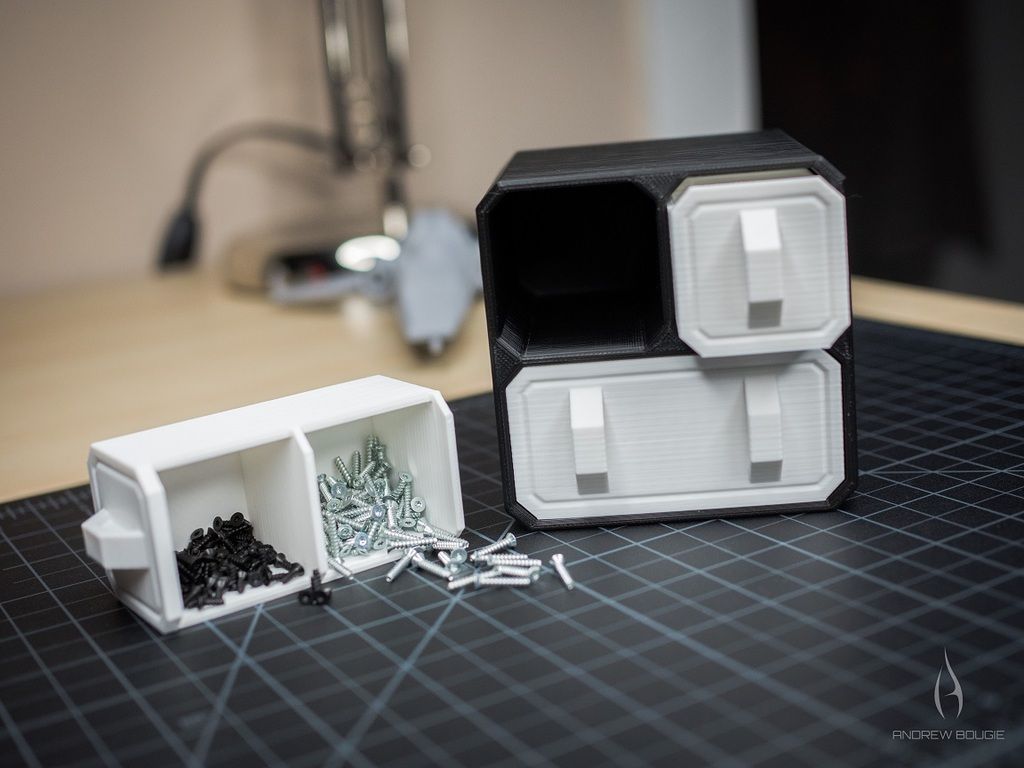

Bike phone holder

Want to mount your smartphone on the handlebars of your bike? Then see this project: Bike phone holder . Files for FreeCAD are included.

Another view

Drawer handle

Need a drawer handle? No problem, the Simple Drawer Knob project. The original FreeCAD file is included in the downloads.

Phone Wall Mount

Want to put your phone on the wall? Here is the project: Wall Mount for Vtech 6419cordless phone.

Smartphone speaker

Do you want to make a horn for your smartphone? The Parametric Acoustic Horns project will allow you to use a python program to generate the required horn in FreeCad.

You can hear the difference:

As a conclusion

This is of course a small part of those models that are posted on Thingiverse, and new projects appear every day.

If you don't have access to a 3D printer yet, you can:

- do a search for hackspaces in your city, there are usually 3D printers there and they are available for small orders

- look for fablabs, there should also be a 3D printer

- search 3D printing service (in your city)

3D Universe

You are here

Home

Additive manufacturing is increasingly being cited as a driver of innovation. The 3DFAB + Print conference, organized by Messe Düsseldorf Moscow, gave an opportunity to take a look at the vast expanses of the additive manufacturing universe. nine0003

Hot topic. Perhaps the organizers themselves did not expect such an influx of visitors thirsting for new information, who filled not only all the chairs in the conference area, but also the aisles. The conference was attended by 37 speakers and more than 400 listeners. Leading players who have gained experience in the young Russian market of additive technologies, sharing their experience, did not forget to warn those who are thinking about entering the market.

Money, time, geometry

The question of the cost and expediency of using technology is always important. This was emphasized by Oleg Lysak, CEO of CML AT, which is engaged in process engineering in the field of additive technologies. He gave impressive "anti-examples" when a grown product is an order of magnitude more expensive than one made using traditional technology. nine0033 Thus, the pilot project "3D Printing Marine Spares" in the port of Rotterdam revealed a price of 2,400 euros plus 150 euros for testing when manufacturing a valve seat, against a price of 203 euros for production using traditional technology. Another spare part, namely the bracket, cost 1628 euros in additive manufacturing plus 1500 euros for testing. The part in traditional production cost 480 euros. A joint project of 3D Systems, SolidWorks, Haas Factory Outlet and Mastercam to print a drill head, in addition to the high price, showed the impracticality of printing due to the size and high probability of defects. Thus, it makes no sense to use additive technologies to replace traditional ones, only the design of new products and structures will make it possible to use all the advantages of 3D printing. nine0033 Irina Arapova, marketing specialist at Picaso, also identified dead-end areas, according to company professionals: “Desktop 3D printing is not needed by anyone due to restrictions on geometry and cleaning of supports. Dual extruder printers are useless due to slow print speed and poor process stability.”

Thus, it makes no sense to use additive technologies to replace traditional ones, only the design of new products and structures will make it possible to use all the advantages of 3D printing. nine0033 Irina Arapova, marketing specialist at Picaso, also identified dead-end areas, according to company professionals: “Desktop 3D printing is not needed by anyone due to restrictions on geometry and cleaning of supports. Dual extruder printers are useless due to slow print speed and poor process stability.”

But, as it turned out, not everything in additive manufacturing converges on the problems of price and equipment efficiency. In 2015, the Dutch company Additive Industries, which manufactures metal printing equipment, introduced the first modular printer design. In 2017, the first sales took place in companies of the Airbus and BMW level. But, according to Lysak, the company will not supply this equipment to Russia, because it does not yet see a market in our country. nine0033 Fedor Antonov, CEO of Anisoprint, who presented the first Russian composite 3D printer, claims that there are no affordable solutions on the market that allow manufacturing complex-shaped functional parts. Either cheap, but with small capabilities, or with great capabilities, but expensive.

Either cheap, but with small capabilities, or with great capabilities, but expensive.

If we summarize the opinions of many speakers, then small runs are more profitable, that is, it is both faster and cheaper to do on a printer, large series are best done on traditional equipment using traditional technologies. nine0033

Statistics, forecasts, problems

Kirill Merenkov, head of the RP center of Consistent Software Distribution, shared information provided by Aerospace Technologies LLC. These are data for 2014, but the situation is unlikely to have changed dramatically. Thus, the world's top three consumers of equipment for additive technologies include the USA (38%), Canada (12%), Japan (9.7%), Russia's share is 1.4%. No less interesting is the forecast for the use of additive technologies until 2020 in terms of the main priorities. Leading the way is accelerating product development and manufacturing products to individual specifications. nine0033 Dmitry Trubashevsky, Sales Director of Solver Group, presented interesting information. Plastic printing prevails - 89%, metal printing accounts for 10%, all other materials - 1%. At the same time, the share of amateur and semi-professional printers is 91.6%, and professional and industrial - 8.4%. According to a study by the International Data Corporation (IDC), in 2016 the global market for 3D printers was $13.2 billion, in 2017 it was $16 billion, and by 2020 it is projected to be $28.9 billion.billion. The growth dynamics of the number of 3D printers is as follows: 2015 - 220,000 units, 2016 - 450,000 units, by 2020 the number of printers in the world will reach 6,700,000 units. In 2016, 29.6% of printers were in the automotive industry, 17.8% in aviation, space and military, 7.5% in tooling, 6.9% in architecture, 3.3% in private printing, and 34 .9% for everything else.

Plastic printing prevails - 89%, metal printing accounts for 10%, all other materials - 1%. At the same time, the share of amateur and semi-professional printers is 91.6%, and professional and industrial - 8.4%. According to a study by the International Data Corporation (IDC), in 2016 the global market for 3D printers was $13.2 billion, in 2017 it was $16 billion, and by 2020 it is projected to be $28.9 billion.billion. The growth dynamics of the number of 3D printers is as follows: 2015 - 220,000 units, 2016 - 450,000 units, by 2020 the number of printers in the world will reach 6,700,000 units. In 2016, 29.6% of printers were in the automotive industry, 17.8% in aviation, space and military, 7.5% in tooling, 6.9% in architecture, 3.3% in private printing, and 34 .9% for everything else.

According to the representative of the Department of Machine Tool Building and Investment Machine Building of the Ministry of Industry and Trade of the Russian Federation Anton Grechko, in 2017, Russian companies manufactured and sold 2,600 printers, 19industrial additive systems, which include 3 machines for working with metal powders. The largest state corporations, including Roscosmos, Rosatom, Rostec and other leading scientific and industrial organizations actively use 3D printers in their production and research processes.

The largest state corporations, including Roscosmos, Rosatom, Rostec and other leading scientific and industrial organizations actively use 3D printers in their production and research processes.

Due to the large number of applications from various companies about the creation of Russian 3D printers, Anna Tsygantsova, Lasers and Apparatura Group, noted the main stages in the manufacture of a serial machine ready for implementation: development of a prototype machine and its key components, finalization of this sample based on the results testing, adaptation of documentation and manufacturing technology for mass production, preparation of production. In addition, the successful implementation of the machine is impossible without a high-quality study of the technology carried out by the manufacturer. Parallel development of equipment, design of the final product, software and technology should be carried out. In this regard, constant communication between the corporation producing the final product and the manufacturing equipment manufacturer is significant; cooperation with universities is required.