Make anything 3d printer review

Favorites — Make Anything

As someone who has been 3D printing non-stop since 2012 and testing dozens of different machines for my YouTube channel, I thought I would share my insights here to help guide newcomers when it comes to buying a 3D printer, 3D pen, and other awesome tools for art and design. While needs and experiences may vary, these are my verified favorites!

Full disclosure : As an Amazon Associate I earn an affiliate payment from qualifying purchases using the Amazon short URLs on this page. Using these links does not change the price of your purchase, but it does help me! This page also includes affiliate URL’s through programs with eBay, GearBest, AliExpress, MatterHackers, and Sovol3D. Thank you for supporting the Make Anything mission to provide helpful information and resources for makers, designers, artists, creators, and more!

With thousands of 3D printer models out in the wild, it’s hard to try them all. That said, I have experienced more 3D printer models than most, so I've compiled this list of suggestions based on my best experiences with 3D printing! Whether you're most concerned about price, size, quality, ease of use, etc. .. you might prefer a different printer, but hopefully you'll find my notes helpful in making that decision.

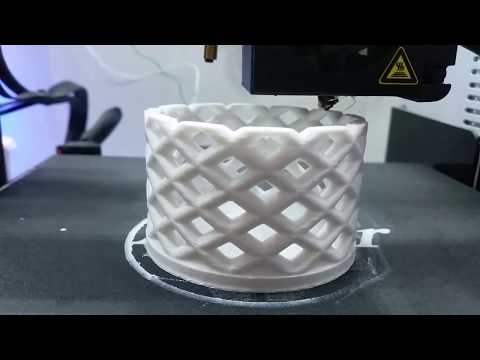

Having worked with this printer for several years now, it has become my most reliable machine. This fantastic direct drive printer offers excellent versatility and results at the lower end of the price spectrum. Sovol’s SV01 impressed me with its pristine layer quality, leaving nothing to criticize in that department. I originally had trouble with flexible filaments, but after installing the upgrade that comes with current models, this printer can handle just about any filament under the 250˙C temp. range.

As of writing this in 2022, this is the printer I would currently recommend to most newcomers to 3D printing.

Where to Buy:

Sovol3D Official Site

Amazon

AliExpress

eBay

My Default Slicer Profile for this printer:

Simplify3D

Where to Buy:

AliExpress (Official Artillery3D Store)

Amazon

eBay

GearBest

Artillery seemingly appeared out of nowhere in 2019 with their flagship Sidewinder X1 3D printer. During a time when just about every hobby printer manufacturer was releasing a CR-10 Style 300mmx300mmx400mm printer with one little difference or another, this one stood out for having great specs across the board at a similar price to competition. The X1 has a sleek and solid structure, with matte black 2040 aluminum extrusions mounted on a low-profile sheet metal base, all electronics neatly packed inside. The key standout feature is probably the extrusion system : a direct drive extruder that feeds into a volcano hot end capable of printing a wide variety of materials (including the most flexible filaments) at impressive speeds. I’m also amazed by how silent this printer can run. You’ll forget it’s on!

During a time when just about every hobby printer manufacturer was releasing a CR-10 Style 300mmx300mmx400mm printer with one little difference or another, this one stood out for having great specs across the board at a similar price to competition. The X1 has a sleek and solid structure, with matte black 2040 aluminum extrusions mounted on a low-profile sheet metal base, all electronics neatly packed inside. The key standout feature is probably the extrusion system : a direct drive extruder that feeds into a volcano hot end capable of printing a wide variety of materials (including the most flexible filaments) at impressive speeds. I’m also amazed by how silent this printer can run. You’ll forget it’s on!

See my video reviews to learn even more great features.

My Default Slicer Profile for this printer:

Simplify3D

Other Printer Profiles :

Anycubic i3 Mega Simplify3D Profile

While I’ve only recently started using the Mynt3D Super 3D Pen, it has quickly won me over, matching or exceeding dozens of other contenders in nearly every category. In the past, I’ve had many slim 3D pens die from overheating, but Mynt3D has managed to create one of the most comfortable pens without sacrificing reliability. It feeds on common 1.75mm filament, which means refills are cheap and abundant, and from my own experience and other user testimonies, this seems to be among the most clog-proof pens out there which is great for longevity!

In the past, I’ve had many slim 3D pens die from overheating, but Mynt3D has managed to create one of the most comfortable pens without sacrificing reliability. It feeds on common 1.75mm filament, which means refills are cheap and abundant, and from my own experience and other user testimonies, this seems to be among the most clog-proof pens out there which is great for longevity!

Where to Buy:

Official Amazon Seller

Watch my video review to see the pen in action.

Mynt3D continues to deliver with their Professional level 3D pen. This pen is basically the Super 3D Pen with the addition of an OLED display that shows temperature and filament settings, plus more precise temperature control. Unlike the Mynt3D Super Pen, which has a tiny dial that requires a tool to adjust, the Professional Pen simply has a (+) and (-) button to adjust the temp. by 1 degree Celsius at a time. It’s a convenience more than a necessity, but if you can afford the upgrade it’s definitely an improvement!

The max temperature is 230, sufficient for any standard 3D pen filament. It’s also really silent, and withstood multiple hours of continuous use with no problems.

It’s also really silent, and withstood multiple hours of continuous use with no problems.

This is my top choice for reliability and value!

Where to Buy:

Official Amazon Seller

Where to Buy:

Official 2020 Model on Amazon

3Doodler is the company behind the original 3D pen, and they have continued to lead the way with a continuously improving and evolving line of 3D pens. I've tested most of their pens, and I think the Create+ is their best yet. The pen has a dual gear extrusion system that feeds filament smoothly and reliably. You can also swap nozzles for different sizes and even shapes, like a flat ribbon or a star pattern. My biggest gripe is that 3Doodler pens use sticks of 2.85mm filament. These sticks run out quickly, so you find yourself constantly adding filament, and buying refills directly from 3Doodler can add up quickly. The good news is that I’ve had success using third party filament with the Create+. 2.85mm/3mm filament is becoming less common, but it’s still used for some 3D printers, so it can be found by the spool.

2.85mm/3mm filament is becoming less common, but it’s still used for some 3D printers, so it can be found by the spool.

The Cheapest 3D Pens - $10-20

While many people getting into 3D pen art may want the most advanced model of 3D pen, some of us just want a cheap handheld plastic extruder that will fix and join 3D prints or want to try 3D pens without spending much. Luckily, even some of the cheapest 3D pens available work really well! While buying these cheap pens can be a gamble in terms of quality control, I’ve had the best results with the Scribbler V2 style 3D pens. Still, if you’re risk averse, check for a money-back guarantee!

Where to Buy:

GearBest $12

eBay $12

AliExpress

Iceland Blue PLA from Fillamentum

Fillamentum Extrafill PLA is probably my favorite filament to print with. The filament is wound immaculately on clear spools, the color choices are unique, plentiful and just some of the prettiest choices around. Wizard’s Voodoo and Mint are two of my favorite colors.

The filament is wound immaculately on clear spools, the color choices are unique, plentiful and just some of the prettiest choices around. Wizard’s Voodoo and Mint are two of my favorite colors.

MatterHackers BUILD & PRO series PLA : MatterHackers provides excellent filaments in both the lower (BUILD) and higher (PRO) price range. Filaments come in a wide range of colors/materials, so you'll spend less time diagnosing failed prints and more time printing awesome models! Both BUILD and PRO PLA print equally great, but the PRO PLA seems to have more opaque colors, better color consistency, and a longer shelf life. Fast, free shipping in the US. (The Light Blue PRO PLA is my favorite blue for sure!)

GreenGate 3D 100% Recycled PETG : GreenGate3D has achieved something of a “holy grail” of 3D printing with their filament. It’s made of 100% recycled scrap plastic, sourced and manufactured in the USA, beautiful, versatile, and somehow still priced competitively. We partnered up to offer Devin Montes “Cool!” Grey PETG, the perfect ultra-light grey to bring out the best in your prints.

We partnered up to offer Devin Montes “Cool!” Grey PETG, the perfect ultra-light grey to bring out the best in your prints.

Polyalchemy Elixir and FX PLA are in a league of their own when it comes to flashy finishes. Elixir filaments are extremely shiny, like colorful chrome. The FX filaments mimic natural stone finishes with tiny specks and variations in color.

Essential Tools

Besides 3D Printers and Pens, there are many tools that I consider essential for 3D printing and design. Here are some of my selections :

E-6000 industrial adhesive : While many people prefer cyanoacrylate (super glue) for connecting 3D printed parts, I find E-6000 to be an excellent alternative. It dries clear and slightly flexible, so connections are less brittle. A 1 hour working time also makes it less stressful than an instantly curing adhesive.

Digital Caliper : This is a tool I use any time I'm designing a model on my computer.

I use it to measure parts when building functional parts, and even when making something from scratch, it's a useful reference to get an idea of the real world scale of my models. For a long time I used a cheap, plastic caliper, but upgrading to a (still rather cheap) steel caliper greatly improved the accuracy of my measurements. The caliper I bought is no longer available, but there are many affordable and highly-rated steel calipers available on Amazon.

I use it to measure parts when building functional parts, and even when making something from scratch, it's a useful reference to get an idea of the real world scale of my models. For a long time I used a cheap, plastic caliper, but upgrading to a (still rather cheap) steel caliper greatly improved the accuracy of my measurements. The caliper I bought is no longer available, but there are many affordable and highly-rated steel calipers available on Amazon.Tweezers : Most printers tend to leak a bit of filament while heating up the nozzle. While you can have the printer draw out a purge line or put a skirt around your model, little bits of filament can still get stuck here and there. A pair of pointed tweezers are great for picking things out from under your nozzle.

Wire Clippers : Many printers come with a pair of these wire clippers because they are excellent for cutting filament. You want a clean end on your filament to prevent jams, so these are super handy.

The cheap ones work fine for most 3DP uses, but if you want top quality go for these KNIPEX cutters.

The cheap ones work fine for most 3DP uses, but if you want top quality go for these KNIPEX cutters.

A custom domain name adds a level of professionalism to any content hosted online. Whether it's your website, portfolio, social media, etc... NameSilo offers the best deal on domain names. Cheap, easy, and secure! Click the banner on the left to find your domain today.

The 4 Best 3D Printers for 2022

We independently review everything we recommend. When you buy through our links, we may earn a commission. Learn more›

- Office

- Printers & Scanners

UpdatedSep 2022

Updates

We’ve updated this guide to include the Artillery Sidewinder X2 as a pick, revised the Prusa Mini+ and Prusa i3 MK3S+ sections with new details, and added a section discussing Ender-3 printers.

What can you make with a 3D printer? Almost anything you want—from vases to GoPro mounts to phone cases—provided you don’t mind that it’s made out of plastic. Whether you’re a tinkerer interested in prototyping or a tabletop-gaming enthusiast seeking to expand your arsenal of miniatures, a 3D printer might be the manufacturing tool you need. We recommend the Prusa Mini+ printer because it’s the most reliable printer we’ve tested, and we find it to be an especially good value at $400 or so. It’s also easy to use and relatively inexpensive to operate.

Whether you’re a tinkerer interested in prototyping or a tabletop-gaming enthusiast seeking to expand your arsenal of miniatures, a 3D printer might be the manufacturing tool you need. We recommend the Prusa Mini+ printer because it’s the most reliable printer we’ve tested, and we find it to be an especially good value at $400 or so. It’s also easy to use and relatively inexpensive to operate.

Our pick

Prusa Mini+

This printer consistently cranked out high-quality prints in our tests and has a huge print volume.

The consistency and the thoughtfully chosen, repairable parts of the Prusa Mini+ will please more advanced users who need a dependable 3D-printing machine. It’s also a bargain, with unusual features at this price such as a large, 7-by-7-by-7-inch printing area (also known as the print volume, or the total space you can print within) and a color display, as well as 24/7 customer support. Prusa printers are the quietest models we’ve tested, too, and they’re compatible with a wide range of plastic types.

Advertisement

Upgrade pick

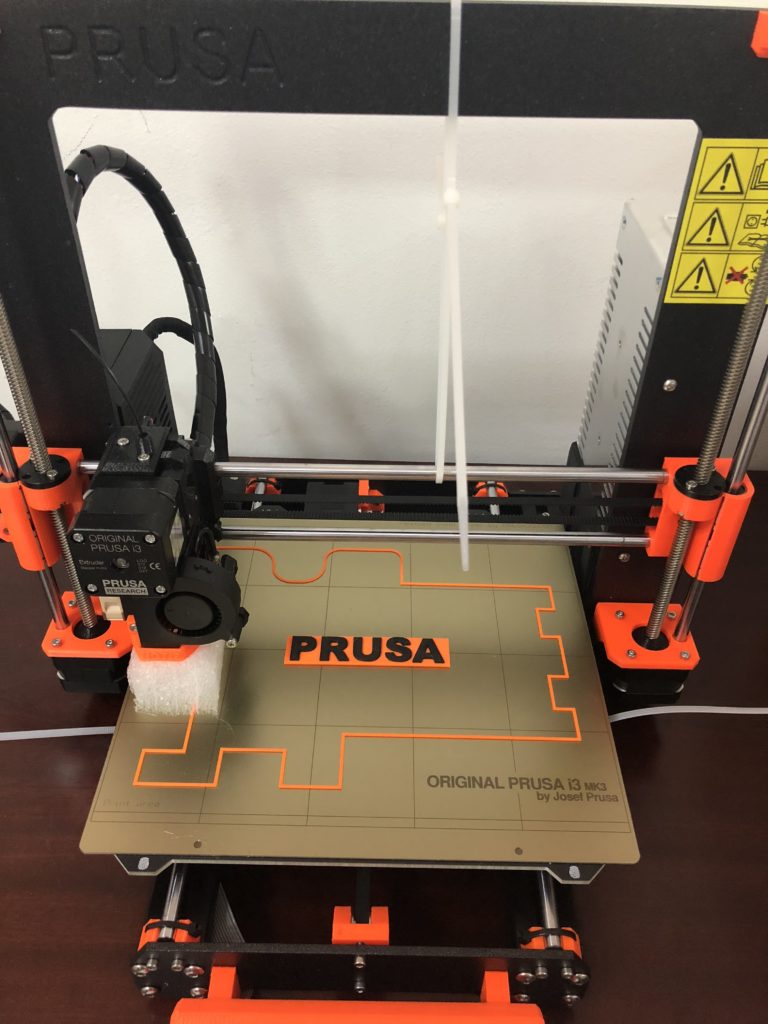

Prusa i3 MK3S+

This model offers the reliability and quality of a Prusa printer plus the largest print volume available.

The Prusa i3 MK3S+ is a worthy upgrade from the Mini+ for its 9.9-by-8.3-by-8.3-inch printing area, more stable z-axis, and better extruder. It comes with parts that are likely to last longer (though no color screen as on the Mini+) and an upgraded motherboard that can better detect and correct errors while the machine is printing. Its setup is also faster and easier than that of the Mini+.

Budget pick

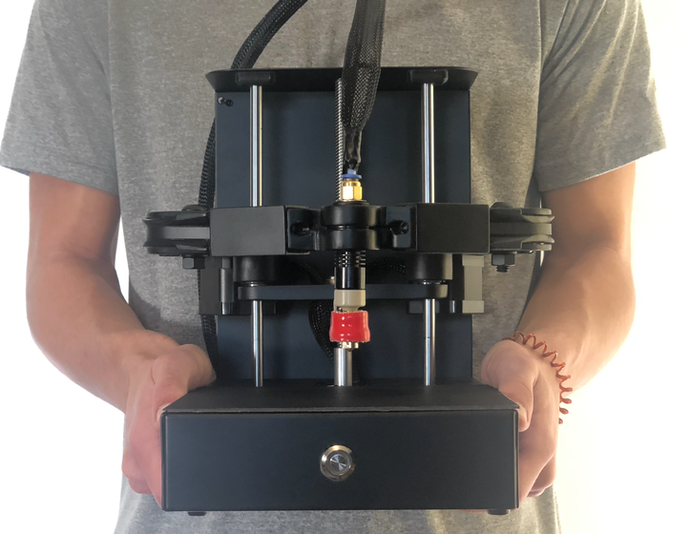

Monoprice MP Cadet

The MP Cadet is cheap, reliable, and small enough to fit on any desk.

If you’re a total beginner who doesn’t want to invest too much, or if you’re looking for a printer that’s safer for children to use (similar machines are advertised for kids as young as 8), the Monoprice MP Cadet might be a better option. In our testing, it consistently turned out flawless (though less detailed) prints as long as the designs weren’t too complex. It has a small, desk-friendly footprint. It’s also less than half the price of the Prusa Mini+, but it doesn’t offer as many features or produce the same level of detail, and it has a smaller, 3.9-by-4.1-by-3.9-inch print volume.

In our testing, it consistently turned out flawless (though less detailed) prints as long as the designs weren’t too complex. It has a small, desk-friendly footprint. It’s also less than half the price of the Prusa Mini+, but it doesn’t offer as many features or produce the same level of detail, and it has a smaller, 3.9-by-4.1-by-3.9-inch print volume.

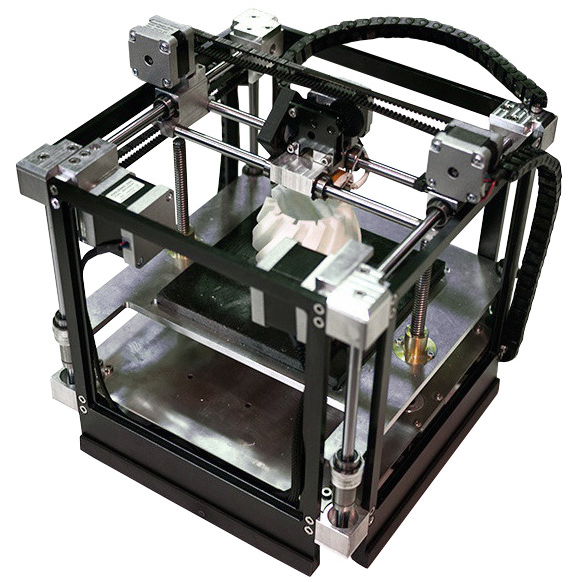

Also great

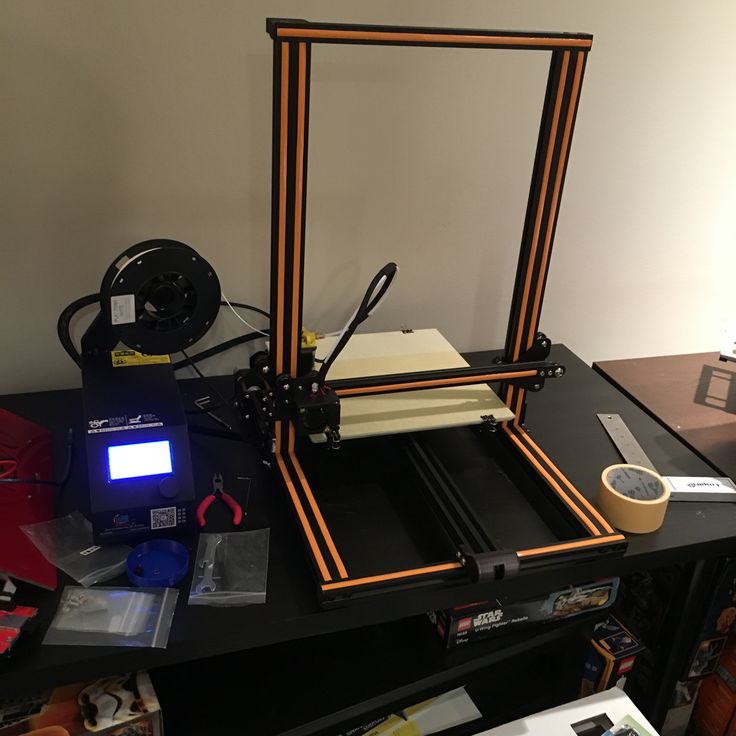

Artillery Sidewinder X2

This model is best for larger or taller printing jobs, such as cosplay or art pieces.

If you’re trying to print a sci-fi helmet or custom shelving brackets, a larger printer allows you to make the entire part in one shot rather than splitting it into smaller components and gluing them together. The print bed of the Artillery Sidewinder X2, an 11.8-inch square with a height of 15.7 inches, gives you a lot more room for bigger jobs. This model also offers easy setup and an intuitive menu, and in our tests it produced fantastic prints.

Everything we recommend

Our pick

Prusa Mini+

This printer consistently cranked out high-quality prints in our tests and has a huge print volume.

Upgrade pick

Prusa i3 MK3S+

This model offers the reliability and quality of a Prusa printer plus the largest print volume available.

Budget pick

Monoprice MP Cadet

The MP Cadet is cheap, reliable, and small enough to fit on any desk.

Also great

Artillery Sidewinder X2

This model is best for larger or taller printing jobs, such as cosplay or art pieces.

The research

- Why you should trust us

- Who should get this

- What you should know about 3D printers

- How we picked

- How we tested

- Our pick: Prusa Mini+

- Upgrade pick: Prusa i3 MK3S+

- Budget pick: Monoprice MP Cadet

- Also great: Artillery Sidewinder X2

- Care and maintenance

- What about the Ender-3 and other Creality printers?

- What to look forward to

- The competition

- Sources

Why you should trust us

Dave Gershgorn is a senior staff writer at Wirecutter and an avid 3D-printing enthusiast. He has printed through dozens of rolls of filament, has owned multiple printers, and has designed custom 3D-printable models for home improvement, product testing, and cosplay. His current personal printers are the Prusa i3 MK3S+ and the Elegoo Mars 3.

He has printed through dozens of rolls of filament, has owned multiple printers, and has designed custom 3D-printable models for home improvement, product testing, and cosplay. His current personal printers are the Prusa i3 MK3S+ and the Elegoo Mars 3.

Signe Brewster has been researching, studying, and testing 3D printers for tech publications including Gigaom, TechCrunch, and now Wirecutter since 2013. She has printed hundreds of 3D models, and through that experience she has learned how to spot the annoyances that can come with using an emerging technology.

In the course of researching this guide, we interviewed several 3D-printing experts, including Sean Charlesworth, a 3D-printing specialist for Tested, and Justin Kelly, an entrepreneur who founded LaserGnomes and Proto House.

Who should get this

People who need to quickly make prototypes or custom plastic parts can get the most mileage out of a 3D printer. These machines are also useful tools for anyone who likes tinkering or teaching children about STEM concepts. You can find plenty of downloadable designs online at 3D-model libraries such as Thingiverse. The range of possibilities is even wider if you know how to use CAD (computer-aided design) software. And anyone can work with a 3D printer: Most printers are easy enough to use that a child (with adult supervision) can print any of the endless variety of toy designs available.

These machines are also useful tools for anyone who likes tinkering or teaching children about STEM concepts. You can find plenty of downloadable designs online at 3D-model libraries such as Thingiverse. The range of possibilities is even wider if you know how to use CAD (computer-aided design) software. And anyone can work with a 3D printer: Most printers are easy enough to use that a child (with adult supervision) can print any of the endless variety of toy designs available.

What you should know about 3D printers

Be warned that no 3D printer is unbreakable. A day will come when you’ll need to replace a part or get your hands dirty in some other way. Replacement parts are available for the Prusa Mini+ and MK3S+, but not all 3D printers are equally easy to fix. You might want to avoid 3D printing altogether if you aren’t confident that you’d be able to perform a minor repair on the equivalent of a household appliance.

Prospective buyers should also be aware that the 3D-printing industry is in a constant state of upheaval. MakerBot, which was long considered the frontrunner among home 3D printers, stopped marketing to hobbyists and home users several years ago in order to focus on commercial and educational institutions. Many of the printers we have tested have come and gone within the span of a year or two. So it’s not out of the question that you might someday find yourself without much support from the company that made your printer. It’s also possible that a new breakthrough will suddenly leave you with outdated technology.

In addition, a 3D printer brings health and environmental concerns. When a printer melts plastic as part of the extrusion process, it releases volatile organic compounds and other particulates. The CDC recommends (PDF) using printers in a “negatively pressured area with a dedicated ventilation system,” which is not a feature found in your average home. It’s a good idea to weigh how comfortable you are with exposure to some fumes before buying.

On the environmental side of things, consider that you’re investing in a machine that works primarily with plastics. It’s possible to recycle or compost certain types of 3D-printed plastics (polylactic acid, or PLA, being the most sustainable of the common varieties), but the process can be complicated. There’s also the option to invest in a spendy recycling system of your own.

How we picked

The Monoprice Maker Select v2 at work. Video: Signe BrewsterWe turned to articles from 3D Hubs, Make, PCMag, and Tom’s Guide, plus customer reviews on sites like Amazon, to develop a short list of the best 3D printers for beginners. We then interviewed our experts on what to look for in a printer.

You could spend anywhere from $200 to $1 million on a 3D printer. The best options for hobbyists are priced at $1,000 or less. As with any piece of technology, printers in different price ranges offer different mixes of features. Printers really do get better the more you spend—and sometimes they’re also easier to use. Some higher-priced machines offer specialty features such as dual-color printing or a webcam for monitoring your print remotely, while other expensive units are known for their exceptional reliability.

Printers really do get better the more you spend—and sometimes they’re also easier to use. Some higher-priced machines offer specialty features such as dual-color printing or a webcam for monitoring your print remotely, while other expensive units are known for their exceptional reliability.

We skipped 3D printer kits, which are less expensive but require a great deal of assembly, in favor of machines that print good-looking parts straight out of the box with as little maintenance required as possible.

No matter what price range you’re considering, we’ve concluded that the best 3D printers offer the following features:

- High-quality prints: Without too much tweaking, the printer should put out smooth-looking models with layers that are 0.1 mm or thinner and barely visible.

- Easy-to-use hardware: Even a complete beginner should be able to put the printer together, load filament, start a print, and remove a finished model from the print bed.

The bed should also level itself or be simple to level manually (a sloping print bed can cause printing errors).

The bed should also level itself or be simple to level manually (a sloping print bed can cause printing errors). - Ample connectivity options: Ideally, you should be able to start a print over Wi-Fi or transfer the file over a USB cable. Loading files onto an SD card that you plug into the printer is also okay. A design that requires you to keep a computer tethered to the printer at all times via USB is a serious flaw but not necessarily a dealbreaker.

- Intuitive software: Beginners should be able to jump right into using a printer’s software, including making adjustments to models before printing. The software should come preloaded with print settings but provide options for more experienced users to fine-tune. It’s a big plus if a printer is compatible with Ultimaker Cura, which has become somewhat of an industry standard and a favorite of ours.

- Large-enough print volume: It would be nice to have the ability to print objects as large as you want, but the reality is that most models found in libraries like Thingiverse are designed for small 3D-printer beds, with workarounds for combining several printed pieces to create a larger object.

As a result, beginners need only a print bed that’s large enough to print models about the size of a small tissue box.

As a result, beginners need only a print bed that’s large enough to print models about the size of a small tissue box. - Heated bed: Heated beds prevent prints from warping, help models stick to the print bed, and allow you to print using a wider range of materials. (ABS, one of the two most common types of plastic used for 3D printing, and other materials shrink as they cool. Without a heated bed, you are limited to PLA, the other main type of plastic.)

- Compatibility with any brand of filament: Some companies embed chips in the spools of plastic that feed into their 3D printers, requiring you to buy refills directly from the printer manufacturer. Proprietary filament is generally more expensive, and if the company that makes it goes out of business, you won’t be able to use the printer.

- Suited to everyday life: The machine should look at home sitting on a desk. Ideally, it isn’t too big or heavy, and it’s relatively quiet so you can’t hear it from every corner of the house.

Although some printers are marginally faster than others, large prints can take days; even small prints take hours. A quiet printer is much easier to live with. Printers should also be able to print in polylactic acid, or PLA, plastic. While melting any type of plastic releases volatile organic compounds and other particulates into the air, the CDC considers PLA to be safer (PDF). PLA also has a sweet, inoffensive smell—still, it’s best for both children and adults to use a 3D printer in a well-ventilated room.

Although some printers are marginally faster than others, large prints can take days; even small prints take hours. A quiet printer is much easier to live with. Printers should also be able to print in polylactic acid, or PLA, plastic. While melting any type of plastic releases volatile organic compounds and other particulates into the air, the CDC considers PLA to be safer (PDF). PLA also has a sweet, inoffensive smell—still, it’s best for both children and adults to use a 3D printer in a well-ventilated room. - Enclosed printing chamber: Enclosing the print space keeps prints at a consistent temperature to prevent warping and other printing imperfections. It’s an especially good idea to have an enclosed chamber if you are printing with acrylonitrile butadiene styrene, or ABS—one of the two most popular printing materials—which is more prone to warping because it shrinks when it cools. Although enclosed printing chambers are nice to have, they’re not essential, and they’re actually fairly rare among inexpensive 3D printers.

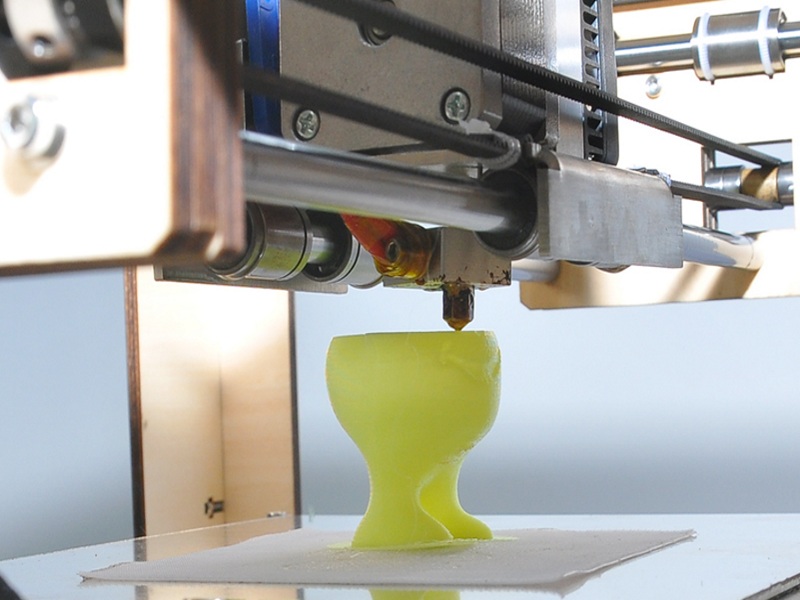

How we tested

Photo: Signe BrewsterWe time how long we take to get each printer from the box to set up on our desk, and we jot down notes on the initial software installation and navigation process. Then we get to printing. We allow each printer eight attempts to produce as many acceptable models as possible. We rate each print as either a success, a mediocre effort, or a failure. Successful prints look smooth, with no obvious imperfections. Mediocre prints have readily visible layers or imperfections but still look like a completed model. Failure takes many forms—everything from broken filament string that causes the print to stop to wild spaghetti-like misprints due to software or hardware errors.

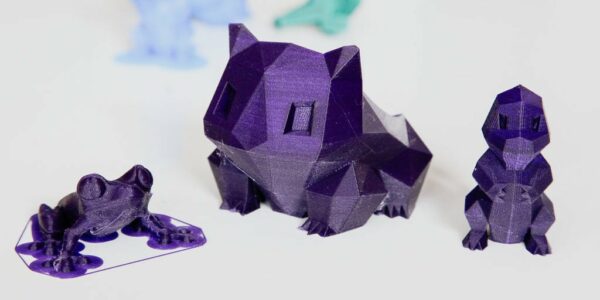

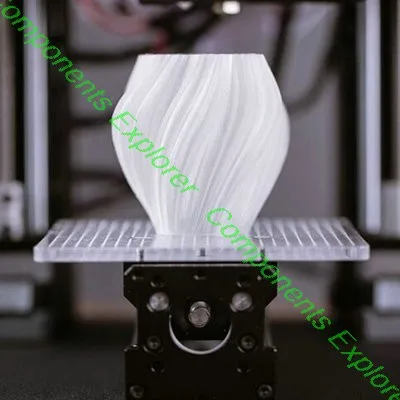

Witness the terrifying results of two prints that did not stick to the Monoprice MP Cadet’s print bed correctly. Photo: Signe BrewsterPrinters usually come with several models preloaded; we always start by printing one of these because they’re carefully optimized for the printer. Errors in these prints indicate that there is likely something wrong on the hardware end that we need to adjust. After the first successful print, we move on to designs we’ve found on Thingiverse. For our 2020 and 2021 testing, that group included “Low-Poly Bulbasaur” and “Low-Poly Charmander” by Thingiverse member flowalistik, “Curved honeycomb vase” by eggnot, and “Skull lamps - Voronoi Style” by shiuan. Our 2022 test added the “3DBenchy” model by CreativeTools and the “Nano All In One 3D printer test” from Printables member Steeveeet. These models had a range of detail, overhangs, and scale that would give us an impression of the printers’ strengths.

Errors in these prints indicate that there is likely something wrong on the hardware end that we need to adjust. After the first successful print, we move on to designs we’ve found on Thingiverse. For our 2020 and 2021 testing, that group included “Low-Poly Bulbasaur” and “Low-Poly Charmander” by Thingiverse member flowalistik, “Curved honeycomb vase” by eggnot, and “Skull lamps - Voronoi Style” by shiuan. Our 2022 test added the “3DBenchy” model by CreativeTools and the “Nano All In One 3D printer test” from Printables member Steeveeet. These models had a range of detail, overhangs, and scale that would give us an impression of the printers’ strengths.

Almost any 3D printer is capable of putting out successful models—experienced users know (or can figure out) how to tweak settings and hardware to get such results. But beginners (or even intermediate users like us) aren’t as likely to know what to do or to care enough to spend time fine-tuning. For the purposes of our testing, we give the printers the basic care they need to function—an initial bed-level check combined with factory-recommended settings—but we don’t tweak the printer or software to get better prints unless something goes wrong.

We also note how many times we have to repair the printers, how often each machine needs its print bed leveled, and how difficult it is to remove completed models from the print bed. These are general issues that pop up for any tier of 3D printer, but some printers are better than others at reducing the time you have to spend cleaning and repairing them.

Our pick: Prusa Mini+

Photo: Sarah KobosOur pick

Prusa Mini+

This printer consistently cranked out high-quality prints in our tests and has a huge print volume.

The Prusa Mini+ offers the best overall 3D-printing experience thanks to its combination of print quality, reliability, and desk-appropriate size, all offered at a relatively low price. It produced some of the best-looking prints among the machines we tested, it works with a wide variety of filament brands and types, and it comes preassembled. (You can save some dough and buy a kit to assemble the Mini+ yourself instead, though we didn’t test kits because of the added skill involved.) Prusa printers are the quietest we’ve tested, which makes them especially bearable to work alongside in an office.

(You can save some dough and buy a kit to assemble the Mini+ yourself instead, though we didn’t test kits because of the added skill involved.) Prusa printers are the quietest we’ve tested, which makes them especially bearable to work alongside in an office.

Across eight test prints, the Mini+ produced eight perfect models, the best result from any printer we’ve tested. It can print layers as thin as 0.05 mm, half the thickness that most of the printers we’ve tested can achieve. As a result, it prints objects that look especially glossy and smooth. Unlike with most of the other printers we’ve tested, we’ve never seen an obvious error in printed models from the Mini+.

We decided to use the free PrusaSlicer software program to prepare files for printing. We still prefer the detail packed into Ultimaker Cura, another free program compatible with a wide range of printer types, but we found PrusaSlicer easy to use and reliable in how it prepared files for the Mini+. It has plenty of customization options for the average 3D-printer owner.

We used a USB stick to transfer files from our computer to the printer, but Prusa has published a guide to a DIY upgrade that allows you to send files over Wi-Fi. Once you plug in the USB stick, you can use a knob to scroll through the menu and file list on the Mini+’s color screen, which we found to be much easier to parse than the blue and white, text-only screen of the Prusa i3 MK3S+.

Although the MK3S+ has a larger, 9.9-by-8.3-by-8.3-inch PEI print bed, the Mini+ is no slouch with its 7-by-7-by-7-inch print volume. (For an even larger print bed, check out our also-great pick, the Artillery Sidewinder X2.) Most free models you’ll find available on library websites like Thingiverse are made for this size of print bed, so it’s not often that you’ll max out its abilities. We were able to remove the bed and bend it to pop off prints, but usually we used a scraper and gentle pressure instead. The Mini+ isn’t flashy, but it’s especially practical. It automates as many quality checks as possible, so there’s less manual setup each time you print. It’s also built out of replaceable parts; that’s useful if you plan to run the printer continuously and want it to have as long a lifespan as possible. And Prusa’s printers are upgradable, whether you want to add nicer parts or swap in features from the latest printer.

It’s also built out of replaceable parts; that’s useful if you plan to run the printer continuously and want it to have as long a lifespan as possible. And Prusa’s printers are upgradable, whether you want to add nicer parts or swap in features from the latest printer.

The Mini+ can print in layers as thin as 0.05 mm, which aids in its ability to print finely detailed models. Photo: Sarah Kobos

Although the Mini+ is small enough to fit on a desk, it can still print models as large as 7 by 7 by 7 inches. Photo: Sarah Kobos

The Mini+ can print in layers as thin as 0.05 mm, which aids in its ability to print finely detailed models. Photo: Sarah Kobos

The Mini+ can print in standard plastics such as PLA and ABS, plus materials like nylon and wood blends. If you’re interested in even more exotic materials, the MK3S+ is a better choice. Prusa makes a line of reasonably priced filament in many types of materials that we have enjoyed using, but the Mini+ is compatible with filaments from other brands, too. We have used Hatchbox filaments with good results in other printers in the past, but we haven’t tested them on the Mini+.

We have used Hatchbox filaments with good results in other printers in the past, but we haven’t tested them on the Mini+.

The Mini+ has a decidedly old-school look among 3D printers. But we actually prefer its exposed components to the sleeker looking printers we’ve tested because the design makes the printer easier to repair.

Flaws but not dealbreakers

It took us just over an hour to assemble the “preassembled” version of the Mini+. That’s the longest process for any printer we’ve tested. From ensuring that we attached wires in the right place to fiddling with screws at awkward angles, the experience was more of a headache than we expected after the relatively easy assembly required for the MK3S+. The instructions are sometimes vague, so we recommend a close read. However, once we had the Mini+ assembled, it was quick and easy to get ready for printing.

Spending more on a 3D printer gets you, well, more: Touchscreen controls and the ability to print over Wi-Fi are two features we’ve enjoyed on more expensive printers. One benefit of using a USB stick instead of Wi-Fi is that you can save multiple prints to the stick at once; that way, when the first job finishes, you can remove the print and start the next one without having to go back to your computer. But we look forward to Prusa’s addition of Wi-Fi abilities in the future.

One benefit of using a USB stick instead of Wi-Fi is that you can save multiple prints to the stick at once; that way, when the first job finishes, you can remove the print and start the next one without having to go back to your computer. But we look forward to Prusa’s addition of Wi-Fi abilities in the future.

The Mini+ has a totally open design, which means that it releases the VOCs and particulates that it produces while using certain types of filament like ABS. You might notice a maple-syrup or plastic smell from the melting filament. If you’ll be using the machine in a home environment, it’s a good idea to use a “healthier” plastic such as PLA. It’s also a good idea to print at the lowest temperature possible for your chosen material; the lower the temperature, the less bad stuff the printer releases into the air. If you plan to spend time in the same room as a running 3D printer and don’t have a ventilated hood or HEPA air filter, turn on a fan or crack a window to improve ventilation (PDF). It’s also a good idea to wear gloves to prevent skin transfer.

It’s also a good idea to wear gloves to prevent skin transfer.

Upgrade pick: Prusa i3 MK3S+

Photo: Signe BrewsterUpgrade pick

Prusa i3 MK3S+

This model offers the reliability and quality of a Prusa printer plus the largest print volume available.

The Prusa i3 MK3S+ offers the reliability and print quality of the Mini+ along with a larger print bed, a more stable design for greater printing detail, and a better extruder that can handle a wide array of materials. It also comes preassembled or in a DIY kit, though we found the preassembled kit much simpler to set up than the Mini+.

In eight test runs, the MK3S+ made five perfect prints, second only to the Mini+. Like the Mini+, it prints layers as thin as 0.05 mm, creating more detailed models than most competitors in its price range. Of the three jobs that were failures, two were due to setup error and one was due to a clog that we were able to resolve. Unlike with most of the other printers we tested, we never saw an obvious error in the printed models. The print quality of the MK3S+ can be attributed to its sturdy frame and dual z-axis lead screws, which keep layer lines tight and consistent.

Of the three jobs that were failures, two were due to setup error and one was due to a clog that we were able to resolve. Unlike with most of the other printers we tested, we never saw an obvious error in the printed models. The print quality of the MK3S+ can be attributed to its sturdy frame and dual z-axis lead screws, which keep layer lines tight and consistent.

It took 32 minutes for us to set up the MK3S+, about average for the printers we’ve tested. Our test unit came assembled, but we took some time to run through the initial setup wizard. Although most of the setup is automated, you should pay close attention during the bed-level calibration; using the knob next to the printer’s computer screen, you need to lower the print nozzle until it nearly touches the bed, slightly squishing the melted filament. We made some mistakes the first time we booted up the printer. We recommend carefully reading the messages on the screen while the setup wizard is running, as well as studying the printer’s instruction manual. The manual is wordy at times, but we prefer that to the minimal or confusing instructions that other printer makers tend to include.

The manual is wordy at times, but we prefer that to the minimal or confusing instructions that other printer makers tend to include.

Several software options are available for the MK3S+; we used Cura, downloaded directly from the Ultimaker website. Cura is compatible with a wide range of printers, so during setup you should pick the MK3S+ profile to ensure that the software is tailored to your machine. We’ve used Cura for years without issue. Beginners can start a print quickly, without much thought, or drill deeper into the settings in the software’s intuitive menus when they’re ready to do more fine-tuning. It’s also worth checking out PrusaSlicer, which, as the name implies, is Prusa’s version of slicing software; there, the company offers expertly tuned profiles for its printers and filaments, as well as helpful features like variable layer height based on where your model has the most detail. It also has great features for generating custom support material, which is like scaffolding around your print that helps your printer lay down material at gravity-defying angles. In PrusaSlicer you can “paint” the areas on your model where you want support material, and the slicer will build that scaffolding up from the build plate to meet those specific areas, making the print less prone to failure.

In PrusaSlicer you can “paint” the areas on your model where you want support material, and the slicer will build that scaffolding up from the build plate to meet those specific areas, making the print less prone to failure.

You can print on the MK3S+ over Wi-Fi directly from PrusaSlicer if you install a Raspberry Pi Zero W into your machine, or you can save your file to an SD card and insert it into the machine. Using a knob, you can scroll through the black-and-white menu on the MK3S+’s small screen to select which model you want to print. It isn’t the flashiest or most intuitive system, but it is similar to what you’ll find on most other $1,000 printers.

The MK3S+’s controller is functional but barebones. Higher-end printers often have color touchscreens. Photo: Signe BrewsterThe MK3S+ has plenty of cool features, our favorite of which is the removable 9.9-by-8.3-by-8.3-inch PEI print bed. Its direct-drive extruder allows you to print with flexible filaments like TPU to make custom phone cases, for example, or rubbery feet for gadgets. The extruder also includes a filament-runout sensor, which automatically pauses a print if you don’t have enough filament to finish. And this machine is modular and built out of replaceable parts, so you can swap in the latest upgrades.

The extruder also includes a filament-runout sensor, which automatically pauses a print if you don’t have enough filament to finish. And this machine is modular and built out of replaceable parts, so you can swap in the latest upgrades.

The MK3S+ can print using standard filaments such as ABS and PLA, as well as more interesting materials like nylon or those that contain carbon fiber. It’s compatible with a wider range of filaments than the Mini+ (its hotend, the structure that melts and extrudes plastic, can reach 572 degrees Fahrenheit, compared with the Mini+’s 536 degrees), though most people don’t need to take advantage of its more unusual filament options.

Although this machine doesn’t look as stylish as some of the other 3D printers we’ve tested, its 15-by-17-inch footprint is small enough for it to fit on a desk. It’s also impressively quiet (though you’ll still know it’s on when you’re in the same room). As people who have each tried to sleep within earshot of 3D printers whirring and singing in their robotic tones, we can attest to the importance of a printer that is seen and not heard. As is the case with the Mini+, we recommend cracking a window to avoid inhaling the fumes that the MK3S+ releases due to its open design.

As is the case with the Mini+, we recommend cracking a window to avoid inhaling the fumes that the MK3S+ releases due to its open design.

Budget pick: Monoprice MP Cadet

Photo: Signe BrewsterBudget pick

Monoprice MP Cadet

The MP Cadet is cheap, reliable, and small enough to fit on any desk.

If you aren’t sure you want to commit to using a 3D printer regularly, or if you just want to spend a bit less, the Monoprice MP Cadet is a good budget option. In our testing, this $200 printer made prints that looked just as good as the results from printers that cost several times more, and its small size makes it especially desk friendly. Its removable, unheated bed is also more suitable for little fingers and releases finished prints with ease (though it puts your prints at risk of warping). However, this machine lacks the relatively advanced features you get from more expensive printers such as the Prusa Mini+ and i3 MK3S+.

However, this machine lacks the relatively advanced features you get from more expensive printers such as the Prusa Mini+ and i3 MK3S+.

Among the eight test prints we attempted, the MP Cadet produced four great-looking prints, one mediocre print, and three failures. The MP Cadet can print layers as thin as 0.4 mm; they’re eight times thicker than the MK3S+’s 0.05 mm layers but still thin enough that prints look tidy (even if you can see each individual layer). This machine did a mediocre job of printing the skull lamp file, which has lots of small details and overhangs that ended up looking a bit sloppy but still came out intact.

The first failed print happened right away, as the print head immediately dug into the print bed, damaging its soft surface. We discovered that we had readied the print in Cura with a profile for the Monoprice Mini. Once we downloaded a version of Cura directly from Monoprice and selected the MP Cadet profile, the printer operated normally. The next two failures occurred when we tried to print the pack-of-gum-sized Charmander: Partway through the print, the Charmander figure lifted off the bed and adhered to the print nozzle instead, creating a half pocket monster, half spaghetti nightmare creature. Because the MP Cadet’s print bed is unheated, prints don’t adhere as well as they could. Using a layer of painter’s tape and dabbing at it with a glue stick before starting prints solved the problem. The upside of an unheated bed is that you can remove models as soon as the print job is done. We didn’t find any sort of scraping or bending necessary to pop off prints—another advantage of an unheated bed.

Because the MP Cadet’s print bed is unheated, prints don’t adhere as well as they could. Using a layer of painter’s tape and dabbing at it with a glue stick before starting prints solved the problem. The upside of an unheated bed is that you can remove models as soon as the print job is done. We didn’t find any sort of scraping or bending necessary to pop off prints—another advantage of an unheated bed.

Setting up the MP Cadet took us 30 minutes. It arrived assembled, but we ran into some kinks with Monoprice’s instructions. First, the company advertises that you can print from an iOS or Android app called PoloPrint, but the app is difficult to use, and owners complain of connection issues. Second, during our tests the printer offered the option to start printing the models loaded onto the microSD card in the printer—our hitting the print button did nothing, though, and we found the interface confusing. Instead, we recommend using Cura to load files onto the microSD card and then initiating prints on the printer’s screen.

Instead, we recommend using Cura to load files onto the microSD card and then initiating prints on the printer’s screen.

As with the MK3S+, you can prepare models for printing on the MP Cadet with Cura. Despite the initial snafu we had in downloading the correct version, we appreciate that all of Cura’s features are available even when you’re working with such an inexpensive printer.

The MP Cadet’s print bed is relatively tiny, at just 3.9 by 4.1 by 3.9 inches. That’s big enough for it to print game pieces, toys, and some household parts; many downloadable designs also allow you to print them in several pieces and then assemble them to create a larger object. However, if you want to print big designs on a regular basis, a printer with a larger bed is worth the investment.

The MP Cadet is noticeably smaller than most printers, with an overall footprint of just 8.3 by 8.3 inches. However, because its print bed is not enclosed and it doesn’t have a heated bed, you need to keep it away from open windows and in an area with a relatively constant temperature so that the air doesn’t warp prints. The work area should also have good airflow, such as a small fan nearby. The melting filament gives off a maple-syrup or plastic smell, so in addition to having airflow in the room, you should avoid sitting right next to the printer as it operates to avoid inhaling the fumes. The MP Cadet is noisier than the Prusa i3 MK3S+, too, though it isn’t unbearably loud.

The work area should also have good airflow, such as a small fan nearby. The melting filament gives off a maple-syrup or plastic smell, so in addition to having airflow in the room, you should avoid sitting right next to the printer as it operates to avoid inhaling the fumes. The MP Cadet is noisier than the Prusa i3 MK3S+, too, though it isn’t unbearably loud.

Also great: Artillery Sidewinder X2

Photo: Dave GershgornAlso great

Artillery Sidewinder X2

This model is best for larger or taller printing jobs, such as cosplay or art pieces.

For larger prints, the Artillery Sidewinder X2 offers a great balance of size, ease of use, and premium features for just about the same price as our top pick. Its 11.8-by-11.8-by-15.7-inch print bed gives you lots of space for 3D-printing cosplay helmets or lampshades, for example, and its direct-drive extruder makes it great for flexible filament, as well. This machine isn’t for everyone, though, due to its size and impracticality for most everyday prints. It’s physically much larger than all of our other picks, so you need a dedicated space for it that’s at least 24 inches deep, 18 inches wide, and 36 inches tall. A larger print bed also means a tougher time leveling that bed, compared with the experience on our smaller picks. But if you want a printer that can keep up with your Mandalorian cosplay idea, the Sidewinder X2 can do it.

This machine isn’t for everyone, though, due to its size and impracticality for most everyday prints. It’s physically much larger than all of our other picks, so you need a dedicated space for it that’s at least 24 inches deep, 18 inches wide, and 36 inches tall. A larger print bed also means a tougher time leveling that bed, compared with the experience on our smaller picks. But if you want a printer that can keep up with your Mandalorian cosplay idea, the Sidewinder X2 can do it.

The Sidewinder X2 has an easy setup process similar to that of many other partially assembled 3D printers. You simply need to mount the printer’s gantry, a fancy word for the tall part of the printer that moves the extruder around, to the base. Doing so requires inserting four screws to secure the printer’s gantry to the base and then plugging in a few well-labeled cables. Much of the wiring is located inside the printer’s frame, so cable management wasn’t an issue in our tests, and there are no cables to snag while the machine is printing. However, the manual that comes with the Sidewinder X2 is not translated perfectly and can be a bit confusing. The internal wiring can also make the printer more difficult to repair compared with our other picks if a part breaks after dozens or hundreds of hours of printing.

However, the manual that comes with the Sidewinder X2 is not translated perfectly and can be a bit confusing. The internal wiring can also make the printer more difficult to repair compared with our other picks if a part breaks after dozens or hundreds of hours of printing.

In our tests, the initial calibration was a slightly more manual process than for our other picks, as the Sidewinder X2 has a Level menu that moves the extruder to preloaded points around the print bed. You tap the touchscreen to move the extruder to a specific point, slide a piece of paper between the nozzle and the bed, and then turn a knob on the underside of the printer to raise or lower the bed until you feel only slight resistance from the nozzle when moving the paper. You repeat this step at four other points around the bed. It takes a bit of experience to dial in this process, but the Sidewinder X2 makes it easier and faster than most other manually leveled printers do. Printers with larger beds are always more difficult to level, since a larger area is more prone to warping or slight imperfections. Despite that, we found the Sidewinder X2 to be even across its entire bed surface.

Despite that, we found the Sidewinder X2 to be even across its entire bed surface.

We prepared models for the test prints in Cura, though a profile in the software for the Sidewinder X2 isn’t readily available. Instead, we used the included profile for the Sidewinder X1 and modified the build volume to match that of the X2. While Cura profiles and similar resources exist online for our other printer picks, the Sidewinder X2 generally has a smaller community of users, so it’s a bit tougher to find people with similar problems and solutions if something goes wrong.

The Sidewinder X2 produced excellent test prints and did especially well on the taller prints that were larger than anything possible from our other picks. For instance, we scaled the honeycomb vase test model up to 10.5 inches tall, and the resulting print had equally smooth surfaces from bottom to top. Longer prints, such as a 34-hour print we ran for a colleague’s cosplay outfit, ran without issue or incident and produced nearly perfect results. (The imperfections were due to user error when we set it to generate supports.)

(The imperfections were due to user error when we set it to generate supports.)

However, this printer is best for people who know they want to print a lot of large objects. It’s physically very large and would commandeer the kind of desk found in a bedroom or a small office. The Prusa models are even easier to set up and maintain, have much better support communities, and are more repairable.

Care and maintenance

A 3D printer can be a finicky machine. Performing basic maintenance can go a long way toward preventing breakdowns and print flaws.

If your printer doesn’t automatically level its print bed, periodically check the print bed and adjust it if necessary. The Monoprice MP Cadet is self-leveling, while the Prusa Mini+ and MK3S+ have a calibration option (called the Wizard) in their menus. Most of the time, if your print isn’t sticking to the bed or is otherwise failing, it’s because the bed isn’t correctly leveled.

Some printers have print beds made of materials that prints adhere to extremely well—and judging from our experience, maybe a little too well. Adjusting print temperatures and a few other settings can help prevent sticking, but such tweaks aren’t always enough. Many printers now come with removable, flexible print beds; if your printer has one, remove the bed and carefully bend it to release your model. Don’t force it, or you’ll risk damaging the bed’s finish. If the print is still stuck, heat the bed back up to its printing temperature and see if the model pops off easier. Next, use a scraper to carefully unstick the edges of the print and then move in a sawing motion toward the center. If you’re still stumped, one final trick is to remove the print bed and stick it in the freezer for an hour. This should shrink the print a little and make it easier to remove.

Plastic remnants can build up over time on the print bed. A cloth and warm water are usually enough to remove them; more-stubborn grime should come away with a bit of rubbing alcohol that’s at least 90% isopropyl alcohol.

If you’re having trouble with uneven layer lines on the sides of your print, this is often caused by loose axis belts, or a lack of lubrication on the screw that raises and lowers the z-axis. Many printers allow you to tune the tension of the printer’s belts, and you can clean the z-axis screw with 90% isopropyl alcohol and lubricate it with a dry-film PTFE lubricant.

Finally, be sure to follow each printer maker’s rules for heating up and cooling down the printer, which will help to prevent clogs.

What about the Ender-3 and other Creality printers?

If you read 3D-printing forums and subreddits, you’ll see many experienced 3D-printing enthusiasts recommending the Creality Ender-3, Ender-3 V2, or Ender-3 Pro as a first printer. The Ender-3 Pro can be often found on sale at Microcenter for just $100, and it’s a better printer than our budget pick, the Monoprice MP Cadet, on nearly every metric. There’s also an avid community of Ender-3 owners who post DIY upgrades and guides on how to use the machine, a crucial aspect of learning to operate the printer and troubleshooting when things go wrong.

There’s also an avid community of Ender-3 owners who post DIY upgrades and guides on how to use the machine, a crucial aspect of learning to operate the printer and troubleshooting when things go wrong.

So why don’t we recommend it as a top pick or even a budget pick? In our experience, we’ve found that the Ender-3 line requires more setup and more maintenance, and in comparison with our picks it poses a much more difficult learning curve for those who are just getting into 3D printing. As an example, crucial tasks like leveling the print bed on the Ender-3 require using separate calibration files that might have to be run multiple times or manually moving the print head across the bed, in contrast to Prusa’s and Monoprice’s easier, more automatic workflows. This manual work adds many minutes of pre-print setup for a 3D-printing newcomer versus seconds for our top picks, and in turn it leads to a higher chance of the machine sitting in the corner gathering dust. These processes become rote after time and are made easier by optional upgrades, but initially they require some dedication to learn.

Prusa models also earned the top-pick and upgrade-pick spots due to the company’s excellent support and fantastic forum filled with helpful printer owners. Ender-3 owners are more likely to find someone with the same problem, but owners of Prusa models are more likely to find a solution.

That doesn’t mean we don’t like the Ender-3 line. They’re actually great machines for those who are already mechanically adept or who don’t get easily frustrated learning a new, complex hobby. However, they’re not the best 3D printers for most people.

What to look forward to

We’re testing the Anycubic Kobra Max against the Sidewinder X2 as a printer that’s also great for its large bed size. Shipping delays prevented us from including the Kobra Max in this version of the guide, but we’ll include its test results and any potential changes to our recommendations in the next update.

The competition

The Creality Ender-3 S1 Plus is an addition to the Ender-3 line with a high-resolution display and a larger print volume. We found it to be louder, more complicated to set up, and more difficult to level in comparison with the Artillery Sidewinder X2.

The Creality Ender-2 Pro, a $170 competitor to the Prusa Mini+, seems built to look nearly identical to that model. However, in our tests its menus were confusing and made the printer more difficult to operate than any of our picks. Its fans were also drastically louder than those of any other printer we tested.

In some ways, the Dremel DigiLab 3D40 impressed us: For about 50% more than you typically pay for the Prusa i3 MK3S+, you get an enclosed print area, a huge print bed (though not quite as large as that of the MK3S+), a touchscreen, and cloud-based printing. However, its prints in our tests didn’t look quite as nice as those of the MK3S+. We also found removing prints to be difficult, and we managed to ruin two flexible beds when the top layer ripped off during print removal. Finally, we dislike that the 3D40 prints only with proprietary spools of PLA—if you want to use other types of Dremel filament, you have to spend several hundred dollars more on the Dremel DigiLab 3D45.

We also found removing prints to be difficult, and we managed to ruin two flexible beds when the top layer ripped off during print removal. Finally, we dislike that the 3D40 prints only with proprietary spools of PLA—if you want to use other types of Dremel filament, you have to spend several hundred dollars more on the Dremel DigiLab 3D45.

The Tiertime Up Mini 2 was a top pick in a previous version of this guide because of its consistently nice-looking prints. However, when we tested the updated Up Mini 2 ES, software issues got in the way of producing a single print. We tried updating the printer and then “activating” it several times, including with the help of customer support and a press-relations representative. But we continued to get a pop-up telling us to activate our printer and alerting us that slicing had failed. Even if we had resolved the software issue, the difficulty it added to setup was enough to leave a permanently sour taste in our mouths.

The Monoprice MP Cadet narrowly beat out the Monoprice Maker Select v2, our former budget pick. Although the MP Cadet was much easier to set up and produced better-looking prints in our tests, we still think the Maker Select v2’s comparably huge print bed makes it a bargain if you can find it these days. If you don’t mind tinkering a bit to get the right settings, the Maker Select v2 could be a better option. However, setting up the Maker Select v2 took us 45 minutes, and it suffered from a clog after just a few prints.

Although the MP Cadet was much easier to set up and produced better-looking prints in our tests, we still think the Maker Select v2’s comparably huge print bed makes it a bargain if you can find it these days. If you don’t mind tinkering a bit to get the right settings, the Maker Select v2 could be a better option. However, setting up the Maker Select v2 took us 45 minutes, and it suffered from a clog after just a few prints.

Once our upgrade pick, the LulzBot Mini has been discontinued and replaced with the LulzBot Mini 2. The new machine addresses some of the qualms we had with the original Mini by adding an onboard controller and an even larger print volume. However, a North Dakota entrepreneur recently acquired its parent company, Aleph Objects, and moved operations to Fargo. We have not yet tested a Mini 2, and the company did not reply to our requests for information.

If you’re looking for a printer that can print in two colors, the FlashForge Creator Pro is one of the best-reviewed options. However, in our tests it printed only one great-looking model, along with six okay-looking models and one failure. We liked the printer’s streamlined software, which made it easy for us to select what parts of a model to make which color. You load models onto the printer with an SD card, so queuing up a few prints at a time is also easy, and it has a large, 8.9-by-5.8-by-5.9-inch print volume.

However, in our tests it printed only one great-looking model, along with six okay-looking models and one failure. We liked the printer’s streamlined software, which made it easy for us to select what parts of a model to make which color. You load models onto the printer with an SD card, so queuing up a few prints at a time is also easy, and it has a large, 8.9-by-5.8-by-5.9-inch print volume.

We decided to test the Monoprice MP Select Mini v2 based on feedback from our readers and positive reviews. It’s inexpensive, equipped with a color screen, and easy to set up. But we had problems with print quality, and the printer sometimes stopped altogether in the middle of a job.

The easy-to-use MakerBot Replicator Mini+ restored our trust in the brand after MakerBot hit a rough patch with reliability. However, the company discontinued the printer as it further narrowed its focus on education. The MakerBot Replicator+ combines the advanced features of the Mini+ with a more impressive build volume (11. 6 by 7.6 by 6.5 inches), which makes it an ideal choice on paper, but we decided against testing that printer due to its $2,000 price. Most hobbyists should start with a more affordable machine.

6 by 7.6 by 6.5 inches), which makes it an ideal choice on paper, but we decided against testing that printer due to its $2,000 price. Most hobbyists should start with a more affordable machine.

The Qidi Tech I is a near-exact copy of the FlashForge Creator Pro that cost a bit less at the time of our research. It offers a massive print bed, dual extruders, and a solid design. It also had hundreds of positive reviews on Amazon when we checked. However, we were unable to get this printer for testing.

This article was edited by Ben Keough and Erica Ogg.

Sources

Sean Charlesworth, Tested, phone interview, 2016

Justin Kelly, Proto House, phone interview, 2016

Dan Ackerman, The best 3D printer in 2020 for beginners and budget creators, CNET, February 28, 2020

Tony Hoffman, The Best 3D Printers for 2020, PCMag, February 7, 2020

Matthew Mensley, 2020 Best 3D Printers, All3DP, January 2, 2020

Anatol Locker, 3D Printing With Kids: What You Need To Know, All3DP, November 5, 2015

About your guides

Dave Gershgorn

Dave Gershgorn is a senior staff writer at Wirecutter. He’s been covering consumer and enterprise technology since 2015, and he just can’t stop buying computers. If this weren’t his job, it would likely be a problem.

He’s been covering consumer and enterprise technology since 2015, and he just can’t stop buying computers. If this weren’t his job, it would likely be a problem.

Signe Brewster

Signe Brewster is an editor on Wirecutter's PC team. She also writes about virtual reality. She previously reported on emerging technology and science for publications like Wirecutter, MIT Technology Review, Wired, Science, and Symmetry Magazine. She spends her free time quilting and pursuing an MFA in creative writing.

Further reading

The Best Robotics Kits for Beginners

by Signe Brewster

Our favorite robotics kits have a few things in common: a satisfying building experience, easy-to-understand coding instructions, and a friendly face. They also won over our discerning kid critics.

The 25 Best Gifts for 4-Year-Olds

by Kelly Glass and Wirecutter Staff

Many of the best gifts for 4-year-olds give kids lots of options for building and experimenting with mechanics and movement.

The Best Electronics Kits for Kids and Beginners

by Signe Brewster

We tested electronics kits with kids ages 7 to 12 and got feedback from parents and makers to find the most engaging ways for kids to learn about electronics.

Wirecutter is the product recommendation service from The New York Times. Our journalists combine independent research with (occasionally) over-the-top testing to save people time, energy and money when making buying decisions. Whether it's finding great products or discovering helpful advice, we'll help you get it right (the first time). Subscribe now for unlimited access.

- About Wirecutter

- Our team

- Staff demographics

- Jobs at Wirecutter

- Contact us

- How to pitch

- Deals

- Lists

- Blog

- Subscribe to our daily newsletter

Dismiss

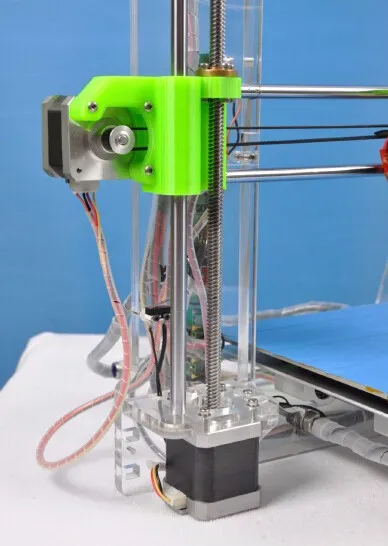

Selpic Star A / 3D printers, machines and accessories / iXBT Live

Today we are going to review a 3D printer from Selpic.

A US based company specializing in the manufacture of various printing devices. At the moment, he has two miniature handheld printers and cartridges for them, as well as the printer that will be discussed today (they are currently running a Kickstarter campaign and are available for pre-order at a price of $99).

There is a website where you can view and purchase all products. Free international shipping (DHL) is available.

This printer is positioned as the most optimal for beginners due to the ease of assembly and installation, as well as low cost. But it's also open source, allowing advanced users to make modifications.

Printer promo video:

The package with the printer is light and small, its weight is just over 3 kilograms.

Packing:

Contents:

Among other things, the kit includes one set of 10 meters of PLA plastic, as well as an 8GB flash drive and a Netac card reader.

To my surprise, there are no instructions in the package, although the main audience of printers is beginners. As it turned out later, the instruction was in electronic form on a USB flash drive, but there is not a word about how to connect and work with the laser head.

Also on the flash drive are drivers, G-codes for two models for printing, and a Cura application installation file for macOS and Windows.

The length of the cable for connecting the printer to the computer is 51 cm, as for me, this is a significant drawback, especially if a person uses a stationary PC, not a laptop.

The length of the power cable is sufficient and is 149cm.

Features:

The features I would also include the presence of a heating platform, a 2.4-inch touch screen and a laser engraving head (1.6 W). It should be noted that these accessories are not included in the basic package and are purchased separately.

It would be nice if the manufacturer provided the ability to choose the power of the laser engraving head. However, it can also be purchased separately on Aliexpress.

However, it can also be purchased separately on Aliexpress.

Comparison with analogues:

Printer assembly steps:

Photos in the assembled state:

Minor production flaws:

without removing anything).

Bottom view:

The disadvantage is the lack of anti-slip inserts. Not that it slides much on smooth surfaces, but they wouldn't get in the way anyway.

The plastic holder can carry loads up to 250 grams. The weight of the plastic that comes with the kit is 30 grams. It is worth noting that the holder clings to the printer simply on hooks, that is, without a strong and reliable fixation, and at the slightest movement it walks back and forth and strives to fly off.

After turning on the printer, it must be calibrated, the distance between the nozzle and the desktop in each corner should be minimal (adjustment is done using the wheels in each corner).

Next, load the printing material: you need to click on the "+" and the nozzle will start heating (about 1 minute), after which we push the plastic into the hole until it comes out of the extruder (then click on "+" again to complete the process).

All processes are accompanied by light indicators of control buttons and are described in detail in the instructions.

Printing is set up and started in the Cura application.

Application Setting:

Print Setting:

The standby nozzle temperature is about 23 degrees. Heating up to 180° occurs in an average of 2.5 minutes.

After the first start of printing, it started to do something like this:

As I understand it, this was due to too small a distance between the nozzle and the working surface. In order for everything to be normal, you need to accurately guess with the optimal distance: so that it is not too tight, but also so that the A4 sheet does not crawl freely.

Noise during operation averages 47dB. The biggest noise comes from the extruder fan.

Printing rocket (height 4 cm) took 1 hour 25 minutes.

The problem was that the bottom of the figurine stuck too strongly to the working surface, so much so that the rocket broke away from it and flew away, and I had to tear it off, melting the plastic with fire and tearing it off with a knife.

Printing of the second figurine (height 5 cm) was made from a memory card (the file must be in the root of the card), it took 3 hours and 35 minutes to print it.

As for the print quality, there are no questions about it, especially the cost of the printer and the fact that it can be used almost immediately from the box.

Print timelapse:

Unfortunately, due to the lack of instructions on how to connect and work with laser engraving, I can not say anything about its operation. If anyone can tell me how to connect it and make it work - I will be grateful!

Results

Summing up, we can say that the idea of a ready-made printer for beginners with advanced features is definitely interesting and promising, but the implementation requires some improvements.

Among the advantages, I would like to note the following: ease of installation and operation, light weight and compact size, large print area and quiet operation, as well as the possibility of various customizations.

The disadvantages include the lack of instructions for working with the laser head and paper instructions, the lack of anti-slip feet, a short cable for connecting to a PC and an unreliable implementation of the plastic holder for printing.

Considering that Ali now has a lot of inexpensive printers with similar characteristics, the manufacturer should also not miscalculate the price so that it is competitive.

You can purchase a printer here:

• Kickstarter

• The official website of the manufacturer

Branches of this printer on the 4pda

Small guide for choosing a 3D printer for beginners / Habr

The reason for writing this article was the article “ I wanted to buy an inexpensive 3D printer, but I watched YouTube and got sick of ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

First, a few caveats.

This article will not contain advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y under any circumstances”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

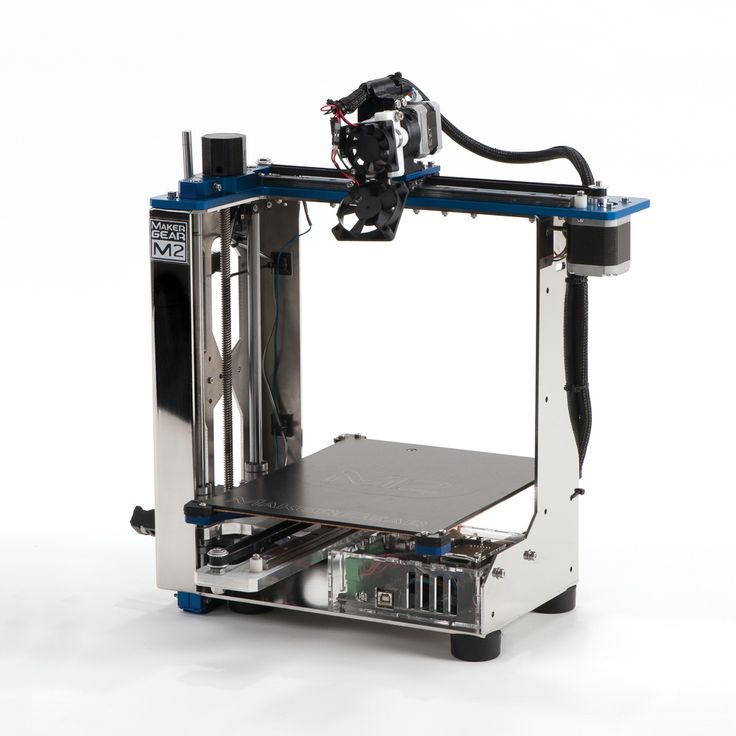

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

Photo from the personal archive There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusing, which is fed in the form of a rod and SLA (LCD) - printing with a photo-curing polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

To be honest, I almost never did SLA printing and I still don’t have an LCD printer in my home zoo (but it may appear soon), so I will mainly talk about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

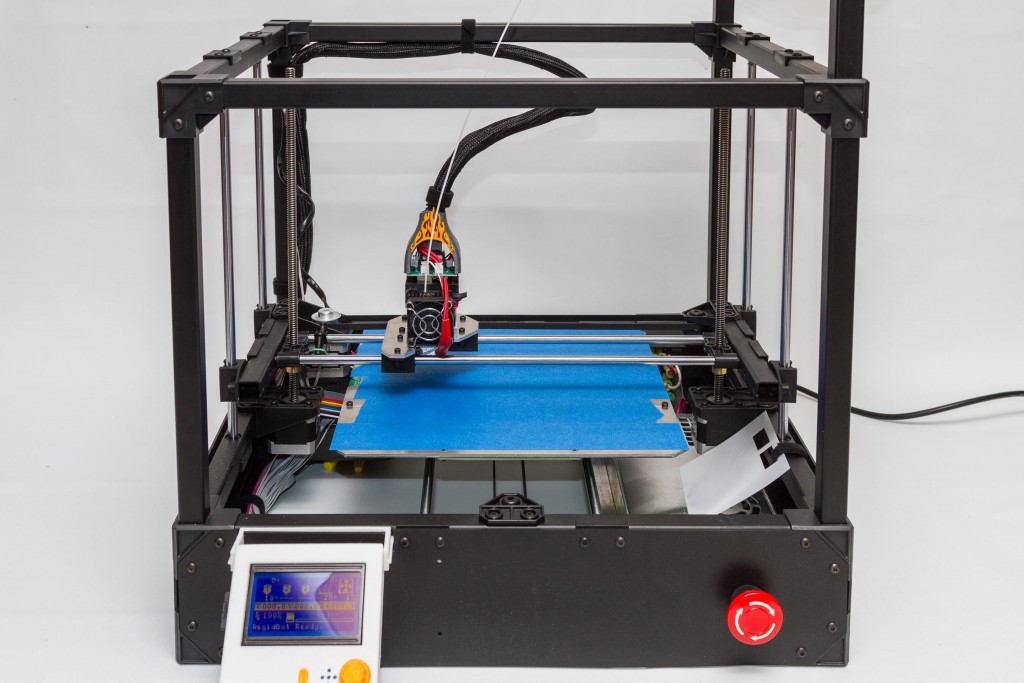

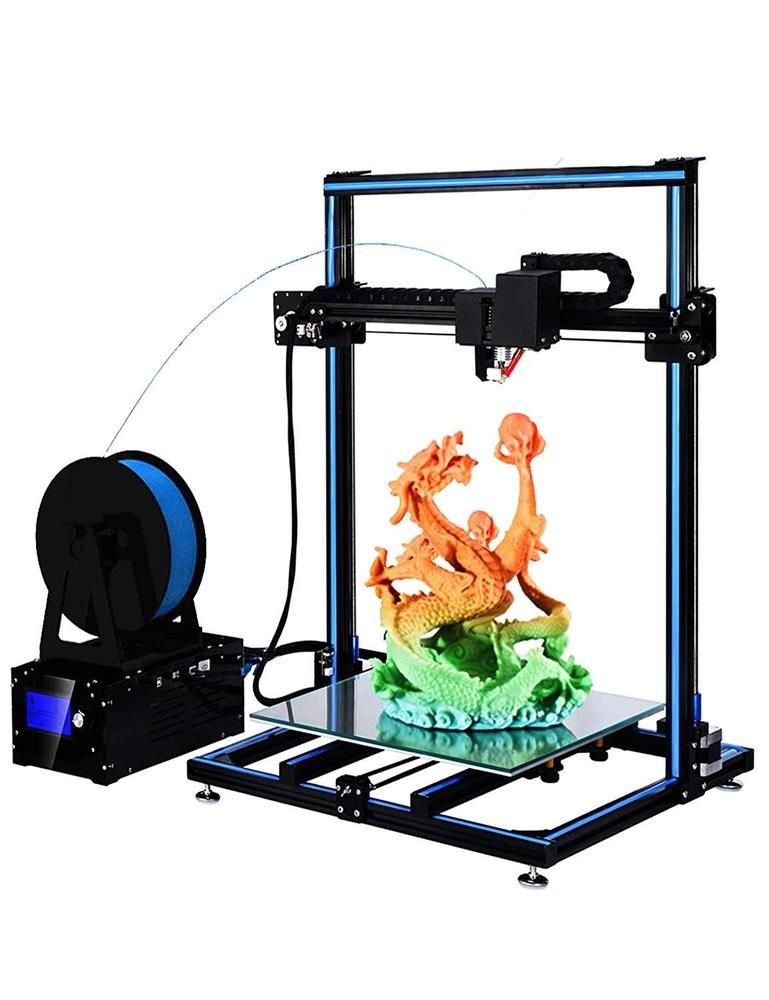

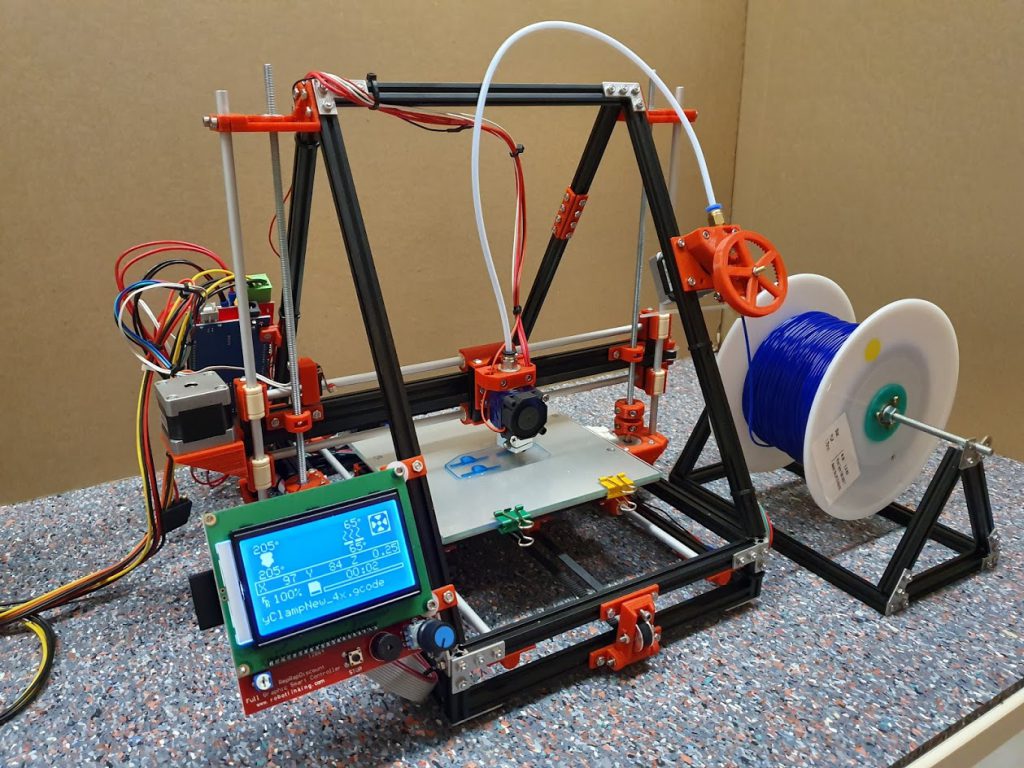

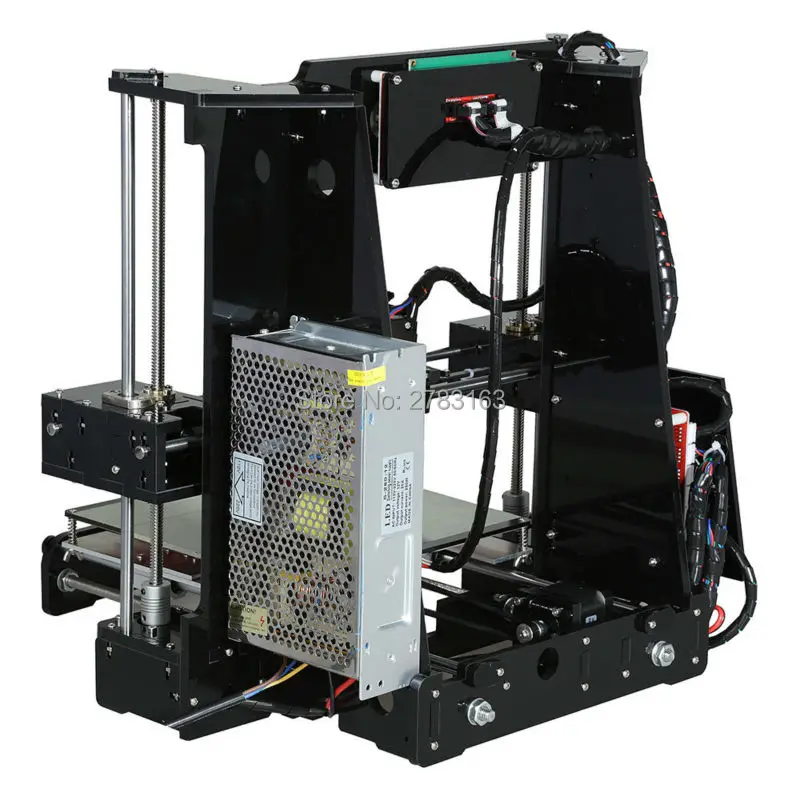

Drygostables - printers with a horizontally movable table. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

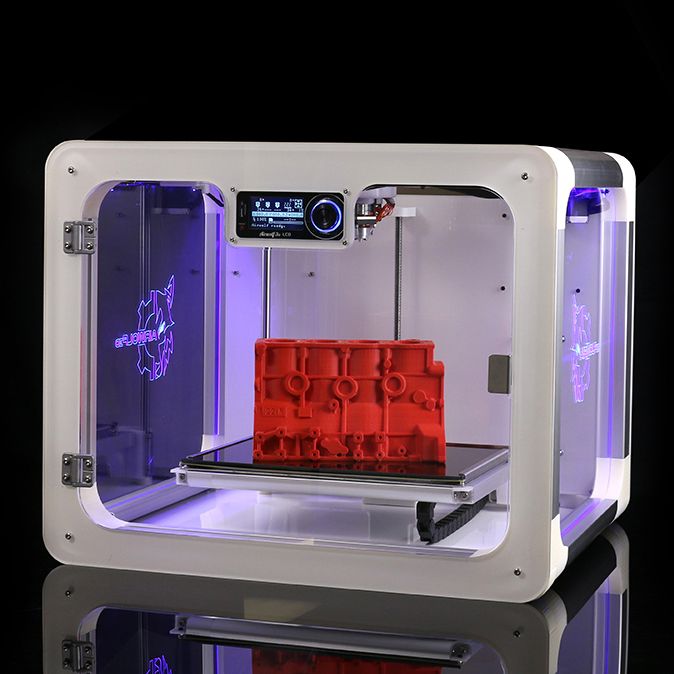

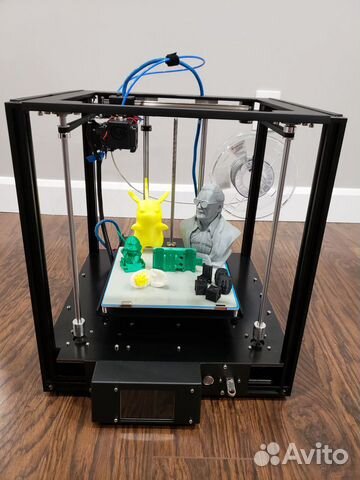

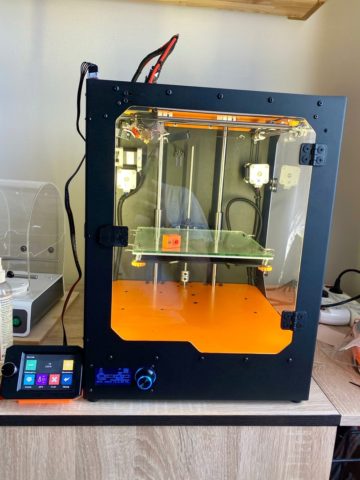

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

Typical cubes Delta - printers with the so-called delta kinematics, when the print head, using a system of rods, is attached to carriages that move along vertical guides. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

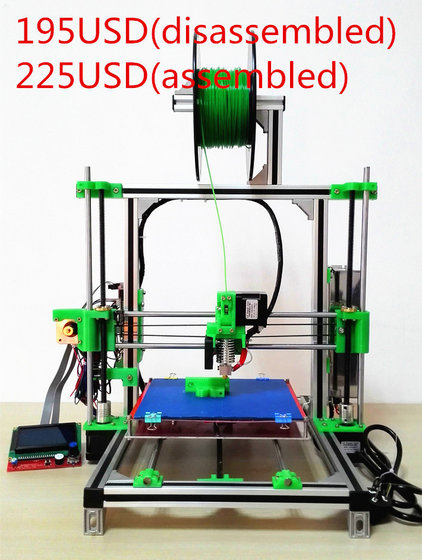

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-