Sagrada familia 3d print

From Handcrafted Stone to 3D Printing: The Technological and Material Evolution of Gaudí's Sagrada Familia

From Handcrafted Stone to 3D Printing: The Technological and Material Evolution of Gaudí's Sagrada Familia

© Expiatory Temple of the Sagrada Família- Written by Eduardo Souza

A masterpiece is often defined as the most remarkable work in an artist's career, one which highlights the height of their techniques and ideals. The Mona Lisa by Leonardo da Vinci; Michelangelo's Pietá; the Beatles' Sgt. Pepper's Lonely Hearts Club Band album. There are many examples, which are not always unanimously agreed upon. But what if what many consider to be the masterpiece was started by someone else, the credited creator didn't live to see its completion, and almost all of its documentation was destroyed? Catalan architect Antoni Gaudí and his world-famous Temple Expiatori de la Sagrada Família are examples of these complications. From a highly crafted stone construction to the most modern 3D printing techniques and high strength concrete, numerous technologies were and continue to be incorporated in the project's construction.

In 1882, architect Francisco de Paula del Villar began the project for the Church following the guidelines of the time, and thus employed standard neo-Gothic elements: five longitudinal naves, ogival windows, buttresses, and a pointed bell tower. Due to differences with the Catholic Church, however, Villar resigned from the work and Antoni Gaudí, a 31-year-old architect, was appointed responsible in 1883, as shown in the work's chronology. While the cruciform plan of the original project was maintained, Gaudi brought numerous significant changes to the building such as angular columns and hyperboloid vaults, eliminating the need for buttresses. By removing these important structural pieces that could withstand the horizontal thrusts of the heavy roof, the architect proposed the building's iconic branched and angled columns instead.

Since then, the project has consistently been under construction, and is expected to be completed in 2026, the centenary of Antoni Gaudí's death. But one can imagine that a work in progress for over 130 years, with some stoppages, experienced several changes in construction methods and materials. “The first period of construction, the one that had Gaudí as the architect responsible for the work, goes from 1883 to 1936. At that time, traditional materials of the time were used, especially stone masonry with lime mortar as a binder.” [1] Between 1914 and 1926 Gaudí lived on the church's construction site, dedicating himself exclusively to the work and building numerous plaster models of the pillars, naves, facades, and other construction elements, with the aim of conveying his ideas to employees.

Shortly before that, in 1901, the first cement plant in Catalonia was founded by Eusebi Güell, Gaudí's friend, supporter and patron. Researchers [3] point out that one of the reasons why reinforced concrete took a long time to reach Catalonia was because of the region's optimized traditional Catalan techniques, such as masonry arches (Catalan vaults) supported by metal beams, which had a good cost-benefit ratio for construction and reduced the need for other solutions.

Researchers [3] point out that one of the reasons why reinforced concrete took a long time to reach Catalonia was because of the region's optimized traditional Catalan techniques, such as masonry arches (Catalan vaults) supported by metal beams, which had a good cost-benefit ratio for construction and reduced the need for other solutions.

From there, Gaudí began experimenting with the material, which was used in the construction of Parc Güell, Casa Milà and the Colônia Güell church. In the construction of the Sagrada Familia, reinforced concrete was used for the first time on the spiers of the façade of the Natividade, built between 1915 and 1934.

Ten years after Gaudí's death, who was run over by a tram near the construction site, a fire destroyed most of the plans and drawings in the office. Luckily, some models were saved, which allowed for the redoing of much of the project's documentation according to the architect's ideas.

Some periods of stoppage due to World War II and the Spanish Civil War delayed the work. Many of the finishing decisions, some structural solutions, and some detailing and connections between different materials had to be defined by subsequent generations of architects and engineers working on the building, who sought as much fidelity as possible to Gaudí's original ideas.

“From 1944 onwards, the buildings for which concrete was already one of the most important materials resumed construction. During these years, they used, above all, cyclopean concrete in the filling of the walls and reinforced concrete in the structural elements [2].“ From the 60's onwards, reinforced concrete began to be widely used in construction, but in the 90's, a new stage begins at the most famous construction site in the world. It is at this time that public interest in the Sagrada Familia greatly increases, causing visits and revenue to accelerate. As a result, the work began to incorporate many new advances in the construction process, including several cranes and the beginning of experiments in computer modeling of complex geometries. “Two events symbolize the changes that have taken place since then: the increase in revenue that has allowed us to accelerate the pace of construction, and the introduction of new technologies in terms of materials, design, and construction processes. The main objective in recent years has been the construction of the naves. This resulted in the lifting of the perimeter walls (completed in 1999), the columns and interior vaults, and the curves of the main body, which are now finished; they are currently operating on the transept and apse [2]”.

As a result, the work began to incorporate many new advances in the construction process, including several cranes and the beginning of experiments in computer modeling of complex geometries. “Two events symbolize the changes that have taken place since then: the increase in revenue that has allowed us to accelerate the pace of construction, and the introduction of new technologies in terms of materials, design, and construction processes. The main objective in recent years has been the construction of the naves. This resulted in the lifting of the perimeter walls (completed in 1999), the columns and interior vaults, and the curves of the main body, which are now finished; they are currently operating on the transept and apse [2]”.

Almost all the building elements are currently built in concrete in the Sagrada Familia Church, often covered in natural stone. Concrete appears in various forms: precast elements, reinforced concrete, solid concrete, and parts with special concrete of very high structural strength, such as in the apse and transept columns, where microsilica was introduced in the concrete mixture, reaching a resistance of 80 MPa. In other portions of the structure, because of Gaudí's complicated geometry, the fittings, and the impossibility of increasing cross sections, concrete features had to be developed with high fluidity and strength.

In other portions of the structure, because of Gaudí's complicated geometry, the fittings, and the impossibility of increasing cross sections, concrete features had to be developed with high fluidity and strength.

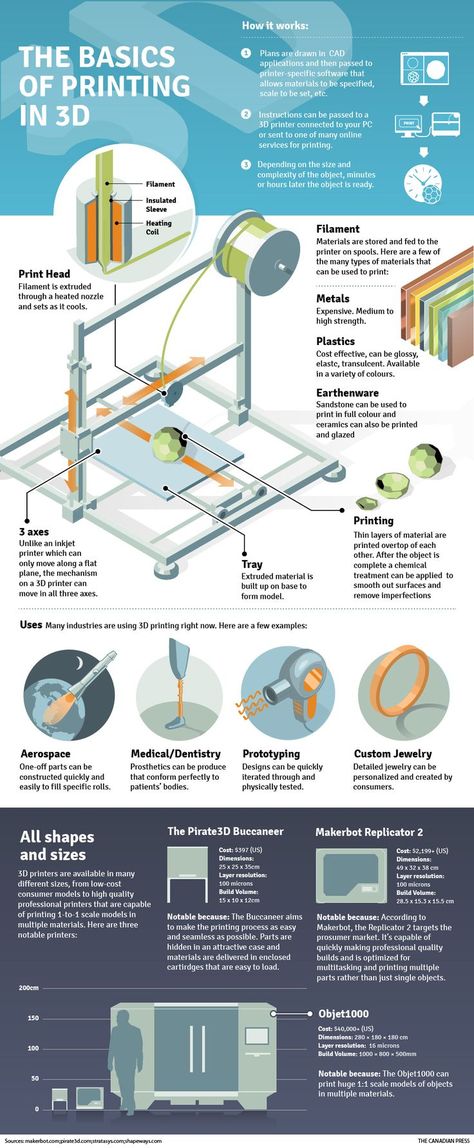

In addition, in recent decades, the Sagrada Familia has embraced contemporary digital design and construction technologies. Architects and artisans use programs like Rhinoceros, Cadds5, Catia, and CAM to understand complex geometries and visualize the building as a whole. The process uses stereolithographic 3D printers that build the prototypes layer by layer, resulting in a plaster-like material, a method that allows builders to manually alter the prototypes to meet specific building demands.

© Andy Tam / ShutterstockThe construction of the Sagrada Familia has taken so long that building technologies and materials have changed significantly from beginning to end. Many researchers wonder if it could have actually been built with the materials at the time it was designed while still following every form imagined by the genius of Catalan modernism. Would the project have been adapted by Gaudí if he had lived to resolve all of the design issues? Or is his genius, as some researchers have pointed out, that he has developed a project that allows for the incorporation of new technologies and materials over time?

Would the project have been adapted by Gaudí if he had lived to resolve all of the design issues? Or is his genius, as some researchers have pointed out, that he has developed a project that allows for the incorporation of new technologies and materials over time?

- [1] Rosa Grima López. El Hormigón en el Templo de la Sagrada Familia. Available at this link

- [2] R. Espel, J. Gómez, R. Grima, A. Aguado. La evolución de la construcción del Templo de la Sagrada Familia. Informes de la Construcción 61(516). December 2009. Available at this link

- [3] Rosa Grima López, Antonio Aguado de Cea & Josep Gómez Serrano. Gaudí and Reinforced Concrete in Construction. Available at this link

This article is part of the ArchDaily Topic: New Practices, proudly presented by PERI. PERI’s Future Products and Technologies’ department researches disruptive technologies that have the potential to change the construction industry fundamentally. The aim is to recognize the signs of the future and to help shape this future. Through a methodical approach, PERI thus expands its core competencies and acts as a clear pioneer on the market. Learn more about our monthly topics. As always, at ArchDaily we welcome the contributions of our readers; if you want to submit an article or project, contact us.

The aim is to recognize the signs of the future and to help shape this future. Through a methodical approach, PERI thus expands its core competencies and acts as a clear pioneer on the market. Learn more about our monthly topics. As always, at ArchDaily we welcome the contributions of our readers; if you want to submit an article or project, contact us.

Cite: Souza, Eduardo. "From Handcrafted Stone to 3D Printing: The Technological and Material Evolution of Gaudí's Sagrada Familia" [Da pedra artesanal à impressão 3D: a evolução tecnológica e material da Sagrada Família de Gaudí] 01 Dec 2021. ArchDaily. Accessed . <https://www.archdaily.com/964178/from-handcrafted-stone-to-3d-printing-the-technological-and-material-evolution-of-gaudis-sagrada-familia> ISSN 0719-8884

How 3D Printing Changes the Possibilities for Architects: the Sagrada Familia in Barcelona Goes 3D | 3D Printing Blog

Begin typing your search above and press return to search. Press Esc to cancel.

Press Esc to cancel.

by Elizabeth | March 6, 2015 | Architecture

How 3D Printing is Changing Architecture: Learning from the Sagrada Familia Team in Barcelona

by Elizabeth | March 6, 2015

The world-famous Sagrada Familia cathedral in Barcelona has been using 3D printing since 2001 to continue the work of the great designer Antoni Gaudí. This modernist architect was not able to finish the work during his life, so the Sagrada Familia consortium has to design much of the cathedral themselves. With the assistance of 3D printing, Gaudí’s glorious magnum opus is well on its way to completion.

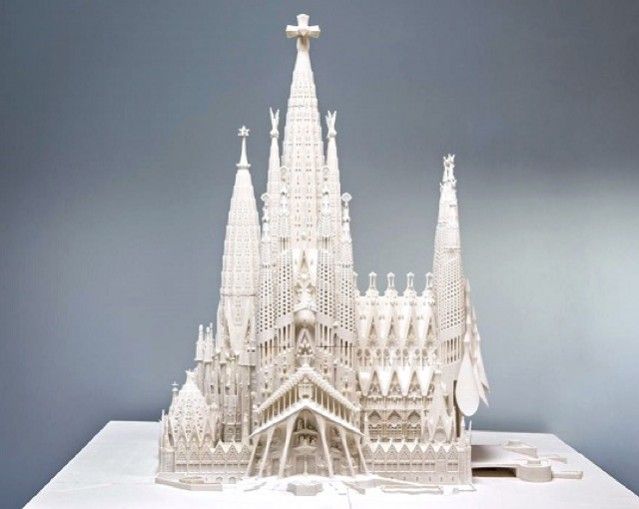

Photo Credit © Expiatory Temple of the Basílica de la Sagrada Família

Modern Architecture: from 2D to 3D

The great architect Antoni Gaudí knew the importance of moving from a 2D plane to a 3D one when he was designing his magnum opus, the Sagrada Familia. He knew that by holding something in your hand, you can instantly get a better idea of the way a decorative feature or intricate element would look on a building when compared with a static 2D drawing. That is why since the project’s official start in 1882, Gaudi and his predecessors would often handcraft models of the elaborate building to get a better understanding of the design.

That is why since the project’s official start in 1882, Gaudi and his predecessors would often handcraft models of the elaborate building to get a better understanding of the design.

Photo Credit © Expiatory Temple of the Basílica de la Sagrada Família

Unfortunately, many of the blueprints were destroyed during the Spanish Civil War and the remaining ones are often incomplete. Consequently, the Sagrada Familia consortium has been creating various prototypes to visualize the complex designs and figure out how a new part can fit in the broader picture. Before they had encountered 3D printing, they handcrafted the models. Because of the complex nature of Gaudí’s design, this was a time-consuming and expensive process.

Photo Credit © Expiatory Temple of the Basílica de la Sagrada Família

3D Printing Architectural Models

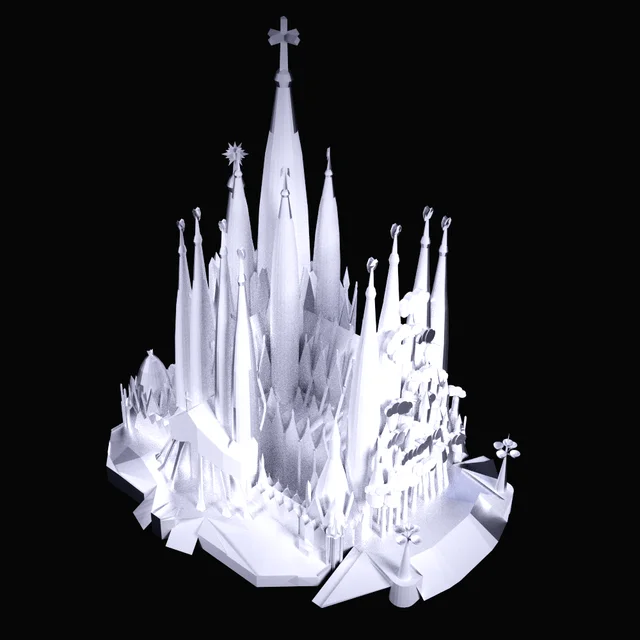

With the rise of 3D printing technology, working with 2D designs to construct the Sagrada Familia no longer makes sense. 3D printing is the ideal method to represent the whimsical, spiky forms and twisted towers in the perfection they deserve. Since turning to 3D printing in 2001, the team has relied on Materialise’s Magics software to prepare their designs for the printer. Among other things, they use this software to fix their files, cut the pieces into printable sizes and add small pins and perforations so that these pieces easily fit together.

Since turning to 3D printing in 2001, the team has relied on Materialise’s Magics software to prepare their designs for the printer. Among other things, they use this software to fix their files, cut the pieces into printable sizes and add small pins and perforations so that these pieces easily fit together.

Photo Credit © Expiatory Temple of the Basílica de la Sagrada Família

Making prototypes in 3D allows architects to work in a more detailed way and at a scale the human hand cannot produce. It helps the architects create various complex prototypes, thus guiding decisions about the cathedral’s design, while staying true to Gaudi’s style. Using 3D printing has helped keep the Sagrada Familia vision together, and with its aid the cathedral is anticipated to be complete in 2026, as you can see in the video below.

Photo Credit © Expiatory Temple of the Basílica de la Sagrada Família

Creating and 3D printing your own architectural scale models

If you wanted to get started in 3D printing architecture scale models but don’t know where exactly to begin, we recommend that you check out our beginner friendly step-by-step tutorial for SketchUp, a beginner-friendly software that is often used by architects.

You might have to start a bit smaller than designing parts for the Sagrada Família, but even great architects like Antoni Gaudí had to learn the basics first. If you already have a 3D printable file, upload it to our website and order your 3D pint via our online 3D printing service. Architects love our polyamide material for their 3D printed scale models.

full-color 3D printing saves architecture firm time and money

“Due to the complexity of form and geometry, working with Gaudí's architectural ideas doesn't make sense in 2D. If Gaudí were alive today, he would definitely use the 3D printer to the maximum, since most of his work took place in three dimensions” - Yordi Kol, Chief Architect.

If Gaudí were alive today, he would definitely use the 3D printer to the maximum, since most of his work took place in three dimensions” - Yordi Kol, Chief Architect.

At the end of 1883, Antoni Gaudi was appointed to carry out work on the Temple of the Sagrada Familia, a task that he did not abandon until the end of his life at 1926 year. But even after that, a large number of architects continued to work on his idea.

When work on the church began in 1882, architects and masons used conventional two-dimensional drawings. But Gaudí quickly realized that the geometry they wanted to create required a completely different approach. The usual flat drawings were not as useful as one would expect.

The complexity of the forms of the temple led Antoni Gaudí to use a three-dimensional approach. The design of the Sagrada Familia required the creation of 3D models to visualize architectural solutions and test the feasibility of such structures. At the very beginning of the work, Gaudí selected a team of architects and sculptors who developed ideas, many of which were subsequently discarded, and some of which we can see implemented today.

“Due to the complexities of form and geometry, working with Gaudí's architectural ideas has no bearing on the two-dimensional dimension,” says chief architect Jordi Koll.

Gaudí was a dreamer and innovator who experimented with forms and concepts and he always used the latest technology available.

Problem

Since the death of Gaudí in 1926, seeing the completed Temple has been a dream of his followers, architects and residents of Catalonia, and even more so since the end of the Spanish Civil War, when all the workers in Gaudí's workshops were looted, and many of his works and sketches were destroyed.

However, a huge amount of materials and documents were preserved by his followers, including parts of a disassembled model, and this became the starting point in the task of completing the construction of the Temple the way Gaudí wanted it to be.

Challenges

The current technical management of the church is busy studying the complexity of Gaudí's original project, and the current task involves the following aspects:

- Consumables and the creation of a plaster model based on the remaining fragments of Gaudí's work

- Development of an assumption to identify missing parts

- Creation of a model in plaster to demonstrate the work

- Strength checks of the proposed design

- Design of final parts (concrete, stones and other materials).

Preserved forms and models, as well as photographs, documents and drawings, help in the work on the project. Gaudí's original designs are restored and revised countless times in order to ensure that the result is consistent with Gaudí's original ideas, as well as to ensure the technical feasibility of the work.

For decades this task has been done by hand. However, creating all the details with your own hands is too long and costly. It also required a huge amount of material, since a person cannot create a prototype in dimensions less than 1 to 25.

Since the funds for the completion of the temple came mainly from donations, the completion of the construction seemed so far away.

Solution

Architects Jordi Koll, Jordi Fowley and Mark Berry began to explore automated part cutting technologies such as 3DCAD software.

After analyzing the input data, they created a 3D model of the required part. This allowed them to better understand the geometry and proportions that were conceived by the great architect, thus, year after year, they were able to understand how Gaudí wanted the temple to be.

The real revolution occurred after the introduction of 3D printers into the market, which made it possible to automate the process of creating a physically tangible prototype from a three-dimensional model, and they made it possible to do this quickly, inexpensively and at the highest level.

Sagrada Familia has ordered two 3DSystems ProJet printers that allow full printing, and these printers have made the job incredibly easy. Employees can now devote all their time to model analysis instead of wasting time on various calculations and physical model making.

Results

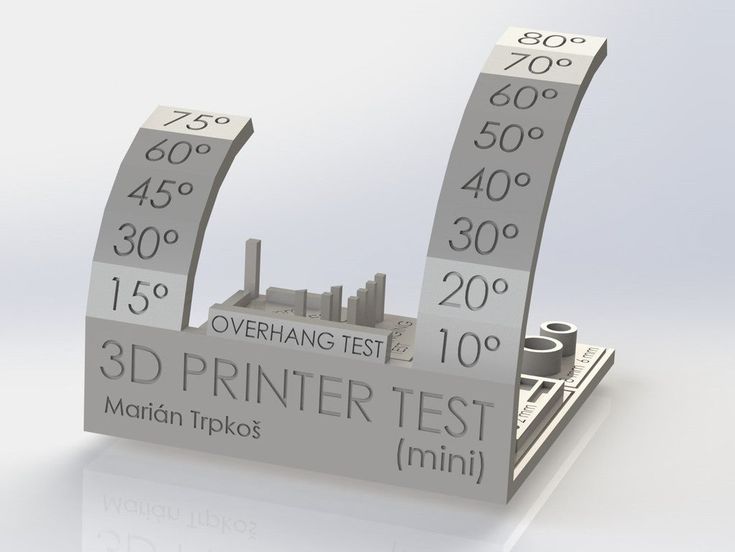

- Higher Quality Models: Projet printers effortlessly create small parts with quality that far exceeds manual processing.

- Material saving: printers can print in 1:50 and 1:100 scale (as opposed to 1:10 or 1:25 for manual work), and the remaining material after printing can be reused.

- More models in less time: large print areas and fast printing mechanisms (2-3 cm in Z-axis per hour).

- Improved communications: understanding between technicians and builders has been greatly improved.

- Fewer errors: saving time and money.

Conclusion

As Antonio Gaudí would have done, only the best and most modern technologies are used to work on the temple. With 3D modeling software and 3D printing technology, prototyping has become easy and affordable. Speed is, and always has been, a critical factor for continuous analysis and selection of ideal solutions.

In 125 years, thanks to new technologies and employees of Sagrada Familia, the interior of the Temple will fully coincide with the ideas and concepts of Gaudí.

“If Gaudí were alive today, he would definitely use the 3D printer to the maximum, since most of his work took place in three dimensions” - Yordi Kol, Chief Architect.

Original: http://www.3dsystems.com/sites/www.3dsystems.com/files/393_Sagrada%2520Familia%2520Final.pdf

Application of 3D printing in temple construction

Construction stories

andarchitecture

Author: Semyon Popadiuk

Author: Semyon Popadiuk

Purpose | Task | Solution | Results | Conclusion

At the end of 1883, Antoni Gaudi was commissioned to continue work on the Sagrada Familia in Barcelona. He worked on the project until his death in 1926. Since then, various architects have continued the work begun by Gaudi, following his original idea. Today, two 3D printers are helping architects follow the Grand Master method, saving time and money.

He worked on the project until his death in 1926. Since then, various architects have continued the work begun by Gaudi, following his original idea. Today, two 3D printers are helping architects follow the Grand Master method, saving time and money.

Sagrada Familia: Expiatory Sagrada Familia, designed by Antonio Gaudí.

Issue: complex, unusual shapes and damaged original layouts.

Solution: 3D printing with two Spectrum Z510 printers (now replaced by ProJet 660 Pro).

Results:

- higher quality models, including functional elements;

- material savings;

- more models in less time;

- better understanding and interaction between project participants;

- fewer mistakes, save time and money.

Sagrada Familia 3D printed model

When preparations for the construction of the temple began in 1882, architects, masons and stonemasons used the traditional two-dimensional approach. Gaudí understood that the geometric form they were dealing with required a different method. Two-dimensional drawings were completely useless here, with the exception of planning the geometric axis of the temple and columns.

Gaudí understood that the geometric form they were dealing with required a different method. Two-dimensional drawings were completely useless here, with the exception of planning the geometric axis of the temple and columns.

The complexity of the form of the Sagrada Familia forced Antoni Gaudí to turn to a three-dimensional approach. The design of the temple required three-dimensional layouts to visualize architectural solutions and analyze the possibility of their implementation. From the very beginning, Gaudí brought together a group of modellers and sculptors to study various options that were later rejected or accepted. The latter we see today in the temple.

“Due to the complexity of surfaces and shapes, working with Gaudí designs in two dimensions does not make sense from an architectural point of view,” says chief architect Jordi Colle.

Gaudí was a dreamer and innovator who experimented with forms and concepts. He always used the most advanced technology available in his time.

Do you need to print a layout, prototype or casting master model? We carry out orders for 3D printing with photopolymer, gypsum and wax on equipment from leading manufacturers! Ask your question or leave an online application:

Order a service

Target

After the death of Gaudi in 1926, the dream of all his students, architecture lovers and all Catalans was to see the Sagrada Familia in its finished form. This dream was further strengthened after Gaudí's workshop was destroyed during the Spanish Civil War and most of his writings, drawings, photographs and three-dimensional models were destroyed.

Numerous materials and documents, as well as the surviving parts of the damaged models, were rescued by Gaudi's colleagues, and this became the starting point for solving the serious task of completing the construction of the temple in the form in which Gaudi conceived it.

Task

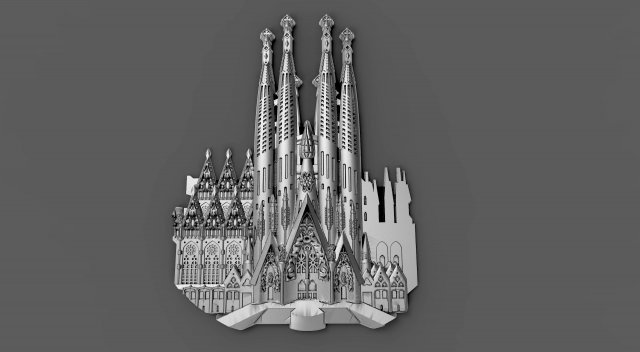

Three-dimensional models of the Sagrada Familia, created on 3D Systems printers using full-color 3D printing technology

Today's technical office for the construction of the temple is tasked with studying Gaudí's original design in all its complexity. This implies:

This implies:

- inventory and organization of plaster model fragments from the remains of damaged original models;

- developing hypotheses about missing parts;

- making three-dimensional plaster models before planning actual construction work;

- development and verification of the plan for the construction of the temple;

- real construction (concrete, stone, Catalan arches).

Surviving samples and layouts, as well as photographs, documents and drawings, help to carry out the project. Gaudí's models have been restored, reproduced, checked and modified as many times as necessary to ensure that they are consistent with the original design and that they can be realized during the construction process.

For decades, this work was done by hand, but the process was long and costly. This also led to very high costs for materials, since the human hand cannot create dummies of proper quality at a scale of less than 1:25.

Since the construction of the Sagrada Familia is carried out solely on donations, its completion at times seemed a very distant dream.

Solution

Architects Jordi Colle, Jordi Fauli and Mark Barry began to explore the most advanced technologies used in the aircraft and automotive industries, such as 3D design software. After processing the data, they created a 3D file of the desired part. This allowed them to better understand the mathematics and proportions inherent in Gaudí's designs. Years of studying the material, they slowly discovered what was in it.

A real revolution in work occurred with the advent of 3D printers: they made it possible to automatically turn into reality three-dimensional CAD drawings with unprecedented detail, accuracy and in just a few hours. Sagrada Familia's technical bureau has purchased two 3D Systems Spectrum Z510 CJP 3D printers, which greatly simplify the team's task. Now employees can devote most of their working time to research and reconstruction of models in order to make calculations and solve the problem as a whole. The result is 3D CAD part files that the Spectrum Z510 printers continue to print flawlessly.

Results

3D printers in the interior of the Sagrada Familia

Better models: The Spectrum Z510 3D printers are capable of reproducing fine details easily and with greater accuracy than the human hand can.

Material saving: The 3D printer is able to create the original model in 1:50 and 1:100 scales (and Gaudí's 1:10 and 1:25 scales) and the leftover material can be reused.

More layouts in less time: Large print chamber and faster printing (2-3 cm per hour vertically).

Better understanding and interaction between project participants: 3D printing models provide better understanding between technical offices and builders.

Fewer errors: this saves time and money.

Functional elements: The plaster-like material used by 3D Systems printers is similar to that used to create the original models, making it easy to combine original and modern parts.