Dye i5 gopro mount 3d print

▷ dye i5 gopro 3d models 【 STLFinder 】

dye i5 gopro mount

thingiverse

Use an m5 thread screw and bolt for this kind of mount instead of gopro screw because it wont fit. I built it like this so it wont snap . update: So as of today August 9, 2018 I'm still using it without any problems. I start using this since feb...

Dye i5 Gopro session 5 mount

thingiverse

Test piece, will print and test.

Dye i5 Top Camera Mount

thingiverse

This is an adapter so you can mount a camera on the top of your dye i5 (maybe i4 too). The pictured design is a little out of date, I rounded and smoothed out the whole model. You will need a short M4 screw along with a nut and a GoPro mounting...

Dye i5 Top Camera Mount

prusaprinters

Adapter to mount a gopro on top of your dye i5 (maybe i4 too).The pictured design is a little out of date, I rounded and smoothed out the whole model. You will need a short M4 screw along with a nut and a GoPro mounting screw and nut...

Gopro mount Dye i4

thingiverse

Gopro mount for Dye i4

Contour GPS Low Profile DYE I5 Camera Mount

thingiverse

I got a new DYE I5 Mask and adjusted my Contour GPS mount to use the Camera mount in the mask. ...

Parts Needed:

1/4-20 Jamb Nut - Install in the nut trap inside the mount

M3 Screw 25mm Long - For Clamping

M3 Nut - For Clamping

...

Parts Needed:

1/4-20 Jamb Nut - Install in the nut trap inside the mount

M3 Screw 25mm Long - For Clamping

M3 Nut - For Clamping

Dye Proto FS GoPro Mount

thingiverse

I've searched for a GoPro-Mount for my Dye Proto FS Fullface-Mask, but didn't found something, so I created a mount by myself. If you did a print: Please post a "i've made one" and share your experience on the comments-tab! and if you like my...

GoPro Mount For Dye i4 Paintball mask

thingiverse

Sturdy GoPro mount for your dye i4 paintball mask. You will need two 1/8in nuts and bolts to put this together, as well as the nut and bolt from an existing GoPro mount. ...How I Designed This SolidWorks 2014

...How I Designed This SolidWorks 2014

Dye i5 Top Camera Mount. (remix) not my designe

thingiverse

orginal file: https://www.thingiverse.com/thing:3286019

gopro mount for dye i4 airsoft/paintball mask

pinshape

I decided to design this mount because the only other top mount gopro mounts for the dye i4 masks were $15-$30 dollars USD so i'd thought i'd make a simpler more affordable version. The hardware i used to mount this on my mask was EVERBILT nylon...

nxt I5

grabcad

Pieza nxt forma I5

i5

thingiverse

Customized version of http://www. thingiverse.com/thing:40703 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=40703 Instructions Using the following options:...

thingiverse.com/thing:40703 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=40703 Instructions Using the following options:...

i5

thingiverse

Customized version of http://www.thingiverse.com/thing:40703 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=40703 Instructions Using the following options:...

I5

thingiverse

Customized version of http://www.thingiverse.com/thing:1731842 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=1731842

Dye bath

grabcad

Textile dye bath

suporte gopro mascara Dye e similares

cults3d

Proibido a comercialização deste produto em todo o territorio Brasileiro. Sujeito a penas e multas conforme as leis. Se deseja comprar o produto para comercialização por favor entre em contato conosco para firmarmos um contrato de livre...

Sujeito a penas e multas conforme as leis. Se deseja comprar o produto para comercialização por favor entre em contato conosco para firmarmos um contrato de livre...

gopro mount for dye fma airsoft paintball

thingiverse

https://www.thingiverse.com/thing:4441076 presented a thumb screw to replace the wing nut on the front-left corner of the BIBO bed. It is too wide for the other two positions. I have created a smaller version to fit the right-front corner and the...

Dye machine

grabcad

Narrow fabic machine for dyeing

Symbol Dye

thingiverse

A small Dye with different symbols on it, my first model.

Dye Rack

thingiverse

The dye bottles are a snug fit with their labels on them. Perhaps scaling it up ever so slightly in the slicer would resolve that. ...If I were to redesign it I would probably stagger the slots so the labels are all visible from behind the bottles in...

intel i5 cpu

grabcad

intel i5 cpu

Dell 3567 i5

grabcad

Dell 3567 i5 model

Processor Intel Core I5

sketchfab

Processor Intel core i3 i5 i7 i9

PanelDue I5 Mount Case

thingiverse

This is a case and mount designed for the PanelDue I5. Other accessories needed are M3 heat inserts, 10mm M3 counter sunk bolts, and M4 bolts. ...

The dimensions of the screen I was using were slightly different than the schematic posted on their...

Other accessories needed are M3 heat inserts, 10mm M3 counter sunk bolts, and M4 bolts. ...

The dimensions of the screen I was using were slightly different than the schematic posted on their...

Intel i5 3D model

cgtrader

3D model of CPU Intel i5 Modeled from original component. Detailed enough for close-up renders. Originally modelled in 3DS Max 2014. Final images rendered with Stand Alone standard renderer.---------------------------------------Models: - Editable...

DYE UL Grip Frame

grabcad

DYE UL Grip Frame

Leather Dye Holders

thingiverse

Designed for 4oz dye bottles

Alumilite dye pegboard holder

thingiverse

Alumilite Liquid dye pegboard holder

Intel NUC i5 Case (v2)

thingiverse

A simple case for an Intel NUC i5 computer. ...

For Intel BLKNUC5I5MYBE NUC5I5MYBE

...

For Intel BLKNUC5I5MYBE NUC5I5MYBE

Dye m2/m3 triggers

thingiverse

A trigger for the dye m2/m3 paintball marker

STL file Dye i4 & i5 Go Pro mount S3DP edition・3D printable design to download・Cults

Airsoft M4 Style Drop Stock V2

€2.87

Airsoft ARP9 Drop stock

€2.87

Airsoft Tilted Riser

€3.44

Airsoft Mlock cover

€1.72

Best 3D printer files of the Various category

The Simpsons Otto Cassette Holder

€2.99

Sea Shells

Free

dodge

€1. 50

50

Triple Weaver Rail with Silencer Dummy

Free

Visor Face Shield for Small Printer

Free

Cute Llama - Articulated Animal (print in place, no supports)

Free

GRZ Grenade 420 chopper!

€2.75

3 & 4 - from the Movie 9

Free

Best sellers of the category Various

ItsLitho "Swirl" personalized lithophane Christmas ball

€1.90

Middle Finger Keyholder

€1

Articulated Cute Spider

€2.49

Christmas House

€6.87

Gyarados - Articulated Seasnake

€1. 50

50

The Black Phone Movie The Grabber 2 Part Mask 3 Styles Frown Smile Mouthless STL

€9.79

Articulated Rayquaza Flexible Pokemon Dragon

€1

RS-X-Bow "Government - 1911" style

€6.25

Articulated Eeveelution mega pack

€10

Targaryen Crown - Viserys - House Of The Dragon

€11.66 -20% €9.33

Ghost Booh x10

€1.99

ItsLitho "Drop" personalized lithophane Christmas ball

€1.90

Gengar - Flexi Articulated Pokémon (print in place, no supports)

€2

Polestar 2 cup holder

€5. 85

85

Demogorgon Print-in-place wiggle pet (and keyring option)

€3.50 -25% €2.62

Gremlin 640mm FPV Plank

€0.98

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Painting advice for 3D models (PLA, ABS, PETG, NYLON)

3DPrintStory Reviews Recommendations for painting 3D models (PLA, ABS, PETG, NYLON)

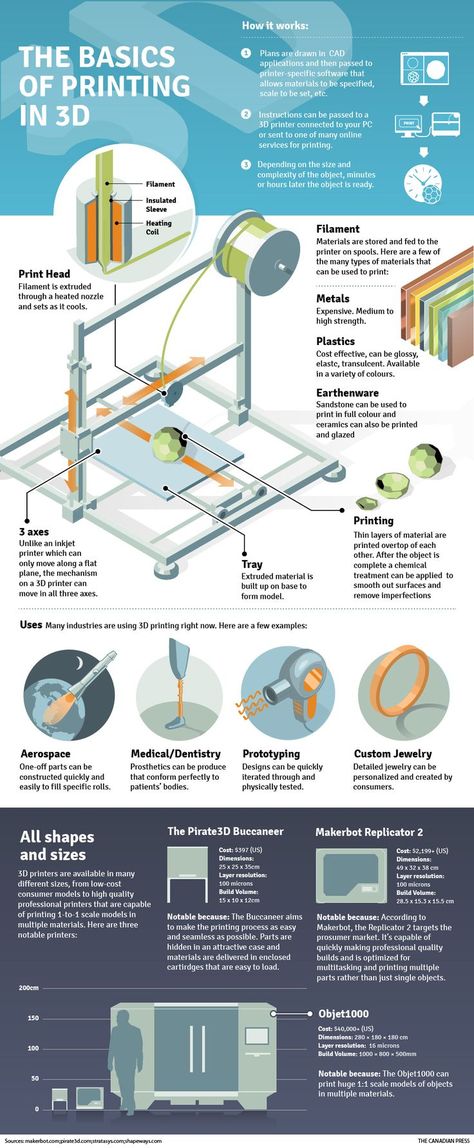

Despite multi-material extruders and a stunning variety of 3D printable plastic colors, you'll still want to paint some of your 3D models sooner or later. The most common reason is to improve the external 3D model, especially if you are printing on an FDM 3D printer where the model is built up by layering material over time. It is FDM 3D printers that form a model with feature lines along the Z axis.

When finishing a 3D model, small cavities between layers are sanded, filled, or both. The result is a smoother surface. Painting can also help protect the model from the environment.

This article is divided into two parts: the first will introduce you to the different techniques for painting a 3D model, and the second will (hopefully) answer all your little questions about painting techniques and how best to do it. Read on to find out how to enhance your 3D models with paint!

Primer is paint's best friend

Priming a printed model improves ink adhesion. With any painting method (other than nylon dyeing), using a primer is a good idea. Spray primer is said to be the easiest way to get good results. The process for using the primer is very simple:

- Clean and sand your 3D model.

- Apply the primer in thin, even coats.

- Sand after the first and last coats until the surface is smooth.

- Let each coat dry according to the instructions supplied with the primer.

Method 1: Paint with a brush

Best for: PLA, ABS, PETG plastics.

If you paint a 3D printed model with a brush, you will definitely achieve a unique "handmade" effect.

Try a few brushes first because it's easier to get good results with a comfortable brush. As a rule, it is enough to use only 1 or 2 different flat brushes.

Brush

- Choose a quality brush that is hard enough to handle the viscosity of the paint you are working on.

- Experiment with different bristle types and handle shapes to find the one that works for you.

- Stop painting to clean the brush as soon as the paint starts to dry. Naturally, the brush must be cleaned after each use. Do not leave drying paint on the brush bristles.

- The brush must be stored on the handle after cleaning and not on the bristles.

Paint

When it comes to brush painting, you're better off using acrylic paints.

Painting process

- Clean and sand your 3D printed model.

- Apply the paint in thin, even coats.

- Let the individual layers dry.

Method 2: Spray painting

Best for: PLA, ABS, PETG plastics.

If you want to paint a 3D printed model uniformly using one color, then using an aerosol will give the best result.

Spray can

Some brands offer nozzles with different specifications.

Shake can according to manufacturer's recommendations before use. Allows the paint to come out more evenly.

Keep the nozzle clean. This is usually achieved by spraying the inverted can slightly at the end of each session.

Keep can away from open flame and store in a cool place. Don't forget that this is a high pressure container!

Paint

When looking for spray paint, you will find that there are many varieties. If you want to use a specific shade, please read the RAL, CMYK and RGB values on the can carefully.

Painting process

- Clean and sand your 3D printed model.

- Start spraying by aiming the jet a little beyond the edge of the object you want to paint.

- Apply the paint by spraying on the surface you want to paint in slow, even strokes.

- Stop spraying by directing the jet a little beyond the object you want to paint.

- Let the paint dry.

Method 3 Liquid Color (nylon only)

Best for: NYLON plastics.

Instead of trying to get paint to adhere to the surface of your 3D printed nylon model, we recommend using liquid dye instead. Note that this will not work with other materials. Although PLA is hygroscopic and absorbs some water from the environment, it cannot be dyed by absorbing dye. ABS and PETG are also not suitable for this technique.

In order for the ink to give a good pronounced color after absorption, it is better to use a translucent or white nylon material when 3D printing. Darker nylon fibers can also be dyed, but the color will be much less pronounced.

Darker nylon fibers can also be dyed, but the color will be much less pronounced.

Colorant

There are many brands of colorant to choose from, but MatterHackers recommends Rit DyeMore for example. But in general, if the dye is intended for synthetic fabric, then everything will be in order.

Staining process

Since nylon is very hygroscopic, it absorbs water even outdoors. This is why you should always dry your nylon material before 3D printing. We recommend painting the finished model, not unprinted.

How to use

Read the manufacturer's instructions for your colorant. In short, using a dye is a pretty simple method:

- Clean up your 3D model. When sanding, remember that painting will not cover scratches and marks on the surface of your model. Everything will be visible even after staining.

- Mix the dye with water and heat in a saucepan.

- Use a thermometer to monitor the dye temperature. Follow the manufacturer's instructions, but keep the temperature below the thermal deflection temperature of the filaments.

- Attach the weight to the 3D print and dip it into the paint pot.

- After coloring, rinse well in a bath of cool water.

- To make sure you get the expected color, it's worth doing a few test coats.

How to tell if a paint will set with a 3D model

Probably the most important factor in causing the paint or liquid of your choice to stick to a solid surface is the difference in surface energy between the liquid and the solid. The one with the most surface tension always wins (surface tension has its own unit called dynamos, or dynamos per square centimeter).

The general rule is that the surface tension of the paint must be at least 10 units lower than the solid material for good adhesion. This means that we have a liquid with a high wetting ability on a solid, and we need wetting.

To get an idea of how well the surface to be painted is wetted, look at the shape of the drop of liquid on the solid surface:

- Apply a drop of paint or liquid to the surface of the 3D model you want to process.

- If the liquid forms a ball, it has too much surface tension to effectively wet the object, and the solid cannot "pull" the liquid onto itself.

- If the liquid spreads over the surface, forming something like a lens, wetting is better.

Is it possible to paint a 3D model from any material?

Painting 3D models from PLA and ABS plastics is a fairly simple task.

PETG can have paint durability issues, but the same techniques apply as for PLA and ABS. But if you really need a rich, vibrant color, then it's best to print your 3D PETG model in the desired color and leave it as it is.

When it comes to nylon, which is used for 3D printing, we must remember that the paint does not set well. In general, it is possible to paint with acrylics and nylons, but this will require some heat treatment to maximize the surface tension and allow the paint to wet. Often this is done with an open flame or plasma... In general, this does not look easy at home, so it is better to use dyes.

Planning before 3D printing

In order to facilitate the process of finishing and painting, before 3D printing your model, we recommend that you consider the following:

- Lower 3D printing resolution saves printing time, but increases processing time.

- Consider the geometry of your model. Your tools should reach where you want to sand or paint.

- Do the smallest details need sanding, priming or both? If so, can they handle it without breaking?

- If dimensional accuracy is important for some parts of your 3D model, you may need to take this into account when modeling. Add material to be sanded to size, or reduce size to make room for primer and paint.

- Primer and paint add thickness and can completely hide the fine details of your model.

- Sanding removes material and makes your 3D model less durable.

Items to improve paint adhesion

And finally, a few simple steps to improve paint adhesion:

- When working with a 3D printed model, wear clean gloves to protect the skin from chemicals and the surface of the model from sebum.

- Remove dirt before sanding, you don't want dirt to get into your model. Often, isopropyl alcohol (rubbing alcohol) on a soft, lint-free cloth works well.

- Use a regular vacuum cleaner with a soft and clean brush to remove sanding particles.

- Sand off any roughness added during the primer.

- Always test chemicals such as paint, cleaning solvents, sanding, or other materials and finishes before moving on to the final model you want to refine.

Printing and painting of car parts

Hello dear community!

In this topic, I would like to move away from the 'home' post-processing of printed parts a bit and describe the process, which is slightly more complex, but also of higher quality, at least in terms of materials.

For 15 years I have been repairing, restoring, sometimes manufacturing plastic parts for cars and motorcycles, and with the advent of the 3D printer, life in general began to sparkle with new colors, in my business it has become a great helper :)

And on the subject - I also visited a car painter , so there is something to tell)

(Attention! A lot of photos and a lot of text)

Collaborating with several auto repair shops, I was sitting in one of them, repairing the next 'puzzles' made of plastic, but an incoming call from good friends of Access Auto amused me - there are parts, all from different machines and only on one side, but you need to make the same ones, but mirrored . ..

..

Here! It's our way!) I finally got a reason to talk about auto painting post-processing :)

I saw the first detail in absentia in the photo:

This is our 2007 AstonMartin DB9 Cabrio.

Aluminum frame with little things on the inside - fun.

The other two will be visible in the text - we have them from two Land Rovers.

You can make it, puff it up, think about it... and make it :) but in our circles it is held in high esteem, when everything is done at once, and preferably in one place. Okay, so let's color it! :)

A couple of photos of prints will not hurt:

Modeled with SolidWorks - doable, but sometimes you want a couple of functions from the artist))) table, adhesion - BF-2, layer - o.2mm, nozzle - 0.4mm, filling - 30-50%, wall, top/bottom - 1.2mm the counterpart was more important to me (grooves at different angles and a clear outline is needed), and let the rest hang on supports in the form of pasta :)

I cut the wheel arch lining into three parts and glued it onto the slurry of ABS + acetone, dried it for a long time, though, but repair / gluing is always best done with related materials, so we'll be patient. It is also possible with a soldering iron, starting from the depth of the seam, at 240 degrees, but the part is with a small filling and there is really nowhere to solder there.

It is also possible with a soldering iron, starting from the depth of the seam, at 240 degrees, but the part is with a small filling and there is really nowhere to solder there.

Next, a ring for the fog light - the fasteners are all at their own angle, I decided not to rack my brains and printed them separately, and then glued them - there are no complaints about the strength. On this description we close - let's rather get to the point !!!

And the essence is this:

It is almost always good and convenient to paint with spray cans, even quickly, I myself indulge in spray cans when this is enough for the job :) but there are tasks where you need to take the final appearance of the product and the quality of the coating more seriously - a smoother surface, better paint, stronger varnish. If we take cheap, easily accessible paints in cylinders, we get paint that is not resistant to alcohols and solvents; moreover, even some car shampoos can corrode it.

As a result, it turns out that not everything is strong and durable, that is colored and glitters :(

The reason is that one-component compositions on the shelves of building products for the most part are just a decoration, a cheap way to give gloss. I’ll immediately say to probable denials - , of course, not all! but many :)

I’ll immediately say to probable denials - , of course, not all! but many :)

But we have three serious and expensive cars, which means we will choose more serious materials, although not expensive, which is beneficial for us, but will not affect the quality in any way.

The only problem is that for 'creativity without bottles' we need a compressor and at least one airbrush :( This should have been said in advance, but among us there are people with garages, workshops, and people with acquaintances and friends, who can help :) as well as our dear comrades who can read and be inspired to purchase air bells and whistles, which will come in handy in a bunch of other projects)))

Well, my garage with all the tools and equipment is full of boxes after the move, so I set up a workshop in the office at the bus station))) Let's go there!

Today we have liquid acrylic filler primer (my favorite), HS acrylic lacquer - with a high solid residue, and little things:

degreaser, solvent 646 for washing spray guns, P-4 or acrylic thinner for primer and varnish. From thick - putty, but I will not show it, because everything is more interesting than it seems;)

From thick - putty, but I will not show it, because everything is more interesting than it seems;)

From crunchy, let there be measuring cups, stirring sticks, brushes for washing the spray gun, a toothpick (useful). PPE is mandatory: gloves (latex surgical gloves do not behave badly), a respirator, etc., as well as an open window or ventilation at hand.

Further chewing and wiping:

1. Lint-free cloth for wiping/degreasing the surface.

2. Scotch brite - very handy when you need to matte the surface before painting.

3. 'Sticky Rag' - sticky cloth to remove dust/specks from the surface of the part.

4. Grid-shaped emery cloth (AbraNet) - much less clogged with dust during grinding, easy to clean and generally a cool thing :) It is not necessary and you can use classic sandpaper. Useful grit 120,180, 240, 320, 400.

5. Foam-based sandpaper, designed for grinding soil, soft base allows you to bend around corners, as well as gently and gently smooth the surface. In my case, these are the names Fine, Micro fine and a piece with a grain of 800.

In my case, these are the names Fine, Micro fine and a piece with a grain of 800.

All materials can be purchased from specialized car paint shops or car markets.

Grinding stones, grinders, types of sandpaper - this is a whole separate topic, so we will omit it, especially since many posts on the portal probably touched on this issue.

Next, I decided to take two spray guns, let's call them 'Small' (nozzle 1mm) and 'Large' (nozzle 1.4mm). Small will be painted and varnished, and Large will be primed.

In the meantime, prepare the details. With sandpaper 120/180, we roughly remove the excess at our discretion, then 240 in front of the primer if desired, but I stopped at 180 and left visible layers and flaws, I just want to show you what the filler primer is capable of without a drop of putty.

I prepared Martin's part a little earlier, so there are only a couple of photos after puttying (I had to :) ) and primer (by the way, I primed it at home with a brush):

The aluminum part was left in the office, both of them are plastic.

The process of priming the rest of the elements cannot be conveyed by photographs, and I could not shoot a video with one hand.

But the essence is simple - there is a system: primer and hardener, it says '5:1', this means that we need to take 5 parts of primer and one part of hardener, the measurement is by volume, so it's good to take measuring cups or a syringe for these purposes at very small volumes. We measure, mix, dilute with P-4 or acrylic thinner to the necessary fluidity so that the spray gun can do it all digest spray. On average up to 10% diluent per total volume. I did not find another 'Very Large' spray gun with a 2.4mm nozzle, so I will have to dilute it even thinner for a 1.4 nozzle, nothing bad will happen if you do not overdo it.

Do not dilute 646,647 with thinners as they contain acetone which can 'kill' the hardener.

So, let's not get distracted, the reaction is going on and soon the soil will begin to thicken, so we prime it.

Primer can in principle be applied 'thick', but with experience. In the meantime, we are not afraid and little by little, at medium pressure, we apply a wet, but not thick (we don’t need snot) layer. It almost looks like painting from a balloon, only in the hands the device is cooler than a jar)))

Make it a rule - any spraying is first done on the edges, edges, edges and then we go to the planes. Very often, small details / insides go out of sight and are forgotten.

Excellent! We go to brew tea / coffee and wait until the surface of the soil dries and becomes matte. When this happens, we apply another layer and so on several times until the soul becomes calm or the tea runs out) I finished my coffee on the fourth layer :) We are not afraid to 'pour' more soil into doubtful places, fill holes, cracks ... do on an already dried coating.

In fact, the ground layer grows, but repeats the silhouette of irregularities without spreading or leveling out, so you can visually deceive yourself, as you will see in the photo now:

Rough coating on the ring and clearly visible stripes of layers on the arch. Beauty?....No?! It's strange))))) Nothing, nothing, that's what I wanted to show, let's leave it to dry for a day at room temperature, this is enough for the soil to polymerize. For this I love automotive materials!) The thickness of the soil is about 0.3-0.4 mm, but it will dry and harden anyway! Cylinders do not know how to do this, or these 0.3 mm must be applied all day with drying for two hours, so that there is no damp mass inside ...

Beauty?....No?! It's strange))))) Nothing, nothing, that's what I wanted to show, let's leave it to dry for a day at room temperature, this is enough for the soil to polymerize. For this I love automotive materials!) The thickness of the soil is about 0.3-0.4 mm, but it will dry and harden anyway! Cylinders do not know how to do this, or these 0.3 mm must be applied all day with drying for two hours, so that there is no damp mass inside ...

In the meantime, the spray gun is thoroughly washed and put on the shelf, one piece of advice - you have soil left in the glass, even a drop, but it can help a lot:

This is a hole in the seam, the defect is one of many. You will later say THANKS to yourself if you take a toothpick on the same day and simply bury these defects with soil.

A day has passed...

Arriving at the station, I immediately took out a can of black matte paint and lightly sprayed on the details so that it became like this:

This is the so-called 'Development' before sanding. There are also special developing primers and powdered soot to tone the surface, but I ran out of both, so matte paint is fine, because it dries quickly and sands well.

There are also special developing primers and powdered soot to tone the surface, but I ran out of both, so matte paint is fine, because it dries quickly and sands well.

And now, after a cup of tea/coffee, we take sandpaper 240/320/400, put it on a bar and grind. I immediately took 400, because it's more pleasant for me to control the process)

It is very easy to clean sandpaper clogged with dust with the same scotch-brite or cloth so that it can grind normally again.

Pay attention to how the development works - all the flaws, all the bumps are visible, and when all this disappears - we can assume that everything is smooth))) I slightly broke the rules and polished one part more to show the transition from the beginning of grinding to the final , and at the same time we see that with only one primer we removed all the curvature from the surface, even the layering went away without a trace and no putty is needed) Of course, provided that the grinding was carried out correctly) As you can see in the photo above, I have sawdust from the ground diagonally, i. e. you basically need to grind not just back and forth, but with an offset - this will allow you to capture a larger area and grind the surface more efficiently and evenly.

e. you basically need to grind not just back and forth, but with an offset - this will allow you to capture a larger area and grind the surface more efficiently and evenly.

Rule - do not start sanding from corners and edges! first we draw the planes, leaving the edge as a guideline and trimming it if necessary, for example:

silky surface of the element :)

And we say THANKS to ourselves for the defects dropped with a toothpick, because they are gone, they have become even)

The arch is ready, it does not need to be painted, so I take a photo and report to the customer:

The next step is painting.

We will get the 'base' paint prepared (by our own hand / colorist) in advance, dilute it according to the recommendations, often it is 2 parts of paint and 1 part of thinner, in my case 646 thinner is suitable for the base, the paint has not flaked from it and feels good.

We clean the parts with a lint-free cloth with a degreaser and, if necessary, remove dust particles with a sticky cloth. Pour paint into the spray gun and go to a secluded place for painting.

There is no paint shop at this station, so I'm waiting for lunch and while no one is there - I paint right in the locksmith :D

The first layer is 'adhesive' - applied with a light spray like a spray of matte paint on the ground, this will help the paint to adhere to the surface. Don't forget to start with the edges and insides, and only then - the surface:

Let dry for 5-10 minutes and put the first 'wet layer', color the gray part.

Nuance - You saw the places where I rubbed the primer to the plastic, in these areas the paint can sometimes shrink, so you can give a light spray a couple more times, and then cover it wet. If the paint has shriveled, dry completely and lightly sand the base with 800 sandpaper, often removing the adhering paint from the skin with a cloth, if this happens. Then we cover the defective place with dust a couple of times and again try to give a wet layer. You can do the same if a large mote stuck on a wet layer and you need to grind it off.

Then we cover the defective place with dust a couple of times and again try to give a wet layer. You can do the same if a large mote stuck on a wet layer and you need to grind it off.

So, the wet layer is when the base lay down greasy on the surface and became glossy, it will soon dry out and become matte again, then you can apply another wet layer. On average, two wet coats are enough, but there are also non-opaque paints that need more layers, or even colored primer, but this already needs to be assessed on the spot.

The technology for applying base paints is very diverse, in my case I will make 2.5 layers, i.e. two wet and the last 'dry' - quickly from a distance I will spray without gloss, this will give depth to the color and show more grain in the metallic:

Let it dry, let's prepare the varnish.

This composition is also two-component and is diluted in the ratio of 2 parts varnish and 1 part hardener, knead, wait 5-10 minutes, mix again and prepare for varnishing. Before this, the spray gun is washed clean.

Before this, the spray gun is washed clean.

If a mote flew in and said 'I'll sit here, then lightly, barely touching, wipe it with sticky)

Motes are not terrible on dark coatings, they are not visible after polishing, but on white or light ones, motes are like evil black)))))

Applying varnish is one of the most dangerous moments. Underfilling - a bumpy surface (shagreen), overflowing - will flow and then it is either difficult to remove these 'painter's tears', or even repaint. Training will bear fruit and you will succeed)

The first layer is adhesive, we wait about 10 minutes, the second is wet, we wait 10-15 minutes, the third is wet, we wait 2-5 minutes for spreading and see how it turned out, if you like it - leave it, if not, you can risk pouring it again, but it’s better to stop at the second wet layer, not all varnishes adequately tolerate a large layer thickness.

Tip - after each layer, apply a little varnish on something, then at this place it will be possible to determine whether this layer has dried up .