Core xy 3d printers

The Top 6 Best CoreXY 3D Printers of 2022

Known for speed and precision, CoreXY 3D printers are some of the most powerful (and affordable) FDM printers.

With FDM 3D printers largely accounting for the multi-billion dollar growth in the 3D printer market, it’s safe to assume that the CoreXY 3D printing system is reaping the benefits of this attention.

But how do they differ from standard FDM builds?

Aside from their speed and precision, CoreXY printers employ an innovative design consisting of belts that control the printer head (and in some cases even printer beds!), giving them productivity-boosting features like a stationary gantry system and motorized X and Y axes.

If you’re ready to take a deep dive into the best CoreXY 3D printer kits, then keep reading as we explore the technology behind CoreXY printers, their advantages, disadvantages, and take a look at the top CoreXY 3D printers on the market and who they work for best!

What is a CoreXY 3D Printer?

If you’re looking to invest in an FDM 3D printer, the most popular style is a Cartesian printer, and it’s within that subset we find the CoreXY system. Now, CoreXY is technically a form of Cartesian 3D printer, but you’ll often find comparisons of the two and that’s because of CoreXY’s unique design.

For more info: read our guide to the 4 main types of FDM printers.

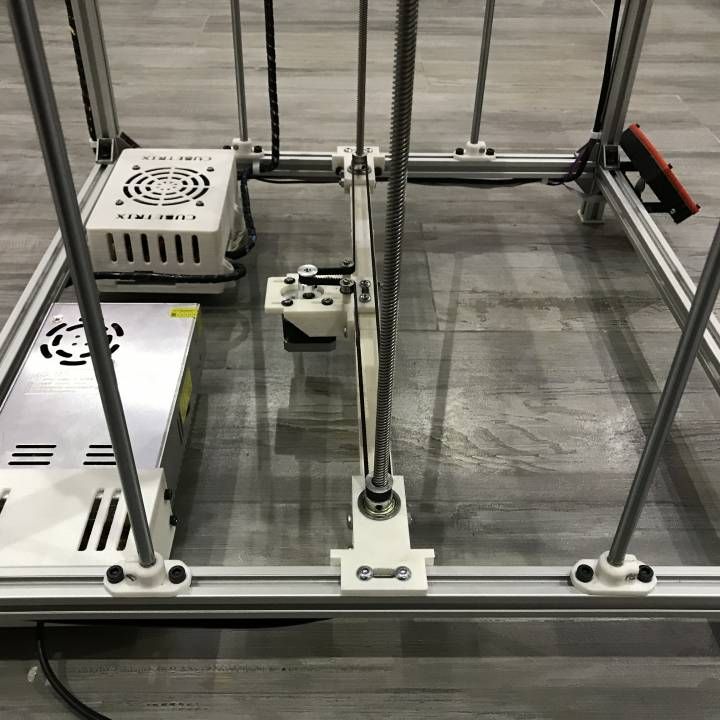

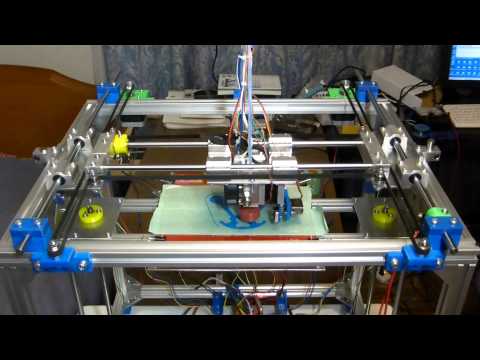

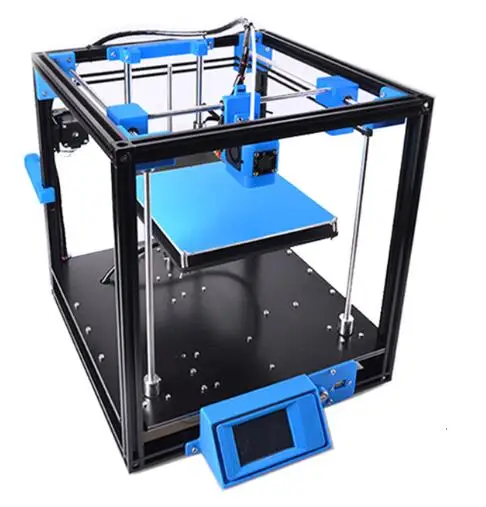

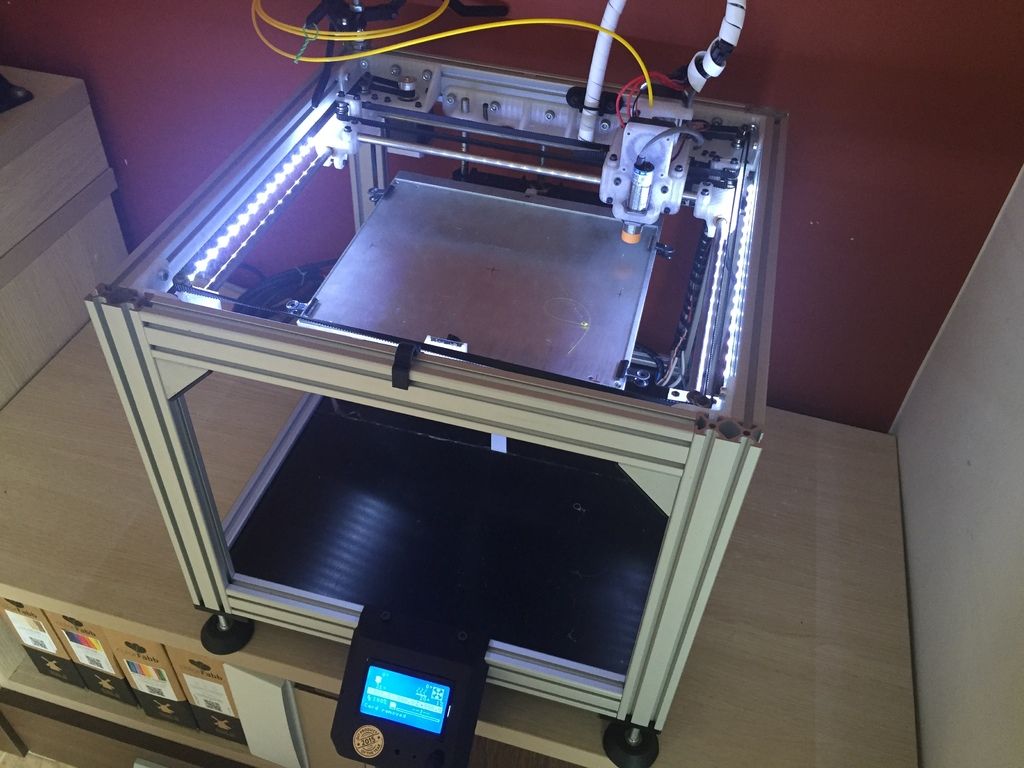

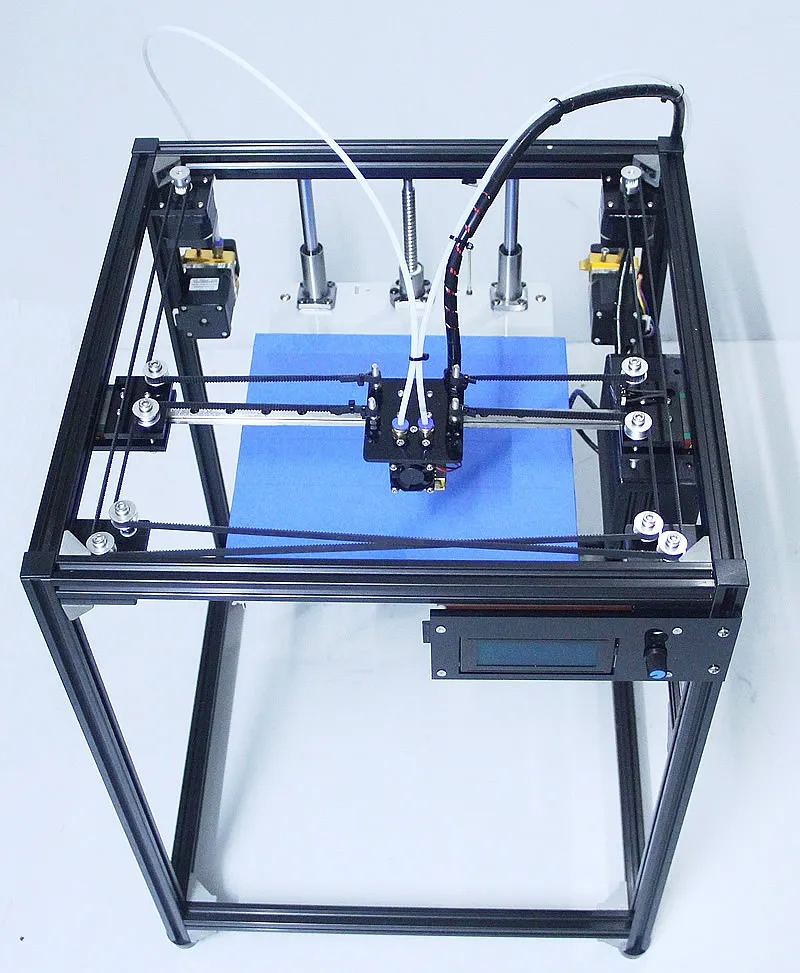

CoreXY is a 3D printing system that was developed by an MIT engineer in 2013. These printers are typically cube-shaped and consist of belts that operate using stepper motors to move the printer head along the X and Y axes. In this case, the printer head is the only object actually moving with any significant speed.

While the printer head moves along the X and Y-axis, the printer bed moves along the Z, and all of these combine to 3D print the model.

This is compared to standard Cartesian printing systems, which are similar as the printer bed moves along the Z-axis, whilst the printer head moves along the X and Y. However, the difference is the printer head is connected to the gantry system, not belts. This means the entire gantry is moving with the printer head, as opposed to just the printer head moving.

With CoreXY 3D printing systems, there’s less opportunity for the gantry system to move. This decreases the chance of excess vibration, which if you’ve ever used a 3D printer before you know too much vibration can lead to side effects like ringing and ghosting. This isn’t to say it never happens, but it’s less likely to.

Higher-end CoreXY models also often come with enclosures made from a variety of materials like plastics, acrylics, and fiberglass. This helps regulate the temperature when printing your models.

The overall result of this technology is increased space efficiency, speed, stability, and accuracy.

CoreXY 3D Printer Advantages vs Disadvantages

Advantages

- Faster print speeds.

- More affordable than other 3D printers.

- Despite higher speeds, it can still deliver accurate and precise models.

- A vertical moving printer bed means it can deliver the same build volume but in a more compact size.

Disadvantages

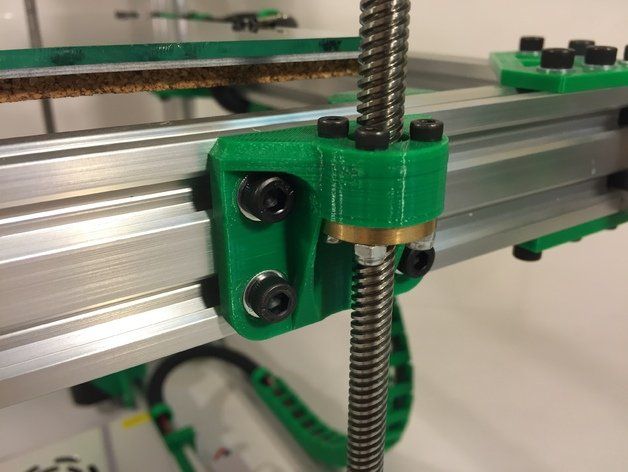

- The belt system can be finicky, if the tension is too high or too low it can lead to increased wear and malfunctions.

- If the printer’s frame isn’t assembled and lined up correctly it will lack accuracy, and the frame can shift over time.

The Best CoreXY 3D Printers

Understanding what CoreXY printers are is only half the battle, now it’s time to compare. Ranking from lowest to the highest price, here are our top CoreXY 3D printers.

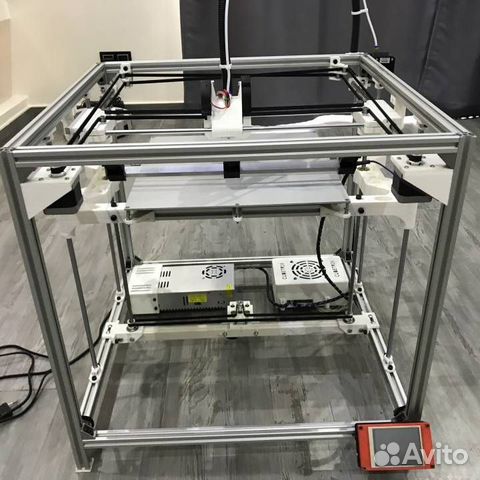

1. Tronxy X5SA

- Price: $329 –– Available on 3DPrintersBay / Available on Amazon here

- Build volume: 330 x 330 x 400 mm

From the trusted global developers at Tronxy comes the X5SA, which proves to be one of the fairest priced CoreXY printers on the market.

With a build volume almost twice as much as the Sapphire Pro, the X5SA comes with assisted-manual bed leveling, where it helps support manual bed leveling by showing off-level areas. The bed is also 24V powered and produces a nice even heating across the surface.

The printer supports laser engraving, an integrated Y-axis guide rail, a double screw motor on the Z-axis, open-source Malin Firmware, and uses the same Bowden extruder as above.

What gives the X5SA its popularity is its customization. You may not get much use out of it on its own, but it’s become a favorite amongst printers who enjoy being able to customize their printer with out-of-the-box modifications, like the coated glass bed. On Tronxy’s site, you can even find an X5SA upgrade kit.

Beginners may find setting up and upgrading this printer daunting, as it’s not the easiest, but experienced hobbyists and professionals will love the price and modification support this printer holds.

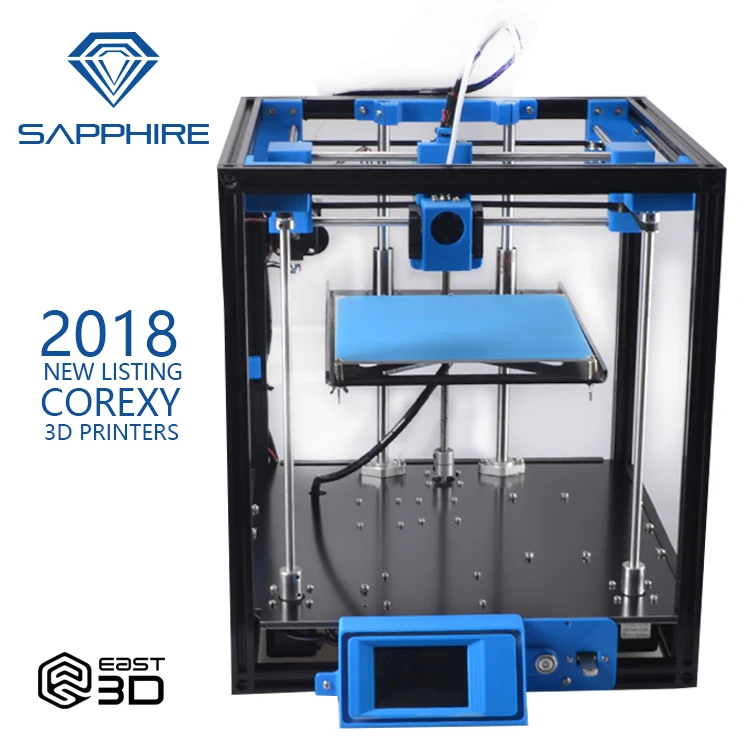

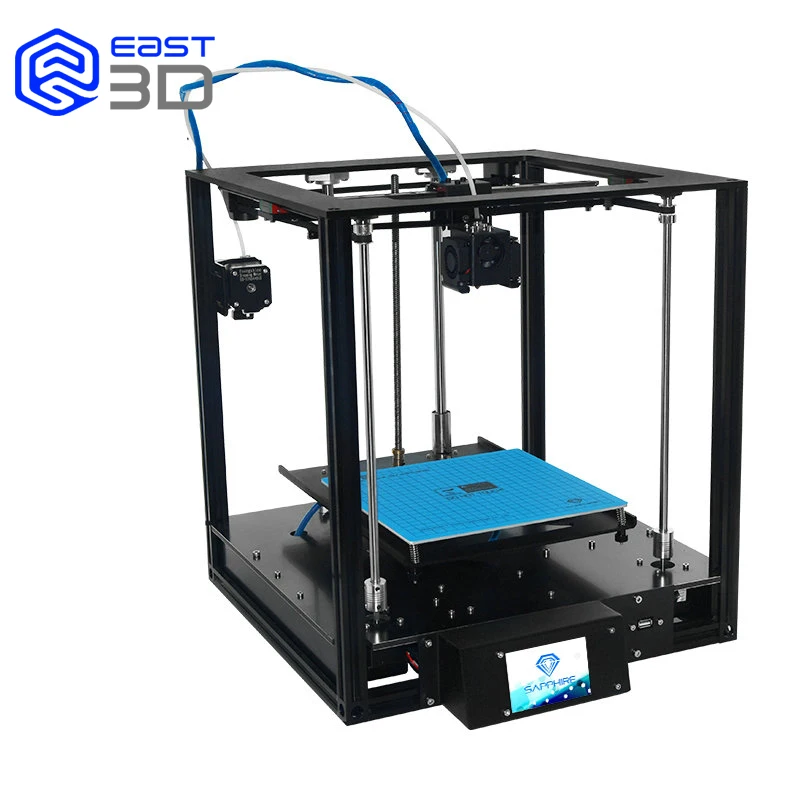

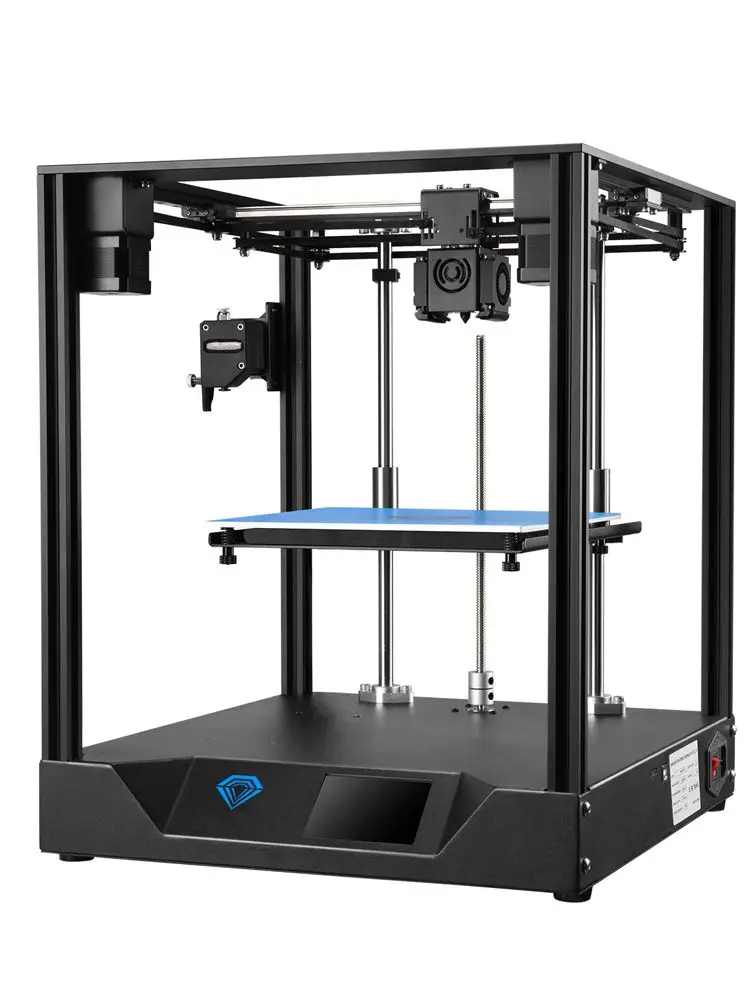

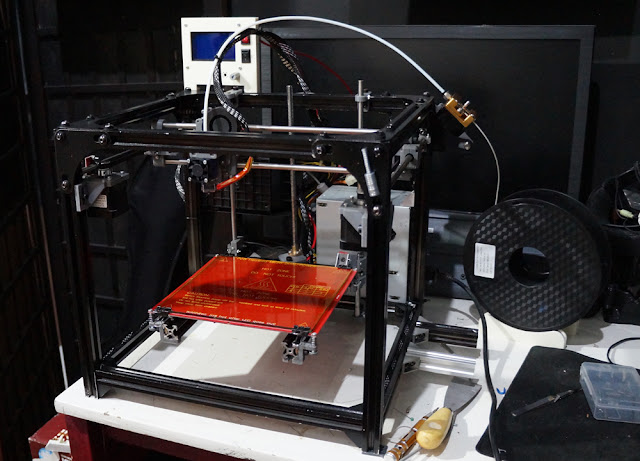

2. Two Trees Sapphire Pro: Best Affordable CoreXY 3D Printer Kit

- Price: $299.99 –– Available on Two Trees Store here / Available on 3DPrintersBay

- Build volume: 235 x 235 x 235 mm

Founded in 2017, Two Trees set out to fill the gap in the market to deliver performance, affordability, and user-friendly assembly all in one printer, and that message still rings true today with the Sapphire Pro.

The Sapphire Pro boasts a number of high-end features for minimal costs, like automatic bed leveling and precision linear rails for the X and Y axes, which help reduce wear over time and create smooth applications.

That’s not all that keeps this printer in the limelight.

It also has a smart power failure detector, so it stops and picks up right where you left off in case of outages, twin turbofans for fast setting of the printed model, a dual-drive Bowden extruder, and a Makerbase MKS 32-bit Robin Nano control board. The printer comes easy to set up and ready to print. You may have to finagle a few settings to achieve the desired effect, but overall, it’s a solid printer for a solid cost.

While this printer is an excellent choice for every user (and every wallet), we really believe this to be the industry standard entry-level CoreXY printer, and perfect for anyone looking to break into the community.

3. Creality Ender 6: Best CoreXY 3D Printer for the Price

- Price: $550 –– Available at Creality’s Official store here / Available on 3DPrintersBay / Available on Amazon here

- Build volume: 250 x 250 x 400 mm

Dubbed the “3D printing industry evangelist”, Creality aims to bring the convenience of technology to everyone, and their midrange Ender 6 3D printer does the job nicely.

Nestled between the Ender-5 Pro and the CR-10 series, this semi-enclosed printer promises to be the fastest and most intelligent one of the series yet. With removable enclosures, as well as an optional top plate for full enclosure, this printer lets you stabilize temperature-sensitive filaments more efficiently.

It has a print speed of up to 150mm/s, and uses the Carborundum glass platform, with similar properties to Anycubic’s Ultrabase platform, giving you ultra-smooth layers.

The Ender- 6 comes with a custom-built, imported, ultra-silent TMC motion controller from Germany, and the TMC-2208 motherboard ensures tranquil silent movement. It also comes with a large 4.3-inch color touchscreen. Although it is manual bed leveling, you can accessorize it with an automatic bed leveling probe for assistance.

The large community surrounding Creality also comes in handy, creating powerful mods as well as offering amazing support. Partnered with the online tutorials and detailed guide, you’ll have this printer assembled in no time.

All in all, the Ender 6 is one of the best technological upgrades for mid-range printers and is best for those looking for optimized speeds at a bargain.

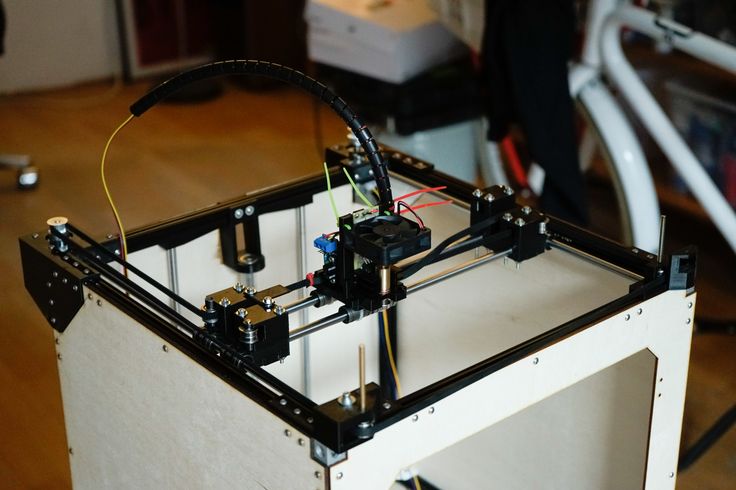

4. Voron 2.4: Best CoreXY 3D Printer for DIY

- Price: $879.00 –– Available on 3DPrintersBay

- Build volume: 250 x 250 x 250, 300 x 300 x 300, and 350 x 350 x 350 mm

Made by engineers for true home micro-manufacturing, Voron started back in 2015 under the belief that a 3D printer should be uncompromised, fun to assemble, and a joy to use.

And that brings us to today with the Voron 2.4.

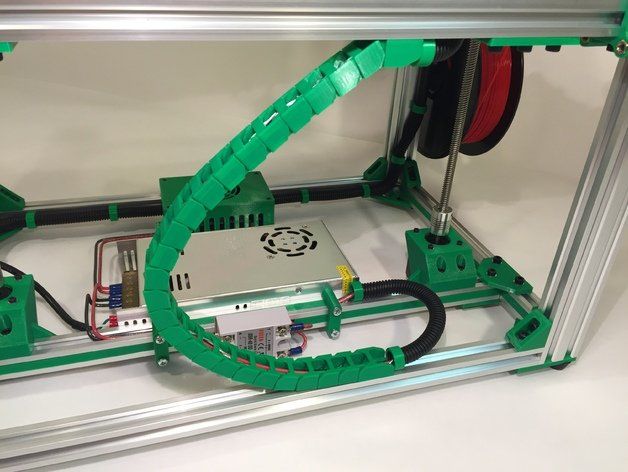

This is a nice entry-level printer into the high-end spectrum that boasts a plethora of possibilities. Not only is it pleasing to look at, but it offers unique features like opting for a stationary bed and linear rails on all three axes to help cut down on vibrations.

The engineers were serious when they said a printer should be fun to assemble, taking DIY CoreXY 3D printers to the next level. In this almost meta process, you’ll need a 3D printer to build this fully open-sourced DIY printer.

In this almost meta process, you’ll need a 3D printer to build this fully open-sourced DIY printer.

The company website has fantastic schematics, so you know exactly what you need, but to get this printer you’ll have to embark on a search for all the parts. However, it does have a zealous community eager to welcome newcomers and help them get started sourcing and building the parts for this printer. The website also has materials itself, like the Bowden drive and printer bed, or you can order bundle kits from third-party sellers at your own risk.

If you go for the kit, each size comes including a 32-bit BTT Octopus mainboard, a Raspberry Pi controller to run Octoprint, a heated chamber, as well as most necessities for the printer.

This printer is definitely an experience, and not for the light-hearted, but if you’re up to the task, you’ll find immense joy in this community and the process of building the Voron 2.4 that’s as unique as your own fingerprints.

5. Creality CR-30 (3DPrintMill)

- Price: ~$1,050.

00 — Available on Amazon here

00 — Available on Amazon here - Build volume: 200 x 170 x ∞ mm

Another Creality special on this list and it’s the slightly more exuberant model, the CR-30.

What first catches your attention about this printer is not only its sleekness but its obvious revolutionary design. While most CoreXY printers are cubic, the CR-30 is triangular with an infinite Z-axis.

The printer bed runs like a treadmill, or a rolling conveyor belt, which promises to increase productivity, cost-efficiency, and save time. There’s even an extension bracket you can add on for printing extra-long models. It has a Nylon-based heated bed that’s easy to replace and has excellent adhesion.

To combat logistical setbacks, its printer head sits at a 45-degree angle. While they keep certain specs under wraps, from what we can tell, the printer comes with an ultra-silent motherboard and silent chip, which seems reminiscent of the Ender 6 specs. Its infinite Z-axis has the capability to make this printer a manufacturing powerhouse, and don’t worry, the revolving belt comes already leveled.

Overall, we recommend this printer for users looking to boost productivity and take advantage of the extra-long printing capability for models.

6. Vivedino Troodon

- Price: $1,574.00 –– Available on 3DPrintersbay here

- Build volume: 300 x 300 x 400 and 400 x 400 x 500 mm

The last price on this list may be jarring, but it’s not without merit.

Coming in 2 sizes, this open-source printer comes with all the fixings of a seamless 3D printing experience. A wireless-capable 32-bit board, auto bed and gantry leveling, dual-gear extruder, linear guides, and silent stepper motors are just a few of the features that make the Troodon worth the price.

With a hot end and heated bed reaching 275 degrees and 150 degrees respectively along with its enclosed build area, you can manage temperature-sensitive filaments with ease. Striking inspiration from the Voron, it too uses a belt on the Z-axis to decrease wobbling.

Unlike the others on this list, it comes completely assembled, ready to print out-of-the-box. And while it supports modification, it creates amazing prints as is. Vivedino’s Troodon printer is for those willing to spend a little extra for massive convenience.

7 Best CoreXY 3D Printers (2022 Updated)

- Last Updated: November 8, 2022

- Pat Nathaniel

CoreXY printers are some of the most reliable and versatile on the market, making them ideal for both hobbyists and artisans.

Unlike other 3D printer design styles, such as the delta 3D printer, CoreXY printer heads only move on the X and Y axis (hence the name).

Why is that a benefit?

Because they are more agile and faster than the competition. Since the head doesn’t have to move on the Z-axis, it can provide much more detail within your builds.

In this article, we’ve compiled a list of the best 7 CoreXY 3D printers.

Let’s get started!

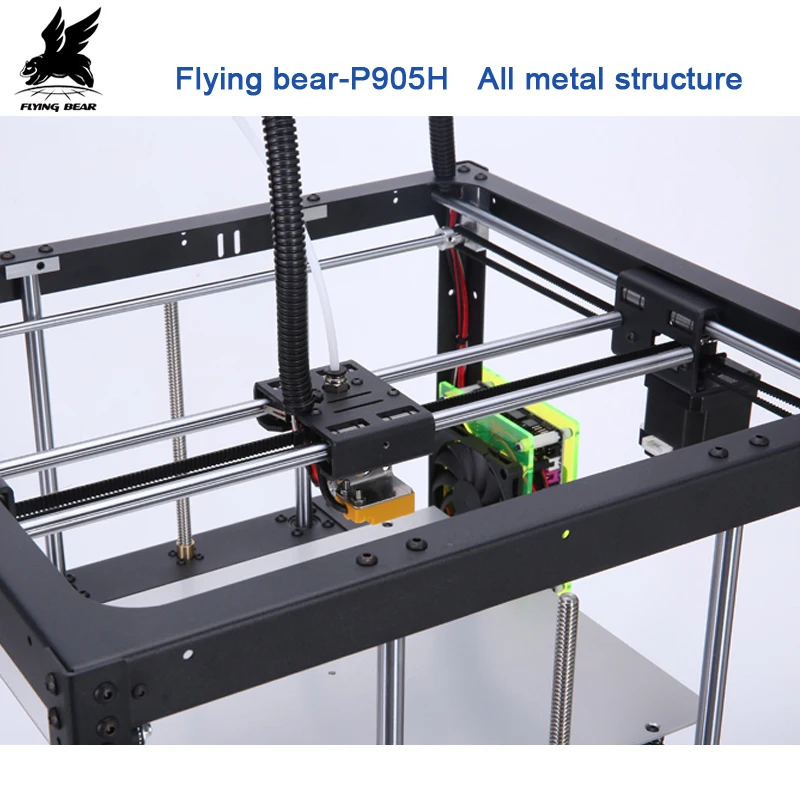

Tronxy X5SA Pro

Build volume: 330 x 330 x 400 mm

Check Latest Price

Creality Ender 6

Build volume: 250 x 250 x 400 mm

Get Discount (Official)

Check Latest Price

Vivedino Troodon CoreXY

Build volume: 300 x 300 x 400 mm

Check Latest Price

Table of Contents

- 7 Best CoreXY 3D Printers At A Glance

- 1. Tronxy X5SA Pro (Best Value)

- 2. Creality Ender 6 (Best Choice)

- 3. Vivedino Troodon CoreXY (Premium Choice)

- 4. Two Trees Sapphire Pro (Best Budget)

- 5. Voron 2.4 R2 CoreXY (Best DIY)

- 6. Rat Rig V-Core 3.1

- 7. SecKit SK-Go³ (Best for Experienced Users)

- CoreXY 3D Printer Buyer’s Guide

- What are CoreXY 3D Printers?

- Advantages of CoreXY 3D Printers

- Disadvantages of CoreXY 3D Printers

- FAQs

- Do These Printers Provide High-Quality Prints?

- Are These Printers More Expensive Than Other Models or Brands?

- Is Assembling a CoreXY Printer Difficult?

- Are These Printers Easy to Use?

- Final Verdict

7 Best CoreXY 3D Printers At A Glance

1. Tronxy X5SA Pro (Best Value)

Tronxy X5SA Pro (Best Value)

2. Creality Ender 6 (Best Choice)

3. Vivedino Troodon CoreXY (Premium Choice)

4. Two Trees Sapphire Pro (Best Budget)

5. Voron 2.4 R2 CoreXY (Best DIY)

6. Rat Rig V-Core 3.1

7. SecKit SK-Go³ (Best for Experienced Users)

1. Tronxy X5SA Pro (Best Value)

3D Printer Type: FDM | Layer Resolution: 0.1-0.4 mm | Materials: PLA, PLA+, TPU, ABS & PETG | Build Volume: 330 x 330 x 400 mm | Print Speed: 20-150 mm/s | Printer Size / Weight: 580 x 645 x 660 mm / 14 kg

The X5SA Pro is for you if you frequently print large projects and prefer a quiet machine.

Be warned however that the instructions it comes with aren’t the clearest so I recommend watching videos online to help assemble it. Because of this, I don’t recommend the X5SA Pro for beginners (unless you like to tinker and DIY).

I like that the printer is quite sturdy once built.

A few other features I like:

Large Enclosure

This CoreXY 3D printer has one of the biggest platforms on the market, with a 330 by 330 by 400 mm printing surface. You can let your creativity shine with larger pieces such as printing cosplay armor.

Automatic Leveling

If you have to use multiple color filaments to build your piece, leveling can be a challenge. With the automatic leveling function, you can keep going without any noticeable errors in your design. This printer also supports manual leveling when applicable.

Titan Extruder

The ‘Pro’ version of the X5SA comes with a Titan extruder which means you can print flexible filament like TPU. And switch to PETG or ABS with ease. The versatility of printing different materials is a huge pro.

Overall, this is a decent CoreXY 3D printer with a few drawbacks. Keep in mind that to get the best out of it modifications may be needed. While these aren’t usually too expensive, it will raise the cost.

While these aren’t usually too expensive, it will raise the cost.

If you want a 3D printer that doesn’t need to be upgraded then check out the next two reviews below.

- Large printing area

- Automatic leveling

- Power sensor

- Filament sensor

- Lifetime tech support

- Silent operation

- Some build instructions can be confusing

- Can take a while to master the leveling feature

Check 3DPrintersOnlineStore

Check Latest Price

2. Creality Ender 6 (Best Choice)

3D Printer Type: FDM | Layer Resolution: 0.1 mm | Materials: PLA | Build Volume: 250 x 250 x 400 mm | Printer Size / Weight: 495 x 495 x 650 mm / 30 kg

If you want a 3D printer that’s more beginner-friendly, than I recommend the Ender 6. This is Creality’s first foray into the world of CoreXY and they did a great job with this entry-level unit.

This is Creality’s first foray into the world of CoreXY and they did a great job with this entry-level unit.

Assembling the Ender 6 was a breeze – it took us only one hour. And what we enjoyed the most was that the test prints came out beautifully.

A few other things we liked:

Large Housing Unit

Although the Ender 6 isn’t as big as the X5SA Pro, it is larger than most other printers. It has a 250 by 250 by 400 mm enclosure, which is almost as big as their CR-10 models. However, with such a relatively massive chamber, you need to make sure that you have enough counter space to house it.

Fast Printing Speeds

Since the Ender 6 uses a CoreXY structure, it can achieve printing speeds of up to 150 mm per second. With an excellent cooling function and smooth FDM head, you can get more precision and better results in less time.

If you want a well-designed, easy to operate machine from one of the most well-known and respected companies the Ender 6 is for you.

- Rugged construction

- Large printing area

- Fast printing speeds

- Touchscreen interface

- Rapid cooling

- Hassle-free assembly

- Suffers from fan noise common to Creality printers

- Colored panels can make it harder to see your products during printing

Get Discount Now (Official Store)

Check Latest Price

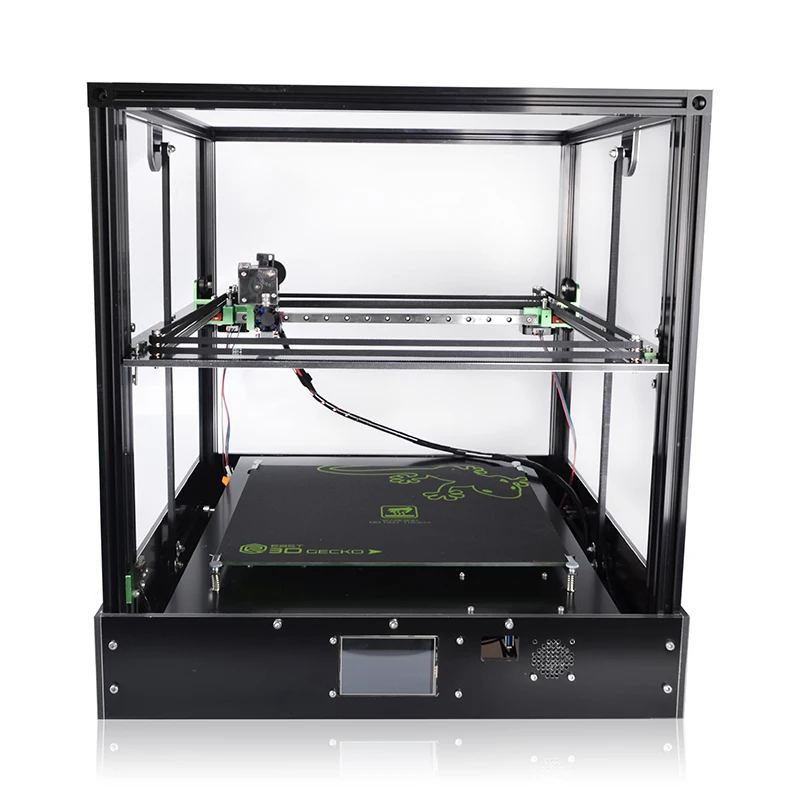

3. Vivedino Troodon CoreXY (Premium Choice)

3D Printer Type: FDM | Layer Resolution: 0.05-0.3 mm | Materials: ABS, PLA | Build Volume: 300 x 300 x 400 mm | Printer Size / Weight: 516 x 643 x 764 mm / 38 kg

If you’re ready to upgrade your 3D printing to the next level, the Troodon is for you. This is one of the largest (and priciest) models on the market, but it is better for advanced printing options.

This is one of the largest (and priciest) models on the market, but it is better for advanced printing options.

Why do I like the Troodon?

Extra Large Printing Area

With a 300 by 300 by 400 mm enclosure (like the X5SA Pro), you have the option to print much larger. Even better, the Troodon works faster than them, too, all without sacrificing precision or build quality.

HEPA Air Filter

One of the primary advantages of buying an enclosed 3D printer is that it can trap potentially harmful fumes. This model goes a step further by scrubbing the air clean so you can work more efficiently, particularly when building multiple models in sequence.

Pre-Built Machine

Rather than having to build this 3D printer yourself, it comes fully assembled. This is part of the reason why the price tag is higher, but it allows everyone to get involved, not just those with engineering skills.

The Vivedino Troodon is one of the more beginner friendly CoreXY printers and is perfect if you want to get high-quality prints from the get-go.

- Pre-assembled housing

- Large design for bigger models

- Rapid printing and cooling

- A HEPA filter traps harmful emissions

- Automatic pause and power sensor

- Quiet operation

- More expensive than other 3D printers

Check 3DPrintersOnlineStore

Check Latest Price

4. Two Trees Sapphire Pro (Best Budget)

3D Printer Type: FDM | Layer Resolution: 0.1 mm | Materials: PLA, ABS, TPU, Flexible, Wood, PVA, HIPS | Build Volume: 225 x 235 x 235 mm | Printer Size / Weight: 405 x 360 x 480 mm / 14 kg

When comparing different 3D printers, you’ll notice that many of them can be quite costly. If you’re hoping to save some money while getting the most value, the Two Trees Sapphire Pro is an excellent choice.

If you’re hoping to save some money while getting the most value, the Two Trees Sapphire Pro is an excellent choice.

Why is this the best budget pick?

Print Different Materials

The Sapphire Pro can do things machines priced higher can’t. Chief among them is print in TPU and flexible filament.

Rapid Cooling

Because these printers use the FDM method of printing, distortion can be possible if the filament doesn’t cool down in time. Thankfully, the Sapphire Pro alleviates that problem so that your finished products will look smoother, uniform and be more durable.

Automatic Pause

Just as you wouldn’t want to dry-fire a gun, running your 3D printer without filament can damage the internal components. The Sapphire Pro has built-in sensors that shut the machine down as soon as the material runs out. This feature is also helpful if there are any blockages or errors while printing.

Another advantage of pausing is that you don’t lose your place while printing. Once you get more filament into the machine, it will resume where it left off, so there won’t be any issues with the results.

Once you get more filament into the machine, it will resume where it left off, so there won’t be any issues with the results.

If you want to experiment with CoreXY design and not shell out a ton of cash then the Sapphire Pro is for you.

- Quieter with TMC2208 stepper motor

- Lighter and more agile printing method

- Large 3.5-inch touchscreen

- Easier to build than other models

- Rapid cooling for smoother, more uniform products

- Automatic pause when filament runs out

- Not designed for commercial purposes

- Some components can overheat, causing damage to the machine

Check Banggood Price

Check Latest Price

5.

Voron 2.4 R2 CoreXY (Best DIY)

Voron 2.4 R2 CoreXY (Best DIY) 3D Printer Type: FDM | Layer Resolution: 0.025 mm | Materials: PLA, ABS, PETG, etc. | Build Volume: 250 x 250 x 250 mm, 300 x 300 x 300 & 350 x 350 x 350 mm

Like the X5SA, the Voron 2.4 R2 CoreXY is for those who have a DIY-can-do attitude and want the ultimate 3D printing machine.

Be warned, however, that you will have to build your model from scratch. Because of this process, you will spend more on this machine than you would with most others on this list.

Why do I like the Voron?

No Vibrations

One of the issues with CoreXY printers is that the arm moves on the Z-axis. As a result, it can shake and rattle the machine, leading to errors during printing. Because the Voron moves the head on all three axes, that is not an issue.

Durable Components

Voron’s mission statement is to create a 3D printer that doesn’t need constant tweaking or upgrading. Buying and assembling these parts means that you will have a printer built to last.

Buying and assembling these parts means that you will have a printer built to last.

HEPA Filter

As we’ve mentioned, 3D printers can emit semi-toxic fumes. To alleviate this potential hazard, the Voron comes with a HEPA filtration system.

- High-quality parts

- Low noise and vibration

- Customizable build

- Vibrant online support community

- Large print area

- On the expensive-side ~$1200 to build

- Requires expertise to build

Check Latest Price

6. Rat Rig V-Core 3.1

3D Printer Type: FDM | Materials: PLA, ABS & PETG | Build Volume: 200 x 200 x 200, 300 x 300 x 300, 400 x 400 x 400 & 500 x 500 x 500 mm

Those who want to pick and choose what goes into their 3D printer must meet Rat Rig V-Core 3. 1. This open-source printer offers the user a fantastic variety of customization, from frame size and print volume to various EVA 3-compatible print heads, controller boards, enclosures, and more.

1. This open-source printer offers the user a fantastic variety of customization, from frame size and print volume to various EVA 3-compatible print heads, controller boards, enclosures, and more.

The print volume ranges from 300 x 300 x 300 mm to 500 x 500 x 500 mm — making V-Core 3.1 the largest printer on this list. The aluminum frame is sturdy and V-Core 3.1 is built like a tank.

Some users experienced reliability issues with certain components on the previous V-Core 3 version, particularly the idlers, but Rat Rig has replaced most of them with new ones. The upgraded machine should let you simply print without worrying about maintenance.

But what if you don’t want to build your own machine? That’s fine — Rat Rig offers packaged options of the V-Core 3.1. Simply pick the build volume you want and you’ll get the same package Rat Rig itself uses at its print farm.

To wrap it all up, Rat Rig V-Core 3.1 is a premium printer and a dream machine for those who want to customize their machine precisely to their needs.

- Amazing variety of customization options

- Large build volume (depending on the frame)

- Active online community

- Good print quality

- Needs a Raspberry Pi, not included in the set

- Customizations can rack up the price

- Not very beginner-friendly

Check Latest Price

7. SecKit SK-Go³ (Best for Experienced Users)

3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU | Build Volume: 310 x 310 x 350 mm

SecKit SK-Go³ probably shouldn’t be your first printer — even the brand’s name stands for “second kit.” But it’s a fantastic machine to move on to once you’ve learned the ropes of 3D printing.

SK-Go³ has a decent print volume of 310 x 310 x 350mm. It won’t print the largest parts, but the size is adequate. The print bed is also supported by a rigid, sturdy all-metal frame, which gives the machine welcome longevity.

It won’t print the largest parts, but the size is adequate. The print bed is also supported by a rigid, sturdy all-metal frame, which gives the machine welcome longevity.

Where SK-Go³ truly shines is in print quality. It prints excellently detailed parts with little to no warping, stringing, or other quality issues. You can get the same high quality with almost any material — if you run into issues, it’ll likely be because of the material’s limitations.

Despite what you might expect, SK-Go³ is surprisingly affordable, particularly when you consider the printing quality. The final price varies somewhat based on the parts you choose, as the manufacturer offers some customization options (mostly a choice between a basic and premium component).

SecKit SK-Go³ brings to the table fantastic print quality and versatility, making it a perfect choice for your second 3D printer.

- Excellent print quality with practically any material

- Good value for the quality

- Small but happy community that the manufacturer actively talks to

- Decent customizability

- Very noisy

- Not for beginners

Check Latest Price

CoreXY 3D Printer Buyer’s Guide

Now that we’ve seen some of the best 3D printer models available, let’s dive into the primary features of a CoreXY machine. Before making a final decision, here is what you need to know.

Before making a final decision, here is what you need to know.

What are CoreXY 3D Printers?

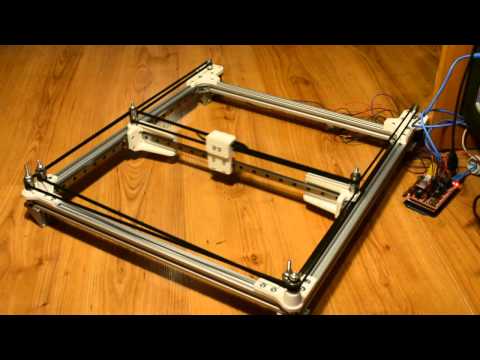

Source: Youtube Thomas SanladererThe name for these printers stems from the fact that the head only moves on the X and Y axes. To create a 3D structure, the base moves along the Z-axis. This design offers some significant benefits, namely speed, and precision.

These machines typically have a square enclosure to allow freedom of movement, and the base has to be able to move freely up and down. Higher-end models will have glass sides to trap fumes and act as a safety barrier.

Another hallmark of a CoreXY printer is that it uses the FDM printing method, which utilizes thermoplastic filament to create structures. Other techniques include stereolithography (SLA), digital light processing (DLP), and selective laser sintering (SLS). Overall, FDM is relatively easy to master and can deliver durable products quickly and reliably.

Source: Youtube David AldrichAdvantages of CoreXY 3D Printers

Here are some primary reasons to purchase a CoreXY 3D printer:

- Speed – Because the printing head doesn’t move in all three axes, it can print faster and smoother than other models.

- Longevity – Another benefit of moving on two axes is that the machine requires fewer parts. These printers are relatively low-maintenance.

- Cost – While you have to pay for more filament, these machines’ upfront costs are far lower than other high-end models.

- Small, Precision Printing – If you aren’t trying to build large objects, CoreXY printers are ideal for smaller pieces. You can also scale down your designs to get more precise details.

Disadvantages of CoreXY 3D Printers

Here are some potential reasons to avoid CoreXY printers.

- Belt Maintenance – Although these machines have fewer parts, the ones they do require care and upkeep. If the belts aren’t aligned correctly, they can yield disastrous results.

- Vibrations – Since the pad moves, it can cause the machine to wobble and vibrate slightly. When this happens, you can spot small imperfections in your finished pieces.

- Complex Setup – You can buy pre-assembled CoreXY printers, but they tend to be more expensive.

Building one of these machines requires some know-how, so beginners may not like the process.

Building one of these machines requires some know-how, so beginners may not like the process.

Do These Printers Provide High-Quality Prints?

Although these machines don’t provide as much precision as other models, they can deliver excellent results.

Are These Printers More Expensive Than Other Models or Brands?

On average, CoreXY printers will be in the middle of the pack, but some units are much more affordable.

Is Assembling a CoreXY Printer Difficult?

These printers are harder to assemble than others, such as Cartesian printers. Part of the challenge is getting the belts in the right position.

Are These Printers Easy to Use?

Yes, once they are assembled, you can utilize the touchscreen to create vibrant finished pieces. However, some specific models can be tricky to master, particularly when it comes to leveling.

Final Verdict

We’ve shown many high-quality CoreXY 3D printers on this list, but our top two are the X5SA Pro and the Voron 2. 4 R2. If you want something easy to use and reliable, the X5SA is an excellent choice. It has a substantial build surface, so you can create larger masterpieces than you would be able to on other models. We also like that it has durable parts that will last for a long time.

4 R2. If you want something easy to use and reliable, the X5SA is an excellent choice. It has a substantial build surface, so you can create larger masterpieces than you would be able to on other models. We also like that it has durable parts that will last for a long time.

If this isn’t your first rodeo and you’re more serious about 3D printing, the Voron is unmatched. While it is far pricier than the X5SA, you get what you pay for. We like the customization options of the Voron, as well as the ruggedness of the build.

Related Articles:

- Best 3D Printer for Multiple Colors

- Best 3D Printer for Resin

- Best 3D Printer for Wax

Kinematics of 3D printers: what are the best types

Kinematics of 3D printers - which device to choose?

The print quality of a 3D printer and how it works depends on several factors. One of the important indicators is kinematics. This article discusses its main types and their features.

This article discusses its main types and their features.

- What is the kinematics of 3D printers?

- Kinds and types of kinematics

What is the kinematics of 3D printers?

Each 3D printer has its own kinematics. Models are equipped with a platform and an extruder. These parts move in a certain direction relative to each other. Kinematics in such a device means the scheme along which the extruder and platform move.

Types and types

There are five types of 3D printer kinematics. The principle of operation of the device and the method of processing the workpiece depend on their features.

Cartesian 3D printers

The most common are 3D printers with Cartesian kinematics. They are based on the Cartesian coordinate system, they work in the X, Y and Z axes. They set the coordinates by which the print head changes position relative to the platform. The printhead has limitations in terms of movement in three axes.

- The extruder moves up when the platform moves in the horizontal X or Y axis.

- The platform moves up in the Z axis, the extruder can move in the horizontal directions at this moment.

- The platform moves along one of the axes in height, the extruder rises along the other axis.

- The platform is static and does not move, the extruder moves in all three axes.

- The extruder moves along the coordinates in height, and the platform moves along the X and Y axes.

The most common options during operation are the first and second.

Cartesian kinematics has a number of advantages.

- This is a simple motion pattern suitable for hobby printing. Many budget models work on its basis.

- The printer can be produced in any dimensions, if necessary, it is upgraded.

- Consumables are freely available. Users are offered a large number of materials and colors.

- The printers can be shipped unassembled.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism. - Devices based on the Cartesian system, suitable for mass production of parts. They are designed to create blanks of different sizes.

Among the shortcomings of printers built on the principle of three coordinate systems, there are two factors:

- models are bulky, after assembly they take up a lot of space on the desktop;

- The print speed is slow.

Cartesian kinematic printers suitable for hobby printing. They help beginners understand the process of work and learn how to create models.

Example of printing on a device with Cartesian kinematics.

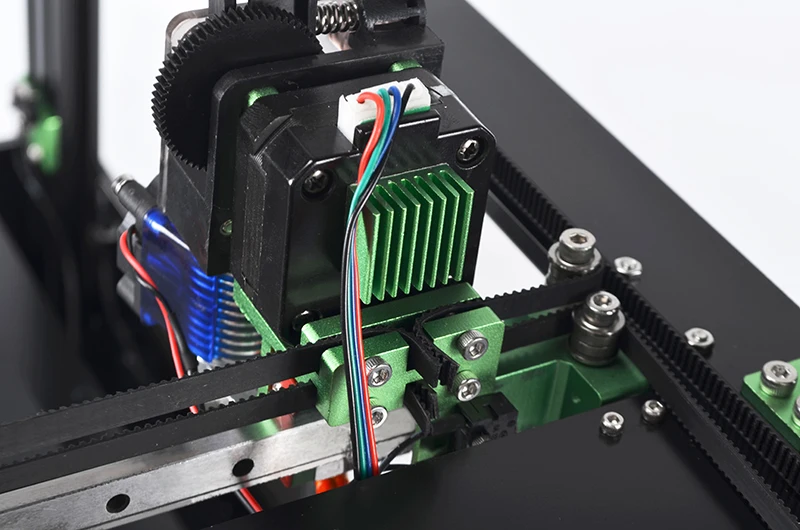

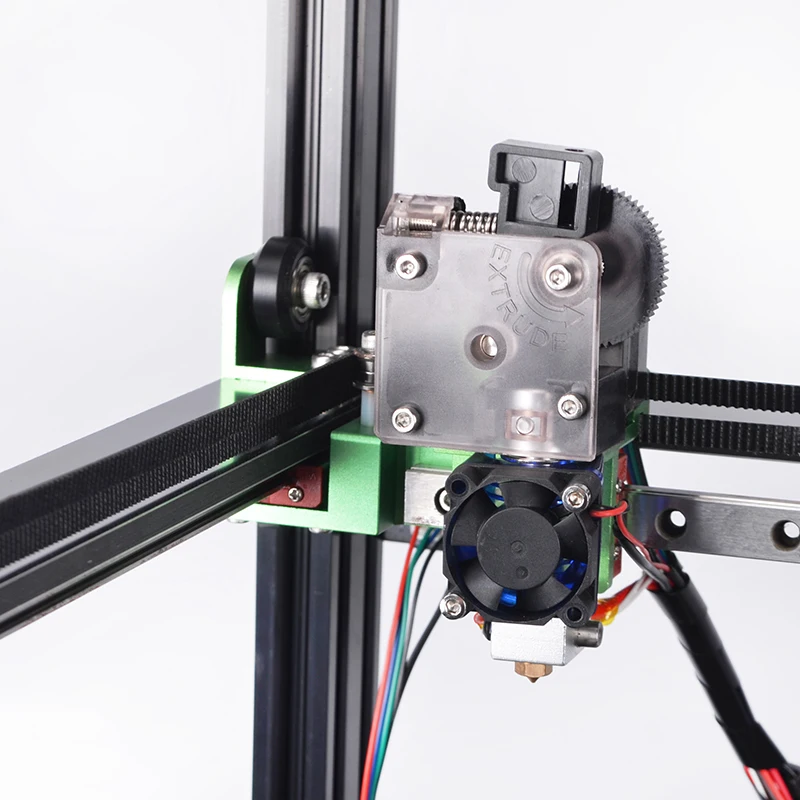

Varieties of Cartesian kinematics CoreXY and H-Bot

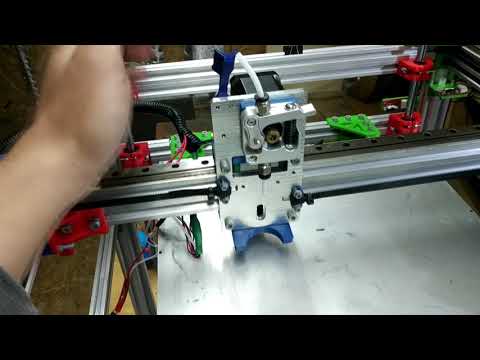

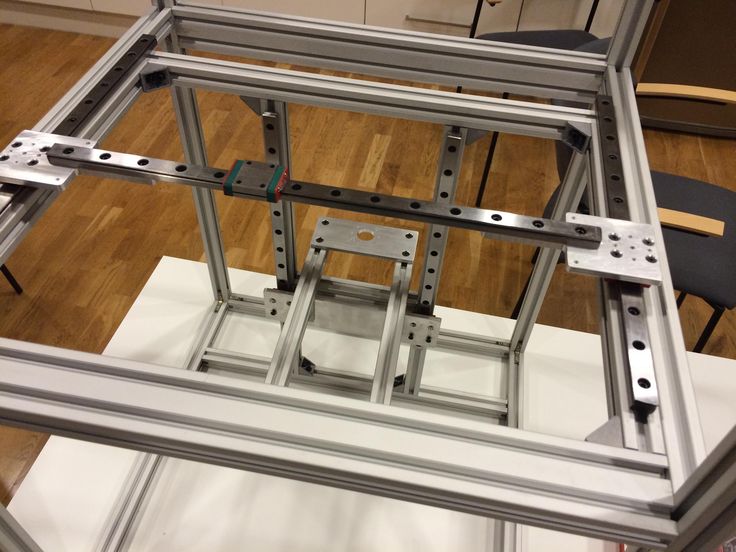

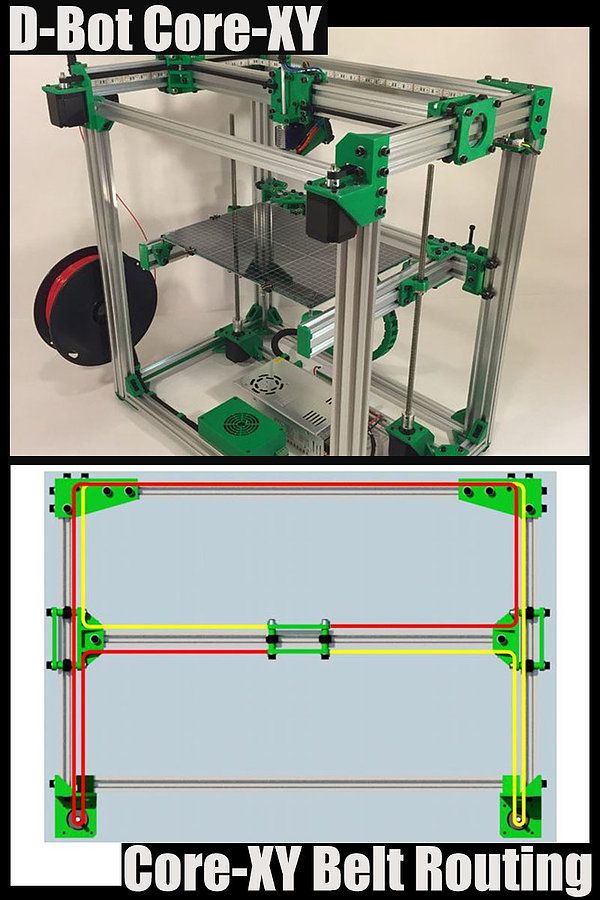

CoreXY has two feed belts, while H-Bot has only one, but it is long - this is the main difference between the two varieties. The common feature in these devices based on Cartesian kinematics is that the platform moves only along the Z axis. The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

Two motors are responsible for the movement along the horizontal axes, one motor along the vertical ones. Such kinematics is common not only in amateur printers, but also in professional ones.

CoreXY and H-Bot based 3D printers are more expensive than conventional Cartesian models. For the production of their cases, a metal alloy or composite materials are used. Rail guides unleash the potential of high-quality printing. This kinematics allows you to achieve good detail with fast printing.

The advantages of CoreXY and H-Bot are:

- high print speed;

- quality detailing of models;

- professional use grade.

But not without drawbacks:

- H-Bot is not implemented on steel shafts;

- the belt tension must be constantly monitored to avoid play;

- high cost of instruments;

- belts can wear out quickly if they rub against neighboring objects during operation, this factor must be taken into account during operation;

- the pulleys on which the belts move must be located strictly perpendicular to each other.

Cartesian kinematic printers are widely used in various industries. They are distinguished by high print detail, a durable metal case, and high-quality components.

Help! Cartesian kinematics allows you to create detailed objects at high speed.

Delta Printers

Delta kinematic printers differ from their competitors in a number of ways. The table remains stationary, and three fixed axes are used to move the print head at once. In such devices, there is no division into the X, Y and Z axis. To move the carriage sideways, you need to lower one axis, and raise the rest.

Help! In the production of 3D printers, the Delta kinematics has not yet found wide distribution. This is a promising direction, which is currently being developed by developers.

Already existing delta printers offer the following advantages.

- Small dimensions.

Devices do not take up much space on the desktop, they are tall, but not wide.

Devices do not take up much space on the desktop, they are tall, but not wide. - High print speed. Models can process 300–400 mm/s.

- A new approach to blank production. The equipment does not print using the same technology as Cartesian. It is interesting to watch the process of processing the model.

Deltas also have a few disadvantages.

- Calibration complexity. A lens is formed on the printed surface, due to which it is impossible to fully calibrate the printing process. This is the main factor slowing down the mass introduction of kinematics.

- Poor accuracy. High print speeds sacrifice accuracy. All axes perform small movements, errors occur.

- Computing power requirement. Deltas are equipped with 32-bit boards, which is why they do not support interaction with 8-bit systems.

- The frame must be rigid. This is necessary to avoid backlash, deviations and distortions.

- Not all extruders will fit. Deltas have weight restrictions, so direct type extruders are not allowed.

Printing accuracy remains high.

On deltas, you can build high-quality vertical models, even with large dimensions. There are no protruding parts on the body, which allows you to independently increase its rigidity.

Polar

The polar kinematic scheme is presented only by one company - Polar. The essence of this technology lies in the fact that it does not have positioning along the X, Y and Z axes. The position of the extruder is set by the angle and radius. The platform of polar 3D printers is round in shape, it moves only along the horizontal axis and only rotates in a circle. The extruder moves up and down.

The advantages of 3D printers based on polar kinematics are:

- the ability to create large objects;

- high energy efficiency;

- material savings;

- small dimensions.

But there are also disadvantages:

- low printing accuracy, which was started by Polar representatives;

- platform does not warm up during operation;

- material handling restrictions - ABS plastic cannot be processed.

Polar printers are less accurate than Cartesian and Delta printers. The manufacturer recommends using such models for educational purposes; they are not yet suitable for professional printing.

Printing example shows that accuracy cannot be achieved. All features are blurred, the figure lacks sharpness and clarity.

With robotic arms

Printers with robotic arms are a design with a mechanically programmable extruder gripper arm. This is a multifunctional robot: it can carry out welding, painting, milling, etc.

The extruder can move in different directions: in layers, along complex paths in three dimensions, at different angles. Thanks to this set of functions, it is possible to create complex designs.

The main advantages are:

- versatility: the device can perform several types of tasks when replacing the extruder;

- are suitable for industrial applications: you can print large objects with almost no size restrictions.

But there are also disadvantages:

- low accuracy: such equipment is inferior to Cartesian kinematics;

- large size: devices take up a lot of work surface space.

These models are not suitable for professional 3D printing. They can be considered as an object for a hobby or a tool for it. For industrial purposes, such devices work only when high precision in the execution of parts is unimportant.

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics based on horizontal rotation of the platform. The movement is achieved by the articulation of the linkage mechanism.

These instruments are highly accurate and repeatable, and operate with a minimum of noise and vibration. SCARA also surpassed the Cartesian models in terms of processing detail: the difference is that the former work noticeably faster.

Advantages of such kinematics:

- print accuracy;

- high workpiece processing speed;

- small dimensions and weight.

But there are also disadvantages:

- stiffness restrictions in the area of the X and Y axes;

- high cost;

- is not the widest area of use.

SCARA kinematic devices are devices that combine the functions of a 3D printer and a manipulator. Device actions are programmed through software or an installed mobile application.

The choice of kinematics for 3D printers depends on the requirements for technology and application.

- Cartesian models remain the most common. They combine high accuracy, good speed, small dimensions. They can be used for amateur 3D printing. They work in a Cartesian coordinate system, the platform and the extruder move along the X, Y, Z axes.

- CoreXY and H-Bot are varieties of Cartesian kinematics. They are highly detailed blanks, suitable for professional use. Their disadvantage is the complexity in the process of operation. The user must constantly ensure that the belts do not come into contact with foreign objects and are well tensioned.

- Delta printers are uncommon models whose weak point is print accuracy. In the process of working with the device, there are problems with calibration, as well as with the choice of extruder.

- Polar printers are produced by only one company - Polar. These devices cannot provide high accuracy of the workpiece, so they are used only for educational purposes. During operation, the platform does not warm up, which limits the choice of materials.

- Robotic 3D printers are versatile devices that are used for more than just model making. Such devices can mill, weld, paint. The technique is inferior in accuracy to the Cartesian varieties.

- SCARA is one of the modern kinematics, which can not be used in all areas. It features high precision and good printing speed, it can be used as a professional instrument. The main disadvantage of SCARA is its high price.

- February 17, 2020

- 9794

Get expert advice

3D printers with different kinematics: comparison, pros and cons

Author: Vasily Kiselev, owner and managing director of Top 3D Group

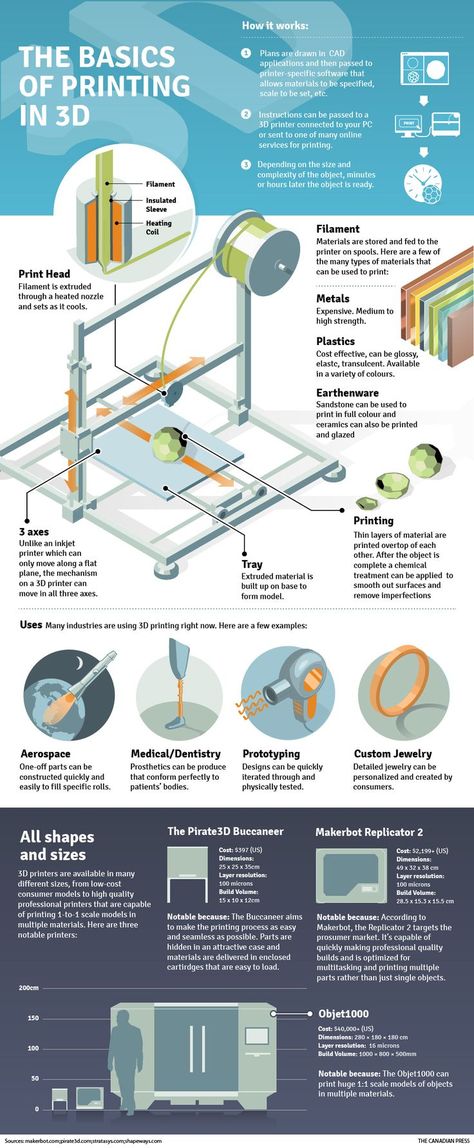

There are many printing technologies for 3D printers: digital LED projection (DLP), laser stereolithography (SLA), selective laser sintering (SLS) , thermal sintering (SHS), etc. In this article, we talk about the features of FFF technology, about the printers that use it, and about its strengths and weaknesses.

In this article, we talk about the features of FFF technology, about the printers that use it, and about its strengths and weaknesses.

Introduction

FFF (Fused Filament Fabrication) printers, also known as FDM (Fused Deposition Modeling) printers. They are devices for creating three-dimensional objects, as the name implies, by layer-by-layer application of molten thermoplastic to the working surface. FFF printers are used for both commercial and home model printing.

Types of kinematics of 3D printers

Each 3D printer has its own kinematic scheme, according to which the mechanical parts of the device are set in motion: platforms and extruders. Below we will look at four types of FDM 3D printer: Cartesian, Delta, Polar, and Robotic Arm.

In the FFF / FDM 3D printer market, Cartesian kinematic devices are the most common. Based on the Cartesian coordinate system, this technology works on the basis of three axes - X, Y, Z. The movement of the mechanical parts of the device is carried out along one or more of them, i.e., the coordinates specified along the axes implement the pattern of movement and position of the print head relative to the platform .

Based on the Cartesian coordinate system, this technology works on the basis of three axes - X, Y, Z. The movement of the mechanical parts of the device is carried out along one or more of them, i.e., the coordinates specified along the axes implement the pattern of movement and position of the print head relative to the platform .

The number of options for moving the print head and platform is limited:

-

The platform moves along one of the horizontal axes - X or Y, the extruder moves along the other and in height.

-

The platform moves in height, along the Z axis, and the extruder moves in two planes, forward-backward and left-right.

-

The platform moves along one of the axes and in height, the extruder - along the other axis.

-

The platform is stationary, the extruder moves in all three axes.

-

Platform moves in XY direction, extruder moves in height.

The second scheme is the most common - when the platform for printing moves along the Z axis (up and down), and the extruder works in two dimensions, along the XY planes.

Advantages of Cartesian

Of all the types of FDM 3D printer kinematics, Cartesian ones show almost perfect results stability. FDM consumables are low cost and come in the widest range of colors and materials. Often, Cartesian 3D printers are used for commercial purposes - for printing on order and for the sale of household objects, souvenirs and jewelry.

Cartesian 3D printers have long and firmly established themselves in the lives of hobbyists and professionals of 3D printing. Therefore, there are many thematic communities on the network with comprehensive information about the design of printers, working with them and creating models, from simple to complex.

Cartesian models can be decomposed for printing, which allows you to create 3D printed objects of any size, not limited by the volume of the printer. Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

Varieties of CoreXY and H-Bot Cartesian kinematics

These kinematic diagrams are often found in commercial applications. Differ in original methods of positioning of an extruder. In both kinematics, the platform moves up and down.

Source : smoothieware.org

H-Bot 3D printer kinematics are based on similar mechanics, but with a different belt drive. In this case, there is only one belt and it is stretched in a shape resembling the letter H (ash) circled around the contour, for which the scheme was called ash-bot.

Source : smoothieware. org .

org .

One example of such 3D printers is the Designer X PRO. This model is fast because thanks to the JetSwitch function, printing with 2 materials has become even faster (up to 5 seconds in normal mode and 250 ms in draft mode). And the newly designed print head with 1 micron accuracy, frame structure, precision mechanics and next-generation hardware platform will allow you to print high-quality models comparable to industrial products. Possesses function of the two-material press. The software has full control over the process, which minimizes errors and increases the productivity of the 3D printer.

Print example:

Delta printers Delta printers both externally and in the way of implementing the mechanics differ from Cartesian ones. The main difference lies in the way the extruder moves relative to the desktop. Delta kinematics, compared to Cartesian models, has a higher print speed, but less accuracy at the edges of the model. Other benefits: Small size. The design is high, but in length and width does not take up much space. No protruding parts. You can independently increase the rigidity of the frame and close the case. Possibility to build high vertical models. High price category. Difficult to self-assemble. It will be difficult for beginners to assemble the structure accurately enough, so it is recommended to use ready-made solutions that come assembled. The specifics of working with polar coordinates: less common software and more expensive electronics, because higher requirements for the processing power of the filling. One example of such a 3D printer is the Tevo Little monster. It is mainly used for commercial activities, design, advertising and educational purposes, and is also used as a home 3D printer. Differs in the high speed of the press and small dimensions. Works with many materials: PLA, ABS, Flexible PLA, HIPS, WOOD, PVA, Nylon. Print example: Source : https://twitter.com/ A rather new but interesting polar kinematic scheme is introduced to the market by the company of the same name Polar. As the name implies, printing uses a polar coordinate system - instead of the usual XYZ, the positioning of the extruder is set by radius and angle. Source : http://www.purdue3dpc.org The platform of such 3D printers is round, rotates in a circle and moves entirely along one horizontal axis, while the extruder moves only up and down. Polar 3D printers allow you to create large objects while saving money through high energy efficiency. They still have low accuracy, but in the long run, perhaps the manufacturer will be able to solve this problem. Source : https://about.polar3d.com/ These 3D printers include the Polar 3D model. In this 3D printer, there is no heating of the print bed, which makes it difficult to use ABS. It has modest dimensions, good performance, but low accuracy compared to delta printers and models with a Cartesian coordinate system. The manufacturer recommends purchasing a model for educational purposes. Print example: 3D printers with robotic arms This is a design with a mechanical programmable gripper with a replaceable extruder. If we are talking about large industrial specimens (and there are also more compact ones), then, in addition to the functions of a manipulator and a 3D printer, such a robot can perform welding, milling, painting and other operations. Source : http://www.dubox.me/ Although the mechanics of 3D printing with a robotic arm is mainly used in industry, there are models for individual use, with a wide range of functions. Dobot Magician Educational Robot Arm has many functions. It can draw, write, grab and move objects, perform laser engraving, etc. Work example: SCARA SCARA (Selective Compliance Articulated Robot Arm) - kinematics based on the movement of the working unit in a horizontal plane due to rotation in the joints of the lever mechanism. The devices built on this scheme are distinguished by very high accuracy and repeatability, much higher than that of traditional robotic arms, low noise and vibration levels, and compactness. If we talk about Cartesian and SCARA robots of comparable size and mass, then scara is usually not only more accurate, but also faster. At the same time, these devices are expensive, have limited rigidity in the XY axes, a smaller area of work and freedom of movement. An example of such kinematics is the Dobot M1 robotic arm. This is a compact desktop robot that combines the functions of a 3D printer and a manipulator. Actions are programmed through the software installed on the computer or a mobile application. It has interchangeable heads for printing, engraving, soldering and assembling. Working example: Source : https://thegadgetflow. The advantages of 3D printers with a robotic arm are obvious - such a printer is not limited by the volume of the working chamber, which it does not have - with the same print area, the device itself takes up much less space. Source : https://spectrum.ieee.org/ The extruder can move not only in layers, as in desktop printers, but also along complex paths in three dimensions, and at different angles, which facilitates the process of creating complex designs. A definite plus is also the fact that these are usually universal designs, when replacing the extruder with other blocks, they perform many tasks. In terms of printing accuracy, manipulators will not compete with Cartesian 3D printers, but due to their versatility and large size, industrial robots are actively used in 3D printing in industrial environments, where they are almost indispensable. Miniature desktop robots are good primarily as a visual aid, as well as a hobby object or a tool for it. When choosing a device before buying, first of all, decide on the goal - why do you need a 3D printer? Business, work or play? The versatility of FFF/FDM 3D printers is that they are suitable for different applications. Whether you want to learn 3D printing and acquire a new hobby, live out your creative fantasies or start a business, there is a suitable machine for each of these goals, you just need to choose. You can purchase a suitable device and consumables at https://top3dshop.ru, a retail division of Top 3D Group, a leading integrator of additive equipment in Russia. And also on the site: https://top3dshop.com, if you do not live in the CIS countries. List of sources used: What are the advantages of the FDM technology? - Professional 3D Printers // [Electronic resource]: dddrop. Application of FDM three-dimensional printing technology in the digital manufacture of custom edentulous mandible trays // [Electronic resource] : Scientific Reports - Electron. Dan. – nature.com – Access mode: https://www.nature.com/articles/srep19207 (Accessed: 08/03/2019). Reconstruction and Development of a 3D Printer Using FDM Technology // [Electronic resource] : Procedia Engineering - Electron. Dan. – sciencedirect.com – Access mode: https://www.sciencedirect.com/science/article/pii/S1877705816311651 (Accessed: 08/03/2019). Catalog // [Electronic resource] : 3D Printers - Electron. Dan. – top3dshop.com – Access mode: https://top3dshop.com/3d-printers/ (Accessed: 08/03/2019).

Advantages and disadvantages of delta bots  The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates.

The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates.

Polar 3D printers  Imagine a turntable - the printer's printhead works like a pickup stylus moving across a record. The only difference is that here the “plate” not only rotates, but the “needle”, on the contrary, is limited in movement.

Imagine a turntable - the printer's printhead works like a pickup stylus moving across a record. The only difference is that here the “plate” not only rotates, but the “needle”, on the contrary, is limited in movement.

Pros and cons of polar mechanics

com/

com/

Analysis of robotic kinematic schemes

Conclusion

com - Electron. Dan. – dddrop.com – Access mode: https://www.dddrop.com/fdm-technology/ (date of access: 08/03/2019).

com - Electron. Dan. – dddrop.com – Access mode: https://www.dddrop.com/fdm-technology/ (date of access: 08/03/2019).

Learn more