Robo 3d print speed

Robo R1+ Print Speed - 3D Printing - Talk Manufacturing

JoshMcCullough

#1

I was curious what print speed people are reaching, while maintaining reasonable quality, with the Robo R1+. I just got mine a week ago and am currently printing at 120mm/s with little to no quality issues. The review here on 3D Hubs indicates that this printer’s print speed is 50mm/s – I’m curious why they chose this number.

Any way, what is the maximum safe speed that this hardware is capable of printing at before something catches on fire or breaks, or the quality shows significant issues?

3 Likes

3DPrintingBeast

#2

I like to print at 50mm which is safe. 100 mm is the max.

3DNG

#3

For easier, no feature or surface rich objects I can go with 80 mm/s making the appropriate heat adjustments. For more intricate, small or otherwise tricky parts I go as low as 30 mm/s. It all depends on what you are doing and how you plan to do it. Not all parts should be printed the same, for the sake of the desired results in the overall project. I use Simplify3D, allows me to do different speeds/settings at different stages of the print which really comes in handy and can slash printing times by 1/3 on extreme cases. But that’s just my experience. Happy printing!

Infinite3Ds

#4

60mm/s is our Robo’s sweet spot. We usually never go past 80mm/s unless we run a speed test.

We usually never go past 80mm/s unless we run a speed test.

milks

#5

65mm/s for me - it’s worth noting that quality issues at higher speeds might only surface under certain circumstances, e.g. when printing something tall and thin. The bed moving in the Y axis is one reason it’s not great for high speeds.

JoshMcCullough

#6

I’ve been running 140mm/s and the results have not convinced me to go any slower. But I’ve been printing track pieces for the most part, which are pretty straight-forward prints.

Robo 3D R2 High Performance Smart 3D Printer

Sorry, this product is currently unavailable

Perhaps some of these categories are of interest:

- 3D Printer Accessories

- 3D Printer Filament

- 3D Printer Resins

- 3D Printers

- CNC Machines

- Clearance

- Sale

- Digital Designs

- Education & Curriculum

- Laser Cutters & Engravers

- Sale

- Refurbished Machines

- Software and Add-ons

- Home

- Store

- Robo 3D R2 High Performance Smart 3D Printer

The Robo3D R2 high-performance 3D printer is all about making 3D printing easy and convenient. With features like auto bed leveling, a built-in camera, and onboard slicing, the Robo R2 is ready to bring your large-scale projects to life today. The R2 has a fantastic form factor and boasts a massive build volume of 8 x 8 x 10 inches. The R2 is controllable via an onboard 5" touchscreen or remotely using Robo app, this 3D printer is easy to incorporate into your existing workshop or office.

With features like auto bed leveling, a built-in camera, and onboard slicing, the Robo R2 is ready to bring your large-scale projects to life today. The R2 has a fantastic form factor and boasts a massive build volume of 8 x 8 x 10 inches. The R2 is controllable via an onboard 5" touchscreen or remotely using Robo app, this 3D printer is easy to incorporate into your existing workshop or office.

Remove from wishlist Add to wishlist loading...

Product No. M-KK5-CNCE

| List Price: | $1,499.00 |

|---|---|

Disclaimer: This product is no longer supported by the manufacturer.

Feature Rich with a Large Build Area (8 x 8 x 10in)

The Robo R2 combines all the features you want in a 3D printer like automatic bed leveling, WiFi connectivity, and a large build area for more options in what you can 3D print. A built-in 5" touchscreen allows you to adjust settings directly on the printer and monitor your prints as they work. The Robo R2 features an efficient, modern design that will look great in your home or office, which makes bringing 3D printing into your workflow easy.

The Robo R2 features an efficient, modern design that will look great in your home or office, which makes bringing 3D printing into your workflow easy.

Filament run-out detection saves your prints

Never lose a print due to running out of filament ever again; the Robo R2 monitors the filament feeding into the machine and automatically pauses if it runs out. It also alerts you to this condition so you can get your R2 back up and running to finish your project. Printers without this technology don't know when the filament spool runs out, so they will continue printing and risk your part failing.

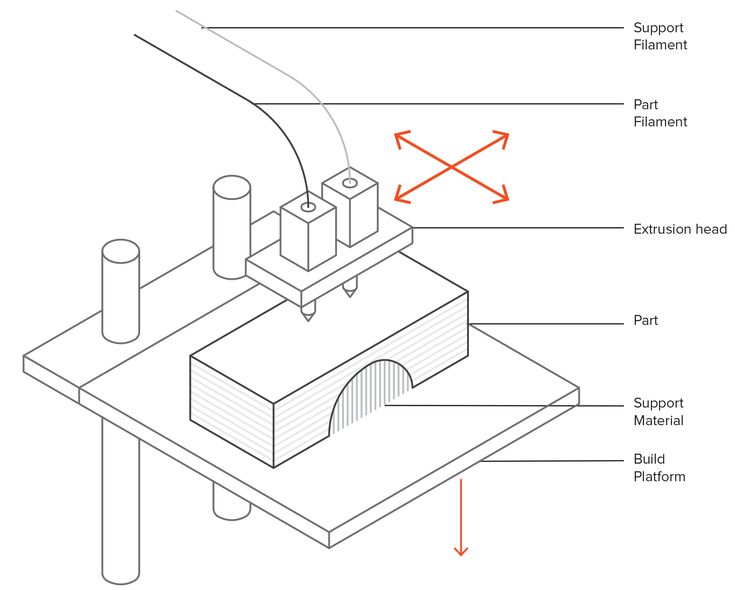

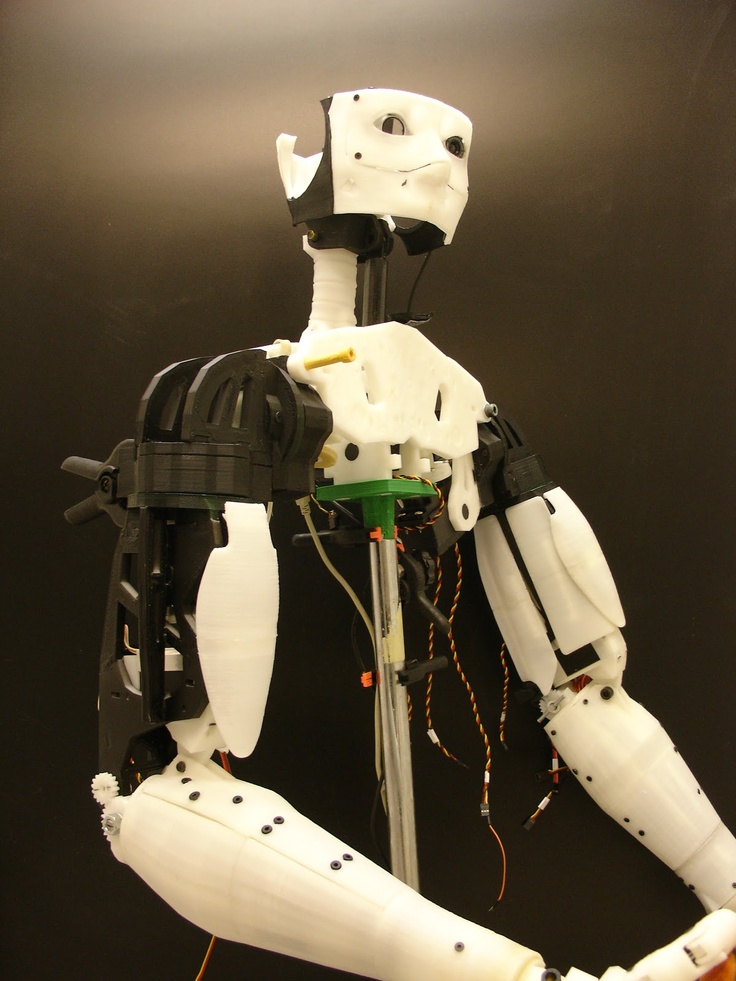

Upgrade to dual extrusion

The Robo R2 comes standard with a single extrusion head, but is upgradeable to include a second nozzle for dual-material 3D printing. Create multi-color prints or create detailed models with water-soluble PVA supports that dissolve away after printing.

Heated print bed

The Robo R2 includes a heated print bed, opening up even more material options. Print with materials like ABS, Nylon, or PETG in addition to materials like PLA that don't require a heated build plate. The print bed being heated doesn't change the fact that it easily comes out of the machine after a print is finished for easy part removal or changing of the surface sheet.

Print with materials like ABS, Nylon, or PETG in addition to materials like PLA that don't require a heated build plate. The print bed being heated doesn't change the fact that it easily comes out of the machine after a print is finished for easy part removal or changing of the surface sheet.

Monitor your prints remotely

The Robo R2 connects to the Robo app and allows you to not only control your printer remotely but also use the integrated camera to monitor your prints in real-time and see how things are going. Gone are the days of starting a print and hoping everything goes well while you are away, the Robo R2 keeps you informed on the status of your project and lets you stay in command even from out of the office.

What's in the box?

- Robo R2 printer

- Power cable

- Spool of filament

- Quick start guide

- USB with 3D models

- 1-year Autodesk Fusion 360

- Tool kit

- Print removal spatula

- Allen keys

- Tweezers

- Grease

Technical Specifications

- Print size (inches): 8” x 8” x 10”

- Print size (mm): 203.

2 x 203.2 x 254 mm

2 x 203.2 x 254 mm - Layer resolution: 20–300 microns

- Print plate leveling tech: Automatic Leveling Calibration

- Filament diameter: 1.75mm

- Print technology: Fused Filament Fabrication (FFF)

- Print speed: Up to 16 mm3/s

- Travel speed: Up to 250 mm/s

- Print head: Quick Change Nozzle

- XYZ accuracy: 12.5, 12.5, 5 microns

- Nozzle diameter: 0.4mm

- File transfer: USB, WiFi

- Size (w x h x d): 16.75" X 16.5" X 23.75"

- Weight: 25.5 lbs

with what resolution 3D printers are printed

threaded parts of the printed parts

6 safe ways to remove 3D scribes

9000 3D-spent at home gives us the opportunity to give us the opportunity to produce given objects at a very low cost. However, the time it takes to turn a 3D model into a physical object is not as short as one might think. The size and quality of the print has a decisive influence on the speed of printing, and it can take many hours to get the final result. In fact, various tests show that printer speed has a much smaller effect on print time than size and quality settings.

In fact, various tests show that printer speed has a much smaller effect on print time than size and quality settings. Desktop printers

3D print speed settings

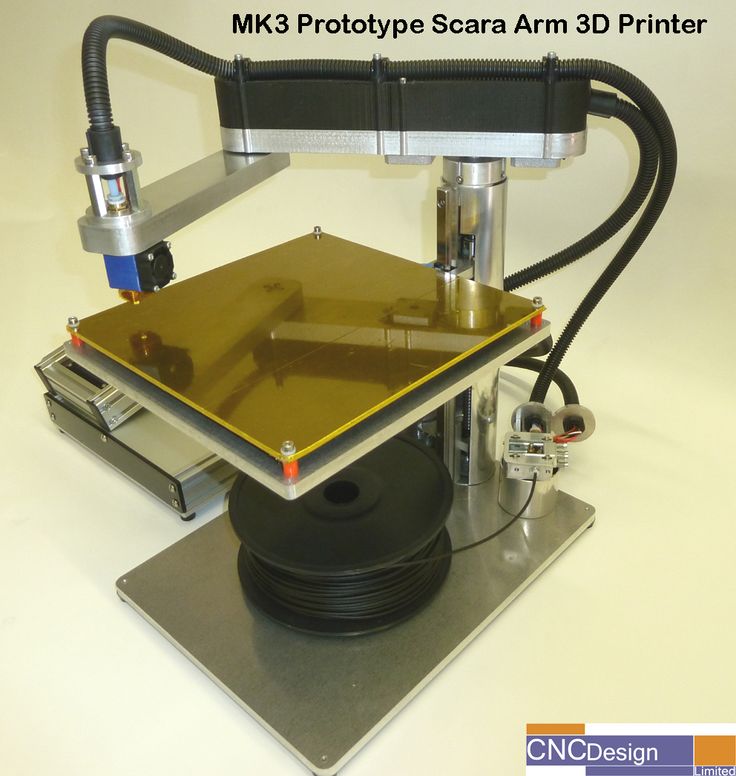

In general, there are currently three blocks of speed settings supported by 3D printers. The first block includes speeds from about 40 to 50 mm / s, the second - 80-100 mm / s, the fastest printing is carried out at about 150 mm / s. Some printers can even print at speeds over 150mm/s.

Usually, though, faster 3D printing means lower quality. At speeds above 150 mm/s, the quality drops significantly, and problems can arise, since the filament is prone to slip at such speeds.

How to set the print speed

Typically, the 3D print speed is set in the slicer software used to prepare the 3D model for printing. In Cura, for example, you just need to enter the desired print speed in the Print speed field in the Basic tab (in previous versions, you first had to switch to the Advanced mode and open the Speed tab).

Cura calculates the duration of the print process based on print speed and quality settings.

As soon as the print speed ( Print speed ) or other setting is changed, Cura recalculates the print time and displays it (see arrow). Cura's calculations turn out to be very close to real-time printing.

How long does 3D printing take in practice?

To find out how fast 3D printers actually print, two popular desktop printers, the Ultimaker 2 and the Wanhao Duplicator 6, were tested on two more or less complex objects.

These two models were printed:

3DBenchy. This 3D model is designed to test and measure the speed of 3D printers; it is quite complex and requires attention. The boat is 6 cm long, 4.8 cm high and 3.1 cm wide. Here you can get the 3DBenchy STL file for testing for free.

3DBenchy's 3D printing speed is relatively slow, the model is quite difficult to print (Photo: 3DBenchy. com).

com).

Universal tablet stand (up to 1.2 cm thick). The stand is 14 cm long, 4.2 cm high and 9.8 cm wide. The STL file is available for free on Thingiverse.

The stand is quite large and difficult to print (Photo: Thingiverse).

These objects were printed at two speeds, 100 mm/s and 50 mm/s, at similar settings. Here are the results:

Printer

Model

50 mm/sec

100 mm/sec

Ultimaker 2

3DBENCHY

h 09 min 9 min.0003

1 h 55 min

Wanhao Duplicator 6

3dbenchy

2 h 13 min

1 h 51 min

Ultimaker 2

Stand

9000 H 23 min4 h 36 min 9000 min

Wanhao duplicator 6

Stand

6hrs 27mins

4hrs 45mins

- For the smaller models, the difference between slow and fast printing is not particularly striking: almost 2.25 hours versus less than 2 hours.

Unless you're insanely short on time, choose a slower speed for better print quality.

Unless you're insanely short on time, choose a slower speed for better print quality. - For large models, the print speed varies more significantly: 6.5 hours versus 4.75 hours.

Cunning. If you don't have your own 3D printer, download the free Cura software from the Ultimaker website. Cura has profiles for most desktop printers (FDM), so you can check how long it takes to print a specific 3D model on a particular device - just import the STL file and play with Cura settings. To try another 3D printer, select Machine > Add new machine.

Does high-speed sintering promise the fastest 3D printing?

On an industrial scale, even more impressive prospects dawn on the horizon. The University of Sheffield has announced that its scientists have built a £1m-funded 3D printer that can produce plastic parts as quickly as traditional mass-production methods such as injection molding.

The process is called high-speed sintering (HSS), which melts the polymer layer by layer (similar to the additive printing process), but instead of using lasers, HSS prints on a powder substrate with infrared-absorbing inks. After the layer is printed, it is exposed to infrared radiation, the ink-coated powder is heated, resulting in melting, while the non-irradiated powder remains cold.

A team led by Prof. Neil Hopkinson claims that their machine is capable of producing parts up to 1 m³, i.e. with a washing machine, which is three times more than existing printers can. The print speed is dependent on the size of the object, however, Hopkinson estimates that small components will be created at speeds of less than one second per part.

What use is this to us? The good news is that HSS technology has been licensed to industrial 3D printer manufacturers on a non-exclusive basis, and new machines are expected to hit the market in 2017. This means that in the near future we can expect the transition of this industrial technology to the "home" level.

This means that in the near future we can expect the transition of this industrial technology to the "home" level.

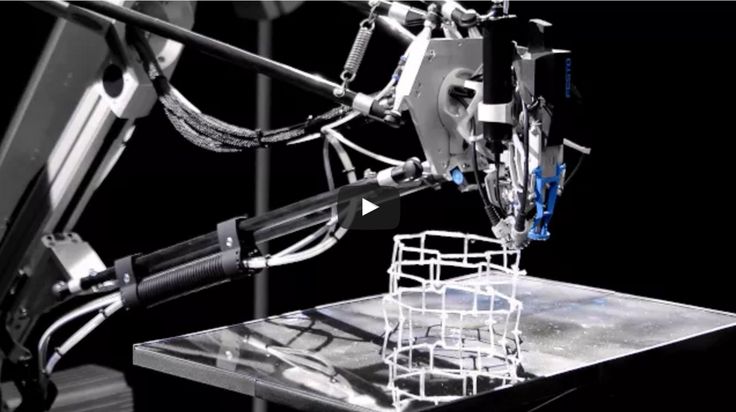

Carbon M2 3D Printers and Robots: High-Speed 3D Printing / Sudo Null IT News CLIP technology, a flushing station and a robotic arm to service the entire system. The system is designed for high-speed printing of finished parts in production, but can also print prototypes. We tell and show.

Video

Carbon Speedcell

- Print technology: CLIP DLS (proprietary form of photopolymer stereolithography)

- Construction area, mm: 189 x 118 x 326

- Accuracy (pixel size), µm: 75

- Purpose: production

- Interface: Wi-Fi, USB, Ethernet

- Print speed: dependent on media/settings; up to 25-100 times higher than other printing technologies

Application

The SpeedCell system is highly scalable and can be used for both prototyping and series production.

Device

At the heart of the SpeedCell system are Carbon M2 3D printers using Continuous Liquid Interface Production technology, or CLIP for short. The method of continuous printing in a liquid medium was patented in 2014 and today it is the fastest method of photopolymer printing, surpassing SLA and DLP in tens of times

Carbon M2, the company's second generation of printers, was introduced last year. Its displacement is twice the parameters of the debut model M1, while maintaining all other key characteristics.

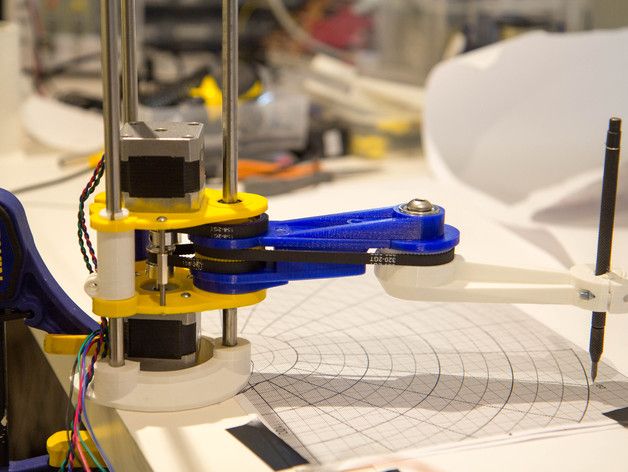

Robots

To speed up the work of such an "additive cell", Carbon suggests using a manipulator. Upon completion of printing on one of the 3D printers, the robotic arm removes the platform with the finished object, moves it to the washing station, and then installs a clean platform on the 3D printer.

Ultrafast printing machines and systems are becoming more accessible to manufacturing companies that want to move away from traditional methods of manufacturing parts or complement them with additive technologies.