Resin vs plastic 3d printer

Resin or filament 3D printing: Which is best for you?

Joker bust designed by Wekster (Image credit: Windows Central)Resin or filament 3D printing: Which is best for you?

Best answer: You'll want a filament (FDM) printer for printing large models such as cosplay accessories. Resin (SLA/DLP) printers are best for miniatures with extra detail like tabletop game pieces.

What is filament (FDM) printing?

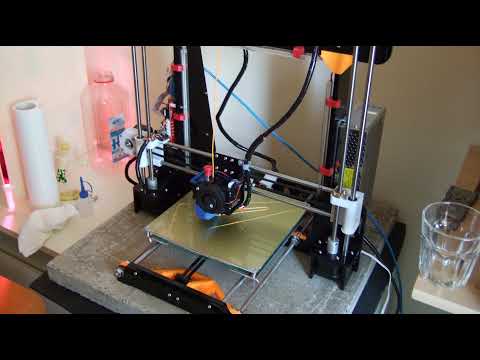

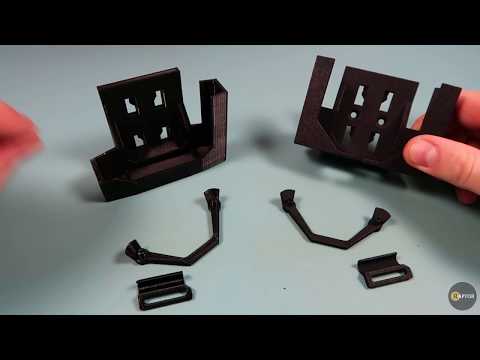

Fused deposition modeling (FDM) is the style of printing most people recognize. A string of plastic called a filament is melted through a hot end and deposited on the build plate, and the next layer is then placed on top of the previous layer.

FDM printing is used far and wide in modeling and producing larger parts like cosplay armor and helmets. The nature of the printing makes it very easy to set up and very easy to learn. Most maker spaces around the country use FDM printers as they are cheap and reliable, with plenty of options for 3D printing filament on a budget.

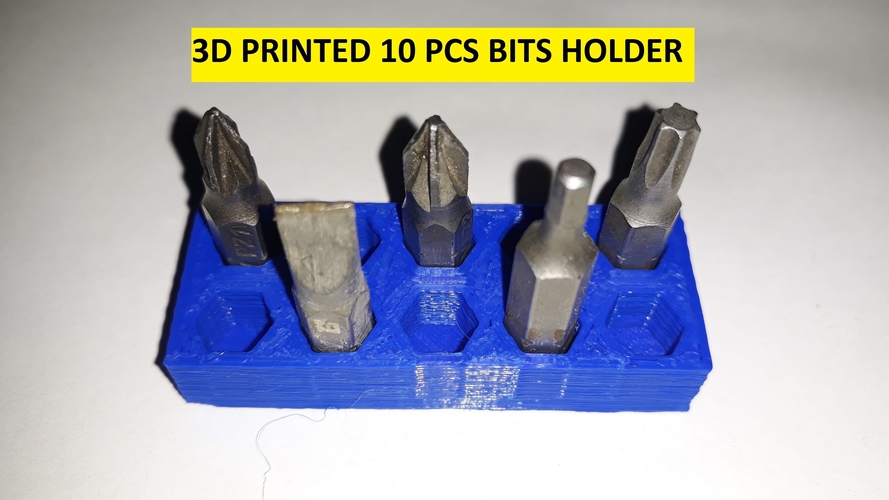

FDM printing is also very good at making practical prints. Many printers can print exotic materials like carbon fiber and nylons that are incredibly strong. These can be used to make strong models and moving parts.

When you want to make smaller models in finer detail, FDM printing can run aground. That isn't to say that a well-tuned FDM printer can't give you incredible detail; they can. If you look at the Joker model we used by Wekster, you can see that although the model isn't as smooth as the resin version, it still looks excellent.

What is resin (SLA/DLP) printing?

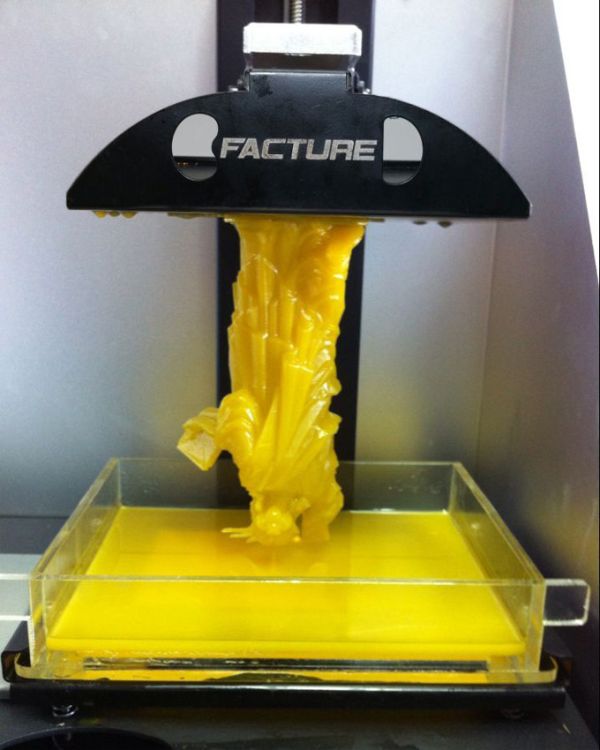

Stereolithography/digital light processing (SLA/DLP) printers are 3D printers that print using light to cure liquid resin into layers. The cheaper versions use an LCD to shine a UV image into the resin, which cures it into a solid layer. The print bed then rises slightly to let the next layer cure.

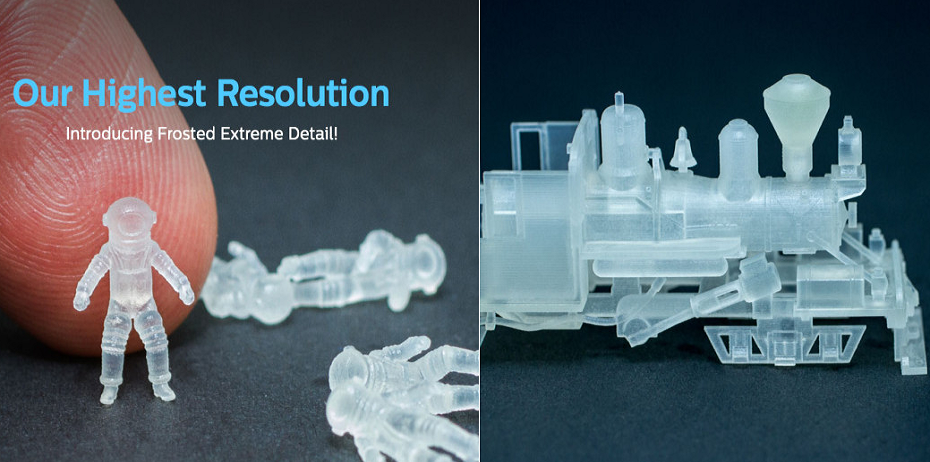

Resin allows you to print a model with fine details, far more than a standard FDM printer can produce, and the result tends to need far less post-processing work to give you a finished product.

The downside is that they tend to have smaller build plates than FDM printers, so you can't make large pieces on them. Resin also tends to be a little slower than filament as it needs to cure. You will also have to wash the model afterward to get the full effect.

There have been great strides to solve both these problems, though. You could buy the excellent Anycubic Wash and Cure V2 station and considerably speed up the curing process. There are also enormous options like the Peopoly Phenom resin 3D printer that will print your parts on a much larger scale, providing the best of both worlds.

Which should you buy?

To build large-scale models, cosplay items like armor and helmets, or produce prototypes rapidly, an FDM 3D printer is likely the right choice. It gives you the greatest range of options, often at a reasonable price. The Creality Ender 3 V2 is an affordable way to start filament printing and features a resume function, so you won't lose progress on a print if there's a power cut.

Creality Ender 3 V2

For a first-time FDM 3D printer, you won't break the bank with the Creality Ender 3 V2. Its features and print quality make it one of the best 3D printers you can buy on a budget.

If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then a resin (SLA/DLP) printer is best. The level of resolution that a resin printer can bring is extraordinary if you're willing to take a few extra steps to cure and clean your models. The Elegoo Mars has the right entry-level price for newcomers. The Mars is a revelation for anyone who has never used a resin printer before as it is so cheap and yet produces amazing prints every time.

Elegoo Mars Pro 2

The Elegoo Mars is impressive. For far less than you might think, you can have a resin printer that makes amazingly detailed models reliably.

Get the best of Windows Central in in your inbox, every day!

Contact me with news and offers from other Future brandsReceive email from us on behalf of our trusted partners or sponsorsBen is the channel editor for all things tech-related at Windows Central. That includes PCs, the components inside, and any accessory you can connect to a Windows desktop or Xbox console. Not restricted to one platform, he also has a keen interest in Valve's Steam Deck handheld and the Linux-based operating system inside. Fueling this career with coffee since 2021, you can usually find him behind one screen or another. Find him on Mastodon @[email protected] to ask questions or share opinions.

That includes PCs, the components inside, and any accessory you can connect to a Windows desktop or Xbox console. Not restricted to one platform, he also has a keen interest in Valve's Steam Deck handheld and the Linux-based operating system inside. Fueling this career with coffee since 2021, you can usually find him behind one screen or another. Find him on Mastodon @[email protected] to ask questions or share opinions.

Resin vs. Filament 3D Printers

If you are looking to buy a 3D printer for home use, there are two different technologies that you can choose from: Filament or Resin. You might be asking: is filament or resin better for 3D printing? The answer is: it depends what you will be using it for. Each technology is a different tool meant for a different job. In this article, we will look at the tradeoffs of both filament and resin 3D printers to give you a good idea of which type is right for you. Whether you are buying your first 3D printer or have significant experience in printing, both of these printing technologies have a lot to offer and one of them is likely to be the best choice for your application.

First, a very brief overview of how each of these technologies works:

Filament printers build parts by melting plastic and depositing it into many stacked flat slices, or layers, which together form a 3D part. Each layer is created by moving the nozzle in a specified path while it deposits melted plastic. Once the layer is completed, the nozzle is moved up, and the next layer is built on top of the last one, until a full 3D part is created. Filament printers are also referred to as FDM (Fused Deposition Modeling) or less commonly FFF (Fused Filament Fabrication) machines. These terms are interchangeable.

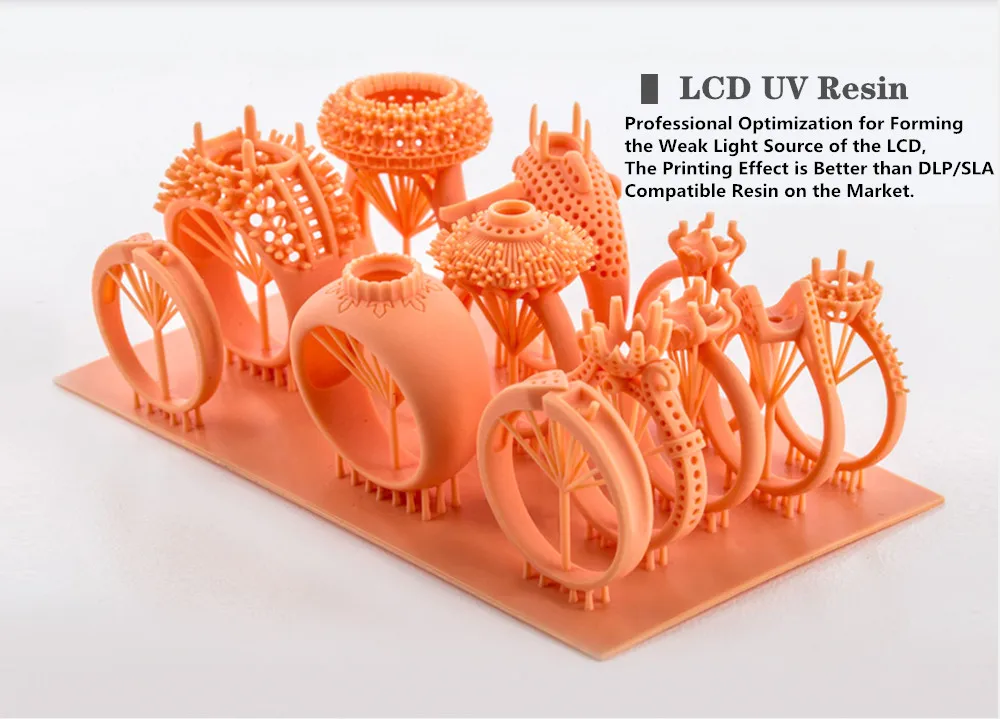

Resin printers form parts from liquid resin which cures, or solidifies, when it is exposed to UV light. Similar to Filament printers, resin printers build parts in layers, but do so by exposing each slice to a pattern of UV light to solidify the resin in the desired locations. You’ll see two types of common resin printers, DLP (digital light processing) and SLA (Stereolithography). These technologies differ in how they cure the resin: DLP printers use a UV LCD screen (basically a small monitor) to cure an entire layer at once, while SLA uses a focused laser which traces a path through each layer. From the outside, these printers are very similar. Since most lower cost resin printers use the DLP technology, we will focus on that technology in this article.

These technologies differ in how they cure the resin: DLP printers use a UV LCD screen (basically a small monitor) to cure an entire layer at once, while SLA uses a focused laser which traces a path through each layer. From the outside, these printers are very similar. Since most lower cost resin printers use the DLP technology, we will focus on that technology in this article.

Keep reading to learn more about FDM vs SLA and how to choose the best 3D printer for your needs.

Resin printers form each layer at the base of the vat by shining UV light on selected portions of the liquid resin. Once solidified, the print bed rises a small amount, liquid resin flows into the gap, and the process repeats.

Filament printers form a thin layer with melted plastic, then lift the nozzle a small amount. The printer repeats this process for each layer until the full part is formed.

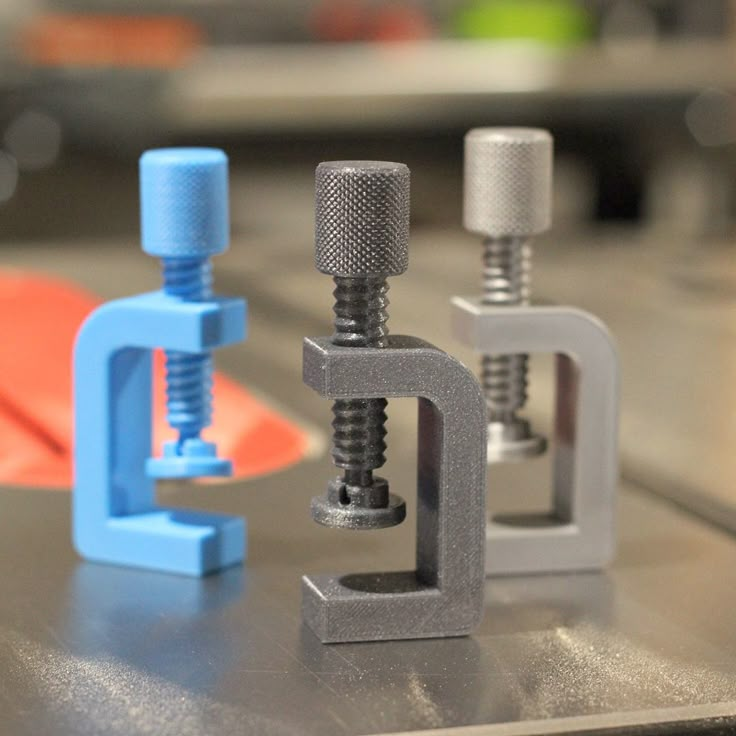

When considering which of these types of 3D printers to purchase, you’ll first need to think about what types of objects you are planning to make. Filament printers are superior for producing strong, larger parts, while resin printers excel at producing fine details and can print much more precisely on small parts.

There is more to the story, though. There are a few important factors to consider when choosing which of these technologies is best for your specific needs.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Print Quality

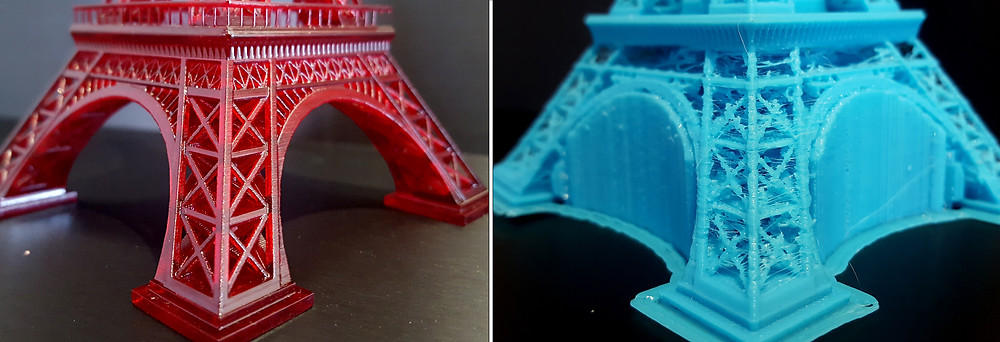

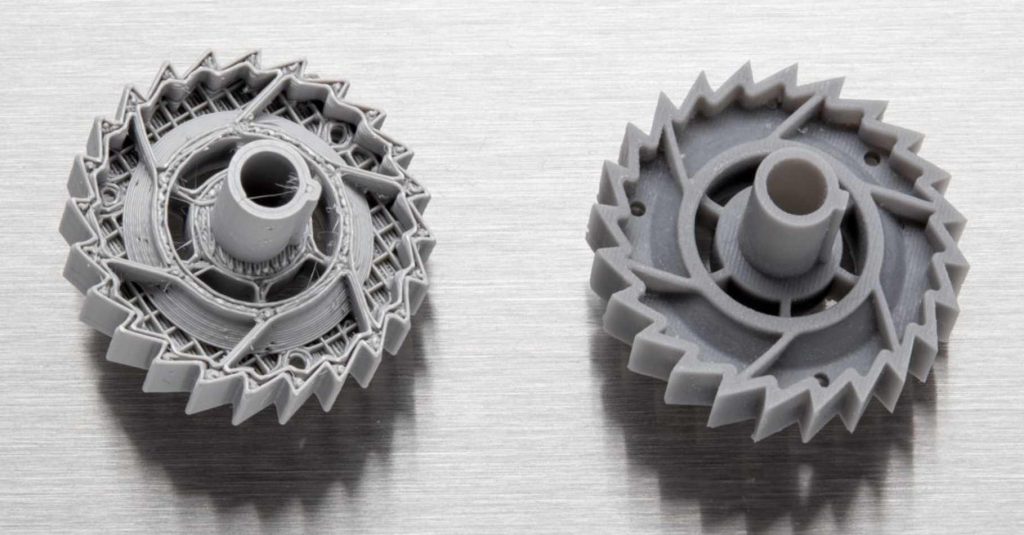

Resin printers are known for their superior surface quality, both in their ability to resolve small details on prints and for producing models with no visible layer lines. Resin prints actually do have layers, but they are so thin that they are not typically visible to the naked eye. For comparison, each layer on a resin printer is typically 25 - 50 microns thick, while filament printer layers are typically 100 - 300 microns thick.

For comparison, each layer on a resin printer is typically 25 - 50 microns thick, while filament printer layers are typically 100 - 300 microns thick.

Resin printers are able to capture very fine details because the resolution of each layer is defined by the size of pixels on the LCD screen, which are typically ~70 microns for consumer DLP 3D printers. By comparison, filament printer resolution is limited by the size of the opening in the nozzle where melted material is deposited, which is typically 0.4 mm (400 microns). It is possible to install smaller nozzles on filament printers, but the smallest viable nozzles are still 200 microns. Such a nozzle will also increase the printing time for the filament printer.

A resin print (left) compared to a filament print (right). Resin printers are superior at capturing small details and producing a very smooth surface finish without visible layer lines, but make sure to consider all of the factors when making a decision on which technology you prefer.

If you are looking to make small, detailed objects such as mini-figures, jewelry prototypes, or parts where high accuracy is critical, resin printers are a great choice.

Printed Part Durability

Parts printed from filament offer high durability, even when using standard plastics such as PLA. In addition, you can use alternate materials such as PETG and ABS which offer increased strength and heat/UV resistance for parts used outdoors. Parts printed by an FDM 3D printer do have substantially less strength when forces are acting across layers, so it is critical to consider the orientation of parts to maximize strength.

Standard resin prints are fairly brittle and are typically not preferred for functional parts that will be exposed to substantial forces. Additionally, since the resin is reactive to UV, exposure to sunlight causes the prints to become increasingly weaker. That said, there are high-strength resins on the market which do help improve the strength of resin prints. Unfortunately, we have found that this resin can be difficult to fully clean off of the printed part and often leaves sticky residue on prints. We have had more success blending this resin with standard resins to balance these negative effects with the improved strength.

Unfortunately, we have found that this resin can be difficult to fully clean off of the printed part and often leaves sticky residue on prints. We have had more success blending this resin with standard resins to balance these negative effects with the improved strength.

Overall, filament printing is a better choice for functional parts, since it offers improved strength and more options for larger parts, which we’ll look at next.

Build Volume

Filament printers have substantially larger build volumes than resin printers.

If you are looking to print larger parts, filament printers have a clear advantage. Entry level filament printers such as the Creality Ender 3 have a build volume of 220 x 220 x 250 mm, and many larger volume printers are available as well:

Standard resin printers have a much smaller build volume. Entry level printers such as the Creality Halot-One and Elegoo Mars are standardized at 130 x 80 x 160 mm, while more premium large format Resin printers such as the Elegoo Saturn are 192 x 120 x 150 mm, which is still substantially smaller than even the entry level filament printers.

Printing Speed

With typical settings, filament printers can produce single objects much faster. If you add more objects to the print bed, as you might expect, the print time will increase proportionally. This is because the nozzle must trace each part individually.

Resin printers, however (specifically the DLP type) can print multiple objects just as fast as a single object, since the LCD is exposed to each layer for a fixed amount of time regardless of how many parts you are printing. In these cases, resin can often be substantially faster for cases where you need a lot of parts. This is limited by the small size of the print bed, and one advantage of larger resin printers like the Elegoo Saturn is taht you can quickly print a lot of parts on their larger print beds.

Initial Assembly and Setup

Assembly

Most filament printers require some assembly, but the difficulty can vary. Printers such as the Creality CR-10 and Ender 3 Max arrive mostly assembled, and only take around 15 minutes to assemble. Smaller printers such as the Ender 3 V2 ship in more pieces and usually take around an hour to assemble. Once assembled, leveling the print bed can take a bit of trial and error.

Smaller printers such as the Ender 3 V2 ship in more pieces and usually take around an hour to assemble. Once assembled, leveling the print bed can take a bit of trial and error.

Resin printers, due to their smaller size, typically ship nearly fully assembled. For the Elegoo Mars we use, the only required assembly was sliding the print bed assembly onto the printer. Leveling the bed is simpler than filament printers - you just loosen a few screws in the bed, home it with a sheet of paper underneath, and retighten.

Many filament printers like the Creality Ender 3 V2 are shipped in many parts and require an hour or so to assemble. However, newer filament printers like the Ender 3 Neo series are being shipped almost fully assembled

Most resin printers ship nearly fully assembled due to their smaller footprint and simpler design.

Software Setup

Once assembled, it can take some time to learn all of the different settings that are available for filament printers in the printer slicer software to get the best quality prints. Many modern slicers such as PrusaSlicer and Cura have premade profiles for most Creality printers which make this process easier, but it is still important to learn how the various settings work since adjustments are often needed to optimize printing for certain types of models. You’ll also need to experiment with how models are oriented on the printer to get the best results.

Resin printers have far fewer settings to configure, and it is easy to get printing quickly once the printer is assembled. The only settings you will need to ever change are the layer time (how long each layer is exposed to the UV light to cure) and settings for support material. Print orientation is also important for resin printers to make sure the print stays adhered to the bed for the entire print.

Resin printers have few settings to configure, and typically print well out of the box

Filament printers have quite a few settings to get familiar with when dialing in your printer.

Overall, resin printers are substantially easier to initially set up, due to their very simple assembly and simplicity of print settings.

Ease Of Use

While resin 3D printers are simple to get set up, the liquid resin adds some complications to using the printer. It is important to note that the resin is a skin irritant, so its important to wear gloves whenever you are coming into close contact with the resin, such as removing completed prints or removing the resin vat. The level of irritation can vary from person to person. We’ve heard stories of people getting serious burns from minutes of contact with the resin, however personally we have not ever had a reaction to small splashes on the skin that can sometimes occur (though we wash them off with soap as soon as it happens to be safe). In addition, the resin has a distinct chemical odor that some people find unpleasant, though there is no conclusive evidence that it is harmful to breathe. It is still recommended to keep resin 3D printers in a well-ventilated area.

In addition, the resin has a distinct chemical odor that some people find unpleasant, though there is no conclusive evidence that it is harmful to breathe. It is still recommended to keep resin 3D printers in a well-ventilated area.

Because completed prints will have remaining liquid resin on the surface once they are finished, you will need to post process all prints using a solvent such as Isopropyl Alcohol (IPA). You can purchase specific washing stations for this purpose, or use a lower cost pickle strainer. The solvent will become clouded with resin and become ineffective after a a few uses and will need to be replaced and disposed of safely (you can’t pour it down the drain).

Swapping colors requires carefully pouring the resin from the vat into the resin container, then cleaning the vat (or purchasing dedicated vats for each material).

Another challenge with using resin is that changing materials can be time consuming. To do so, you’ll need to carefully pour the resin from your vat back into the resin container, clean the vat out completely, and pour the new resin in the vat. We have purchased a number of spare vats which we use for common colors to avoid the need for changing the color in the vat. The vats can be easily exchanged but the cost of additional vats can add up.

To do so, you’ll need to carefully pour the resin from your vat back into the resin container, clean the vat out completely, and pour the new resin in the vat. We have purchased a number of spare vats which we use for common colors to avoid the need for changing the color in the vat. The vats can be easily exchanged but the cost of additional vats can add up.

Overall, filament printers are easier to use once they are set up. All of the materials can be handled safely with no protection, and no post processing is required for most prints, other than removing support material, if needed. Swapping colors is also simple, and is just a matter of pulling out the old filament and inserting the new material.

Maintenance

Resin printers have few moving parts—the only one is the Z axis Lead screw which lifts the print bed as the print forms. For that reason, they are much less likely to encounter mechanical issues. However, there are a couple of components that you will most likely need to replace over time:

The FEP film on the bottom of the vat can bend or tear - as you print more parts, the thin film which forms the bottom of the vat can become bent or develop slight leaks.

When this occurs, you can either replace the film or get an entirely new vat for a fairly low cost. The FEP film replacement is not too difficult but takes some time since there are a lot of screws securing it to the vat.

When this occurs, you can either replace the film or get an entirely new vat for a fairly low cost. The FEP film replacement is not too difficult but takes some time since there are a lot of screws securing it to the vat.The LCD can develop issues over time - such as dead pixels or regions, which will cause sections of your prints to have holes in them. Replacement LCDs are available, but require disassembling the outer shell of the machine. Once you access the LCD, you can plug the new LCD in with no soldering or wire splicing required.

Filament printers have moving parts in all 3 axes, which means that over time, parts of the motion system will need replacement or tightening. We have found that these types of repairs are fairly infrequent. Most of the maintenance of filament printers relates to the filament path - the extruder which pushes filament, and the hot end which melts it before depositing it onto the part.

The extruder gear, which contacts the filament and pushes it into the hot end can wear over time, and the spring loaded extruder mechanism can crack if your 3D printer is using an extruder made of plastic.

These issues can be avoided by ensuring your printer has a steel extruder gear and an all-metal extruder.

These issues can be avoided by ensuring your printer has a steel extruder gear and an all-metal extruder.The internal components of the hot end tend to wear out over time since it is exposed to high temperatures. You can replace most individual components of the hot end, or replace the entire assembly if time is more of a factor than cost. We have a detailed guide on repairing these hot end issues, and feel that repairing the hot end is fairly simple.

Overall, filament printers require a bit more maintenance, but there isn’t a substantial difference here.

Cost

In the past, purchasing a resin 3D printer was substantially more expensive than a filament printer. However, there are a number of lower-cost resin machines on the market now using DLP technology. Because of this, budget resin 3D printers are priced in the same range as entry level filament 3D printers. This means that if you’re looking for a budget resin 3D printer or a budget filament 3D printer, you have plenty of options. For higher end printers, resin tends to be more expensive. We’ll look at some side by side comparisons to give you a general idea:

For higher end printers, resin tends to be more expensive. We’ll look at some side by side comparisons to give you a general idea:

Budget / Entry Level

Filament Printer: Creality Ender 3

(view on Amazon)

Resin Printer: Elegoo Mars

(view on Amazon)

Mid-Range

Filament Printer: Creality CR10S Pro

(view on Amazon)

Cost: $500-600

Upgraded features such as silent motors, unibody design, touch screen, all metal dual gear extruder

Large build volume: 300 x 300 x 400mm

Resin Printer: Elegoo Saturn

(view on Amazon)

High-End / Industrial

Filament Printer: Ultimaker S3

Cost: $4,000 - 5,000

Industrial-grade components and warranty, wireless printing

Build volume: 230 x 190 x 200mm

Resin Printer: Phenom Prime MSLA

Cost: $3,000 - 4,000

6K UHD LCD, warranty, Masked SLA technology for improved resolution and speed

Build volume: 276 x 155x 400mm

Ongoing Costs

Its important to consider the total down of ownership of a 3D printer, because the ongoing costs can be a more substantial portion of the total cost than the purchase price of the machine itself. The majority of ongoing costs are the materials you use to make parts: the filament or resin.

The majority of ongoing costs are the materials you use to make parts: the filament or resin.

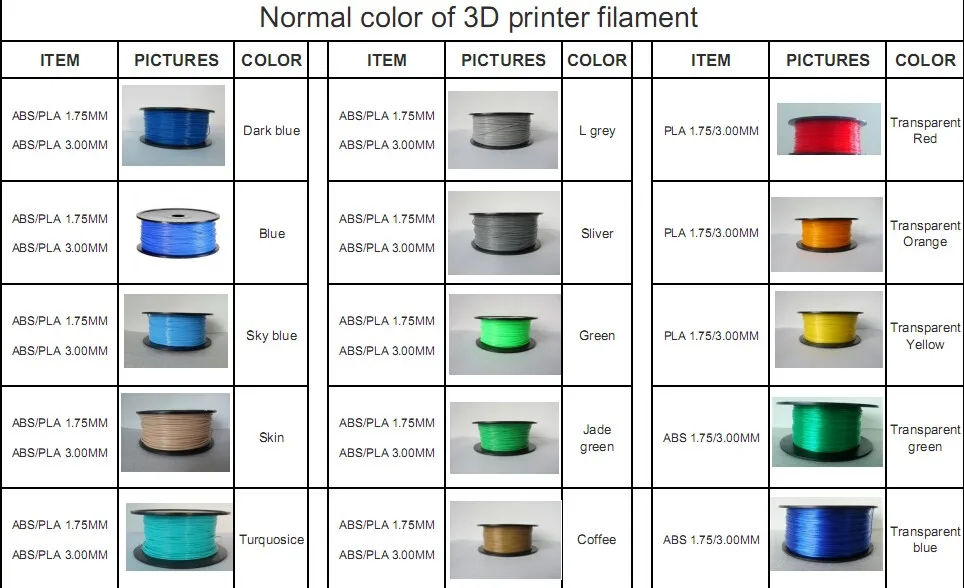

Filament

Typically sold in 1KG rolls

Cost: $15 - 25 per roll

Usage depends greatly on part size

View our filament purchasing guide

Resin

Sold in 500g to 1kg sizes

Cost: $30-40 per 1kg

Since parts are smaller, lasts longer

View Resin on Amazon

Overall, the cost of resin is higher per kilogram, but you will likely use less with a resin printer due to its smaller build size. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out. For filament printers, parts typically use a meshed infill pattern, which saves material.

For filament printers, parts typically use a meshed infill pattern, which saves material.

Another smaller cost to consider is maintaining the 3D printer and making sure you have required supplies. Resin printers cost a bit more in this area, since you’ll need to maintain a stock of disposable gloves and a solvent such as IPA to post-process prints. Repair parts for either type of printer are typically fairly inexpensive, and you won’t be buying them often.

Making Your Decision

Now that you have a general idea of which technology is better for your needs, the next step is to take a look at a few printers in each category to learn more. If you are looking for your first 3D printer, a good place to start is with our entry level picks for both filament and resin printers.

Filament Printer Top Pick: Creality Ender 3 V2 Neo

The Ender 3 V2 Neo offers a number of improvements over the original Ender 3 series like auto bed leveling, and due to its ease of use and low cost, it is our top recommendation for a first 3D printer. We have purchased many printers in the Ender 3 series and have been very pleased with them.

We have purchased many printers in the Ender 3 series and have been very pleased with them.

Check prices for the Creality Ender 3 V2 Neo on Amazon here.

Resin Printer Top Pick: Elegoo Mars 2 Mono

The Elegoo Mars is a great resin 3D printer at a low cost. The 2 Mono version includes an upgraded LCD and build plate which are definitely worth the added cost. We have used two Elegoo machines in our workshop and have seen impressive results considering the low price point. They were very easy to set up and begin printing with, and have been very reliable.

Check prices for the Elegoo Mars 2 Mono On Amazon here.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0053

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0053

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0053

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0053

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0053

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0053

nine0053

Pros:

Cons:

Flexible Resin

The rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0053

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0053

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0053

nine0053

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0053

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0053

nine0053

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0053

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0053

nine0053

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0053

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A Biocompatible)

114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0053

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0053

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0053

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

nine0113 Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you! nine0053

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

INSTAGRAM nine0053

In contact with

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Known for its daVinci line of desktop 3D printers, XYZprinting is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.