3D printing customers

How Businesses & Consumers Are Using 3D Printing Technology

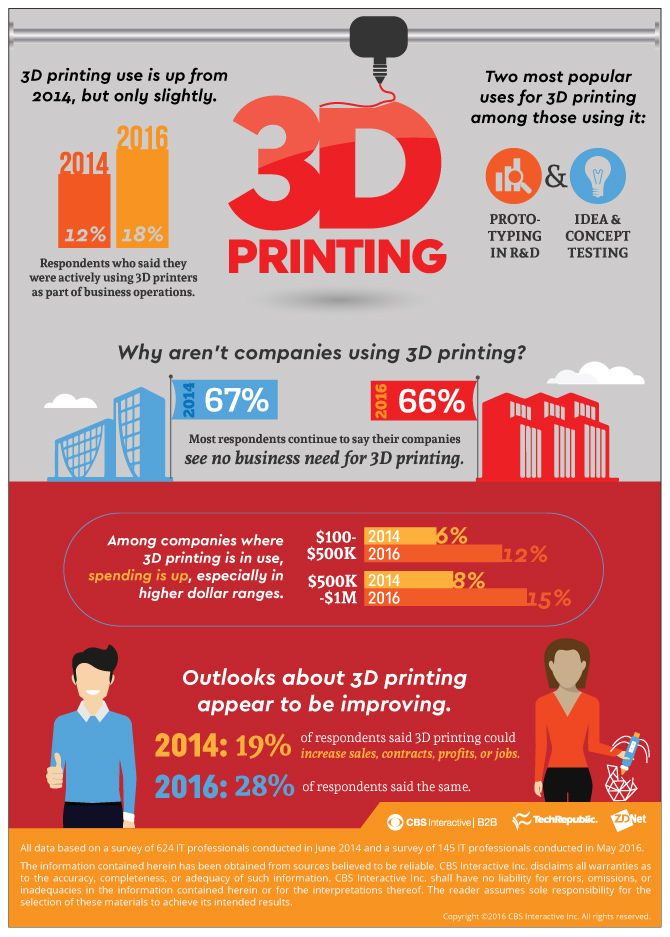

While there have been some exciting advancements in printing, perhaps none is more impactful or more interesting than the advent of 3D printing. 3D printing technology has already made a major impact on manufacturing and production methods. Not only is it exciting, but it’s also potentially profitable, even for home users. Below are the basics you should know about 3D printing and how the technology is being used today by businesses small and large.

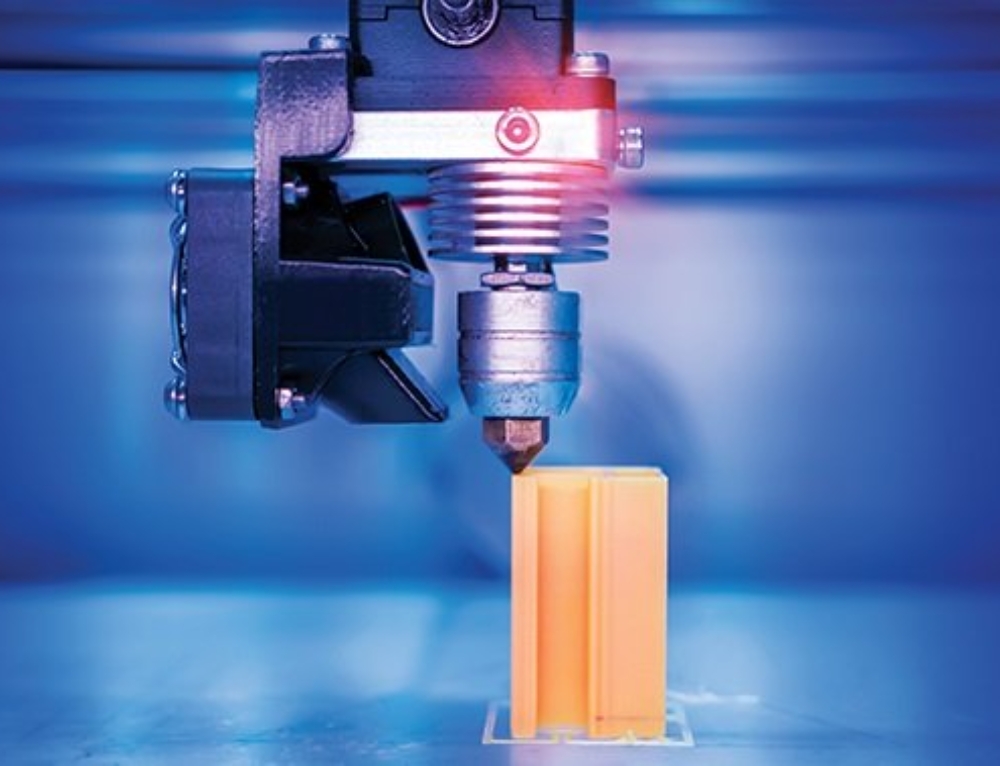

3D Printing - An OverviewSo what is 3D printing, (a.k.a. additive manufacturing)? The technology, invented in 1984 by Charles Hull, works by using a three-dimensional digital design, which is sent to the 3D printer. The 3D printed object is created, based on the design, by using sequential layers of your material of choice (filament), heated and shaped by a laser source, layered on top of each other until the solid object is complete.

Common Uses of 3D Printing3D printing can be a great source of revenue and educational materials. Below are some of the most effective ways businesses, educators, and hobbyists are using 3D printing technology.

Working in Tandem with Traditional Manufacturing Methods

While 3D printing has not replaced traditional manufacturing methods, like CNC machining, 3D printing already has found a strong foothold in the manufacturing industry. More and more manufacturers are implementing 3D printing to test and perfect designs and models. When used in conjunction with traditional manufacturing, stronger, more reliable parts are created. Manufacturers are also using 3D printing to “enable mass customization, increase design freedom, allow for the reduction of assembly, and serve as a cost-effective low volume production process” according to Sculpteo.

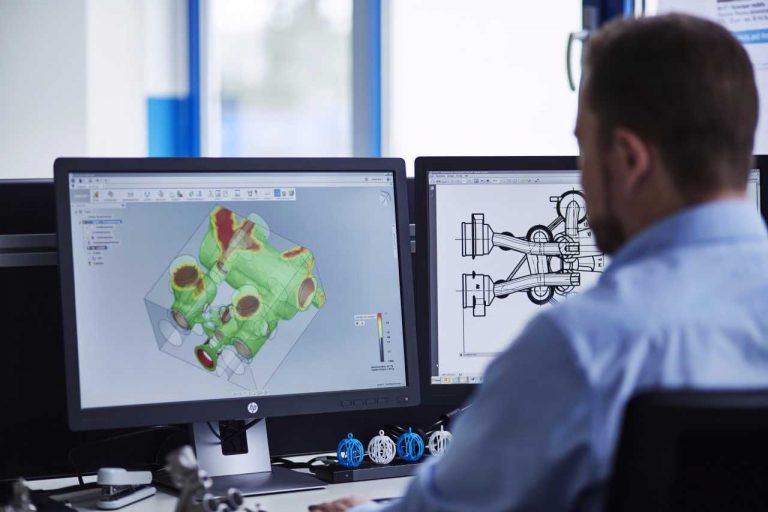

3D Modeling

One of the most advantageous ways to businesses, hobbyists, and educational programs are utilizing 3D printing is to by creating, selling, and teaching 3D design. In the classroom, allowing students to design their own creations and then print them out with a 3D printer allows them to get first-hand experience with the 3D design and manufacturing of process.

3D Printed Models/Parts

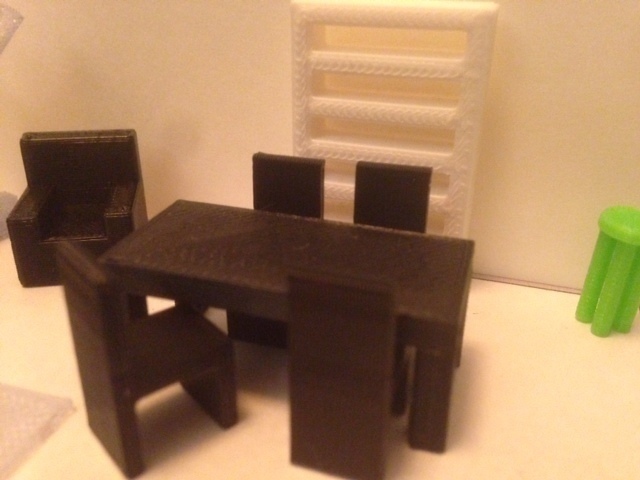

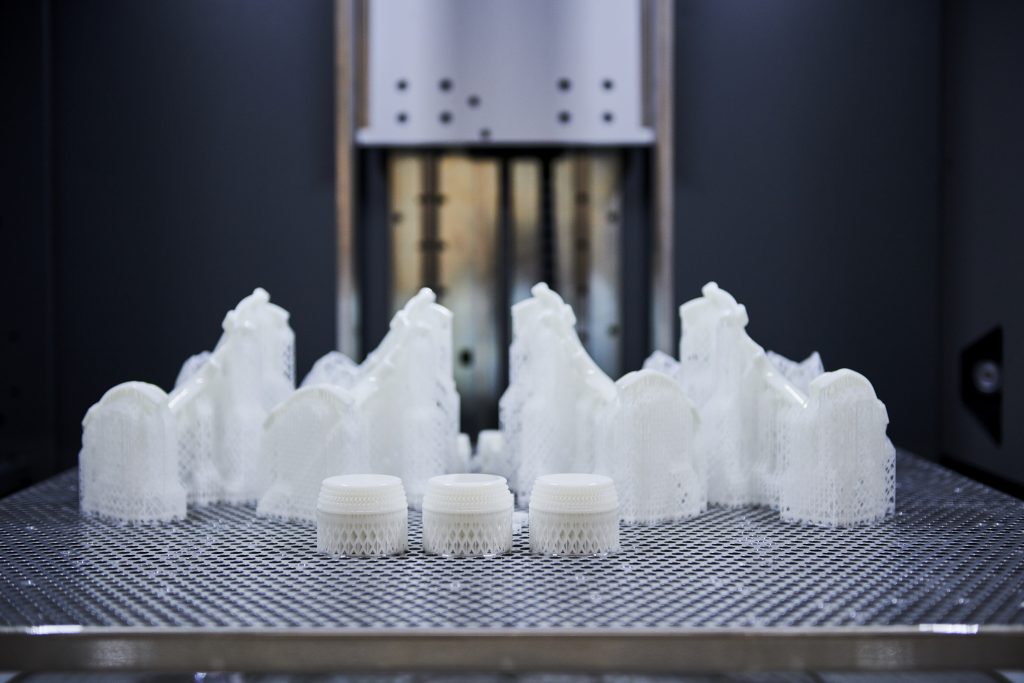

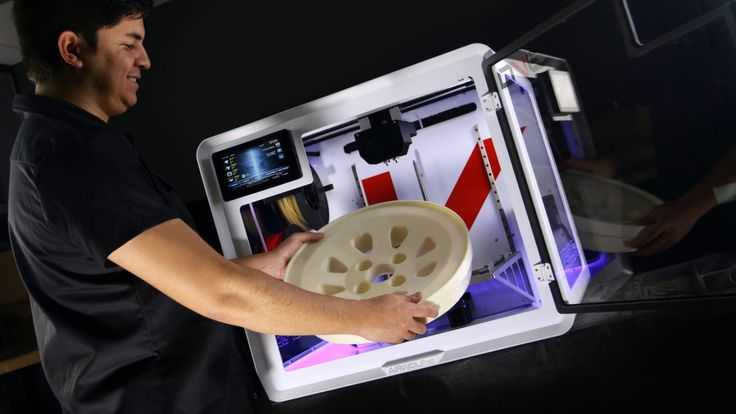

Before implementing 3D printing into a manufacturing process, many businesses are purchasing custom-order parts from vendors and 3D print farms. Consumers are also able to purchase custom-made models and even low-cost, new build homes that are 3D printed within a day!

The market for 3D printed products is vast, and it’s still growing. One of the most significant benefits of 3D printing is that it simplifies the production process, turning homes into mini-manufacturing hubs. Online orders can easily be fulfilled with a few clicks of a button, as the 3D printer does most of the work.

Rapid Prototyping

Prototyping with 3D printing allows businesses and consumers to design, test, revise and create full-scale models in a matter of days instead of weeks. Rapid prototyping also aids in the visualization of new products, using 3D printed models as “functional prototypes to enable cost-efficient, real-world predictions.” With traditional manufacturing methods, prototyping may take weeks and comes with high production costs due to the manual work and expensive machines required. However, 3D printing allows businesses and consumers to quickly create physical models at a fraction of the cost.

However, 3D printing allows businesses and consumers to quickly create physical models at a fraction of the cost.

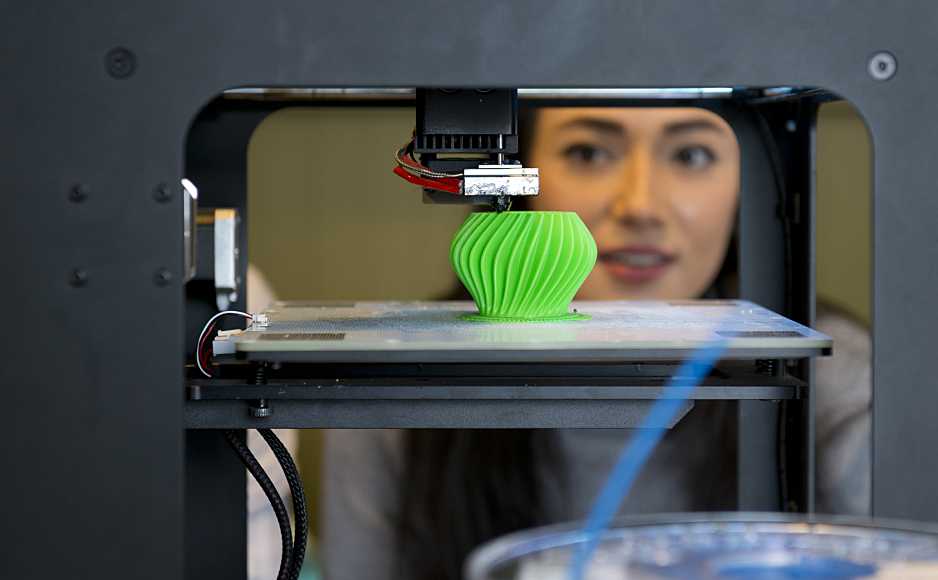

Teaching Students & Enthusiasts How to Use 3D Printers

One of the most insightful ways 3D printing is utilized is in the classroom. Students today are eager to learn about new technology, and there is a large community of enthusiasts who also wish to learn.

Experienced users know the limitations of the instruction manuals that come with any technology, so students benefit from gaining hands-on experience and useful knowledge in this increasingly in-demand technology. The skills learned as students move from designing 3D models to making their creations come to life in the 3D print lab can be directly applied to the workforce after school.

ImageNet is sponsoring a 3D printing educational program - ongoing now! If you'd like to get a 3D printer for your school, sign up for our 3D Seeds Program!

Printing as a Service

The market for printing as a service using 3D printers is growing more sophisticated. There are now networks like 3D Hubs and Make XYZ that offer 3D printer owners the opportunity to make money by merely listing their printer on their site. Customers can then place orders and have their designs printed as a service.

There are now networks like 3D Hubs and Make XYZ that offer 3D printer owners the opportunity to make money by merely listing their printer on their site. Customers can then place orders and have their designs printed as a service.

Even jewelry designers have turned to 3D printer owners to print out their designs and have them shipped to customers as a way to expand without sacrificing too much time. For independent jewelry designers and folks in a similar trade, outsourcing production to professionals with 3D printers is one of the easiest and most comfortable ways to expand without taking on extra overhead.

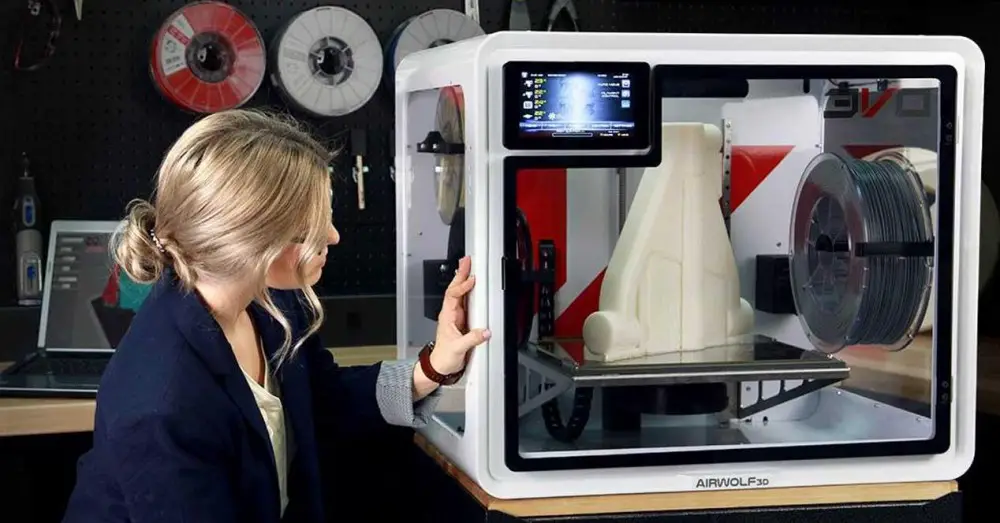

Find the Right 3D Printer for the Job with ImageNetWith 3D printers increasing in popularity among entrepreneurs, the ROI is growing exponentially. The advantages of getting in on rapid prototyping and additive manufacturing are incredible.

Success in this arena starts with finding the right 3D printer for the job. ImageNet has what aspiring entrepreneurs and businesses alike need to succeed in 3D printing. From 3D printers to use in the classroom, to large production 3D printers made for rapid-prototyping and printing with materials like carbon fiber and metal, our variety of printers, accessories, and materials is unmatched. Better yet, they’re conservatively priced.

From 3D printers to use in the classroom, to large production 3D printers made for rapid-prototyping and printing with materials like carbon fiber and metal, our variety of printers, accessories, and materials is unmatched. Better yet, they’re conservatively priced.

Take a look at ImageNet’s impressive selection of 3D printers, from desktop printers perfect for classrooms or small businesses, to industrial and metal 3D printers capable of rapid prototyping and more! Shop at ImageNet's 3D shop, or consult with our 3D experts about how 3D printing can deliver a strong ROI for you today!

How to Attract Clients To Your 3D Printing Business | by Zmorph SA

Making money out of your 3D printer is not an easy task but certainly achievable. Here are some tips for running a 3D printing business.

To help your business grow and thrive, we gathered tips and advice from industry professionals, successful entrepreneurs, and your potential clients. These tips won’t work like a magic spell and make you rich in a blink of an eye, but could be helpful in establishing and maintaining your business.

3D Printing group on Facebook gathers a huge number of 3D printing enthusiasts, makers, and professionals. Everyone can join it, get his questions answered or share his knowledge. We asked people on the group for their advice for beginning 3D printing business owners. Ja Stoddart shared this with us:

Don’t give up yer day Job, while you are getting started, Go to School, get a degree in Design or Engineering, and a minor in Business, Get some Creed, and never stop trying.

It’s actually a great piece of advice before you start. Don’t rush things because the competition is huge. Sometimes it’s better to focus on your studies or getting more experience in an already established company. This is also a good time for you to start building your credibility and contact list.

Good sample pack and a set of example prints are a must-have for every 3D printing businessTips on how to attract clients to your #3Dprinting #business #entrepreneurship

CLICK TO TWEET

Be visible before you launch a 3D printing business. Talk with people and make new friends. You won’t succeed without a proven record of activity on forums, Facebook groups, 3D Hubs Talk, 3DPrinting Reddit, and other places. You need to list and regularly visit all these places where your potential clients might be. Be nice and helpful while posting under your real name or nickname that you’ll carry into your future company.

Talk with people and make new friends. You won’t succeed without a proven record of activity on forums, Facebook groups, 3D Hubs Talk, 3DPrinting Reddit, and other places. You need to list and regularly visit all these places where your potential clients might be. Be nice and helpful while posting under your real name or nickname that you’ll carry into your future company.

Answering questions, sharing your knowledge, and commenting on the state of 3D printing technology won’t take you far, though. The next step is building your online portfolio. Either with the machines that you’ve built, original hardware designs, 3D models, or high-quality prints. Photos of your works on Instagram and videos on YouTube can do wonders, especially when you invest some additional time into editing them and promoting around the web.

Source: Simone FontanaItalian designer Simone Fontana started building his recognition long before launching his own company 3DNA. He’s been printing and post-producing impressive props, like guns from video games or even a working skateboard. His advice for online activity is:

His advice for online activity is:

You need to be always really active on social media. I find Instagram and YouTube really powerful and sometimes for some designs, Reddit can be extremely useful.

Overall the best thing is to combine social networks. I often post on Reddit about my youtube video, and for instance, once I was able to receive over 50k views in less than 24 hours. This will bring more attention and work.

Simone also recommends sharing at least some of your designs for free, so people can make them themselves and get to know your work better this way. There’s always the danger of someone else trying to profit out of your work, though. Remember to add watermarks on your models as well as make sure that you’re the first one to post them in all major 3D printing file libraries.

When running your own 3D printing business you need to meet a lot of new people, talk with hundreds of potential clients. Jacob Rogers points out that:

You either need huge margins or a huge customer base, because most people do not repeat as customers at the consumer level.

Large prints with high-profit margins can grow a small business, but you end up maintaining on countless small, low-profit prints.

These small, low-profit prints took most of Jacob’s time and resources. He wasn’t able to maintain his business because of that and decided to go back to designing yacht components.

Source: Alex Tapia / 3D Printing Facebook groupMany professionals working with 3D printing we talked to mentioned that it’s the design side that can get you more profit than doing prints on request. Dorian Ferrari’s advice is:

The best money is going to be on the design side. I have my printers on 3D Hubs, I’ve made $750 from it. My design services pay the bills plus. Treat every customer as if they’re a priority. Price fair, but ensure you price appropriately. Develop a niche, as it will separate you, and bring you better clients. General modeling services are almost a commodity as everyone with a free or cheap CAD or design program believes they can model.

What I’ve specialized in are servicing inventors and small businesses that don’t know how to get a concept through production. I help my clients all the way from product concept to mold-ready designs that can be produced in injection molding machines.

As it turns out many potential customers expect a full range of services — not only printing an item but designing it from scratch. Greg Carror has a similar experience:

Going beyond simple 3D printing services can boost your business significantlyWe currently have 50 Prusa i3s and concentrate mainly on designing new 3D products for businesses. Most marketing companies we work with have told us their clients believe getting volume prints with SLS/Full Color is still too expensive.

We design branded, functional products that businesses can give out to their customers. You can make money as a hobbyist on 3D Hubs but as a company, you need volume or high-end prints.

Once you get some credibility by doing various projects for a wider range of clients, it’s good to look for a niche you’re the best at. Sometimes you can discover it by accident as it may not be the industry or type of projects you initially thought about. Just like Robert Bateman did:

Sometimes you can discover it by accident as it may not be the industry or type of projects you initially thought about. Just like Robert Bateman did:

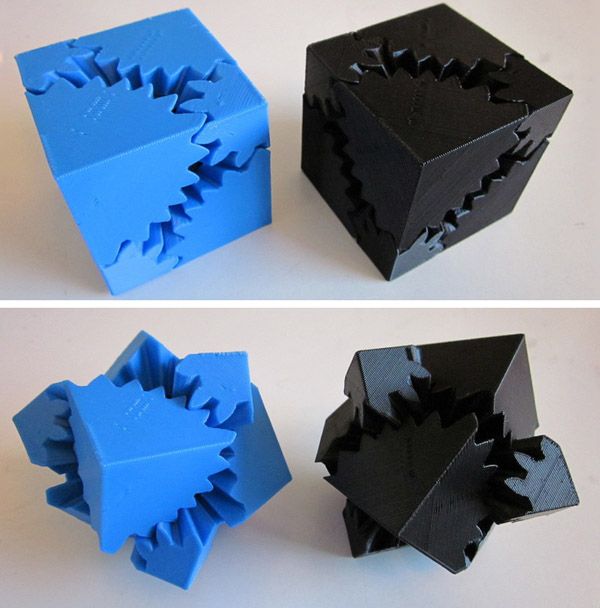

I design my own products, sure I also print interesting things I find online but I do not sell them. I made trays for a company that uses them to fill bottles in their Electronic Cigarette Juice operation, It pays pretty well, I also make small gears for Business copiers that they can no longer get parts for. Just go and do it, it will be successful if you work at it.

Robert is right in saying that you probably won’t succeed overnight but can achieve a lot by gaining experience and learning new things with every project. You should also keep your eyes and ears open for new products, gadgets or jigs and fixturesthat you could design and sell to companies. Again, having many contacts on your list can help in building your 3D printing business this way.

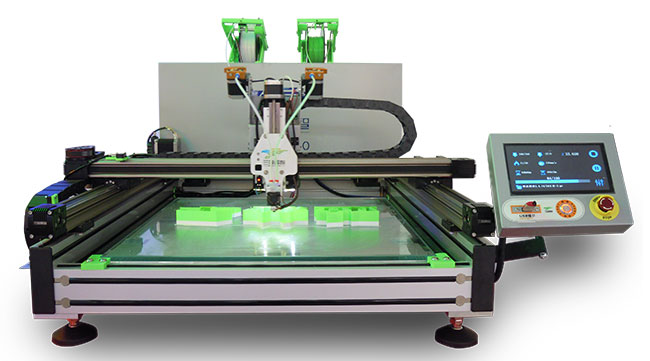

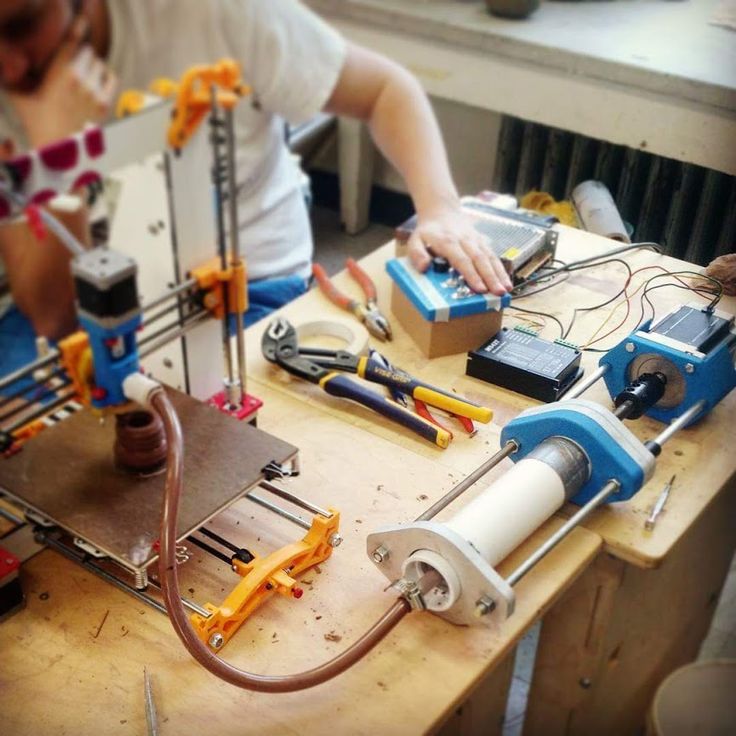

Source: JavelinThe quality of prints depends not only on your skills but also from the machine that you use to manufacture the object. This is why for running a 3D printing business you need reliable tools that can operate at peak efficiency around the clock. Some build their own 3D printers based on open source DIY designs but most of the companies and professionals utilize ready-to-use desktop machines.

This is why for running a 3D printing business you need reliable tools that can operate at peak efficiency around the clock. Some build their own 3D printers based on open source DIY designs but most of the companies and professionals utilize ready-to-use desktop machines.

Preet Jesrani from DesignBox3D told us why he would recommend ZMorph multitool 3D printers to people starting and already running their businesses:

ZMorph 2.0 SX in actionIf you are planning on printing batches of pendants or necklace pieces for example, as long as the design can be printed, you can go about the task of researching which printer will be the most suitable.

When you plan to focus on 3D printing with plastic-based materials, ZMorph 2.0 SX Basic Set will be an excellent choice due to the built-in closed loop functionality. But if you plan on using various mediums for creating your products or prototypes, there is no question — choose a ZMorph 2.

0 SX Full Set able to 3D print, cut with CNC toolhead, and engrave with a laser.

When running your 3D printing business never forget about 3D Hubs. It’s currently the biggest and most popular platform for ordering custom 3D prints from local providers. It changed a lot in recent years with more and more professionals looking for high-quality prints from reliable partners, so you should be ready for that.

3D Hubs is a place to be for all 3D printing business.Balazs Kisgergely from 3D Hubs shared with us the following tips:

- Create a great (visual) profile to get orders. Start with lower introductory prices and increase them later.

- Do all it takes to get good reviews, they’ll attract more customers.

- Printing for orders is a great way to start a business and build out a customer base if you don’t have one.

- Give away promo material with your orders so customers will remember you, plus you can advertise your design business this way.

- Try to find your niche (architecture, engineering, design for customers, etc.).

- Use Facebook and LinkedIn to get in touch with your customer base. I can also recommend 3D Hubs Talk for community and advice.

- For promotion, I’d say Instagram is by far the best. Build out a following, follow others who are relevant, do share 4 shares and generally read a lot of tips online.

- Don’t be afraid to reach out to 3D printing and your local media. They love local stories and you’ll get featured if you actually make great designs or products.

- In the meantime try Etsy and Ebay for selling 3D printed gadgets, figures, and trinkets people would like.

You can always use this piece of advice Bass Blom wrote us on Facebook…

use plenty pretty girls in pics ;)

There’s no simple and universal set of rules on how to succeed with your 3D printing business. Different things work depending on time, place, and even people’s moods. Sometimes you just need to adapt to the situation, just like many successful entrepreneurs do, so always try to be flexible and keep an open mind.

Sometimes you just need to adapt to the situation, just like many successful entrepreneurs do, so always try to be flexible and keep an open mind.

Leave a comment below and share your stories, so other people can learn from your experience.

3D printing Voronezh - 3D Smart Service

3D printing with us is easy!

Get a quote

and order 3D printing

Get the finished product

and tell your friends about us :-)

Our capabilities

Our advantages

3D Smart is a service in Voronezh. We print products from more than 10 types of thermoplastics (including ABS, PET-G, PLA, HIPS, engineering plastics) on professional 3D printers using FDM/FFF and SLA (photopolymer printing) technology. This is sufficient for most domestic and industrial tasks. The specialists of our service pay special attention to the quality of products, using the most modern equipment and advanced 3D printing technologies. Therefore, our clients are not only private customers, but also enterprises from all over Russia. nine0007

Therefore, our clients are not only private customers, but also enterprises from all over Russia. nine0007

3D printing on a 3D printer using FDM technology is ideal for solving everyday tasks such as restoring broken or worn plastic parts of household appliances, strollers, bicycles, cars. 3D printing in Voronezh is indispensable for research or development, it opens up great opportunities for startups to launch new products on the market. The advantages of FDM technology (fuel deposition modeling) are: low cost of printing, high accuracy, minimum production time of the product and the possibility of its further processing and painting. nine0007

If industrial quality or small-scale production is required, then we will offer 3D printing in Voronezh on industrial equipment or molding into silicone molds. We will help you choose the technology and materials, optimize the model or make a digital model according to a drawing or sketch.

3D Smart 3D printing service in Voronezh provides rapid prototyping of complex shapes. In addition, we provide services for large-scale 3D printing and assembly of composite products (prototypes, layouts). Our experts are ready to offer the most comprehensive advice on the manufacture of products by additive manufacturing. nine0007

In addition, we provide services for large-scale 3D printing and assembly of composite products (prototypes, layouts). Our experts are ready to offer the most comprehensive advice on the manufacture of products by additive manufacturing. nine0007

You can get a cost estimate and advice on the selection of 3D printing technology by sending a request by mail or through the form on the website.

We ship orders by courier or transport company throughout Russia, see the Delivery section for more details.

3D printing quick calculation

We use 3D printing for:

- industrial equipment parts

- production or restoration of gears, bushings

- restoration of plastic car parts, autotuning

- restoration of household appliances parts

- restoration of parts for strollers, bicycles, scooters, etc.

- parts for home appliances repair services

- molds for biscuits and clay

- creation of housings for radio-electronic equipment (REA)

- computer case tuning

- production of souvenirs and exclusive gifts (cups, figurines, spinners, key chains, etc.

)

) - parts for modeling (RC car, aircraft, ship modeling, etc.)

- parts for board games

- dummy parts

- industrial design

- manufacture of tackle for fishing

- accessories for atelier, badges, inscriptions

- small-scale production of plastic products

- making master patterns for casting

- parts and prototypes for start-ups, inventors and businesses

- parts for airsoft and paintball

- home decor

- jewelry nine0035 for hobbies and other applications

Home

Interest in custom 3D printing has been growing rapidly in recent years. It has found wide application in everyday life. In a crisis, and not only, people are increasingly resorting to the restoration of worn or broken plastic parts instead of throwing away appliances or prefabricated car components. After all, by replacing just one plastic part, you can completely restore a broken device. And if earlier it was not possible due to the lack of appropriate spare parts or recovery technologies, now this barrier has been removed. nine0007

And if earlier it was not possible due to the lack of appropriate spare parts or recovery technologies, now this barrier has been removed. nine0007

3D printing in Voronezh will help not only to restore a car or household appliance assembly, but also to modernize it by introducing your own idea into the mechanism. And most importantly, now only a few hours pass from the idea to its implementation in the device. And we will help you with this. Let's create together!

Order 3D printing

Business

With the help of 3D printing, you can make almost any product from plastic. In a matter of minutes or hours, parts are produced that are very costly or impossible to make by other available methods. A 3D printer can be compared to a CNC machine, but the printer has a wider range of capabilities. nine0007

Modern production can no longer do without parts made on 3D printers. In a highly competitive environment, manufacturing plants are shifting to fast and flexible ways to manufacture plastic parts. This allows you to set up the production of new or upgraded equipment in lightning time from 1 day, without resorting to any costs.

This allows you to set up the production of new or upgraded equipment in lightning time from 1 day, without resorting to any costs.

We cooperate with a number of enterprises producing parts for industrial equipment, and are interested in expanding partnerships. If necessary, our specialists are ready to consult on the introduction of parts printed on 3D printers into production, updating the range for manufacturing parts using traditional methods, including obsolete technologies. 3D printing will allow your enterprise not only to significantly speed up the production of finished products, but also free up a significant part of the budget by replacing traditional methods of manufacturing plastic parts. nine0007

3D printing for modern manufacturing enterprises opens up great opportunities for the rapid prototyping of new products, the rapid launch of a small or medium series of plastic parts for equipment, the preparation of plastic molds without complex and costly tooling. For enterprises with a history that have a fleet of Soviet equipment at their disposal, we can offer the manufacture of unique parts for these machines, the industrial production of which has already been discontinued. Thus, it is possible to extend the service life of old equipment without significant costs. nine0007

Thus, it is possible to extend the service life of old equipment without significant costs. nine0007

Recently completed orders

SLA photopolymer printing of souvenir fish

https://3d-smart.ru/wp-content/uploads/2022/10/rybki-iz-fotopolimera_3d-pechat_01.jpg 683 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2022-10-16 13:51:192022-10-16 13:51:19SLA photopolymer printing of souvenir fishDental equipment case made of polyamide

https://3d-smart.ru/wp-content/uploads/2022/10/pechat-korpusa-poliamidom_01.jpg 683 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2022-10-15 14:19:442022-10-15 14:19:44Polyamidedental equipment case Table-top mock-ups of EW equipment

https://3d-smart.ru/wp-content/uploads/2022/06/maket-oborudovaniya-rehb_3d-smart_01.jpg 683 1024 FreeArrowS https://3d-smart. ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2022-06-16 23:36:080002 3D printed gear with polyacetal https://3d-smart.ru/wp-content/uploads/2021/12/3d-pechat-shesternej-poliacetalem_01.jpg 768 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-12-06 00:05:472021-12-06 00:05:473D-printing of gears with polyacetal

ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2022-06-16 23:36:080002 3D printed gear with polyacetal https://3d-smart.ru/wp-content/uploads/2021/12/3d-pechat-shesternej-poliacetalem_01.jpg 768 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-12-06 00:05:472021-12-06 00:05:473D-printing of gears with polyacetal 3D-printing of experimental cases

https://3d-smart.ru/wp-content/uploads/2021/11/3d-pechat-ehksperimentalnyh-korpusov-voronezh_01.jpg 683 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-11-23 22:20:382021-11-24 09:44:363D - printing of experimental casesBucket prototype

https://3d-smart.ru/wp-content/uploads/2021/11/3d-pechat-vedra-voronezh_01.jpg 1024 768 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-11-22 00:32:232021-11-22 00:32:23 Prototype bucketModel of special equipment ROIN R-100

https://3d-smart. ru/wp-content/uploads/2021/10/maket-spectekhniki-roin-100-3d-smart_01.jpg 683 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-10-29 22:01:072021-10-29 22:01:07 Model of special equipment ROIN R-100

ru/wp-content/uploads/2021/10/maket-spectekhniki-roin-100-3d-smart_01.jpg 683 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-10-29 22:01:072021-10-29 22:01:07 Model of special equipment ROIN R-100 Model of special equipment ROIN R-300

https://3d-smart.ru/wp-content/uploads/2021/10/maket-spectekhniki-roin-300-voronezh_01.jpg 683 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-10-28 00:15:172021-10-29 22:01:31 Model of special equipment ROIN R-300Model of a two-stroke internal combustion engine

https://3d-smart.ru/wp-content/uploads/2021/08/maket_dvigatelya-vnutrennego-sgoraniya-voronezh_01.jpg 984 1024 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2021-08-08 12:24:502021-08-08 12:28:44two-stroke internal combustion engine layout https://3d-smart.

ru/wp-content/uploads/2020/09/3d-pechat-krepleniya-velosipeda-voronezh_01.jpg 853 1280 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2020-09-06 22:54:272020-09-06 22:54:273D-printing bike mount with mortgages

ru/wp-content/uploads/2020/09/3d-pechat-krepleniya-velosipeda-voronezh_01.jpg 853 1280 FreeArrowS https://3d-smart.ru/wp-content/uploads/2019/04/logo_3d_smart_80.png FreeArrowS2020-09-06 22:54:272020-09-06 22:54:273D-printing bike mount with mortgages PreviousNext

Ask a specialist:

Phone in Voronezh. Consultations daily from 9.00 to 19.00

+7 919 239-40-01 | whatsapp | Viber

3D printing service 3D Smart

st. F. Engels, 82

Voronezh

Phone: +7 919 239-40-01

Mail: [email protected]

3D printing on order - Center for 3D printing and prototyping

3D printing to order The company Center for 3D Printing and Prototyping provides 3D printing to order in the cities of Cheboksary, Kazan and Yoshkar-Ola. https://3d-print21.ru/3D printing for your business

Implementation of your ideas, prototypes, layouts.

Learn more

Printing with multicolor plaster

For creating colored full-size products.

Learn more

Fusion 3D printing

Low price, high speed.

Learn more

About the company

We make your dreams come true

Our business began at the very dawn of 3D printers in Russia. Even then, we imagined the prospects of the industry and began to master a new business for ourselves. nine0178

Find out more about us

Testimonials from happy customers

Based on my experience with the company, I can say that the entire process from contact to implementation is under strict control. This allowed me to relax and not waste my nerves - and this is the most important thing! The quality of the product completely satisfied me, everything is as it should be.

Ilyin Nikita, 33 years old

I did not expect, but everyone in the company is passionate about their work. When I came with a layout of my small architectural plan, I was asked for a long time what was there and why, in general, about all the specifics. This is very nice and, as I understand it, it also affects the final quality and cost of implementation. Was satisfied with the work. The layout is of high quality - no roughness. nine0007

Artur Efremov, 28 years old

My experience with the company is only positive. Before that, I applied to other companies, but nowhere did I meet such enthusiasm in work. I think I will definitely come back here.

Sergey Prokopiev, 23 years old

All reviews >

Company services

Laser cutting and 3D engraving

3D modeling

3D visualization

nine0200 3D scanning3D CNC milling

Manufacture of enclosures

Rapid Prototyping

Model making

Handling customer materials

Silicone mold making

Silicone casting

If you are looking for an artist to implement your idea, then we are glad to welcome you on our website. We are the Center for 3D Printing and Prototyping! Flagships of 3D printing in Chuvashia and the city of Cheboksary. nine0007

We are the Center for 3D Printing and Prototyping! Flagships of 3D printing in Chuvashia and the city of Cheboksary. nine0007

We attract not only talent, but also new technologies to the region, introducing them into production along the way. In addition, we modernize our existing equipment and introduce new proprietary technological solutions. All this allows us to improve the quality of products and leave our customers satisfied.

Services of our center

Our company is constantly developing and expanding into new areas of activity. Therefore, we provide not only 3D printer services, but also a wide range in related areas:

- 3D printing;

- 3D printing with plaster;

- 3D printing with photopolymer;

- 3D printing SLS;

- FDM 3D printing;

- Construction 3D printing;

- 3D scanning;

- Laser cutting;

- 3D engraving;

- 3D modeling;

- 3D visualization;

- 3D CNC milling;

- Manufacture of cases; nine0036

- Rapid prototyping;

- Turning work;

- Making layouts;

- Prosthetics;

- Robotics;

- Quadracoptics;

Implementation of an idea from start to finish

An extensive range of services we provide allows you to implement ideas from the beginning (it can be just an idea in your head, or ready-made drawings, layouts) to the very end (this is the direct creation of an object you have conceived) - without attraction of additional forces of contractors. We can scan your object, model a model, make drawings, provide you with a prototype, create a layout and realize the object in a real form using 3D printing. nine0007

We can scan your object, model a model, make drawings, provide you with a prototype, create a layout and realize the object in a real form using 3D printing. nine0007

Our mission is to help the person who has contacted us. That is why we are constantly expanding not only production volumes, but also the manufacturability of the entire production process, introducing new technologies and non-standard solutions. For us, our company is not just a business, but a place where your ideas are realized.

Our specialists are full of enthusiasm in the implementation of the tasks. Work does not become a routine for them, because each new order is special in its own way. The involvement of our specialists in the process, as well as their high qualifications - this is what allows us to occupy a leading position in the region in all areas of our activity. nine0007

Friendly atmosphere

It is very important for us to create a friendly atmosphere for a person who comes to us. This allows him to speak more openly about his ideas without fear of being misunderstood, or not understanding something himself.