Hemp 3d printer filament

Entwined - Hemp Filament for 3D Printing

Sold out

$40.00

Combine quantities across all items on your order to get discount levels

12 Days of Filament - December 9-20

Just add items to your cart to SAVE 15% on everything and 30% off ReFuel.

No minimums and no discount code needed!

We offer discounts for Educational, Government Agencies, Veterans, Non-Profits, and 1st Responders

Entwined™ is hemp-infused 3D printer filament, the first and only commercially-available 3D printing filament produced from USA-grown and processed industrial hemp. Industrial hemp crops require no herbicides, no pesticides and grow more densely compared to corn. Entwined hemp filament uses only a small amount of colorant, allowing it to maintain a true natural brown. There's a large amount of visible bio-fill, something you don't get with standard PLA.

"Natural" color Entwined is also colored with a small amount of brown colorant that helps the product run well and stay in spec for our high-quality standards. It will now be a darker brown than the photos.

NOTE: This is not a product designed to make the filament stronger. The Hemp is there for color, texture, and to keep it out of the landfills. This is a novelty product that makes beautiful prints. Entwined Hemp-Filled PLA is made with a small percentage of Hemp byproducts, including hurd and fiber mixed with our Workday PLA.

| Are composites biodegradable? |

| Our composite materials made with Coffee, Beer, Hemp and others are made of over 90% sustainable PLA plastic and a smaller percentage of the recycled product from the material they contain. They have two primary purposes: 1) to utilize byproducts that would otherwise be placed in landfills, and 2) to create unique and interesting filaments with which to print beautiful items. Because there are not yet any truly 100% biodegradable plastics, they may be the closest you can get to a biodegradable plastic at this time. |

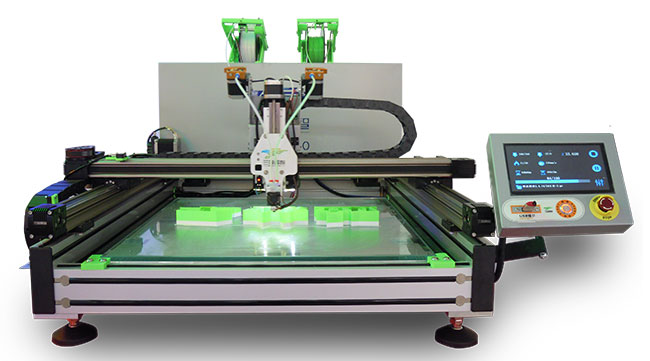

Entwined hemp filament can be printed on any machine capable of printing with PLA using standard PLA settings.

Entwined SDS

Entwined TDS

Print Settings

Entwined prints well at 180-210 C. In general, a good starting point is 10 degrees cooler than you typically print PLA. A heated bed is not necessary, though if you have one, set it to 45-60 C.

Filament Information Quality:

All 3D-Fuel 3D printer filament is manufactured in our own production facility located in Fargo, North Dakota. We have complete control over the manufacturing process and are able to ensure consistent quality for every spool. Learn more about 3D-Fuel USA filament quality.

We have complete control over the manufacturing process and are able to ensure consistent quality for every spool. Learn more about 3D-Fuel USA filament quality.

Diameter Tolerance:

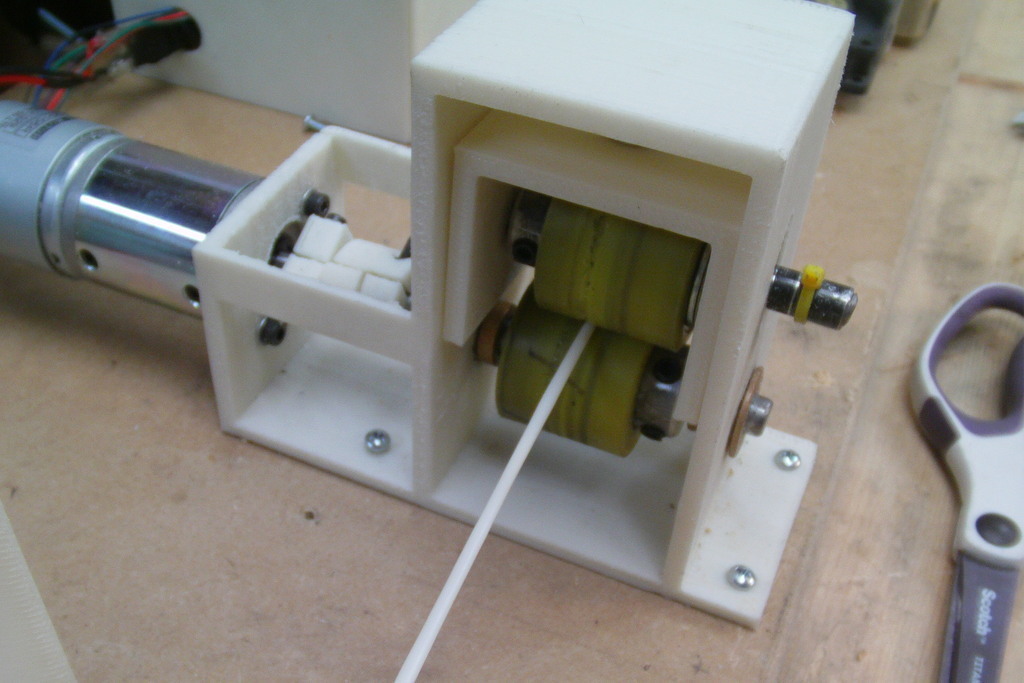

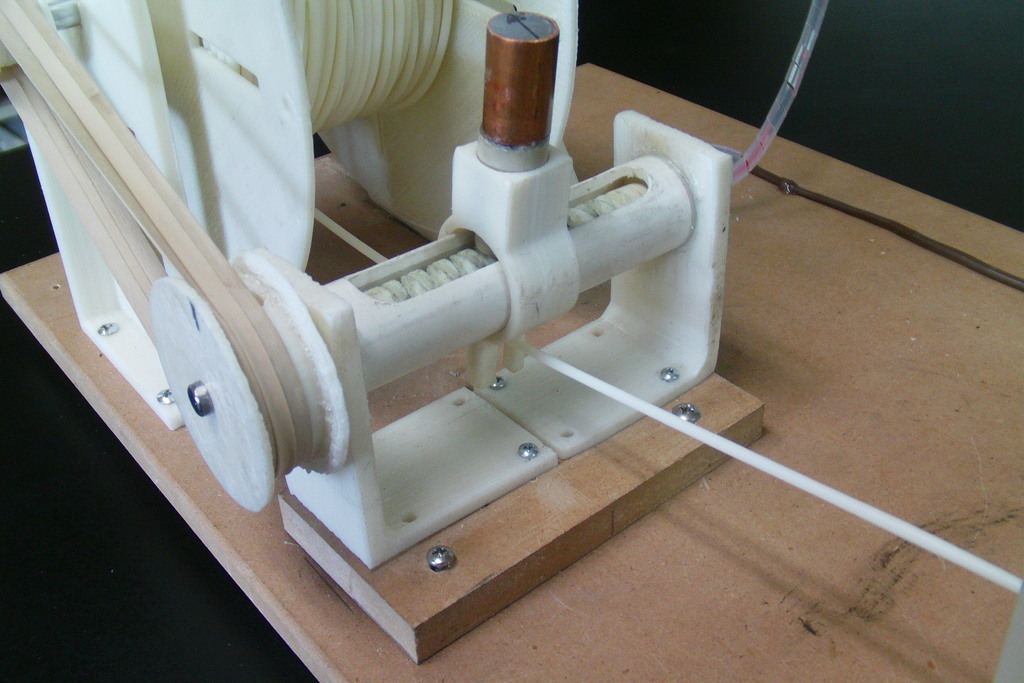

Variable diameter can cause big problems in your 3D printer. We use a multi-axis laser measurement system to control our filament diameter and ovality in real time during production. Every spool has the diameter and ovality measurements listed right on the box.

Packing Information:

500g (1.1 lbs) or 1 kg (2.2 lbs) of Entwined Hemp Filament plastic filament arrives on an easy-to-use plastic reel and is vacuum sealed with a desiccant packet to keep out any moisture. Test Printing: The 3D-Fuel test lab features multiple brands of 3D printers including MakerBot, Raise3D, LulzBot, FlashForge, and more. We 3D print what we manufacture to ensure that our filament provides the absolute best quality possible. Download an Entwined™ brochure in PDF format

Hemp 3D printer filament: A sustainable alternative

Published on September 20, 2018 by Michelle J.

Cannabis has over recent time been a growing topic of debate. As it is discussed in various ways for its medical uses, environmental benefits and sustainable abilities, it is only natural that Hemp 3D printer filament would also come up at some point. While it is not the only alternative 3D printer filaments we covered on 3Dnatives, here is what you need to know about this 3D printing material.

The history

One material that historically has been a big part of the world culture in over 10.000 years is: hemp. It was one of the first plants domesticated by Humans and have been used in day-to-day life for its solid fibres, nourishing seeds and natural medicinal properties. It was even commonly used as paper and the growth of the plant encouraged by Kings. However around the 1950s a decline came about when cannabis was demonized for its euphoric properties. Since then the full plant has been looked down upon in big parts of the USA and Europe and the use of the material declined drastically.

Industrial hemp material

In recent years however, the focus have turned back into a positive spin for the versatile material. More and more places are changing legislation, such as in California, and opening up for implementing the plant into everyday life. So as Hemp is an environmental-friendly material, it could be the solution to a lot of environmental problems. The plant reduces water consumption, pesticide use, and much more. The versatility of the plant can be used for a ton of things, such as biofuel and textiles. This is where 3D printing comes into play, as a lesser-known usage of this plant is for 3D printer filament. Along with hemp filament being developed it brings a new aspect to the additive manufacturing industry.

Manufacturing process

3D printing is improving the manufacturing processes in terms of reducing the environmental impact of manufacturing by reducing waste and speeding up the processes while often using less energy. Still, there are a way to go before a completely closed loop system and environmental-friendly filaments on the market. Mistakes and bad 3D prints happens from time to time. When using traditional plastics this can build up a lot of unwanted and unneeded waste. A way to counteract this is to print with biodegradable or recyclable material, such as PLA and Hemp. Because of hemps natural abilities it has no need for pesticides, it fertilises the soil it grows in and can grow more densely than other crops. Already these aspects make hemp a good material to work with as an eco-solution. PLA, which hemp is often combined with, is already biodegradable on its own. This based in PLA being sourced from materials such as sugar canes and cornstarch. Therefor combining PLA and Hemp in a hybrid material will bring new possibilities to the table.

Mistakes and bad 3D prints happens from time to time. When using traditional plastics this can build up a lot of unwanted and unneeded waste. A way to counteract this is to print with biodegradable or recyclable material, such as PLA and Hemp. Because of hemps natural abilities it has no need for pesticides, it fertilises the soil it grows in and can grow more densely than other crops. Already these aspects make hemp a good material to work with as an eco-solution. PLA, which hemp is often combined with, is already biodegradable on its own. This based in PLA being sourced from materials such as sugar canes and cornstarch. Therefor combining PLA and Hemp in a hybrid material will bring new possibilities to the table.

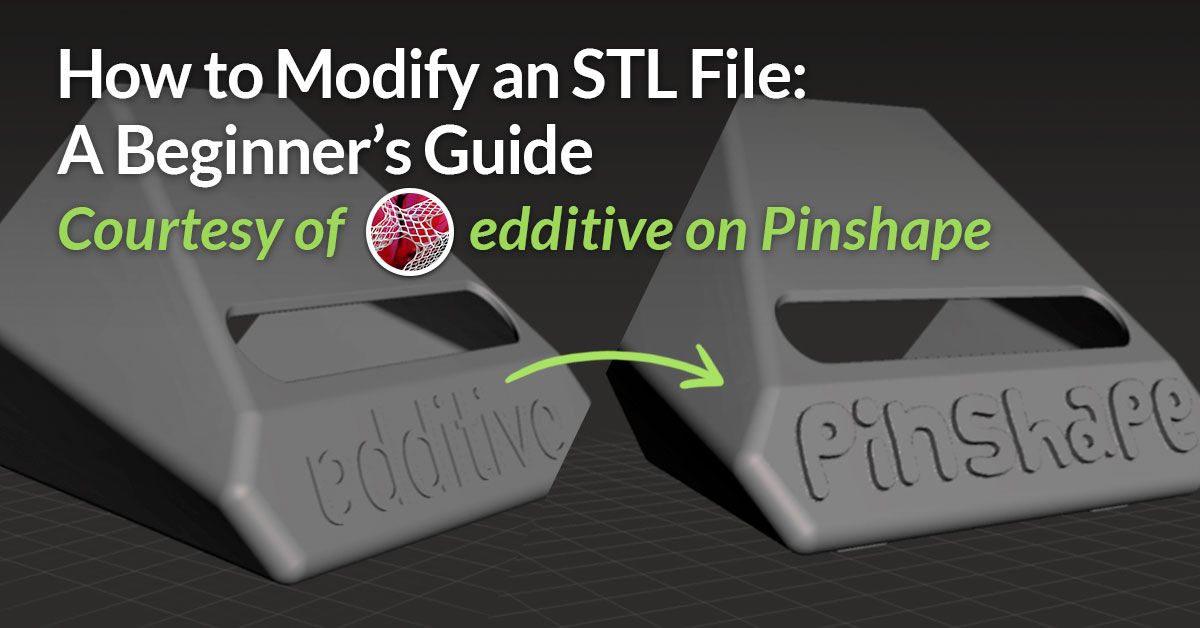

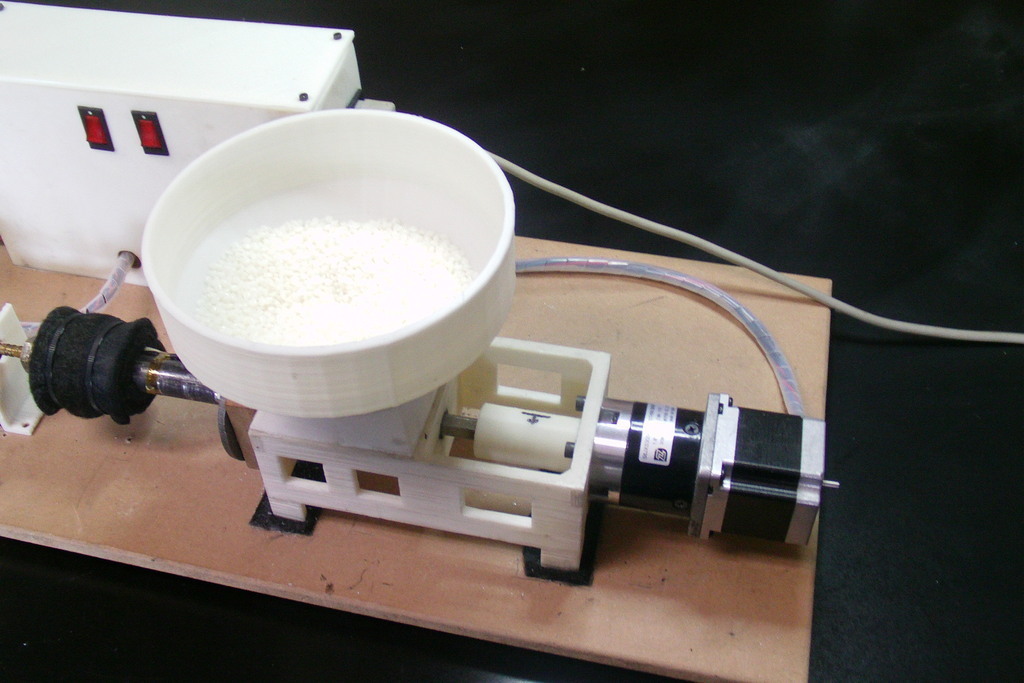

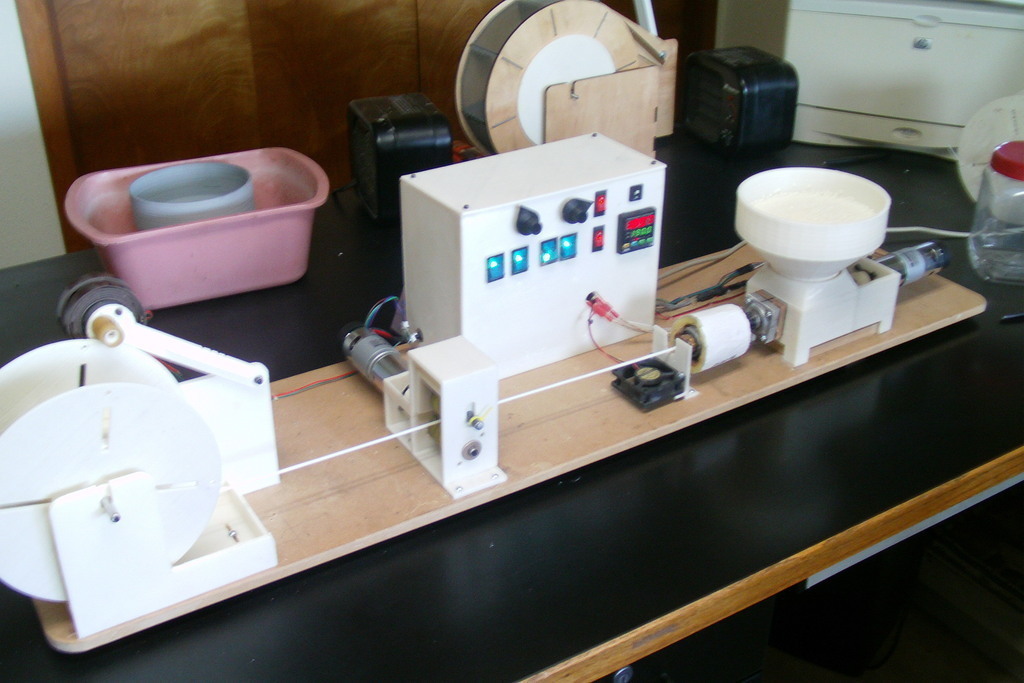

The process of making hemp filament is fairly simple. Most commonly you will see a material like PLA as a polymer base. The hemp fibre is grounded up into fine particles and mixed into it. This process is done in the same way a lot of other hybrid filaments are made. However, it is often made without added colour to keep the positive impact all the way through and has a special texture to add to the print. With this and as hemp is good for the environment, it is no wonder that there is a demand for it.

However, it is often made without added colour to keep the positive impact all the way through and has a special texture to add to the print. With this and as hemp is good for the environment, it is no wonder that there is a demand for it.

The debate on how legal the various filaments are, depends on the individual locations. In France the law is set to the filament having less than 0,2% Tetrahyrdocannabinol or THC for short. But the general laws are currently changing in various locations around the world. One place where legislation seems to be moving fast over recent years is the US. In 2014 then president Obama signed the agricultural act of 2014. This amongst other, allowed for universities and state departments of agriculture to start cultivating industrial hemp for limited purposes, opening up for the market to develop. This year alone at least 38 of the states considered legislation related to the hemp industry, covering everything from clarifying laws to establishing new licensing requirements and programs. Out of this at least 5 states have enacted legislation to establish hemp research and industrial pilot programs along with more states.

Out of this at least 5 states have enacted legislation to establish hemp research and industrial pilot programs along with more states.

Main producers

There are already a couple of companies out with their version of the hemp 3D printer filament. One such company is 3D4MAKER. They have developed their product for the market of biodegradable plastics with the ability to recycle or compost the filament afterwards.

Another company is 3Dfuel. The company have released a series of eco-friendly composite materials. Partnering with c2renew to produce the line, they came up with 4 materials so far. They consist of Wound Up: a coffee filament, Buzzed: a beer filament, Landfillament: a trash filament and Entwined: their hemp filament. All of which is produced using waste materials and Ingeo PLA to provide functional and sustainable 3D prints. 3Dfuel even released an improved version of their hemp filament. In the v2 version they basically reduced the particle size of the hemp material. The finer particles allows for an increase in the percentage used in the filament with the visible bio-fill creating a unique texture. Showing an interest in improving the possibilities.

The finer particles allows for an increase in the percentage used in the filament with the visible bio-fill creating a unique texture. Showing an interest in improving the possibilities.

A newer company, doing so as well and pushing the natural material is Kanèsis. Starting out slow with a campaign that didn’t take off, they still managed to fund their HempBioPlastic or HBP®. The company persisted, launched their website and have worked to develop solutions for a sustainable world ever since. On their site they sell the HBP filament as well as a Weed filament. The main difference between the two, being the THC levels. The Italian company is sole committed to natural materials designed for the manufacturing industry, bringing down the environmental impact and providing all-around benefits.

Kanèsis’ HempBioPlastic or HBP®

How to use Hemp 3D printer filament

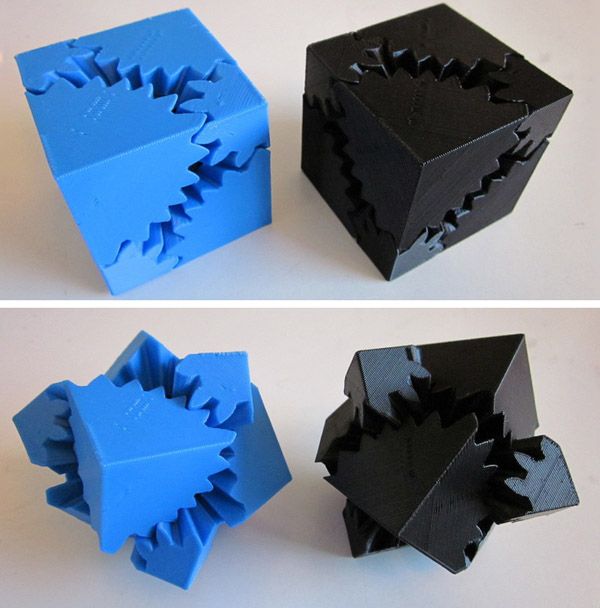

The general printing properties of most of the hemp 3D printer filament closely resembles PLA filament. However, it might be even easier to print with as it, depending on which producer you buy it from, can print at 10°C lower than PLA. The filament is also odorless, which helps for indoor use in smaller spaces. And it has low-warp, making a heated bed unnecessary when printing. Though if you have one an optimal heat setting seems to be around 45°C. Since hemp 3D printer filament is easy to print and works in the same manner as PLA, it can be used in a variety of ways. However, do to the ease of use, along with the biodegradable attributes it would be good for daily prototyping. Not to mention other projects of experimenting that wouldn’t have the need for colouring. Of course if you are searching for a specific look or texture to your print, it might be worth checking out as well. Although the hemp filament is a hybrid filament at this point, it seldom has the same texture as traditional PLA.

The filament is also odorless, which helps for indoor use in smaller spaces. And it has low-warp, making a heated bed unnecessary when printing. Though if you have one an optimal heat setting seems to be around 45°C. Since hemp 3D printer filament is easy to print and works in the same manner as PLA, it can be used in a variety of ways. However, do to the ease of use, along with the biodegradable attributes it would be good for daily prototyping. Not to mention other projects of experimenting that wouldn’t have the need for colouring. Of course if you are searching for a specific look or texture to your print, it might be worth checking out as well. Although the hemp filament is a hybrid filament at this point, it seldom has the same texture as traditional PLA.

The price varies quit a lot form one hemp printer filament to the next. Kanesis sells their HBP and Weed filament for around $37 for a 500g spool. 3D4MAKERS is around the same kg price with a 750g spool for ca. $48. In the more expensive corner you can look to 3Dfuel’s entwined that sells for $45,99 for 500g. Depending on the producer the prices varies, along with the actual plant material percentage in the filaments.

In the more expensive corner you can look to 3Dfuel’s entwined that sells for $45,99 for 500g. Depending on the producer the prices varies, along with the actual plant material percentage in the filaments.

3Dfuel created a short video to introduce you to the concept of hemp 3D printer filament:

So while there are bio-filaments on the market already, it is only the start. Both established and new companies will continue to develop and improve their products. What to you think of the hemp 3D printer filament? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news on progress, research and more entrepreneurs in 3D printing send straight to your inbox!

Biodegradable thread. In search of the best eco-friendly yarn.

There are still many unclear points in 3D printing. One of them - it will happen when everyone starts printing kilos of harmful ABS plastic without any control. Faced with this terrible future, many companies who started search of biodegradable thread is perfect. The holy grail of 3D printing.

One of them - it will happen when everyone starts printing kilos of harmful ABS plastic without any control. Faced with this terrible future, many companies who started search of biodegradable thread is perfect. The holy grail of 3D printing.

In this article, we will look at market options for if we want our 3D prints to be environmentally friendly. nine0006 in various chemicals included in its composition in natural environmental conditions .

This does not mean that everything that is biodegradable is good for the planet. There is glass, but in order for nature to assimilate the bottle, 4000 years must pass.

To define acceptable and unacceptable times, ISO 14885 (also called EN 13432). This standard specifies Biodegradability under controlled composting conditions . Decomposition level must be greater than for 90% of and this must be achieved within a period of time not exceeding 6 months .

Biodegradable Thread

Now that we have a clear idea of what biodegradable thread should be, we are going to look at the most common options in this sector for purchasing sustainable thread.

PLA

The main material used in 3D printing is PLA. is a polymer composed of lactic acid molecules which are usually obtained by processing corn starch, cassava or sugar cane. Time decomposition of is approximately 2 years .

The approximate cost of this thread is 20 euros per 1 kg coil.

ALGIKS3D

ALGIKS has several on the market fibers made from algae as raw material . They claim to use only harmful algae, so using their fibers is doubly good for the planet. To give the filament consistency, they have to mix this seafood with PLA. Unfortunately, they don't indicate how much they use of each material. nine0013 They guarantee that all material produced is 100% American product . They are also very focused on making their audience American and sell them affinity for the raw material.

They are also very focused on making their audience American and sell them affinity for the raw material.

They guarantee that the production of your thread will continue. the strictest quality control of and that the accuracy tolerance for thread thickness is maximum. All this to ensure that your filament does not clog the nozzles and other delicate parts of our printers.

This thread can be found at an approximate cost of 19euro per spool 300 gr.

Willowflex

Manufacturer Bioinspiration He tells us about this material without telling us where it came from, although in many cases many of its characteristics are compared with those of wood.

They explain to us that their material es is flexible and resistant to cold and heat. To demonstrate the quality of their manufacturing process, they mention a third company that actually manufactures the product to their specifications. nine0013 A very important detail is that we are told that your material impression complies with EN 13432 . That is, in less than 6 months, it degrades by 90%. They also confirmed that the produced compost does not contain heavy metals and is suitable for use in growing plants. Under less ideal conditions than those encountered during ISO certification, they have proven that it decomposes in a couple of years, just like wood.

That is, in less than 6 months, it degrades by 90%. They also confirmed that the produced compost does not contain heavy metals and is suitable for use in growing plants. Under less ideal conditions than those encountered during ISO certification, they have proven that it decomposes in a couple of years, just like wood.

And just like with wood, they assure us that we can use it in our facilities without fear that we will come in one morning and rot. nine0013 El Costa approximate value of this thread 29 € for 300 grams.

hummed

This is the first of several threads created by American 3D Fuel.

Este filamento made with waste resulting from brewing . The filament has a curious gold color and the print temperature is slightly lower than PLA. Ambient at 190ºC. The company also talks about a local product. The thread is produced in North Dakota with the strictest quality control. A 500gr reel can be found for 45 euros. nine0003

A 500gr reel can be found for 45 euros. nine0003

Biom3D

biome company it also has eco-friendly thread. In this case, it is from vegetable starches and oils . Thus, they assure us that the resulting filament is a high quality material with an exceptional finish and can print faster than PLA . However, we could not find the thread in stock in any store.

Enviro ABS

This is the only ABS thread what you will find in comparison. Yes, we said that ABS is not biodegradable. However, 3DPrintlife ha reformulated the chemical properties of the material to make it possible for to be consumed by some bacteria when is discarded. Being an ABS plastic, it retains the impressive characteristics of that material. And as the icing on the cake, they assure us that a share of the income from each reel It will be used plant a tree in one of the most emblematic forests in the US

HempBioPastic

This unique Italian project, which received the necessary donations on Kickstarter to make it a reality, offers plant-based filament . The raised project was completed in September of this year, and they are ready to be sent to patrons. We are assured that 100% of the material is made from waste industrial hemp . This characteristic gives printed objects of curious with veins . Kanesis also assures us that your product in is 20% lighter and 30% stronger than PLA . We can even print at a lower temperature than is required for PLA printing.

The raised project was completed in September of this year, and they are ready to be sent to patrons. We are assured that 100% of the material is made from waste industrial hemp . This characteristic gives printed objects of curious with veins . Kanesis also assures us that your product in is 20% lighter and 30% stronger than PLA . We can even print at a lower temperature than is required for PLA printing.

Filament is currently only being produced for delivery to KickStarter members. We will keep you posted when it finally becomes public.

The already named 3DFuels also has hemp-based thread since 2016. nine0003

Wound up

Another EcoFriendly thread developed by 3DFuel. With nice brown color and using coffee as raw material . Unfortunately, in this case, they were not able to create 100% coffee thread, and had to resort to using PLA as the basis of the resulting polymer. In this regard, they warn us that objects printed in this way cannot come into contact with very hot liquids or foodstuffs . A 500gr reel can be found for 45 euros.

In this regard, they warn us that objects printed in this way cannot come into contact with very hot liquids or foodstuffs . A 500gr reel can be found for 45 euros.

Conclusion

We can appreciate this producers of they make a great effort to produce filamentos with individuality and at the same time Respect for the environment . Some have even better performance than PLA. However, PLA is still more affordable

We hope you enjoyed this biodegradable thread article and encouraged you to be more environmentally friendly in your experience. If we ever have access to any of these curious threads, take it for granted that we will analyze it in the blog. nine0003

Do you know of any biodegradable filaments that we haven't listed here?

3d printer with hemp filament — Stock Video © mattiamarty #145424293

3d printer with hemp filament — Stock Video © mattiamarty #145424293Sign In to See December Deals

Images

VideosEditorialMusic & Sounds

Tools

Business

Our Prices

All Images

LoginRegister

Download this video,

by registering an account

Already have an account? Enter

I accept the terms of the user agreement to be used to news and special offers

3D printer with good hemp thread - video from Mattiamarty

- Find similar video

- 145424293

- AutoAMATIAMARTY

- Duration: 00: 12 Sight 9004 licensed videos: Filling and production of bottles plant2Cosmetics industry, mascara plant1Mechanism of automatic impact machine5Nanotechnology laboratoryAluminum extrusion warehouseClose-up of concrete equipment in the workshop.

4K .Filling and bottle productionCosmetics industry, mascaraPlantation bottle production and filling3Molten cheese packaging machineNew prefabricated plate close-up productionMachine oil filling and packaging production lineProduction. Arc cutting operation, close-up Industrial meat processing shown at food and beverage exhibition .The worker goes to the oven and then to the blow molding machine .MOSCOW, RUSSIA - OCT 11, 2012: Machine packaging of sausages at the international exhibition of machinery, equipment and ingredients for the food industry "AgroProdMash" in Expocentre .Conveyor belt of printing press printing machine in operationFood industry packaging assembly line closing1

4K .Filling and bottle productionCosmetics industry, mascaraPlantation bottle production and filling3Molten cheese packaging machineNew prefabricated plate close-up productionMachine oil filling and packaging production lineProduction. Arc cutting operation, close-up Industrial meat processing shown at food and beverage exhibition .The worker goes to the oven and then to the blow molding machine .MOSCOW, RUSSIA - OCT 11, 2012: Machine packaging of sausages at the international exhibition of machinery, equipment and ingredients for the food industry "AgroProdMash" in Expocentre .Conveyor belt of printing press printing machine in operationFood industry packaging assembly line closing1 Show more

Usage information

You may use this royalty free video "3D hemp filament printer" for personal and commercial purposes under the Standard License. The Standard License covers a variety of uses, including advertising and UI design on websites and apps.

You can buy this stock footage and download it in high resolution up to 3840x2160.

Depositphotos

- About stock

- Our plans and prices

- Solutions for business

- BLOG DEPOSITPHOTOS

- Abstract

- API

- vacancies

- New Images

- Free registration of the supplier

- Encom Deutsch

- Français

- Español

- Russian

- Italiano

- Português

- Polski

- Nederlands

- 日本語

- Česky

- Svenska

- 中文

- Türkçe

- Español (Mexico)

- Ελληνικά

- 한국어

- Português (Brasil)

- Magyar

- Українська

- Română

- Bahasa Indonesia

- ไทย

- Norsk

- Dansk

- Suomi

Information

- FAQ

- All documents

- is available at

- available in

- Bird in Flight -Journal about photography

Contacts

- +49-800-000-42-21

- Contact us

- Reviews about Depositos

© 2009-2022.

Learn more

As they are mostly PLA, they are compostable in an industrial compost, will eventually biodegrade (won't last forever like petrol-based plastics), and are made from plants.

As they are mostly PLA, they are compostable in an industrial compost, will eventually biodegrade (won't last forever like petrol-based plastics), and are made from plants.