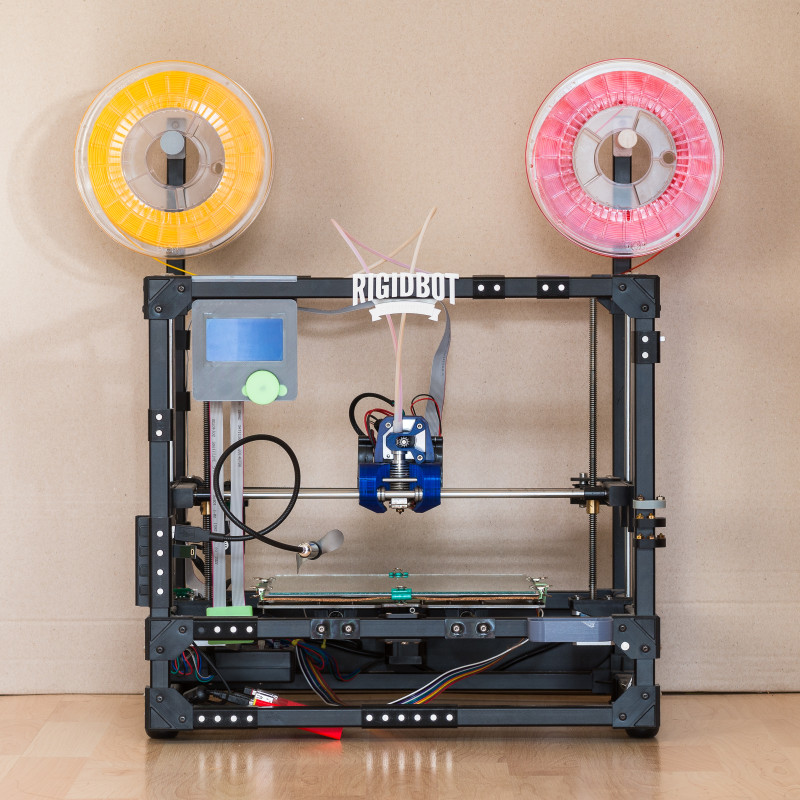

Gold filament 3d printer

Gold MH Build Series PLA Filament - 1.75mm (1kg)

- Home

- Store

- 3D Printer Filament

- Filament by Color

- Gold Filament

MH Build PLA is an affordable PLA filament intended for producing quality, 3D printed parts. MH Build PLA comes in a wide selection of bold colors to choose from. MH Build PLA is made with price in mind for any maker, from beginner to advanced, in a wide selection of bold colors.

Remove from wishlist Add to wishlist loading...

Available Add-ons (2)

Show More Addons

Product No. M-9UV-322N

| List Price: | $20.87 |

|---|---|

| Price: | $20.87 |

| Price: | $... |

| Order Now: | Ships calculating. |

Buy 1

$20.87 /ea

Buy 2

$20.81 /ea

Buy 3

$20.81 /ea

Buy 4

$19.82 /ea

Buy 5

$19.82 /ea

Buy 6

$18.36 /ea

Buy 7

$18.36 /ea

Buy 8

$17.94 /ea

Buy 9

$17.94 /ea

Buy 10

$17.35 /ea

Buy 11

$17.35 /ea

Buy 12+

$16.17 /ea

MH Build Series - Affordable PLA 3D Printer Filament for Every Maker

MH Build 3D printing filaments are designed with price in mind; we have taken the best aspects of PLA filament - it is renewable, biodegradable, and adaptable - and created an affordable solution for every 3D maker. MH Build filaments include PLA, ABS, and PETG. So if you’re a pure beginner with a limited budget, or an additive manufacturer looking to save on production costs, MatterHackers MH Build PLA is the filament to get any job done.

PLA, aka Polylactic Acid, is a multipurpose material commonly used in 3D printing. PLA filament is a bioplastic, which means it is made from renewable natural resources such as corn starch and tapioca products. As a biodegradable material, it is much better for the environment, especially compared to petrochemical-based alternatives. All MH Build filament is sealed with desiccant for storage and freshness.

PLA filament is a bioplastic, which means it is made from renewable natural resources such as corn starch and tapioca products. As a biodegradable material, it is much better for the environment, especially compared to petrochemical-based alternatives. All MH Build filament is sealed with desiccant for storage and freshness.

- Recommended Extrusion Temperatures: 205±15°C

- Recommended Bed Temperature: Not needed, but if printer has heated bed, 40±15 °C

- Spool Dimensions (Approx.): 200mm Total Diameter x 50mm Inner Hole Diameter x 65mm Height

- 1 kg spool

- True Diameter: 1.75mm

- Dimensional Accuracy: ±0.05mm

- Density: 1.25 g/cm³

- Volume: 0.80 L

- Length: 332.60 m

- Download the Technical Data Sheet

- Download the Safety Data Sheet

Learn More About 3D Printing With PLA Filament

Your success in 3D printing is our goal, so we have created many guides to help you create the highest quality 3D printed parts possible.

- How to succeed when printing with PLA

- How to smooth and finish your PLA prints - Part 1

- How to smooth and finish your PLA prints - Part 2

3D Print Gold PLA Filaments

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

Filters:

- Gold / Brass

-

3DJAKE ecoPLA Glitter Gold 6 Model types- Made in EU

- High-quality

- Easy to print

-

3DJAKE ecoPLA Ultra-Satin Gold 4 Model types- Made in the EU

- High quality

- Easy to print

-

Fillamentum PLA Extrafill Gold Happens 2 diameters- Variety of colours

- Easy to print

- High precision processing

-

3DJAKE ecoPLA - Gold 6 Model types- Made in EU

- High quality

- Easy to print

-

Spectrum SILK PLA Glorious Gold- Unique aesthetic properties

- Reduced visibility of layers

- Silky shine over the entire surface

-

Formfutura High Gloss PLA Gold 4 Model types- Extremely high gloss

- High light diffusion and reflection

- Very smooth and silky surface

-

AzureFilm PLA Gold- High strength

- Excellent print quality

- No warping

-

AzureFilm Silk Gold- Silky look

- Shiny finish

- Easy processing

-

eSUN PLA+ Gold- Increased strength and toughness

- Excellent layer adhesion

- High printer compatibility

-

Spectrum PLA Glitter Aurora Gold 2 Model types- Great quality

- Warping free

- High strength filament

-

eSUN eSilk PLA Gold- Very shiny surface

- Easy to print

- No heatbed required

-

Fiberlogy FiberSilk Metallic Gold- Aesthetic look

- Easy to print

- Good adhesion

-

Fiberlogy Easy PLA True Gold- High precision

- Good adhesion

- High quality

-

Fiberlogy FiberSilk Metallic Brass- Aesthetic look

- Easy to print

- Good adhesion

-

Polymaker PolyLite Silk PLA Gold- Silky, glossy print surface

- Easy processing

- Versatile use

-

colorFabb PLA / PHA Pale Gold 2 diameters- High stability

- High quality

- Attractive colours

-

Formfutura EasyFil™ PLA Gold 4 diameters- Easy to print

- Available in many colours

- Almost no warping

-

eSUN eTwinkling Gold- Glitter effect

- Easy to print

- No heatbed required

-

eSUN eSilk-PLA Rose Gold- Silk look & texture

- Easy to print

- No heating bed required

-

AddNorth E-PLA Gold- Easy to print

- Low processing temperature

- Wide range of colours

-

Spectrum SILK PLA Rose Gold- Unique aesthetic properties

- Reduced visibility of layers

- Silky shine over the entire surface

-

Spectrum PLA Pro - Pearl Gold 2 Model types- High durability

- Easy removal of the models

- No shrinkage

-

Re-pet3D rPLA Honey Gold- For precise quality printing

- Biodegradable

- Sustainable

-

Spectrum PLA Pearl Gold 2 Model types- Great quality

- Warp-free

- High strength filament

All prices incl. VAT.

VAT.

3D printing with gold thread: properties and uses

Author Kirill Sokolov Reading 7 min. Views 84 Published by

Gold, with its characteristic color and luster, has always been a highly valued metal throughout almost the entire history of mankind. Often used in the jewelry industry, the ability to work with gold and create custom pieces remains a valuable and exclusive skill set. Those with 3D printers might ask: Can 3D printing technology be used to create custom designs that are made of gold or mimic the look of gold?

Both of these questions are still answered. . As you might expect, budget comes into play. What options do you have if you want to 3D print your own gold jewelry?

Contents

- Option 1: Silk Gold PLA Filament

- Option 2: 3D SoluTech Real Gold PLA Filament

- Option 3: GizmoDorks Gold ABS Filament

- Is there a technology for real gold 3D printing?

- Closing thoughts

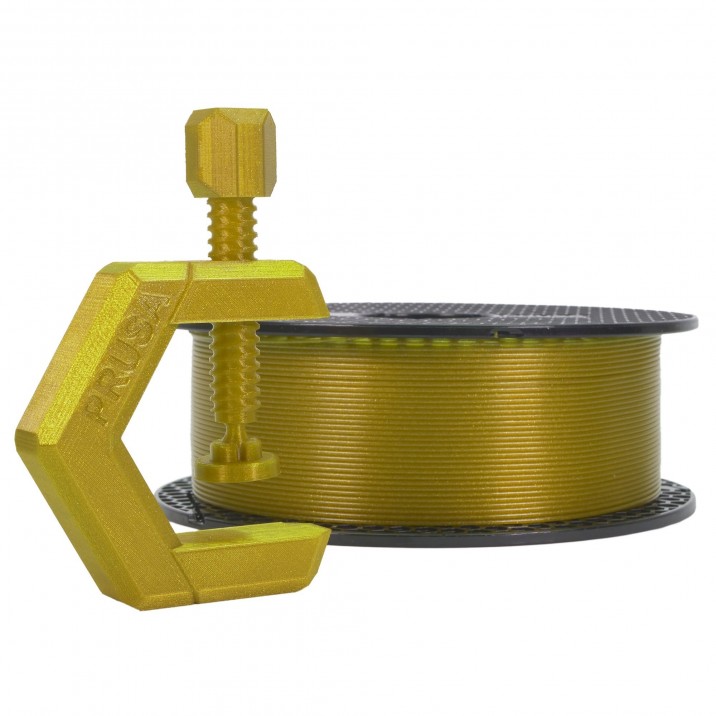

Option 1: Silk Gold PLA Filament

This Silk Gold PLA Filament from CC3D is one of the most popular options for anyone who wants to try their hand at 3D printing something that looks like gold. The average reason for the popularity of this thread is that it is very cheap. This is just another way of saying that the filament does not contain real gold.

The average reason for the popularity of this thread is that it is very cheap. This is just another way of saying that the filament does not contain real gold.

This thread uses gold colored silk threads embedded in a PLA matrix. The use of silk is an amazing idea that makes the material reflective enough to mimic the sheen of real gold. Prints made with this filament naturally come out shiny and glossy, although a little sanding and polishing won't hurt to get rid of the layer lines.

Besides the low cost of the filament, another advantage of using silk instead of metal particles is that the filament is not exclusively abrasive. Using the standard brass nozzle of most solid filament 3D printers is always problematic as solids tend to wear down brass materials fairly quickly. This is not a problem for silk threads.

Silk Gold PLA filament prints at normal PLA printing temperatures - ranging from 195 to 230°C. As with regular PLA, a heated bed is not a strict requirement when working with Silk Gold PLA, although a bed heated to around 60°C is still ideal. Silk Gold PLA is a relatively simple and beginner-friendly filament that provides visually pleasing results.

Silk Gold PLA is a relatively simple and beginner-friendly filament that provides visually pleasing results.

Since the filament does not contain solid particles, you will miss the characteristic mass of 3D printed projects. made from solid thread. This weight gives 3D prints a certain level of premium quality. A print made from PLA Silk Gold looks good, but you're not going to fool anyone that it's made from real gold.

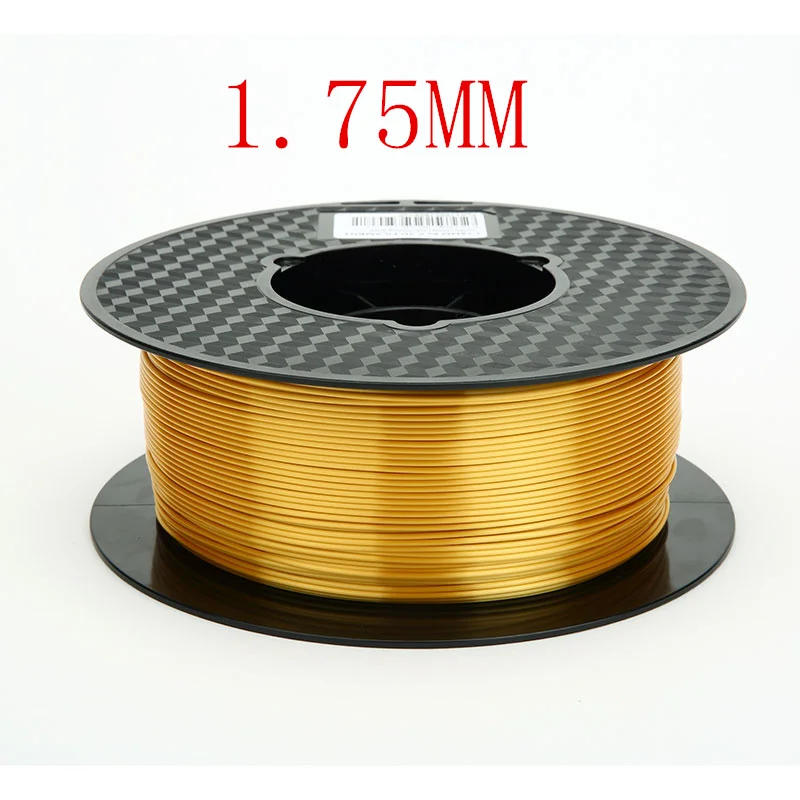

Option 2: 3D SoluTech Real Gold PLA Filament

This real gold filament from 3D SoluTech is another viable and inexpensive option if you want your prints to be elegant. Even though the thread's marketing used "real gold", nothing could be further from the truth. This is standard color PLA with no solids, which is both a good and a bad thing.

The absence of any metallic particles in this true gold filament means it is no more difficult to print than standard PLA. You can print at low temperatures and without a heated bed without worrying about layer sticking or warping issues. You can also safely use the standard nozzle without worrying about wear.

You can also safely use the standard nozzle without worrying about wear.

Since almost everyone who has tried 3D printing knows how to work with PLA, this might be the easiest way to add some gold to your 3D prints.

However, in this case quality takes a backseat to ease of use. Prints made with Real Gold filament look more like brown bronze than gold. The closest metallic analogue of a thread made of real gold will be copper. Because it does not contain any naturally shiny materials, a full range of finishing techniques, from sanding and polishing to priming, will be required to achieve the "shine" of the finished print.

Despite its shortcomings, SoluTech Real Gold Filament is still a compelling choice for 3D printer enthusiasts who want to get a little creative but don't want to work with complex filament material. The filament still looks great and "pops out" when properly tuned. This is an inexpensive filament that is easy to work with and requires no modification to your standard 3D printer. Just met your expectations, as it can not be like "real gold" in any way.

Just met your expectations, as it can not be like "real gold" in any way.

Option 3: GizmoDorks Gold ABS Filament

Famous 3D filament brand GizmoDorks uses their ABS based gold filament instead of PLA. This should be a good choice for those who want their gold prints to have an extra factor of strength and heat resistance. Naturally, GizmoDorks gold filament comes with the usual difficulties of ABS printing.

Like SoluTech Gold Thread, GizmoDorks Gold Thread does not contain solids, but is simply colored ABS. This simplifies the whole technique of 3D printing this gold filament, especially if you are already used to working with ABS. Compared to PLA, ABS printing is slightly more stable in terms of chemical and thermal resistance. It's also robust enough for limited functional use, although we assume you'll be using this thread to build display elements.

The finish of this gold thread is also somewhat dull, but closer to a yellowish toffee color than bronze. The bright finish looks great even without any trim. However, this thread is a great opportunity to practice ABS finishing techniques using an acetone steam bath. This technique melts a very thin layer of plastic onto an ABS print, giving it a perfectly smooth and shiny surface.

The bright finish looks great even without any trim. However, this thread is a great opportunity to practice ABS finishing techniques using an acetone steam bath. This technique melts a very thin layer of plastic onto an ABS print, giving it a perfectly smooth and shiny surface.

If you have worked with ABS before, you probably know that it is not easy to print with it. The high printing temperature required for ABS, combined with its thermal shrinkage index, makes it especially prone to warping. Achieving the perfect combination of bed temperature, print speed, and nozzle temperature takes a bit of work. The consistency and quality of this thread from GizmoDorks is pretty good, so it should help you eventually improve your technique.

Is there a technology for 3D printing with real gold?

The only thing that all of the above options have in common is that none of them uses real gold. Unlike other metals such as brass or copper, gold is very expensive even in small quantities. A 1kg spool of filament impregnated with real gold would likely cost tens of thousands of dollars, which is not very suitable for a process that requires repetitive cycles of trial and error.

A 1kg spool of filament impregnated with real gold would likely cost tens of thousands of dollars, which is not very suitable for a process that requires repetitive cycles of trial and error.

way to turn 3D models into pure gold objects, but they rely on different 3D printing technologies. The most commonly used are direct metal laser sintering (DMLS) and investment casting. Sintering is carried out using a laser to cure the powdered raw material, similar to the selective laser sintering (SLS) process.

Lost wax casting is a more indirect way of using 3D printing to work with gold. Instead of printing in gold, this method starts by using a 3D printer to create a wax model. An impression is made of the model, usually enveloping it with plaster. When the mold hardens, the bottom of the mold is pierced and subjected to high temperatures to allow the wax to run off. The mold is then filled with liquid metal—in this case, gold alloy.

Unfortunately, none of these methods can be done at home. A DMLS machine can cost up to $150,000 and houses aren't quite equipped to handle molten metal. Think about how valuable gold is and how technically complex and expensive the equipment is, it is best to entrust this work to specialists. Gold 3D printing services are offered by professional 3D printing companies such as i.materialise and Cookson Gold.

A DMLS machine can cost up to $150,000 and houses aren't quite equipped to handle molten metal. Think about how valuable gold is and how technically complex and expensive the equipment is, it is best to entrust this work to specialists. Gold 3D printing services are offered by professional 3D printing companies such as i.materialise and Cookson Gold.

Closing thoughts

3D printing in gold will be a dream come true. many manufacturers of jewelry and decorations. The sheer versatility of 3D printing, combined with the value and manufacturability of gold, will open up many opportunities for more imaginative uses of one of the most precious metals in human history.

However, 3D printing technology is not. not quite there yet. You can create faux gold 3D printer designs using filaments that mimic the look of gold, but real gold will use more traditional methods. 3D printing is still used in the art of gold working, but in a more indirect way, such as in the production of a wax model for lost wax casting.

Attention! Never leave 3D printers unattended. They can pose a fire safety hazard.

New 3D printer prints 10 times faster than existing models / Sudo Null IT News and control electronics. Right: Photographs taken while printing an ABS spiral cup at the start of printing, 120 seconds and 360 seconds later

Massachusetts Institute of Technology (MIT) engineers have developed a new print head design for FDM/FFF 3D printing, that is, fusing layer modeling. Instead of a traditional wheel, they used a "screw" method of feeding a textured thread. This increased the contact area with the filament, which dramatically increased the heating rate, extrusion force and printing speed.

FDM/FFF is the most common printing method used in low cost desktop 3D printers. Ten times faster printing allows you to print small plastic parts not in an hour, but in a few minutes (see illustration above). The assembled prototype showed a speed of 127 cm³/h, which is about 7 times faster than commercially available FDM printers. The maximum extrusion speed (282 cm³/h) is about 14 times faster than theirs. With modern conventional 3D printers, the speed usually does not exceed 20 cm³ / h, which is really slow.

The maximum extrusion speed (282 cm³/h) is about 14 times faster than theirs. With modern conventional 3D printers, the speed usually does not exceed 20 cm³ / h, which is really slow.

The existing FDM/FFF 3D printing technology has a number of built-in limits on the maximum print speed - these are restrictions on the speed of the print head on the support frame, the extrusion force and the length of the thinner chamber. MIT engineers were able to overcome these limitations with a specially designed extruder, a laser-heated filament thinner, and an H-shaped support frame with two servo motors. This made it possible to increase the extrusion force, the heating rate of the filament, and the speed of movement of the print head, respectively.

Dependence of fusing speed on printing resolution in various printer models, with restrictions on the speed of movement of the printhead on the support frame, extrusion force and the length of the thinner chamber. The total area under all three limiting curves corresponds to the theoretically possible speed of the system. The icons show the performance of four commercially available 3D printers. The right shows the penetration of temperature through the heat-conducting material, which at high feed rates does not have time to heat up

The icons show the performance of four commercially available 3D printers. The right shows the penetration of temperature through the heat-conducting material, which at high feed rates does not have time to heat up

The extrusion and heating mechanisms are housed in a compact print head that accepts textured plastic filaments and quickly heats them up before printing.

Left: photo of printhead with feeder and hot end laser heater. Right: sectional model of the working part. Shown here is how the laser interacts with the filament as it passes through a quartz chamber lined on the inside with reflective gold foil. After the laser heating chamber, the thread enters the contact heating chamber

The print speed depends on how fast the print head moves, which in turn depends on the print resolution. Thus, maximum speed and maximum resolution are unattainable at the same time, so you have to find an acceptable compromise, sacrificing one of these two characteristics.

The developers of FastFFF believe that high-speed 3D printing opens up opportunities for new ways to use this technology and for new business models where compact parts are produced in a couple of minutes rather than an hour. The dramatic acceleration gives reason to believe that the scope of 3D printing will expand. “If I can prototype a part, maybe a bracket or a gear, in five to ten minutes instead of an hour, or most of my lunch break instead of the next day, then I can design, build and test products faster,” says Anastassy John Hart (Anastasios John Hart), Associate Professor and Director of the Laboratory for Manufacturing and Productivity and the Mechanosynthesis Group. — If I am a repairman and I transport a fast 3D printer in a car, I can print custom parts for repairs as soon as I find out the cause of the breakdown. No need to go to the warehouse and look for this part. The professor mentioned the possibilities of using high-speed 3D printing in emergency ambulances and in areas remote from civilization.