Liquid 3d printer kickstarter

Anycubic Photon Ultra DLP Launches on Kickstarter

Following on the success of their Photon resin printer series, Shenzhen-based printer manufacturer Anycubic has announced that they are launching the next iteration, dubbed the Anycubic Photon Ultra, on Kickstarter. This one has eschewed LCD technology in favor of the latest DLP chip from Texas Instruments, so will offer higher quality prints with a lower energy consumption.

The original Photons have found a large following with both makers and researchers alike due to its low cost, high resolution and compatibility with a wide range of resins.

The latest Photon machine from Anycubic offers all this and a lot more. Let’s take a look at what is on offer.

Benefits of DLP

The Anycubic Photon Ultra features a print volume of 102.4 mm (L) * 57.6 mm (W) * 165mm (H), and thanks to use of their new DLP screen from Texas Instruments, is capable of printing at 720p resolution. Most budget-friendly desktop SLA systems make use of LCD screens, which has a number of downsides compared to DLP systems.

The switch to DLP technology from LCD brings a number of benefits such as: low to no maintenance, extremely high-resolution prints, and much lower power consumption.

DLP printers use a projector that reflects all the light to a pixel via a micromirror, therefore, there is no light convergence, which allows for crisper black/white contrasts. LCD printers converge all the light to a pixel, which can cause bumps and shadows on the edge of models. When displaying thin lines and small-size texts, DLP printers are clearer than LCD printers with purer colors and richer layers, resulting in more delicate texture and sharper corners of models.

For these reasons, a DLP printer with 720p resolution can offer a much higher quality print than a monochrome LCD printer with a 2k or 4k resolution. The 16 x anti-aliasing on the Photon Ultra helps to smooth the edges and corners of prints, which reduces layer lines, also adding to the quality of the print.

Lower Maintenance

LCD screens by nature, degrade over time. They degrade in an even quicker time when using them in 3D printers, where continuous use can lead to LCDs being replaced every 3-5 months.

LCD crystal substrates found in LCD screens degrade under the UV light typically used for resin printing. This is unavoidable, no matter the quality of your LCD screen.

LCD screens are therefore, just like the photopolymer resins they are used to cure, a consumable. And consumables equal expenses. In short, by using the DLP technology, you will be reducing your expenses on consumable items. The Texas Instruments DLP technology does not suffer these same issues because it doesn’t use liquid crystals, and the internal projector enables the printer to be used for more than 20,000 hours. Over that time an average user would save $600 by using the long-life DLP system compared to an LCD-based one.

Over that time an average user would save $600 by using the long-life DLP system compared to an LCD-based one.

The Photon Ultra costs less than 500 bucks on Kickstarter, so that’s not a bad saving.

Quieter, Faster, More Efficient

The Photon Ultra operates at 40% light efficiency, which is 15 times higher than the 2.5-3% that LCD printers usually operate at. It uses far less energy and is rated at 12W with an average power consumption of 8.5W. The printer consumes between 0.017 – 0.034 kWh to print a 100mm high model. The lower power consumption equals less heat, which means the Photon Ultra doesn’t need any cooling fans, making it very quiet indeed.

As mentioned earlier in the article, the previous Anycubic Photon models have been popular with researchers due to their compatibility with a wide range of resins. The Photon Ultra has options for adjustable UV power, which enables users to continue to experiment and discover new resin applications.

The latest Photon gets a speed boost as well, with the Photon Ultra being capable of printing at 1. 5 seconds per layer. This is compared to LCD printers such as the Anycubic Photon Mono X, whose speed is 1.5 – 2s per layer. The Photon Ultra can print up to 5x faster than more traditional point light source type SLA printing.

5 seconds per layer. This is compared to LCD printers such as the Anycubic Photon Mono X, whose speed is 1.5 – 2s per layer. The Photon Ultra can print up to 5x faster than more traditional point light source type SLA printing.

Where to get it

Anycubic’s Photon Ultra is launching on Kickstarter on September 14th, 2021, where it will be available for pre-order in a worldwide exclusive. The campaign will run for a duration of one month, where early backers will be able to purchase at the launch price and also avail of other perks and bonuses. The launch price is $399 for the first 100 backers and $499 after that.

It will retail on Amazon for over $599 after the Kickstarter campaign, so head over to their Kickstarter webpage and get your orders in if you would like to take advantage of the early buyer perks, or if you would like to see the full specs of the new DLP system from Anycubic.

Large-format Phrozen Transform SLA 3D printer achieves Kickstarter goal in 3 minutes

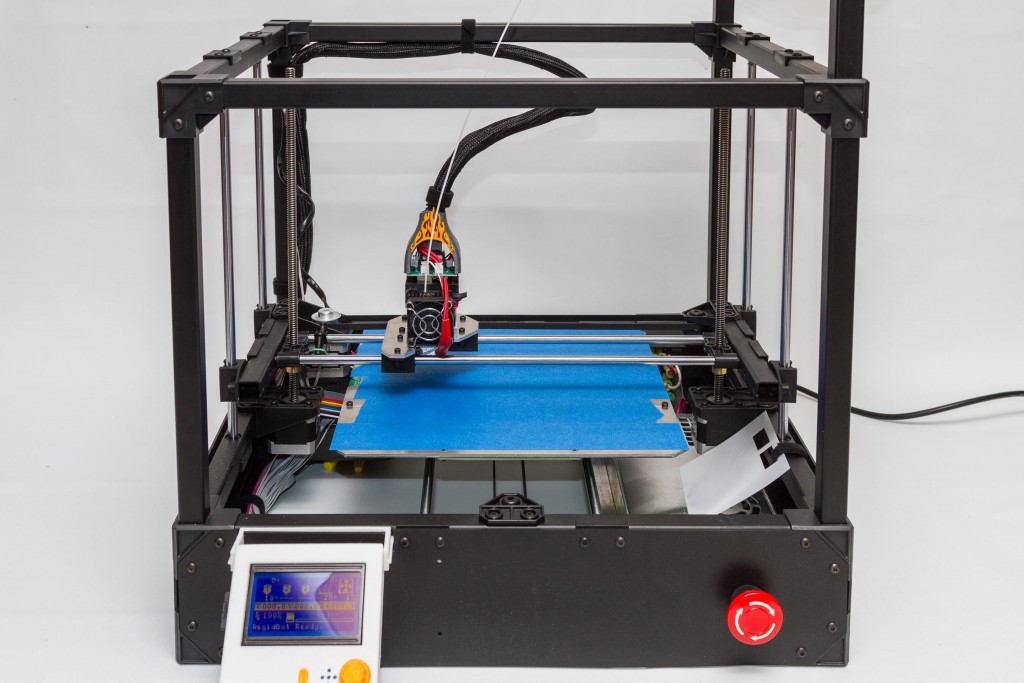

The first deluge of distributed manufacturing came in the format of FDM (fused deposition modeling) 3D printing as the patent on that technology expired in 2009.

The second wave that we’re currently riding consists of SLA (stereolithography) liquid resin 3D printers as the patents on their underlying technologies expired between 2013 and 2015. We just covered the $299 Paladin SLA 3D printer, and while the Phrozen Transform costs about four times more, its build volume is over 14 times larger. So, you do the math.

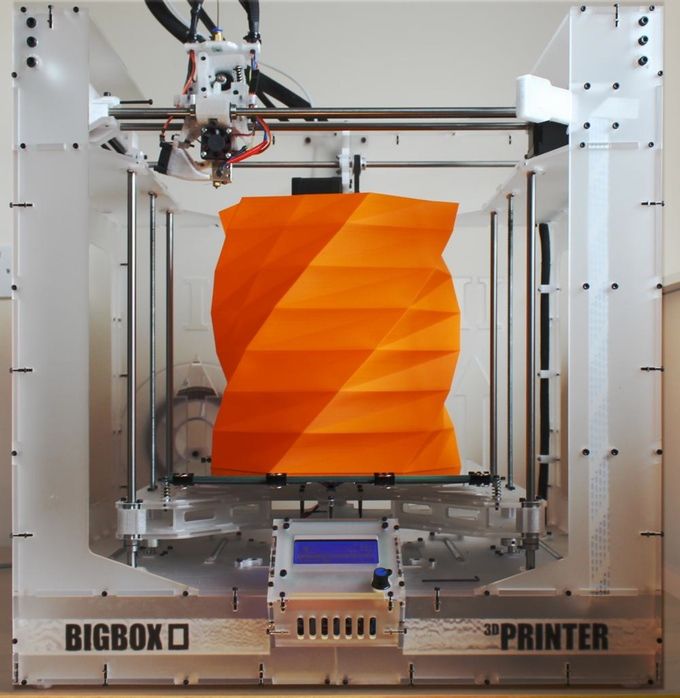

With a 13.3-inch 4K LCD screen and a build volume of 29.2 x 16.5 x 40cm, the Transform is the largest consumer-grade SLA 3D printer yet, which probably explains why the Kickstarter campaign met its funding goal of $30,000 in three minutes; it’s now breaching the quarter million dollar mark. The Transform has an extra-thick, CNC-milled aluminum alloy frame with dual Z rails and ball screws to maintain an XY resolution of 76 microns for all 400 millimeters of printable height.What’s more, the 13.3-inch screen can be swapped out with two 5.5-inch screens that have an even higher XY resolution of 47 microns; both screens can print the same ultra-high resolution object simultaneously, a feature that could be quite useful to dentists and jewelers. It takes only 30 seconds to swap the screens out. Both sizes of screen allow for Z resolution of 10 microns and print speeds of 30 vertical millimeters per hour; that means a part that would occupy the entire build chamber would take only 13 hours to 3D print.

It takes only 30 seconds to swap the screens out. Both sizes of screen allow for Z resolution of 10 microns and print speeds of 30 vertical millimeters per hour; that means a part that would occupy the entire build chamber would take only 13 hours to 3D print.

The LCD screens are powered by a ParaLED Matrix of 405nm UV-LEDs that provides more parallel light to the large screen, a necessary improvement to maintain consistent resolution. Though it’s compatible with third-party resins, several resins were developed specifically for the Transform, such as Stiff, Wax Pro Castable, Tough, Semi-Clear, and TR250, a hard material with low shrinkage and good heat resistance. The standard setup that comes with just the 13.3-inch screen can still be reserved for $1,299, which comes with five bottles of resin. The deluxe version that additionally comes with the dual 5.5-inch screens can be had for $1,549, also including the resin.

The Phrozen team has worked together for five years and has gone through six generations of SLA 3D printers, starting with the Phrozen Make that was successfully launched on Kickstarter in April of 2017. They have a lot of experience and motivation to bring the Transform to market. “Our users always asked us ‘Why there are few SLA 3D Printer that can print in large build volume?’ Many great designs were limited because of the low build volumes. When making large prints, the design has to be partitioned for printing and assembled afterward. Phrozen Transform will significantly improve a print’s strength and the efficiency of printing.” said Ray Wu, co-founder of Phrozen.

They have a lot of experience and motivation to bring the Transform to market. “Our users always asked us ‘Why there are few SLA 3D Printer that can print in large build volume?’ Many great designs were limited because of the low build volumes. When making large prints, the design has to be partitioned for printing and assembled afterward. Phrozen Transform will significantly improve a print’s strength and the efficiency of printing.” said Ray Wu, co-founder of Phrozen.

Compare

Remove all

Compare up to 10 products

Is thePeachy Printer another kickstarter 3D printer or a new player on the market? / Sudo Null IT News

Articles about new 3D printers appear on Habré regularly and promptly, but so far (two days have passed since the start of the campaign) there has been nothing about this printer. I'll fill this gap, so:

Peachy Printer is the most affordable ($100) 3D printer and scanner.

Watch the introductory video, which reveals the principle of operation and explains where this cheapness came from.

Peachy does not refer to the already familiar printers operating with the melting of ABS / PLA rods, but to printers using Laser stereolithography

(I note that printers with stereolithography used to be on kickstarter, for example, a year ago www.kickstarter.com/projects/formlabs /form-1-an-affordable-professional-3d-printer - but what was called "affordable professional 3D printer" sold for more than $2000)

In our case, laser stereolithography implies that there is a liquid photopolymer (or as it is usually called, resin - "resin") and there is a UV laser that controls the curing process and layer by layer "grows" the model we need.

The Peachy printer uses some surprisingly simple yet (seemingly) effective ways to cut costs:

no separate (except for the laser module itself) electronic components. All control of the module is through the output of the computer's sound card, and feedback is through the microphone input. The printer needs two containers, in the upper one - a water-salt solution, in the lower one - a photopolymer. Water drips drop by drop into the lower tank (on the way it closes the contacts that transmit liquid level data to the microphone input), and thereby raises the photopolymer layer higher and higher. The software, in the form of a module for the Blender 3D modeling program, translates the model in the form of instructions for deflecting mirrors that control the laser.

Water drips drop by drop into the lower tank (on the way it closes the contacts that transmit liquid level data to the microphone input), and thereby raises the photopolymer layer higher and higher. The software, in the form of a module for the Blender 3D modeling program, translates the model in the form of instructions for deflecting mirrors that control the laser.

Wikipedia on stereolithography

Sample work Peachy

unsightly views of the Module-Mirror and Laser

Create www.peachyprinter.com zealously took up promotion and launched two crowdfunding campaigns at the same time.

www.kickstarter.com/projects/117421627/the-peachy-printer-the-first-100-3d-printer-and-sc

www.indiegogo.com/projects/the-peachy-printer-the-first-100-3d-printer-scanner

Kickstarter has already collected $32,000 out of $50,000 (actually Canadian dollars, but this is approximately the same as in US dollars)

They started on indie later and haven't collected anything yet.

There is no doubt that the required amounts will be collected, but there is a considerable fly in the ointment in our (or rather, in their) barrel of photopolymer:0006! Yes, there will be five more new printers in ten months!

I didn't write anything about “and the scanner”, as they promise to publish details about this a little later.

Update:

One Google+ user posted a link to a video that was on peachy's official channel but has since been removed from it. Presumably because of the quality of the video (and also because there is a lot of smoking on that video). There you can see the operation of the module in more detail. (from the second minute)

There you can see the operation of the module in more detail. (from the second minute)

P.S . About the photopolymer - the author writes that a special modification of the photopolymer sold on makerjuice.com is being developed for them, the specifications of the original polymer can be read at makerjuice.com/docs/SubG-MSDS.pdf

P.P.S I assume that the name Peachy is derived from Pitch - http://en.wikipedia.org/wiki/Pitch_(resin) perhaps somehow sideways and peach (peach) kissed. And if, as they suggest, look into a banal dictionary, you can find out that "Peachy" → "A slang word for 'thats great'".

Kickstarter launches fundraising campaign for DLP 3D printer at the most ridiculous price

Archive

Follow author

Subscribe

Don't want

LittleDLPer

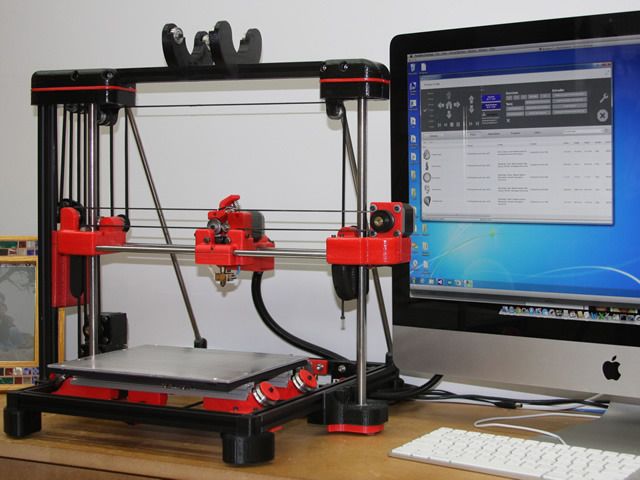

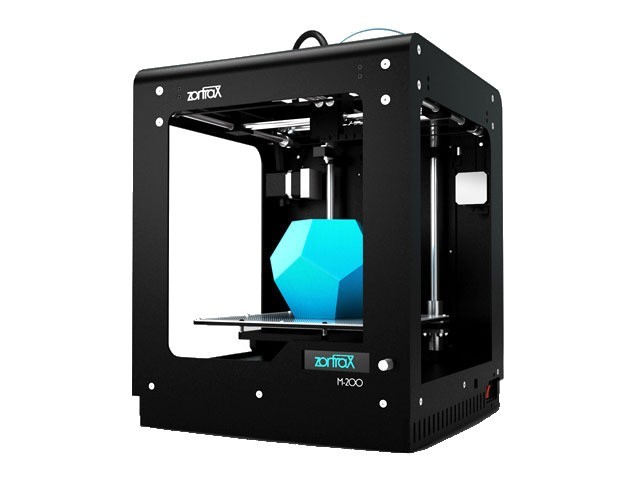

Incredibly, in just one year, prices for consumer 3D printers have plummeted. For example, Micro3D is being sold on Kickstarter for as little as $299, and the crowdfunding platform is launching a MOD-t fundraising campaign for under $300 next week. But do not forget that most 3D printers, which are falling in price, work on the technology of deposition modeling.

But do not forget that most 3D printers, which are falling in price, work on the technology of deposition modeling.

If you're looking for the highest quality products, you're better off with a liquid resin printer. These printers are based on laser stereolithography/digital light processing technology. They have a light source or laser installed, under the influence of which the liquid photopolymer hardens. The result is high-quality products that show even the smallest details. However, these printers are much more expensive. For example, a Form 1 3D printer based on laser stereolithography technology now costs 3299 dollars.

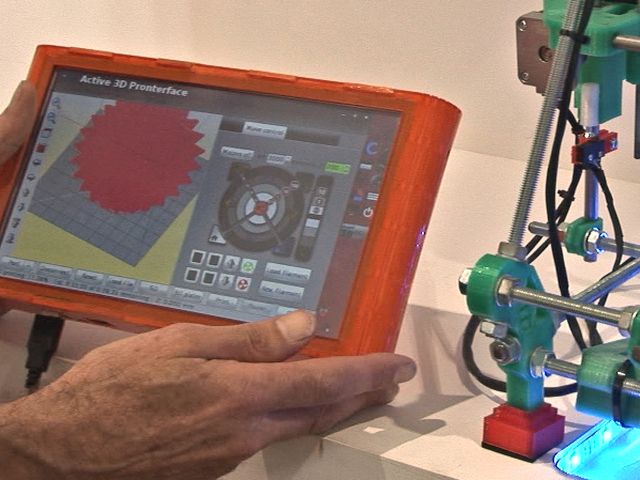

But one man named Brad Hill (also known as goopyplastic) decided to change the situation. He managed to build LittleDLPer, an open source 3D printer based on digital light processing technology. Now Hill plans to raise funds on Kickstarter and exhibit his creation at the Maker Faire, which will be held in Kansas City on June 28. Everyone will be able to see the printer in action at the MakerJuice pavilion.

Unlike most other liquid resin 3D printers, the LittleDLPer won't leave you without your pants.

“The kit without the projector will cost Kickstarter backers less than $500,” says Hill. – The projector I recommend costs about $310, but the design of the printer allows you to use any suitable projector and thus significantly reduce its overall cost. For example, I originally used a Dell 2300mp projector that I bought on eBay for $95.”

For those who want to find the materials and build the printer themselves, Hill's printer is "slightly cheaper than a Kickstarter build kit." While he's not 100% sure yet, Hill still hopes to ship some assembled 3D printers worth around $1,000.

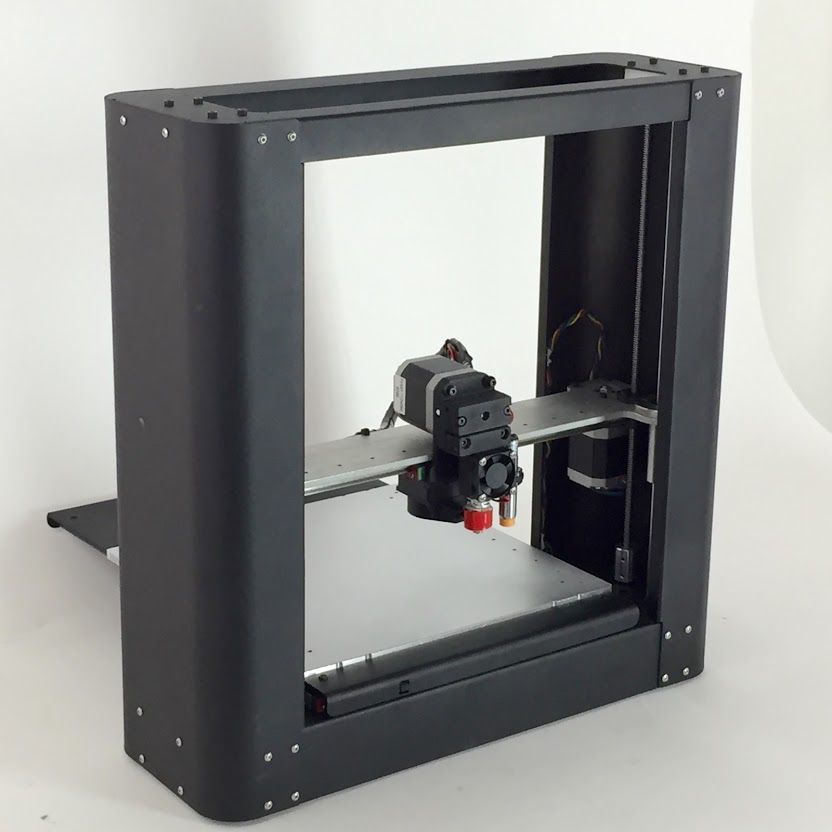

Hill doesn't just want to bring to market a low-cost 3D printer based on digital light processing technology. He wants to offer people the ability to easily and quickly assemble such a printer on their own. The assembly process is comparable to assembling any of the simple RepRap printers. Hill's other goal is to be able to print high-quality products on a low-volume printer.

Hill's other goal is to be able to print high-quality products on a low-volume printer.

“While it can be redesigned with different components, I still recommend sticking to a particular configuration,” says Hill. – Initially, I planned to build an inexpensive printer for the jewelry industry. It is also a great option for creating scale models. Yes, costly 3D printers like the Form 1 are a great choice for many manufacturers, but the LittleDLPer is just as good in terms of quality, not to mention the price.”

Hill now has a working LittleDLPer prototype that has printed over 50 prints in different resin types and layer thickness settings. Some of these objects were printed with a layer thickness of only 25 microns.

Hill was able to assemble an inexpensive 3D printer but still use high quality components such as integrated lead screw steppers and linear slides.

The recommended working volume of the 3D printer is 60mm x 40mm x 100mm, although this can easily be changed. In terms of speed, LittleDLPer takes approximately 2 minutes to print 1mm with a layer thickness of 0.05mm. It will take about 80 minutes to print a product with a height of 40 mm. The printer is compatible with most commonly used UV curable photopolymers, including MakerJuice and MakerSolid.

In terms of speed, LittleDLPer takes approximately 2 minutes to print 1mm with a layer thickness of 0.05mm. It will take about 80 minutes to print a product with a height of 40 mm. The printer is compatible with most commonly used UV curable photopolymers, including MakerJuice and MakerSolid.

Stay tuned on Kickstarter until June 28th. You can also subscribe to LittleDLPer website news so you don't miss the start of the campaign.

Article prepared for 3DToday.ru

Subscribe to the author

Subscribe

Don't want

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

Volgograd schoolboy Mikhail Kozenko joined the ranks of 3D-makers by designing his own 3D-...

Read more

four

Subscribe to the author

Subscribe

Don't want

One of the most promising and least developed areas of 3D printing is bioprinting.