Best 3d dental printer

This is the Best Dental 3D Printer for Dentist

Dental 3D printers or 3D printing is a fast-growing technology in various business areas, most particularly in the field of a laboratory. A Dental 3D printer features a laser or light, blends or fuses a powder, and polymerizes a fluid with the technologically guided precision needed to generate small objects with complicated details.

A Dental 3D printer can generate models, parts as well as full restorations regardless of materials. Adding a 3D printer to your laboratory or practice can enhance effectiveness. There are many types of dental printers intended for the particular production level, laboratory sizes, and specific tasks. When choosing the most reliable 3D printing, check the program the printer is well-suited, the materials are capable of printing, and the support and training presented by the company.

3D Dental Printer in dentistry is exploding, and the market is full of different types of printers. We will help you get the right one by reviewing some of the best models on the market. They are all made from high-quality materials and have excellent capacity. Read on!

Our dental formula is one of the key aspects that symbolize beauty. If you have problems with them, you can fix them quickly, thanks to the advancement in technology. The 3d dental printer has significantly improved the experience of patients in dentistry.

They provide affordable fabrications by utilizing the printed dental appliance. It is a technology that is finding its way across other industries all over the world. Though this is the case, it is undeniable that the dental printer is a unique innovation in digital dental practice.

Every professional enjoys having a versatile device that can make their work more enjoyable. A 3d dental printer is one of those devices that bring joy to dentists. It can print functional dental appliances like monolithic dentures, nightguards, and clear aligners. It can also help dentists produce certified final products and not only models or prototypes. The printed items are therefore ready to use without requiring any polish.

The printed items are therefore ready to use without requiring any polish.

As a lab technician looking for a 3d printer, the cost is not as important as the functionality. It would help if you searched for one that can efficiently utilize functional resins to develop diverse applications, including dentures base and indirect bonding trays. Such a printer can boost the dental workflow and expand the capabilities of digital dental practice.

Though many printers can fabricate surgical guides, not all can print final appliances as 3d dental printers do. These are different since they can use biocompatible resins to give you an impressive final appliance.

As you make a 3d printer comparison, you should understand the printer’s fabrication ecosystem to avoid being limited to only a few applications. You need a broad range of applications that you can use in digital dental practice. Your printer should also be in a support ecosystem designed for dentistry.

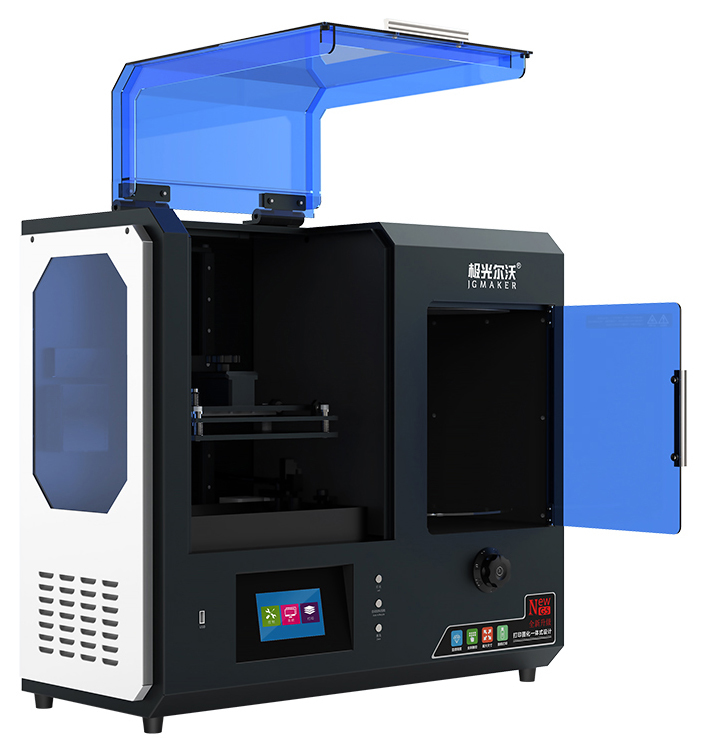

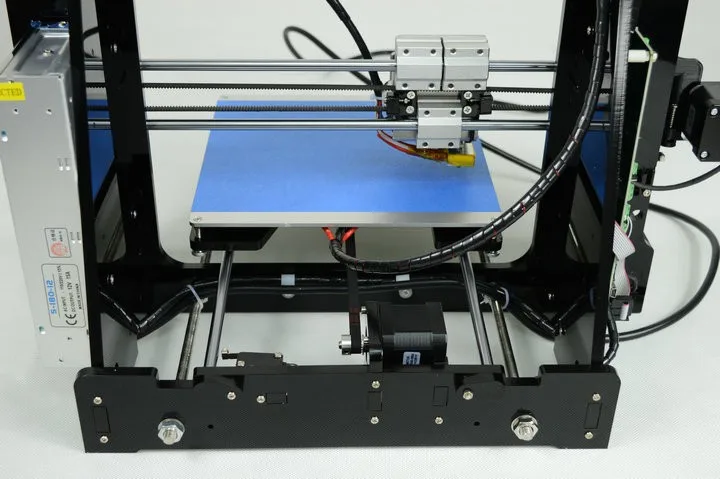

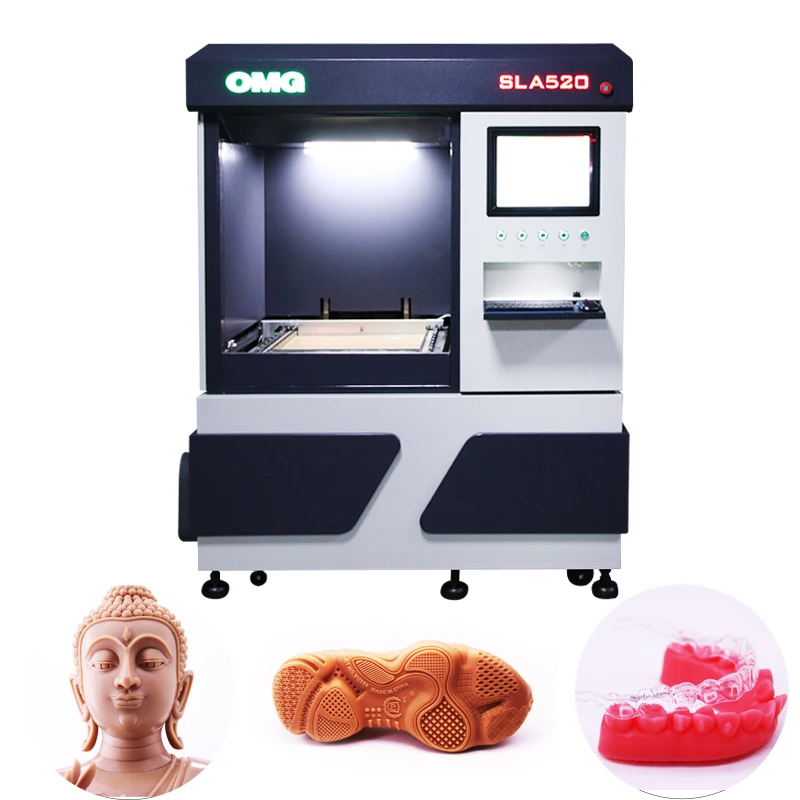

Types of 3d printersWe can categorize 3D printing into two. If you have a big dental lab where you create many appliances every day, you should choose the industrial 3d printer. This type includes machines that have a high capacity to work. They are large and are suitable for high-volume laboratories.

If you have a big dental lab where you create many appliances every day, you should choose the industrial 3d printer. This type includes machines that have a high capacity to work. They are large and are suitable for high-volume laboratories.

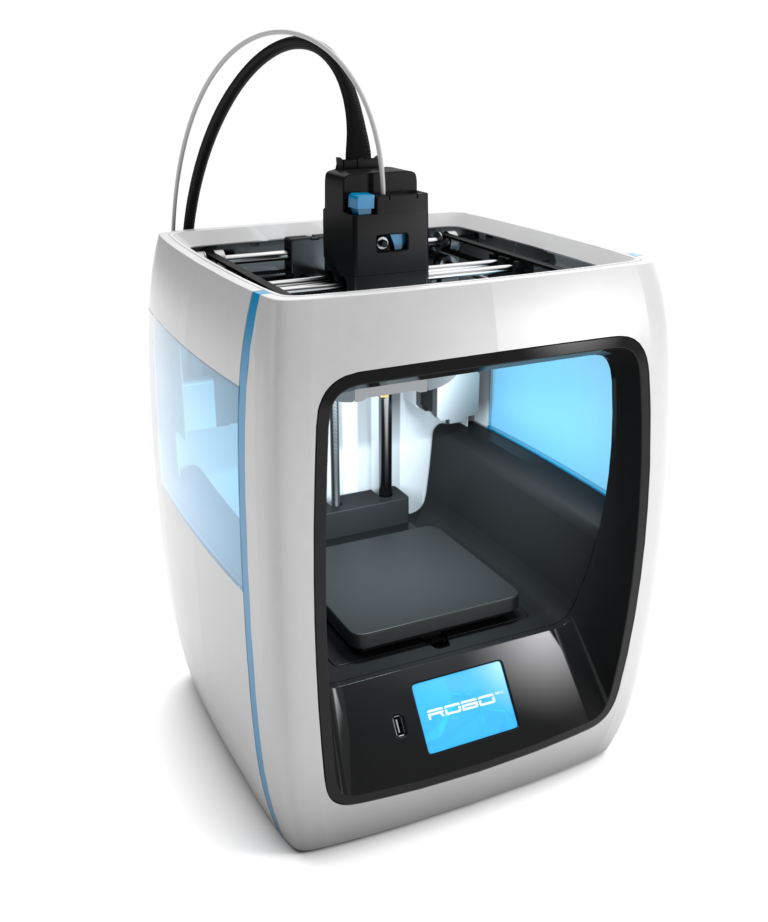

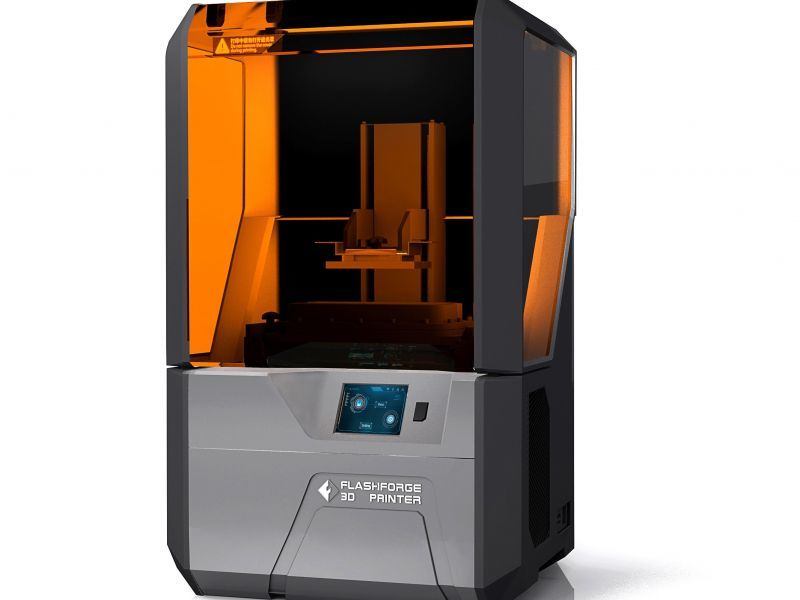

An oral surgeon or a prosthodontist working at a small clinic needs a desktop 3d printer. The 3d dental printer comes at a lower price than the industrial type and has a manageable size. A Desktop dental printer is versatile but has a smaller platform. Regardless of the kind of dental printer you choose, you should ensure that it has certified resin capabilities to boost your dental workflow. It can help you print dentures, bridges, or even crowns so that you can offer your patients expanded treatment options.

A lot of dental labs rely on 3d dental printers to access customized items. Every patient has a unique morphology which makes dentists use matching implants or prostheses to match this. 3d printers make it easy for you to get an accurate model for a patients’ dentition for a successful dental restoration.

Many patients with dental problems need quick solutions, and 3d printing delivers that and much more. It is time-saving and also cost-effective. By modifying a 3d design, you can make a 3d printed device to fit well in a patient’s mouth to ease discomfort. It prevents you from redoing the entire process, like in the case of injection molding.

The market is full of dental printers and business models that try to make a difference in digital dental practice. As you make the dental 3d printer comparison, you should go for one that offers a wide variety of dental materials and uses advanced technology to increase productivity. It should also be able to help you create different dental appliances at a low cost.

The Benefits of Employing 3D Printer in Your LaboratoryUnlike the traditional plastic model, a 3D Printer is a more durable, precise, and stable alternative. The edges and lines on 3D printers are sharp, so there is no need for a lab technician to wear them down. 3D Printed model, on the other hand, has a complex formation with a superior level of detail.

3D Printed model, on the other hand, has a complex formation with a superior level of detail.

These days, 3D printed implant model is the most after the product as it comes with high-quality detachable dies and an exceptionally flexible and detachable gingival mask. This is made of material comparable to a human gum, which is soft, thus allow lab technicians to do the job almost as if it was prepared straight in the mouth of the patient.

The most important benefit provided by 3D dental printing is that it saves you lots of time. After intra-oral scanning, the digital copy of the result is sent straight to a dental laboratory. The digital copy is received in just a matter of minutes as sending is effected electronically. The lab tech can start working right away. 3D dental printing also provides organized and clean working areas for the tech without dealing with plaster or inhaling grinding dust.

Here is the Best Dental 3D Printer for Dentist1. Roland DWX-51D Dental Milling MachineThe DWX-51D 3D Dental Printer from Roland is intended for the flawless production of dental prosthetics. Using this machine doesn’t need expertise or experience as it is built for error-free and accurate filing. Due to its auto-milling features and touch button controls, the making of premium crowns, bridges, onlays, inlays, and abutments has been made almost foolproof.

Roland DWX-51D is made to produce crowns, copings, abutments, complete bridges, and other prosthetics from wax, zirconia, composite resin, PMMA gypsum, and gypsum with matchless accuracy and speed.

Produced and made up by Roland DG’s group of experts in Hamamatsu, Japan, this product has united its present range of proven dental technologies. The company has installed thousands of dental milling centers ever since entering the dental industry and gained an excellent reputation for trustworthiness and high-quality service. The after-sales support, customer service, and care are second to none.

The company has installed thousands of dental milling centers ever since entering the dental industry and gained an excellent reputation for trustworthiness and high-quality service. The after-sales support, customer service, and care are second to none.

This printer helps speed up the workflow in your clinic and increases revenue streams. 51D works with recent materials, and it connects seamlessly with digital CAD software and 3D scanners.

Roland 51D dental printer equipped with essential features including New C-clamp for fast adjustment and proper alignment, ten-station ATC, or Automatic Tool Changer for nonstop milling. It is also equipped with Diagnostic notification technology that alerts the technician of the status of the machine. The

5-axis dental milling mechanism can 5-axis synchronized machine to attain complex. Accepted for 3M ESPE LavaT Ultimate Restorative and comes with a mighty vacuum and anti-static ionizer intended for super clean calibration and dust reduction. It has advanced air blower technology to help hard to machine material.

It has advanced air blower technology to help hard to machine material.

There are many good reasons why dentists should consider this 3D dental printer in their clinic, such as its compact design is ideal for small hospitals or labs. It has a simplified virtual panel that allows for past operation; an advanced clamping system firmly holds a broad range of materials, the capability to connect 4 DWX-51D tools to one computer, well-matched with the industry-standard program.

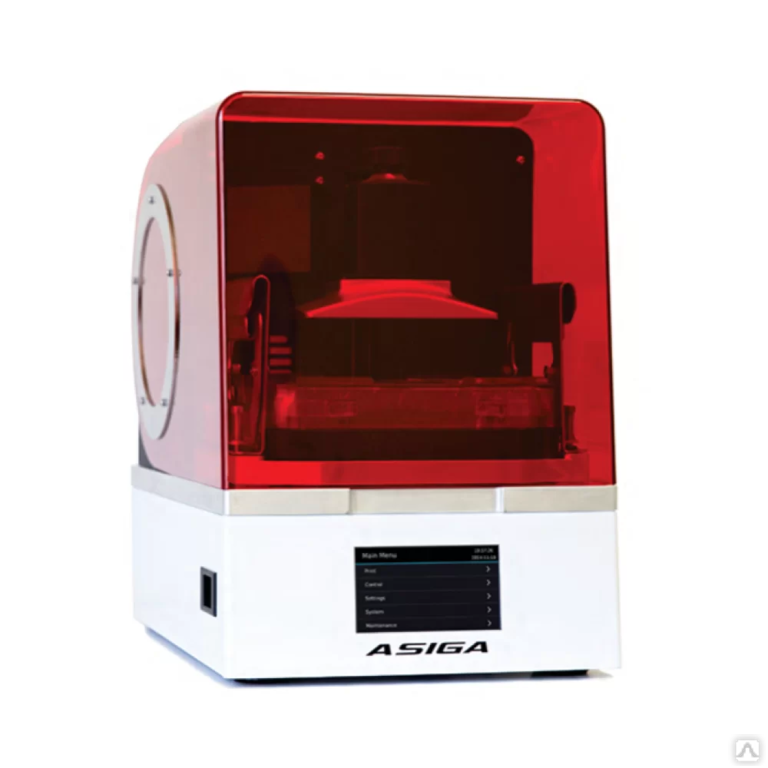

2. Whip Mix Asiga Max 3D PrinterIf you want the most advanced 3D Dental Printer, the Asiga Max 3D printer from Whip Mix is the best choice. This provides exceptional output in a little footprint. Incorporated with 62μm High Definition print precision, this dental printer is optimized for crown and bridge, orthodontics, dental versions, surgical guides, custom rays as well as partial denture in the lab and clinical setting. This accommodates any material from any supplier for the utmost flexibility.

The Whip Mix Asiga scopes boast an open material scheme, so resins from 3rd party providers are well-matched for utmost versatility. Unlike another dental printer that uses a laser, this one uses a DLP light that leads to fine detail. This printer comes with a small footprint touchscreen interface: Wi-Fi connectivity and auto-support generation.

Benefits of Whip Max Max 3D Dental Printer- Compact desktop solution

- 385nm wavelength

- UV-LED projector armed with High Definition chip

- Constant adjustment of layer thickness

- It has a light sensor for a constant projector performance.

Bego Varseo S is very popular due to its stylish and compact design and a bigger structure plate. Network capacity allows fast BEGO service through remote management. The unique cartridge system allows you to change the material easily, nominal material aging, and low consumption of material.

Bego Varseo S 3D printer has a 3D printing system made by dental labs for dental labs. The coordinated range of an in-house made dental printer, scientifically tested material, flashlight device, software tools, and services signifies a fast, simple, and cost-effective production of the wide selection of dental restoration in your lab with unrivaled precision complete flexibility.

Benefits of BEGO Varseo S- Variability: Expandable and a wide range of components and indications

- Easy to Use Display: Fast and easy to learn display for easy and fast access to essential functions.

- Efficiency: About 30 percent bigger building plate, which is bigger than another dental printer available, allows constant printing of more objects. It is also armed with an exceptional cartridge which allows you to change the material fast.

- Network Capability: Improved connectivity allows fast service through remote control.

This dental 3D printer is committed to various dental applications like Temporal Crowns and Bridges, Drill Guides, Bases, Models, Invisible aligners, and Bite Splint.

The BEGO Varseo S can work with diverse materials like:

- VarseoWax CAD/Cast:

- VarseoWax Model

- VarseoWax Surgical Guide

- VarseoWax Tray

- VarseoWax Splint E

- VarseoWax Base

4.

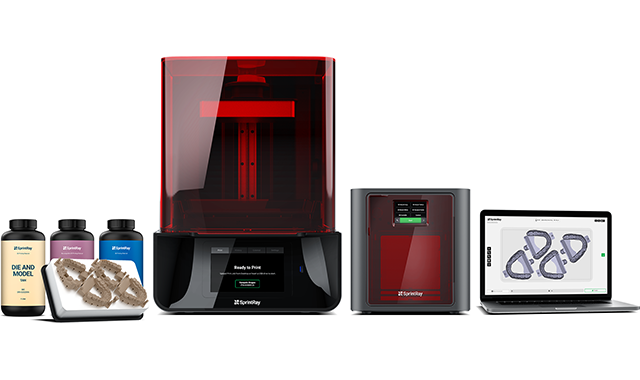

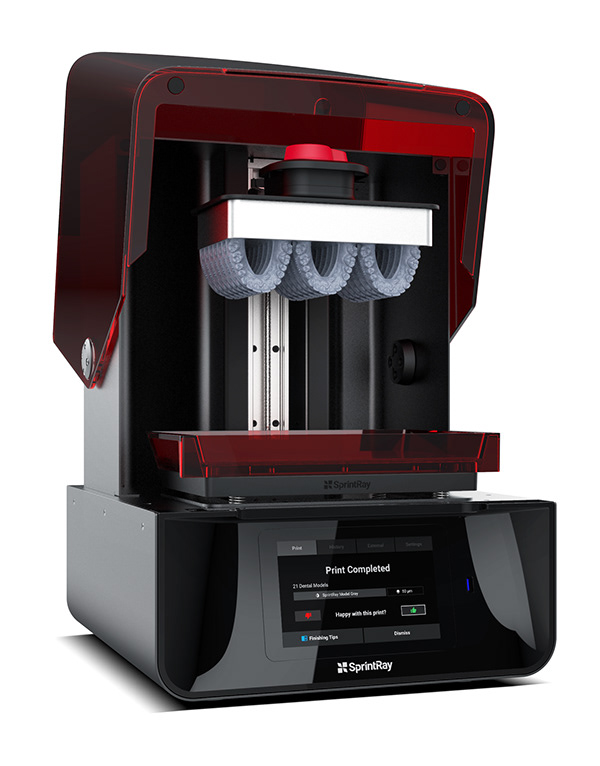

Moonray S 3D Printer ($4,440.00) – A highly reliable and durable dental printerAre you looking for a printer compatible with a wide range of resin materials, choose the Moonray S 3d printer. This Moonray S 3d printer comes from the SprintRay manufacturer from the US. It uses the proprietary RawWare software, which increases its compatibility levels. It is also easy to use and reliable, thanks to the DLP-projection system used.

It gives you a good print quality with the option of using alternative resins on your machine. Unlike other models, this comes with WIFI connectivity making it wireless to improve its performance.![]() The connection makes it easy to integrate files from design to the final print.

The connection makes it easy to integrate files from design to the final print.

The 3D printer uses liquid resin photopolymer, which solidifies when they get into contact with light. Unlike traditional processes, Moonray uses DLP projectors that cast UV light to the footprint. It, therefore, eliminates the need to trace precise coordinates used in conventional methods since the photoreaction, in this case, occurs simultaneously.

This desktop printer can tune the light to the precise wavelengths for it to cure the liquid resin. The excess wavelength energy does not heat the surrounding resin. You can adjust the layer height to provide room for 50 or even 100-micron layers.

PrecisionThe manufacturers use a patented UV DLP projector to increase the accuracy of the Moonray S printer. It is of high quality and has resin curing control. Your 3d dental printer offers dimensional stability to deliver consistent 3d prints. The high-quality resin gives it a consistent reaction when exposed to UV light. The company provides standard resins that provide expanded capabilities. Your prints can, therefore, be highly detailed and accurate.

The company provides standard resins that provide expanded capabilities. Your prints can, therefore, be highly detailed and accurate.

The Moonray s printer is among the fastest in the world of resin 3d printers. It operates ten times faster compared to standard resin 3d printers and offers a quality light source. It can integrate different models into one print.

Optimized supportThe Rayware software used in this printer enables it to develop optimal support structures without wasting any material. The algorithm used is concise, allowing you to expand your workflow. The print resolution is also high, thanks to the use of advanced curing technology.

Durability3d dental printers require a high cost of maintenance due to the consumables. Traditional resin tanks have PDMS on the bottom layer, which starts clouding after a while, thus distorting the DLP light as it penetrated through the resin. The PDMS finish needs replacement and refurbishment, which can be costly.

Moonray S 3d printer, on the other hand, saves you some of the expenses since it is made from a patented resin tank which is durable. The tanks can last longer than traditional resin tanks, and they don’t need replacements, thus saving you time and costs.

Key features- Build volume: 127x81x200mm

- Z-height: 25 mm per hour

- Micron layers: Up to 100

5.

Planmeca Creo C5 ($7,777.00) – An efficient 3d dental printerFeel free to print different objects from various design software using an open interface from planmeca creo. This is a 3d printer allows you to create dental objects like surgical guides and models with precision. Every dental lab should try using this type to increase their efficiency and provide different dental services to their clients.

If you have a large clinic, this can help you grow your business to create dental splints. The future looks bright as the device will soon support the development of orthodontic models, temporary fillings, impression trays, and temporary bridges and crowns.

It comes from the Planmeca Oy Company that is popular for producing dental devices across the world. Over the years, they have been producing digital dental units, 3D and 2D images, and digital CAD/CAM solutions. The development of the 3d dental printer is beneficial to a lot of clinics. One can create temporary orthodontic models as well as those that involve complicated geometry.

DLP technologyThe manufacturers of this type of 3D printer make use of Digital light processing technology to make it useful. Thanks to this technology, you can create different objects from UV curable resin. You can harden resins using UV. It produces quality dental applications from medical materials that have been approved. It also comes with planmeca creo software.

Printing areaThis provides a large printing area, accommodating horizontal printing. It would take you two hours to fabricate dental models and 45 minutes to create surgical guides. The printing area can provide room for up to 25 surgical guides or 6 dental models simultaneously. It also offers in-house printing, thus reducing costs and saving you time.

It also offers in-house printing, thus reducing costs and saving you time.

- Dimensions: 42x72x32

- Weight: 30 kg

- Building volume: 130 x 81.5 x 130mm

- Applications: Dental models, Surgical guides

6.

Asiga Pico2 – High-resolution printerGet a dental digital printer that combines reliability, speed, and precision to help you deal with dental prosthetics. The manufacture equips this with both Ethernet and Wi-Fi connectivity to help you create final prints. The connectivity enhances seamless workspace integration. You can manufacture different dental restorations such as onlays, crown and bridge, inlays, and partials.

Product descriptionPerformance and flexibilityYour 3d dental printer comes with UV-LED options that increase performance and make it more flexible to use on various applications. It is compatible with 3d scanners as well as CAD software like Dental wings and Exocad.

Its ability to function in an open system makes it flexible since you can use any resin material you wish to work with, such as the whip mix resin. The manufacturers also equip this printer with composer software. It uses the upside-down stereolithography print system.

Support systemThe Asiga Pico2 offers flexible support to prevent collisions and an onboard PC that stores various builds. This digital printer can support various operating systems such as Linux and Windows. It offers an auto-support mechanism to increase efficiency and provides you with free updates. You can also schedule your workflow using the build time estimator provided by this printer.

User-controlIt also comes with build settings that put you in control all through the process of creating prosthetics. You also get a remote control that allows you access to your printer by logging in. You can also easily change over materials within 30 seconds. You only need to squeeze the tray handles to release the tray as you insert a new tray and clamp it.

The high resolution makes the final prints accurate and consistent. It comes with an easy setup that gives you enough time to work on different pieces fast without hindrances. The dental printer makes use of slide and separate technology that increases accuracy and dental precision. The technology can achieve low fabrication forces.

Ease of useIts ability to fabricate small items makes it easy to use. It features a user-friendly touchscreen interface and a calibration system that works within a few seconds, thus saving you time. Your packaging also includes a calibration toolkit and a curing device for ease of use.

Key features- Volume range: 52 x 29 x 76 mm

- Resolution: 27- 37 µm.

- Material: Resins from whip mix

7.

NextDent 5100 – Affordable and accurate dental digital printerDo you need an affordable 3d dental printer that performs well? Get the NextDent 5100 today. NextDent 5100 makes use of Figure 4 technology to provide you with high speed so that you can create different dental appliances as well as sacrificial castings.

NextDent 5100 makes use of Figure 4 technology to provide you with high speed so that you can create different dental appliances as well as sacrificial castings.

Advanced technology and dental software can help any clinic produce models, dentures, surgical guides, crowns and bridges, and orthodontic splints. If you make a dental 3d printer comparison, you will prefer this over others due to its speed, efficiency, and precision.

Product descriptionBiocompatible materialsUnlike other dental printers, this has biocompatible materials that can address different dental applications. The materials come in different aesthetic colors to match with that of a patient’s gums or teeth. The materials are also certified and comply with the medical device regulations set in place. The materials also increase flexibility and offer clinics diverse solutions to make improvements in digital dental practice.

Trusted workflowThe printer is also compatible with software solutions to give you a trusted workflow. It provides you with good results without depending on human intervention. You can also use it alongside other 3D system components, such as the LC3D mixer for stirring materials. It is suitable for large dental labs and clinics with numerous operations.

It provides you with good results without depending on human intervention. You can also use it alongside other 3D system components, such as the LC3D mixer for stirring materials. It is suitable for large dental labs and clinics with numerous operations.

You can use it to perform many applications like pressable wax restoration, night guards, and dentures. Some printers are not versatile in what they can do, but this is. It, therefore, saves you on costs and can make your business expand. The cost of operation is low, and the productivity is unmatched.

SpeedApplications such as dentures take time, but this digital printer makes it a fast process, thus reducing the production time. It also cuts down on the dentist’s frequency for the patient, thus increasing convenience for your patients.

It is user-friendlyYour digital printer also comes with a touchscreen that has clear indicators. This makes it easy to use. You can also exchange the resin trays when working on different applications and remove print platforms using one hand. With this printer, you don’t need to worry about wasting materials.

You can also exchange the resin trays when working on different applications and remove print platforms using one hand. With this printer, you don’t need to worry about wasting materials.

- Build volume: 124 x 72 x 196 mm

- High-quality material

- Digital light printing technology

- High speed

These are just the top 3 3D dental printer dentists available today. Each one is integrated with state-of-the-art features to make dental printing precise and easier for you.

Are you new to the digital dental practice? Here are a few basics. What is 3d printing? A dentist makes three-dimensional objects from a digital file. It involves additive processes where the dentist lays down different layers of material to create a solid object.

What makes it different from traditional manufacturing techniques is that you use a few materials in 3d printing to come up with complex and functional shapes. The process starts by creating a 3d model on your computer using some data you generate using a 3d scanner. For you to make the model printable, you have to slice it into numerous horizontal layers.

The process starts by creating a 3d model on your computer using some data you generate using a 3d scanner. For you to make the model printable, you have to slice it into numerous horizontal layers.

3d printing systems can help you optimize your designs and transform your workflow. You can use it to create tools, dental implants, and also prostheses. In the future, 3d printing may use in bio-printing. Unlike in the past, professionals can now conduct oral scanning and develop CAD designs on their own then 3d print using these printers. The dental business keeps on progressing daily, and new technologies continue coming up.

Dental digital printers come at different prices, but your needs should guide you on finding the right one. High-quality parts should be a priority when comparing 3d printers. These include frames, motors, and electronics. They may be more costly, but they assure you of durability. We also offer other 3D Printers for Dentists.

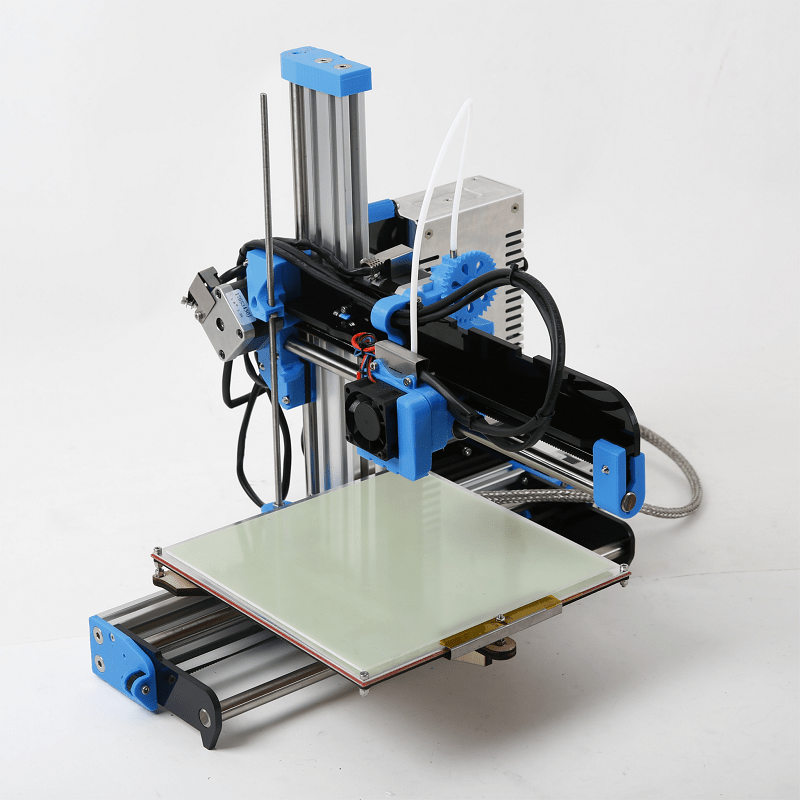

Some printers come fully assembled, while others are semi-assembled. If it is your first purchase, get one that does not require assembly. DIY kits are also available for experienced professionals looking for semi-assembled printers. Choose a reputable brand that offers some tutorials when considering the semi-assembled types. Use the information on our reviews to learn more about the models to make a wise decision.

If it is your first purchase, get one that does not require assembly. DIY kits are also available for experienced professionals looking for semi-assembled printers. Choose a reputable brand that offers some tutorials when considering the semi-assembled types. Use the information on our reviews to learn more about the models to make a wise decision.

5/5 (1 Review)

LCD Resin Printers for Crowns and Other Dental Appliances from China etc

Since the introduction of the first 3D printing technology in 1986, additive manufacturing has been showing impressive growth in the constantly increasing range of industries adopting the cutting-edge technologies. Dentistry is among those taking all the benefits of 3D printing most willingly and rapidly.

Credit: placervilledentistry.com

This is Top 3D Shop, and in this article, we are going to discuss different aspects of digital dentistry and find out which 3D printing solutions are the best fit for this application.

Biocompatible dental 3D printing for labs and clinics

Credit: dentalhospitalthailand.com

The traditional workflow in dentistry implies the cooperation of two parties involved in the process — dental clinics on the one side and prosthesis laboratories on the other, the interaction between the two requiring quite a lot of time and logistics. Since every patient has a unique dentition, dental labs mostly use manual production methods which are usually slow and assume the work of highly skilled dental technicians, still leaving a lot of room for probable imperfections in the final result. The use of 3D printing provides wide opportunities for low-cost mass customization, saving time and ensuring extremely high precision of printed models. A wide range of dedicated biocompatible materials with various properties allows for the creation of orthodontic models, crowns and bridges, surgical guides, aligners, retainers, splints, dentures, and other dental products that perfectly match the patient’s anatomy.

Applications of 3D printing in dental industry

Aligners

Credit: china-ortholab.com

Aligner production is an example of using 3D printing as a bridge to traditional manufacturing methods. First the dentist takes the impression of the patient’s mouth by means of intraoral scanning with further converting the scanned data to a CAD model, which is then edited to specify the stages of desired teeth shifting. When this is done, the model for each stage is printed, usually employing SLA technology. After that each printed model is placed into a thermoforming machine where a clear aligner is wrapped around it creating the patient-specific set of aligners.

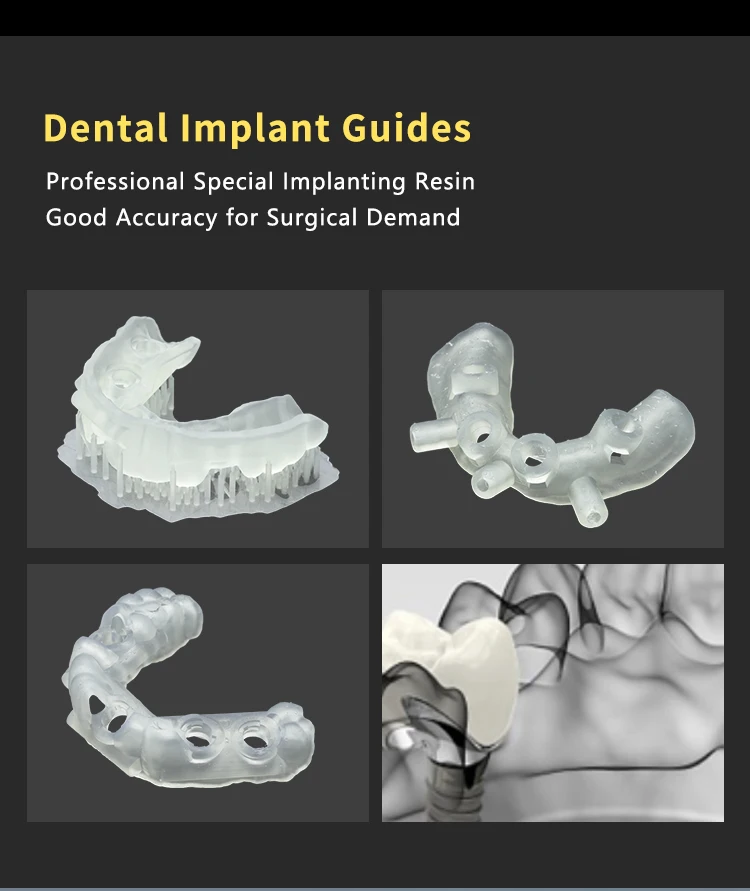

Surgical guides

Credit: creativedentistry.ca

Surgical guides are used in medicine, dentistry in particular, to assist the surgical procedures. In dentistry surgical guides are of great help in implantation as they ensure the precise placing and fitting of the implant. The guides are placed directly over the patient's teeth and then removed during or after the surgery when no longer needed. Surgical guides not only increase the accuracy of the procedure, but also make it faster and less invasive thus shortening the recovery time. Different manufacturers offer special surgical guide resins to ensure the best printing results.

The guides are placed directly over the patient's teeth and then removed during or after the surgery when no longer needed. Surgical guides not only increase the accuracy of the procedure, but also make it faster and less invasive thus shortening the recovery time. Different manufacturers offer special surgical guide resins to ensure the best printing results.

Crowns

Credit: dentalimplantxperts.com

3D printed dental crowns are becoming more widespread with the development of new biocompatible materials. First additive manufacturing was used only as a bridge to investment casting process helping create accurate casting patterns. Now there are a variety of materials, from special permanent crown resins, like Formlabs Digital Dentures Resin, to various metal alloys, that allow printing high-quality permanent crowns taking all the advantages 3D printing provides.

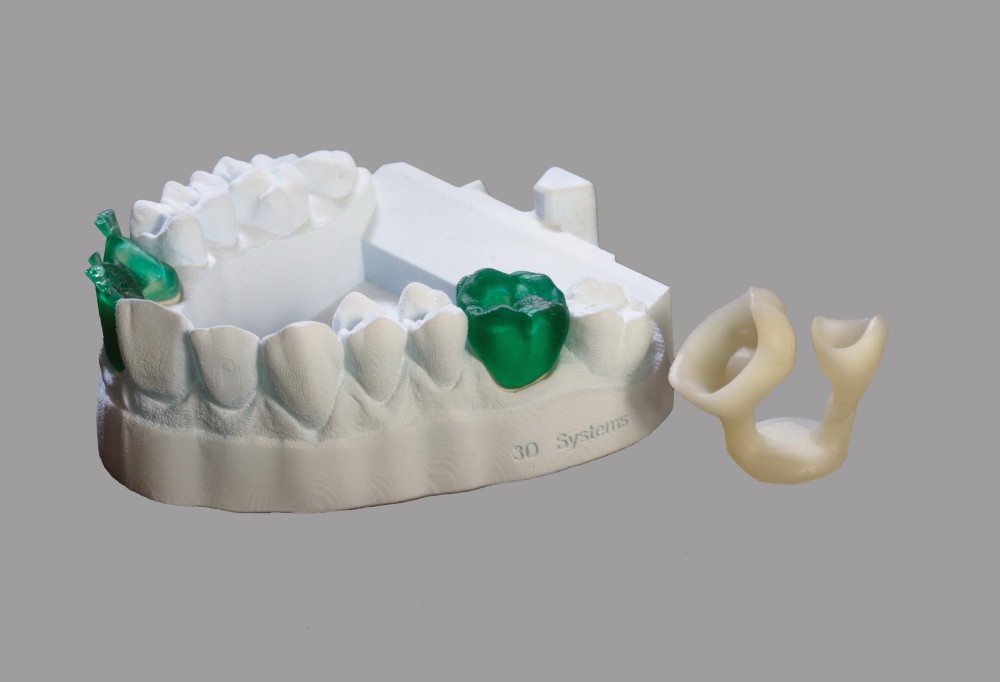

Dental models

Credit: dental.formlabs.com

Dental full arch or crown and bridge models with removable dies help dentists while planning denture restoration. Dental models are printed based on the digital impression of the patient's mouth so they are indispensable when it comes to checking fixed prosthetics that will be later used in a patient's treatment. Special materials, like Formlabs Dental Model Resin allow for precise models with matte smooth surface and a high level of detail.

Dental models are printed based on the digital impression of the patient's mouth so they are indispensable when it comes to checking fixed prosthetics that will be later used in a patient's treatment. Special materials, like Formlabs Dental Model Resin allow for precise models with matte smooth surface and a high level of detail.

How are dental models 3D printed?

The process of 3D printing in dentistry always starts with the dentist taking a digital impression of a patient’s mouth with an intraoral or desktop scanner. The obtained data is converted to a CAD model which can be saved and then used as a basis for creating dental print models when needed. The digital model is sliced using appropriate software and sent to the printer. Once printed, dental parts usually require some post-processing steps depending on the technology and type of material used.

Does dental 3D printing require special training?

The process of dental 3D printing is mainly automated and generally requires less special skills than dental technician’s work. Still, certain training is required, especially for those not familiar with additive manufacturing technologies in general. 3D printing equipment and material manufacturers usually offer training programs and support for their customers. In fact, digital dentistry allows for chair-side creation of some patient-specific dental products, while more complex parts have to be printed in dental labs by skilled professionals.

Still, certain training is required, especially for those not familiar with additive manufacturing technologies in general. 3D printing equipment and material manufacturers usually offer training programs and support for their customers. In fact, digital dentistry allows for chair-side creation of some patient-specific dental products, while more complex parts have to be printed in dental labs by skilled professionals.

How to get digital models for a 3D printer

As mentioned, a dental 3D scanner (for example, Shining 3D Aoralscan 3) is used to capture the patient’s dental anatomy and take a digital impression of their teeth and gums. This digital impression is converted to a CAD file that is edited to create a digital model of the specific dental product, for example, a crown, depending on the particular case and treatment plan.

How to print dental custom trays

In traditional dentistry trays are used to get a patient's teeth impression, usually with plaster. The implementation of 3D technologies offers much more convenient and precise digital impressions made with an intraoral scanner. Yet impression trays are still widely used in dentistry either by those who prefer conventional methods, or in cases when digital scanning is impossible for some reason. The use of standard trays has always been a compromise as they can not guarantee the necessary precision which a custom-made 3D printed tray provides. The process of printing is the same as with other dental products, and the final result ensures getting highly precise dental products in a shorter time. Different manufacturers offer special resins for impression trays production.

The implementation of 3D technologies offers much more convenient and precise digital impressions made with an intraoral scanner. Yet impression trays are still widely used in dentistry either by those who prefer conventional methods, or in cases when digital scanning is impossible for some reason. The use of standard trays has always been a compromise as they can not guarantee the necessary precision which a custom-made 3D printed tray provides. The process of printing is the same as with other dental products, and the final result ensures getting highly precise dental products in a shorter time. Different manufacturers offer special resins for impression trays production.

Credit: dental.formlabs.com

Criteria for top dental 3D printers

Precision

Print precision is one of the key points to be considered when choosing a dental 3D printer. If you are going to print not only educational models just to show your patients the treatment process in detail (in that case almost any desktop 3D printer will do), but working dental products, then you should look for a high resolution device, as even subtle discrepancy can lead to a completely unsatisfying result.

Speed

Speed is always of great importance when it comes to business. High print speeds are helpful, whether we speak about dental labs or in case of chair-side printing in dental clinics, where rapid printing helps minimize the number of a patient’s appointments with the dentist.

Biocompatible materials support

It’s by far the main feature the printer should possess to be called dental. All dental products that come in contact with the patient’s mouth or skin should be certified biocompatible in your area, so it’s highly recommended to check the material compatibility list while choosing a dental 3D printer.

Dental printing materials

For today, the most popular technology for dental 3D printing is vat photopolymerization, which includes SLA, DLP and LCD-based processes, all of them using liquid resins that are cured by a light source. Hence the choice of special dental resins in the market is really vast. All dental resins are biocompatible and can be used for printing temporary or permanent dental parts with required properties.

Credit: megadas.com

Metal 3D printers are becoming more and more widespread in dentistry as they work with different metal and metal alloy powders, for example, titanium or cobalt chromium, traditionally used for fabrication of crowns, dentures, and stents. DMLS printers are capable of producing durable extremely precise models in a short time.

Another popular technology for dental 3D printing is material jetting that prints with liquid materials — plastics or polymers — which are cured by UV light. The technology boasts the exceptional accuracy of the printed models, but the printers utilizing this technology are usually bulky and expensive.

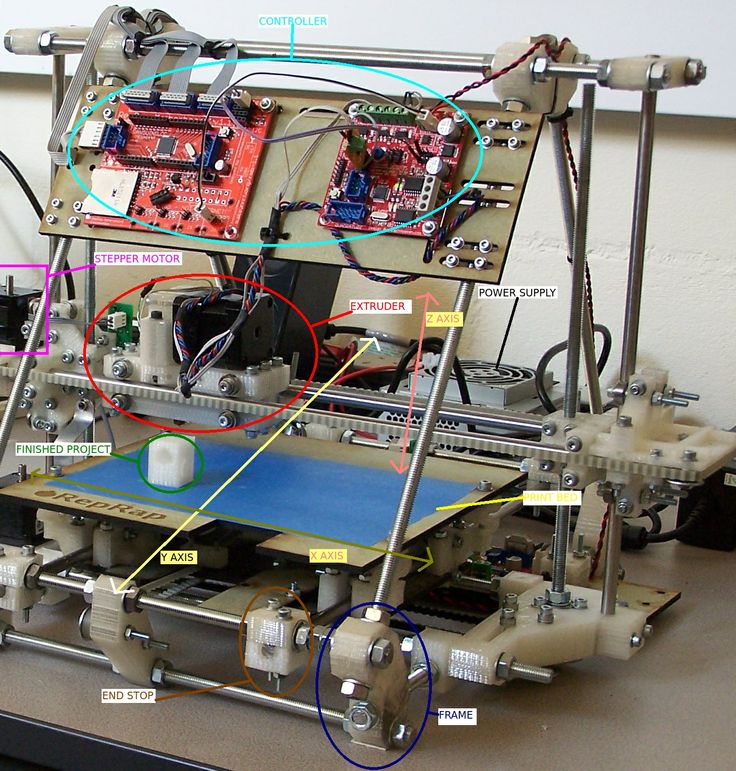

As for FDM printing, despite its popularity in a lot of other industries, it has not been widely used in dentistry, as FDM machines usually demonstrate lower accuracy than the other technologies mentioned above. However, new FDM 3D printer models show much higher resolution, accuracy, and dimensional stability, compared to their predecessors, and now dental industry can take advantage of all the benefits of FDM technology.

Best dental 3D printers 2022

Resin 3D printers

Phrozen Sonic 4K 2022

The Phrozen Sonic 4K 2022 is a desktop LCD-based resin 3D printer equipped with a monochrome 4K (3840 x 2160) LCD screen with the resolution of 772 PPI and the lifespan of 2000 hours. Due to the upgraded dedicated ParaLED Matrix 3.0 technology, the device can print layers at a minimum height of 10 microns. Together with the XY resolution of only 35 microns, it allows creating incredibly accurate precise models with a perfectly smooth surface finish. The Sonic 4K 2022 is a reliable and fast 3D printer capable of building a single layer in just two seconds. It can be operated via PC or a built-in 5" touchscreen and boasts wide connectivity options including Ethernet, USB, and Wi-Fi interfaces. The Phrozen Sonic 4K 2022 is designed to meet all the dental printing requirements. Apart from common for the Phrozen 3D printers ChiToBox slicer compatibility, the Sonic 4K 2022 comes with the proprietary Phrozen Dental Synergy Slicer targeted specifically at dental applications.

Credit: @bellwoodlab / Instagram

Pros

- High resolution and accuracy

- Fast print speed

- Sturdy aluminum construction

- Wide connectivity options

- 5" operating touchscreen

Cons

- The build volume is not very large

Phrozen Sonic XL 4K 2022

The Phrozen Sonic XL 4K 2022 is a professional desktop resin 3D printer designed specifically for the dental industry. The model is a larger version of the Phrozen Sonic 4K 2022 with a more spacious build volume of 200 x 125 x 200 mm. This allows printing fairly large parts or multiple dental models in one go for efficient time saving. All other printer specs are similar to the previous model, with the only difference in the XY resolution of 52 microns, compared to 35 microns of the Sonic 4K 2022, due to the larger build volume of the Sonic XL 4K. Despite this, the device is capable of producing astonishingly detailed precise parts with a flawlessly smooth surface finish at a high speed of 2 mm per layer. The printer is compatible with ChiToBox and comes with the designated Phrozen Dental Synergy Slicer. The Phrozen Sonic XL 4K can be successfully used not only for dental applications, but in jewelry fabrication and any other industry where the quality of the parts is of paramount importance.

The printer is compatible with ChiToBox and comes with the designated Phrozen Dental Synergy Slicer. The Phrozen Sonic XL 4K can be successfully used not only for dental applications, but in jewelry fabrication and any other industry where the quality of the parts is of paramount importance.

Credit: @ALICEADMD / Twitter

Pros

- Large build volume

- Fast print speed

- High print quality

- Open material system

- Wide connectivity options

Cons

- The XY resolution is a bit lower compared to the Sonic 4K 2022

Uniz Slash 2

The Uniz Slash 2 is a professional desktop LCD 3D printer with a 8.9" 4K LCD screen. The device boasts an amazing print speed of up to 200 mm/h ensuring extremely high time-efficiency of the printing process. The minimum layer height of 10 microns allows for highly detailed accurate models with flawless look and feel. With a sizable build volume of 192 x 120 x 200 mm you can print either large models or small runs of smaller parts at a time. The printer is equipped with an effective heat management system and a proprietary liquid cooling mechanism. All these features make the Uniz Slash 2 an indispensable tool for dentistry, jewelry, or any other industry with strict part quality requirements.

The printer is equipped with an effective heat management system and a proprietary liquid cooling mechanism. All these features make the Uniz Slash 2 an indispensable tool for dentistry, jewelry, or any other industry with strict part quality requirements.

Credit: @coutelas_v / Instagram

Pros

- Incredibly high speed

- Automatic bed leveling

- High print quality

- Durable resin tank

- Cloud-based services

Cons

- No control screen

Uniz NBEE

The Uniz NBEE is a resin LCD-based 3D printer designed specially for the dental industry. The NBEE features extremely high print speed, being able to produce six dental models in 5 minutes. The printer’s build volume is 192 x 120 x 180 mm. With the minimum layer height of 25 microns, the device prints aligners, removable dies, surgical guides, crowns, bridges, and other dental appliances with exceptional quality. The NBEE can print either with a wide range of special Uniz photosensitive dental resins or with third-party materials.

The NBEE can print either with a wide range of special Uniz photosensitive dental resins or with third-party materials.

Credit: uniz.com

Pros

- Extremely high speed

- High print quality

- Wide range of compatible dental resins

Cons

- High price

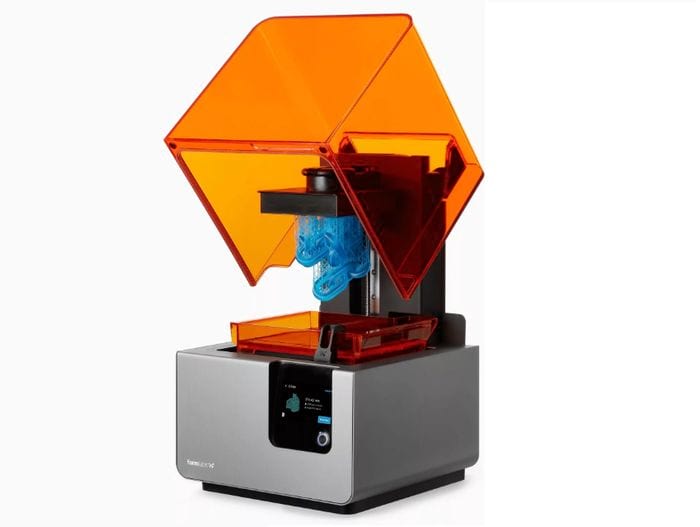

Formlabs Form 3B+

Credit: dental.formlabs.com

The Formlabs Form 3B+ is based on proprietary LFS (Low Force Stereolithography) technology that is aimed at improving the surface finish of the prints. The Form 3B+ is designed for digital dentistry and can print with minimum layer thickness of 25 microns. The build volume of the printer is 145 x 145 x 185 mm. The device can come alone or with post-processing equipment, including the Form Wash and Form Cure machines. Formlabs offers a wide range of biocompatible resins for different dental appliances (for example, Formlabs Dental LT Clear Resin).

Credit: dental. formlabs.com

formlabs.com

Pros

- High print quality

- Wide range of biocompatible resins

- Can be a part of a complete solution

Cons

- Compatible only with proprietary materials

- Lower print speed, compared to LCD models

Nexa3D NXE400

The NXE400 is an industrial resin 3D printer based on proprietary Lubricant Sublayer Photo-curing (LSPc) technology. Due to this technology, the NXE400 is by far one of the fastest resin 3D printers in the market. The machine features a large build volume of 274 x 155 x 400 mm. The print quality the NXE400 is capable of is incredibly high. The NXE400 can be regarded as a reliable 3D printer for a dental lab, as now it supports all biocompatible photopolymer dental resins by Keystone Industries. Apart from that, the NXE400 is compatible with a wide range of other resins, including xPeek, xABS, and xFlex.

Credit: 3dprint.com

Pros

- Extremely high print speed

- High-quality prints with smooth surface finish

- Large build volume

- Wide range of compatible materials

- Dental biocompatible resins support

Cons

- Price can be too high for small companies

FDM 3D printers

Raise3D E2

The Raise3D E2 is an industrial desktop FDM 3D printer featuring the Independent Dual Extrusion System (IDEX) which opens up versatile printing opportunities, from dual-material and dual-color printing to using mirror and duplication modes that allow you to double the production volume. The E2 can print with the maximum nozzle temperature of 300 °C and is compatible with a wide range of filaments, such as PLA, ABS, HIPS, PC, TPU, TPE, Nylon, PETG, ASA, PP, PVA, glass and carbon fiber filled composites, and others. Featuring the auto bed leveling function and a flexible removable heated build plate, the E2 provides perfect first layer adhesion for high-quality accurate printing. The minimum layer height of 20 microns makes for detailed accurate parts with the quality perfectly suitable for printing dental models.

The E2 can print with the maximum nozzle temperature of 300 °C and is compatible with a wide range of filaments, such as PLA, ABS, HIPS, PC, TPU, TPE, Nylon, PETG, ASA, PP, PVA, glass and carbon fiber filled composites, and others. Featuring the auto bed leveling function and a flexible removable heated build plate, the E2 provides perfect first layer adhesion for high-quality accurate printing. The minimum layer height of 20 microns makes for detailed accurate parts with the quality perfectly suitable for printing dental models.

Credit: @priamond.de / Instagram

Pros

- IDEX system

- Auto bed leveling function

- Wide range of compatible materials

- Enclosed chamber with a HEPA filter

- Minimum layer height of 20 microns

- Flexible removable build plate

Cons

- Auto bed leveling can take pretty much time

Creality CR-5 Pro High-temp Version

The Creality CR-5 Pro High-Temp version industrial-grade FDM 3D printer sports a fully-enclosed impressively large build chamber of 300 x 225 x 380 mm. The extruder is equipped with a 0.4 mm nozzle with the maximum temperature of 300 °C and a cooling fan that helps prevent stringing and warping issues. The CR-5 Pro High-temp is compatible with a wide range of filaments, including high-temp materials, such as PLA, TPU, and ABS. Proper first layer adhesion is provided by the high-quality carbon glass heated print bed. A bunch of advanced features, such as auto bed leveling, filament run-out sensor, or print resume function make for consistent reliable printing experience.

The extruder is equipped with a 0.4 mm nozzle with the maximum temperature of 300 °C and a cooling fan that helps prevent stringing and warping issues. The CR-5 Pro High-temp is compatible with a wide range of filaments, including high-temp materials, such as PLA, TPU, and ABS. Proper first layer adhesion is provided by the high-quality carbon glass heated print bed. A bunch of advanced features, such as auto bed leveling, filament run-out sensor, or print resume function make for consistent reliable printing experience.

Credit: Just Vlad / YouTube

Pros

- Large build volume

- Wide range of compatible materials, including high-temp filaments

- Carbon glass heated print bed

- Auto bed leveling function

- Filament runout sensor

- Print resume function

Cons

- 100 microns minimum layer height

Metal 3D printers

Farsoon FS121M

The Farsoon FS121M is an MLS (metal laser sintering) printer that can perform as a reliable and efficient device for a number of industries, dentistry being one of them. The FS121M sports a large build volume, which is a cylinder of ⌀ 120 x h 100 mm, and a high build speed, allowing for the production of up to 160 dental crowns in 3 hours. The device is equipped with a single 200W fiber laser, used in the Flight series printers. The Farsoon FS121M is a fully open system, providing compatibility with a great number of proprietary and third-party metal powders, including 316L, 17-4PH, Maraging Steel Grade 300, HX, Cu, CuSn10, CoCrMoW, and CoCrMo.

The FS121M sports a large build volume, which is a cylinder of ⌀ 120 x h 100 mm, and a high build speed, allowing for the production of up to 160 dental crowns in 3 hours. The device is equipped with a single 200W fiber laser, used in the Flight series printers. The Farsoon FS121M is a fully open system, providing compatibility with a great number of proprietary and third-party metal powders, including 316L, 17-4PH, Maraging Steel Grade 300, HX, Cu, CuSn10, CoCrMoW, and CoCrMo.

Pros

- Large build volume and compact footprint

- High print quality

- Fast print speed

- Use of more powerful and durable fiber laser

- Open system

BLT-A160D

The BLT-A160D is an industrial-grade SLM metal 3D printer designed specifically for the dental industry. The machine can print with Titanium and Cobalt Chromium alloys that are widely used in dentistry for producing high-quality stents and dentures. The A160D features a build volume of 160 x 160 x 100 mm and can print 20 cobalt chromium brackets for 7 hours or 20 two-way titanium alloy stents for 4 hours. The minimum layer height of 10 microns allows printing durable parts with smooth surface finish. Two 200W lasers ensure fast and accurate printing. The intelligent software provides real-time monitoring of the printing process, a safety interlocking mechanism, and a self-diagnostics function.

The A160D features a build volume of 160 x 160 x 100 mm and can print 20 cobalt chromium brackets for 7 hours or 20 two-way titanium alloy stents for 4 hours. The minimum layer height of 10 microns allows printing durable parts with smooth surface finish. Two 200W lasers ensure fast and accurate printing. The intelligent software provides real-time monitoring of the printing process, a safety interlocking mechanism, and a self-diagnostics function.

Credit: xa-blt.com

Pros

- High print quality

- Fast print speed

- Intelligent software

- Build plate construction for fast loading

- Water-injection filter

Cons

- Build volume is quite small for large-scale manufacture

Dental 3D printing software

Almost all dental 3D printing solutions include proprietary software specially designed for dental practices and labs. It usually guides the user through all the stages starting with uploading a 3D scan to a CAD file with the following creation of a 3D digital model of the custom-tailored dental product. The slicer converts the CAD model to a printable file, usually STL, and prepares the model for printing. When the task is done, the software sends the print job to the printer.

The slicer converts the CAD model to a printable file, usually STL, and prepares the model for printing. When the task is done, the software sends the print job to the printer.

Credit: uniz.com

The use of dedicated software recommended by the manufacturer provides maximum compatibility and ensures the best results without any downtimes.

Post-processing equipment

Printing with resins, which is the most popular material in digital dentistry, always implies several post-processing steps; that is why a lot of dental printers can be purchased as part of a complete solution, including, besides the printer itself, machines for washing and post-curing the printed parts.

Credit: anycubic.com

Is dental 3D printing expensive?

Compact dental resin 3D printers suitable for in-office printing can cost about a few thousand dollars, while industrial-grade large machines’ price can be as high as tens of thousands dollars and more. Such devices are good for dental labs with big production volumes as they allow for fast continuous printing thus providing the fast ROI.

Such devices are good for dental labs with big production volumes as they allow for fast continuous printing thus providing the fast ROI.

Pros and cons of dental 3D printing

Pros

- Digital dentistry is capable of producing highly accurate dental appliances that can be easily customized at no additional cost.

- 3D printing saves a lot of time both for patients and practitioners.

- The cost per part is in many cases lower for 3D printed models compared to those produced by traditional methods.

- The dental technician’s work requires much more expertise than creation of digitally printed models.

- The process of dental 3D printing is usually highly automated.

- The final result in dental 3D printing is more predictable and reliable than in traditional dentistry.

Credit: dentalproductsreport.com

Cons

-

The startup price is rather high.

-

Dental 3D printing requires special training (usually provided by the printer’s manufacturer).

-

Not all materials can be used for 3D printing (though the existing variety is already wide enough and growing constantly).

Bottom line

Dental 3D printing is one of the most rapidly growing additive manufacturing industries, and its popularity among both practitioners and patients is easily explained. Digital dentistry saves time and money, provides much higher quality of the printed dental appliances, and makes the treatment less painful and invasive for the patient and more convenient for the dentist.

All about a 3D printer in dentistry: features, applications, technologies

The first attempts to use 3D printing in dentistry were made by specialists from Align Technology in the 1990s. Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

The process of making teeth was looked at from a radically new point of view.

But development did not progress as fast as we would like: it took almost 20 years to achieve satisfactory print quality and optimize performance. The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar.

The advantages of using a 3D printer in a short time to solve almost any problem. With a dental 3D printer, a significant number of required instances can be modeled in a single session. All projects are saved in files, so in the future you can re-make the same model if necessary.

It is no longer necessary to send the patient for 2-3 days to wait for the production of plaster models. Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

Speed and maximum precision increase the level of treatment and really save resources and time.

What you can print

Let's highlight the most common uses of 3D printing in dentistry. Using the printer, you can create:

- demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in the occlusion;

- ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

- surgical guides for implantation, individual trays, guides for maxillofacial surgery.

Such a promising direction as the printing of permanent and temporary orthopedic structures, removable denture bases is actively developing.

About the types of printing

As we have already found out, the main task of a 3D printer for dentistry is to reduce the time of manufacturing restorations and reduce the cost of production without loss of quality and accuracy. We will understand the printing technologies and their features.

We will understand the printing technologies and their features.

Stereolithography (SLA or SL). With this technology, a laser beam selectively impacts a container of liquid resin through the printable area. Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Stereolithography gives the best surface finish on parts and is most commonly used in today's 3D printer models. SLA machines provide a large area of restoration construction and work with a wide range of materials designed for a variety of tasks.

To switch from one material to another, it is enough to change the cartridge and the resin bottle. Relatively compact dimensions, ease of workflow and affordable price make SLA printers the best choice for dental laboratories. An example of SLA models - Form 2 and Form 3 from Formlabs, SLASH PLUS from Uniz Technology, Basic Dental from Omaker, Asiga PICO2.

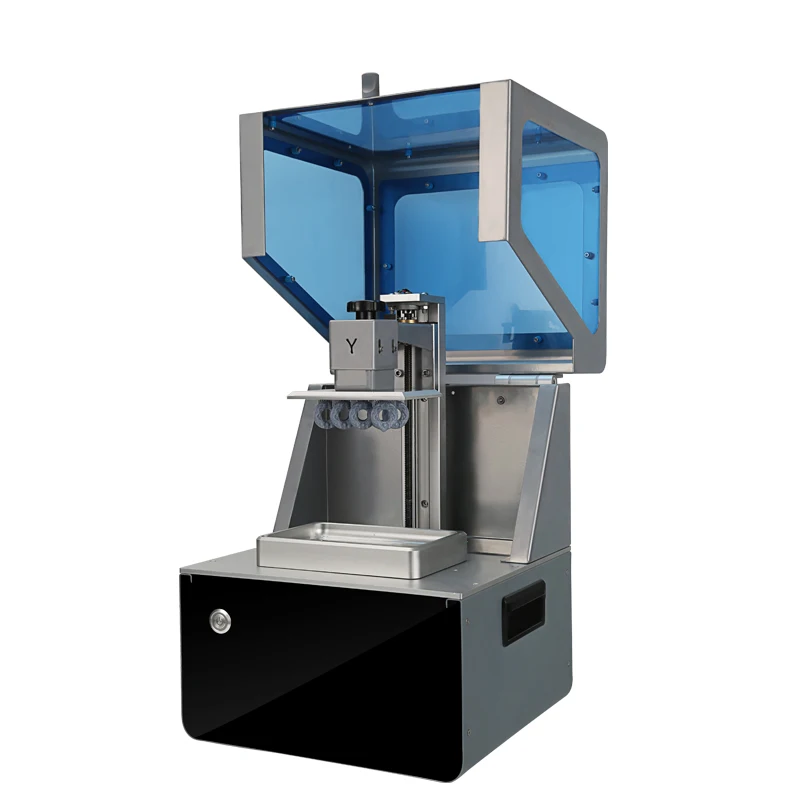

Digital LED projection (DLP). Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Due to the nature of the illumination of the LED projector, there is a tendency for voxel lines-layers formed by small rectangular bricks of material. Models made by DLP have inferior surface quality to SLA models. But it is worth noting that DLP printers print much faster than laser ones. Examples of DLP printers include Varseo S by Bego, AccuFab-D1 by Shining 3D, D2-150 by Veltz 3D, Versus by Microlay.

PolyJet technology. The process is similar to that of a regular inkjet printer, but instead of inkjet drops on paper, the 3D printer blows layers of liquid resin onto the printable area. The layers harden when exposed to light.

Once upon a time PolyJet gained popularity in the dental industry, but its development was slowed down by two factors: the high cost of equipment and the impressive dimensions of the devices. Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

PolyJet systems produce parts very quickly, but are limited in scope due to expensive proprietary consumables. Therefore, in the context of our industry, it is better to buy a dental 3D printer with SLA technology.

SLS and EBM. Allows titanium printing of ready-made elements for replacement of jaw parts. These technologies work on the principle of laser sintering of metal clay, a special metal powder for dentistry. So, the SLS and EBM systems allow you to work with a biocompatible titanium alloy. Since pure metal powder does not require a binder filler, the finished models do not differ in porosity. To achieve the required mechanical strength, the products do not require additional firing. An example of a printer capable of printing with metals is the EP-M150T from Shining 3D.

Filament printing. Technology is not relevant in dentistry and now we will explain why.

Technology is not relevant in dentistry and now we will explain why.

Printed with filament, a material similar to fine garden trimmer wire. The wound filament is charged directly into the 3D printer head, which moves on three axes.

Compared to other materials for 3D printing, this filament is quite inexpensive, but gives low accuracy compared to powders. The most popular types of filament are ABS and PLA plastic.

Comparison of the main 3D printing technologies used in dentistry

To clearly show the main pros and cons of each technology, we compare them in a table format.

| Stereolithography (SLA) | Digital Light Processing (DLP) | PolyJet technology | SLS and EBM technologies | |

| Precision | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface finish | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Print speed | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Availability of materials | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Metal printing | ||||

| Benefits |

|

|

|

|

| Drawbacks | Slow single print speed |

|

|

|

Our CV

PolyJet technology is becoming a thing of the past due to high cost and imperfect print results. SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

← General requirements for the placement of portable X-ray machines | TOP 5 Illuminated Physiodispensers →

How to choose a 3D printer for dental use

3D printing is making its way into more and more products around us. Sculptures, shoes, even food. Well, the happiest ones can already use the achievements of additive technologies for more comfortable treatment of their teeth.

The increasing popularization of new methods of treatment leads to the fact that new market niches appear, which are still very easy to occupy in our time. Accordingly, there is the prospect of a quick return on investment, obtaining a valuable asset, diversifying the sources of income for individual businesses.

In such a favorable situation, more and more investors decide to invest in this particular area - the production of dental products using 3D printing. And the question arises, how to spend these attracted investments? Or, to paraphrase, what kind of 3D printer to buy for use in a dental clinic?

Which 3D printers are in demand in dentistry

Printing multiple jaw impressions at the same time using the Phrozen Sonic 4K 9 printer0335

The situation on the market is so favorable that even those who previously were either very remotely or not at all connected with dentistry decide for themselves to enter this niche. Sometimes it is not even related to medicine at all. Therefore, I want to start with what actually needs to be made and how.

Variety of popular dental products

Only a small part of the range of 3D printed products

Most likely I will not be mistaken if I assume that absolutely anyone reading these lines has gone to the dentist. In recent years, dentists have ceased to scare children, visiting the dentist has become less stressful. And already without negative thoughts, we can choose dental products presented in catalogs, presentations or which experts talk about personally.

In recent years, dentists have ceased to scare children, visiting the dentist has become less stressful. And already without negative thoughts, we can choose dental products presented in catalogs, presentations or which experts talk about personally.

There are several groups of products that can be produced with a 3D printer. The most innovative can be called products for bite correction - aligners.

Less obvious is the use of additive technologies for the creation of surgical templates, the transfer of checks.

It may seem surprising, but a temporary crown, a temporary bridge can be printed on a 3D printer.

The ability to print a prototype of the jaw, in particular, to check the fit of implants, is of great help to dentists.

For those who are familiar with jewelry, it will be clear that products that are produced by casting using a burnt model created on a 3D printer will work well. It can be crowns and bridges and liners and many other metal products.

You can also print a matrix for later use in the thermoforming process.

3D printing technologies used in dentistry

In FDM dentistry, 3D printers are used less often, but it happens. FDM 3D printer Stratasys

To a large extent, it is precisely such a wide range of products that are profitable to manufacture using a 3D printer that leads to a high demand for 3D printing in dentistry. Just by looking at this incomplete list, it becomes approximately clear which technology is used most often in dentistry.

SLA and LCD 3D printers can print with enough precision, suitable materials and are easy to use, so dentists are more likely to use them.

FDM 3D printers are less commonly used. Basically, enlarged models of jaws, presentation models are printed on them. Occasional auxiliary tools.

Let's take a closer look at the use of SLA and LCD 3D printers. The main difference between these technologies, from the point of view of application in dentistry, is that the LCD printer is designed to print small models with high resolution, while the SLA 3D printer can print a relatively large model without quality loss. Products required by dentists are not often large. The demand for SLA 3D printers, although it exists, cannot be compared with the demand for LCD models. LCD 3D printers have a printable area large enough to produce both aligners and jaw models. In terms of size, most dental products are not large. At the same time, the accuracy of such printers is sufficient - it is important to mention here that this is the case if we are talking about 4K or higher resolution print screens of such printers. LCD printers are more compact, easier to maintain, and cheaper.

Products required by dentists are not often large. The demand for SLA 3D printers, although it exists, cannot be compared with the demand for LCD models. LCD 3D printers have a printable area large enough to produce both aligners and jaw models. In terms of size, most dental products are not large. At the same time, the accuracy of such printers is sufficient - it is important to mention here that this is the case if we are talking about 4K or higher resolution print screens of such printers. LCD printers are more compact, easier to maintain, and cheaper.

In general, the choice of a printer for dentistry in 95 percent of cases will result in the purchase of an LCD 3D printer, so we will concentrate on machines using this technology.

Denote the initial conditions

Having familiarized ourselves a little with the niche that we will occupy, it is necessary to pay attention to who will use these 3D printers.

First of all, equipping a dental clinic with 3D printers should be profitable - we will pay considerable attention to issues related to the rate of return on investment and the optimal use of equipment.

Newcomers to dentistry, although they have the potential to gain a foothold in the 3D printing niche for dentists, will pick up all the bumps along the way, they are more likely to need advice about dentistry in general than advice on how to use 3D printing. Therefore, we will cover, for example, an already existing dental clinic or dental office.

At the same time, those who already use 3D printing most likely know what they lack and what is not very necessary. I suggest that such a reader go straight to the description of the advantages of individual models - most likely you will be able to find offers that are interesting to you.

Equipment of the new 3D printing laboratory

A 3D printed lab might look like this

So, it turns out that we are discussing the choice of a 3D printer for a new 3D printed laboratory in an existing dental clinic or dental office.

The level of investment should be relatively low - for an individual dentist who runs his own practice, the investment should be minimal.

A large dental clinic will be able to afford not only to allocate a separate, well-equipped room for a 3D printed laboratory, but also to hire specialists who will serve the laboratory without combining this activity with anything else.

In addition to an LCD 3D printer, a 3D scanner, a washing and backlighting station will be useful. When creating a 3D printed laboratory in a large clinic, you can immediately plan the purchase of machines for creating products by casting according to a burnout model and by thermoforming.

Both LCD and SLA 3D printers require a separate, well-ventilated area with a desktop. If for a small office it can be a separate closet-sized room, then in a large clinic it is worth thinking about allocating an appropriate area not only for the printers themselves, but also for post-processing tables, for storage racks for materials, for service jobs.

Who is an expert in dental 3D printing

Only a doctor can be an expert in 3D printing in dentistry

A separate question is who will work directly with 3D printers.

It would be more profitable for a large clinic to immediately hire specialists with experience in using 3D printing in dentistry. At the same time, in a small clinic or in the case of a private dental practice, the dentist or dental technician himself can relatively quickly learn how to use and maintain a 3D printer.

The dentist must still evaluate and accept the products. It is quite common to hold joint seminars for dental technicians and dentists at the same clinic.

It is very important to understand that only a dentist can be an expert in dental 3D printing, evaluate the quality of printouts, and set criteria! Even the most experienced 3D printer can't do this alone.

Key criteria for choosing a 3D printer for a dental lab

When selecting any machine for commercial use, the selection criteria must be clearly defined. Often it is the clarity of such criteria that determines the payback period and the overall value of the machine.

Earlier, we touched on issues related to what exactly dentists require from the 3D printers they use. Let's cover these requirements more fully and arrange them in order of priority.

Imprint accuracy is the main criterion

Rough model of the jaw. The color shows the deviation in dimensions from the original (mm)

The main criterion for choosing a modern 3D printer for use in a dental clinic is accuracy, or rather resolution. The tasks of modern dentistry, which specialists are ready to delegate to machines, require the ability to manufacture high-precision products. For LCD 3D printers, a resolution of 2K nominally may be suitable - the accuracy of aligners, for example, is allowed up to 50 microns - but the actual quality of the resulting printouts may be lower than declared by the manufacturer of the 3D printer, both due to the characteristics of the materials used, and in connection with the presence of the human factor. Therefore, dentists use LCD printers with a print screen resolution of at least 4K.

Therefore, dentists use LCD printers with a print screen resolution of at least 4K.

The accuracy of the prints will be higher, with a shorter illumination time of the photopolymer. The Mono LCD screen will help reduce the time needed to expose one layer. The presence of such a screen will not only increase accuracy, but also speed up the printing process.

Print area - rate of return on investment

Even the largest laboratories use groups of identical 3D printers

A very important criterion that can be assessed by the passport of a 3D printer is the printable area. The larger the printable area, the faster you can produce a series of printouts - this is the peculiarity of using an LCD 3D printer. Due to the fact that a client of a dental clinic quite often needs to receive a series of products on hand during a visit - again, aligners, or immediately need to print a complex model with small details, the total print area will help to carry out the service faster.

At the same time, the print area of one printer may not be so large - remember that products for dentistry are rarely large. To speed up the production process, most often they buy several identical or very similar printers. Most often the same manufacturer.

Such a 3D printing farm will not only be cheaper than a single printer of a comparable printing area, but will also allow you to accept multiple clients at the same time. Maintenance and repair of printers is also simplified - one or a pair can be taken out of operation without stopping all production.

The choice in favor of several printers with a smaller print area is also justified in terms of the fact that it is recommended to invest in 3D printing gradually. Buying a dozen 3D printers at once is justified only when you know for sure that you have a large flow of customers and the total workload of the 3D printing laboratory will be about 60 percent.

In general, buying multiple 3D printers will reduce your initial costs and risks, while the overall larger printable area will allow you to make more profit.

Usability, reliability, ease of maintenance

Unfortunately, most of the mistakes when choosing a 3D printer for a dental clinic are associated with underestimating the importance of the usability of a 3D printer. These machines will be serviced by a person, which means there is a human factor. You know from experience that work is more productive when you work comfortably. Research confirms the validity of this personal experience. The more convenient it is to work on a 3D printer, the fewer mistakes the operator will make, which means less money will be spent - both material and time.

The reliability of a 3D printer - design, electronics, individual elements - will be economically justified. Less breakdowns - less downtime - less costs.

Ease of maintenance reduces costs in the same way

Post-processing

The process of removing supports is not easy

It must be borne in mind that after printing, absolutely all printed models require post-processing. At a minimum, this is flushing and backlighting. As a maximum, a printed, washed, illuminated part, from which the supports were removed, can be a semi-finished product that has yet to be worked on. A 3D printer should provide the ability to not be a stand-alone device, but to work in an ecosystem.

At a minimum, this is flushing and backlighting. As a maximum, a printed, washed, illuminated part, from which the supports were removed, can be a semi-finished product that has yet to be worked on. A 3D printer should provide the ability to not be a stand-alone device, but to work in an ecosystem.

What might be useful but not worth emphasizing

The standard marketing policy of any retailer is to try to convince you to buy a product based not so much on direct value as on features that sound and look good on paper, but do not greatly affect the quality of the product itself. A good example is the color of a delivery vehicle. If you do not take the possibility of applying advertising images and colors from the brand book, the delivery vehicle can be of any color. But the seller may try to convince you to buy this particular car by appealing to its color.

Similarly, when choosing a 3D printer for a dental clinic, some criteria are not as valuable as they sound.

Range of materials used

Most modern LCD 3D printers use ultraviolet wavelengths of 380nm-405nm to illuminate the photopolymer. The ability to use specific materials seems like a very useful feature, but in fact, you either know for sure that you will use such materials, or you will not use them. It is enough to understand what range of tasks the 3D printer will solve and choose accordingly. At the same time, it will be useful to be able to use the selected materials more conveniently, for example, a system of material profiles.

It is important to expand the range of materials used unnecessarily - it is not economically feasible.

Additional software - pros and cons

Software that helps you print. FormWare Phrozen Edition.

The whole process of creating printouts involves the use of several software products. And, if software that will allow you to facilitate or speed up printing without loss of quality is useful, then different programs for modeling or, for example, creating print time-lapses will never be used. The specialist models in the environment he is used to, and time-lapses are just a beautiful feature.

The specialist models in the environment he is used to, and time-lapses are just a beautiful feature.

Remote printing and control

When you think of 3D printing, there is often an assumption that I pressed a button, an hour later I came, and everything is ready. It's actually not that automated. In principle, it is better to keep the machine under supervision at least during the start of printing. This means that remote printing will not be so popular. At the same time, I note that after the operator of a 3D printer gets used to working with a particular machine, he will know most of its features, the ability to transfer files to the device remotely, or even remotely control printing will be useful.

Remote control will bring more benefit to an experienced operator, although a beginner in 3D printing will gain experience quickly if desired.

Top Best Dental 3D Printers

Based on what I have outlined, I will try to create a rating of the value of 3D printers for dentists.

Phrozen Sonic 4K

This 3D printer is specially designed for use in dental clinics. A good price/quality ratio makes this 3D printer an excellent choice for both a small clinic and as one of several printers in a large 3D printing laboratory. Mono LCD allows you to reduce the exposure time of the layer to 1 second, and the large area of \u200b\u200bthe 6.1” matrix allows you to print more models at the same time, making the production process even faster! With the FormWare Phrozen Edition software, post-processing can be facilitated by optimally positioning supports, and reduce printer control time by arranging more models in the same print volume. If you have a dedicated 3D printer operator, the function of remotely sending files to print will be useful.

Phrozen Sonic Mini 4K

Mini version of the popular printer. At a lower price, it has the same resolution and matrix size - 6.1” @ 4K. It will be a good choice for a private practice dentist's office. Also one of the options for entering 3D printing for a medium-sized clinic is that it performs well both as a single 3D printer and as an additional printer, if there are several more advanced ones. A fairly high print speed is achieved due to Mono LCD, which allows you to reduce the exposure time to 2 seconds.

Also one of the options for entering 3D printing for a medium-sized clinic is that it performs well both as a single 3D printer and as an additional printer, if there are several more advanced ones. A fairly high print speed is achieved due to Mono LCD, which allows you to reduce the exposure time to 2 seconds.

Peopoly Phenom

Large Format - 276 x 155 x 400mm build area - MSLA 3D printer (LCD+LED). The use of MSLA technology allows you to get high-precision prints on a 12.1” @ 4K matrix without distortion. Well suited for large clinics that want to increase their 3D printing capacity. At the same time, the extended life of the LCD panel will significantly reduce the overall cost of maintaining this machine.

FormLabs Form 3B

The LFS 3D printer is a higher priced printer. A special technology of low-intensity stereolithography and a specially designed light processing unit allows you to quickly obtain high-precision printouts up to 145x145x185 mm in size with a laser positioning accuracy of 25 microns.