Reprap 3d printer buy

Build a reprap - RepRap

This page has been flagged as containing duplicate material that PartsSupplies also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that Darwin/Buyers Guide also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that What Tooling Do You Have also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page is out of date --Sebastien Bailard 04:34, 31 October 2010 (UTC)

This page is not only out of date, but contains in part simply nonsense - especially the "Software installation" section. For the lack of editors, this page should be removed. --Traumflug 21:18, 13 April 2011 (UTC)

Contents

- 1 Build a RepRap

- 2 Overview

- 2.

1 Object Creation Software

- 2.2 System control Software

- 2.3 Installing the Software (experimental)

- 2.4 Thermoplast extruder

- 2.5 Positioning system

- 2.6 Shopping list

- 2.

There are multiple ways to build a RepRap or RepStrap; the method selected for these instructions has been chosen to minimize skills and tools needed. If you wish to explore other options click Alternative Build Documentation.

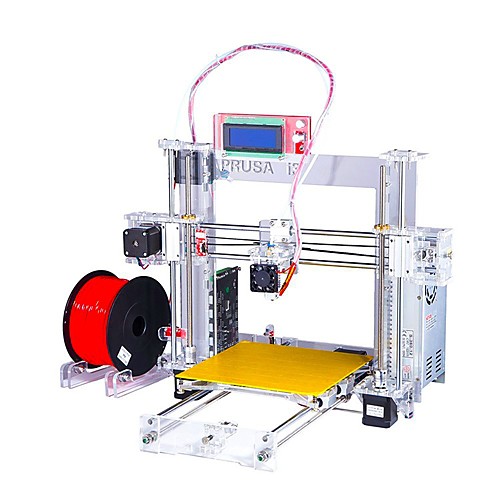

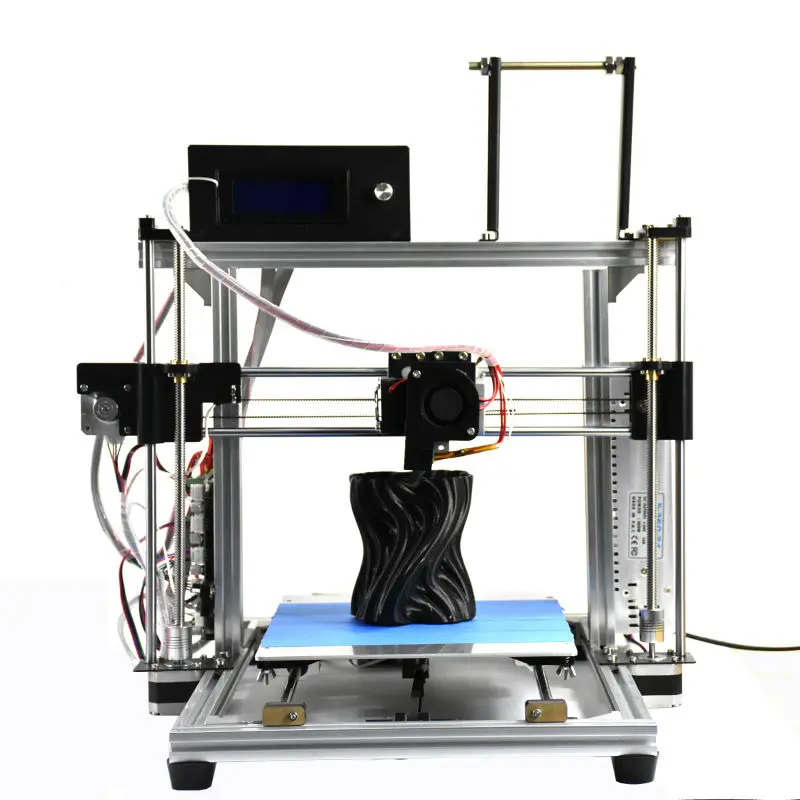

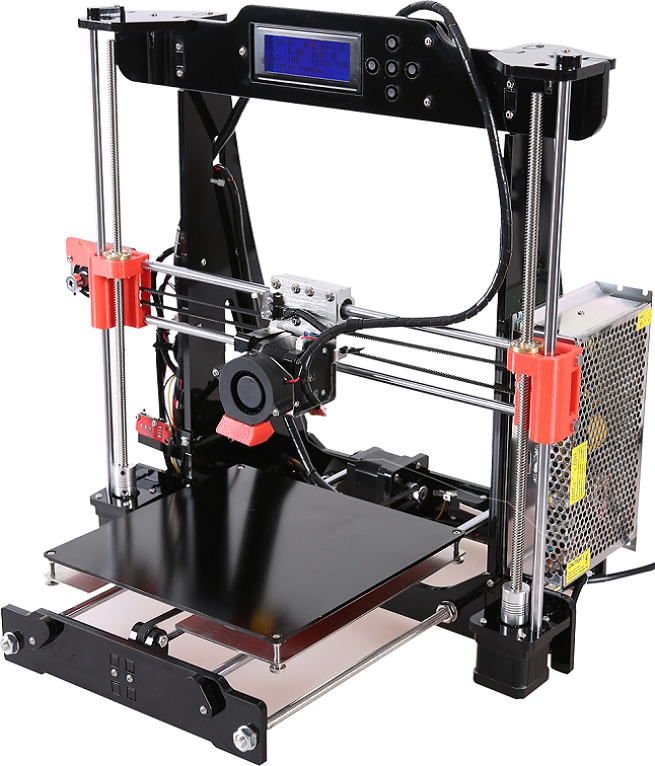

The Classic RepRap Design is "Darwin" pictured on the right. There are very full and accurate building instructions in Make Your Own RepRap.

The RepRap was carefully designed to use only parts that can be made on a RepRap and other cheap parts that you can get anywhere. It was also designed to require few skills to assemble. The one snag is you have to find someone to supply you with the parts that must be made on a RepRap.

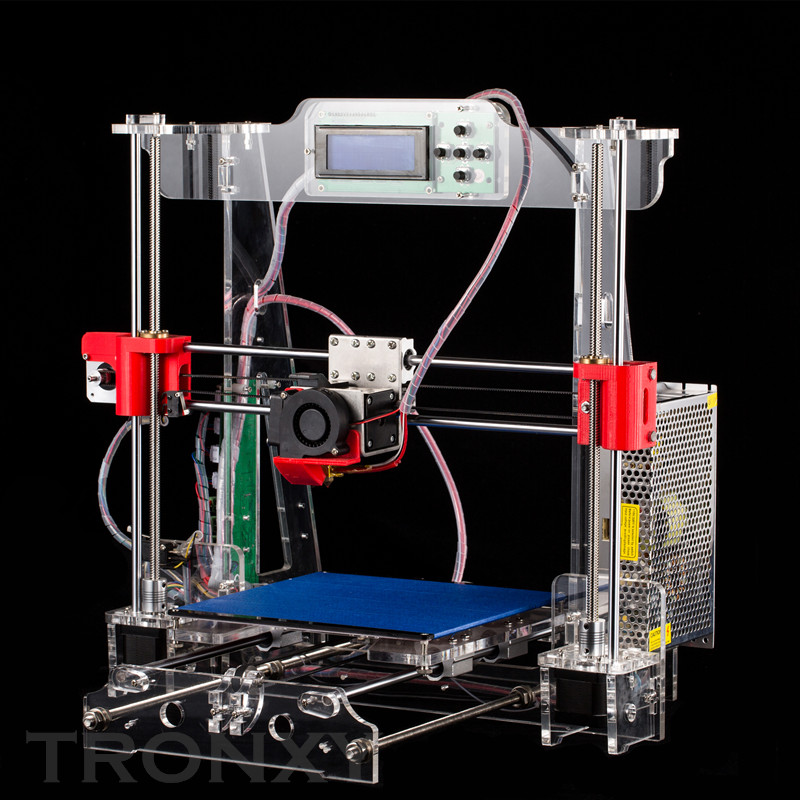

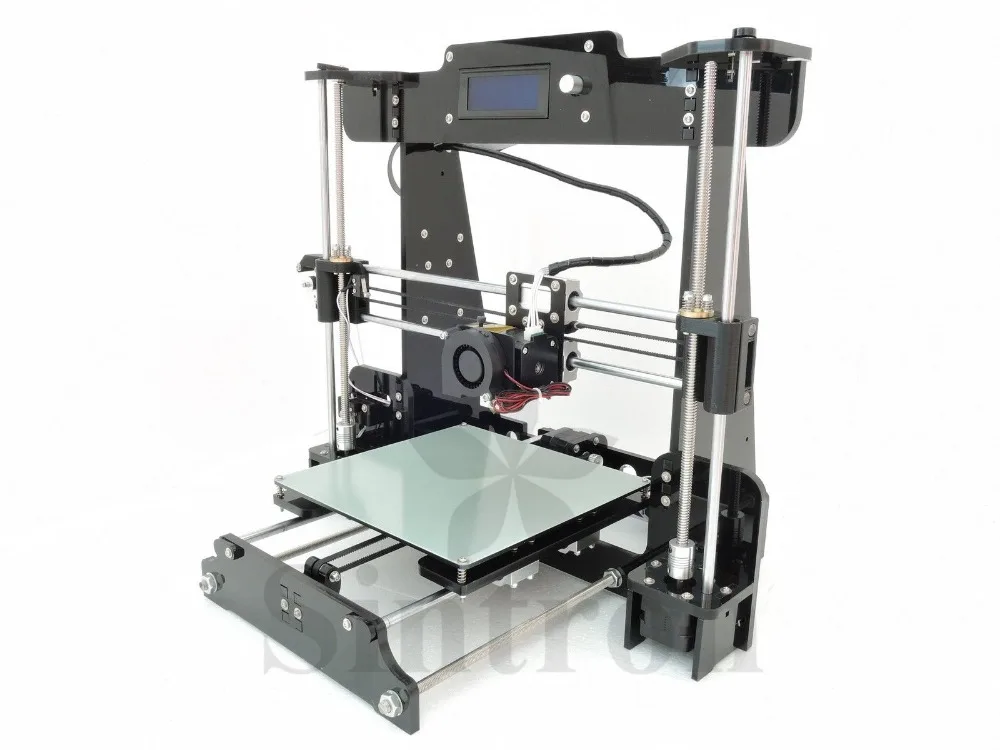

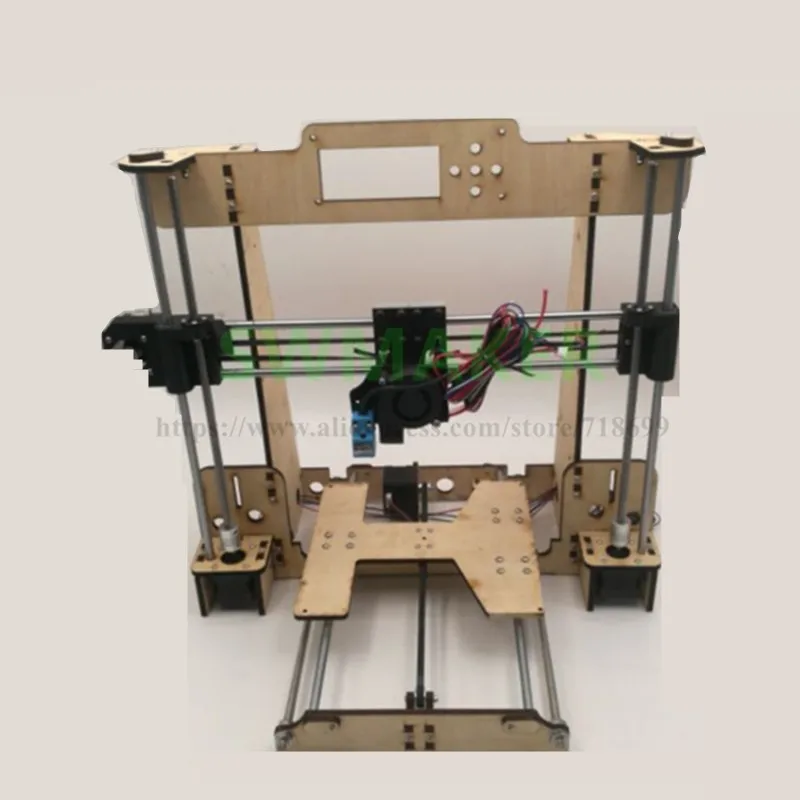

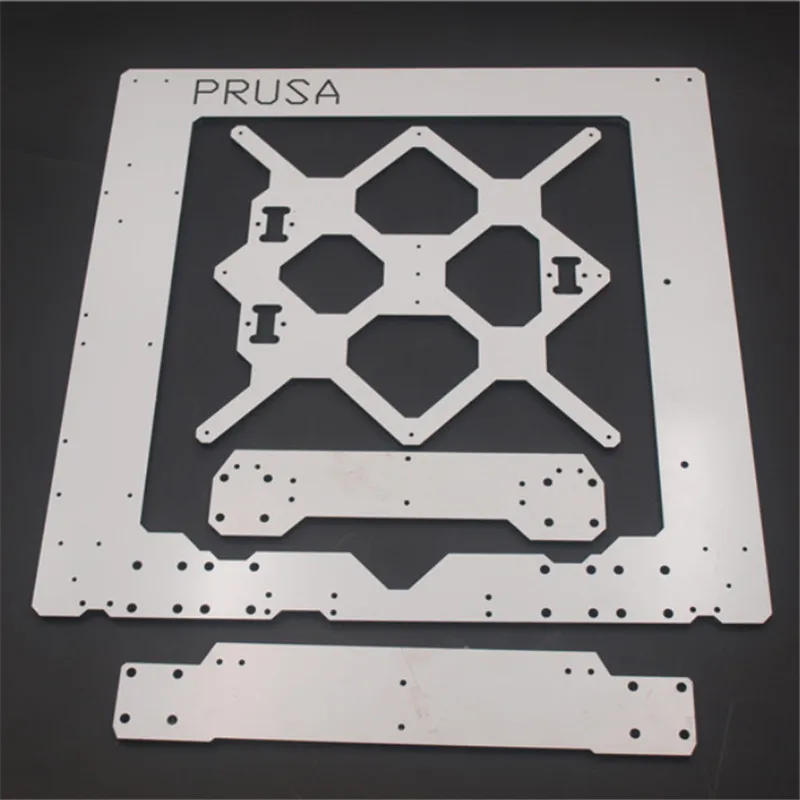

RepStrap Darwin Clones are RepRap designs which are fairly accurately copies of the Darwin design but the RepRapped parts are replaced by parts created some other way, Perhaps molded plastic or laser cut acrylic or plywood. Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

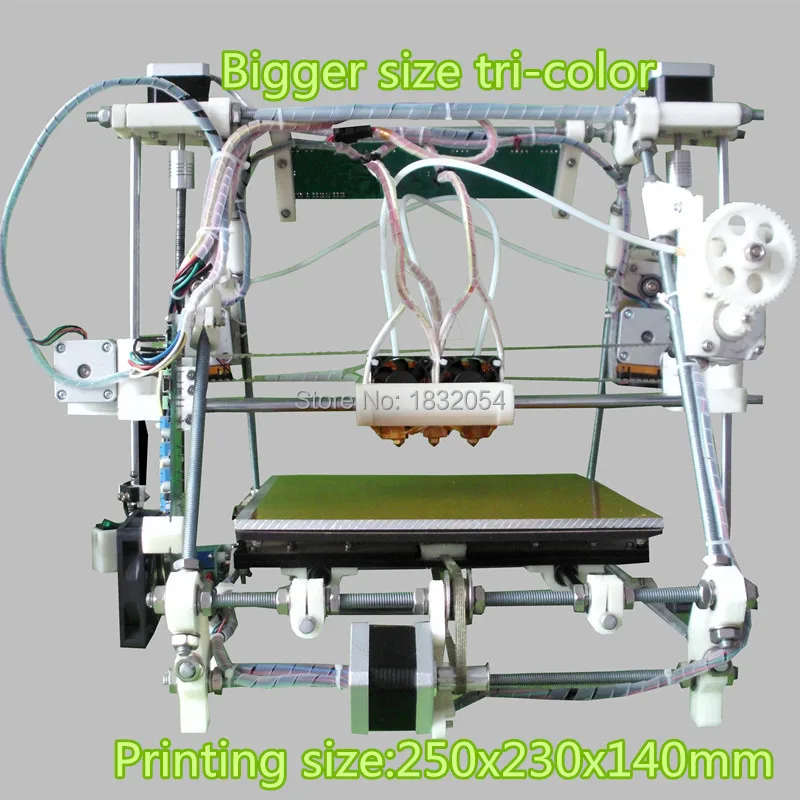

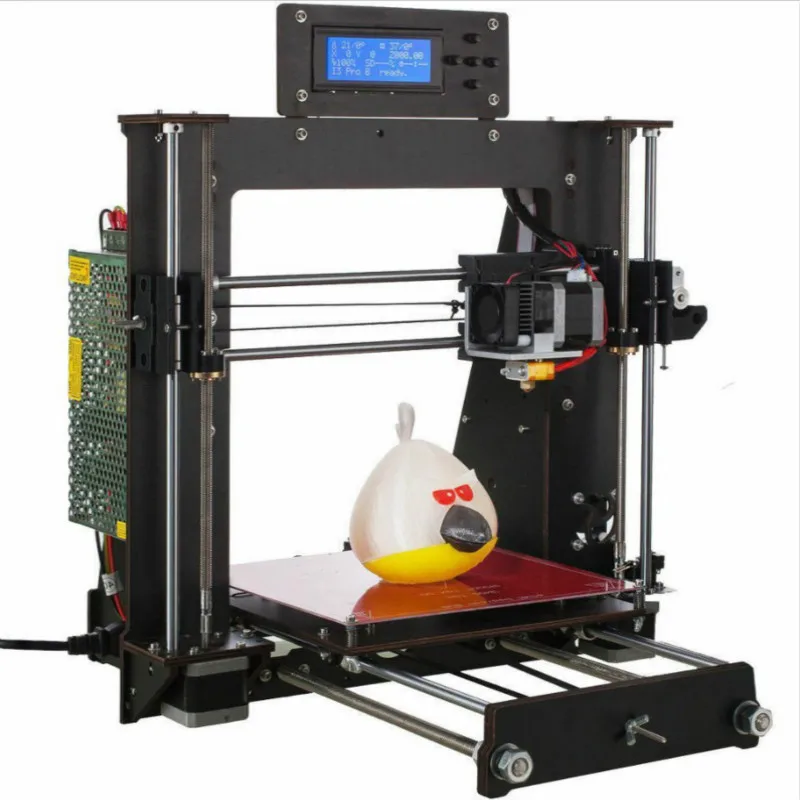

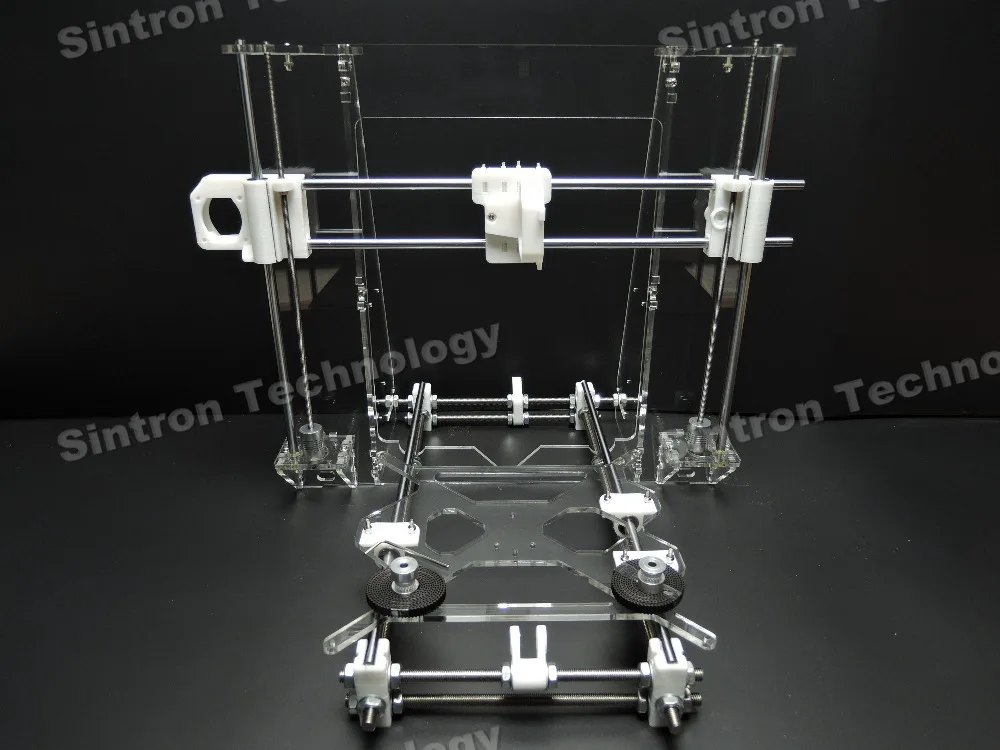

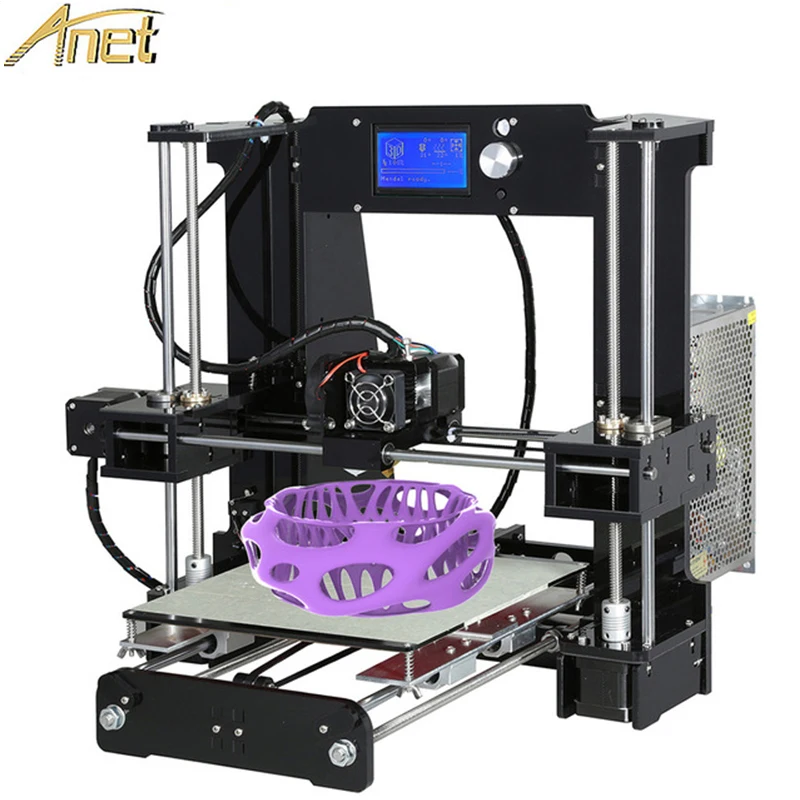

Other RepStraps, these are 3D printers capable of making RepRap (Darwin) parts but are not structurally similar to Darwin. These machines may vary a lot but may be separated into two kinds. Those like Darwin in which the extruder (print head) is moved in the x and y directions and the work is slowly lowered as the print progresses and others where the work is moved in the x and y directions under a stationary head which gradually moves upwards as the print progresses. Here are some references to various RepStrap Machines.

If this is your first RepRap that you are building, here is a basic guide of which build option you should choose:

- If you have a friend nearby that can print out the RepRap part on their RepRap or some other 3D printer. Choose the Classic Darwin

- If you don't have access to a 3d printer then you have 3 options.

- You can build a Classic Darwin, but this means you will have to use a commercial service to print out parts for you; it can easily cost over $1000 for just those parts depending on what deals you can get. This option is probably the most expensive option.

- You can build a RepStrap Darwin Clone. This means you can either buy a lasercut acrylic kit from Bits from Bytes or make some part yourself by machining them. This option is becoming the more common option especially because soon you will be able to buy a lasercut kit from Ponoko which has offices in the US. This is also usually cheaper than the first option.

- The third option is to build non-clone RepStrap that does not have the same frame as a Darwin, such as McWire which uses pipes for the frame. This option is usually the cheapest, but each RepStrap has it own weaknesses. The good thing is that when complete they can print out parts so that you can build a Classic Darwin. The electronics are compatible with Darwin so you only have to buy them once.

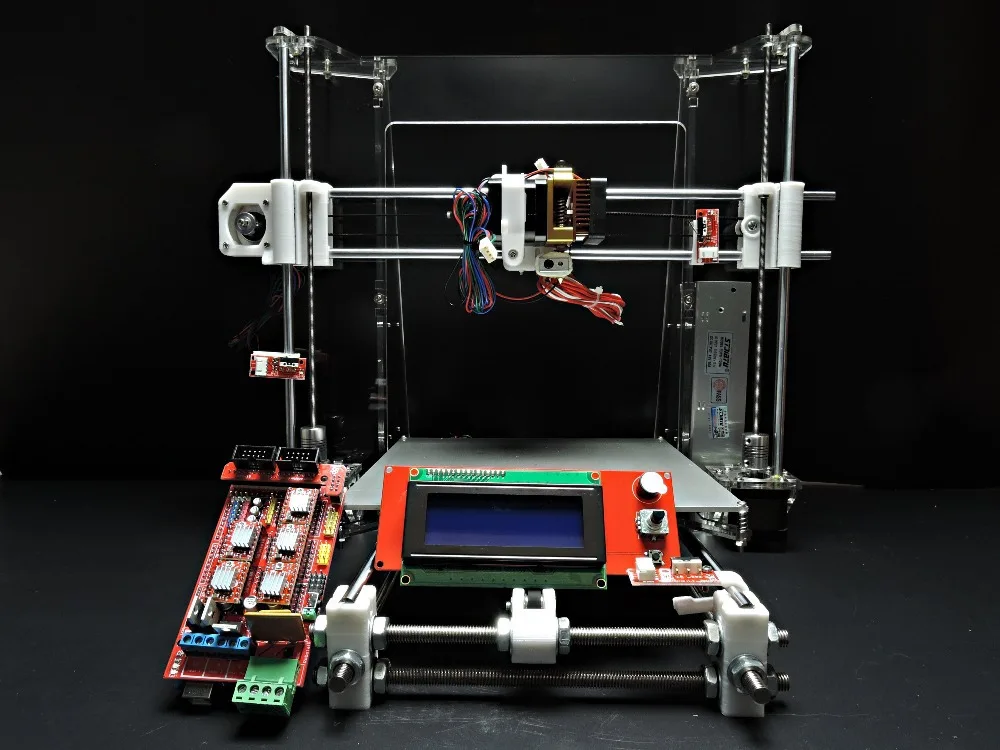

A RepRap or RepStrap (A RepRap can build itself, a RepStrap can build something that can build itself) can be divided into several key areas:

- Object creation Software

- System control Software

- Thermoplastic extruder

- Positioning system (the Cartesian Bot)

- The electronics to control the positioning system

Object Creation Software

Art of Illusion is currently the software most recommended for designing objects to be printed. It's not a CAD package but it is easy to use. The software allows you to create and manipulate 3D shapes. You can store these shapes in STL file format. STL files are object files that are used in Rapid Prototyping. These STL files can be printed off into real 3D objects using your 3D printer (RepRap).

The software is free (GNU GPL version 2) and it is available for Mac OS X, Windows and Linux. If you want to try it out without installing it's available bundled in the Linux distribution liveCD with the rest of the hosted software for the RepRap project.

System control Software

RepRap is controlled via USB or an RS232 interface. You may find a description or download from RepRap Host Software.

There is a RepRap variant which allows you to print an object from a file saved onto a SD card.

Installing the Software (experimental)

This set of instructions tells you how to set up all the software you need for a Reprap in one big blow under Linux Debian.

It involves 5 steps that anyone should be able to complete in a few hours of his/her spare time.

It's easy.

Really.

Warning: Proceed at your own risk. The instructions are not double checked yet.

Prerequisites

You'll need

- a PC (not too old)

- broadband internet access

- some time

Step 1: If you have Windows, go to [Here], get your copy of the Debian installer with one click and start it.

If you already have Linux: Install Debian Lenny some way or the other (you know how to do that ;-)) and continue with Step 3.

Step 2: Follow the instructions. I suggest installing on a 4GB USB stick - but you can also install it all on your hard disk. Be careful to select "testing" instead of stable - this installs Lenny instead of etch. Otherwise the standard settings should be ok in most cases. Don't say "yes" to things you might regret. After a while, a standard system should be installed. Don't forget to install the GRUB boot loader.

Step 3: Log in and say

sudo apt-get install firefox

on the command line.

Step 4: Start firefox and download this Media:Reprap_setup.sh script.

Step 5: Run the script from the shell with

sudo ./Reprap_setup.sh"

Now all the software specific to Reprap is retrieved and installed.

This includes the AVR-Tools, Subversion, Java3d, the Reprap-source tree etc. Installing all that will take some time.

Having successfully reached this point you should try to start the software in reprap-host with:

ant run

If you now see the main window of the host software, you're done.

Congrats! You have made it!

You still have to learn how to use it - but that is another story and another tutorial.

Thermoplast extruder

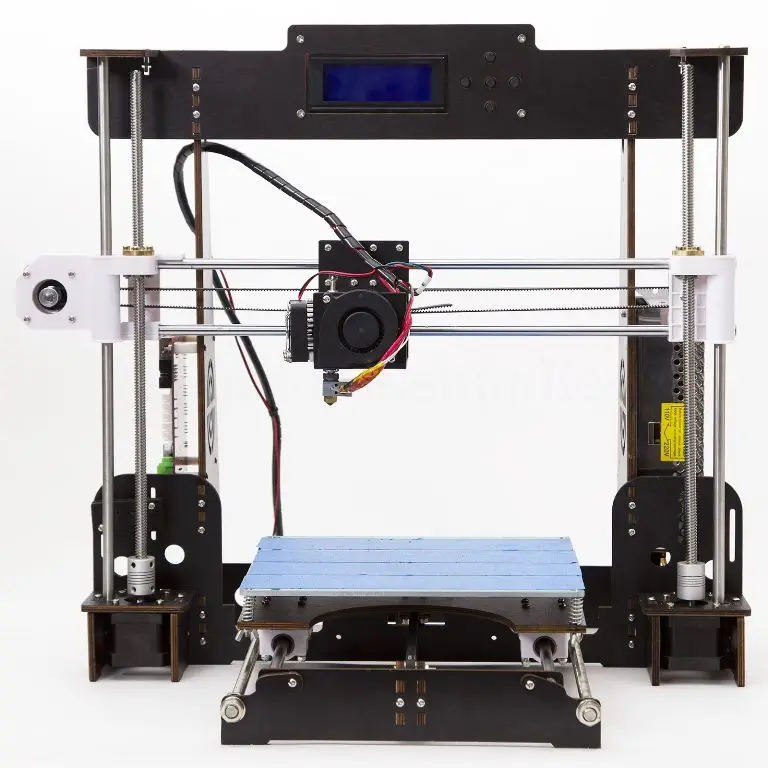

There are three different extruders all of which, in the end, perform the same function. There is the "official" extruder that can be made by another RepRap. Then there are the kits which are mass produced so it is easier to start printing your first parts. Both kits are designed to be interchangeable with the official extruder.

- RepRapable Thermoplast Extuder

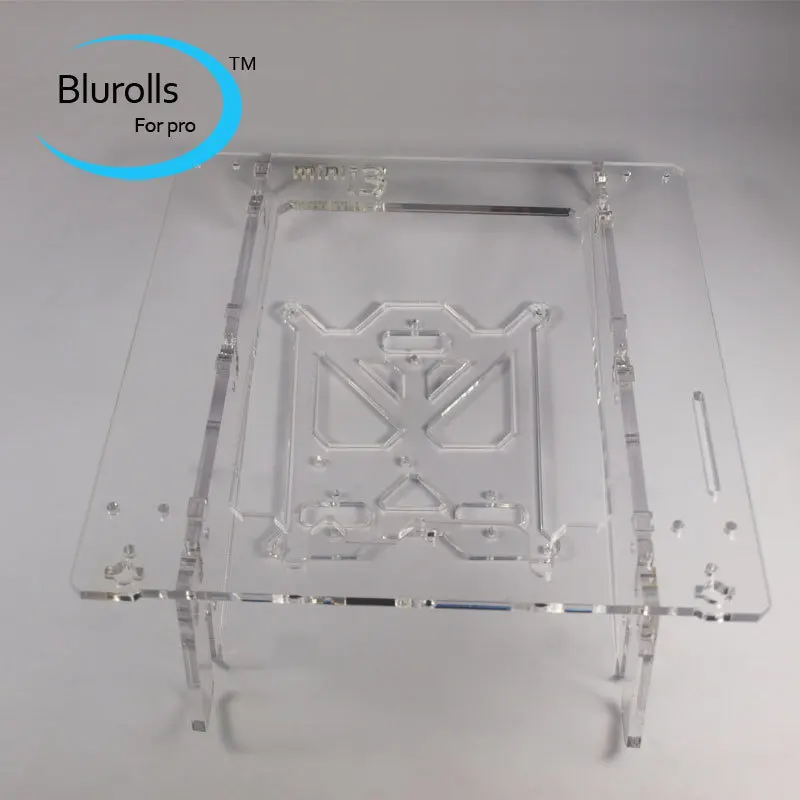

Can be made by another RepRap or commercial rapid prototyper. These are not the only ways the parts can be made but are the easiest. Some builders have made them from machining aluminum or plastic. Others by making molds and casting from resin. This is only for the main pieces of the extruder. The drive screw and other mechanics must be bought or machined. - Kit from Bits from Bytes (laser cut acrylic)

There is an extruder kit currently available from Bits from Bytes who are based in the UK. The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

Bits from Bytes Extruder Assembly instructions

Bits from Bytes Extruder 3d Model - the model requires a recent copy of Adobe Acrobat.

There are videos of the construction process, in the 'Tutorials' section of the website.

Bits from Bytes Heater Barrel Assembly

Bits from Bytes Extruder Drive Assembly

- Kit from Ponoko (laser cut plywood)

A kit will soon be available via Ponoko which has offices in the US.

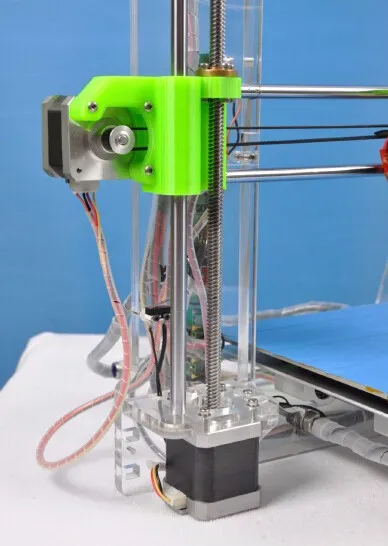

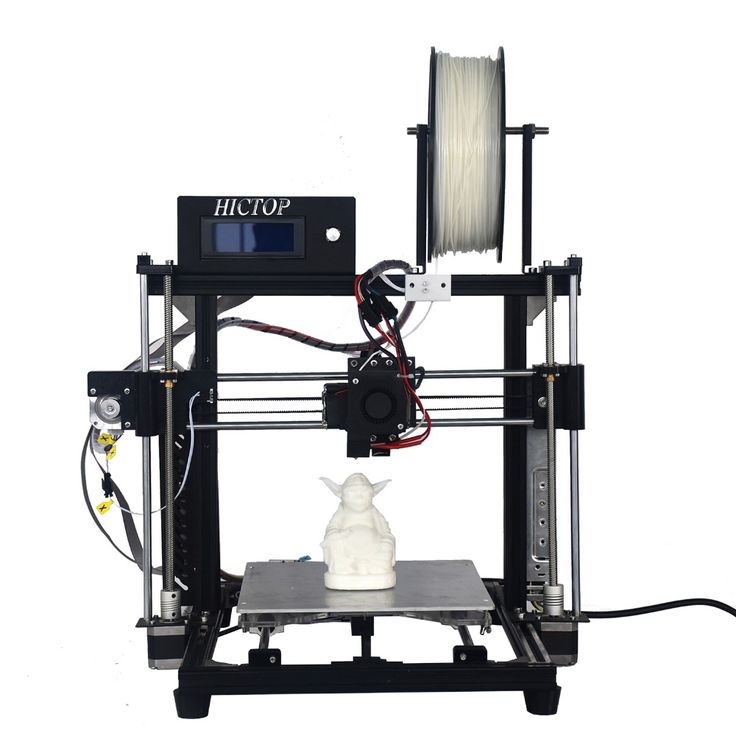

Positioning system

The positioning system is the greatest part of the size of a RepRap. It is what moves the extruder head from place to place. Kits are available from Bits from Bytes, either the FULL Mechanical Kit - Silver or Gold contain all the components necessary to build a positioning system and extruder. Assembly instructions are available on the bits from bytes website in the 'Assembly Instructions' area:

Bits from Bytes Assembly Instructions

Shopping list

The following list contains all the components necessary to build a RepStrap and enough plastic to print a RepRap. Some handtools are required for assembly, but the only power tool used is a soldering iron.

Some handtools are required for assembly, but the only power tool used is a soldering iron.

Extruder and Positioning System

Bits from Bytes - FULL Mechanical Kit - Silver or Gold

Ponoko - coming soon

(only one required)

Electronics

Plastic

The extruders all use 3mm diameter plastic filament/wire. ABS is the recommended plastic for its combination of strength, availability and dimensional stability. Suitable plastic is available from RRRF in 5lb reels. It is also available by request from plasticweldingrod.com.

Total

Shipping and tax vary by country of order but $1000 total is a reasonable approximation.

About - RepRap

From RepRap

Jump to: navigation, search

About | Development | Community | RepRap Machines | Resources | Policy

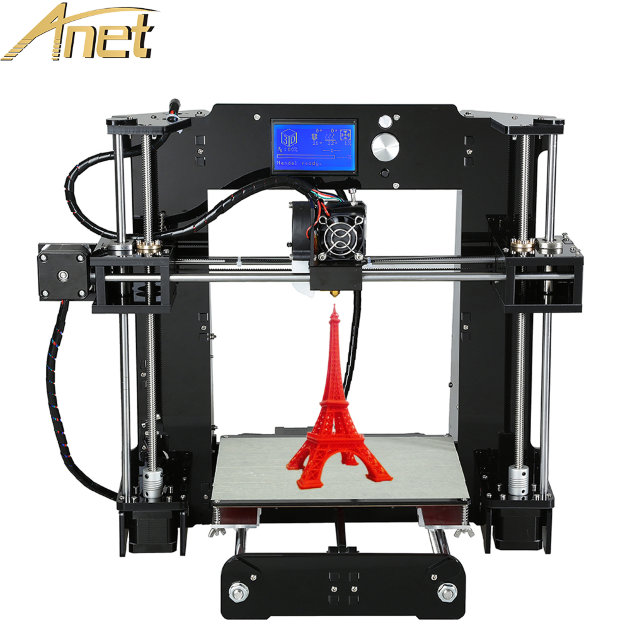

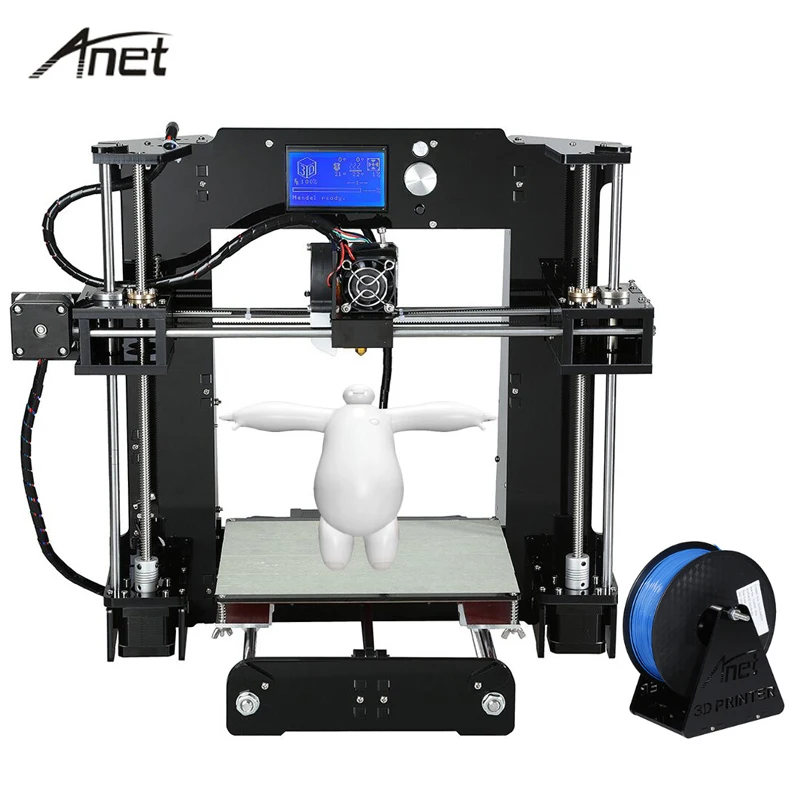

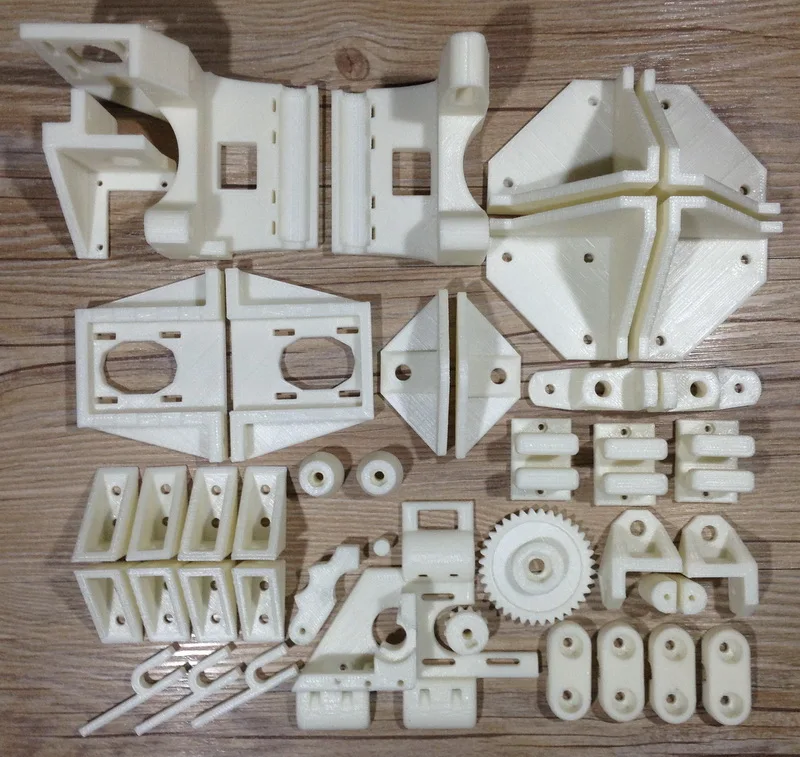

an exhibition of repraped parts

Look at your computer setup and imagine that you hooked up a 3D printer. Instead of printing on bits of paper this 3D printer makes real, robust, mechanical parts. To give you an idea of how robust, think Lego bricks and you're in the right area. You could make lots of useful stuff, but interestingly you could also make most of the parts to make another 3D printer. That would be a machine that could copy itself.

Instead of printing on bits of paper this 3D printer makes real, robust, mechanical parts. To give you an idea of how robust, think Lego bricks and you're in the right area. You could make lots of useful stuff, but interestingly you could also make most of the parts to make another 3D printer. That would be a machine that could copy itself.

Contents

- 1 The Realization

- 2 Machine Self-Replication

- 3 Scholarship and History

- 4 Spread the Word

- 5 Glossary

- 6 Also See

- 7 Longer Video

The Realization

RepRap was invented by Adrian Bowyer and the idea first appeared online in February 2004.

The word RepRap is short for Replicating Rapid-prototyper. It is the practical self-copying 3D printer introduced in the video on the left - a self-replicating machine. This 3D printer builds the parts up in layers of plastic. This technology existed before RepRap, but the cheapest commercial machine then would have cost you about €30,000. And it wasn't even designed so that it could make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €350). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under an open source license (the GNU General Public License). So, if you have a RepRap machine, you can use it to make another and give that one to a friend...

This technology existed before RepRap, but the cheapest commercial machine then would have cost you about €30,000. And it wasn't even designed so that it could make itself. So what the RepRap team are doing is to develop and to give away the designs for a much cheaper machine with the novel capability of being able to self-copy (material costs are about €350). That way it's accessible to small communities in the developing world as well as individuals in the developed world. Following the principles of the Free Software Movement we are distributing the RepRap machine at no cost to everyone under an open source license (the GNU General Public License). So, if you have a RepRap machine, you can use it to make another and give that one to a friend...

The RepRap project became widely known after a large press coverage in March 2005.

Machine Self-Replication

Not counting nuts and bolts the latest RepRap can make 70% of its parts; the other parts are designed to be cheaply available everywhere. The primary goal of the RepRap project is to create and to give away a makes-useful-stuff machine that, among other things, allows its owner cheaply and easily to make another such machine for someone else.

The primary goal of the RepRap project is to create and to give away a makes-useful-stuff machine that, among other things, allows its owner cheaply and easily to make another such machine for someone else.

To increase that 70%, future versions of RepRap will be able to make their own electric circuitry - a technology we have already proved experimentally - though not their electronic chips. After that we'll look to doing transistors with it, and so on...

Adrian Bowyer (left) and Vik Olliver (right) with a parent RepRap machine, made on a conventional rapid prototyper, and the first complete working child RepRap machine, made by the RepRap on the left. The child machine made its first successful grandchild part at 14:00 hours UTC on 29 May 2008 at Bath University in the UK, a few minutes after it was assembled.

Scholarship and History

Academics and others seeking peer-reviewed journal articles on RepRap may care to start with this paper in Robotica. The citation and link are:

The citation and link are:

- Jones, R., Haufe, P., Sells, E., Iravani, P., Olliver, V., Palmer, C., and Bowyer, A.,: RepRap - The Replicating Rapid Prototyper, Robotica (2011) volume 29, pp. 177–191. Cambridge University Press.

For great insight to RepRap as a self replictor see:

- Bowyer, A., 2014. 3D printing and humanity's first imperfect replicator. 3D Printing and Additive Manufacturing, 1(1), pp.4-5. https://www.liebertpub.com/doi/abs/10.1089/3dp.2013.0003

If you are interested in the legal aspects of this technology, then you may care to read this paper:

- Bradshaw, S., Bowyer, A. and Haufe, P.: The Intellectual Property Implications Of Low-Cost 3D Printing, ScriptEd, April 2010 pp.5-31. Also available here.

If you are interested in how the RepRap can be used to assist in sustainable development see:

- J. M. Pearce, C.M. Blair, K.J. Laciak, R. Andrews, A. Nosrat, and I. Zelenika-Zovko, 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development, Journal of Sustainable Development', 3(4), 17-29, 2010.

'

'

If you are interested in the economics of RepRap see:

- B.T. Wittbrodt, A.G. Glover, J. Laureto, G.C. Anzalone, D. Oppliger, J.L. Irwin, J.M. Pearce (2013), Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers, Mechatronics, 23 (2013), pp. 713-726. http://dx.doi.org/10.1016/j.mechatronics.2013.06.002 open access (self built Mendel)

- Emily E. Petersen and Joshua Pearce. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5(1), 7; doi:10.3390/technologies5010007 open access (commercial Lulzbot RepRap)

- Emily E. Petersen, Romain W. Kidd, Joshua M. Pearce, Impact of DIY Home Manufacturing with 3-D Printing on the Toy and Game Market. Technologies 2017, 5(3), 45; doi: 10.3390/technologies5030045 open access

- Aubrey L. Woern and Joshua M. Pearce. Distributed Manufacturing of Flexible Products: Technical Feasibility and Economic Viability, Technologies 2017, 5(4), 71; doi:10.

3390/technologies5040071 open access

3390/technologies5040071 open access - André O. Laplume, Bent Petersen, Joshua M. Pearce, Global value chains from a 3D printing perspective, Journal of International Business Studies 47(5), 595–609 (2016). doi:10.1057/jibs.2015.47 open access

If you are interested in the environmental benefits of RepRap see:

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Life Cycle Analysis of Distributed 3-D Printing and Conventional Manufacturing of Polymer Products, ACS Sustainable Chemistry & Engineering, Engineering, 1 (12), (2013) pp. 1511–1519DOI: 10.1021/sc400093k Open access

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products. MRS Online Proceedings Library, 1492, mrsf12-1492-g01-02 open access

There is also a study on the spread of RepRap and its population:

- Erik de Bruijn: On the viability of the open source development model for the design of physical objects, November 8th 2010, University of Tilburg, The Netherlands.

For a reasonably up-to-date literature review of RepRap technology see:

- RepRap Lit Review

To get a copy of the entire RepRap Blog from its very start as a single PDF file download this (41MB; thanks to Gary Hodgson). The images in the early posts of the online blog are broken, but they are all in that file.

There are many reports, student RepRap projects and theses that are available as PDF files from this site. They are all linked from relevant pages but in addition we should, perhaps, index them as well. In the mean time you can get a complete list of all of them by following this link.

The very first RepRap - the RepRap Darwin made by Adrian Bowyer and Ed Sells at Bath University - is now in the collection of the London Science Museum.

Spread the Word

You can freely use the RepRap Logo (see the licence terms on the left) and QR code:

Glossary

- RepRap - n. any free rapid prototyping machine that can manufacture a significant fraction of its own parts; v.

t. (in lower case: to reprap) to make something in a RepRap machine.

t. (in lower case: to reprap) to make something in a RepRap machine. - RepStrap - n. any free rapid prototyping machine that doesn't make its own parts, but is intended to make parts for a RepRap.

- reprapper - n. a person engaged in making or using RepRaps or RepStraps.

- reprapable - adj. capable of being made in a RepRap machine.

Also See

- Adrian Bowyer's One sheet Description of the RepRap Project

- Background

Longer Video

Here is a recent talk and Q&A by Adrian Bowyer about RepRap and self-replicating manufacturing machines.

Category "RepRap" - a community of 3D printer owners 3DToday

A section for real do-it-yourselfers: all sorts of information on building and improving handicraft printers.

RepRap

6

Subscribe to the author

Subscribe

Don't want

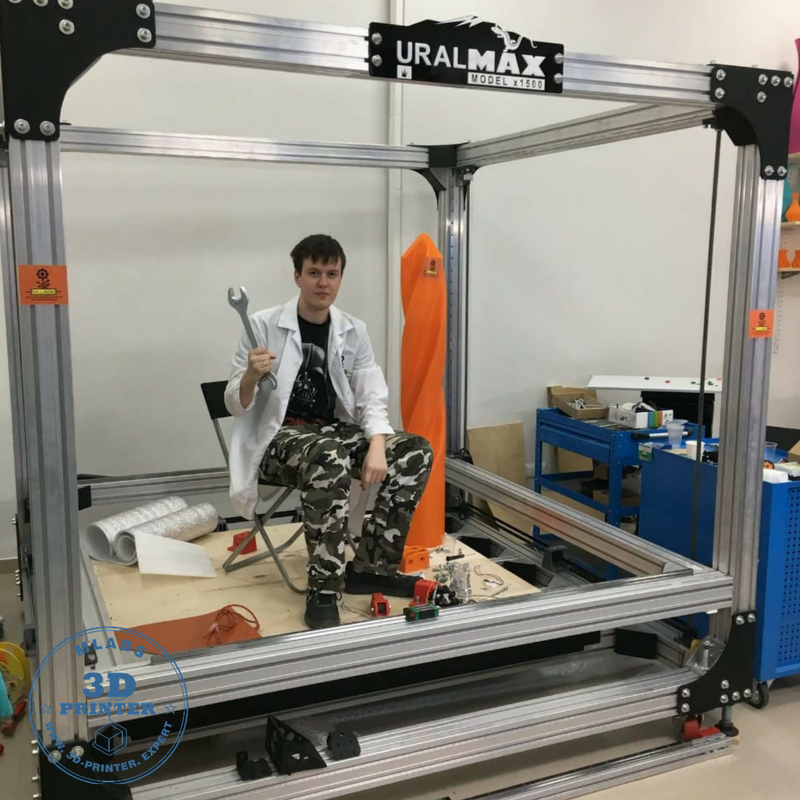

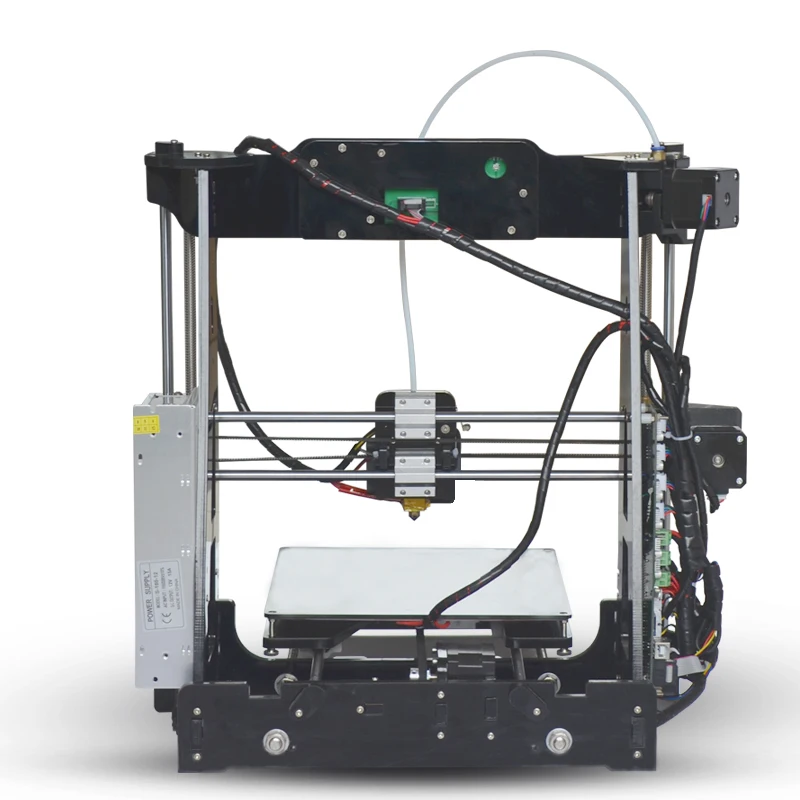

Greetings dear community! I have been preparing this post for a long time, but I was waiting for the logical conclusion of the project. So-ready. The idea was to make a 3D printer with good accuracy, rigidity and no reason to upgrade. 3D printing "dived" a little over a year ago, with an extended 3018 to 3040 and an individually assembled laser engraver with the functions of a drawer and a plotter. The start was with Ender 3, which led to its possible modernization, the apotheosis of which was the Direct Extruder. Everything would be fine, but it became ...

So-ready. The idea was to make a 3D printer with good accuracy, rigidity and no reason to upgrade. 3D printing "dived" a little over a year ago, with an extended 3018 to 3040 and an individually assembled laser engraver with the functions of a drawer and a plotter. The start was with Ender 3, which led to its possible modernization, the apotheosis of which was the Direct Extruder. Everything would be fine, but it became ...

Read more

campo

Loading

02/26/2023

1858

RepRap

4

Subscribe to the author

Subscribe

Don't want

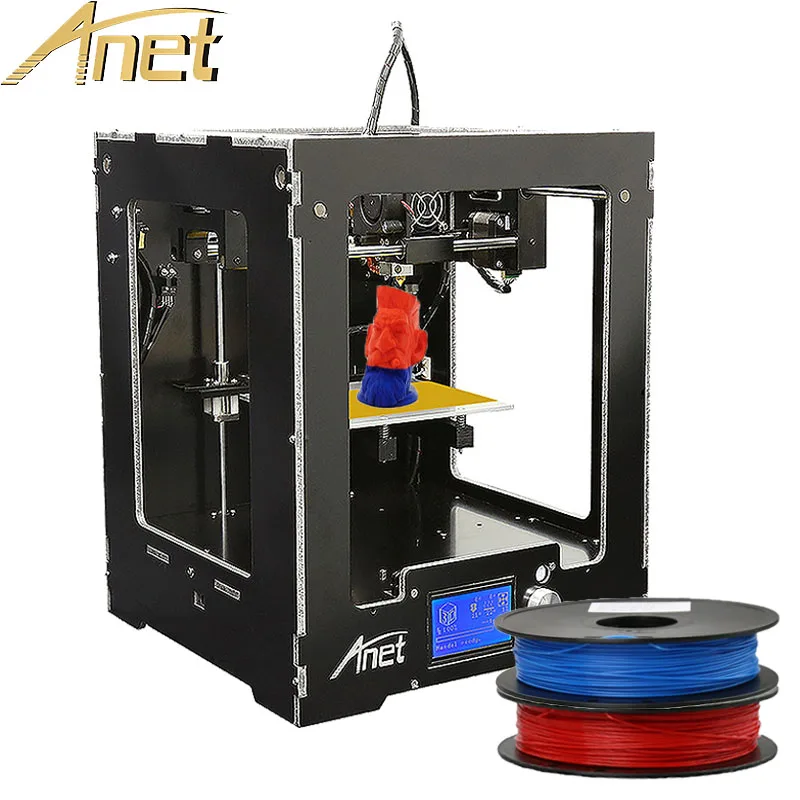

Hello everyone, honestly I never planned to write any articles, but apparently life decided otherwise. Like many here, a hobby that has grown into a "freelance" part-time job, 3d printing has turned the apartment into a working workshop, and the number of printers has increased to 3 in one corner and this is obviously not the limit. But I think this is a separate topic for discussion. It all started with the familiar to many popular Chinese Creality Ender 3 Pro, which, after its appearance in the apartment, destroyed my free...

But I think this is a separate topic for discussion. It all started with the familiar to many popular Chinese Creality Ender 3 Pro, which, after its appearance in the apartment, destroyed my free...

Read more

petez

Loading

02/25/2023

1699

RepRap

12

Subscribe to the author

Subscribe

Don't want

Hello plastic snot lovers!

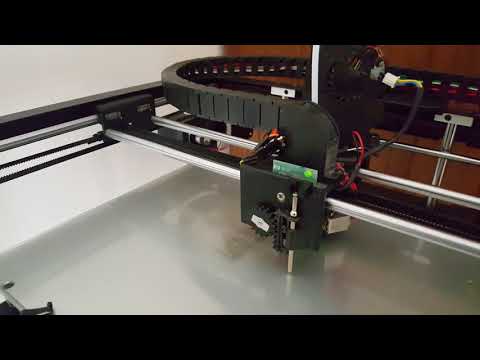

My first printer was a Kossel Delta. And he was a good guide on how not to make a printer. This is why I had to assemble my own. The sore spot of the delta is all (crossed out) hands. The quality of Chinese cheap analogues of traxxas did not suit me, it would seem - why not collect your own? At the entrance we have: a ball D10 with a hole and thread M4. The task is to design and print the hinge.

The task is to design and print the hinge.

It took a fair amount of iterations. The problem is simple -...

Read more

SL_ST

Loading

02/25/2023

3129

RepRap

15

Subscribe to the author

Subscribe

Don't want to

A long time ago I was swallowed up by the idea of creating my own printer. To embody in it a bunch of ideas that I really wanted to see in reality. But somehow there was no free finance to implement these ideas. And the model was already almost completed, and was gathering dust on disk. In short, gritting my teeth, I decided to share it with the public (https://grabcad.com/library/sl_st-3d-1).

People met her differently.

Instantly there were those who got to the bottom of minor details (the choice of fasteners). Depriving...

Depriving...

Read more

RepRap

21

Subscribe to the author

Subscribe

Don't want to

I was going to deal with dropsy later, but the printer decided to force me to do it immediately. Making parts for the control unit, I decided to make the start button green, and for this it is necessary to change the filament. In the morning I press the "filament change" button, and the previous ABS sits dead in the head. Nothing can be done, you have to "shake the old days" and make dropsy, otherwise these surprises will be regular ... And that's what "shaken" ...

For the cooling tank, the thermal barrier used 2 brass sleeves 12 gauge under the primer ...

Read more

RepRap

14

Subscribe to the author

Subscribe

Don't want

personal religion does not allow to violate the general aesthetics. I looked at the cabinets-pencil cases (besides the printer, there is still something to fill it with), but something adequate in stock and taking into account the departure of my Ender 3 table, 60 cm deep, there is little/expensive/does not fit, etc.

I looked at the cabinets-pencil cases (besides the printer, there is still something to fill it with), but something adequate in stock and taking into account the departure of my Ender 3 table, 60 cm deep, there is little/expensive/does not fit, etc.

Stumbled upon https://www.thingiverse.com/...

Read more

RepRap

2

Subscribe to the author

Subscribe

Don't want

Level 3: Icarus Head

As already mentioned, the weakest point of Qidi I-mate S (and indeed Qidi printers in general) is the head. But on the other hand, this problem is fully recognized by the owner community. And this community has reliably and in the best way solved this problem by creating their new head, which is modular, and allows you to build a solution for yourself for any budget and any need.

This mod is called Ikarus, now version 2. 5 is current, where the change...

5 is current, where the change...

Read more

RepRap

2

Follow Author

Follow

Don't Want

Level 2: Finishing the Z Axis

Qidi has terrible quality control in production, but great customer service. I faced horror right after purchase, and in the first hour of owning the I-Mate S, I had to understand how it understands.

Despite the careful packaging, thick layers of foam, a bunch of zip ties that fixed the moving parts inside, and other gadgets, my copy came with a vertical guide shaft that was simply not secured in ...

Read more

RepRap

2

Subscribe to the author

Subscribe

Don't want

A little about the experimental

Qidi I-Mate S in the stock configuration is a typical middling, but with claims. This is a frame-based printer with Ultimaker kinematics, a maximum Z-resolution of 50 microns (0.05 mm), a good declared build volume of 270x200x200 mm, a good heating pad under the table that really pulls 120 degrees, and the ability to close the entire volume in order to print without problems ABS. It differs from the basic I-Mate model, in fact, only in the top and side covers...

This is a frame-based printer with Ultimaker kinematics, a maximum Z-resolution of 50 microns (0.05 mm), a good declared build volume of 270x200x200 mm, a good heating pad under the table that really pulls 120 degrees, and the ability to close the entire volume in order to print without problems ABS. It differs from the basic I-Mate model, in fact, only in the top and side covers...

Read more

RepRap

5

Subscribe to the author

Subscribe

Don't want

Good day, dear friends!

I have recently taken up 3D printing and modeling and have recently been using this forum. So once disclaimer: the Chukchi is not a writer.

In general, I started my 3D journey with a budget, but pretty good Anycubic kobra go printer. I really liked the printer, very simple and high quality, both in printing and in the assembly itself. Well, since I'm a beginner, I decided to try different materials. The printer prints PLA smoothly and stably...

Well, since I'm a beginner, I decided to try different materials. The printer prints PLA smoothly and stably...

Read more

- 1

- 2

- ...

- 78

What is a 3D printer?

RepRap 3D printers

Application

Application

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

Home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

248

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

12

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D-Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co. , Ltd.

, Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plas

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB-Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear, LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

12

Solidscape Inc.

8

MBot3D

4

B9 Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

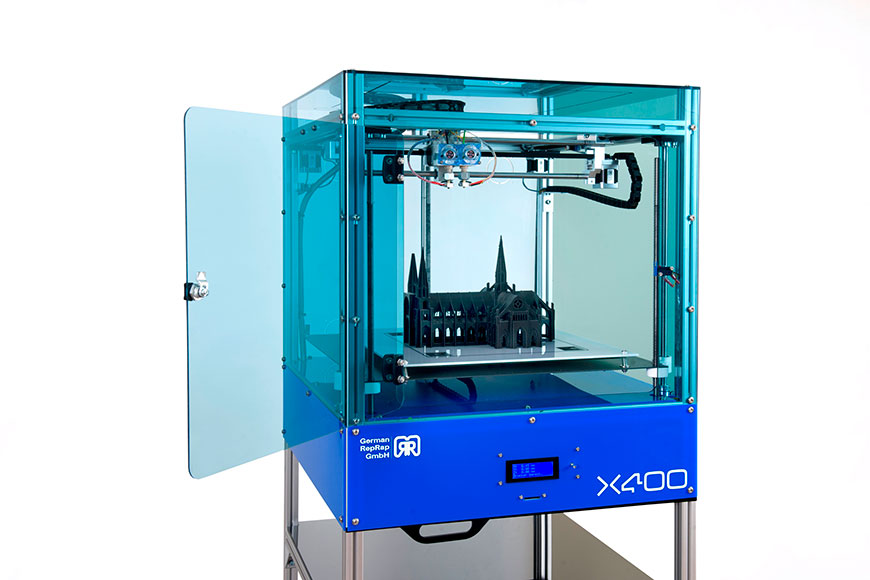

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

PieceMaker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

MakerFarm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3DMonstr

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd

, Ltd

4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS+ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co. , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

ABC 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

7

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett-Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 3D printer

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

Z Rapid Tech

21

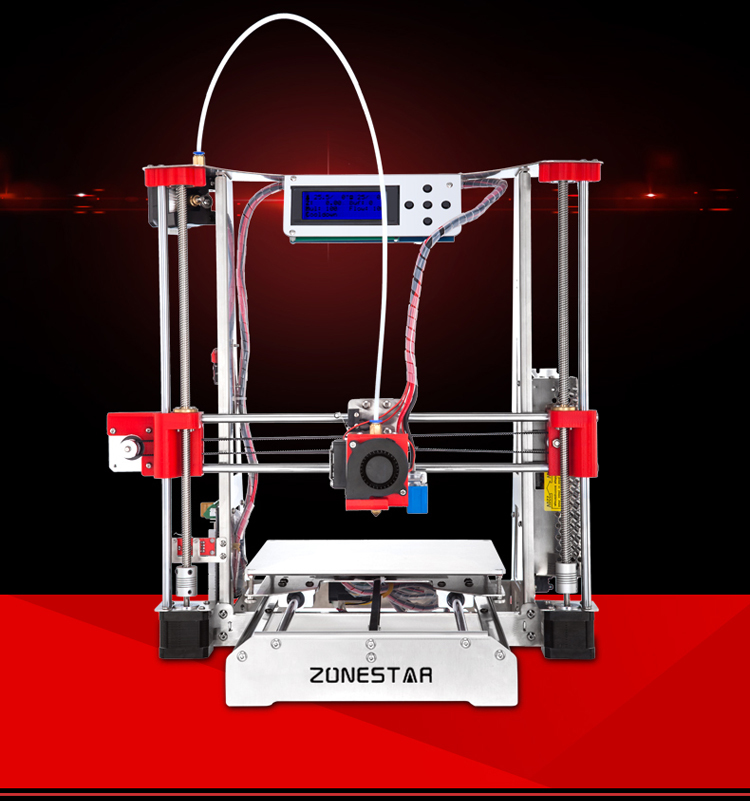

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co.