Reasons to buy a 3d printer

11 Reasons Why You Should Buy A 3D Printer – 3D Printerly

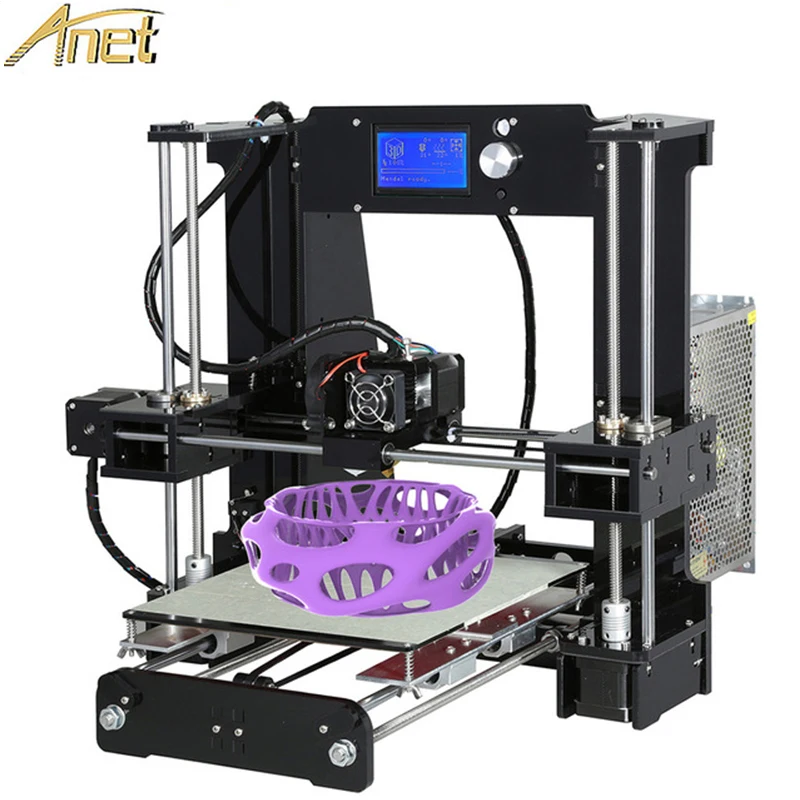

3D printing used to be an expensive craft which would set you back several hundred dollars just to get started.

This, along with the high cost of printing materials and less beginner-friendly printers meant that it was quite challenging to get in to. Today it’s a much brighter scenario, where the average individual can get started with just $200 and get to printing great things.

In this article, I will go through a list of reasons why you should buy a 3D printer when you can. Even if you are already own, a 3D printer read on because I’m sure you will learn some things that may surprise you!

1. It’s a Great Hobby to MasterThere are many people out there who have spare time on their hands but just don’t have a hobby to spend that time on.

That’s where 3D printing can definitely help. There is a real community of 3D printing hobbyists who use some of their time to create great things and begin projects for things that are very useful, or just for the fun of it.

Regardless of your reason, you will learn a lot about your own creative and technical abilities after getting involved with a 3D printer.

If you want your 3D printing experience to be worth the investment in the long run, I’d advise that you learn the design and programming aspect of it.

This may seem daunting at first, but the programs out there today are beginner-friendly, and can be a very fun experience becoming well-versed in it.

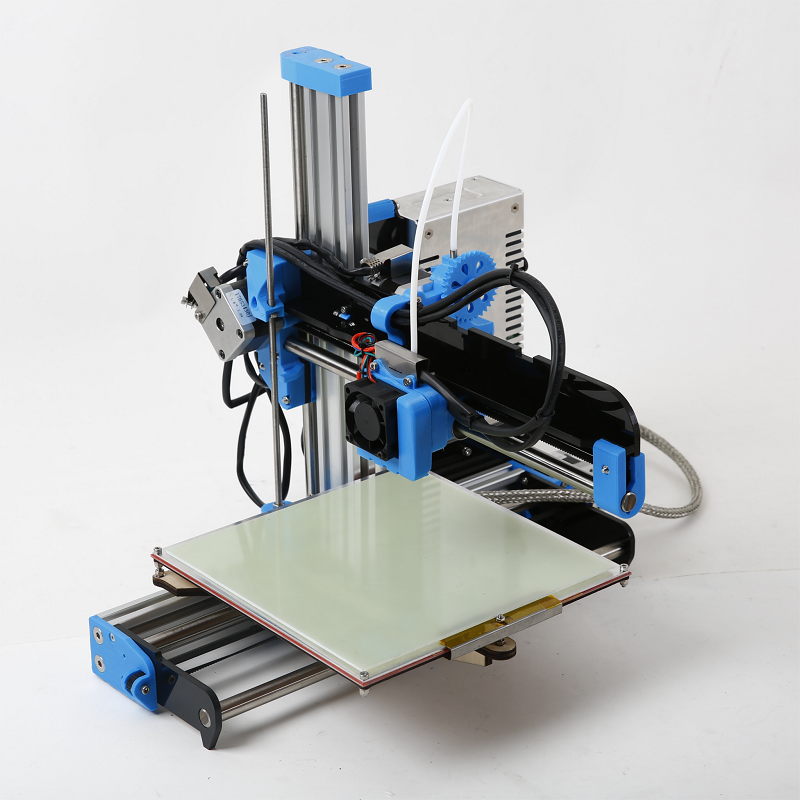

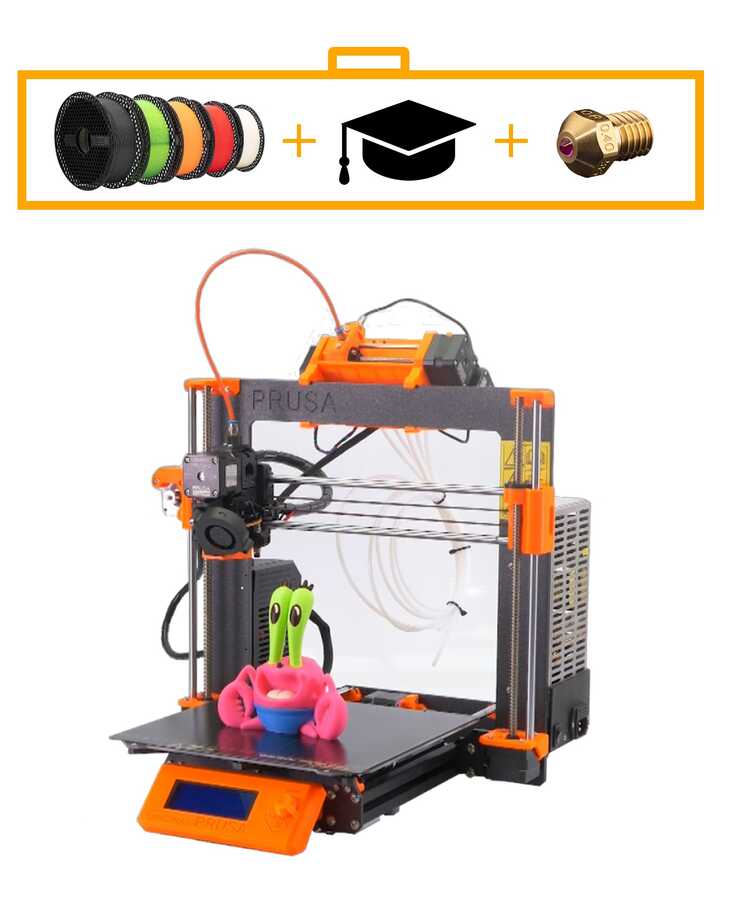

You should be buying a 3D printer that has the correct balance between price, performance and durability. Many 3D printers that are $200-$300 work to a good enough standard to get you started.

On the other hand, if you want your 3D printer to be a premium one from the start and have excellent longevity, it could be worth forking out more for a higher priced 3D printer with great features, performance and warranty for your intended application.

After you gain a good level of experience, you’ll get to understand the key differences in what you can 3D print and at what quality. At this stage, this is when I would recommend you spend more to get something more premium for your 3D printing desires.

At this stage, this is when I would recommend you spend more to get something more premium for your 3D printing desires.

If you are thinking about getting into 3D printing, there can be a good amount of creativity involved if you want there to be. I would definitely recommend learning how to use free Computer Aided Design (CAD) programs to create your own designs.

Being able to convert ideas, into designs then into a 3D printed object makes the world of a difference in how much you can achieve with 3D printing.

Without creating your own designs, 3D printing can be quite limiting in some respects, in so far as you can only print what other people design.

In fairness, there are several designs all over the internet on websites like Thingiverse which will give you a lot more designs than you could ever ask for, but after some time it could get quite repetitive.

A cool thing about this is once you get to a good stage of CAD , you can share your designs with other people for them to print, and actually get feedback and praise from other users for your creativity.

There is somewhat of a learning curve to become comfortable in creating your designs through CAD programs, but the long-term impacts will be very beneficial to your 3D printing journey.

Not only this, but there are many other applications of CAD beyond the 3D printing scope so it’s a transferable skill of sorts.

3. DIY Fixes for Household ProblemsThis ties into the last point with creativity and being practical with your personal situations. An example from one 3D printer hobbyist comes from when his dishwasher broke and couldn’t be repaired.

He also couldn’t get a vital part from the manufacturer due to it being a discontinued model.

With his previous experience in design, he sought out to come up with the solution. This was a great opportunity he had to model the part in a free CAD program then print it out.

It isn’t as simple as it seems, however, as he needed to refine and improve the design a few times but it resulted in a new part for his dishwasher which was actually better than the original.

Not only did he prove his ability to get the job done with some persistence, but he got bragging rights from the wife too!

Another bright side is, if it that part does ever break again, he has the original design saved to be able to just print one again without the extra design work involved.

In this situation, rather than buying a new dishwasher, the cost of the 3D printer and the filament used would’ve been much more cost-efficient.

If he had started 3D printing when this problem arose, there would be an initial learning curve to get the experience required to do such a task. Since it was already a hobby of his, he could get right into the task.

4. Creates Things for Other HobbiesThe application of 3D printing really goes far and wide, being able to tap into other hobbies and industries with ease. Engineers, woodworkers and other technical individuals have applied 3D printing to their field to make a whole host of useful items.

This video by Marius Hornberger shows some of the real-world applications that 3D printing has done for him and his space. Note, this guy is an expert so don’t expect to be able to do what he does at an early stage, but it’s definitely something to work towards!

Once you get to an advanced stage of 3D printing, this is the type of benefit you can apply to the rest of your activities in the future.

You can really see how far 3D printing can expand horizons into other fields and industries. My article here on 3D printing applications in the medical field shows just a glimpse into it’s potential.

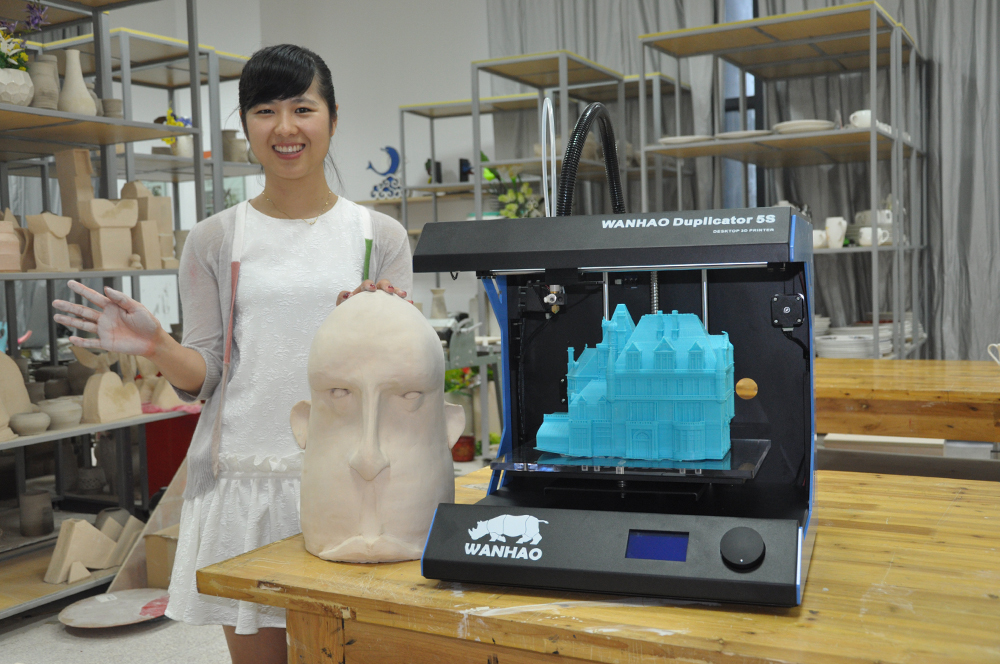

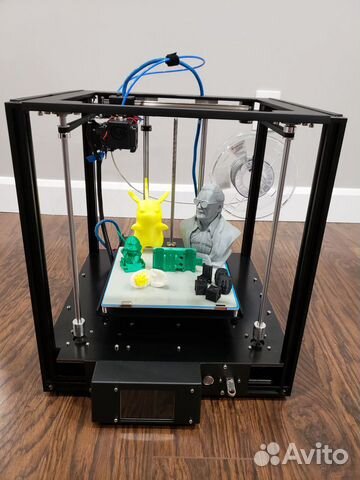

5. 3D Printing Gifts for People/ChildrenYou’ve probably seen a few 3D printed objects and many of them are figurines, action figures and small toys that look pretty cool. A lot of these objects are great gifts for comic and cosplay enthusiasts, general anime fans and basically every child out there.

A lot of these objects are great gifts for comic and cosplay enthusiasts, general anime fans and basically every child out there.

Being able to print favorite superheroes and marvel characters in a wide range of colors really is sweet to see. A glow in the dark Batman model, or a slick golden snitch from Harry Potter, the possibilities are endless.

If not for yourself, this can be a few Birthday/Christmas presents off your list, as well as the knowledge that you created this wonderful object with your own hands…kinda.

Many gifts these days are quite general and predictable, but with a 3D printer and your imagination at your disposal, you can really get ahead of the gift-giving curve.

6. It’s Really Fun Once You Get the Hang of ItI’ve seen people create customized chess pieces, miniatures for Dungeons and Dragons, create their own games and build up sweet collections with 3D printing. This is a hobby which can be very fun and rewarding once you get over the initial learning curve.

Many times you don’t even have to go through a learning curve. When you have a well-built printer and have your settings down accurately, your prints should come out just as you picture, with a smooth, sturdy finish.

Your 3D prints don’t have to be just aesthetically pleasing, they can be functional objects that help you in your day-to-day activities.

I think one of the best things you can do with it is getting your family and friends involved in creating designs and seeing the final product. It’s a great way to bring people together in a fun and practical activity.

There’s a reason 3D printers are making their way into schools, universities and even libraries. There is just so much you can do with them.

People have printed survival whistles capable of going over 100 decibels, a happy birthday cake topper sign, tap sprinkler attachments, smartphone stands and much more!

7. Get a Head Start in a Rapidly Growing Industry3D printing is growing at a rapid pace and the technology behind it is only getting better and better. We’ve seen advances with printing prosthetics, prototypes, houses, and even 3D printers themselves (although not completely…yet).

We’ve seen advances with printing prosthetics, prototypes, houses, and even 3D printers themselves (although not completely…yet).

It’s still somewhat in the early stages of development and once more people realize it’s potential, I can see a real snowball effect of 3D printing spreading around the world.

Lower income countries within Eastern Europe and Africa are seeing increases in 3D printing production as it gives people the ability to produce their own goods and equipment.

Being able to simply transport a 3D printer and the material to a location, then printing out objects saves massively on transport costs, especially to places with hard to access areas.

The numbers really speak for themselves. I’ve seen consistent annual growth figures for 3D printing sectors in the 15% range and even higher in the lower income areas. Just imagine in 10 years how far 3D printing will go, don’t be behind everyone else!

In just the last 3 years we’ve seen a massive influx of 3D printing manufacturers, to the point where printers are very affordable and beginner-friendly. It used to be a niche where only technically gifted people would be able to make real use of it, but times have changed.

It used to be a niche where only technically gifted people would be able to make real use of it, but times have changed.

There are many 3D printer enthusiasts out there who have made their craft a source of income. In today’s digital world, it’s increasingly easier to connect with people who demand specific objects and are willing to pay for that object.

Even though there are 3D printing services out there, this is a market people can still tap in to, or you could create your own!

If you have a niche which have a high demand for objects such as board games or children’s toys, you can target this to make money. You could build up a following on social media, forums and create your own website if you are really dedicated to this goal.

Some ideas that people have run with are Nerf guns and luxury vases, and they look to be pretty successful.

Even training people to 3D print can earn you some money. Many people are beginning to see the potential of 3D printing and want to learn how to become well-versed in the craft.

Many people are beginning to see the potential of 3D printing and want to learn how to become well-versed in the craft.

You could offer training to people or even create 3D printing courses to the growing number of people who are interested.

Being able to design and print objects to requested specifications is a well sought after skill, and people are willing to pay you for such a service. Get really good at it and it can be a side hustle for years to come.

9. Help Educate Your Children to be Technical & CreativeAlthough 3D printing is in its infancy stages, it has great benefits in the educational sector, especially for the younger people out there. Many educational organizations such as schools, universities and hospitals have introduced 3D printing in many creative ways.

There are many new learning possibilities with 3D printing, such as seeing actual designs from the computer come to something real and physical.

Being able to interact with the finished product and show people what you’ve created is a special kind of opportunity for children out there.

Everyone knows that children get excited when they can engage with practical activities. 3D printing is exactly that, and it takes bored students away from the usual reading and gives them interest in education.

3D printing isn’t the easiest thing to learn, but once you do learn it you can bet you’ll come out better at critical thinking and problem-solving.

It is an activity that really trains your logic and brain power as well as the creative mind. Being able to 3D print objects of complex shapes and sizes has the effect of creating innovation and the possibilities that students can create are never ending.

When people get the hands-on experience rather than just listening or reading, they can remember information at a better rate. Not only do students get the practical experience, but they retain the information at a relatively better rate than normal.

Universities in many places now have 3D printers for students to use at their own leisure. In the future, more and more universities and organizations will adopt this, so give your children the opportunity to start early and be the top of the class!

10. 3D Printing Can Be Environmentally FriendlyAccording to Science Direct, with a global adoption of the additive manufacturing process (3D printing), we could reduce global energy use by 27% in the year 2050.

The nature of 3D printing means that there is little to no waste because the material is being added to the final product compared to traditional methods of manufacturing, which takes away from a bigger object to make the final product.

Traditional manufacturing lends itself more to larger objects and high volume, while additive manufacturing is more suited to specialist smaller, intricate parts.

In many cases, additive manufacturing won’t be feasible for demands in production as supply won’t be able to keep up.

In cases where we can switch to additive manufacturing, it’s seen as a benefit to the environment.

Printing materials in this fashion reduces waste and mostly uses only what will be in the final product. The amount of electricity these printers use is relatively low compared to other traditional manufacturing methods.

I’ve written about how much electricity is used in 3D printing.

The usual process of manufacturing is quite a long process, from material extraction, to assembly, to the actual manufacturing and so on, it can leave a sizeable carbon footprint overall.

3D printing doesn’t have the several steps involved in making a final product, more so the minimal refining and assembly stage.

We also can greatly reduce factors such as transportation, storage facilities, logistics and much more.

This gives 3D printing and additive manufacturing the comparative advantage in environmental impact.

The negative I can point out with 3D printing is it’s widespread use of plastic, which does unfortunately generate its own carbon footprint in the material extraction.

The good thing here is the ability of 3D printers to use a wide range of materials so you are not inclined to use these materials if you choose not to.

11. 3D Printing Gives a Competitive EdgeAn example being how its introduction into the hearing aid industry created a massive takeover in how they are manufactured. Over a very short period of time, the whole industry changed its technique to incorporate 3D printing into its creation.

A real majority of companies which adopt the additive manufacturing process of 3D printing report their ability to gain a competitive advantage over other companies.

According to Forbes, it is 93% of companies using this technology in 2018 that gained this, and it’s due to reduced time to the market, adaptability in manufacturing and a shorter production process.

Not only do companies gain this advantage, but they also increase their product quality and service through the 3D printing technology. The speed of innovation allows lead times for model building to go from weeks or days to a matter of hours in many cases.

The speed of innovation allows lead times for model building to go from weeks or days to a matter of hours in many cases.

The cost of production is greatly lowered wherever 3D printing is adopted. There is real freedom of choice in design and customization for complex, yet durable manufactured products.

The costs of 3D printing is greatly reduced for many reasons, one of the main ones being the reduction in labor costs due to the 3D printer doing most of the work.

Once the design is created, and the settings are input, 3D printers do most of the work after that, so labor costs can be reduced to almost zero in the manufacturing process.

It so happens that 70% of companies that use 3D printing in their field increased their investments in 2018, compared to 49% in 2017.

This just comes to show how much of a change 3D printing is making in the world of business and innovation, and I can only see it growing in the long term.

50 reasons to Have a 3D Printer

Hello Machine Bros!

Some say that 3D printers belong to the fourth industrial revolution, also known as industry 4. 0, and inherent in any revolution come questions, questions that we ask ourselves to determine if we are actually facing one, and whether or not we should join it. Time goes by and sales of 3D printers have also been growing, people have become increasingly interested in these machines that are capable of materializing our computerized designs in plastic. Do you have doubts about whether you should buy a 3D printer or not? Let me give you 50 reasons to have a 3D printer!

0, and inherent in any revolution come questions, questions that we ask ourselves to determine if we are actually facing one, and whether or not we should join it. Time goes by and sales of 3D printers have also been growing, people have become increasingly interested in these machines that are capable of materializing our computerized designs in plastic. Do you have doubts about whether you should buy a 3D printer or not? Let me give you 50 reasons to have a 3D printer!

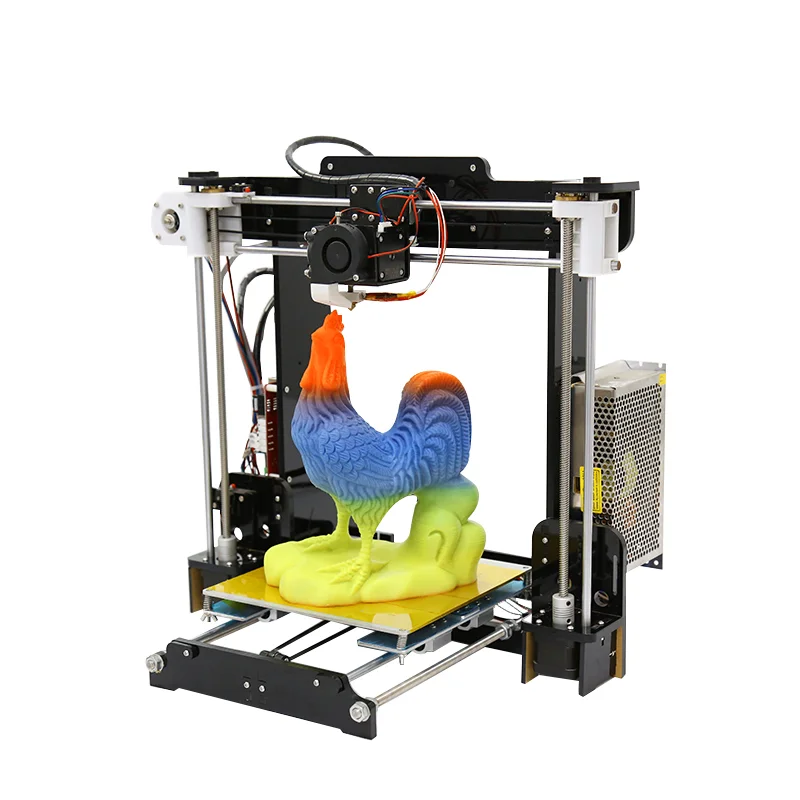

1. Wide variety of colors and materials to choose from

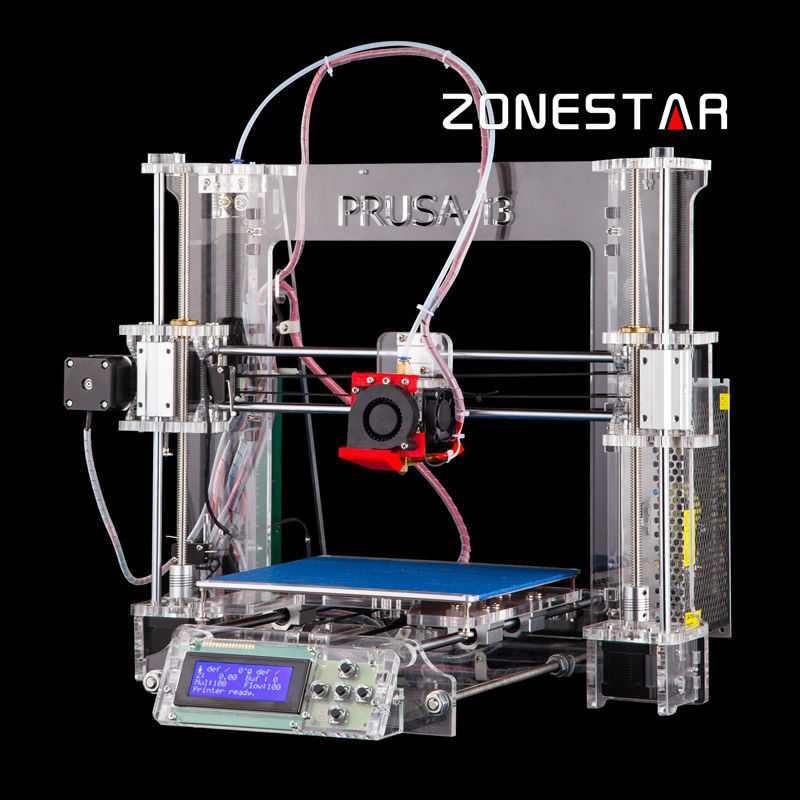

2. 3D Printers have dropped a lot in price

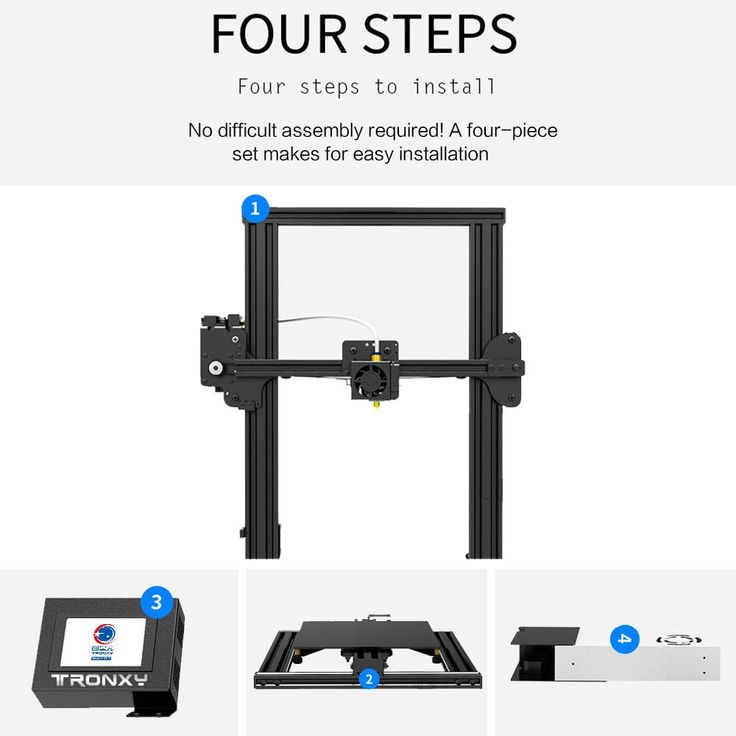

3. N3D printers are much easier to use

4. There is a large community of people with 3D printers

5. 3D print parts that are broken

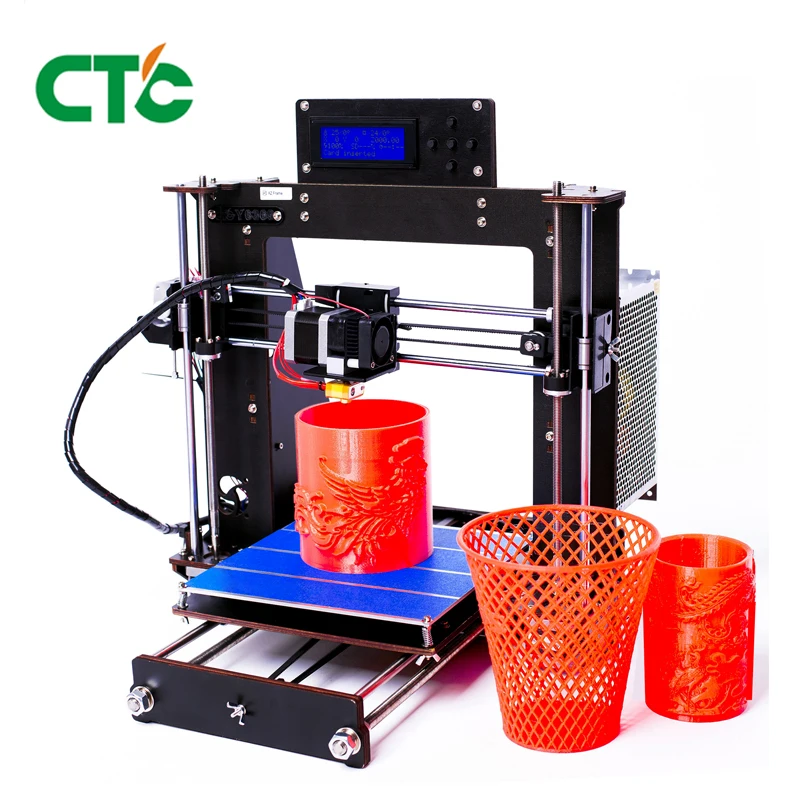

6. 3D print items to sell

7. 3D printing helps in the education of children

8. 3D printing can sometimes be friendly to the environment

9. 3D printing can help you generate income

10. A 3D printer is an interesting tool for architecture

11. 3D printing in the fight against Covid-19

3D printing in the fight against Covid-19

12. Invent using a 3D printer

13. 3D print personalized gifts

14. 3D print decorations to your home

15. 3D printing is fun

16. Sometimes it is faster to print something in 3D than to order it online

17. Create unique objects using a 3D printer

18. 3D printing is a great hobby

19. 3D printing is an useful tool for other hobbies

20. 3D printing in an innovative and fast-growing industry

21. 3D print cosplay

22. 3D print the gamepads of your gaming console

23. 3D Print Legos

24. 3D print a drone

25. 3D print RC cars

26. 3D Print custom pots for your plants

27. 3D print your own rocket models

28. 3D print jewelry

29. 3D print sculptures

30. 3D print custom accessories for your fish tanks

31. 3D print parts of the human body

32. 3D print board games

33. Prototyping with a 3D printer

34. 3D Print your Warhammer 40k models

3D Print your Warhammer 40k models

35. 3D Print your own Pokémon

36. 3D print gears

38. 3D print your custom tools

38. Design and 3D print your own photo frames

39. 3D print custom phone cases

40. Encourage your children’s creativity

41. If you are a teacher, 3D printing could help you explain certain topics more easily

42. 3D print boxes for your electronics, Arduino or Raspberry pi projects

43. 3D print robots

44. Materialize your 3D scanned objects

45. 3D print busts of people

46. 3D print smartphone holders

47. 3D print boxes and stands for storage

48. 3D print personalized reading markers

49. 3D Print your clips to organize your papers or bills

50. 3D print pill containers

1. Wide variety of colors and materials to choose from

This would be the first of many advantages of getting a 3D printer.

Currently, there are a wide variety of filaments to choose from.

Just to name the best known we have: PLA (Biodegradable), ABS, PETG, TPU (Flexible) and Nylon. Many others have wood, metal, ceramic, gloss in the dark finishes and this just to mention a few features.

These filaments also have an extensive selection of colors to 3D print.

If you want to know more about 3D printing filaments, we recommend you the Guide to Select 3D Printing Filaments

3D printing filaments2. 3D Printers have dropped a lot in price

This would be the second advantage of buying a 3D printer in these times.

The truth is that they have dropped a lot of prices.

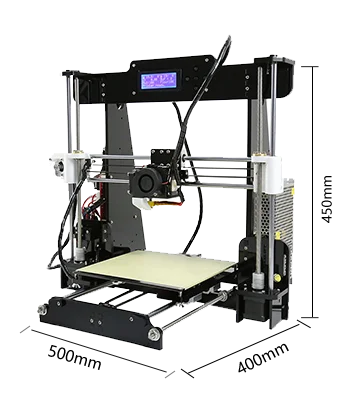

Believe it or not, by mid-1986 Charles Hull developed a 3D printer that used SLA technology, it had a cost that was around $ 300,000USD for that time.

Today you can get a small 3D printer for just under $ 300USD. In other words, it has become a much more accessible technology.

3. N3D printers are much easier to use

This is the third advantage of acquiring a 3D printer.

At the moment there is already a good variety of software for 3D printing, both paid and free, and for different technologies such as FDM and SLA.

It is just a matter of finding which one you like the most and which one best suit your needs.

4. There is a large community of people with 3D printers

We want to emphasize that currently there is a large and extensive community of users who have 3D printers, many of them call themselves Makers.

What’s interesting about this is that you will find many forums, video tutorials, web pages and endless content that you can access to learn about this technology and improve your 3D prints. This is something extremely valuable and outstanding because now there is a kind of collective intelligence.

Find in this link a great list of 3D communities.

5. 3D print parts that are broken

Has it happened to you that you broke a part of an object or device that you liked, and either you do not get the part because it’s not sold anymore, or there is simply no stock of the part in your country, and bring it from another country would be more expensive than expected.

Well, you can 3D print that broken piece, thus saving the device you did not want to lose.

3D printed parts and restored object6. 3D print items to sell

Well, as you just read, do you have an object in mind with which you can fill a need in a niche market?

With a 3D printer, you can 3D print that object in different materials and colors and then sell it, which is excellent because you would be generating extra income.

3D printed Spinner7. 3D printing helps in the education of children

Have you had to explain a complex subject to a child?

You know how difficult it can be to make yourself understood in subjects that are somewhat complex for a child, whether it be a subject of biology, astrology, physics, chemistry, etc.

If we have graphic help it is easier for the child to understand.

I will give you an example, you want to explain to a child the difference in size between the planets with respect to the sun.

It would be great to 3D print those planets together with our huge star (The Sun), so that the child has a more visual reference of what you are explaining.

The child could spark a passion for our vast universe and can become a future astrophysicist.

So, 3D printing gives you the opportunity to simplify learning, make it more interesting, intuitive and fun.

In this link, you will find a list of educational web pages on 3D printing. Like 3D NASA models, models of human body parts, science, dinosaurs, and much more.

Students observing a 3D printer8. 3D printing can sometimes be friendly to the environment

If you ever thought that 3D printing would only bring a lot of plastic waste that would end up in the sea, polluting the environment, it turns out not necessarily.

Luckily, we can find biodegradable material such as PLA, one of the most popular filaments for 3D printing.

You can even 3D print the first designs of a prototype in PLA until you get the desired results, to finally print on a more durable material like ABS, PETG or Nylon, just to name a few.

Although it is important to note that, because it is biodegradable, it does not imply that it can be thrown into nature.

9. 3D printing can help you generate income

There are different ways that a 3D printer can help you to generate income.

We did some research and we found many business ideas that you can undertake using this technology, and you can find this information in our article named “Create your 3D printing business with a low budget“.

10. A 3D printer is an interesting tool for architecture

In architecture we can also find useful things to do with a 3D printer.

Whether you must scale your future work to study it, or 3D print your possible constructions in small dimensions to make models and thus carry out your presentations.

3D printing could greatly simplify these works for you.

3D printed architectural model11. 3D printing in the fight against Covid-19

It was necessary to mention this, generally those of us who have 3D printers love technology, and we encourage the use of it to provide solutions to problems efficiently.

For today’s date, in the middle of the year 2021 humanity has been subjected to a rather important problem, a virus that can be spread very easily and with a significant mortality rate.

Therefore, the Makers decided to unite and provide different solutions to fight the Covid-19, that’s why designs (Commonly in CAD and STL files) of masks and protectors were designed and shared around the world to help reduce the easy spread of this coronavirus.

These files reached all parts of the planet and were replicated by the Makers on their 3D printers.

The interesting thing about these events is that, just as this 3D printing technology is helping in this battle, it will be able to help resolve or lessen the effects of future misfortunes that we could face as a society.

3D printed protective masks12. Invent using a 3D printer

If you are one of those who always likes to invent, design and create things. A 3D printer adjusts perfectly to your tastes and needs.

The inventions you have in mind, can be materialize with a 3D printer. You can 3D print, test, correct and reprint until you get the desired object for your inventions.

3D printed airbrush holder13.

3D print personalized gifts

3D print personalized giftsIf you want to show someone how much you love them, nothing better than a personalized gift.

It is a gift that can be very original and no one else will have one like it.

With a 3D printer, you can print these types of gifts that in the end are priceless for this particular person.

Imagine giving away a personalized jewelry item, a personalized phone protector, or a custom-made gift for that person you love so much.

Giving gifts of this type is a very good gesture that will brighten anyone’s day.

3D printed spinner containing the initials of the name of a person14. 3D print decorations to your home

3D printing allows us to decorate our homes to our tastes, in a personalized and original way there are many decoration pieces that you can manufacture by printing them in 3D.

You can take a look at Thingiverse to see what I’m talking about.

Examples of 3D printed decor items you can find on Thingiverse15.

3D printing is fun

3D printing is funI assure you that, if you consider yourself a maker, you will love 3D printing, it is impressive to see your digital designs become physical, it is a process that is fun and enjoyed from start to finish.

16. Sometimes it is faster to print something in 3D than to order it online

Let’s suppose that a mechanical part of an electrical device is damaged, this part is not available in your country, you got it from Amazon, and it will take 3 days to reach your home.

But it turns out that since you have a 3D printer, you realize that you can print that piece in 4 hours.

You save the shipping costs and the 3 days you had to wait.

Isn’t 3D printing wonderful?

17. Create unique objects using a 3D printer

3D printing gives you the possibility of having unique objects, objects that you will not see anywhere else in the world.

With 3D printing you can customize anything, originality will be part of your life, from something as simple as a spoon, to a lens case.

All these objects can have your own brand, that which distinguishes you as a person and would distinguish your objects from others.

3D printed custom logos18. 3D printing is a great hobby

There are people who like to cook, others to knit, some to fish.

There are many hobbies, and 3D printing is one of them and it could be for you.

3D printing gives you the opportunity to manufacture an infinity of pieces, where your imagination and creativity will be your best allies for this hobby.

3D printing is a process that you enjoy, since you design, configure, print, and post-process your prints.

You will love, when you will see your designs being materialized.

19. 3D printing is an useful tool for other hobbies

If you have a hobby like airplanes, rail, car, ship modeling, model building, robotics, electronics, or creating projects with Arduino or Raspberry Pi. Believe me that for these hobbies and for many others, a 3D printer will be quite a useful tool to get the most out of your hobby.

You can 3D print spare parts, protections, bumpers, tires, buildings, bolts, support, boxes, propellers, tools and anything to complement it with your hobby.

So, I invite you to investigate on the internet all the options you can get from a 3D printer in relation to your hobby.

20. 3D printing in an innovative and fast-growing industry

3D printing is a revolutionary technology, which is booming.

If you buy a 3D printer at this time, you would be starting in a technology and a world with a great future, if you do not believe me, I invite you to see the following video where they talk about 3D printing as a revolution, and what the future holds in terms of this wonderful technology.

Click here to access the video.

21. 3D print cosplay

If you love Cosplay, surely 3D printing will be interesting for you.

The best Cosplayers turn to 3D printing to complement their outfits in mind-blowing ways, from making parts of Iron Man’s armor to producing Wonder Woman bracelets.

22. 3D print the gamepads of your gaming console

What gamer would not like to be able to have their custom gamepads?

Can you imagine having a gamepad with the design of your favorite video game? With 3D printing this is also possible.

Check out these designs posted on Thingiverse so you have a clearer idea of what you can achieve with 3D printing and your gamepads.

Examples of gamepads mods you can find on Thingiverse23. 3D Print Legos

Legos are great, they stimulate creativity and they are fun.

Now, 3D printing your Legos is another level, if you are a fan of Legos, you could try printing your own and personalized ones.

Examples of Legos you can find on Thingiverse24. 3D print a drone

If you like airplane models and robotics, you surely love drones.

Having knowledge of programming, electronics and a bit of aeronautics, you only need a 3D printer to make your own drone prototypes.

With the 3D printer you can print those plastic parts necessary to put your drone to fly through the skies.

Find here some DIY drone projects.

Structure of a 3D printed drone25. 3D print RC cars

Well, if you prefer motor racing to an airplane model, just as you can manufacture drones, you can also design and produce your own radio-frequency controlled cars.

For this, you will need the same knowledge as to build a drone (Electronics, programming, design).

With a 3D printer you can manufacture the structure of your RC cars, supports, bolts, tools among other things.

Structure of a 3D printed RC carFind in this link information about a RC car project using 3D printers.

26. 3D Print custom pots for your plants

This world of 3D printing is so vast and wonderful that it encompasses even gardening enthusiasts.

With a 3D printer you could create your custom pots for your favorite plants.

Examples of pots you can find on Thingiverse27.

3D print your own rocket models

3D print your own rocket modelsDo you like scale rockets?

With a 3D printer you can make your own models, assemble and paint them.

3D print whatever you want, from the Apollo spacecraft with its Saturn rocket, through the space shuttle Endeavor, and even the model of SpaceX’s latest Demo-2 mission in conjunction with NASA, where they powered the Crew Dragon capsule with the Falcon rocket 9, this in order to reach the International Space Station.

Example of a Falcon 9 that you can find in Thingiverse to print28. 3D print jewelry

For jewelry, 3D printing can also be a useful tool.

You can create your personalized jewelry items, adding value to your work.

There are many examples of 3D prints converted into jewelry and costume jewelry. After 3D printing, you can paint and do any type of post-processing treatment that gives an amazing finish to your inventions.

I will leave you here a link with an example.

3D printed jewelry item29.

3D print sculptures

3D print sculpturesIf art is your thing and you like to produce sculptures, a 3D printer could be very helpful in your creations.

Various artists have already opted for this technology to reproduce their artistic expressions in plastic.

You can make small sculptures in a single print, or huge sculptures by printing the pieces of your sculpture, and then assemble the whole set and shape your creations.

For your artistic productions, you will have various 3D printing materials, multiple colors, and a wide variety of post-processes to improve the finishes.

3D printed sculpture30. 3D print custom accessories for your fish tanks

For aquatic enthusiasts, having a 3D printer would allow you to have personalized ornaments and accessories in your fish tanks.

There will be no other fish tank or aquarium like yours, since you will be able to 3D print the objects that your printer allows you, your ability to print and your imagination, of course you will have to print on waterproof materials (Discard the PLA right away).

31. 3D print parts of the human body

Whether you are a doctor or a biology teacher, printing 3D models of human body parts could make your education easier when you explain them to your students, providing a more graphic content.

To give you an example, in the field of medicine, you could give your patients a simpler explanation of possible procedures, thus generating more tranquility in them.

Obviously, this possibility of 3D printing body parts could help other professions and fields.

Example of bone models (in this case bones belonging to the face) that can be found in Thingiverse to later print in 3D32. 3D print board games

If you enjoy table games, you could 3D print your own in a personalized way, whether the game already exists or you want to create a new one from scratch.

It could also restore a board game you already have, 3D printing missing parts or parts of it.

Example of a custom chess that can be found on Thingiverse33.

Prototyping with a 3D printer

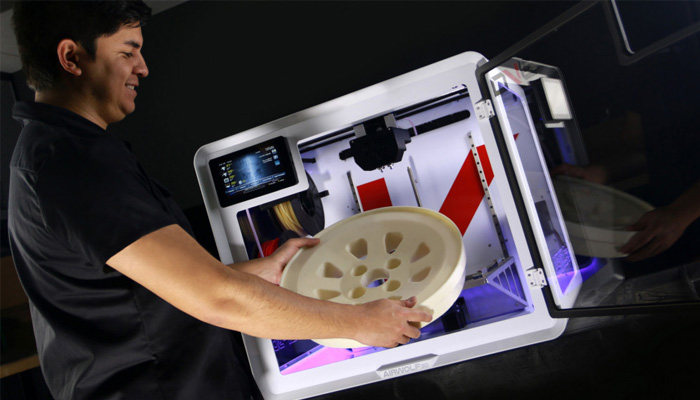

Prototyping with a 3D printerOne of the things that 3D printing revolutionized the way of doing things was this, prototyping.

Prototyping using 3D printers greatly reduced costs and simplified the process.

We talk about not having to manufacture plastic injection molds every time we want to modify the design.

Now you design the prototype in the CAD of your choice, followed by this you carry out the corresponding simulations by software, if your prototype meets all the requirements and conditions you pass to 3D printing, where you will finally have your design in physical form, you will be able to do the corresponding tests, make corrections and print again if necessary, in this way until you have a 100% functional prototype, to then start mass production with plastic injection if you wish.

34. 3D Print your Warhammer 40k models

If you are a big fan of this strategy miniatures game, you will be able to get the best out of a 3D printer.

With a 3D printer, you will be able to 3D print your own Warhammer figures, as well as you will be able to manufacture the pieces and parts to recreate your land and scenery of the best possible way.

35. 3D Print your own Pokémon

We have to talk about a classic like Pokémon, a franchise that has been present during the growth of some generations.

If you enjoy collecting your own Pokémon, with a printer you can make your own and greatly expand your collection.

A 3D printed Pokémon (Pikachu)36. 3D print gears

Has it happened to you that your equipment is damaged and the broken part ends up being a simple gear?

Many times, you even have to get rid of the entire equipment and replace it with a new one since the gear is not sold as a spare.

With a 3D printer, you can 3D print your own parts to restore that equipment.

You can also 3D print gears for your projects or inventions that require gears that are not easily available in the market, you will be able to create gears adjusted to your needs.

If you want to know more about 3D printing and gears, check out the following links:

- Easy Way of How to Design Gears

- How to Replicate and 3D Print Gears

38.

3D print your custom tools

3D print your custom toolsThe right tools greatly simplify manual work.

With a 3D printer, you could go so far as to manufacture special or customized tools that you require for a certain job, where the necessary tool is not easily obtained or you must resort to specialized markets to obtain it.

If you are one of those people who like to build or repair things by themselves, a 3D printer could be quite useful.

3D printed adjustable wrench38. Design and 3D print your own photo frames

For photography enthusiasts this reason will seem interesting.

Once you have that photograph that took so much work to take, you will want to display it properly, what better way to do it than with a personalized photo frame?

Imagine being able to 3D print a custom-designed photo frame, designed to be allusive to a certain photo. With a 3D printer you can achieve this.

Examples of photo frames you can find on Thingiverse39. 3D print custom phone cases

With 3D printing you have the possibility to print on flexible materials (TPU for example) your own original covers, so you will never get bored of always having the same smartphone cover.

40. Encourage your children’s creativity

I can’t think of a better way to encourage your children’s creativity than with a 3D printer.

They will be able to 3D print their own toys, their action figures, their dolls, their cars, planes, science models, among other things.

In addition, at the same time, they will be learning something useful, which could encourage them to choose professions such as engineering or design in the future.

In the beginning, the child will need to depend on a website like Thingiverse to download the designs, but if the child ends up liking 3D printing, he/she will surely be interested in the design and look for ways to learn how to design her/his own toys.

41. If you are a teacher, 3D printing could help you explain certain topics more easily

3D printing helps in education, teachers are able to 3D print parts or objects that allow a more visual explanation.

Also, if you are a teacher in more advanced fields such as robotics, electronics or mechanics, 3D printers will be very useful to you. We are talking about being able to print boxes for your electronic projects, mechanical parts of your prototypes and even parts of your robots.

We are talking about being able to print boxes for your electronic projects, mechanical parts of your prototypes and even parts of your robots.

42. 3D print boxes for your electronics, Arduino or Raspberry pi projects

This is an attractive possibility for lovers of Arduino and electronics.

Once you finish a project with Arduino or Raspberry pi, you are faced with the dilemma on which box to put the finished prototype.

With 3D printing, you will solve this, because you will be able to 3D print custom housings that perfectly fit your inventions.

3D printed housing for electronics project43. 3D print robots

If you are passionate about robotics, you will find many useful things to do with a 3D printer, there are a wide variety of examples on the web of robots built on the basis of 3D printing and Arduino.

Almost all the mechanical apparatus and the base structure of the robot can be 3D printed.

Robot Poppy humanoid, an Open Source project. This robot has 3D printed parts.

This robot has 3D printed parts.44. Materialize your 3D scanned objects

The technology is wonderful and moving at an impressive rate.

So much so, that currently you can scan in 3D using your smartphone or specialized cameras.

We can scan an object and from there obtain a 3D file where we have digitized the scanned piece.

Once we have this file, we can work it in CAD software to modify it and/or scale it, to later print it in 3D.

45. 3D print busts of people

Since we touched on the topic of 3D scanning, it is necessary to mention this other reason to acquire a 3D printer.

At the moment it is fashionable to create busts of people using this technology.

There are individuals wishing to have a bust alone or accompanied.

They are 3D scanned and then their 3D printed bust is delivered to them.

It is important to note that this is not limited only to the pleasure of having a bust of yourself, for example, body parts are also scanned to make prosthetic housings, this in order to give a more aesthetic finish to the prostheses, and more closely resemble the appearance of the user.

46. 3D print smartphone holders

Here we have another good reason to have a 3D printer.

You can make the supports you want to hold your phone, such as supports for cars, motorcycles, for a desk, for taking photos, among other types.

Examples of smartphone mounts you can find on Thingiverse47. 3D print boxes and stands for storage

Whether you like sewing and want to keep your tailoring tools organized, or maybe you like electronics and need to keep your electronic components organized, and you might even want to keep the screws you have organized and cataloged at home, with 3D printing you can produce boxes to keep the objects of your preference stored and organized.

There are people who have even printed wallets, to keep their money and personal documents stored in them.

Can you imagine how great it would be to have your own personalized and original 3D printed wallet?

Example of a tool holder you can find on Thingiverse48. 3D print personalized reading markers

If reading is one of your hobbies and pastimes, you will love what you can do with a 3D printer.

As mentioned in the title of this reason number 48, you can 3D print your bookmarks, even allusive to the book you are reading.

Examples of bookmarks you can find on Thingiverse49. 3D Print your clips to organize your papers or bills

Are you one of those who prefer to keep your documents, sheets or tickets organized with clips?

Well, here we have another good reason or advantage of having a 3D printer.

It is as simple as that you can create your original clips to organize your papers, and you could even make clips relative to the document.

Think about the possibility of delivering your organized works (whether you are a lawyer, an engineer, or any other profession) with a clip that represents you as a professional or as a company.

Examples of clips available on Thingiverse50. 3D print pill containers

If you know someone who forgets if they took a pill on a certain day, 3D printers can bring a creative solution to this.

You can 3D print pill containers that have 7 divisions, each division would have inscribed something that represents a day of the week, for example, the letters: Mo, Tu, We, Th, Fr, Sa and Su.

If you want or need it, you could also make a container with 31 divisions that indicate the days of the month and the divisions would have the numbers from 1 to 31 inscribed.

So, you could be sure that every day of that month you took the corresponding pill, this would be useful for example for contraceptive pills (just to name one of many pills for which this would be useful).

Example of a pill container available on ThingiverseIf you have other reasons that you think we should add to this list, please leave us a message.

See you soon Machine Bros!

OTHER ARTICLES

Ultimaker 3d Printers | 6 reasons why every architect needs a 3D printer. 3d printers Ultimaker

Using 3D printers in architecture has a number of advantages. 3D printing not only saves time and money, but also streamlines workflows. With 3D printing, you can provide rendered concepts to clients more frequently to ensure the most iterations to simplify the customer approval process.

1. Viewing an enlarged and three-dimensional image

Whether you're looking at the original design of a building or a large-scale urban model, the ability to see things in 3D and not in blueprints allows you to dive into a project faster. Interacting with a design, rather than just viewing it on screen, can be essential to understanding how a design interacts with its environment. 3D printing greatly simplifies communication both within and outside the design team.

2. Iterate without wasting resources

Small design changes can be printed over and over again, allowing you to fully understand how these changes affect the overall concept, and whether they will reflect the necessary aesthetics that you are trying to achieve in project. Thanks to 3D printing, you can significantly reduce the cost of creating an architectural model and increase the number of rendered changes.

3. Saves you time and money

Traditional methods of creating architectural models are complex and labor intensive. Some firms can outsource them, which carries a large amount of costs, even at the stage of preliminary negotiations. Wouldn't it be great if you could create a solid model full of intricate detail in a few days? nine0003

Some firms can outsource them, which carries a large amount of costs, even at the stage of preliminary negotiations. Wouldn't it be great if you could create a solid model full of intricate detail in a few days? nine0003

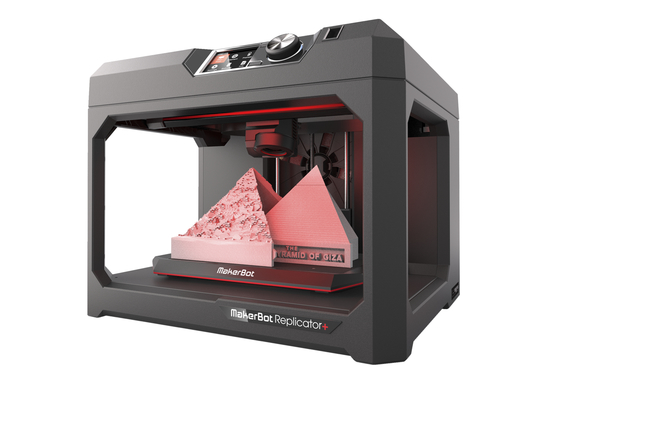

Having a desktop 3D printer in your office gives you complete control over the process of creating 3D models. A modern 3D printer, such as the Ultimaker S5, has automatic plate leveling and end-of-material control, so employees don't have to spend time checking prints. Ultimaker Cura's pre-made media profiles make 3D printing simple and intuitive. This allows you to spend more time on what really matters - the actual design of the project. nine0003

4. A range of materials to use

A large number of different materials for 3D printing will allow you to approach any design challenge with confidence. For example, using different shades of white can add a sense of elegance to a model, while special textured materials made to look like wood or bronze can enhance the overall aesthetic or highlight how buildings fit into a larger design project. Ultimaker 3D printer allows you to use third party consumables! nine0003

Ultimaker 3D printer allows you to use third party consumables! nine0003

5. Implementing Complex Designs

3D printing really proves to be an invaluable tool for displaying complex designs and parts. Complex geometries, which are usually a problem for traditional building model making methods, are easily achieved with 3D printing. This improves the design process so architects can help clients understand what a complex roof or façade will look like, or even demonstrate how sunlight and shadows will play out during the day. nine0003

6. Combining traditional methods with new technologies

Although 3D printing can replace traditional methods of making architectural models, it can also be used as a complement to them. Complex geometric systems and parametric designs can be expressed in ways that have never been possible before. Creating architectural models from scratch is a job traditionally done by architects that can be streamlined by the introduction of new technologies. nine0003

nine0003

These are just a few examples of how a 3D printer can help with your project. With the Ultimaker ecosystem, you can quickly produce high-quality prints to help your team work more efficiently.

We will keep you up to date with the latest news!

Your iGo3D team

Our groups in social networks:

YouTube

VKontakte

10 reasons to contact the prototyping center

Analytics and business

Rapid prototyping

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

1. Supply chain management | 2. Large selection of materials | 3. Variety of colors and finishes | 4. Large format 3D printing | 5. Professional quality parts | 6. Cost reduction | 7. Save time | 8. Scalability | 9. Expert advice and assistance | 10. Services of professional designers nine0003

The 3D printing services business is growing faster than ever. This happens because more and more people are striving to realize their ideas by means of additive technologies. Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

Today, 3D printing services are based mainly on working with professional clients. Of course, orders are also carried out for individuals, but most of the market is the B2B segment. nine0003

Even if you have access to a 3D printer, sometimes it's better to hire an outside contractor. Let's say you need a part in a material or color you don't have, and you'd rather not buy the whole lot. It is much wiser to order the missing part, and not to purchase all the equipment and inventory that may not be needed in the future.

We will look at ten reasons why additive manufacturing using a service can be more profitable. nine0003

Do you have projects that you would like to realize using 3D printing, 3D scanning or 3D modeling? Order a service from our company!

Leave a request

1.

Supply chain management

Supply chain management Additive technologies have been improved over the years, and today they allow the production of both prototypes and final parts, especially when solving certain problems. nine0003

In general, the development and manufacture of a particular part can be expensive due to high tooling costs. 3D printing is an extremely flexible technology. Manufacture of many different products and refinement of their designs is no longer a complex problem, which makes additive manufacturing a reliable solution to problems with the active use of redesign.

Outsourcing 3D printing jobs saves costs and lead times © Leo Gregurić via All3DP nine0003

Today, many research groups and companies rely on 3D printing services as a supply chain. It is extremely useful for them to be able to easily create and deliver custom parts.

2. Large selection of materials

One of the strong selling points for 3D services is the variety of consumables (and technologies) on offer. Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies. nine0003

Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies. nine0003

Prototyping centers offer, as a rule, the three most popular additive technologies: FDM, SLA and SLS. Accordingly, polymer filaments or granules, photopolymer resin and plastic powders are used as consumables.

A wide range of options gives the customer the opportunity to obtain the material that is required for a particular project, based on mechanical and chemical properties and aesthetic requirements.

nine0002 The variety of materials is practical not only for professional needs. The Professional 3D Services Center will also offer simple materials that may not be available to a private person. Buying a certain material and printing a product from it on your own can be more expensive than simply ordering the manufacture of a single part from this material.iQB Technologies experts recommend an article: 9 products that are more profitable to make on a photopolymer 3D printer nine0074

3.

Variety of colors and finishes

Variety of colors and finishes With such a wide range of materials available, 3D printing service customers are not limited in their choice of colors and finishes. Creating the perfect combination for a specific task has never been easier.

Colors

FDM filaments (PLA, ABS, PETG, and others) are typically offered in a wide range of colors. The plastic granules from which the thread is made are easily dyed. nine0003

More advanced combinations of plastics in the form of filaments, such as polymer composites or nylon, are difficult to dye and their color range is not as rich.

With regard to SLA technology, various colors are available for photopolymers. True, there are not as many of them as for PLA. Methods like SLS use industrial grade nylon powder, which comes in white, black, or some color in between. This is also due to the difficulty of coloring.

nine0002 Technology available for full-color 3D printing © Hubs There are full-color 3D printers that are ideal for creating visually appealing prototypes and teaching models, such as anatomy and geography. Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Finish

The surfaces of products created on a 3D printer can be subjected to various post-processing methods. Details are processed until the layers are completely indistinguishable and, as a result, look as if they were not printed at all.

But this is only the beginning. Processing can include sanding, polishing, galvanizing and painting, and many other finishes. Not every 3D printing material is suitable for all post-processing methods, and the service provider should explain this point to you when ordering. nine0003

In addition to the huge selection of options, one of the biggest benefits of ordering a finishing service is quality and convenience. Post-processing can take a lot of time, and entrusting the work to professionals, you will be sure of a high-quality and reliable result.

4. Large Format 3D Printing

Sometimes you may need a large printer © WASP Team via Youtube

An additive manufacturing services company typically operates multiple 3D printers to meet high demand (and meet deadlines) and various other requests. This provides a number of advantages, among them - the flexibility of product sizes. nine0003

Sometimes splitting a large part into multiple sub-elements is not the best solution, so an additive setup with a large build platform is needed. An individual or company often does not have access to large 3D printers, while many 3D service providers do.

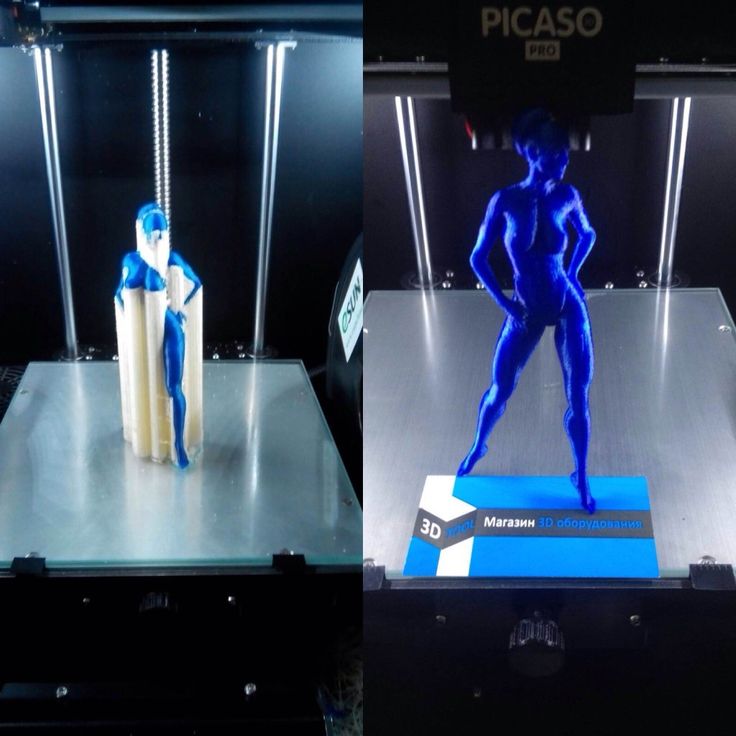

5. Professional quality parts

3D printers are becoming more reliable, and even the most affordable technology is showing impressive accuracy. However, many products (say, jewelry) require more precise workmanship or tighter tolerances to ensure perfect compatibility (for example, functional units). The professional results offered by the 3D printing service guarantee consistently high-quality workmanship in terms of precision and finish. nine0003

nine0003

Professional machines are more reliable in terms of repeatability. This is an important factor to consider when printing a large number of parts that require constant and tight tolerances.

But not only machines determine the final result. The people who work with 3D printers make a significant contribution to the production of professional quality parts. They have the knowledge and experience to advise you on how to best prepare your model, select the most suitable material, and finally create the final part. nine0003

A high-quality prototype created on an industrial SLA printer at the TWIZE Prototyping Center © TWIZE

6. Cost reduction

If you need to make something on a 3D printer, there are two options: either buy equipment and print the parts yourself, or order printing and receive finished products. Using a 3D printing service can save you money.

When a business is considering launching its own additive manufacturing, outsourcing through a service provider first makes sense. This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment. nine0003

This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment. nine0003

There are other scenarios as well. Some businesses can save money in the prototyping phase by having them 3D printed before putting the final version into production through another process such as injection molding.

However, outsourcing a project can save a lot of money until a “tipping point” is reached, at which point the cost of acquiring the equipment becomes a worthy investment. nine0003

Considering starting a 3D services business?

We share our experience in the article 3D printing as a business: the most profitable concepts of the RP Center

We will consult and select ready-made solutions. Contact us!

7.

Save time

Save time When ordering 3D printing from a service provider, you don't have to worry about printer setup and maintenance. In fact, you make a payment and get the parts you need. Everything is done on a turnkey basis, and you don't have to think about all the additional costs associated with setting up, maintaining and operating the equipment. nine0003

3D printing of some parts may require time that you do not have © Leo Gregurić via All3DP

And even if you have printers, they may not be enough to print a large number of products in a short time. Since prototyping centers usually have a large stock of equipment, large batches can be produced very quickly.

Of course, the order may take a long time, so choose the service wisely. But the turnaround time for an order (printing from standard media with standard post-processing) may well be shorter than the total time it takes to set up, maintain, and operate the related equipment. For many, this alone is enough to apply for a service to a contractor. nine0003

nine0003

In addition, the production of an object on a 3D printer takes hours or days - this requires control, which not everyone can do.

8. Scalability

Since the advent of 3D printing, it has been described in the mainstream media as a slow process. What is usually meant is that additive manufacturing cannot compete with traditional methods such as injection molding when it comes to high volume production.

nine0002 There is some truth in this, but it is important to understand that 3D printing is a very effective process in certain circumstances. When you need to produce large batches of the same parts, this is not the best option, but 3D printers are more than capable of producing in small and medium volumes.This is especially beneficial when we are dealing with individual designs or iterations, that is, when classical methods involve much more time and money. nine0003

For this reason, 3D printing services in particular can provide scalable manufacturing solutions that meet the needs of even medium volume production. Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

3D service providers can deliver scalable solutions © BMW Group

nine0004 9. Expert advice and assistanceAs already mentioned, 3D printing services are available to a large number of different customers. These can be both individuals who want to print a cartoon character figurine on a 3D printer, and world-famous corporations seeking to optimize their workflows. In any case, consultation is an important factor that can help close the deal.

The additive manufacturing experts at the 3D Services Center can help customers determine the right course of action before launching a project. Working with the client on the specific needs of his project, he is explained the available options. nine0003

Identifying the exact applications for 3D printing as well as discussing technical issues and specifics (such as what material is best for the purpose) are all part of the consulting service.