3D smart printer

Smart 3D

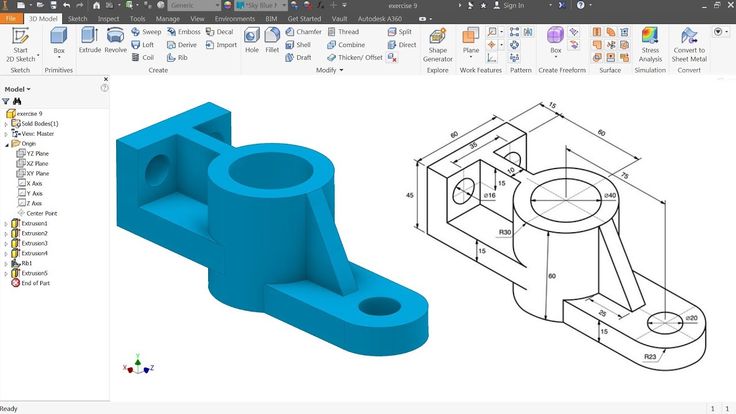

An Additive Manufacturing solution conceived to streamline the process from prototyping to production

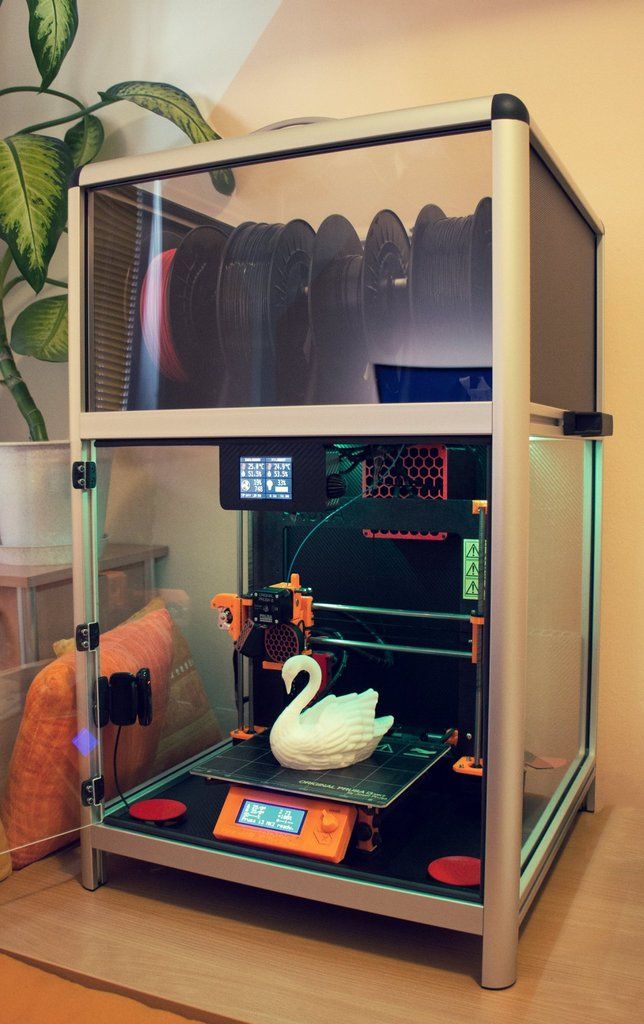

Smart3D Multimaterial Dryers dry multiple different materials quickly and simultaneously while protecting their properties

A wide range of Smart3D Materials and our Material Partnership Program provide the market’s broadest material capabilities

Powerful software modules range from cloud or LAN office networks,

to serverless print farm management or the factory’s full workflow

A platform designed for the repeatable production of high performance parts

A reliable and capable 3D printer is only one of many elements required to ensure the performance, repeatability and uptime needed in a manufacturing process.

Heated chamber

Materials are printed near their glass transition temperature to achieve optimal performance

Hybrid Drying Technology™

Industrial-grade drying and protective feeding guarantee that the material’s properties are preserved

High performance materials

Smart3D Materials complement with our Material Partnership Program to serve the widest range of applications on the market

Top-quality components

A solid construction with best-in-class components guarantees optimal accuracy at high speeds

Solutions tailored for the office and the manufacturing floor

MACRO PU

Macro Prototyping Unit is the most capable FFF 3D printer for office use by a designer or engineer.

MACRO PM

Macro Production Module is a manufacturing engine for low-volume production batches of end-use parts.

The professional way to run production batches with FFF

Redundant and secure management

A modular approach

From prototyping at an office to managing a factory’s full workflow, both hardware and software come as packages that can serve different user needs.

Secure serverless connectivity

Bringing redundancy and network security to an unknown level in Additive Manufacturing, Smart3D products are nodes in a neural network without a central server.

Industry 4.0

All Smart3D devices are highly interconnected and share information with each other. They were designed for automation and can be easily integrated to third-party software.

A modular approach

From prototyping at an office to managing a factory’s full workflow, both hardware and software come as packages that can serve different user needs.

Secure serverless connectivity

Bringing redundancy and network security to an unknown level in Additive Manufacturing, Smart3D products are nodes in a neural network without a central server.

Industry 4.0

All Smart3D devices are highly interconnected and share information with each other. They were designed for automation and can be easily integrated to third-party software.

A scalable investment

1. Macro Prototyping Unit

Macro PU has been conceived as the highest performing 3D printer to be directly acquired by a company’s engineers as an operating expenditure.

2. Macro Production Module

The first Macro PM is a low initial investment to adapt the technology to a production setup, using the same software and material set as in the engineering process.

3. Multiple Production Modules

The addition of PM’s enables factories to easily scale production according to their manufacturing demand, deploying all the advantages of Additive Manufacturing.

Dryers - Smart 3D

Skip to contentMultimaterial Dryer

Low moisture for high performance

Multimaterial Dryer

Low moisture for high performance

Are you familiar with these printing failures?

Jams

Soft or brittle parts

Bad surface finish

Bad extrusion flow

Stringing

Let’s deal with the elephant in the room: moisture!

These are a few indications of possible moisture content in your failed prints:

Filament cracks or popping noise as filament is pushed through extruder

Holes in the top of parts

Bad adhesion to bed

Repeated prints are inconsistent or fail with no change in parameters

Extruder motor stops but filament keeps coming out

Extruder jams

Extruder tip bubbles with a burst of steam, stringy or drooly

Why is humidity a silent killer for my 3D prints?

Precise control over the material’s mass flow rate is directly correlated with the moisture control of printed material. Moisture will lead to hydrolysis, breaking the polymer chains. In addition, while filament is melted in the hotend, moisture turns into vapor inside the hotend’s melting chamber, generating pressure. This pressure needs to be released, release that depends on the material’s viscosity. The result may be a back pressure jam or flow variations in the extrusion.

Moisture will lead to hydrolysis, breaking the polymer chains. In addition, while filament is melted in the hotend, moisture turns into vapor inside the hotend’s melting chamber, generating pressure. This pressure needs to be released, release that depends on the material’s viscosity. The result may be a back pressure jam or flow variations in the extrusion.

Heat-based solutions cannot deal with moisture effectively

Time

Drying cycles are typically 24-72 hours long

Quantity

These solutions cannot process more than a few pounds of material

Moisture rate

Achieving a relative humidity of less than 10-30% (depending on the material) is hard or even impossible with such techniques

Versatility

Materials with different thermal properties may not be dried simultaneously

Performance

Since this method depends on contact with dry air, moisture may be found even after a full drying cycle

Cost

Up-to 10 times more energy efficient than heat-based solutions

Why are other current solutions suboptimal for engineering needs?

In addition to being time and cost ineficient, drying with temperature may either ruin your Filament by altering its physical properties or not dry it properly.

The Smart3D Multimaterial Dryer is the only current solution that integrates our Hybrid Drying Technology™ at the end-user level

Preserve the properties or your materials

Our Hybrid Drying Technology™ dries your filament and preserves its properties, ensuring your material is in its best conditions to be printed.

Dry over 10 times faster

This system allows the filaments to be dried much faster than any other current solution on the market. In less than 3 hours, you can have the Dryer’s full storage capacity in perfect conditions and ready to use.

Large drying capacity

Unlike other drying solutions on the market, the Smart3D Multimaterial Dryer has a large drying capacity of 44. 18 liters and can dry and store or up to 12 large 2.2kg spools, depending on spool size.

18 liters and can dry and store or up to 12 large 2.2kg spools, depending on spool size.

Store your dry filament

The drying chamber also works to keep your filament dry. The controlled ambient chamber keeps the moisture out, so after drying your materials, you can keep them inside until use.

Achieve perfectly dry filament

Our technology ensures that your previously humid filament will achieve its optimal dryness level.

* Hybrid Drying Technology is a registered trademark of Industry Supplies, Inc.

** Images for illustrative purposes, subject to change without notice, the final product may vary from that shown.

Among others, these filaments should never be

stored in ambient air

PA

The effect of moisture on PA is profound, as it may fully saturate in as little as 10 hours.

PVA

Being a soluble support material, PVA’s ability to absorb water is a fundamental characteristic. Even mild humidity is enough to ruin an entire spool of unsealed filament.

Even mild humidity is enough to ruin an entire spool of unsealed filament.

TPU

Drying Polyurethane with heat-based solutions is not recommendable due to its low glass transition temperature.

TECHNICAL SPECIFICATIONS

Dimensions

Product dimensions: W: 500 mm / 19.6” - D: 890 mm / 35” - H: 1000 mm / 39.4”

Internal storage capacity: W: 310 mm / 12.2” - D: 700 mm / 27.5” - H: 340 mm / 13.4”

Maximum spool diameter: 300 mm / 11.8

Performance

Cycle duration: <3h

Drying capacity: 44.18 liters (up to 12 large 2.2kg spools)

Compatibility: Filament spools of any material and brand

Electrical

Rated voltage: 110 - 240V / 50 - 60 Hz

Software

Reports and statistics: Temperature, humidity and drying cycles

Updates: via Ethernet

I4. 0 compliant: Yes

0 compliant: Yes

Smart3D Filaments

The wide range of Smart3D Filaments is enriched by a Material Partnership Program to provide manufacturer-approved preset printing profiles with the leading suppliers of industrial-grade 3D printing materials.

COMPANY

About Us

Privacy Policy

Contact Us

STAY UPDATED

Copyright © Industry Supplies, Inc.

10 new products from Xiaomi, which you might not know about

This material was written by a site visitor and rewarded for it.

Hello everyone. I am sure that many have missed the collections of new products from Xiaomi and sub-brands of this popular Chinese company. That is why, today we will look at the top 10 new products from Xiaomi, which you might not know about. By the way, before starting, I want to recommend that you subscribe to my Telegram channel TechnoReview , with new ones from Xiaomi, where they come out the fastest, and sometimes you can find coupons and promotional codes with discounts there. Go.

Go.

Wetting Robot Polypexes Xiaomi Lydsto W2

Buy on Aliexpress -36%

Recommendations

Buy 9000

The collection opens with a new robotic cleaning robot with an auto-discharge base that heats the water supplied to the cloths up to 50 degrees Celsius for greater cleaning efficiency. In addition, the base washes and dries rags when charging the robot. The base has a color display with animated indication of all processes occurring with the device. For greater clarity of the robot, I suggest watching the full review on my YouTube channel. nine0004

Smart drive of any curtains Xiaomi Mijia

7 Buy on AliExpress -20%

Cost - US $ 59.6

was put in the second place by a smart curtain engine that is appropriate for any types of cornice. The beauty of this device is that you have absolutely no need to purchase new curtain rails. It is enough just to install a motorized block on your existing eaves of any shape and hook a curtain onto it. After that, you can create scenarios with a light sensor and others. The battery lasts for about 2 months of battery life. nine0004

The beauty of this device is that you have absolutely no need to purchase new curtain rails. It is enough just to install a motorized block on your existing eaves of any shape and hook a curtain onto it. After that, you can create scenarios with a light sensor and others. The battery lasts for about 2 months of battery life. nine0004

Portable mini -stying machine Xiaomi Moyu

Buy on AliExpress -17%

Cost -US $ 75.4

You will not believe the portable PRODUMICA mini washing machine. In the unfolded position, the device has a height of 237 millimeters and a width of 247 millimeters. The weight of the machine is about 1.5 kilograms. The gadget fits easily into a regular suitcase. The washing machine has three modes of operation, including hot water. The device is perfect for camping and travel enthusiasts. nine0004

Xiaomi K200 Laserdrucker

Buy on Aliexpress %

Cost - US $ 333. 8

8

, but the Xiaomi is produced by the Xiaomi Printer Xiaomi K200 control via smartphone. To implement remote control, of course, a Wi-Fi connection is required. In addition to printing, the printer allows you to scan documents, print them or transfer them to devices connected to it. nine0004

Multifunctional gateway Xiaomi AQARA M2

Buy on AliExpress -30%

Buy on Yandex Market

9000then the multifunctional gateway of the sub-brand Xiaomi Aqara model M2 again appeared on Ali. The hub has support for pairing with 128 smart home devices, and can also act as a router. Moreover, it has a built-in IR sensor that allows you to remotely control your TV and other equipment. Traditionally, all Aqara gateways have a built-in speaker. nine0004

Ultrabook Xiaomi Book Pro 14 2022

Buy on AliExpress -53%

Buy Yandex Market 9000 -13%

9000 9000 9000 Recently, the new Xiaomi Book Pro 2022 ultrabook has appeared on the market, which is equipped with a 14-inch OLED display with a refresh rate of 90 Hertz. Buy on Aliexpress -22% - US $ 252.7  The device is running an AMD Ryzen 5 6600H processor, there is also a version with an i7-1260P, but it costs almost twice as much. On board 16 GB of RAM. For graphics, either NVIDIA GeForce RTX 2050 or AMD's Radion 660M. nine0004

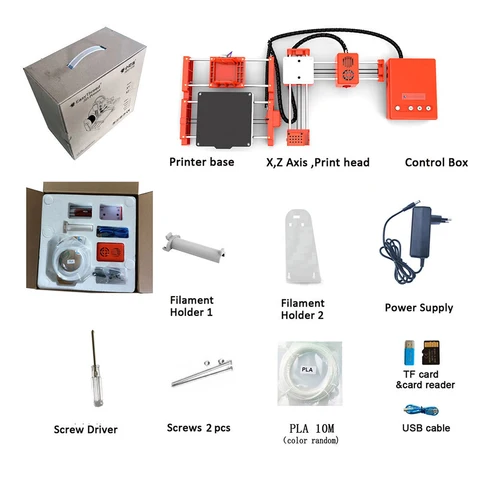

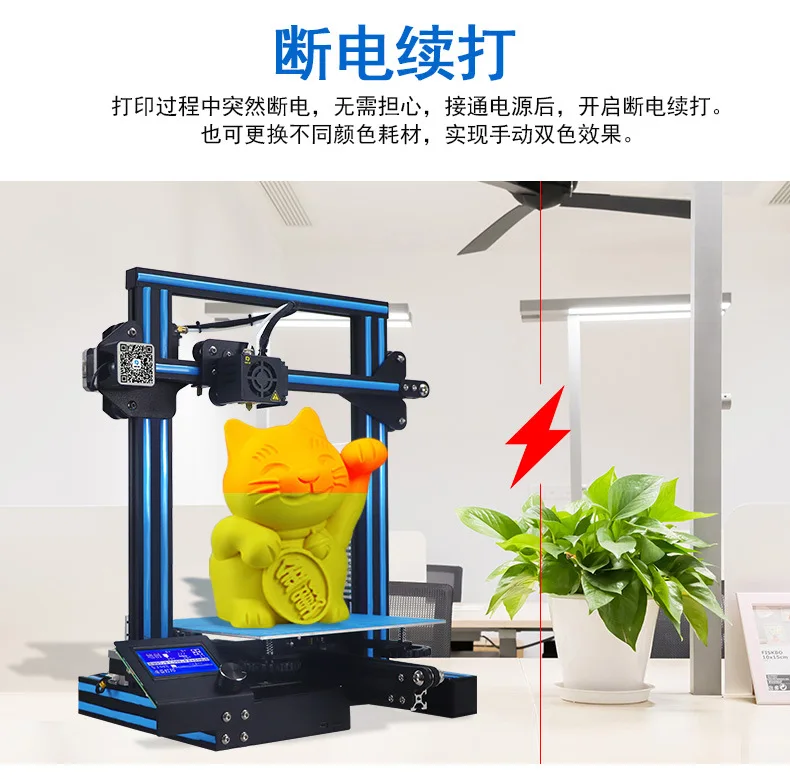

The device is running an AMD Ryzen 5 6600H processor, there is also a version with an i7-1260P, but it costs almost twice as much. On board 16 GB of RAM. For graphics, either NVIDIA GeForce RTX 2050 or AMD's Radion 660M. nine0004 Smart 3D printer Xiaomi Kokoni

Vertical vacuum cleaner with Auto unloading Xiaomi Lydsto H5

Buy on Aliexpress 9000%

Buy on Yandex Market 000

Cost - US $ 331.9,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 . The Xiaomi Lydsto Wireless Handheld Vacuum Cleaner h5 provides a suction power of 25,000 Pa. Equipped with a brushless motor with a speed of 100,000 rpm. Thanks to the 1000 Watt base, the self-cleaning speed is only 12 seconds. Crevice nozzle and turbo brush are equipped with LED lighting. nine0004

The Xiaomi Lydsto Wireless Handheld Vacuum Cleaner h5 provides a suction power of 25,000 Pa. Equipped with a brushless motor with a speed of 100,000 rpm. Thanks to the 1000 Watt base, the self-cleaning speed is only 12 seconds. Crevice nozzle and turbo brush are equipped with LED lighting. nine0004

Xiaomi Vface Microcurrent Facial Massager

BUY ON ALIEXPRESS

Price - US $96.7

The device is produced on the Xiaomi Youpin crowdfunding platform on behalf of the Vface sub-brand. The tool has a small touch screen to adjust the operating modes. The package includes a case for storage and carrying. nine0004

Smart Wet with three rollers Xiaomi Roborock DYAD

Buy on Aliexpress -52%

Buy on Yandex Market 9000 -5% 9000

smart washing vacuum cleaner with three cleaning rollers from the sub-brand Xiaomi Roborock model Dyad.

The device has a dirt detection sensor and automatically increases the suction power. The kit includes a base for charging and rinsing the rollers of the vacuum cleaner. The maximum suction power is 13000 Pa, which is much more than the vast majority of washing vacuum cleaners from other brands. nine0004

The device has a dirt detection sensor and automatically increases the suction power. The kit includes a base for charging and rinsing the rollers of the vacuum cleaner. The maximum suction power is 13000 Pa, which is much more than the vast majority of washing vacuum cleaners from other brands. nine0004

I hope that many of the devices from Xiaomi were new to you, and you spent your time knowingly. Do not forget to subscribe to my Telegram channel TechnoReview , where new items from Xiaomi come out the fastest. Good luck and good mood to all. Bye.

This material was written by a site visitor and has been rewarded.

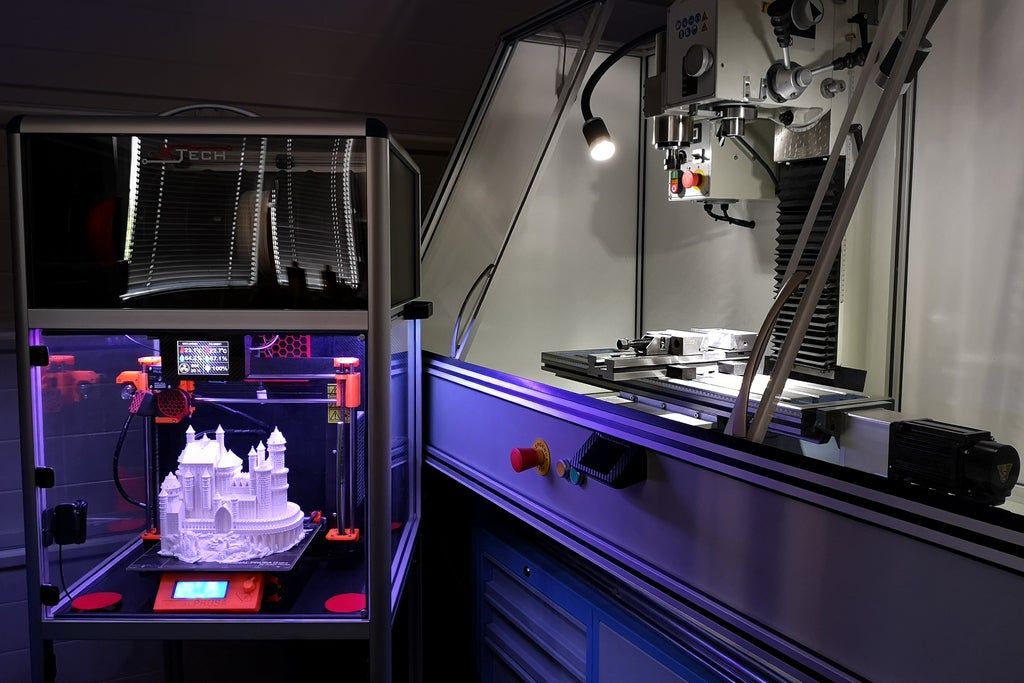

Ultimaker 3d Printers | Ultimaker S5. Powerful. Reliable. Universal.3d Printers Ultimaker

Meet an easy-to-use desktop 3D printer with a large build area that delivers professional-grade precision. Designed for long, continuous, trouble-free operation.

The Ultimaker S5 combines a dual extruder system, an intuitive interface, advanced communication options and a filament control system.

Scale up your 3D printing experience!

Construction area: 330x240x300 mm 9The 0246 is the largest in Ultimaker's line of 3D printers, yet still comfortable for desktop use.

Unrivaled accuracy from first to last layer:

Improved automatic multi-point calibration and advanced filament feed control let you go about your business while the 3D printer does its job. Advanced 3D printing environment The Ultimaker S5 features a closed chamber, new anodized aluminum print bed. nine0004

This solution will be useful, first of all, to engineers for printing with special materials. Also, a glass table is included with the 3D printer.

Filament control system.

You will no longer experience the problem of printing failing because the filament ran out during printing. The material feed control system will automatically pause printing and notify you of the need to replace the material.

Two extruders. nine0246

The Ultimaker dual extrusion system, which allows printing both in two colors and in two different materials, is one of the most popular on the market. Print with materials such as nylon, CPE or PLA, along with water-soluble PVA support, and easily realize various complex geometries.

Print with materials such as nylon, CPE or PLA, along with water-soluble PVA support, and easily realize various complex geometries.

Smart Print Cores.

Smart core system provides fast replacement, customization and ease of setup. Print cores are available with nozzle diameters from 0.25 to 0.8 mm. nine0004

Productivity has never been so friendly!

The 3D printer is equipped with a 4.7″ color touch screen for easy navigation.

The updated menu will make it easy to work with the printer for both a specialist and a beginner. And before printing you can see a preview of your model.

The power supply is now integrated into the 3D printer body and does not take up additional space on the table.

As we know, a 3D printer is part of a successful 3D printing process. An important role is played by the software environment and applications. nine0004

The new Ultimaker APP allows you to easily control the 3D printing process on multiple 3D printers from a common local network, and receive important notifications from your 3D printers wherever you are.