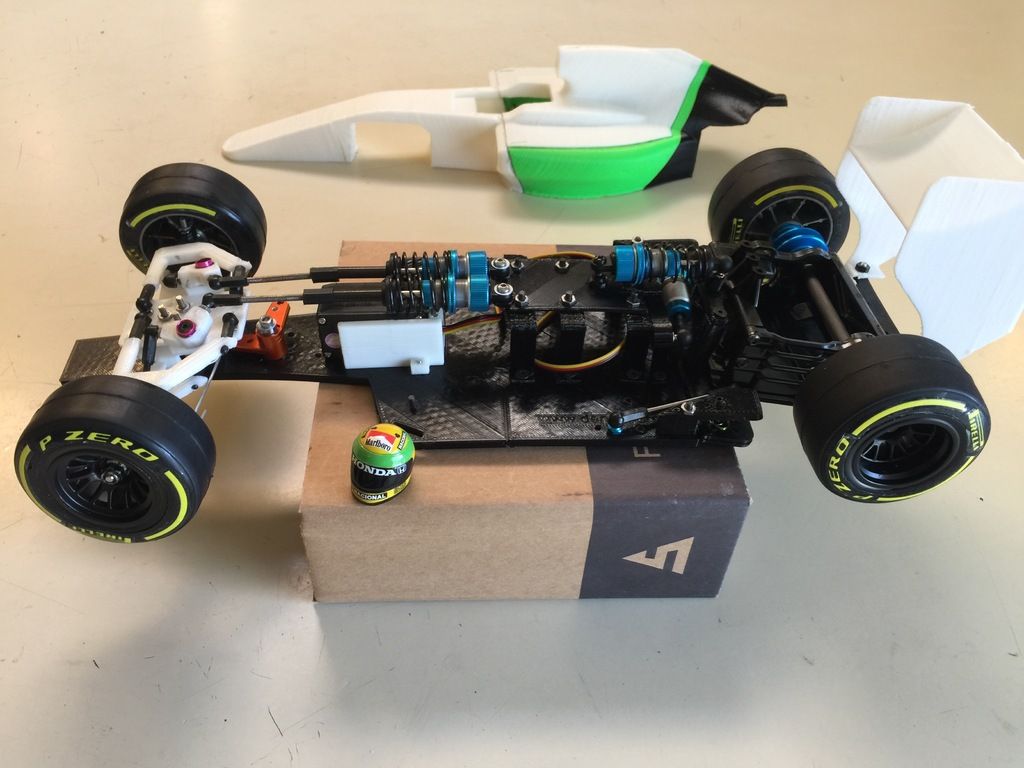

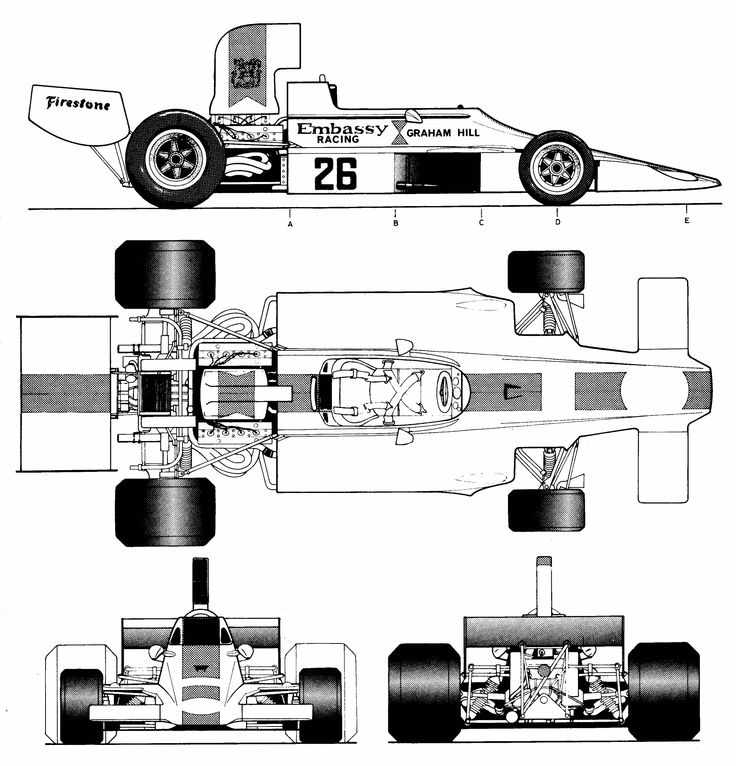

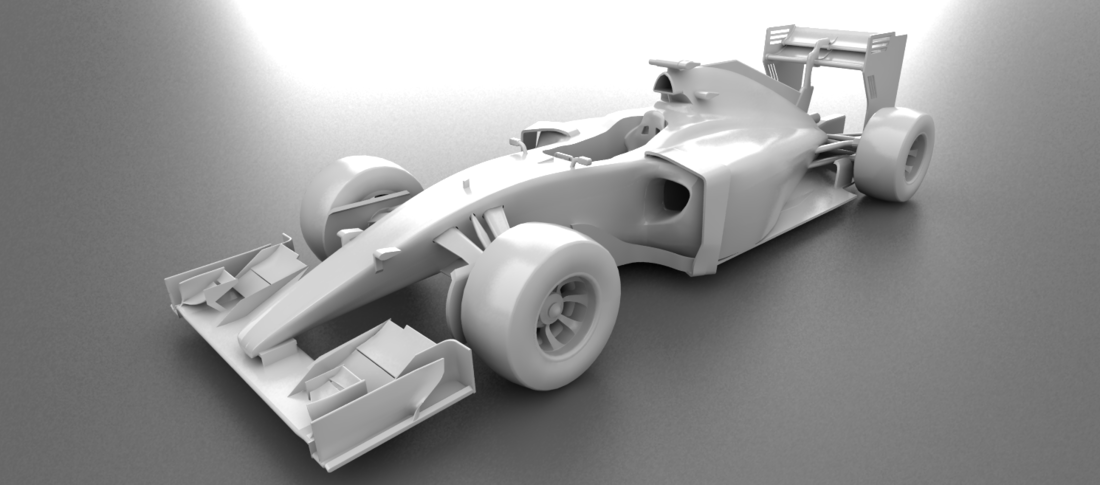

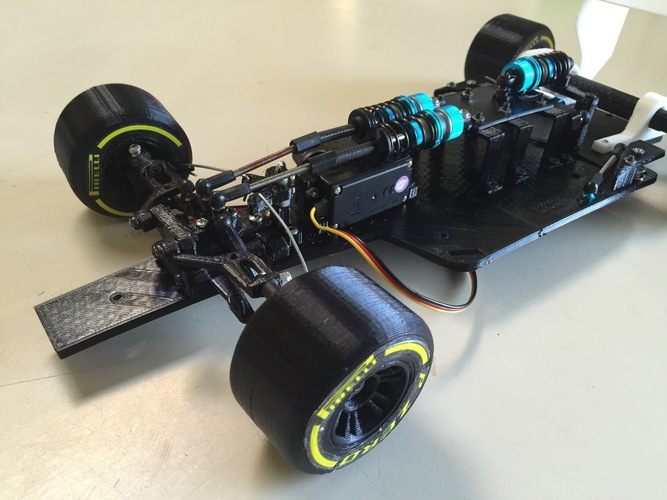

3D printed formula 1 car

3D Printed OpenR/C Formula 1 car by DanielNoree

-

No Prints Yet

Be the first to upload a Print for this Design!

Please consider supporting me on Patreon: https://www.patreon.com/Daniel...

Please respect the license under which this project is released. Thank you!

Questions & Answers OpenRC Electronics

Add your car to the OpenRC buildmap: https://zeemaps.com/map?group=1888242

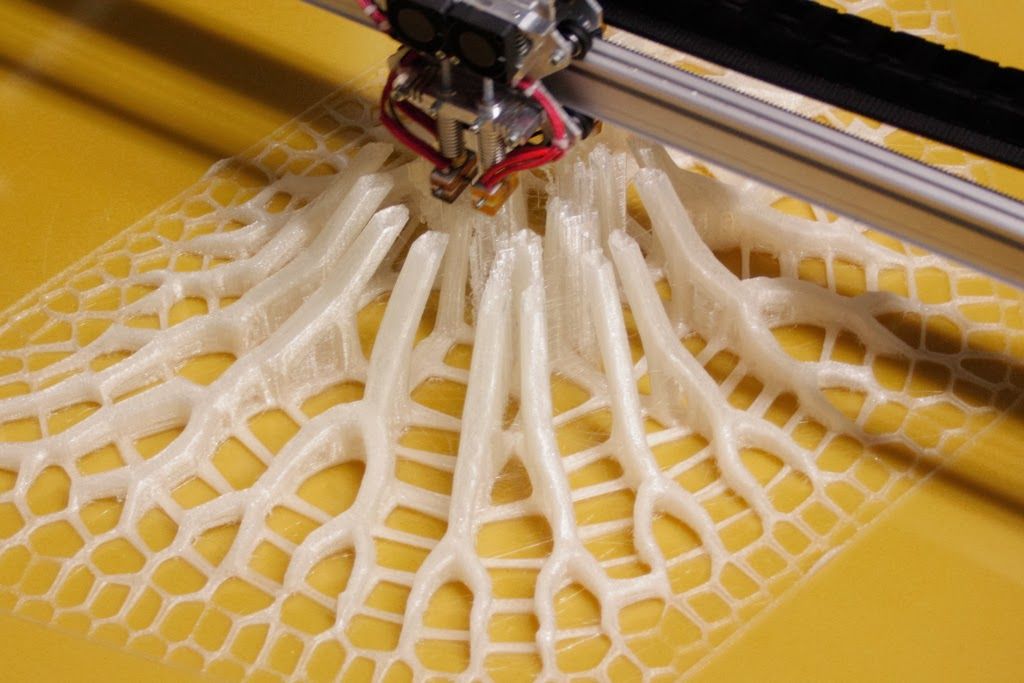

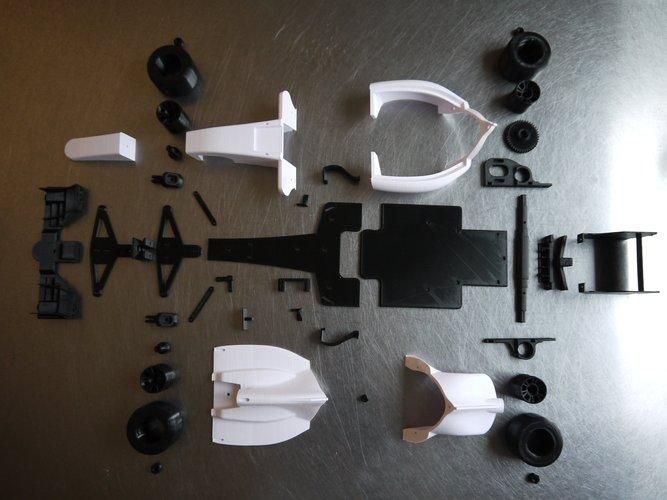

This is the OpenR/C Formula 1 car. It´s the third generation OpenR/C car and this time around focus is on simplicity! You can print everything in PLA except the tires which are done in NinjaFlex! Of course you can print it in any material you like but for those that want to print a car but only have PLA at hand, this is the project for you!

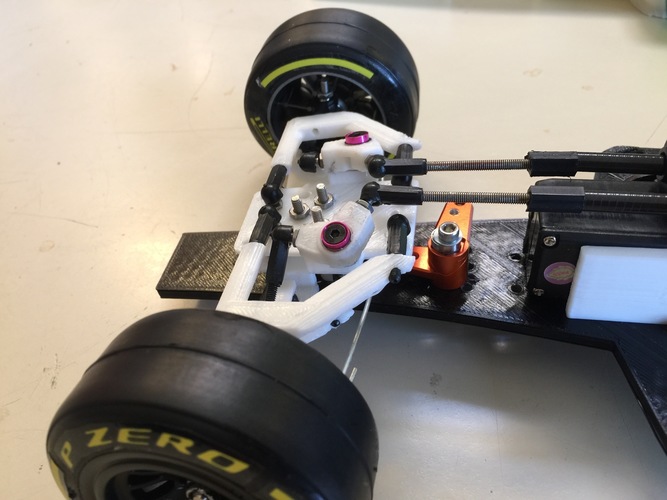

A note on the servo saver. It´s designed to be used with PLA, the upper and lower BOM applies force similar to a spring in a convetional servo saver. Of course the pressure depends on the type of material used, infill etc. Fine tuning can be done adding washer under or over the servo saver.

The "Main Turning Vane´s" needs to have it´s lower part trimmed using a "exacto knife". Then slide it the chassie plate and push it over the "Lid" and it should snap into place-

Any questions can be made in the Facebook group here: https://www.facebook.com/groups/1111886228841596/

Or in the Google+ Community here: https://plus.google.com/u/0/communities/112745535...

Complete hardware/electronics kit is available here: http://www.3dprintnpack.com/product-page/4054b44d-0bfb-cfed-4661-451da35810da

Parts that need support added:

Front Spoiler.stl

Front.stl

Rear Rim.stl

Rear Wing.stl

Servo Saver Lower.stl

Things to buy:

Ok, obviously you need some filament which you´ll get from your favourite filament supplier.

You also need M3 screws and nuts which you can get at your local hardware store. Check the BOM list for what to get.

Some bearings are needed aswell, check the BOM list or buy a kit from FastEddyBearings.com

Last but not least you need electronics and here´s what i got, all from HobbyKing:

ESC and motor combo

Battery

Micro Servo This is what i bought and i think it´s not very good, please let me know if you have a better revommendation.

Transmitter and Receiver (i use something else but this is a "cheap" alternative)

If you are new to this whole R/C hobby you´ll also need a LiPo charger for the battery. Ask in the Google + Community for recommendations.

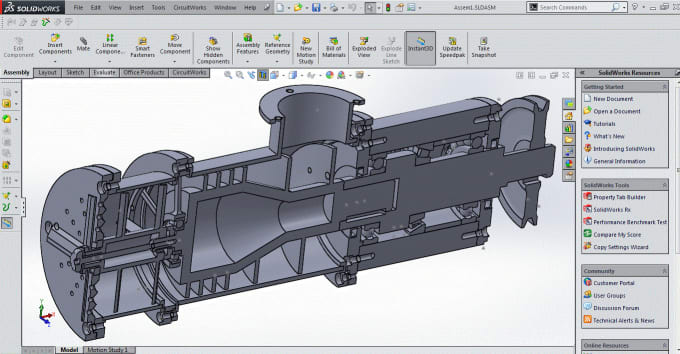

Full assembly STEP file is available here: https://dl.dropboxusercontent.com/u/6748864/OpenR...

Rain tires designed by Thomas Palm are available here.

Low profile rimas & tires designed by Thomas Palm are available here.

Making "donuts"... =) (video)

Like my FaceBook page - https://www.facebook.com/Danie...

Subscribe to my YouTube channel - https://www.youtube.com/user/D. ..

..

INSTAGRAM https://www.instagram.com/dani...

TWITTER https://twitter.com/DanielNore...

GOOGLE+ https://plus.google.com/u/1/+D...

FACEBOOK https://www.facebook.com/danie...

GOOGLE+ OPENRC COMMUNITY https://plus.google.com/commun...

FACEBOOK OPENRC GROUP https://www.facebook.com/group...

F1 3d Print - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(439 relevant results)

Formula One Car STL File・3D Printing Template for Download・Cults

Army Jeep

2 €

Classic scooter bike

1. 40 €

40 €

Touring bike

1.40 €

Bicycle

1.40 €

nine0003 Chopper motorcycle print-in-place1 €

Off-road vehicle

2 €

Bicycle

1.40 €

Superbike 2

1 €

Decorative cyclist

1 €

Super Bike

0.50 €

Cat planter

0,50 €

Army Jeep

2 €

Best 3D printer files in Game category

majorette bache mercedes N°233 public works 1/78 1/64

0,50 €

Trucks for Z-18 Penny Skateboard

Free

Deudeuche

1. 75 €

75 €

CTR Kart - Crash Bandicoot

Free

Marble ramp DIY (marble run)

Free

Dendroid Free 3D print model

Free

Hopping Kangaroo 3-layered-animal cnc/laser

Free

Ronan, MakerFaire Saint Malo's Mascot

Free

Bestsellers in the Game category

Heavily armored warriors Catafrac - set of limbs

1,85 €

Eldstokkr Steel-Master & E-ROXs

9.41 €

nine0003 Enourmous Imperial heavy tank10 €

Batman's crossbow weapon / Seal in place

2,50 €

WARFORGED VOIDWALKER EXOSUIT UPGRADE KIT

9. 41 €

41 €

Destroyers of Nehron Lochust

3 €

Flying unicorn

1.77 €

Imperial Heavy Weapons & Regimental Flags [OFFERED]

3 €

chaos terminators

€16.75 -fifty% 8.37 €

FLEXIBLE CHRISTMAS SNOWMAN

2,60 €

nine0003 Catafrac Heavy Armored Warriors - Civil War Wargear Pack2,50 €

USS EnterSurprise - printable game container for tiny F14 jet fighters

3.76 €

CRAMER Truggy RC 4x4 Full 3D Printed

7,50 €

Bicycle

1. 40 €

40 €

8,47 €

Voidwalker Exosuits Truescale

14.83 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

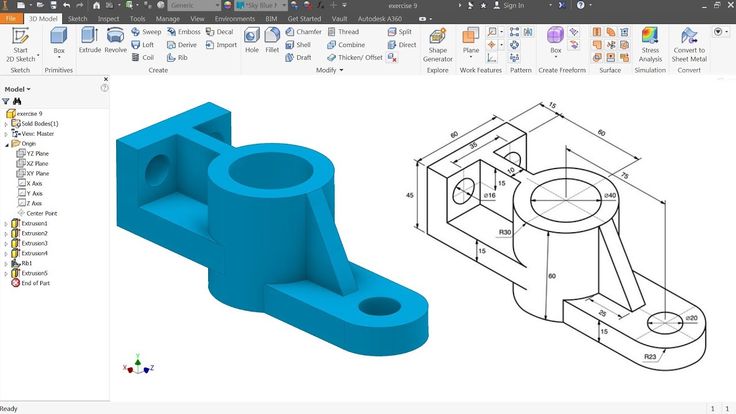

3D technologies in the Formula 1 project

Implementation stories

Automotive industry

Author: Yakov Bondarev

Author: Yakov Bondarev

R&D partnership | The ever-improving car | Quick design check | New possibilities of using wind tunnel | High speed and precision of parts manufacturing | New directions of development

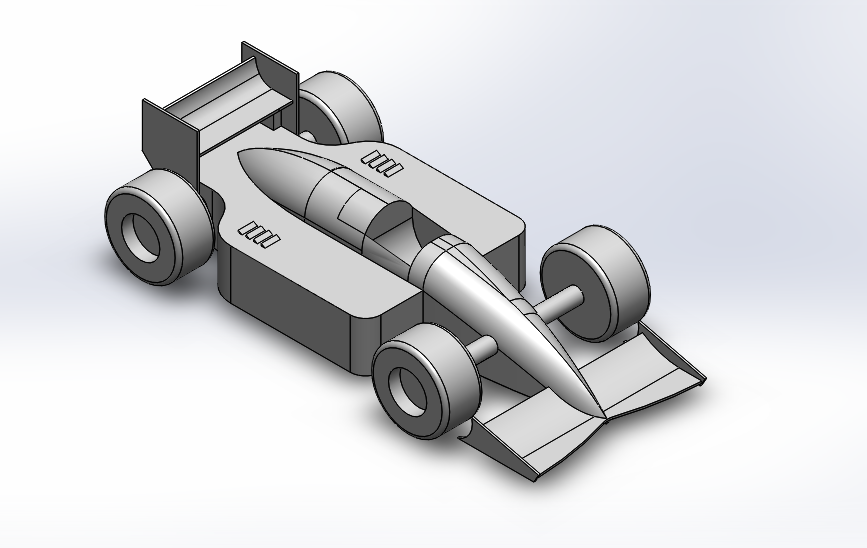

Formula 1 racing is a technical sport based on continuous innovation and requires high reliability from cars. Racing teams, including Renault Sport Formula One, are constantly striving to match and exceed the ever-improving results of the leaders. In this sport, the research and development process never stops, and technical partnerships are essential for an organization to achieve its goals. Renault Sport Formula One's collaboration with 3D Systems accelerates the development process and drives innovation at every stage, from wind tunnel and wind tunnel testing to the production of reliable finished parts. nine0006

Racing teams, including Renault Sport Formula One, are constantly striving to match and exceed the ever-improving results of the leaders. In this sport, the research and development process never stops, and technical partnerships are essential for an organization to achieve its goals. Renault Sport Formula One's collaboration with 3D Systems accelerates the development process and drives innovation at every stage, from wind tunnel and wind tunnel testing to the production of reliable finished parts. nine0006

Renault Sport Formula One team breaks new ground for innovation through R&D partnership with 3D Systems

“Race after race, more and more complex composites and aerospace alloys are being used, rigorously selected in research and development labs,” explains Renault Sport Formula One Technical Director Nick Chester. “At the end of every racing season, we expect our car to be more than a second per lap faster than it was at the beginning, and our technical partners are just as ruthlessly selected. We're not interested in relationships that don't help us improve our performance." nine0006

We're not interested in relationships that don't help us improve our performance." nine0006

The yardstick of ongoing innovation and strong collaboration explains the Renault Sport Formula One team's choice of 3D Systems and its 3D printing technology suite.

R&D partnership

Based in Enstone, UK, the Renault Sport Formula One team has been using 3D Systems technology since 1998. She was one of the first to use 3D printing for prototyping and closely monitored the development of this technology. Early on, the technology was used to test designed parts for functional and dimensional requirements, and to make jigs and fasteners for precise assembly. As the partnership between the two companies developed, 3D Systems engineers helped the Renault Sport Formula One team understand and use their existing capabilities, materials and methodologies. That the team was able to keep their wind tunnel loaded is a testament to the positive impact of the partnership with 3D Systems and the development of innovative automotive parts using 3D die-casting and 3D metal printing (DMP). nine0006

nine0006

3D Systems laser stereolithography technology enables Renault Sport Formula One team to respond quickly to technical challenges

“The support provided by 3D Systems has also evolved as our collaboration has expanded,” explained Mr. Chester. “Looking back, as materials properties improved, the team sought to expand the range of applications for fast manufacturing materials to more complex engineering problems. The number of automotive components produced using additive manufacturing is increasing every year, bringing significant benefits to the team in terms of application flexibility and reduced production time and costs.” nine0006

Among the 3D Systems installations currently used by Renault Sport Formula One are six stereolithographic 3D printers and three selective laser sintering (SLS) machines. Materials are used ranging from Accura® for fixtures and fasteners, burnout models and wind tunnel parts to DuraForm® PA and DuraForm GF for car-mounted parts such as electrical junction boxes and air-cooling ducts. From material suitability testing to part design optimization, the partnership between Renault Sport Formula One and 3D Systems ensures the best possible results both on and off the race track. nine0006

From material suitability testing to part design optimization, the partnership between Renault Sport Formula One and 3D Systems ensures the best possible results both on and off the race track. nine0006

The ever-improving car

Each year, the Renault Sport Formula One team designs and builds a new car that takes into account changes in the rules and follows a natural cycle of R&D to improve the performance of the car. As an example of the challenges that the changes to the Formula 1 rules entail, are the 2017 innovations allowing heavier larger tires, a wider front wing, a lower and wider rear wing and a taller diffuser. This means that parts from 2016 could not be reused in 2017. nine0006

As soon as the racing season begins, the tension only grows: sometimes there is only a week between races to make technical changes. From dedicated racetracks to rough and twisty street tracks, every race presents engineers with new challenges in terms of track architecture, climate and asphalt type.

The team prepares for the unique features of each track and uses all the time in the small gaps between races to bring the fruits of research into cars and equipment. Clearly, the speed and accuracy of 3D printing is of great value when preparing for new races. “The car is improving every day during the racing season,” says Patrick Warner, Lead Digital Manager for Renault Sport Formula One. “We need new components at every track, and the benefits of additive manufacturing are becoming ever more relevant.” nine0006

TASK

- Accelerate the R&D process in the automotive industry and promote innovation in a constantly changing environment.

SOLUTION

- 3D Systems complete solutions from printers and materials to application experience.

RESULTS

- Increased Efficiency: A small group of engineers were able to produce hundreds of parts a week for wind tunnel testing.

nine0177

nine0177 - Produce complex automotive parts in hours, not weeks, with SLA and SLS technologies.

- Making more innovative parts using 3D printed die casting patterns.

- Ensuring assembly quality by designing and manufacturing precision fixtures and fasteners that would not be possible or would be too time consuming with conventional technology. nine0177

- Opening new possibilities for the development of innovative 3D printed parts for testing and installation on race cars.

Quick design check

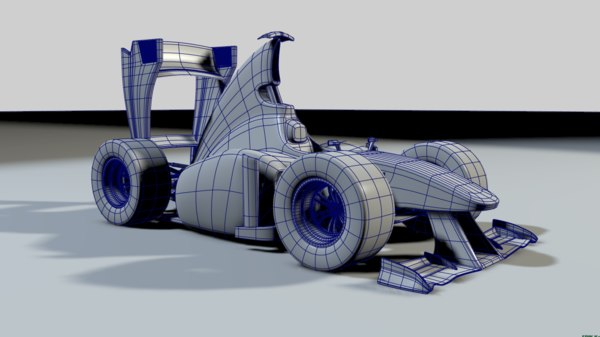

Rapid prototyping using 3D printing was immediately demonstrated in Formula 1 racing, where the parts installed inside the car are densely packed and limited by the contours of the aerodynamic skin. The Renault Sport Formula One team's aerodynamicists quickly realized the potential of 3D printing to validate functional and dimensional requirements based on the complexity of parts produced by 3D Systems. As a result, the use of 3D technologies has grown rapidly, from rapid prototyping to the production of models for aerodynamic testing. nine0006

nine0006

3D-printed burn-out casting patterns enable fast production of large metal parts of great complexity

Aerodynamic testing is an experience-based science,” Warner explains. “We develop and compare new ideas and identify future areas of work. The more ideas we can compare and evaluate, the more successful the races will be." In terms of parts quality, equipment life and performance, SLA technology has proven indispensable for the racing team. nine0006

New ways to use wind tunnel

In recent years, the aerodynamics group within the Renault Sport Formula One racing team has grown significantly and now has 120 employees, including aerodynamicists, technicians and modellers. According to Warner, the development of this area was largely due to the increased use of additive manufacturing technologies from 3D Systems. As one of the main advantages of 3D Systems technology, he points to the ability to build complex internal channels in aerodynamic test models, as well as the ability to collect more pressure readings. nine0006

nine0006

“The model wind tunnel test car has a complex network of pressure sensors,” says Warner. “Before the advent of SLA technology, sensors were installed by drilling pressure tapping holes in metal and carbon fiber parts. The ability we now have to fabricate complex solids with extensive internal channels has revolutionized sensor placement and dramatically increased the number of sensors. It's an aerodynamicist's dream come true." nine0006

The wind tunnel test alone requires 600 parts per week to be 3D printed, Warner estimates, all of which is done by just five digital engineers.

“Using traditional technologies, we could not even dream of such a result,” notes Patrick Warner. “We would need a machine shop the size of a small town. Thanks to 3D Systems, we have a one-stop shop. We have the right equipment, the right materials, and the experience of application engineers who can get to work immediately.” nine0006

High speed and accuracy of parts manufacturing

Metal 3D printing partnership with 3D Systems makes it possible to create innovative automotive components

In terms of performance and efficiency, 3D printing has greatly increased the Renault Sport Formula One racing team's ability to respond to the new challenges posed by the ever-changing rules of Formula One racing. With SLA and SLS technologies, complex fixtures and fasteners, fluid dynamic parts and automotive components can be produced in hours rather than weeks, making 3D technology ideal for solving Formula 1 racing logistical challenges. nine0006

With SLA and SLS technologies, complex fixtures and fasteners, fluid dynamic parts and automotive components can be produced in hours rather than weeks, making 3D technology ideal for solving Formula 1 racing logistical challenges. nine0006

In addition to the huge number of parts tested in the wind tunnel every month, the Renault Sport Formula One team manufactures a number of racing car parts directly. “3D Systems technologies have provided the foundation for a new, efficient manufacturing process that has enabled us to reduce both cycle times and costs, bringing invaluable benefits to the entire team,” said Rob White, CEO of Renault Sport Formula One. - On the one hand, we appreciate the opportunity to test several variants of the same part in a wind tunnel. On the other hand, we see how the number of parts in the car made by selective laser sintering is growing every year.” nine0006

3D printing helps the team create lighter parts that increase the speed and fuel efficiency of the car, as well as conduct accurate and informative consumption tests to improve engine performance and reduce wear. The finished design, along with the bill of materials, is sent to the digital technology team to manufacture the part. Thanks to SLA and SLS technologies, complex automotive components can be produced faster than ever, in some cases the part is ready for inspection even before the drawings are completed. nine0006

The finished design, along with the bill of materials, is sent to the digital technology team to manufacture the part. Thanks to SLA and SLS technologies, complex automotive components can be produced faster than ever, in some cases the part is ready for inspection even before the drawings are completed. nine0006

3D-printed diecast diecast models are also increasingly being used by the racing team for products such as transmission and suspension parts, removing restrictions on the level of complexity of parts and allowing the team's engineers to be more creative in their design. The accuracy of the SLA technology reduces the time required for the manufacture of casting patterns and machining of finished castings.

New directions of development

The benefits of 3D Systems technology, experience and services are closely linked to the key priorities of the Renault Sport Formula One team, such as innovation, efficiency, maximum precision and precision. For Bob Bell, CTO of Renault Sport Formula One, 3D Systems is more than just a technology provider: the two companies have developed a true partnership that delivers results today and creates huge potential for the future.