Rapid 3d printing

3D Printing & Additive Manufacturing Event

North America’s largest and most influential Additive Manufacturing event.

May 2 - 4, 2023

McCormick Place — West Building

Chicago, IL

people

Why Attend

What makes the largest and most influential additive manufacturing event in North America a can’t miss experience in 2022.

event

Event Features

Find out what makes RAPID + TCT next level in 2022.

devices

Digital Experience

RAPID + TCT 2022 – Now Streaming

RAPID + TCT 2023

Don’t miss RAPID + TCT 2023 – Big things are happening in this advanced manufacturing technology, and you will see them all at North America’s largest and most influential Additive Manufacturing event. Registration opens soon!

Explore the 2022 Conference and Event Preview!

Last year’s show featured 400+ exhibiting companies, keynote presentations, thought leadership panel discussions, new product previews, networking and so much more!

Stay tuned for details on why RAPID + TCT 2023 will be the must-attend AM event in Noth America!

The Rapid + TCT Experience

Event and Industry News

-

June 22, 2022

You can rest assured that you held a great event when both the exhibitors and attendees offered thanks and words of praise. That is exactly what I heard throughout RAPID + TCT 2022, and in the week that followed.

-

June 2, 2022

SME and the Rapid News Group welcomed thousands of members of the Additive Manufacturing (AM) community back for another successful installment of the industry’s largest and most influential event, RAPID + TCT 2022, May 17-19 at Huntington Place in Detroit.

-

May 20, 2022

RAPID + TCT 2022 has officially kicked off—this time returning to its roots at Huntington Place in Detroit!

Membership Has Its Advantages

With an All-Access pass to RAPID + TCT, you'll receive a free 1-year SME membership! SME members can connect with peers, gain knowledge related to manufacturing technology and trends, solve problems and participate in leadership opportunities.

Get Your All-Access Pass

View More News

RAPID + TCT Event Overview

For more than 30 years, RAPID + TCT has defined the crucial role of additive manufacturing and empowered the establishment of an industry that continues to conceive, test, improve and manufacture new products at a faster, more cost-efficient pace. The two industry leaders in 3D-technology events, SME and Rapid News Publications, have teamed up to produce the annual RAPID + TCT event, which takes place May 2-4, 2023 in Chicago, IL.

The two industry leaders in 3D-technology events, SME and Rapid News Publications, have teamed up to produce the annual RAPID + TCT event, which takes place May 2-4, 2023 in Chicago, IL.

Known worldwide as North America’s most important and largest additive manufacturing event, RAPID + TCT provides everything you need to know about the latest 3D-technologies, all under one roof. It is where you will witness groundbreaking product announcements, experience hands-on exhibits, learn real-world additive manufacturing solutions from the industry’s most respected experts and network with thousands of industry peers. At the RAPID + TCT conference, over 100 industry leaders go beyond the hype to bring you real-world solutions to advance your manufacturing processes.

Meet our Industry Partners!

The following organizations are critical to the future success of the additive manufacturing industry and we are thrilled that they have joined this collaborative effort that aims to foster industry standardization, thought leadership and growth.

RAPID + TCT 2023

May 2-4, 2023

McCormick Place — West Building

Chicago, IL

Register Now

Event Hours

Tuesday, May 2: 9am - 5pm

Wednesday, May 3: 9am – 5pm

Thursday, May 4: 9am – 3pm

Exhibit Hall Hours

Tuesday, May 2: 10am - 5pm

Wednesday, May 3: 10am – 5pm

Thursday, May 4: 10am – 3pm

About SME and Rapid News Publications

The two leaders in additive manufacturing, SME and owner of the TCT Group, Rapid News Publications, joined forces in 2016 to produce the RAPID + TCT event, combining decades of 3D-technology insights and experience.

SME is the definitive industry source for 3D-technology knowledge, experience, education, and connections. With a community of over 200,000 people, we are fully committed to the advancement and increased adoption of additive manufacturing technology. We also attract students to exciting careers in manufacturing through contests, design challenges, and dynamic hands-on experiences.

SME’s Additive Manufacturing Community provides access to experts, connecting you to the world-class knowledge that is advancing the manufacturing industry. Technical papers, conference presentations, industry news, videos and webinars keep you on the leading edge of development while preparing you for what’s next. Our certifications and training courses empower you to take that next step in your career. And our events give you access to the connections and knowledge you need to create your additive manufacturing success story.

No matter where you are on your journey in additive manufacturing – simply exploring the possibilities, designing new innovations or facing the challenges of scaling up production, SME is your resource every step of the way.

RAPID + TCT Event Advisors

RAPID +TCT Event Advisors are pivotal in assisting SME and TCT with developing and implementing the RAPID + TCT event. This advisory team represents a broad base of the AM industry to help us build a world-class event and conference that educates and inspires all participants, no matter the stage of their career or the size of their business.

The RAPID + TCT Event Advisors provide input on industry trends, technological advances and the future of AM. They also recommend industry thought leaders to present in various areas of the event.

Meet the Event Advisors

Membership Has Its Advantages

SME members can connect with peers, gain knowledge related to manufacturing technology and trends, solve problems and participate in leadership opportunities. Plus, with an All-Access pass to RAPID + TCT, you’ll receive a free 1-year membership! Enjoy all the benefits of membership, including a monthly subscription to our highly respected Manufacturing Engineering magazine, customized research assistance, local chapter engagement, online networking, and discounts on conferences and trade shows, and more.

Is it possible to print 10 times faster on a 3D printer? Tips for increasing the speed of your 3D printer

3DPrintStory 3D printing process Is it possible to print 10 times faster on a 3D printer? Tips for Increasing 3D Printer Speed nine0005

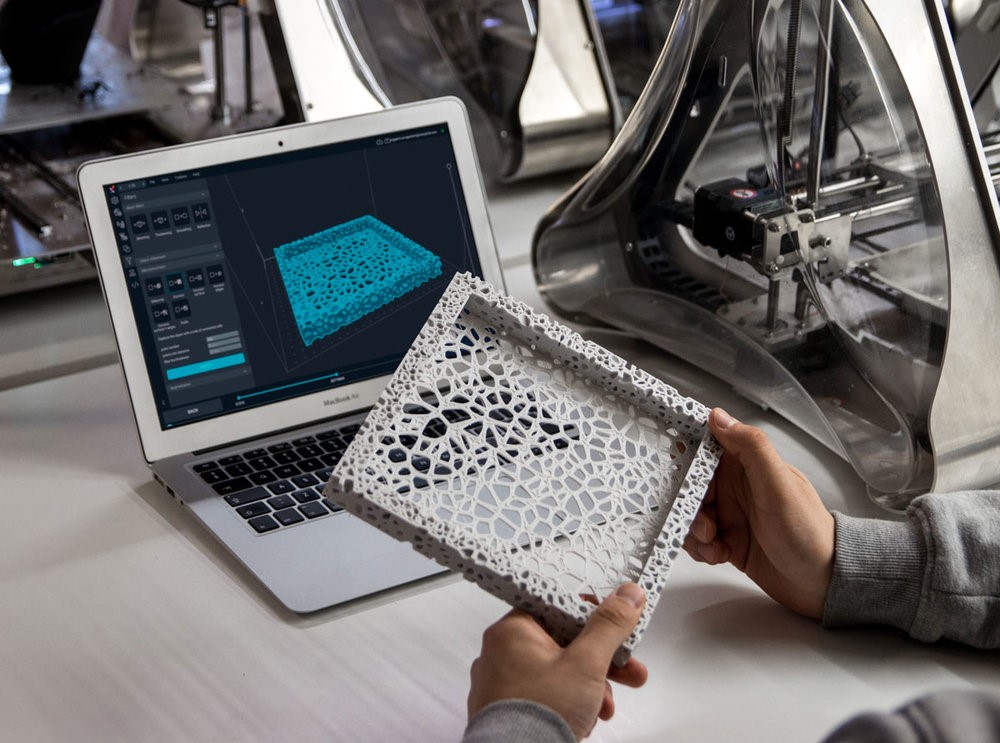

From time to time, all 3D printing enthusiasts think about increasing the speed of a 3D printer and creating figures and models in a matter of hours, not days. Wouldn't it be great if you could 3D print 10 times faster than you can now? This article provides tips on how to increase the speed of your 3D printer without losing quality.

Wouldn't it be great if you could 3D print 10 times faster than you can now? This article provides tips on how to increase the speed of your 3D printer without losing quality.

Before we take a closer look at the secrets that will help you print faster and share ideas for fast 3D printing, it's worth a little imagination about the incredible future. Maybe one day you will buy an affordable and fast device that turns STL files into detailed figures and models from your favorite video games and movies in just a couple of hours or even faster... And this one will really happen. But! Now let's put aside the fantasies and return to the current reality. The reality is that the following tips will actually help you speed up your 3D printing, so let's get started. nine0005

There are great guys - John Hart and Jamison Goh from MIT - the real geniuses of modernizing technology. According to MIT news, these two professors, along with their colleagues, have been working to increase the speed of a 3D printer and have developed an innovative model called Fast FFF.

The name Fast FFF stands for "Production of Fast Fibers". This model is capable of stacking material 10 times faster than any existing desktop 3D printer. In addition, the print head with fantastic 3D printing speed can work with renewable materials. nine0005

As the engineers noted, in order to increase the speed of 3D printing, three main factors had to be taken into account:

- The force applied by the print head when pushing the 3D printing material through the nozzle;

- The time required to heat up the material so that it melts and can flow through the nozzle;

- Print head movement speed.

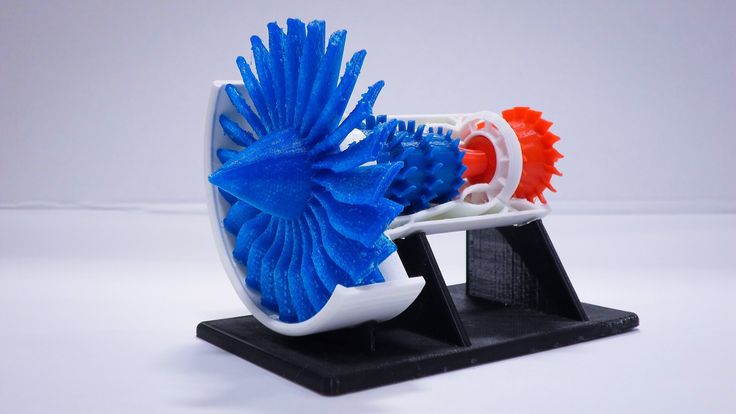

All these things have been improved in the Fast FFF prototype. As a result, it was possible to 3D print two simple eyeglass frames in less than 4 minutes and a complex bevel gear in about 10 minutes. These models were printed with a 0.2mm layer and proved to be strong and durable. nine0005

Fast FFF prototype 3D printer cost about $15,000. This is a good price compared to expensive commercial 3D printers that cost over $100,000 and are about three times slower. But if you compare the price with an affordable home 3D printer under $300 or $500, the Fast FFF is clearly too expensive, even though it can 3D print 10 times faster than a regular FDM 3D printer. And it's currently unclear if an affordable ultra-fast 3D printer for home use will hit the market...

This is a good price compared to expensive commercial 3D printers that cost over $100,000 and are about three times slower. But if you compare the price with an affordable home 3D printer under $300 or $500, the Fast FFF is clearly too expensive, even though it can 3D print 10 times faster than a regular FDM 3D printer. And it's currently unclear if an affordable ultra-fast 3D printer for home use will hit the market...

While you can't get your home 3D printer to 3D print 10 times faster than it is now, or beat the innovative Fast FFF machine, there are secrets :).

Most of the tips that can help improve your 3D printing speed can also affect the quality of your figurine or model. However, sometimes it's worth it.

Adjust 3D print speed

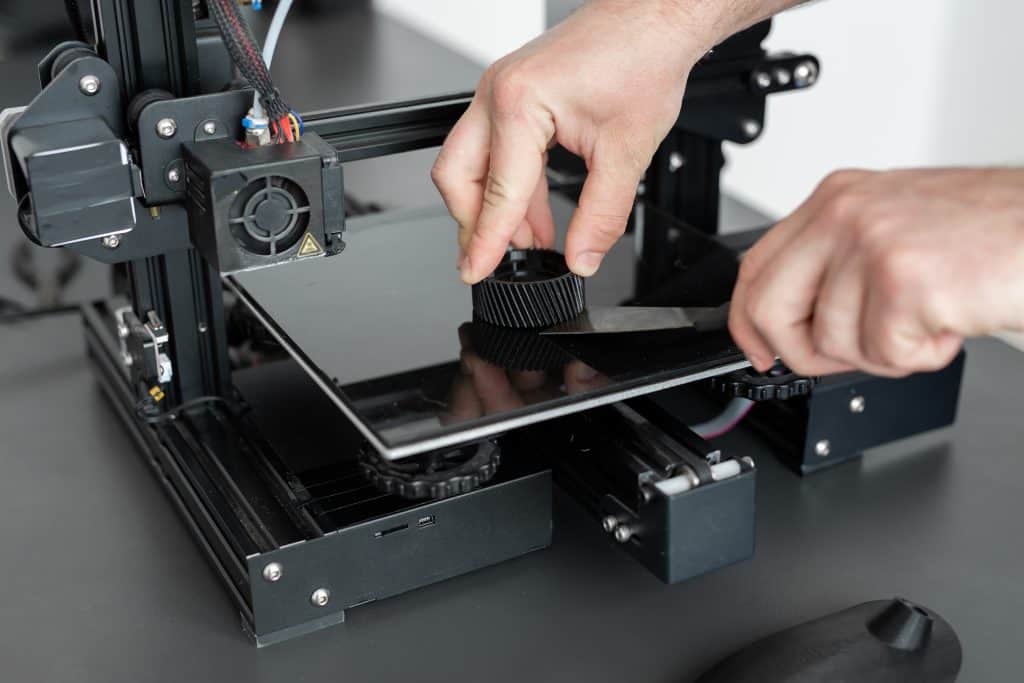

Settings is the first thing you can try if you want to increase your 3D print speed. Every hobbyist likes to work with certain slicing software. It is worth exploring all the possibilities and changing the settings to suit your needs. nine0005

nine0005

The ability to control the speed of the print head is amazing. Sometimes this does not negatively affect the quality of a complex 3D printed model. And when you do something simple, you can significantly increase the speed without losing quality.

Replace nozzle

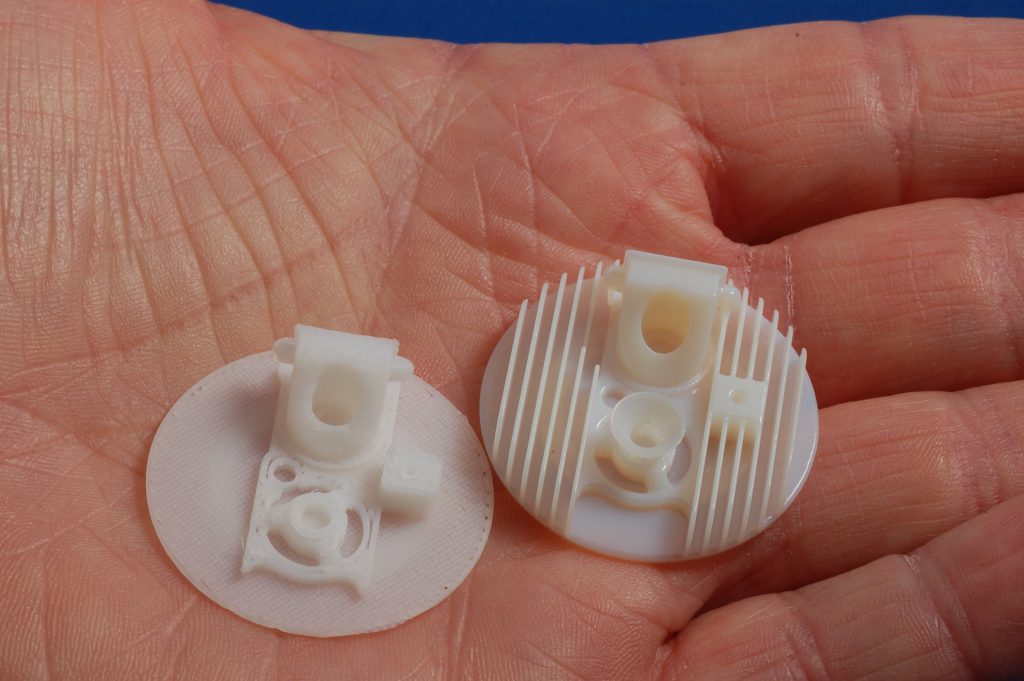

Sometimes you don't care about 3D printing accuracy. In this case, a larger nozzle may suffice. For example, you can change the nozzle on your 3D printer from 0.4mm to 0.8mm. Or you can choose even 1.0mm print head. nine0005

Much depends on your current nozzle size. Standard printheads are 0.2mm and 0.4mm. But choosing a larger size can save time and speed up 3D printing.

Increase layer height

If you increase the speed of the 3D printer by changing the nozzle to a larger diameter, you will also have to increase the layer height of the 3D print. The maximum height you can select is approximately 75% of the current nozzle diameter.

So if you change the nozzle from 0. 4 mm to 0.8 mm, you can increase the layer height to 0.6 mm. These settings will affect the quality of your 3D model and cause you to lose a lot of impressive detail because the layers will be thinner and the speed will be much faster. Keep this in mind when experimenting with nozzle size and layer height. nine0005

4 mm to 0.8 mm, you can increase the layer height to 0.6 mm. These settings will affect the quality of your 3D model and cause you to lose a lot of impressive detail because the layers will be thinner and the speed will be much faster. Keep this in mind when experimenting with nozzle size and layer height. nine0005

Reduce wall thickness of 3D models

100% infill models and figurines take longer to print, but are durable when finished. You've probably guessed how to make 3D print faster by playing with wall thickness and reducing infill. But in this case, you need to be careful, because the thin walls of the 3D model and less infill can lead to poor quality 3D printing.

If you have a resin based 3D printer, you can save resin and increase 3D printing speed by working with the appropriate DLP/SLA Eco version of STL files offered by Gambody - Premium 3D Printing. The Eco version ensures that your walls are thick enough to make your 3D model strong, detailed and of the highest quality. nine0005

nine0005

Print two 3D models at the same time

Another way to speed up your 3D printer without sacrificing product quality is to work on two projects at the same time. This is only possible if both models or figurines are small and can fit on the same 3D printer table without interfering with each other.

This option can be set in the slicing software. Select centering and place both models for 3D printing on the work surface. The main disadvantage of this method is that both models will be printed from the same material, but the final print speed will be significantly increased. nine0005

Do not use supports

When a large amount of support material is needed to 3D print a complex model, printing time will increase. This way, whether you choose to do projects with fewer supports or learn how to 3D print without supports, you can speed up and print the prototypes and figures you need faster.

Change the infill pattern of a 3D model

If you don't want to adjust the infill density, but still want to improve 3D printing speed, try adjusting the infill pattern in the slicer settings. People work with different patterns, but the most popular version for speed optimization is "lines" or "straight lines". nine0005

People work with different patterns, but the most popular version for speed optimization is "lines" or "straight lines". nine0005

Filling in a line pattern is very simple. Your 3D printer will make fewer moves when creating a straight infill figurine and can reduce print time by up to 20%-25%. But the models will not be as durable as those with a triangular or mesh pattern.

Adjust the jerk and acceleration settings

After making changes to the slicing software in the hope of increasing the speed of 3D printing, you can also try changing the jerk settings. They are responsible for how fast the print head can move. Of course, the print head must move smoothly, because increasing the speed can negatively affect the quality of the 3D print and even lead to problems with the mechanical part of the 3D printer. nine0005

There are also acceleration settings that need to be adjusted. They control the speed at which the print head reaches its maximum speed. It's worth playing around with these settings to find a balance between the jerk and acceleration settings to slightly increase print speed without affecting the quality of the 3D model or 3D printer.

For example, if you work with the jerk setting at 10 (low) and select a speed of 60mm/sec, you won't save much time in 3D printing, but the print quality will be ok. Increasing speed to 120mm/s and jerk to 40 will cut 3D printing time by 25%! However, the quality of the printed 3D model will also be greatly reduced. nine0005

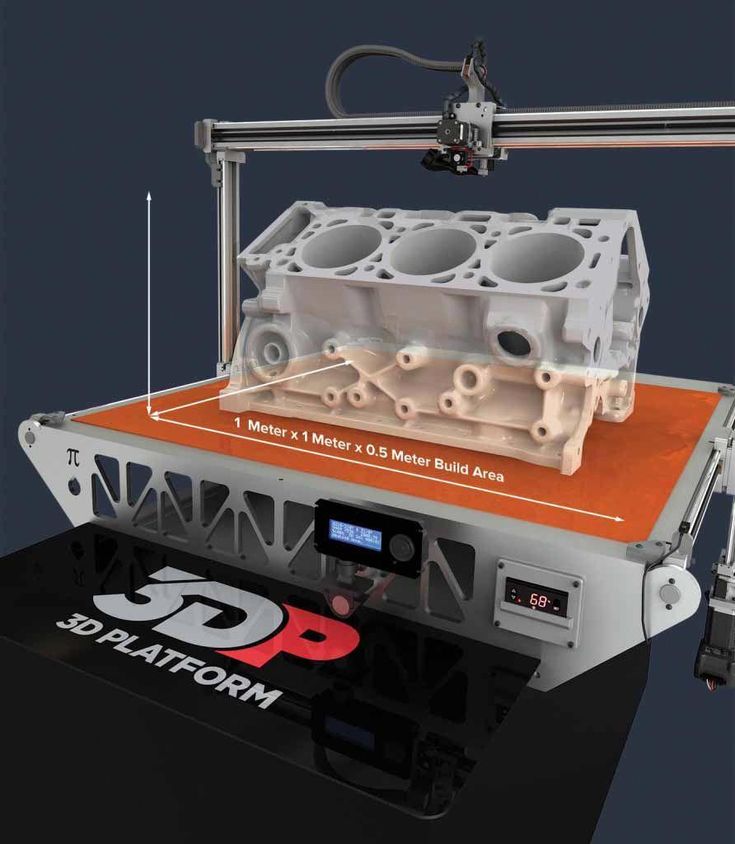

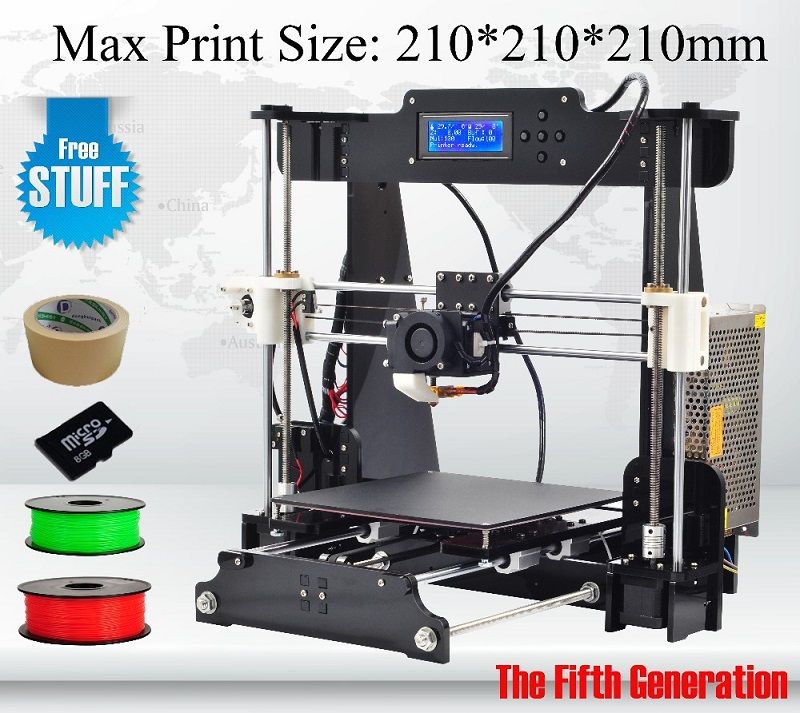

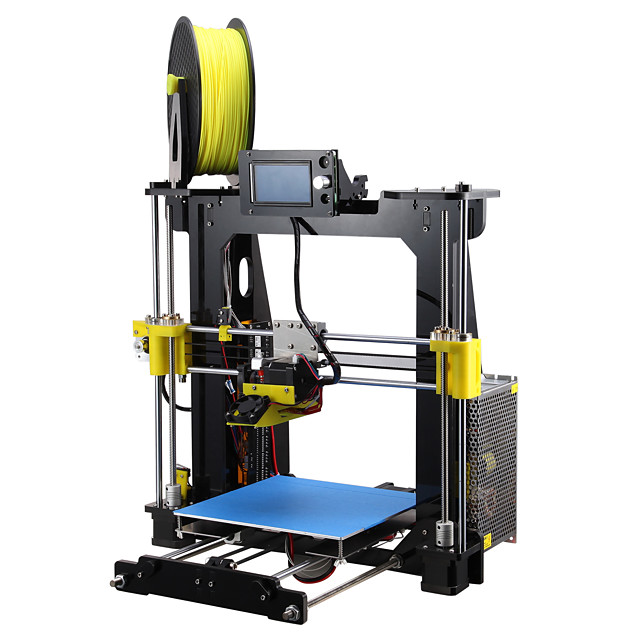

Replace 3D Printer

If you are not satisfied with your current 3D print speed capabilities, you can always look for another 3D printer with higher speed. However, such a device can be expensive. Most printers designed for home use are not as fast as industrial 3D printers.

For example, the cheapest FDM printers can cost as little as $300 or even $200, and they typically print at 60mm/sec. They will never reach the speed of industrial equipment such as the Massivit 1800 which can reach speeds of 1000mm/s. nine0005

Select objects for 3D printing quickly

Another way to increase the speed of 3D printing is to search for new ideas for 3D printing as quickly as possible. It is ideal for beginners who want to learn on the go and improve their skills as they progress from simple models to more complex figures.

It is ideal for beginners who want to learn on the go and improve their skills as they progress from simple models to more complex figures.

How fast do FDM 3D printers print

What resolution do 3D printers print

Threaded connection of printed parts

6 Safe Ways to 3D Print

3D printing at home gives us the ability to produce custom objects at a very low cost. However, the time it takes to turn a 3D model into a physical object is not as short as one might think. The size and quality of the print has a decisive influence on the speed of printing, and it can take many hours to get the final result. In fact, various tests show that printer speed has a much smaller effect on print time than size and quality settings. nine0005

Desktop printers

3D print speed settings

In general, there are currently three sets of speed settings supported by 3D printers. The first block includes speeds from about 40 to 50 mm / s, the second - 80-100 mm / s, the fastest printing is carried out at about 150 mm / s. Some printers can even print at speeds over 150mm/s.

Some printers can even print at speeds over 150mm/s.

Usually, however, faster 3D printing means lower quality. At speeds above 150 mm/s, the quality drops significantly, and problems can arise, since the filament is prone to slip at such speeds. nine0005

How to set the print speed

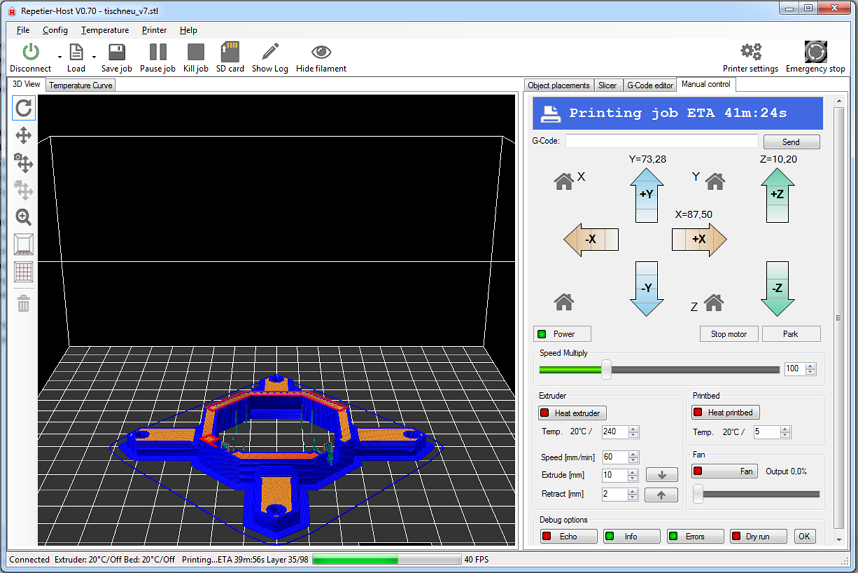

Typically, the 3D print speed is set in the slicer software used to prepare the 3D model for printing. In Cura, for example, you just need to enter the desired print speed in the Print speed field in the Basic tab (in previous versions, you first had to switch to the Advanced mode and open the Speed tab).

Cura calculates the duration of the print process based on print speed and quality settings. nine0142

As soon as the print speed ( Print speed ) or other setting is changed, Cura recalculates the print time and displays it (see arrow). Cura's calculations turn out to be very close to real-time printing.

How long does 3D printing take in practice?

To find out how fast 3D printers actually print, two popular desktop printers, the Ultimaker 2 and the Wanhao Duplicator 6, were tested on two more or less complex objects.

These two models were printed:

3DBenchy. This 3D model is designed to test and measure the speed of 3D printers; it is quite complex and requires attention. The boat is 6 cm long, 4.8 cm high and 3.1 cm wide. Here you can get the 3DBenchy STL file for testing for free.

3DBenchy's 3D printing speed is relatively slow, the model is quite difficult to print (Photo: 3DBenchy.com).

Universal tablet stand (up to 1.2 cm thick). The stand is 14 cm long, 4.2 cm high and 9.8 cm wide. The STL file is available for free on Thingiverse.

The stand is quite large and difficult to print (Photo: Thingiverse).

These objects were printed at two speeds, 100 mm/s and 50 mm/s, at similar settings. Here are the results:

Here are the results:

Printer

Model

50 mm/sec

100 mm/sec

Ultimaker 2

9000 3dbenchy2 h 09 min.0005

1 h 55 min

Wanhao Duplicator 6

3DBENCHY

2 h 13 min

1 h 51 min

Ultimaker 2

Stand

9000 6 h 23 min 9000 4 h 36 min 9000 2 minWanhao duplicator 6

Stand

6hrs 27mins

4hrs 45mins

- For the smaller models, the difference between slow and fast print is not that noticeable: almost 2.25 hours versus less than 2 hours. Unless you're insanely short on time, choose a slower speed for better print quality. nine0020

- For large models, the print speed differs more significantly: 6.5 hours versus 4.75 hours.

Cunning. If you don't have your own 3D printer, download the free Cura software from the Ultimaker website. Cura has profiles for most desktop printers (FDM), so you can check how long it takes to print a specific 3D model on a particular device - just import the STL file and play with Cura settings. To try another 3D printer, select Machine > Add new machine.

To try another 3D printer, select Machine > Add new machine.

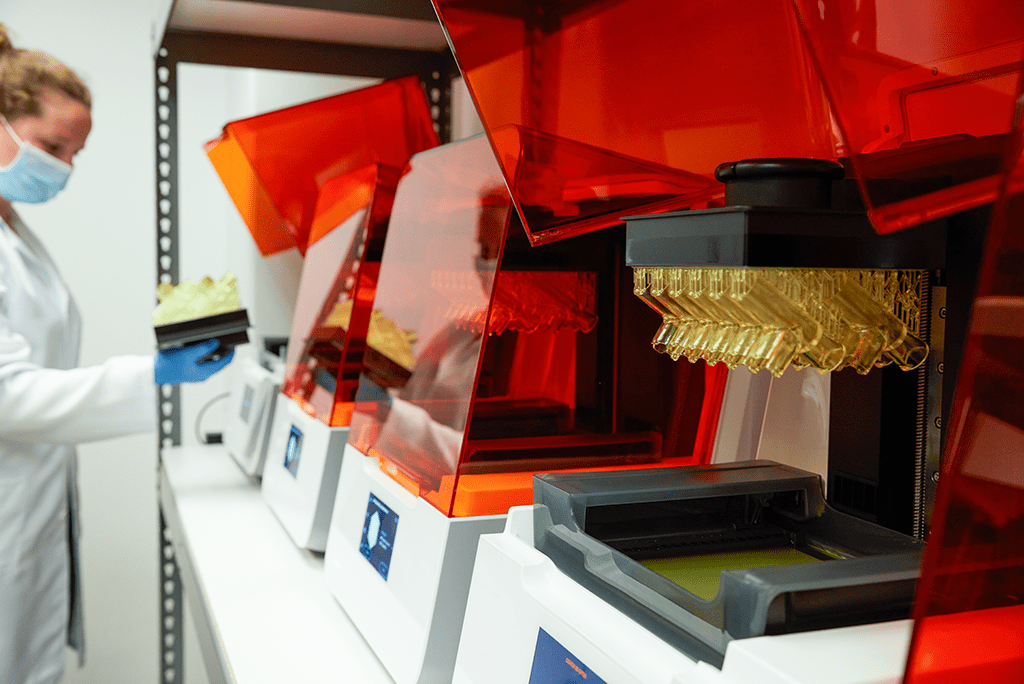

Does high-speed sintering promise the fastest 3D printing?

On an industrial scale, even more impressive prospects dawn on the horizon. The University of Sheffield has announced that its scientists have built a £1m-funded 3D printer that can produce plastic parts as quickly as traditional mass-production methods such as injection molding.

The process is called high-speed sintering (HSS), which melts the polymer layer by layer (similar to the additive printing process), but instead of using lasers, HSS prints on a powder substrate with infrared-absorbing inks. After the layer is printed, it is exposed to infrared radiation, the ink-coated powder is heated, resulting in melting, while the non-irradiated powder remains cold. nine0005

A team led by Prof. Neil Hopkinson claims that their machine is capable of producing parts up to 1 m³, i.