3D printer filler material

Best Filler for PLA & ABS 3D Print Gaps & How To Fill Seams – 3D Printerly

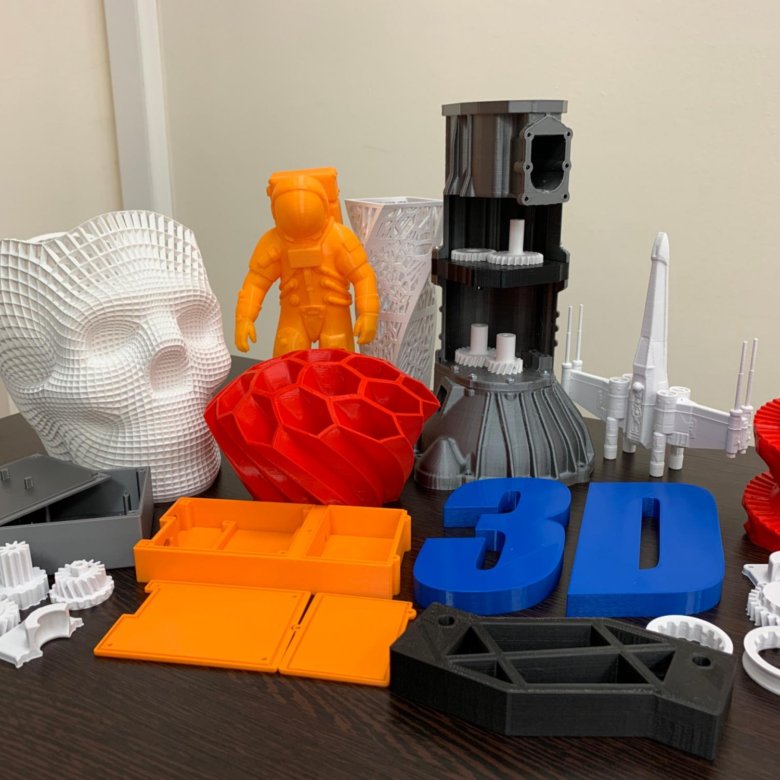

I was looking at some of my freshly 3D printed objects and noticed that there were a few gaps & seams in certain spots. It didn’t look so great, so I had to figure out how to fill up these seams, for my PLA 3D prints and other types.

Keep on reading for a nice list of fillers to use for your 3D prints and then a more in-depth explanation on how people best fill in gaps and seams.

5 Best Fillers For Your 3D Prints

- Apoxie Sculpt – 2 Part (A & B) Modeling Compound

- Bondo Glazing and Spot Putty

- Bondo Body Filler

- Elmer’s ProBond Wood Filler

- Rust-Oleum Automotive 2-in-1 Filler and Sandable Primer

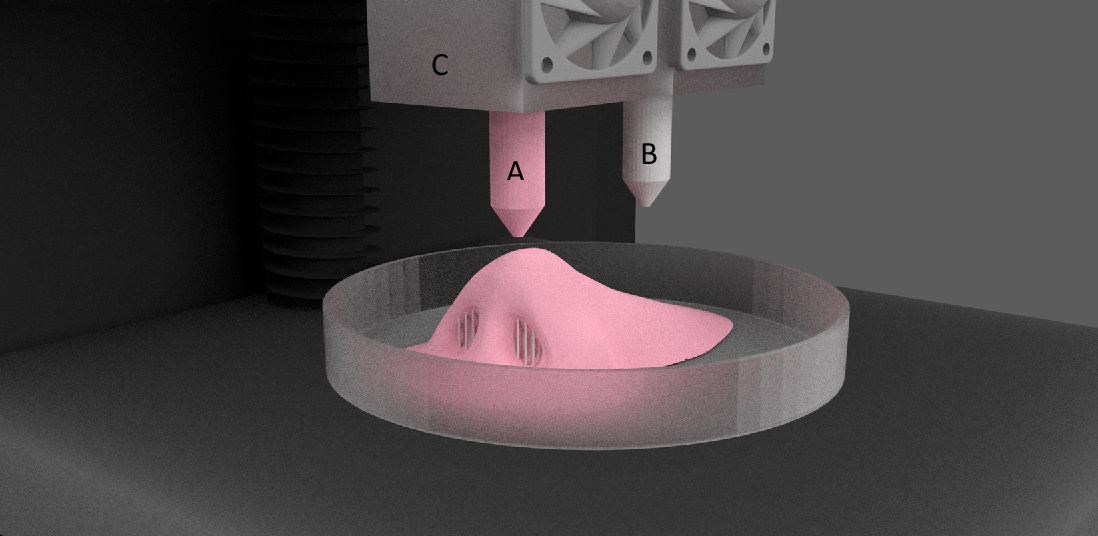

1. Apoxie Sculpt – 2 Part (A & B) Modeling Compound

Apoxie Scult is a popular product among not only crafting projects, home décor, or cosplay, but also for filling in those seams out of your 3D prints.

It manages to combine the benefits you would see from sculpting clay, as well as the high strength adhesive properties of epoxy.

This is a solution which is permanent, self-hardening, and even waterproof, so it can give you the best results out there.

It is smooth enough that it allows you to mix and use it without major tools or techniques.

There is no baking required as it cures and hardens within 24 hours, resulting in a semi-gloss finish. It has the ability to adhere to any type of surface which allows you to use it for sculpting, decorating, bonding, or filling any type of seams and gaps in your 3D prints.

A 3D printer user said that he was in trouble as it was difficult to find a great product for filling the 3D print seam in the matching color. He moved to Apoxie Sculpt because it can be mixed and used in 12 different colors.

You can choose from simple white Apoxie Sculpt, to a range of 4-color packs which can be mixed together to create custom colors to your liking. They even have a PDF color-mixing guide that provides you with detailed instructions on how you can get it perfect.

Wear safety gloves before mixing two compounds and let them sit for about 2 minutes so that these compounds can mix up thoroughly, forming a perfect new color.

Some of the benefits and features are as follows:

- Self-Hardening

- High Adhesion Strength

- Hard and Durable

- 0% Shrinkage and Cracking

- No Baking Required

- Easy to Use

It works by two products together (Compound A & Compound B). It’s easy to work with and is even water-soluble before it cures which makes it so much simpler to apply. Simply use water to smooth out, then use sculpting tools if you have some.

One user uses this product effectively to smooth out joints in their 3D prints, and it works so well that you can barely tell there was ever a seam there. It doesn’t have a super strong hold, but for filling in seams, that’s not a requirement.

Another person uses Apoxie Sculpt to sculpt parts which they then 3D scan and print, an amazing method for prototyping.

Get yourself some Apoxie Sculpt 2-Part Modeling Compound from Amazon today.

2. Bondo Glazing and Spot Putty

Bondo Glazing is well known for its durability and ease of usage. It is extremely fast and shows no signs of shrinkage. It is an ideal option for filling seams and holes in your 3D prints as it provides a perfectly smooth finish.

There is no need for mixing or extra work as it is ready to use right from the tube.

It provides a 3-minute working time and becomes ready for sanding in just 30 minutes. It is non-staining which means that your 3D prints will not get affected nor their color will be damaged.

One of the buyers said that he purchased it as a trial but once he got to use it, he completely fell in love with this filler.

The drying process was much quicker than he expected. The sanding was great and the resultant 3D print model had an excellent polish level finish.

It is known to emit strong fumes and odor until the product is dry, so I’d recommend that you work at an open place or in a well-ventilated area.

Some of the benefits and features are as follows:

- Easy to Use

- No Mixing Required

- Sandable in 30 Minutes

- Non Staining

- Fast Drying

- Low Shrinkage

Several users mention just how easy it is to use and apply, with one user saying it is perfect for smoothing out 3D prints that have a lot of lines in them and to fill in gaps. This isn’t a 2-part product which does make things easier for you to apply.

It sands very well after it cures, and it’s a good idea to put at least a layer of primer before you paint over your models.

A review mentioned how fast it dries and how they originally wanted to use it to cover just their main problem areas, but after it worked so well, they started to use it an almost all the surfaces of 3D prints!

Get you a pack of your own Bondo Glazing & Spot Putty from Amazon.

3. Bondo Body Filler

Bondo Body Filler consists of two parts compound, and it is widely used for bonding purposes in many fields including 3D printing. It is widely used by 3D printer users because it cures extremely fast and provides everlasting durability.

It is widely used by 3D printer users because it cures extremely fast and provides everlasting durability.

It is specially formulated in such a way that it can prevent shrinkage and form shapes in minutes. Bondo Body Filler was originally designed for vehicles, that’s the reason why it includes some of the most amazing features such as high strength and easy usage.

3D printers’ users say that they feel it highly beneficial because it provides expected results, and you can easily sand your models once the filler is hardened which only takes minutes. You can get a smooth finish using different sanding grits.

Some of the benefits and features are as follows:

- Spreads Smoothly

- Dries in Minutes

- Easy to Sand

- Excellent Smooth Finish

- Suitable for almost All Types of 3D Printing Materials

One user said that they use it to cover 3D prints, and it works wonders to hide those little errors, as well as being sandable for a smooth finish.

4. Elmer’s ProBond Wood Filler

Elmer’s ProBond Wood Filler can really get the job done for 3D printer users, with very little hassle compared to other options.

Let’s explain this filler by the words of its users.

A buyer’s feedback stated that he likes to use this filler for his 3D prints because it dries superfast and hardly takes 15 to 30 minutes.

One of the best things about this filler is that it is almost odorless which prevents your room from filling with a weird smell.

Another user advised that if you are going to use this filler for filling seams and layer lines on your 3D prints, you should not overuse it as it may become a problem at the time of sanding. Otherwise, it works pretty well for the 3D print models.

Check out my article on 8 Ways How to 3D Print Without Getting Layer Lines.

Just make sure that you keep it covered by keeping the lid on or placing a plastic cover over the container because it can dry fast if left open.

Some of the benefits and features are as follows:

- Dries Super-Fast

- Odorless

- Easy to Use

- Strong Adhesion

- Easy to Clean

One frustration for many 3D print users is when it comes to putting models together and there being a small gap. You can use this product to simply fill in this gap before you get to painting the model.

This really is a go-to filler for 3D printer hobbyists out there, so do yourself a favor, get the Elmer’s ProBond Wood Filler from Amazon now.

5. Rust-Oleum Automotive 2-in-1 Filler & Sandable Primer

The Rust Oleum Filler & Sandable Primer is a staple product in all kinds of fields and industries that involve DIY, especially 3D printing. If you are looking for top quality models, you should look no further.

It has a 2-in-1 formula that ensures durable and long-lasting results and fills the seams and gaps in your 3D prints while priming the surface as well.

The container comes with a comfort tip which makes the process easy and reduces finger fatigue, unlike some other products out there.

One of the buyers shared his experience stating that it adheres extremely well to filaments like PLA and ABS without requiring any sanding. It allows you to build an even surface and a smooth finish.

The user said that he uses about 3 coats of the primer to make a good and filled surface of the 3D prints before moving forward towards sanding and finishing. It dries rapidly, adheres strongly, sands easily, and in simple words, it is worth buying for your 3D print models.

You can really boost your 3D printing game with this product.

It’s also a versatile product. You can go from spraying your freshly printed model, to priming the bare metal of your car before applying paint to cover those rusting spots.

Some of the benefits and features are as follows:

- Durable

- Primes Efficiently

- Smooth and Even Surface

- Sands Easily

- Best for Finishing

One user who has been using this primer for many years for 3D printing swears by it every time.

Get a can of the popular Rust-Oleum 2-in-1 Filler & Sandable Primer from Amazon today.

How to Fill the Gaps and Seams in Your 3D Prints

Before moving towards the process, make sure that you follow the precautionary measure and wear safety gloves especially if you are using fillers like Bondo Glazing & Spot Putty.

You can get the job done with your fingers while using fillers like Probond Wood Filler.

The process is as follows:

- Find all the seams and gaps in your 3D print.

- Take some filler and apply it on the seams.

- Use your finger to run it along all the edges and minor gaps in your 3D print.

- Keep on applying the filler until the seam is completely filled.

- Once you have filled all the seams, let your print model dry for some time depending on the filler you are using.

- Once it is dried completely, take sand grit and start sanding the parts where filler has been applied.

- Apply different sand grits such as 80, 120, or any that work well.

Start low and move to higher grits.

Start low and move to higher grits. - Keep on sanding the print until you get a clean smooth finish.

- Now you can prime and paint your 3D prints to complete the look

I’d definitely recommend checking out the video below by Uncle Jessy, who takes you through the process of filling in gaps and seams in your 3D prints!

Generally speaking, you want to increase the overall wall thickness of your 3D prints, by increasing the number of walls, or the actual wall thickness measurement in your Slicer.

The top thickness tends to be the important factor as to whether you have those large seams and gaps that you see in many 3D prints. On top of that, the infill density will have an impact on how filled the top of your 3D print will be.

I wrote an article called 9 Ways How to Fix Holes & Gaps in Top Layers of 3D Prints which should be useful to correct this issue!

Ultimate Materials Guide - Tips for 3D Printing with PETG

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage. There are several variations of this material in the market including PETG, PETE, and PETT. The tips in this article will apply to all of these PET-based filaments.

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

Hardware Requirements

Before 3D printing with PET / PETG make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 75-90 °C

Heated Bed Recommended

Enclosure Not Required

Build Surface

Glue Stick

Painter’s tape

Extruder

Temperature: 230-250 °C

No special hot-end required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PET / PETG such as stringing, oozing, and poor bed adhesion.

Invest In a Good Build Surface

Some 3D printers come with a glass bed or blue painter’s tape installed on the bed. Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Calibrate Retraction Settings to Reduce Stringing

One of the few common issues that we see with PETG is stringing. These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model.

These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Optimize Extruder Settings to Prevent Blobs and Zits

When 3D printing at higher temperatures associated with PETG, you may notice small blobs or zits on the surface of your model. These print defects typically occur at the beginning or end of each segment, where the extruder has to suddenly start or stop extruding plastic. There are several ways to eliminate these print defects such as enabling “Extra Restart Distance” or “Coasting” options located in the Extruder tab. Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Pro-Tips

- The glossy surface of PETG is especially useful when using rafts. The part separates easily from the raft and maintains a clean surface finish.

- Try disabling your part cooling fan for the first few layers of the print to prevent warping. This trick especially works well for larger prints.

Get Started with PET / PETG

Now that you are ready to start printing with PET / PETG, here are a few ideas to help you get started – from common applications to popular filament brands.

Common Applications

- Water proof applications

- Snap fit components

- Planter Pot

Sample Projects

- Self-watering Planter

- Water Bottle

- Snap Fit Parts

Popular Brands

- ColorFabb PETG

- eSun PETG

- E3D Spoolworks Edge

- Hatchbox PETG

- HobbyKing PETG

55265 from 5854.1 rubles, manufacturer VERBATIM

VERBATIM

On request

PDF, 66. 17 KB

17 KB

Description

VERBATIM - 55265 - 3D printer filler, 3mm, polylactide, natural

Item number

OC2828669

Request nine0002

55265 specifications:

| Manufacturer | VERBATIM |

| Product Line | - |

| Melting Temperature Max | 220 |

| Filler Color | Natural |

| Fill Material | PLA (Polylactide) |

| Melting Temperature Min | 200 |

| Filament Weight | 1 |

| Diameter | 3 |

| Melting Point | 220 |

| Reel Width | 72 | nine0033

| Spool Hole Diameter | 102 |

Call me back

Thank you!

Your request has been sent. In the near future we will contact you at the specified contacts.

In the near future we will contact you at the specified contacts.

Item added to cart

55265

Delivery time: 10-15 business days

Congratulations!

You got free shipping on your order

Continue shopping

Go to order

Error!

The quantity ordered is not a multiple. The correct amount must be a multiple of .

Sorry, an error occurred

55265

Delivery time: 5-12 days

Continue shopping

Register

and get a discount of 100₽

on your first order

Enter your mobile phone number

nine0002 By clicking on the "Receive SMS with registration code" button, you accept the terms of the user agreement. Enter your personal account

and get a discount

for order

Enter your mobile phone number

By clicking on the "Receive SMS with access code" button, you accept the terms of the user agreement.

Save profile

Data saved!

Are you sure? nine0003

It will be impossible to undo the deletion

Copy BOM

Enter the titleQuota requested

Uploaded file display

The entry starts on the line12

A preview of your file is shown below. Your columns have been mapped based on the content of your file. Please review your selections and use the dropdowns above each column to make any changes, as well as match columns that we were unable to display automatically. Requires a column for both part number and quantity. nine0003

Thank you!

Your application has been sent

Markforged announced tool steel-filled filament

News

Markforged has announced a new filament for 3D printing of metal blanks.

The material contains h23 tool steel filler and is intended primarily for specialized Markforged Metal X 3D printers.

The material contains h23 tool steel filler and is intended primarily for specialized Markforged Metal X 3D printers. Massachusetts-based Markforged has made a name for itself with the first-of-its-kind FDM 3D printers for printing continuous fiber-reinforced polymer parts. Since January last year, the company has added another direction, namely, 3D printing of blanks with polymer-metal filaments. Similar systems are already being offered by rival Desktop Metal, which has fought Markforged in court over intellectual property ownership, although to no avail. Another analogue is offered by the German company Xerion, which presented its system at Formnext 2018.

The process consists of several stages: 3D printing of the blank with a metal-containing filament, removal of the binder polymer with solvents, and then sintering in a muffle furnace. As a result, metal products of high density and fairly precise shape are obtained, requiring only minimal post-processing or not requiring at all, depending on the purpose and shape of the parts, and supports can be removed even before chemical and heat treatment, which greatly simplifies the process.

Markforged already has a filament filled with 17-4 PH stainless steel in its product range, and now the company offers a material based on h23 grade tool steel (similar to 4Kh5MF1S, aka EP572), which is characterized by high wear resistance at low and high temperatures and is used in the production of a press - molds for injection molding, hammer and press inserts, cutting tools and so on. While not the strongest tool steel option, h23 grades can handle heat well and are not prone to thermal fatigue. nine0003

Delivery of h23 steel filament is scheduled for the first quarter of next year. In the near future, the company plans to expand its portfolio with filaments filled with A2 and D2 tool steel, 316L stainless steel, Inconel 625 heat-resistant nickel-chromium alloy, copper and Ti-6Al-4V titanium alloy. Additional information about Markforged offers is available on the company's official website at this link.