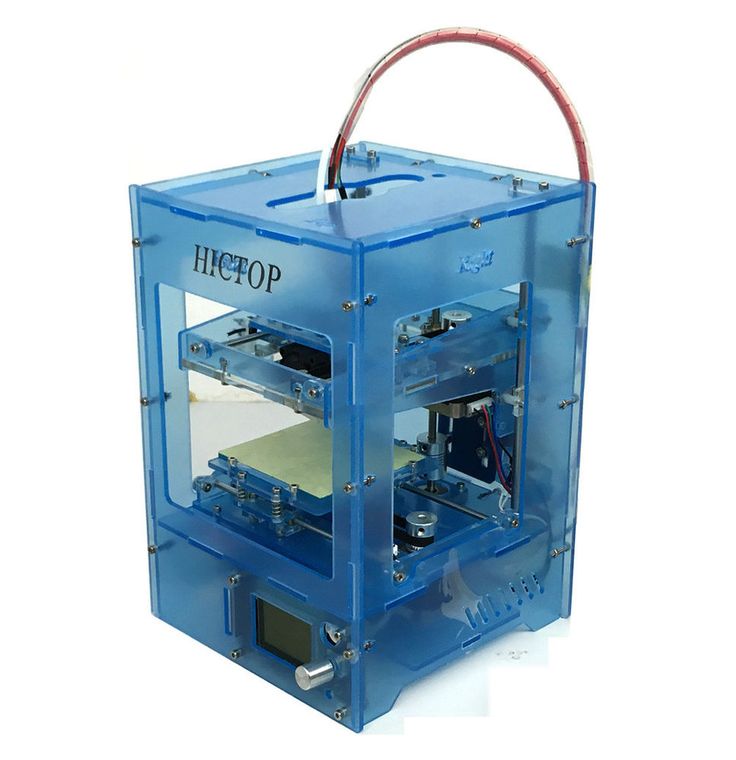

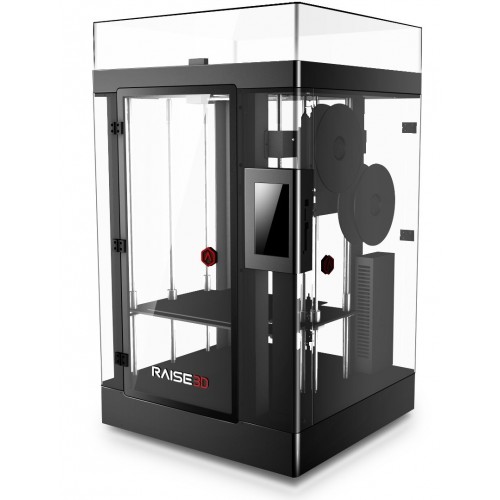

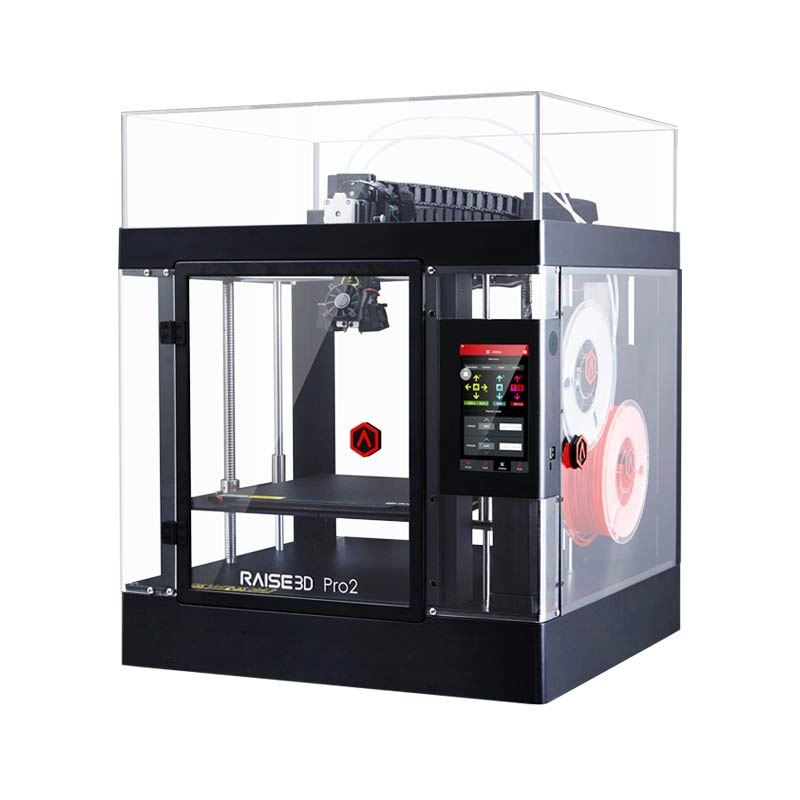

Raise3D pro2 plus dual extruder 3d printer

Dual Extruder 3D Printer | Pro2 Series Starting at $3,999

Dual Extruder 3D Printer | Pro2 Series Starting at $3,999Search for:

Dual Extruder 3D Printers from Raise3D

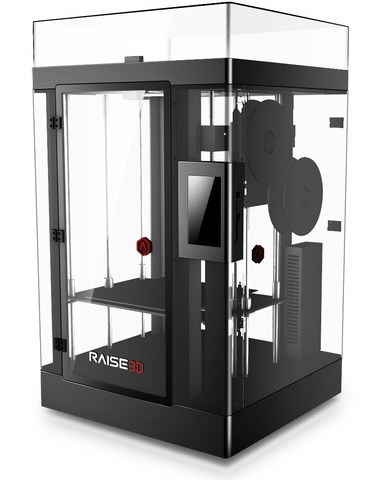

Raise3D’s award-winning Pro2 Series is recognized as a benchmark and gold standard for professional 3D printing applications and 24/ 7 reliability. From Raise3D’s Pro2 Series is the Pro2 and the Pro2 Plus, dual extruder 3D printers with high-resolution, for manufacturing and rapid-prototyping projects of varying sizes.

The Pro2 Series has a metal build plate for even heat distribution, along with a full metal frame for smooth movement and precise positioning, and is compatible with a variety of 3D printing materials. The Pro2 Series is complete with precaution measures to save work, a 7-inch touch screen for efficient monitoring of the 3D printing process, and a HEPA air filter. As with all 3D printers from Raise3D, the Pro2 Series can pair with: ideaMaker, a 3D slicer software, ideaMaker Library, a platform for sharing 3D printer files with those in the Raise3D community, and RaiseCloud, a cloud-based 3D printing management platform. Finally, as with all Raise3D products, the Pro2 Series is both ISO 9001 and ISO 14001 certified.

Raise3D’s award-winning Pro2 Series is recognized as a benchmark and gold standard for professional 3D printing applications and 24/ 7 reliability.

CertificationsThe Pro2 Series is CE, CB, RoHS and FCC certified.

Please visit here for the details of each certificate.

Printer DetailsThe Pro2 dual extruder 3D printer can print up to 12 x 12 x 11.8 inch | 305 x 305 x 300 mm. The Pro2 Plus 3D printer can print up to 12 x 12 x 23.8 inch | 305 x 305 x 605 mm.

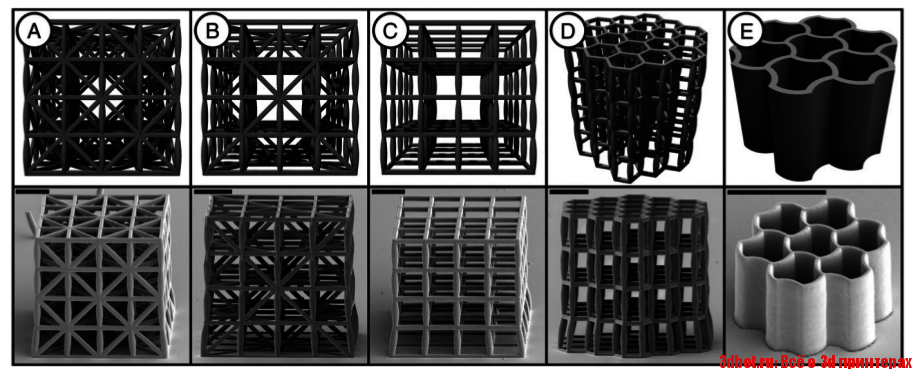

This flexibility allows the Pro2 Series to produce various kinds of tools, parts, and components. Some uses for 3D printers with this kind of build volume is in creating 3D printed tools to make professional manufacturing and rapid-prototyping more efficient.

Some uses for 3D printers with this kind of build volume is in creating 3D printed tools to make professional manufacturing and rapid-prototyping more efficient.

Download spec table

What is a dual extruder 3D printer?A dual extruder 3D printer can produce 3D printed objects with different kinds of 3D printing materials (also known as filaments) and colors within a single print job.

What are the dual extruders for?Dual extruders enable the 3D printer to produce objects with multiple filaments, such as a water-soluble 3D printing material, and multiple colors.

Technical DetailsHigh repeatability

Lightning speed

1.5 mm lifting distance

Compatible with flexible filamentsWhy is high repeatability good for a 3D printer? What does high reliability mean?

3D printing is a process where an object is built up by thin layers. The 3D printer needs to move back and forth along the length of the model to create those thin layers. If the printer loses its position during that back-and-forth motion, the 3D printing process will no longer be aligned, and the 3D printed object will be ruined. The high repeatability and reliability ensure the printer does not become misaligned during the back-and-forth movements.

The 3D printer needs to move back and forth along the length of the model to create those thin layers. If the printer loses its position during that back-and-forth motion, the 3D printing process will no longer be aligned, and the 3D printed object will be ruined. The high repeatability and reliability ensure the printer does not become misaligned during the back-and-forth movements.

What does lightning speed mean?

Lightning speed refers to the overall amount of time the 3D printer takes to print an object. However, this speed is heavily influenced by the type of project being printed and how quickly the printer can switch directions during the back-and-forth movement. Having a <1 second switch time means the Pro2 Series can change directions while printing an object. This shortens the overall time needed to complete a 3D printing process. Keep in mind, the general time savings will still be influenced by the project type.

Why is a 1. 5 mm lifting distance beneficial to a 3D printer?

5 mm lifting distance beneficial to a 3D printer?

Lifting distance refers to the clearance between the idle printing nozzle and the object being printed. There needs to be some distance between both to ensure the printer’s nozzle does not interfere with the printing. The 1.5 mm lifting distance on the Pro2 Series maintains enough distance between the idle nozzle and the model to not affect the printing process.

Capable of Printing a Variety of Filaments Up to 300℃PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Buy Filaments

Material Compatibility Metal Build Plate HEPA Air Filter Touch Screen & Software Monitoring Precaution Measures Full Metal Frame

The Pro2 Series is compatible with a variety of 3D printing materials (known as filaments) to meet project requirementsDepending on the project goals, more than one 3D printing filament is necessary to accommodate varying structural or functional requirements (some such requirements include flexibility, and strength). Sometimes multiple filaments are required within the same print job. Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs multiple filaments.

Sometimes multiple filaments are required within the same print job. Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs multiple filaments.

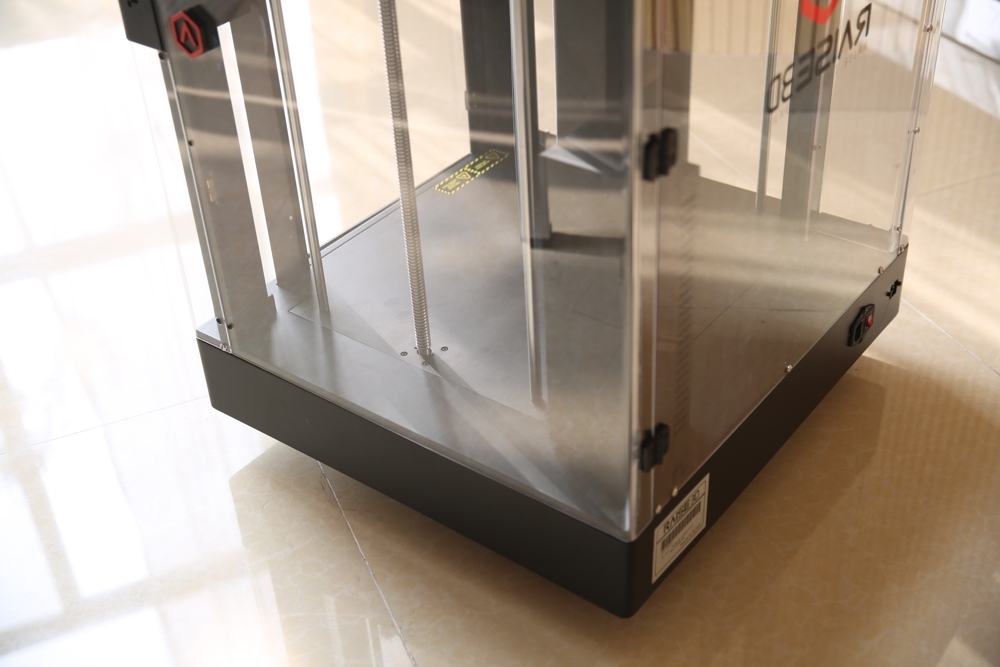

The build plate is a heated, flat surface in every 3D printer where all projects are printed. An even heat surface on a build plate is crucial for creating high-quality 3D printed parts. It also ensures that all 3D printing filaments are not damaged due to unequal heat distribution.

HEPA air filtration removes toxic particles released during the 3D printing processThe Pro2 Series has HEPA air filtration to clean the air of any particles (including nano-particles) released during the 3D printing process. The HEPA air filter works effectively in classrooms, offices, and in large and small workspaces. The Pro2 Series’ HEPA air filtration operates silently, designed to work quietly in the background of any workspace.

The Pro2 Series’ HEPA air filtration operates silently, designed to work quietly in the background of any workspace.

The Pro2 Series’ 7-inch touch screens allow users to interact with the printer directly. It also provides on-screen assistance and visual model selections to simplify operating and monitoring the 3D printer and 3D printing process. As with all Raise3D 3D printers, the Pro2 Series is compatible with ideaMaker, a 3D slicing software, and RaiseCloud, a cloud-based 3D printing management platform. This wireless connection allows users to keep track of every print job while on the move.

Precaution measures are installed to save work in case the 3D printing material runs out or if there is a power outagePower loss can cancel and ruin an ongoing 3D printing project. However, the Pro2 Series’ power loss secures the 3D printing process in an unexpected power outage. In addition, the filament run-out sensor on the Pro2 Series extruders prevents ruined print jobs due to running out of filament.

In addition, the filament run-out sensor on the Pro2 Series extruders prevents ruined print jobs due to running out of filament.

High-quality 3D printing comes from high-quality 3D printers. The Pro2 Series uses a full metal frame to create a specific motion system that allows the machine to smoothly glide as it prints. This motion system works with precise positioning to ensure 3D print jobs are as accurate as possible. Interchangeable nozzles allow the Pro2 Series to print at different levels of detail.

Raise3D EcosystemPair ideaMaker and RaiseCloud with any of our 3D printers to create a Raise3D ecosystem for the best efficiency when 3D printing.

ideaMakerideaMaker is a free 3D slicing software from Raise3D, compatible with Raise3D printers and third-party printers.

Learn More

RaiseCloudRaiseCloud is a cloud-based 3D printing management platform capable of remotely monitoring the printing process and organizing print jobs for more efficient 3D printing.

Learn More

ideaMaker LibraryideaMaker Library provides users with slicing profiles for various filaments, including Raise3D filaments and OFP certified filaments, simplifying the settings of printing parameters for different filaments.

Learn More

Raise3D AcademyAccess Raise3D Academy for step-by-step guides and “how-to” articles, covering topics ranging from setting up and giving maintenance to the 3D printer to performing 3D printing.

Learn More

Raise3D SupportContact Raise3D’s Support Center with any questions regarding a specific printer.

Learn More

Pro2 Series Technical Specifications

DownloadPro2

Pro2 Plus

GENERAL

Build Volume (W × D × H)

Single Extrusion Print: 12 × 12 × 11.8 inch/ 305 × 305 × 300 mm

Dual Extrusion Print: 11 × 12 × 11.8 inch/ 280 × 305 × 300 mm

Single Extrusion Print: 12 × 12 × 23.8 inch/ 305 × 305 × 605 mm

Dual Extrusion Print: 11 × 12 × 23.8 inch/ 280 × 305 × 605 mm

Machine Size (W × D × H)

24.4 × 23.2 × 29.9 inch/ 620 × 590 × 760 mm

24.4 × 23.2 × 43.5 inch/ 620 × 590 × 1105 mm

Print Technology

FFF

Print Head System

Dual-head with electronic lifting system

Filament Diameter

1. 75 mm

75 mm

XYZ Step Size

0.78125, 0.78125, 0.078125 micron

Print Head Travel Speed

30–150 mm/s

Build Plate

Heated aluminum build plate with magnetic holding

Max Build Plate Temperature

110ºC

Heated Bed Material

Silicone

Build Plate Leveling

Pre-calibrated leveling

Filament Run-out Sensor

Available

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Layer Height

0. 01-0.25mm

01-0.25mm

Nozzle Diameter

0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available)

Max Nozzle Temperature

300ºC

Connectivity

Wi-Fi, LAN, USB port, Live camera

Noise Emission (Acoustic)

<50 dB(A) when building

Operating Ambient Temperature

15-30ºC, 10-90% RH non-condensing

Storage Temperature

-25℃ to +55℃, 10-90% RH non-condensing

Filter

HEPA filter with activated charcoal

Technical Certifications

CB, CE, FCC, RoHS

Net Weight

50. 2 kg

2 kg

59.3 kg

Gross Weight (Carton Only)

62.7 kg

71.8 kg

Gross Weight (Carton with Pallet)

70.5 kg

79.6 kg

ELECTRICAL

Power Supply Input

100-240 V AC, 50/ 60 Hz 230 V @ 3.3 A

Power Supply Output

24 V DC, 600 W

SOFTWARE

Slicing Software

ideaMaker

Supported File Types

STL/ OBJ/ 3MF/ OLTP

Supported OS

WINDOWS/ macOS/ Linux

Machine Code Type

GCODE

PRINTER CONTROLLER

User Interface

7-inch Touch Screen

Network

Wi-Fi, Ethernet

Power Loss Recovery

Available

Screen Resolution

1024 × 600

Motion Controller

Atmel ARM Cortex M7. 400 MHZ FPU

400 MHZ FPU

Logic Controller

NXP i.MX6, Quad core 1 GHz ARM processor

Memory

1 GB

Onboard Flash

16 GB

OS

Embedded Linux

Ports

USB 2.0 × 2, Ethernet × 1

Professional Dual Extruder 3D Printer for Everyone

Professional Dual Extruder 3D Printer for EveryoneSearch for:

Agile Production Made Simple

Forged from the Pro2 Series, Raise3D’s newly launched Pro3 Series professional dual extruder 3D printers meet the needs of both production and multi-sized rapid prototyping, with high precision and round-the-clock stable operation. The Pro3 Series is comprised of the Pro3, with a build volume of 300x300x300mm, and the Pro3 Plus, with a build volume of 300x300x605mm, fulfilling the requirements of large-scale production and multi-sized rapid prototyping. A high-quality printer design that includes enhanced features and a smart assistant system known as EVE, all of which make the Pro3 Series dual extruder 3D printers an excellent option for professional 3D printing.

A high-quality printer design that includes enhanced features and a smart assistant system known as EVE, all of which make the Pro3 Series dual extruder 3D printers an excellent option for professional 3D printing.

The Pro3 Series dual extruder 3D printers connect with Raise3D’s 3D printing software ecosystem, that includes a 3D slicing program, ideaMaker, an open-software template called ideaMaker Library, and our cloud-based 3D printing software RaiseCloud.

Pro3: Starting at €4,749.00 Pro3 Plus: Starting at €6,249.00 Pro3: Starting at $5,599.00 Pro3 Plus: Starting at $7,599.00 Enhanced Printing Platform FeaturesThe Pro3 Series features upgraded printing platform features for high-quality printing performance and a better overall experience.

- The auto bed leveling makes setting up a 3D printer quicker and simpler.

- The flexible build plate allows for the effortless removal of 3D printed parts.

- The Z-axis rod stiffness increased by 75% to deliver a more stable performance.

These structural changes enable the Pro3 Series to provide better print results and an easier printing experience.

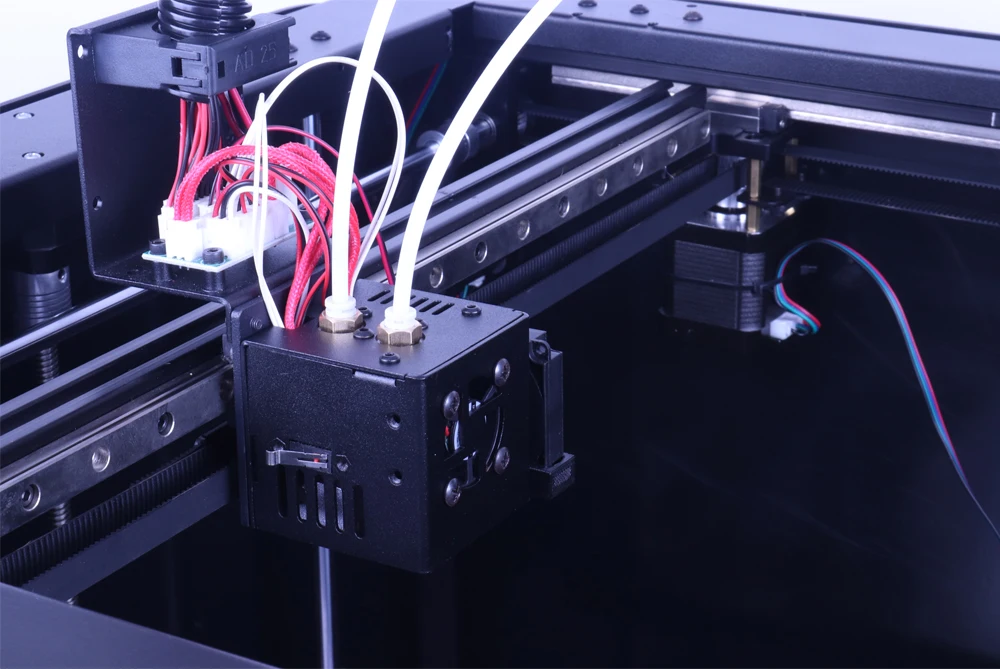

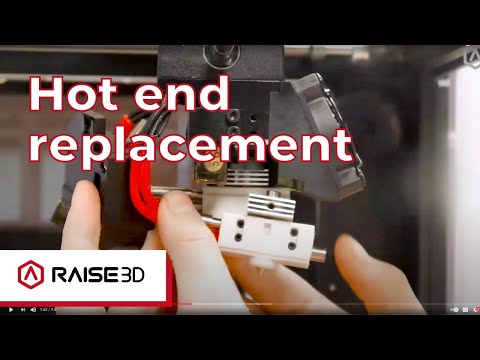

Interchangeable Hot End and Extruder CoverThe Pro3 Series is equipped with an independent modular extruder with a dual extrusion system. This allows the Pro3 Series to print using a variety of filaments, reduce clogging, and allow the convenient disassembly and replacement of components. The hot end of the Pro3 Series is easy to remove, which can be done without using tools, making it simple to replace and maintain. Users can also easily take off the front cover of the extruder to accurately locate common printing occurrences such as filament jams.

Air Flow Manager for Better Heat DissipationThe Air Flow Manager of the Pro3 Series is located on the back of the printer, improving heat dissipation and air circulation, creating a stable environment inside the print chamber. Equipped with a HEPA air filter, Air Flow Manager can also filter and clean the air inside the chamber.

Equipped with a HEPA air filter, Air Flow Manager can also filter and clean the air inside the chamber.

The Pro3 Series has a built-in EVE assistant system, preloaded with common printing problems and corresponding solutions. The EVE assistant can guide users to accurately locate and resolve issues that could affect the final print job. The EVE assistant has a function that gives users reminders about regular scheduled interventions to ensure that printer maintenance is performed on time. It also helps reduce maintenance time and communication costs for an efficient maintenance process.

Professional Dual Extruder 3D PrintersA dual extruder 3D printer can perform more advanced functions such as producing dual color models and dual material models. A professional dual extruder 3D printer will have additional design features resulting in a higher quality print job.

The Pro3 Series professional dual extruder 3D printers have a single-side nozzle lifting technology with fast nozzle switching. Therefore, the nozzles can lift independently and switch within a second, and without being affected by 3D printing material or temperature.

Therefore, the nozzles can lift independently and switch within a second, and without being affected by 3D printing material or temperature.

High repeatability

Lightning speed

1.5 mm lifting distance

Compatible with flexible filamentsWhy is high repeatability good for a 3D printer? What does high reliability mean?

3D printing is a process where an object is built up by thin layers. The 3D printer needs to move back and forth along the length of the model to create those thin layers. If the printer loses its position during that back-and-forth motion, the 3D printing process will no longer be aligned, and the 3D printed object will be ruined. The high repeatability and reliability ensure the printer does not become misaligned during the back-and-forth movements.

What does lightning speed mean?

Lightning speed refers to the overall amount of time the 3D printer takes to print an object. However, this speed is heavily influenced by the type of project being printed and how quickly the printer can switch directions during the back-and-forth movement. Having a <1 second switch time means the Pro3 Series can change directions while printing an object. This shortens the overall time needed to complete a 3D printing process. Keep in mind, the general time savings will still be influenced by the project type.

Why is a 1.5 mm lifting distance beneficial to a 3D printer?

Lifting distance refers to the clearance between the idle printing nozzle and the object being printed. There needs to be some distance between both to ensure the printer’s nozzle does not interfere with the printing. The 1.5 mm lifting distance on the Pro3 Series maintains enough distance between the idle nozzle and the model to not affect the printing process.

User Friendly Features

Lightweight Cable with Digital Temperature Measurement

The Pro3 Series replaces the drag chain cable with a lightweight cable, to reduce the weight of the extruder and keep the center of gravity in the middle during printing for more stable print quality.The Pro3 Series also uses digital temperature measurement, for an accurate temperature reading to help prevent jamming.

The importance of Auto Bed LevelingBed leveling is the process of confirming that the printing platform is as level as possible. The Pro3 Series has this leveling procedure as an automated function. Auto bed leveling will maintain the distance between the print nozzles and the bed, to create a uniform build area. This improves bed adhesion and allows the nozzle to adjust to even the most minor surface contour changes.

Live Monitoring HD Camera

The Pro3 Series uses a HD camera to monitor the entire 3D printing process of every print job. This camera operates by connecting to RaiseCloud, allowing users to keep track of every print job remotely and while on the move. This ability to check the 3D printing process gives peace of mind. The Pro3 Series also comes with an upgraded CMOS sensor to ensure better image quality.

This camera operates by connecting to RaiseCloud, allowing users to keep track of every print job remotely and while on the move. This ability to check the 3D printing process gives peace of mind. The Pro3 Series also comes with an upgraded CMOS sensor to ensure better image quality.

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Buy Filaments

Safety Features

Power Loss Recovery

Either a power outage or a filament outage (when the filament runs out) can cause a print job to be lost if they occur in the middle of the 3D printing process. However, the Pro3 Series has a filament run-out sensor on its extruders to alert when the filament is about to run out and saves the print job. It also has a second-generation power loss function to save the printing status in the event of a power outage and can continue printing from the same point when power is restored.

Another safety feature of the Pro3 Series is that it can automatically detect when a door is opened and will immediately pause the print.

Material Compatibility Flexible Build Plate HEPA Air Filter Touch Screen & Software Monitoring Full Metal Frame

The Pro3 Series is compatible with a variety of 3D printing materials (known as filaments) to meet project requirementsDepending on the project goals, more than one 3D printing filament is necessary to accommodate varying structural or functional requirements (for example, some requirements may include flexibility, and strength). Sometimes multiple filaments are required within the same print job. Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs requiring multiple filaments, giving it extra versatility other printers cannot match.

Having a 3D printer that is compatible with different filament types is both cost-saving and practical for print jobs requiring multiple filaments, giving it extra versatility other printers cannot match.

The Pro3 Series is equipped with flexible build plate. The flexible build plate can be used to easily remove printed parts while minimizing potential damage to the final print. Additionally, the flexible build plate can quickly regain its shape and return to printing quickly. The Pro3 Series is also compatible with a rigid build plate, as well as a high-temperature borosilicate glass build plate.

The updated HEPA air filtration removes toxic particles released during the 3D printing processThe Pro3 Series uses HEPA air filtration to clean the air of any particles (including nano-particles) released during the 3D printing process. The HEPA air filter works effectively in classrooms, offices, and in large and small workspaces and operates silently, quietly working in the background of any work area.

The Pro3 Series’ 7-inch touch screens allow users to interact with the printer directly. It also provides on-screen assistance and visual model selections to simplify operating and monitoring both the 3D printer and 3D printing process. As with all Raise3D 3D printers, the Pro3 Series is compatible with ideaMaker, a 3D slicing program, and RaiseCloud, a cloud-based 3D printing management platform. This wireless connection allows users to keep track of every print job while on the move.

The full metal frame acts as a reliable motion system for smooth movement and precise positioning for higher quality printingHigh-quality 3D printing comes from high-quality 3D printers. The Pro3 Series professional dual extruder 3D printer uses a full metal frame to create a specific motion system that allows the machine to smoothly glide as it prints. This motion system works with precise positioning to ensure 3D print jobs are as accurate as possible. Interchangeable nozzles allow the Pro3 to print at different levels of detail.

This motion system works with precise positioning to ensure 3D print jobs are as accurate as possible. Interchangeable nozzles allow the Pro3 to print at different levels of detail.

Print Results

Check out the Pro3 Series’ print performance from different aspects.

Flatness and Smoothness

Overhang Structure

Geometry Accuracy

Raise3D EcosystemPair ideaMaker and RaiseCloud with any of our 3D printers to create a Raise3D ecosystem for the best efficiency when 3D printing.

ideaMakerideaMaker is a free 3D slicing software from Raise3D, compatible with Raise3D printers and third-party printers.

Learn More

RaiseCloudRaiseCloud is a cloud-based 3D printing management platform capable of remotely monitoring the printing process and organizing print jobs for more efficient 3D printing.

Learn More

ideaMaker LibraryideaMaker Library provides users with slicing profiles for various filaments, including Raise3D filaments and OFP certified filaments, simplifying the settings of printing parameters for different filaments.

Learn More

Raise3D AcademyAccess Raise3D Academy for step-by-step guides and “how-to” articles, covering topics ranging from setting up and giving maintenance to the 3D printer to performing 3D printing.

Learn More

Raise3D SupportContact Raise3D’s Support Center with any questions regarding a specific printer.

Learn More

Pro3 Series Technical Specifications

DownloadPro3

Pro3 Plus

GENERAL

Build Volume (W × D × H)

Single Extruder Print: 11.8 × 11.8 × 11.8 inch/ 300 × 300 × 300 mm

Dual Extruder Print: 10 × 11.8 × 11.8 inch/ 255 × 300 × 300 mm

Single Extruder Print: 11.8 × 11.8 × 23.8 inch/ 300 × 300 × 605 mm

Dual Extruder Print: 10 × 11.8 × 23.8 inch/ 255 × 300 × 605 mm

Machine Size (W × D × H)

24.4 × 24.6 × 29.9 inch/ 620 × 626 × 760 mm

24.4 × 24.6 × 43.5 inch/ 620 × 626 × 1105 mm

Print Technology

FFF

Print Head System

Dual-head with electronic lifting system

Filament Diameter

1. 75 mm

75 mm

XYZ Step Size

0.78125, 0.78125, 0.078125 micron

Print Head Travel Speed

30–150 mm/s

Build Plate

Flexible Steel Plate with Buildtak

Max Build Plate Temperature

120ºC

Heated Bed Material

Silicone

Build Plate Leveling

Mesh-leveling with Flatness Detection

Filament Run-out Sensor

Available

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/

Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Layer Height

0. 01–0.25 mm

01–0.25 mm

Nozzle Diameter

0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available)

Max Nozzle Temperature

300ºC

Connectivity

Wi-Fi, LAN, USB port, Live camera

Noise Emission (Acoustic)

<55 dB(A) when building

Operating Ambient Temperature

15-30ºC, 10-90% RH non-condensing

Storage Temperature

-25℃ to +55℃, 10-90% RH non-condensing

Filter

HEPA filter with activated charcoal

EVE Smart Assistant

Available

Net Weight

49 kg

61. 6 kg

6 kg

Gross Weight (Carton Only)

67 kg

80 kg

Gross Weight (Carton with Pallet)

75 kg

88 kg

ELECTRICAL

Power Supply Input

100-240 V AC, 50/ 60 Hz 230 V @ 3.3 A

Power Supply Output

24 V DC, 600 W

SOFTWARE

Slicing Software

ideaMaker

Supported File Types

STL/ OBJ/ 3MF/ OLTP

Supported OS

WINDOWS/ macOS/ Linux

Machine Code Type

GCODE

PRINTER CONTROLLER

User Interface

7-inch Touch Screen

Network

Wi-Fi, Ethernet

Power Loss Recovery

Available

Screen Resolution

1024 × 600

Motion Controller

Atmel ARM Cortex-M4 120 MHz FPU

Logic Controller

NXP ARM Cortex-A9 Quad 1 GHz

Memory

1 GB

Onboard Flash

16 GB

OS

Embedded Linux

Ports

USB 2. 0 × 2, Ethernet × 1

0 × 2, Ethernet × 1

Raise 3D Pro2 Plus

New Pro2 Series 3D Printers

Features and Benefits - Raise3D Pro2 Plus

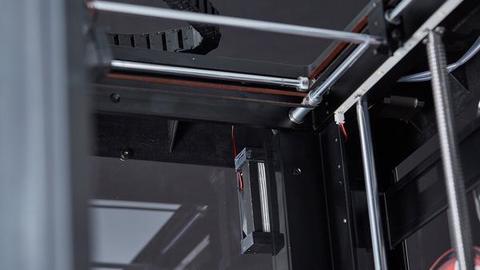

Dual extruder with electronic lift

Prints even the most complex projects. Faster printing. Prints with various materials.

Reprint Accuracy (Incredibly fast switching between extruders (1.5mm lift height.

Over 100,000 reliability tests.

When Just a Large Print Area Isn't Enough

Reliability 24/7 thanks to high-strength aluminum frame.

Large range of materials

by heating up to 300℃

PLA / ABS / HIPS / PC / TPU / NYLON / TPE / FLEX / PETG / BRONZE / WOOD / CARBON

A high resolution

Sophisticated mechanics for superior print quality and model detail.

Unsurpassed layer resolution

Layer thickness 0.01 mm

Replacement nozzles

0.2 mm nozzle for high detail

Precise positioning

0.0125 mm X/Y positioning

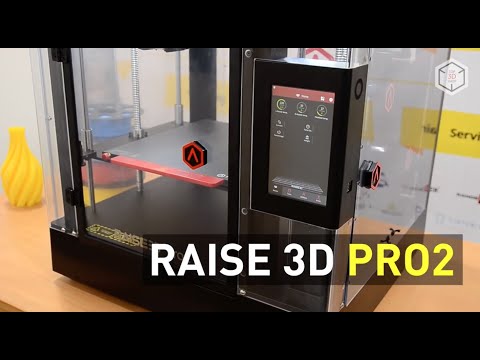

Unique user interface

7-inch touch screen

Visual interface / Quick view / Visual display of the printing process / Full control of all printing parameters

Next Generation Resume System

You will never lose your print results.

“I accidentally unplugged the printer while I was vacuuming the room. At that time, the model had already been printed for 96 hours, there were only 2 hours of printing left.

When I saw this, I was ready to scream in horror, but turned the printer back on and he offered to continue printing. Raise3D literally saved me!”

Sean Robinson

Wireless management and printing

Work more efficiently with ideaMaker by wirelessly connecting to your Pro 2 printer

New generation position control device

High reliability. Precise current control. Smooth movements. Perfect thermal insulation properties.

Precise current control. Smooth movements. Perfect thermal insulation properties.

400MHz ARM Cortex-M7 32bit RISC FPU.

Industrial grade components.

Autonomous motor driver.

Control system with 256 micro steps.

New extruder with filament end sensor

Better thread grip. No slippage. More reliable printing.

Double driven.

4 times the performance.

Smooth and sensitive optical filament end sensor.

New air filter

Environmentally friendly.

The silent protector of your health.

Absorbs >91% of harmful particles

New platform

Good adhesion.

Uniform heating.

Longer service life.

Sturdy and easy to use.

Modern materials.

Silicone table warmer.

Aluminum platform with magnetic holders.

Improved 4+9 table attachment system. Raise3D Pro2 Plus 3D printer Go

Free shipping within Russia

577 000 ₽

Additional services

Unpacking, setup, first run

7 000 ₽

- — Departure of the master

- - Start-up and adjustment

- - Preparing to print

- - Installing Printing Software

- – Software usability consulting

- - Training in the use of

Departure of the master in Moscow,

for other cities - online consultation.

Exchange of old equipment for a new one with a surcharge. Detailed information is available on the page or from our managers.

Official distributor

We work directly with manufacturers.

Any form of payment

An opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When buying a 3D printer from us,

you get a 10% discount on all consumables.

The new Raise3D Pro2 Plus 3D printer models are ideal for low volume production and 3D printed farms. But they are also suitable for use in companies that seek to optimize and reduce the cost of the production process through 3D printing of prototypes, mockups, master models and other products.

But they are also suitable for use in companies that seek to optimize and reduce the cost of the production process through 3D printing of prototypes, mockups, master models and other products.

Pro2 Plus printers are similar in appearance to their predecessors Raise3D N-series, but they are distinguished by a number of design differences and improvements.

Key features and benefits of 3D printers

- More accurate printing

Excellent quality and detail thanks to sophisticated kinematics and interchangeable nozzles with different diameters.

For the highest detail, a nozzle with a diameter of 0.2 mm is suitable.

The minimum layer thickness is 0.01 mm.

The X/Y positioning accuracy is 0.78125 microns.

- Large plot area:

- when printing with 2 extruders: 280×305×605 mm

- when printing with 1st extruder: 305×305×605 mm

- Wide range of materials (due to extruder heating up to 300℃): PLA / ABS / HIPS / PC / TPU / NYLON / TPE / FLEX / PETG / BRONZE / WOOD / CARBON

- Dual extruder with electronic lift for more convenient and high-quality printing with two materials at the same time.

Switching between extruders takes less than 1 second. Lift height 1.5 mm.

Switching between extruders takes less than 1 second. Lift height 1.5 mm.

- User friendly interface:

7 inch touch screen with visual full color interface.

Quick preview, full control of all 3D printing parameters and display of the printing process.

- Next Generation Print Resume System - Preserve print results during a power outage.

- Wireless print management via proprietary ideaMaker software. All the most necessary functions for working with the printer.

- Position control with industrial grade components and standalone motor driver (400MHz ARM Cortex-M7 32bit RISC FPU). Control system with 256 micro steps.

- Extruder with optical filament end sensor.

Better filament grip without slippage for more reliable printing.

- Air filter for safe printing.

Absorbs more than 91% of harmful substances.

- Updated platform with advanced materials for long life, even heat distribution and good adhesion.

- Built-in online video camera to control the 3D printing process.

- High quality optical end switches.

| 3D printer | 1 PC |

| Print Platform | 1 PC |

| Reel holder | 2 pcs |

| Tweezers | 1 PC |

| Circuit breakers | 2 pcs |

| Glass in a protective box | 1 PC |

| Hex key set | 1 set |

| Spatula for removing models | 1 PC |

| USB flash drive | 1 PC |

| Coil plastic | 2 pcs |

| screws | spare |

| Heat resistant gloves | 1 pair |

| Nozzle cleaning kit | 1 PC |

| Filament guide tube | 2 pcs. |