Food grade 3d printing service

The Essential Guide to Food Safe 3D Printing

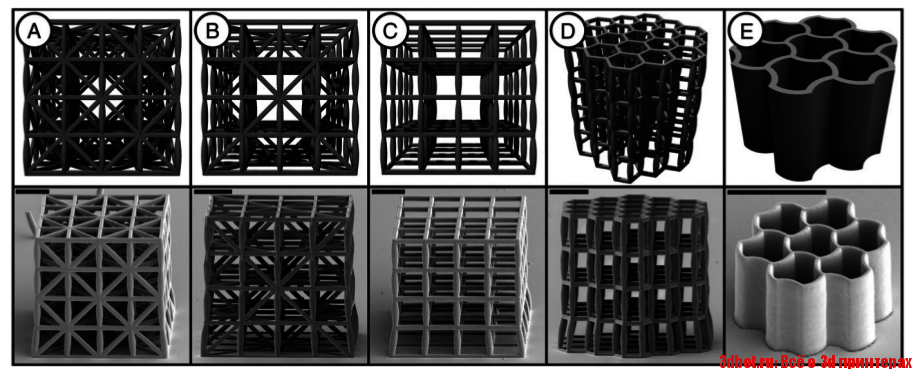

3D printing offers unparalleled design freedom to produce custom parts and complex or organic shapes that would be costly or impossible to manufacture with traditional manufacturing methods.

These benefits can be compelling for a range of food-related applications. However, if 3D printed parts are intended for food contact items, you‘ll have to consider safety practices and regulations to avoid contact with toxic substances and prevent the buildup of harmful bacteria.

Food safe 3D printing is possible and the variety of materials approved as food safe is increasing, but there is a high degree of ambiguity around the workflows and finding the appropriate applicable regulations can be a challenge.

Read on for an introduction to food safety, food safety considerations for 3D printing, and a variety of methods to produce food safe products with common 3D printing processes, including stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS).

Please note

No Formlabs resins are food safe unless users take additional steps.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

To begin, it’s important to clarify a few key terms:

- Food grade means that the material is either safe for human consumption or permitted to come in contact with food.

- Food safe means that a food grade material meets the requirements determined by the intended use and will not create a food-safety hazard.

- Food contact surfaces include any surface that may come into direct contact with food. These surfaces must be made of nontoxic materials and designed to withstand the environment of their intended use, including exposure to cleaning compounds, sanitizing agents, and cleaning procedures.

Food grading and food safety concern a specific way to ingest parts, called migration. Particles as small as a few nanometers and up to several hundred nanometers may get transferred each time various materials encounter with each other, for example from components of the 3D printer to the 3D printed object, and from the object to the food.

Because migration levels are very low on occasional contact, food grading typically concerns items that are in prolonged contact with food such as containers, straws, utensils, plates, and food molds. Different testing institutions will adhere to different government-imposed risk tolerances and approved substances, which for the US is described by the FDA CFR 21 and for the EU in guidelines 10/2011.

Look for these labels indicating FDA and EU approval. Beware that a material being ‘compliant with’ doesn’t mean that it is explicitly approved by the institutions, so always check the technical datasheets for a certificate.

To be considered food safe according to the FDA Food Code, a material has to meet the following requirements:

- No migration of deleterious substances

- Does not impart colors, odors, or tastes

- Safe under normal use conditions

- Durable, corrosion-resistant, and nonabsorbent

- Sufficient in weight to withstand repeated washing

- Finished to have a smooth, easily cleanable surface without breaks and sharp internal angles

- Resistant to pitting, chipping, crazing, scratching, scoring, distortion, and decomposition

- Accessible to inspection

Any FDA or EU approved material includes not only the raw polymer but also the additives or masterbatch. These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

A 3D printed part can turn into a petri dish squirming with bacteria within weeks. Even though some materials will survive the dishwasher, so will dangerous bacteria such as E. coli and salmonella that live in the little nooks and crannies. Some toxic molds find favorable growth conditions on several types of plastic and are hard to remove. Neither cleaning with bleach nor microwaving your polymers is an option for eliminating germs.

While bacteria buildup might not be an issue for disposable items, if you’re planning to create a part for long-term use, using a food safe coating is highly recommended.

The best option to reduce the risk of particle migration and bacteria buildup is by dip coating the 3D printed parts with a food grade epoxy or polyurethane resin, such as Masterbond’s EP42HT-2FG or ArtResin or an FDA approved PTFE (known as Teflon®) to seal their surface.

However, note that coating also doesn’t guarantee food safety for prolonged use as not all of these coatings are dishwasher safe, and they may degrade over time, exposing the original, potentially non-safe surface.

Most 3D printing materials have a low heat deflection temperature (HDT), which means that the 3D printed parts might become brittle and crack, or deform and warp at elevated temperatures. If you’re planning to clean a 3D printed part in a dishwasher, make sure to double check that the material is dishwasher safe and if there are any specific recommendations for washing temperature.

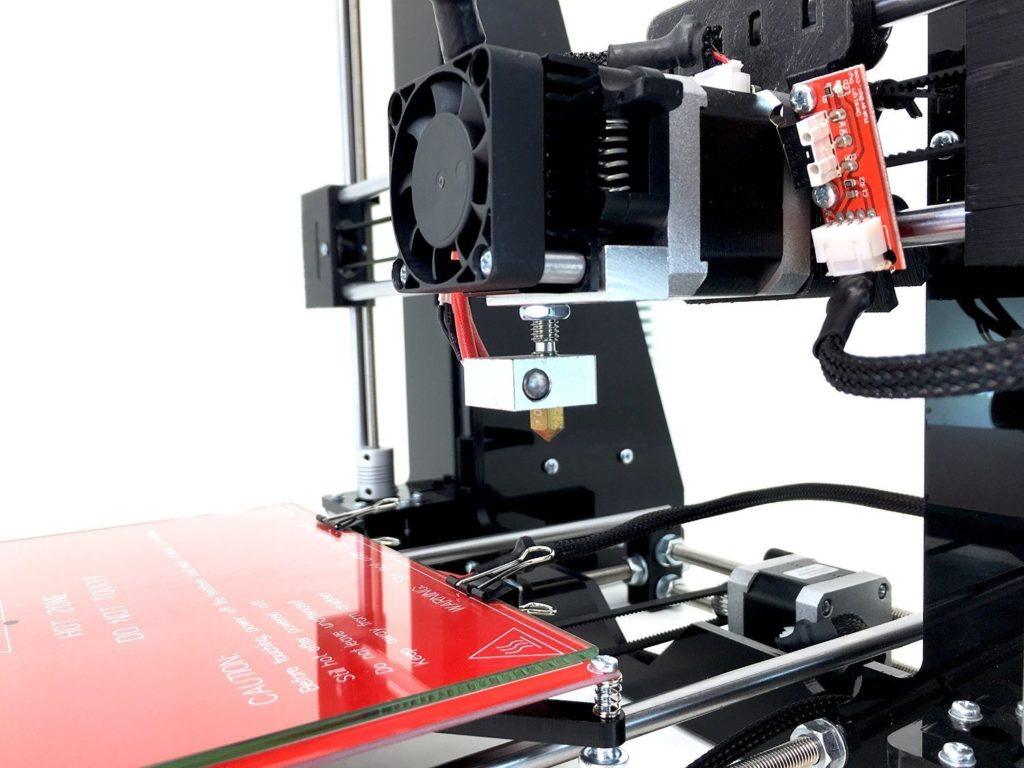

As particles might migrate from components of a 3D printer to 3D printed parts, it is crucial that any components that might come in contact with the 3D printing material or the part are food grade and do not contain or leach harmful chemicals.

This includes taking precautions when using multiple materials, as some materials previously used in the 3D printer might have contained toxic particles and made contact with some components.

Many 3D printing materials are not food safe and might contain toxic chemicals. Only use materials to 3D print parts intended for food contact that are certified for food safety.

As may be expected, the risk of migration is higher if the food is exposed to the 3D printed part for an extended time period. In general, try to limit food contact time and take further precautions for parts that will be in contact with food for longer periods of time.

Think about the reason why you’d like to use 3D printing for a food contact item. If it’s to create custom shapes and forms, in most cases, there are indirect ways to use 3D printing to create these custom parts, for example with molding. See an example in the next section.

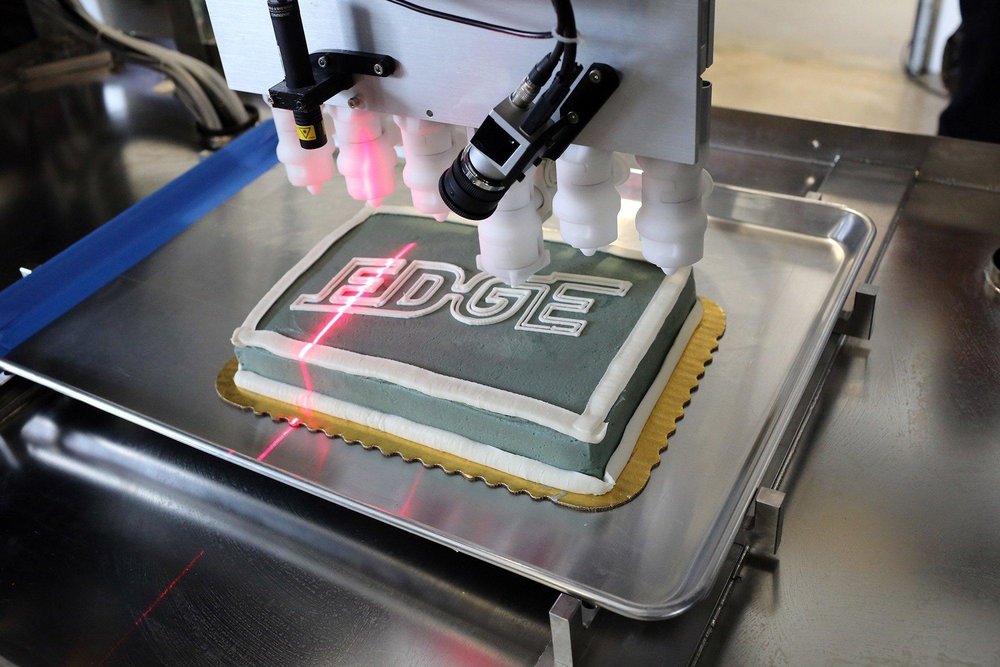

SLA 3D printing uses a laser to cure liquid resin into hardened plastic in a process called photopolymerization, resulting in parts that have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies.

Is resin food safe? The answer is no. Substances may migrate from SLA parts which makes none of the resins and printed parts food safe by default. While some resins for dental and medical applications are certified biocompatible, that doesn’t mean that they’re food safe. These materials are certified for specific applications and should not be used for food contact products.

SLA parts have a smooth surface finish that makes it easier to use coatings to seal their surface and prevent the buildup of bacteria. The factors which affect the ultimate smoothness of a part include resin type, layer thickness, build orientation, mesh triangulation resolution of the 3D model, and the curing profile of the SLA resin. Printed parts require washing and post-curing according to the manufacturer's instructions before the coating is applied. However, note that coatings don’t guarantee food safety, as the coating may interact with the resin or degrade over time, exposing the original, potentially non-safe surface.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Creating custom molds is a common way to leverage the benefits of SLA 3D printing to produce highly detailed custom parts without having the 3D printing parts come into direct contact with food. While SLA 3D prints aren’t suitable for directly molding foods, SLA 3D printers are perfect tools to create mold negatives, which can be vacuum formed using food safe plastic.

The tools and techniques for creating 3D printed food molds are easy to master, and the results are often stunning.

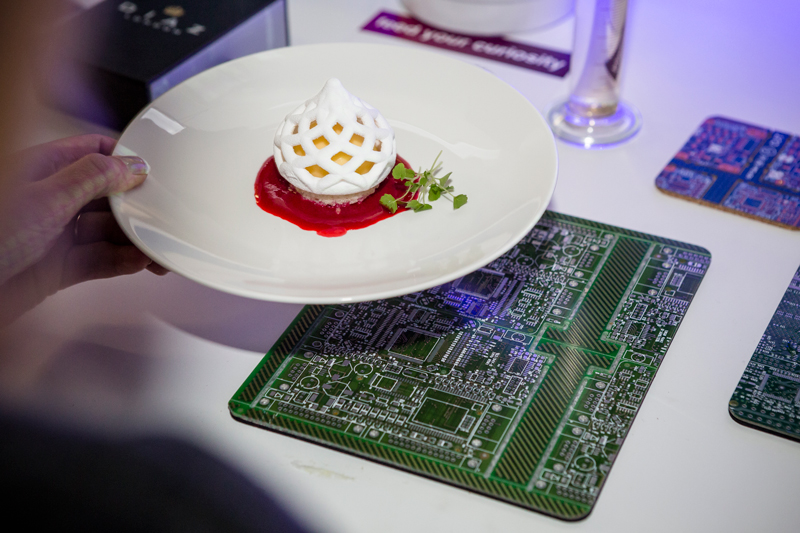

3D printed molds for thermoforming and silicone enabled the creation of unique shapes and designs.

Learn more about creating molds for vacuum forming in our in-depth tutorial.

Electroplating is the process of coating parts with metal using an electric current. The process is most commonly used for decorative purposes or to prevent corrosion by creating a durable surface.

SLA parts are ideal for electroplating due to their smooth surface finish. However, as plastics are nonconductive surfaces, SLA 3D prints have to be rendered conductive by coating with graphite, conductive lacquer, electroless plate, or a vaporized coating.

Food safe metal coatings are available, but as the process involves various chemicals, making sure that the workflow is approved for food contact is the developer’s own liability.

SLA 3D printing offers the unique possibility to produce ceramic parts. After 3D printing, parts can be fired in a kiln to burn out the resin and form a true ceramic part that is strong and heat-resistant. With subsequent food safe glazing, the parts will become more hygienic and resistant to most chemicals.

A variety of food safe glazes are available on the market, but make sure to follow the manufacturer’s instructions in accordance with food safety guidelines.

3D printing in ceramics is ideal for fabricating complex geometries that wouldn’t be possible by hand.

Learn More About Ceramics

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

FDM is a 3D printing process that builds parts by melting and extruding thermoplastic filament, which a print nozzle deposits layer by layer in the build area.

The extruded material is circular in cross-section, which leaves very narrow crevices in between layers with a depth directly proportional to layer height. It is recommended in any case to print at the lowest feasible layer height for food safe parts.

Consequently, the main challenge with FDM parts is avoiding the buildup of bacteria. To be truly food safe in the long term, an FDM 3D print needs to have a smooth surface. Chemical smoothing with solvents like acetone, d-Limonene, or ethyl acetate removes many of the irregularities of the print resulting in a smooth, glossy appearance. However, applying a subsequent food safe coating is still highly recommended.

However, applying a subsequent food safe coating is still highly recommended.

Layers showing on FDM (left) and SLA (right) 3D prints.

Food grade filaments do not contain any composite particles so will not wear down the nozzle into the print. Nevertheless, avoid brass nozzles that contain lead and use a dedicated stainless steel nozzle instead for all food contact items.

Always check the compatibility of your 3D printer’s components with the filament. For example, PEI is a material that is FDA compliant and offers great mechanical benefits but needs to be processed at over 300 °C, which requires a specific printer solution.

The most common questions around FDM food safety concern two popular materials. Is PLA food safe? Is ABS food safe? The answer is, it depends.

Food safe 3D printing filaments include PLA, PP, co-polyester, PET, PET-G, HIPS, and nylon-6, as well as some brands of ABS, ASA, and PEI. Having to run parts through the dishwasher rules out PET, nylon, and PLA because these plastics soften and distort around 60–70 °C. For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

While not reflected in the regulations, some studies suspect that polystyrene may leach styrenes, co-polyesters might cause health concerns and that food grade FDM filaments might lose their safe status due to oxidation and thermal degradation from the printing process.

| Filament | Brand | FDA | EU | Smoothable | Dishwasher safe | Hot liquids |

|---|---|---|---|---|---|---|

| ABS | Adwire PRO | Approved | NA | Yes, acetone | Yes | Yes |

| Innofil3D | Approved except red, orange, and pink | Approved except red, orange, and pink | Yes, acetone | Yes | Yes | |

| ASA | Innofil3D | NA | Compliant | Yes | No | |

| Bendlay | Orbi-Tech | NA | Compliant | Yes, brake cleaner | No | No |

| Biocompound | Extrudr GreenTEC | NA | Compliant | |||

| Co-Polyester | Colorfabb XT | Approved | Compliant | No | Yes | Yes |

| HIPS | Easyfil | Compliant | Compliant | Yes, d-limonene | Yes | No |

| Fillamentum | NA | Compliant | Yes, d-limonene | Yes | No | |

| InnoFil3D | Approved | Approved | Yes, d-limonene | Yes | No | |

| Nylon | Taulman Nylon 680 | Compliant | NA | No | No | |

| PEI | ULTEM® 1000 | Compliant | NA | Yes | Yes | |

| PET | InnoPet EPR | Approved except red and orange | Approved except red and orange | Yes, ethyl acetate | No | No |

| Refil | Approved | NA | Yes, ethyl acetate | No | No | |

| Taulman T-Glase | Approved | NA | Yes, ethyl acetate | No | No | |

| Verbatim | Compliant | NA | Yes, ethyl acetate | No | No | |

| PET-G | Extrudr MF | NA | Approved | Yes, ethyl acetate | No | No |

| HDGlass | Approved | Approved | Yes, ethyl acetate | No | No | |

| PLA | Filaments. ca TrueFS ca TrueFS | Approved | NA | No | No | No |

| Fillamentum | NA | Compliant | No | No | No | |

| Innofil3D | Approved except red, orange, pink, apricot skin, grey, and magenta | Approved except red, orange, pink, apricot skin, grey, and magenta | No | No | No | |

| Copper3D PLActive Antibacterial | Approved | Compliant | No | No | No | |

| Makergeeks | Approved | NA | No | No | No | |

| Purement Antibacterial | Approved | Approved | No | No | No | |

| PLA-HT | Makergeeks Raptor | Approved | NA | No | Yes | Yes |

| Makergeeks Raptor | Approved | NA | No | Yes | Yes | |

| PP | Centaur | Compliant | Compliant | No | Yes | Yes |

| InnoFil3D | Approved | Approved | No | Yes | Yes | |

| Nunus | Compliant | Compliant | No | Yes | Yes | |

| Verbatim | Compliant | NA | No | Yes | Yes | |

| SBS | Filamentarno | NA | Approved only in Russia | Yes, d-limonene | Yes | Yes |

Selective Laser Sintering is a 3D printing process that use a high-powered laser to fuse small particles of polymer powder. The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

While some SLS powders are graded food safe, the particles on the surface of printed parts might not fuse completely, resulting in parts that are inherently porous and do not deal well with moisture and mold growth. Even though the nylon 12 powder can be steam cleaned in an autoclave, it is best to coat SLS parts with food safe coatings to seal their surface.

A common post-processing step for SLS parts is dying. But note that after an SLS part has been dyed, the dye may leach into the printed part which renders the item not food safe.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Food safety with 3D printing is not a simple matter that will boil down to a clear yes or no answer. Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

For further information on food safety and 3D printing, we recommend reading the following:

- FDA Regulations CFR 21

- EU Guidelines 10/2011

- Risk Assessment of 3D Printers and 3D Printed Products

- The Tricky Business of Choosing Plastic for Food Contact Applications

Need Food-Grade 3D Printing - 3D Printing - Talk Manufacturing

neal_white_18

#1

Hello,

I work for a nutritional company and we need ingredient scoops of differing sizes, anywhere from 3ml to 30ml. We are wondering if there are any food-grade options for 3D printing. It seems after looking into PLA and ABS that neither are sufficient for our needs, but we could be wrong (since we’re novices at 3D printing!) Any information would be of great help.

Thank you,

Neal

3 Likes

Pot8oSh4D

#2

Hi Neal,

Colorfabb’s XT- Copolyester is FDA food-contact compliant. Is that good enough?

If not, I thik you’ll find something suitable from Taulman.

Cheers!

Andy

neal_white_18

#3

Thank you for the reply, Andy. That is what we were looking for. Now, is it safe to assume that the majority of 3D printers can use this material to print, or are only certain printers able to handle this type of material?

Thanks!

Neal

AtomJaay

#4

It is my understanding that it is not the toxicity of filament that is the concern, but more the surface finish. A food grade surface cannot be attained even with smoothing methods post print. If you go 100x magnification, you’d see pits and holes which offers a breeding ground for bacteria and cannot be sufficiently cleaned. The standard alternative to apply 3d printing to food safe products is to produce a 3D printed mould to make food safe silicone parts.

A food grade surface cannot be attained even with smoothing methods post print. If you go 100x magnification, you’d see pits and holes which offers a breeding ground for bacteria and cannot be sufficiently cleaned. The standard alternative to apply 3d printing to food safe products is to produce a 3D printed mould to make food safe silicone parts.

Hope that’s helpful.

RobertPaul

#5

Taulman melts at a higher temperature, so you’re not going to want a printer that is lined with ptfe (teflon) for several reasons; you’re going to want an all-metal hotend. Most hotends have ptfe lining. First off it’s toxic, and at the taulman melting range you might be reaching the ptfe melting range. Even if you don’t reach the ptfe melting range you will be degrading the ptfe as you get near it, and the closer you get to it the more likely you’ll get clogs if you’ll be able to print at all.

Pot8oSh4D

#6

Well, there you go, Neal. All kinds of issues and opinions thrown up there!

From my point-of-view, I’d be happy to use a 3D printed container for serving chips at a party. Probably not the dip and certainly not for cutlery and whatever the case, I wouldn’t expect to reuse any of it. As for what I’d be happy printing for a client, that’s a whole different picture.

neal_white_18

#7

Thank you all for your help. It seems that regardless of the material or the printing process we will still run into the cleaning issue. Ideally we would want to reuse these scoops hundreds of times per week, but if we can’t clean them properly they will grow bacteria and eventually contaminate our ingredients, damn!

Ideally we would want to reuse these scoops hundreds of times per week, but if we can’t clean them properly they will grow bacteria and eventually contaminate our ingredients, damn!

Well thanks everyone again. I am open to suggestions if anyone has any with regard to creating what we need! If anyone has any resources for creating silicon parts that would be great!

James_2

#8

I think there is too much worry about what is and is not food safe - the material, the process and the use do need to be considered - XT is styrene free and FDA for food contact (you can also put it in the dishwasher.)

Most printers use brass nozzles which CAN have a small amount of lead in them (2%) but wheather any of this would enter the product - and whether this would be for dry food use or not etc etc.

As to the porosity - well I eat of paper plates and wood spoons - unlikely i would re-use them, but if they are dry when I use them then they are unlikely to cause a problem. Most kitchen have wooden spoons that are washed at below sterile temps with washing up liquid.

So it depends what your actual requirements are. i would not necessarily implant PLA but i would happily eat off it! (once) and would use XT happily if it had been washed.

Some of the all metal hot ends might be steel - but you have to knowwhat has been fed through the nozzle first!

James

James_2

#9

oh, and you could print sample and then cast in a food safe silicone and plastic resin.

James

Alex3DHubs

#10

Hey Neal,

There are some alternative filaments that are close to ‘Food Grade’ safe, such as Madesolid’s PET filament. PET being the material that plastic waterbottles are made out of. Here’s a link;

PET being the material that plastic waterbottles are made out of. Here’s a link;

http://shop.madesolid.com/products/madesolid-strong-filament-1-75mm-1-lbs

The problem with ‘Food Grade’ safe and 3D printed objects is that bacteria can easily live in the non-smooth surfaces, making it dangerous. It would take a fair bit of finishing before the object would truely be food grade safe. Hope this was helpful.

Alex

GeniusIE

#11

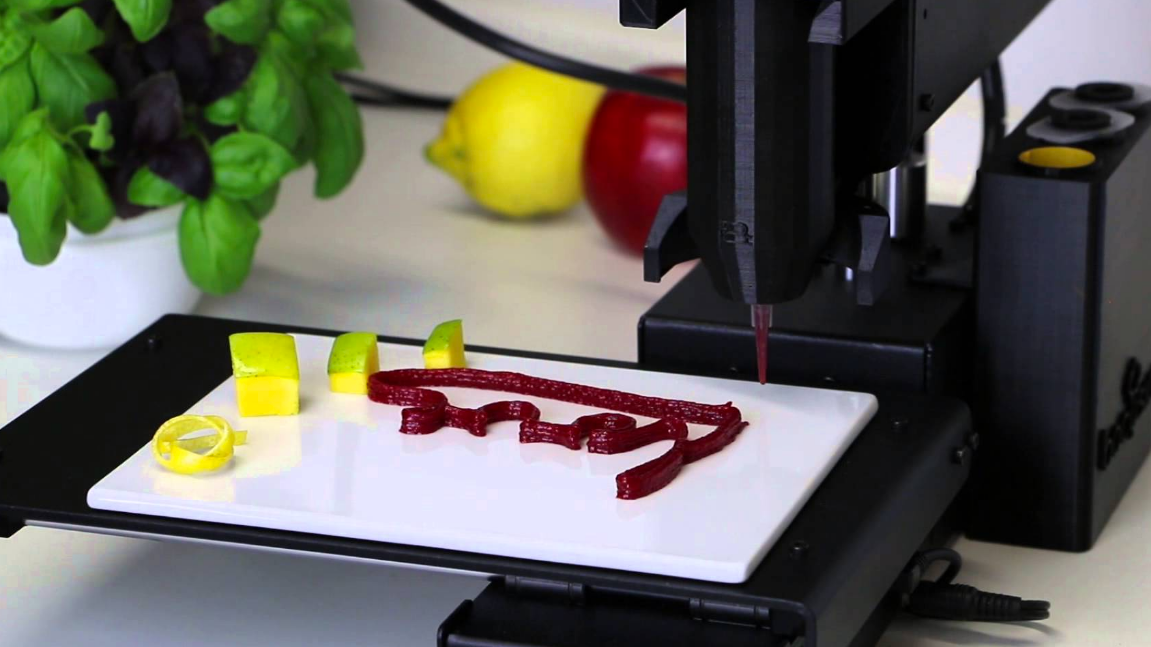

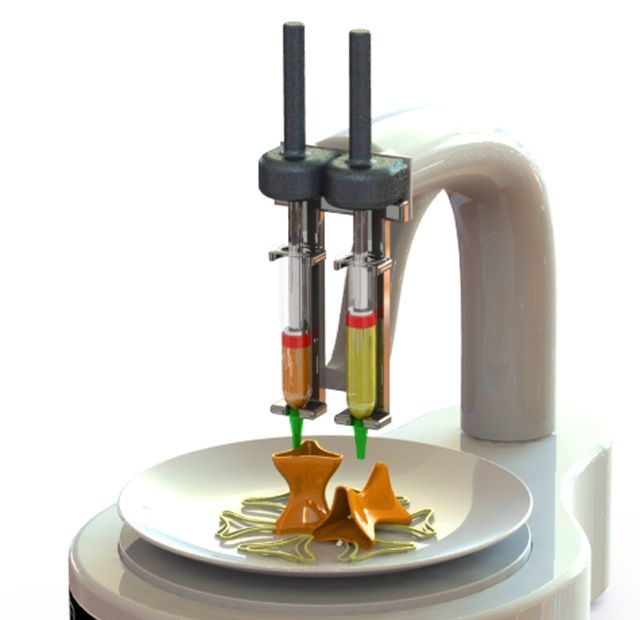

Try the RoVaPaste - $1000 on Kickstarter. I have printed Pizzas, Brownies, Pancakes, Icing & much more. The delivery system is Food Grade and ORD Solutions is working on CFA Approval. Shortly after that FDA Approval. It’s the only 3D Printer that I know which can handle Foodstuffs right out of the box.

https://twitter. com/cmoneyspruce/status/517825888327847936

com/cmoneyspruce/status/517825888327847936

https://twitter.com/cmoneyspruce/status/517824660596326401

I run ORD Printlab and I have printed tons of food with this product - we are currently working with CFA to get the approval on use with food.

Curtis

AtomJaay

#12

There you go… an ORD printer could be used to produce ceramic slurry printed parts that would then need to be glazed and blasted in a furnace. Shapeways also has ceramics as a material choice, I had wondered if those parts qualify for food safe by FDA standards because glaze surface is used in cup, mugs, plates, bowls, etc. The examples at Maker Faire NY looked like items you would buy at Bed Bath and Beyond.

GeniusIE

#13

Thanks AtomJaay,

I am actually putting ceramic through tomorrow and finding a facility to fire it here in Hamilton, ON. I can attempt to glaze it as well to see if it suits these purposes. Note that any process you take on in-house (such as firing your own ceramics) needs to be FDA or CFA approved for sale on its own - those are unavoidable standards. There will be specifics to your process that we can’t seek a general certification for. I can say, however, that we are applying to put the foods right into the printer and print directly onto food safe apparatus like parchment or stainless steel sheets. Feel free to message me at [email protected] for more details!

I can attempt to glaze it as well to see if it suits these purposes. Note that any process you take on in-house (such as firing your own ceramics) needs to be FDA or CFA approved for sale on its own - those are unavoidable standards. There will be specifics to your process that we can’t seek a general certification for. I can say, however, that we are applying to put the foods right into the printer and print directly onto food safe apparatus like parchment or stainless steel sheets. Feel free to message me at [email protected] for more details!

RobertPaul

#14

Then again, you can always just print out of pla and coat it with a thick layer of food grade epoxy.

neal_white_18

#15

Hey everyone,

So I ended up having our scoops printed using Veroclear material from Stratasys. Now I am thinking that I need to coat these scoops with an epoxy, but I’m not sure where to look. Can anyone provide suggestions as to the kind of epoxy/coating I should buy, and where I can find it?

Now I am thinking that I need to coat these scoops with an epoxy, but I’m not sure where to look. Can anyone provide suggestions as to the kind of epoxy/coating I should buy, and where I can find it?

Thanks!

Lauren_Pinshape

#16

Hey everyone! Great question - a lot of people on the Pinshape community were also asking about how to make their prints food safe so we just published a blog article about this very subject. It seems to be highly debated but there are steps you can take to make your scoops more food safe. Here’s a few food safe sealants that we recommended in our blog article.

Yao

#17

Hi Neal, did any solution find your way? if not, we are working on a system for large scale 3D food printing with pastes. https://plus.google.com/+YaovandenHeerik/posts/cBKuEuQHUoF

https://plus.google.com/+YaovandenHeerik/posts/cBKuEuQHUoF

We might be able to help you…

Ethan_Swift

#18

Aloha from Hawaii! Did you ever get approval?

Food industry. Order 3D printing from food grade plastic.

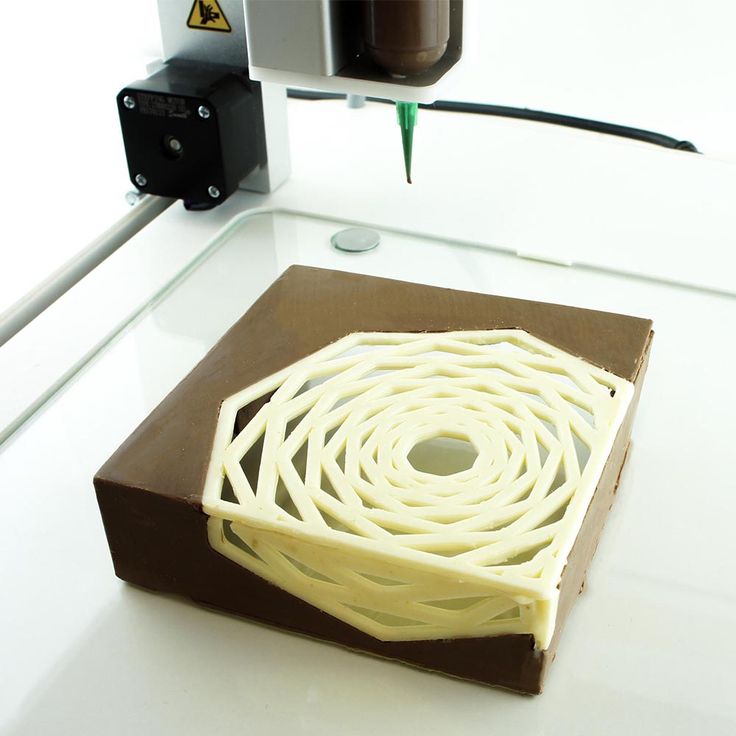

If you think that the food industry and 3D technology are incompatible, then you are deeply mistaken! In fact, this industry uses the services of 3D printing no less than others. With the help of culinary 3D printers, unique sweets are created with complex geometry. For example, with chocolate on a special 3D printer, you can even print a portrait. However, this is not all!

Uniqueness, exclusivity, individuality play a huge role in the modern world — 3D modeling is able to make virtually any object unique, and when it comes to food products, it is first of all forms and packaging. Due to the high cost of 3D printers, not every company can afford the equipment, which can be said about small cookery. There is a way out - to use the services of 3D printing.

Due to the high cost of 3D printers, not every company can afford the equipment, which can be said about small cookery. There is a way out - to use the services of 3D printing.

Our company provides printing services using the most popular and demanded technologies. For the food industry, we can offer the use of safe plastics. Affordable prices and high quality printing we guarantee.

One of the applications of 3D printing in the food industry is the creation of exclusive molds for chocolate, dough and liquid food products. Using the printer, you can print forms for cutting cookies, gingerbread, printing on them. Similar forms can be made for confectionery - sweets, chocolate. This approach allows making the production of confectionery and food products more individual. For example, you can make products for certain holidays, events, etc. And restaurants can get the opportunity to brand bread and confectionery products. All this allows you to raise the image in the eyes of the consumer.

Nowadays, many people earn money by baking cakes. Talent allows chefs to create real masterpieces, and printing can help them create templates for cutting out elements from dough, mastic and chocolate. Such individualized products are able to distinguish products from competitors and open up new possibilities in design.

Since it is not profitable for most food industry enterprises, cafes, restaurants and private cooks to buy an expensive 3D printer, it is much more expedient to use 3D printing services.

Our company offers a huge range of technologies and materials for 3D printing. Our experts are ready to choose the best option that will be safe and applicable in the food industry. We will also make sure that the printed product, if necessary, is sufficiently durable.

To order printing from us, you must provide a file in STL format, which should contain information about the future product. This file is created in special 3D modeling programs. If you do not have such skills, then our specialists are ready to model a three-dimensional object according to your drawings and sketches.

Trust our specialists, and we will implement all your ideas in the shortest possible time.

You can send the file to the email address: [email protected]

3D printing service from plastic, FDM, SBS in Moscow

3D printing with translucent plastic

Its strength, ductility and heat resistance make it a material often preferred in engineering and mechanical applications. The modulus of elasticity is much less than that of ABS. That is, the printed parts are more flexible. Elongation at break >250%. The thread, unlike ABS, does not break, not to mention PLA, which is the most fragile. SBS has a flexible structure. It will not break off or break off when printing. Even if the bar is fed into your extruder at an angle of 90 degrees! The material is transparent (93% light transmission). Coloring the material gives a very beautiful effect.

Finished product specifications:

| 220-230 about C |

| 250% |

| 93 |

| -75°С / +76°С |

Food grade

The raw materials are completely safe, have safety certificates and a certificate for admission to contact with food products. Recommended by the manufacturer for the manufacture of, among other things, medical products and children's toys.

Recommended by the manufacturer for the manufacture of, among other things, medical products and children's toys.

In two years of working exclusively with SBS, we have mastered all the intricacies of producing high-quality bars from this material. Being well aware that SBS, with all its advantages, does not cover the entire spectrum of needs of 3D printers, we worked on creating a new material. Numerous experiments to create composites based on this polymer have yielded results, and a new material for 3D printing has been born, called SBS-PRO. As the name implies, this material is aimed primarily at 3D printing professionals and is initially positioned by us not as decorative, but as structural. Having retained all the advantages of the PROTOTYPER SOFT series, such as the absence of smell during printing, non-hygroscopicity and suitability for contact with food, SBS-PRO acquired several more properties that allow it to be positioned as a full-fledged replacement for ABS, and even surpassing it in many respects.

The main differences between the material and SBS:

- increased tensile strength

- increased adhesion between printed layers (solderability of layers)

- hardened

- high abrasion resistance

- higher temperature resistance

Advantages of SBS-PRO over ABS:

- no hygroscopicity (eliminates the need for special storage and drying of the material before printing, gives confidence in the stability of printing under any storage conditions of the rod)

- no chemical smell when printed

- suitable for food contact

| Specifications | |

| Print temperature | 240-260°C |

| Table temperature | 80-100°C |

| Density | 1.01 g/cm3 |

| moisture absorption | 0. 07% 07% |

| Softening temperature | 85oC |

| Shrinkage in the manufacture of products | 0.2 - 1.2% |

| Minimum wall thickness | 0.3mm |

| Solvents | |

| Solvent (nefras) GOST 10214-78, xylene | Perfectly dissolves and gives plastics of the T-Soft series a unique transparency, similar to glass. Perfectly melts and levels layers. After processing, the plastic does not become cloudy. Solvent treatment is recommended in a dry, well-ventilated area. |

| D-limonene | Slowly and gently dissolves plastic, requires longer drying with warm air (using a hair dryer). In its pure form (citrus terpene) does not become cloudy on the product when dried. After processing, it leaves a pleasant smell of tangerines on the plastic :) |

| Dichloromethane (methylene chloride) | It dissolves plastic well, evaporates quickly and practically does not smell. |