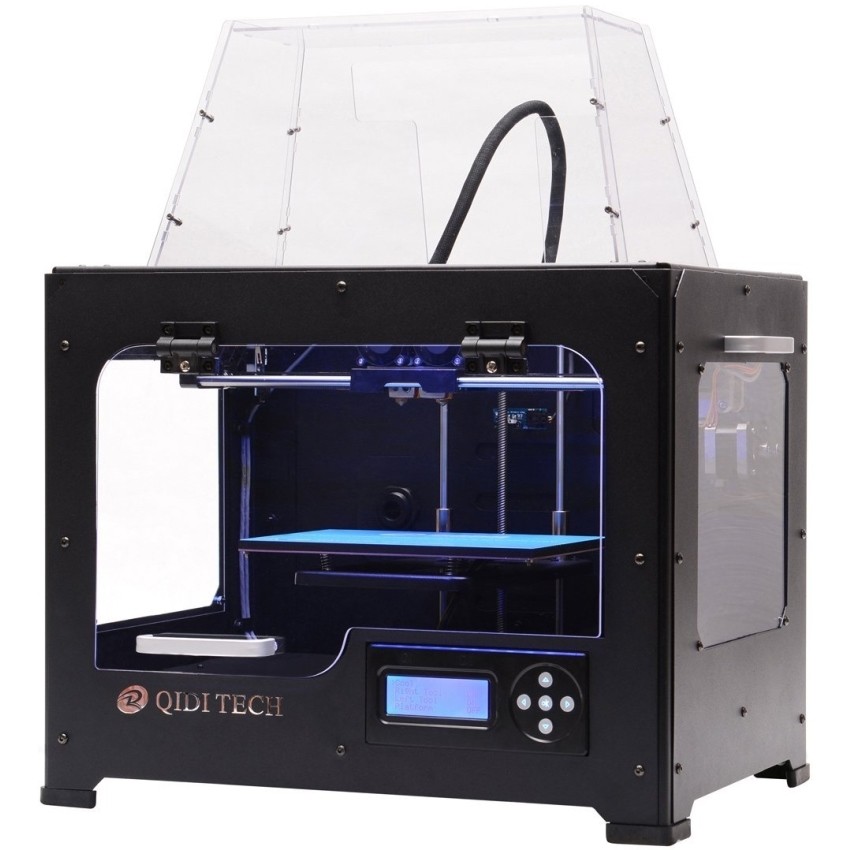

Qidi 3d printer

qidi tech 3d printer – QIDI TECHNOLOGY OFFICIAL STORE

Why Choose Qidi

Worldwide Shipping

Free shipping to US, UK, EU, etc

Fast delivery (3-7 days)

30-day Return

Returns with any reason within 30 days of receipt

Reliable Warranty

2-year warranty

(only for orders placed here)

Customer Support

Feel free to contact us about anything, we will reply as soon as possible.

Best Sellers

-

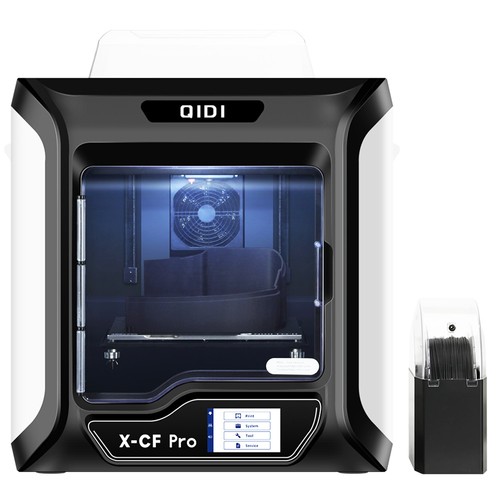

Qidi X-CF Pro, especially designed for printing Carbon Fiber and Nylon

Quick view -

Qidi I-Fast, a pioneer in solving complex printing

Quick view -

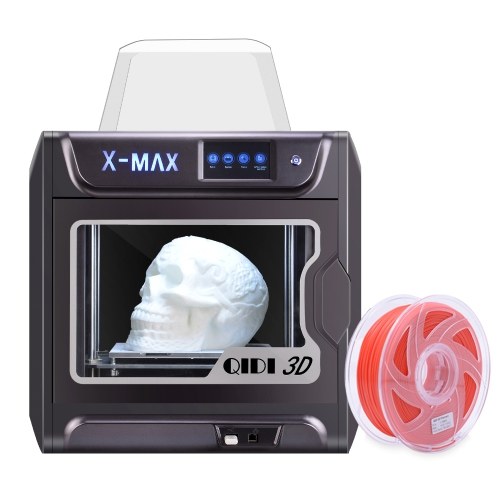

Qidi X-Max, large size 3d printer

Quick view -

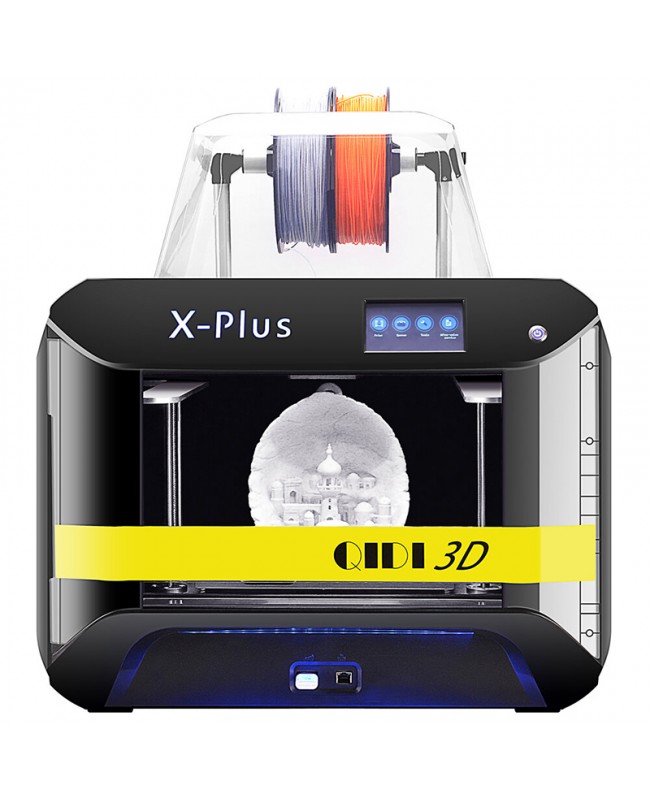

Qidi Tech X-Plus II

Quick view -

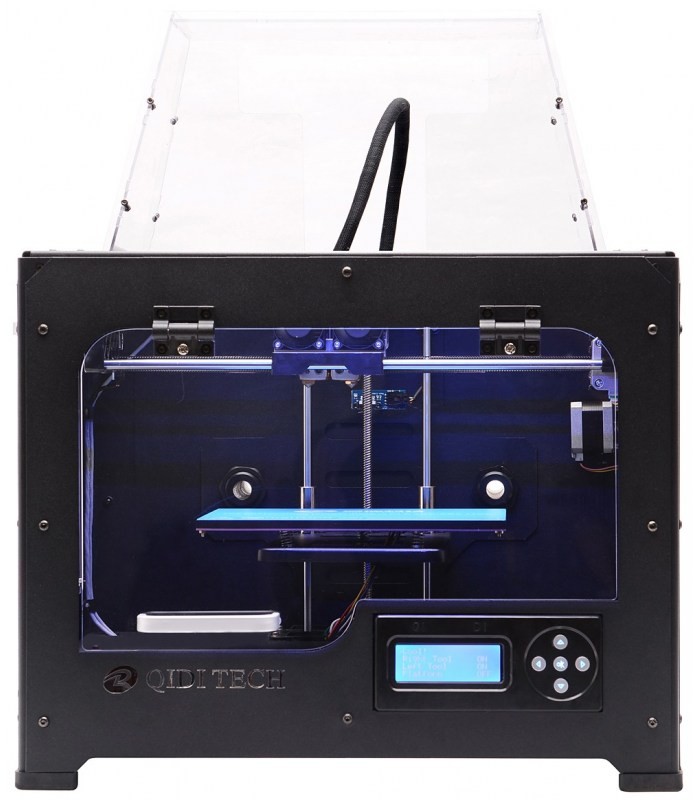

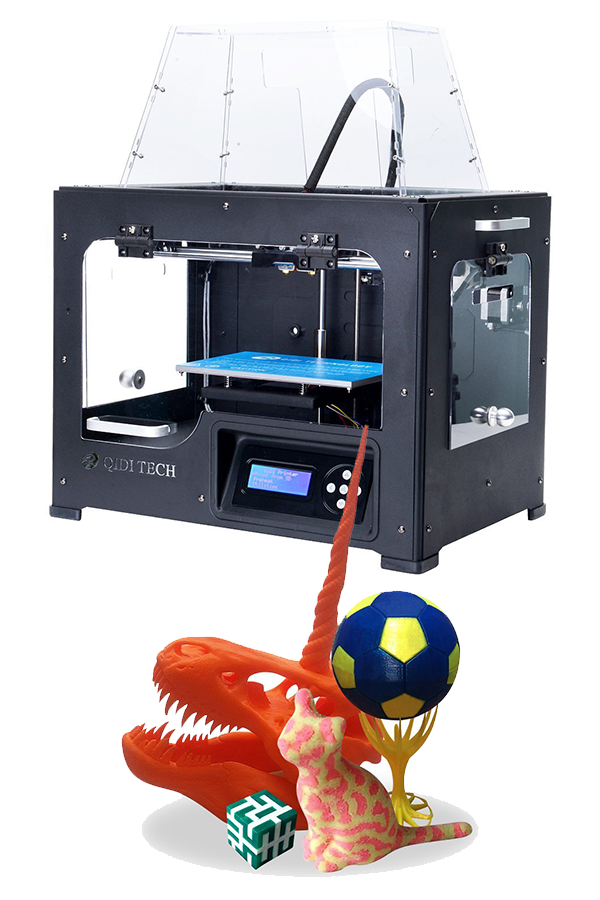

Qidi I-Mates, all metal frame 3d printer

Quick view -

Qidi PA12-CF Carbon Fiber Filament

Quick view -

Qidi UltraPA Nylon Filament

Quick view -

Qidi filament dryer box

Quick view

2022 new model, specially designed for printing carbon fiber & nylon.

QIDI X-CF PRO

• Printing area: 300x250x300mm

• Double gear all metal extruder

• Filament sealed box

• BL Touch auto-leveling

BUY X-CF PRO

The most competitive 3d printer of Qidi

QIDI I-FAST

• Retractable dual extruder, compatible with 2-color printing, filaments + filaments support printing.

• Super large printing area: 330x250x320mm

• High speed printing

BUY I-FAST

X-Max -- A highly acclaimed 3d printer

high-temp single extruder, high precision,

large print size: 300x250x300mm,

5 Inch touchscreen, WiFi connection

Buy X-Max

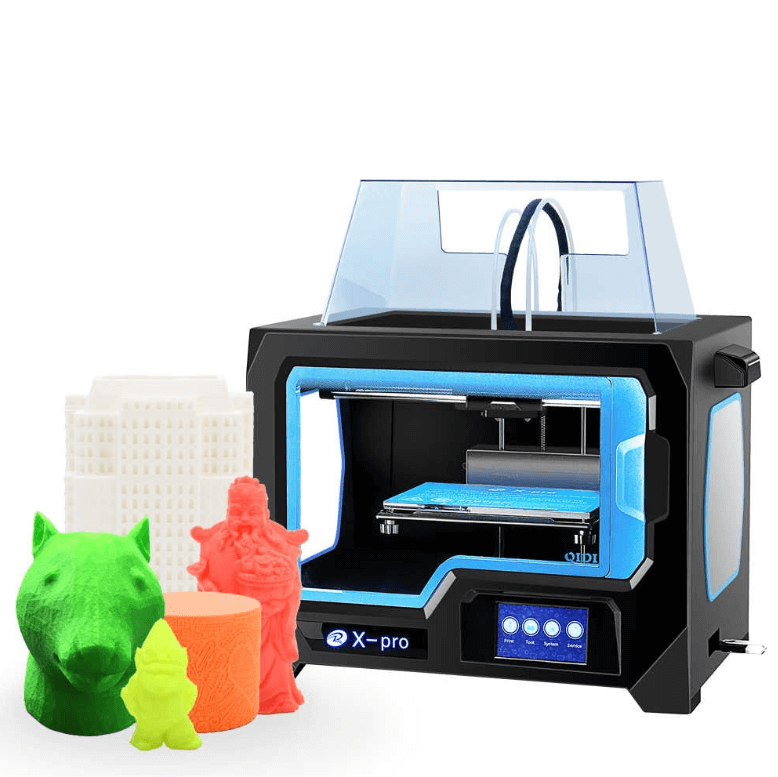

X-Plus, a cost-effective 3d printer

high-temp extruder, high precision,

large print size: 270x200x200mm

Buy X-Plus

I-Mates, a beginner-friendly 3d printer

0. 4mm extruder + 0.2mm hot-end, all metal frame, fully closed structure, print size: 260x200x200mm

4mm extruder + 0.2mm hot-end, all metal frame, fully closed structure, print size: 260x200x200mm

Buy I-Mates

Qidi Technology, make your unprecedented ideas come true.

Qidi Model Display

Choose Qidi to make 3D printing more professional, more accurate and more enjoyable.

Buy 3d printers

Collections

-

3D Printers

-

Accessories

-

Filaments

Who we are

Qidi Technology--An advanced 3D printer company in China, integrating R&D, designing with manufacturing.

We are committed to develop high quality, high performance 3D printers and provide professional 3D printing solutions to our customers around the world.

About Qidi

Certificates

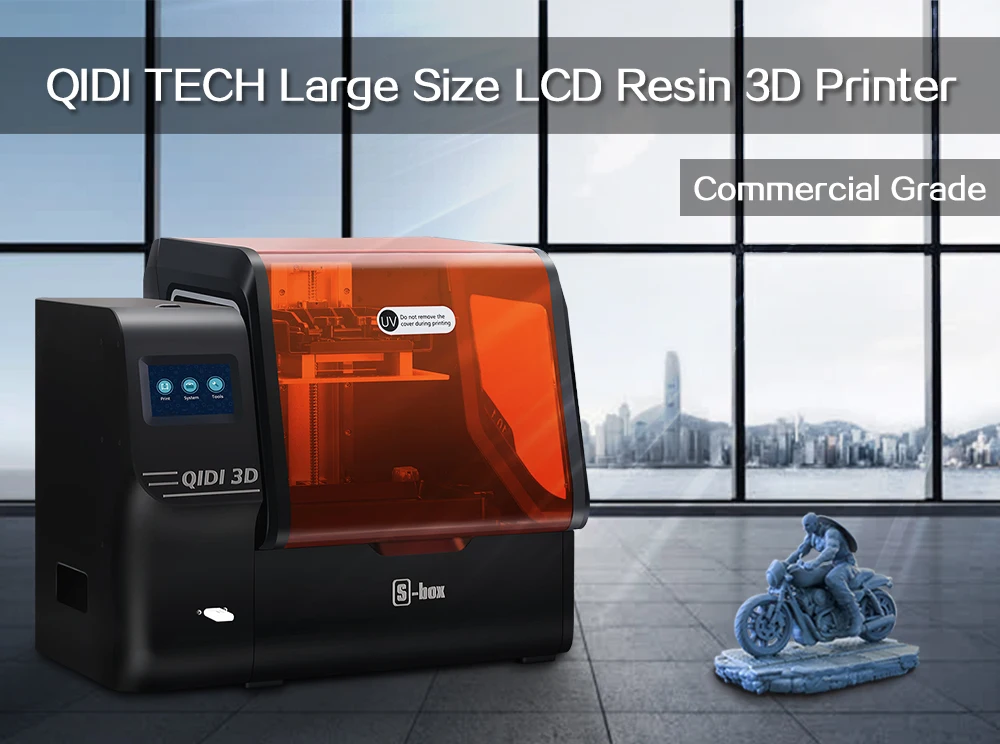

Qidi X-Max, large size 3d printer – QIDI TECHNOLOGY OFFICIAL STORE

Skip to product information1 / of 2

Qidi X-Max, large size 3d printer

- Regular price

- $879.

00

00 - Regular price

-

$959.00 - Sale price

- $879.00

Sale

Quantity

US EU countries UK Canada Australia Japan OthersProduct Description

Parameters

| Machine Size | 580(L)*510(W)*550(H)mm |

|---|---|

| Print Size | 300*250*300mm |

| Print Accuracy | 0. 05-0.2mm 05-0.2mm |

| Print Speed | 30-150mm/s |

| Extruder Quantity | Existing extruder + Additional extruder |

| Extruder Temp | 300℃ |

| Support Material | Carbon fiber, Nylon, PETG, TPU, PC, ABS, PLA... |

| Nozzle Diameter | 0.4mm |

| Compatibility | Windows 64 bit/ Mac |

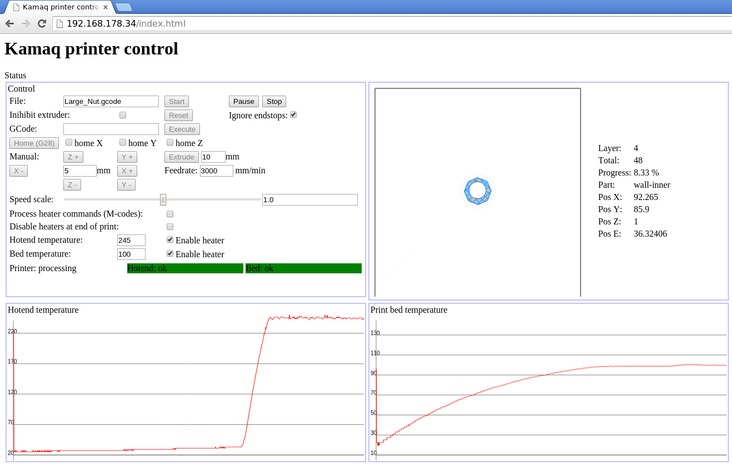

| Compatible Software | QIDI Print/Cura Simplify 3D |

| Power | 450W |

| N.W. | 37KG |

| Voltage | 110-220V |

| Connection Options | WIFI/LAN/USB Pen Drive |

Main Innovation:

Double Z-axis:

Updated the Single Z-axis to Double Z-axis, more stable and solid for large size prints.

Innovative design of double z-axis motor structure with 4 pieces Imported 12mm axis.

Maximum print size is: 11.8''x9.8''x11.8''

(300(L)x250(W)x300(H)mm)

Two Different Ways for Place the Filament:

The first creation of the two different ways for place the Filament.

A. Place the filament outside: The filament feed more smoothly while printing PLA, TPU, PETG. It compatible with any brands of 1.75mm filament.

B. Place the filament inside: For printing advanced material such as Nylon, Carbon Fiber, PC, which requires an enclosed constant temperature printing.

Newly Developed Extruder:

Two Sets of Qidi Tech Third Generation Extruder Assembly with Different Capability.

A extruder : For printing general material such as PLA, ABS, TPU ( already installed on the printer).

B extruder : For printing advanced material such as Nylon, Carbo Fiber, PC.

QIDI TECH One-to-one Service:

If any problems with the X-Max 3d printer, please contact Qidi Tech team and we will reply in 12 hours.

Key Features:

5.0 inch Touchscreen:

5.0 inch touchscreen. Larger interface makes it more intuitive and easy to operate.

Removable Plate:

Movable extraction, curved metal plate, can be used repeatedly, it is more convenient to remove the model after printing. And meanwhile, can minimize the damages or offsets to the build plate.

Qidi Print Slicer:

The Qidi Tech latest generation slicer software version 6.2.2: Redesigned UI interface of Qidi Print software is more convenient to operate. It has been changed the software's slicing algorithm and improves the print quality by 30 percent and speed by 20 percent. Qidi Print software compatible with all types of Qidi Tech 3d printers, life-time free, an alternative to paid software.

This is almost ideal. Anycubic 4max Pro 2.0. Review of a really ready-made solution

At some point, the understanding should have already come that it was enough to play with cheap Chinese drygosts and finally move on to something more serious. This serious FDM printer is the Anycubic 4Max Pro 2. 0. The choice was made for a reason. The price, at the time of writing the review, is about 30-32 tr. or $400. Link to off.shop. The closest competitors are Kidi i mate, but for this money it only has an open case, or the reality 200b, but at a price more expensive and inferior in a number of characteristics. I can't remember anything else.

0. The choice was made for a reason. The price, at the time of writing the review, is about 30-32 tr. or $400. Link to off.shop. The closest competitors are Kidi i mate, but for this money it only has an open case, or the reality 200b, but at a price more expensive and inferior in a number of characteristics. I can't remember anything else.

The printer comes in a huge box and is already assembled. The total weight of the parcel is just over 20kg. Plastic corners are laid in the corners for greater rigidity. Inside the printer itself, everything is fastened together with everything that was apparently at hand. Adhesive tape, ties, polypropylene tape, bubble wrap... In general, we took care of the safety of delivery.

The delivery set here is quite rich: starting from gloves (although this is not a sla printer) and lubricants, ending with a fairly large plastic coil weighing half a kg and a second (not spare) hotend for high-temperature or composite materials.

Let's take a quick look at Tech. Characteristics of the machine:

Characteristics of the machine:

- Press area size 270x210x190mm

- Resolution of the layer height from 0.0.3

- Positioning accuracy X 0.01 Y 0.0125 Z 0.00125

- Printing speed from 20 to 150 mm/s (recommended by the manufacturer - recommended by the manufacturer - recommended by the manufacturer - recommended by the manufacturer - recommended

- The maximum temperature of the hot end is 260, the table is 100 (this is not entirely true, I printed mostly abs, the temperature of the table was 105. You can catch up to 110, but these 5 degrees take a lot of time)

- Filament end sensor (for about 3 months - no complaints)

- Direct extruder with two gears (bmg, like on anycubic mega zero 2.0, review here)

- Double graphite bearings on the z axis axes

- Sheet metal frame (actually because of what the weight is)

The device is positioned as a completely ready-to-use device within 10 minutes (approximately) after opening the box. All you need to do is attach the low filament sensor, remove all shipping ties, tapes, etc., calibrate the table, load the plastic and press print.

All you need to do is attach the low filament sensor, remove all shipping ties, tapes, etc., calibrate the table, load the plastic and press print.

Yes, and everything would be fine, but everything is the same as always. The first pancakes are lumpy: Plastic - complete PLA. Gcode from the manufacturer (upper part), the lower part is already mine, but frankly it turned out terrible. Photos of the shocking shots of the very first print:

For obvious reasons, the pla plastic in the camera simply overheats, floats, flows and, in general, pla plastic is not for the camera. Yes, and not for that I have this printer to print pla. So after a few more tests, I started printing Abs. The temperature varied from 235 to 245 parrots and in the end I got here are the results:

Of course, I tried to print and flex . Well, it's a sin not to try that) To be honest, I didn't sit and pick up a bunch of settings for perfect printing. The task was to see how the printer will cope with this, and whether it will cope. I don’t remember the temperature settings, the speed of the table was 30mm/s for the walls (since the model is essentially only from the wall, I decided to raise the speed a little), and the retract was 1mm at a speed of 10mm/s. It can be seen that the walls were not printed, since 30 for flex is a bit overkill. However, the bottom of the part printed perfectly, the speed was 15mm / s. I suppose that if necessary, I can set the speed lower and not think that I have it somewhere to chew. But since I rarely use flex as a material for printing, it’s not a fact that this knowledge will be useful to me at all)

I don’t remember the temperature settings, the speed of the table was 30mm/s for the walls (since the model is essentially only from the wall, I decided to raise the speed a little), and the retract was 1mm at a speed of 10mm/s. It can be seen that the walls were not printed, since 30 for flex is a bit overkill. However, the bottom of the part printed perfectly, the speed was 15mm / s. I suppose that if necessary, I can set the speed lower and not think that I have it somewhere to chew. But since I rarely use flex as a material for printing, it’s not a fact that this knowledge will be useful to me at all)

What can I say about the pros:

- Excellent extruder

- Print quality on par with more expensive competitors

- Ultrabase (one of the best in cubes), fixed with rigid staples Ability to print with materials with

- shrinkage and flexibility due to heat chamber

- Print speed (for abs I use 80mm/s)

- Excellent structural rigidity

- On/off button (special thanks for that) with auto-off function after printing is completed and the hotend cools down

- Heavy table (in this case it's a plus)

- Built and almost completely set up out of the box (all that was done was table calibration)

- Backlight (bright enough to see what you need)

- Quiet drivers ( not work, namely drivers)

But this printer is not deprived of minuses either:

- Disgusting menu!

- It is very inconvenient to remove models, and in principle to crawl up to the printer

- No air circulation for PLA printing (I don’t care much, but if someone has one printer, then this can be a problem) The printer is quite loud.

Noise is emitted by the shafts themselves to a greater extent. It is comparable to a microfactory. You can't hear it in the next room, but very close by. Do not put such a toy in the bedroom.

Noise is emitted by the shafts themselves to a greater extent. It is comparable to a microfactory. You can't hear it in the next room, but very close by. Do not put such a toy in the bedroom. - Poor airflow. Even the abs in this chamber sometimes floated due to overheating.

- Filament spool holder and sensor - located at the back.... No comment.

Conclusion: With all the shortcomings of this printer, my opinion is extremely positive. For me, an indicator of the quality and convenience of a printer is when you press the print button and go about your business, knowing that when the print is completed, the finished part is waiting for you, and not an error on the screen, or noodles all over the printer. This is with regard to standard plastics by itself.

I printed one piece of nylon on it and it came off on the first run. Well, with whom it doesn’t happen, the border is wider, z-offset by -0.05 and the part remains on the table until the end of printing.

For menus and settings during printing. This is, of course, a perversion. To change anything while printing, you need to go to the main screen, and there, in a bunch of items and sub-items, find the setting that you need and change. You can get used to it, but it takes some time and discomfort of use. Other anycubic touch screen printers work in the same way. Your screen, your board, your nightmares.

At the expense of attaching the coil from behind - it's not very convenient. The printer is close to the wall, and each time you change the plastic you have to move it a little. Everything would be fine, but almost 19Kg moving back and forth is not the most convenient thing to do.

At first it was difficult to understand the slicer settings. Since the printer is "chamber", more or less standard temperature settings showed poor results. at 245 abs, plastic (from different manufacturers) overheated and did not print normally. Parrots had to be lowered to 235, then everything went uphill. I have airflow for abs at 100% in most cases. Delamination never happened.

I have airflow for abs at 100% in most cases. Delamination never happened.

Otherwise, after about 3 months of using this printer, I enjoy it. So if someone is planning to expand the fleet, or as the first printer, then I strongly recommend it for purchase. The machine is durable, practical and will not cause inconvenience , like most of the cheaper analogues, for which you need to buy a file.

Who and why began to print rifles on 3D printers — FURFUR

3D printers are suitable not only for making cute and harmless things. It turns out that they can also print weapons. . But it's hard right now. Technology is advancing, and don't be surprised if some schoolboy robs a store for 150 thousand with the help of a plastic Stechkin. And it won't be a toy.

History

| This eloquent introduction is dedicated to the fact that 3D printers promise us a fun future: as is often the case, devices that can print parts for aircraft, interior items and implants have come in handy in order to produce parts for weapons. |

|

Of course, the Americans were the first to think of this. Before talking about what they have achieved on this path, it is worth recalling that 2012 turned out to be very sad for the United States in a sense. 16 Cases of Mass Murders in Different States: Everyone has heard about the shooting at the premiere of The Dark Knight and the terrible massacre at Sandy Hook Elementary School, where the maniac shot about 20 small children and six adults before he shot himself. After that, Obama decided to take this matter seriously and do everything possible to limit the access of citizens to weapons. I must say that in both cases the AR-15 rifle appeared.

|

AR-15

The AR-15 rifle is not a weapon, it's a gadget. |

The first weapon on a 3D printer

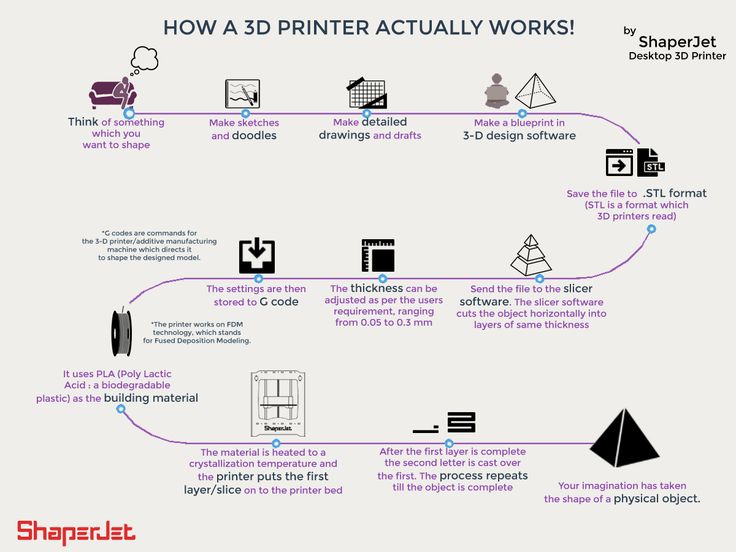

Back to 3D printers. They are becoming more affordable, their prices are falling, in addition, you can always rent from the company. To print an object, you need to download the corresponding CAD file - that is, a diagram of the desired object, created on software that is compatible with your printer. This is where, for example, hingiverse.com comes to the rescue. Prior to the events in Sandy Hook, users posted, among other things, diagrams of parts for weapons. Later, however, these lots were banned. Michael Guslick, writing under the name HaveBlue on the now world-famous forum, tells how he printed on a printer from 1990s receiver type AR (rifle bolt box) and attached to the metal parts of the AR 22 caliber submachine gun. This thing fired about 200 bullets and is completely intact, no matter what the skeptics say. Michael literally blew up the Internet, causing a lot of talk about what kind of future technology has in store for us.

Later, however, these lots were banned. Michael Guslick, writing under the name HaveBlue on the now world-famous forum, tells how he printed on a printer from 1990s receiver type AR (rifle bolt box) and attached to the metal parts of the AR 22 caliber submachine gun. This thing fired about 200 bullets and is completely intact, no matter what the skeptics say. Michael literally blew up the Internet, causing a lot of talk about what kind of future technology has in store for us.

"No, I was not torn into a million tiny pieces and I was not incurably wounded - I must disappoint everyone who was already looking forward to a gloomy hopeless outcome."

Why a receiver? Because he, as the most necessary part, is licensed, the rest can be ordered even by mail. And this opportunity to print the receiver on a printer, which has not yet been suppressed by law, has been adopted by Cody Wilson, which will be discussed later.

|

| Cody WILSON creator of project |

In his 20+ years, Cody has achieved a lot of success: he was included in the list of the 15 most dangerous people on Earth by Wired magazine. And for good reason: Wilson owns the defensedistributed.com project, which aims to distribute weapon blueprints over the web. Moreover, he already has a license.

Cody declares himself, whatever that means, a crypto-anarchist and has his own views on the proper attitude towards weapons in the country. When asked why he is opposed to a ban on high-capacity guns, Wilson argues, “Why would anyone want two houses? Or earning $400,000 a month?” In addition, many are afraid that children can use Wilson's drawings: by printing what is subject to a license, you can at the same time buy the rest of the components via the Internet. And America, it seems, is only a few years since they installed metal detectors in schools.

“There is no consolation for a person who has lost a child, but this does not mean at all that you can forget about your rights if someone else has broken the law. ”

”

Cody's project is not easy: once the printer was taken away from him by the tenant company without any explanation. Wilson, as a lawyer, remained at a loss, but nevertheless subsequently found intermediaries. Now he regularly tests new printed parts, films the process and puts it online. Sometimes he looks like an idiot when the guns fall apart after ten shots, but at the time of the release of the documentary, his organization managed to achieve a very good performance of the parts. Cody, of course, does not print entire weapons, but only receivers and magazines.

|

Steve Israel congressman | Democratic congressman Steve Israel proposes amendments to the gun law that would also ban plastic products. Wilson and his colleagues believe that limiting the sale of weapons is senile stupidity: "If someone wants to kill people, he can do without guns." In addition, they argue about the limitation of natural freedoms and the great power of modern technology: “You will not succeed. |

Designer for serious men. Over the years, the rifle has allowed you to screw everything your heart desires: optics, lights, laser sights. You can change grips and butts, you can even arrange tuning - if only there was money that AR-15 owners willingly spend. Nonsense: after the Sandy Hook massacre, it was decided to limit sales - this forced buyers to stand in hour-long queues at gun stores, which is said to have increased sales by about 1000%.

Designer for serious men. Over the years, the rifle has allowed you to screw everything your heart desires: optics, lights, laser sights. You can change grips and butts, you can even arrange tuning - if only there was money that AR-15 owners willingly spend. Nonsense: after the Sandy Hook massacre, it was decided to limit sales - this forced buyers to stand in hour-long queues at gun stores, which is said to have increased sales by about 1000%.  com

com