3D printer hardened nozzle

3D Printer Nozzle – Brass Vs Stainless Steel Vs Hardened Steel – 3D Printerly

Your printer’s nozzle has started wearing out and negatively effective the quality of your prints, even to the point where your first layers won’t stick down properly.

Or you received your new 3D printer and don’t like the factory nozzle that comes with it. Now you want to replace your nozzle but have a choice of nozzles that you want to know works best.

This is why I’ve decided to write this article, to help you decide which nozzle to go for, and to explain the differences between the main choices. You have Brass, Stainless Steel & Brass nozzles.

The best nozzle for 3D printing is brass for any basic 3D printing since it has good thermal conductivity

The short answer here is, if you want the best quality nozzle for your prints, you will most likely get that with Brass if you are printing non-abrasive filaments. If you want to print food-safe or medical grade parts, then Stainless Steel is the best option. If you want to print abrasive filament, Hardened Steel is the way to go.

There are more details in this topic that you’ll want to know about, so keep reading on to get some good info that will help your 3D printing journey.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

Brass

If you are after a brass nozzle to purchase quickly, I would recommend the LUTER 24-Piece Brass Nozzle Set. Not only are you getting a wide range of brass nozzles sizes with a storage box, it’s also the highest rated on Amazon, mainly because of the premium quality and the great price.

Compatible with MK8 extruders such as the Ender 3, Creality CR-10, MakerBot, Prusa I3 and many more.

Most 3D printers come with a brass nozzle and there’s a very good reason for it.

Brass has great thermal conductive properties meaning it transfers heat from your heater block to nozzle to filament much more efficiently than other nozzle materials.

Brass does however have it’s drawbacks which is why other nozzle materials have been introduced in the 3D printing field.

Brass happens to be a relatively soft metal meaning if it scrapes the bed surface or you print with abrasive filament, it can wear down and damage your nozzles.

A brass nozzle is usually fine when printing non-abrasive filament such as PLA and ABS without certain additives. When you have additives like glass, carbon fiber or metal particles it will increase it’s abrasiveness and be more likely to damage a brass nozzle.

The damage that tends to happen is grooves and ridges on the inner part of the nozzle, closing off the nozzle hole, or increasing the diameter of the hole making it unusable.

Not only are brass nozzles cheaper, they also are easier to machine and manufacture.

Practically speaking, there is no significant advantage you’ll gain by using a Stainless Steel nozzle unless you are printing abrasive filament.

Most people that 3D print are usually printing with PLA, ABS or similar materials that aren’t abrasive.

In these cases, a good quality brass nozzle will do more than fine, although you could do with an upgrade compared to some of the factory brass nozzles you get with your 3D printer.

Stainless Steel

If you are after a stainless steel nozzle to purchase quickly, I would recommend the 20 PCs USPacific Stainless Steel Nozzles with Needle Cleaning Kit. It comes with 4 nozzles with a 0.4mm diameter.

Stainless Steel is one of the other popular nozzle materials that you’ll see people using. It’s main benefit over the brass nozzles is it’s better wear-resistance.

Though it’s wear resistance is better, it isn’t the best out there.

Stainless Steel nozzles are great at fighting against abrasive filaments and not getting worn down.

They can be frustrating to print with due to their likelihood of heating poorly, reacting to retraction and cooling and may cause more clogging.

Check out my article on how to Unclog & Prevent Clogging in Your 3D Printer.

Usually if you tweak your settings to a good level, it shouldn’t be too much of an issue.

The main unique property of stainless steel nozzles is their ability to prevent filament covering the nozzle, so it stays cleaner than most other nozzles.

It may look nicer, but I wouldn’t consider a Stainless Steel nozzle as an upgrade unless it’s for abrasive filament.

You can use Stainless Steel nozzles for basically any material.

The other main benefits that Stainless Steel nozzles have over the other nozzles is it’s food-safe and medical-grade properties.

It can safely be used in applications where food will be involved as it has been accepted by the FDA of being food-safe. Other nozzles don’t share this same benefit.

That is it’s main use, it can print with abrasive materials but Hardened Steel is better suited to this.

Hardened Steel

Hardened Steel nozzles are the next step up in wear-resistance compared to Stainless Steel nozzles.

This is simple steel that has been specially treated to be extremely wear-resistant and can last users a year and beyond with heavy use.

You definitely want to be using hardened steel nozzles when you plan to print with abrasive filament.

The way nozzles are manufactured, it’s difficult to get a smooth interior finish, with metals that are harder.

It’s better to have a smooth interior to be able to extrude evenly. That’s where Hardened Steel falls short, but not so much that it won’t give you high quality prints because they definitely can.

I’d go with the GO-3D Hardened Steel Nozzle from Amazon. They are rated highly, abrasion and corrosion resistant, and compatible with most 3D printers using an M6 thread like the Ender 3.

Thermal Conductivity

So as previously mentioned, brass has the best thermal conductivity so it makes things easier to print with.

Brass nozzles have the ability to melt filament faster, and at a lower temperature because there is less of a difference in temperature between the nozzle and the thermistor.

The thermal conductivity of Stainless Steel and Hardened Steel isn’t bad, but you may have to adjust your temperature settings to get optimal results.

You can also decrease your cooling fans so your material can harden properly before the next layer is extruded.

After you have your ideal settings, it shouldn’t give you issues but it will take some trial and error.

For example, the Steel nozzles can have a hard time heating up as quickly or retaining the required heat that you want for certain materials.

It’s a good idea to use a highly thermal conductive metal to print higher temperature materials but it isn’t a requirement.

Stainless Steel nozzles fall short when it comes to heat conductivity, to the point where your printing may be affected. The level of abrasion resistance that you get some one of these nozzles is far higher than brass, but is still vulnerable to highly abrasive filaments like carbon fiber.

This is where you want to opt-in for a hardened steel nozzle at a minimum. Not only do they have far higher abrasion-resistance, they have better thermal conductivity too!

Not only do they have far higher abrasion-resistance, they have better thermal conductivity too!

The difference in price isn’t something that should put you off, so I would recommend going for a Hardened Steel Nozzle if you plan to print something more exotic, or an abrasive composite filament.

The reason why heat-breaks are made of steel is because of the same reason, steel conducts heat poorly compared to brass.

It basically means it takes longer for the nozzle to get to a high temperature and can have trouble maintaining that constant temperature, especially when you have high printing speeds and cooling fans.

You can sometimes compensate by printing slower, but you may see the negative effects of this lower thermal conductivity through the filament not flowing out as well. You ideally want to use Stainless and Hardened Steel nozzles when necessary rather than as a default.

Durability

When it comes to which nozzle material is the most durable and will last the longest, it goes in the order hardened steel, stainless steel then brass.

Some people have been printing exclusively with hardened steel nozzles and it easily lasts them over a year.

If you don’t like the hassle of constantly changing nozzles after printing with abrasive filaments, it’s definitely a smart move to change to Hardened Steel.

Some users have been using their Hardened Steel nozzle for several spools of Nylon X (very abrasive) and it’s still producing great results after months.

This just goes to show the wear-resistance and durability of these materials.

Just be aware of the possible sacrifices in print performance depending on what materials you are printing.

Typical Stainless Steel nozzles are harder than brass, but it’s much softer than Hardened Steel and more likely to last longer against abrasive filament.

Effects on Print Performance

Many people will assume that a Steel nozzle is going to be superior to a Brass nozzle because it’s a harder, more durable metal that is more commonly used.

If you look into the real reasons why Brass is used, and it’s beneficial properties, you’ll realise that this isn’t necessarily the case.

You do have to keep in mind the possible drop in performance of these nozzles due to the lower thermal conductivity. There is the possibility of a bottleneck where the melting and heating of the plastic inside the nozzle gets blocked up.

In terms of performance, if we compared each type of nozzle material, Brass would take the prize. Stainless Steel is fine when you are printing materials like ABS and PETG.

When comparing performance, it’s hard to say there is a definite benefit that Brass or Steel nozzles have over each other, but there are definitely important factors in play.

For example, when it comes to Steel nozzles you are more likely to get a lower printing speed than with brass because the heat conduction on brass means filament melts faster, meaning higher extrusion speeds.

What Materials You Should Print With Each Nozzle Type

Brass

- PLA

- ABS

- PETG

- HIPS

- Nylon

- TPE

Basically all your normal filaments.

Stainless Steel

- NylonX

- Carbon fiber

- Exotic filaments such as wood-filled, wax-filled or ceramic filled

- Metal filaments such as steel-filled, iron-filled, or brass-filled

- Glow-in-the-dark filaments

- Metal filaments

Hardened Steel

- Same as Stainless Steel nozzles but better

So, Which Nozzle Should I Buy?

3D printer users usually go with brass for their normal activities, Hardened Steel or Plated Copper nozzles.

If you do choose a Hardened Steel nozzle, the last thing you want to do is go for a cheap, clone version. These steel nozzles are a lot more difficult to manufacture than your standard brass nozzles, which is why you have a difference in the price.

Don’t run into easily avoidable printing problems by going the cheap route, as these nozzles are more likely to be poorly manufactured with rough finishes and nozzle holes that aren’t drilled directly in the centre. To avoid the potential extrusion problems you want to opt-in for a genuine E3D nozzle or a well-known trustworthy supplier.

Hardened Steel Nozzle

For your Hardened Steel nozzles, I would recommend GO-3D Hardened Steel Nozzle from Amazon. It’s highly rated, has great quality control and simply gets the job done properly. Don’t waste time and effort trying out cheap, mass produced nozzles.

When it comes to 3D printing, high quality is essential for great, flawless printing, and to minimize frustrations and troubleshooting.

Plated Copper Nozzle

Now one of the nozzles that I haven’t talked about yet is the Geniuine E3D V6 Plated Copper Nozzle, a highly reliable product that does the job very well. With this nozzle you should notice a significant difference in your printing quality and ease of use.

Copper is used because of it’s amazing thermal conductivity, and thrives in events where maintaining a high temperature is essential.

Many people report not having anymore clogs with this nozzle and it comes at a competitive price. One of the best things is how materials are much less likely stick to the nozzle, meaning less maintenance and more time spent printing. It extrudes plastics smoother than your standard brass nozzles.

It extrudes plastics smoother than your standard brass nozzles.

Micro Swiss Plated Brass Nozzle

A final option that I haven’t yet mentioned is the Micro Swiss Plated Brass Nozzle which is wear-resistant and another version of hardened steel. How this nozzle benefits you is it’s long nozzle life, very hard coating which creates a minimal friction nozzle, and thermal conductive properties from the brass. It’s basically a hybrid which works very well.

Since the surface is smoother on this nozzle, it causes less clogs because materials don’t stick to the surface or to small surface scratches on your nozzle. It’s both a smoother and harder surface which gives a great balance in terms of 3D printing.

Bonus: Tungsten Nozzle

If money isn’t a problem for you and you want to be able to sometimes print abrasive materials without having to switch out nozzles, a Tungsten Nozzle is the best option. The benefits of this nozzle are:

- It’s long-lasting and very durable that stands up great to most abrasive materials

- Slick design which significantly reduces wear and tear over time

- Completely non-toxic and easy to replace current nozzle

- Manufacturing based in the US

- Heats up well compared to most hard nozzles and can last years if you print non-abrasive materials

As you can see, there are many choices to picking a nozzle for your 3D printer, but it doesn’t have to be complicated. Some are used for specific materials, others are used as a general nozzle to print most materials. Once you have that figured out, picking a nozzle is pretty simple.

Some are used for specific materials, others are used as a general nozzle to print most materials. Once you have that figured out, picking a nozzle is pretty simple.

I hope you learned a good amount about the differences between these nozzle materials, enough to help you make a good choice about what to print with. If you’re interested in more information, check out this article about How Often You Should Change Your Nozzle or 25 Best 3D Printer Upgrades You Can Do.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

E3D V6 Hardened Steel Nozzle - 1.75 mm

Hardened abrasion-resistant nozzles for long-term use with 1.75 mm filament

14 Customer Ratings

E3D V6 Hardened Steel Nozzle - 1.75 mm

20,69 € 22,99 € -10%

(Price shown includes 19% VAT. - )

Diameter: 0.40 mm

Delivery by Thursday, 24 November if you order by Monday at 07:00.

In stock

Quantity:

There are only 119 items of this product left in our warehouse. More are on the way! The delivery date could be affected if you order more than this quantity.

Free shipping in Germany from 49,90 €.

Features & Advantages

- Strong abrasion resistance

- Especially for abrasive filaments

- Long service life

Item no.: E3D-V6-NOZZLE-HS-175-400, Content: 1 pc, EAN: n/a

Product information & technical details

Item no. : : | E3D-V6-NOZZLE-HS-175-250 |

|---|---|

| Manufacturer No.: | V6-NOZZLE-HS-175-250 |

| Manufacturers: | E3D |

| Content: | 1 pc |

| Item no.: | E3D-V6-NOZZLE-HS-175-400 |

|---|---|

| Manufacturer No.: | V6-NOZZLE- HS-175-400 |

| Manufacturers: | E3D |

| Content: | 1 pc |

| Item no.: | E3D-V6-NOZZLE-HS-175-500 |

|---|---|

| Manufacturer No.: | V6-NOZZLE-HS-175-500 |

| Manufacturers: | E3D |

| Content: | 1 pc |

| Item no.: | E3D-V6-NOZZLE-HS-175-600 |

|---|---|

| Manufacturer No.: | V6-NOZZLE- HS-175-600 |

| Manufacturers: | E3D |

| Content: | 1 pc |

| Item no.: | E3D-V6-NOZZLE-HS-175-800 |

|---|---|

Manufacturer No. : : | V6-NOZZLE-HS-175-800 |

| Manufacturers: | E3D |

| Content: | 1 pc |

| Product types: | Nozzles |

|---|---|

| Nozzle shape: | V6 |

| Compatible with 3D Printers : | Anycubic i3 Mega, Original Prusa i3 MK2, Original Prusa i3 MK2S, Original Prusa i3 MK2.5, Original Prusa i3 MK3, Original Prusa i3 MK3S, Original Prusa i3 MK2.5S, Anycubic i3 Mega S, Anycubic i3 Mega Zero, Anycubic i3 Mega X, BIQU BX, Anycubic 4max Pro, MINGDA Magician X, MINGDA Magician Max, MINGDA Magician Pro, Anycubic Kobra |

| Nozzle Diameter: | 0,25 mm, 0,3 mm, 0.35 mm, 0,4 mm, 0,5 mm, 0,6 mm, 0,8 mm |

| Filament Diameter: | 1,75 mm |

Description

Hardened steel nozzle

If you're doing 3D printing with carbon fibre, filled PLA, or glow-in-the-dark filament, this is the nozzle you need! Filaments filled with carbon cause quick and significant damage to standard nozzles. These incredibly wear-resistant nozzles are designed for the toughest filaments on the market.

These incredibly wear-resistant nozzles are designed for the toughest filaments on the market.

Advantages

Paying a little more for a hardened, wear-resistant nozzle is both practical and economical. This also saves a lot of time because you do not have to constantly replace worn nozzles. With this nozzle, you are ready for future materials. These nozzles should be able to handle almost anything that material manufacturers think about next.

Appearance

Due to the thermal and chemical treatment of the nozzle, they have a somewhat dark, sometimes uneven-looking colour and surface texture, and there may be a small amount of residue on the nozzles despite the final cleaning process. The colour deviation is normal and does not affect the function. Residues remaining on the nozzle are quickly washed away in the first few millimetres of the extrusion, especially if you print them with an abrasive filament!

Identification

All nozzles in the series can be identified individually by markings on the flats of the hexagon head, which makes working even more convenient.

| Number of marks | Diameter |

| 2 diagonal | 0.15 mm |

| 0 | 0.25 mm |

| 1 | 0.30 mm |

| 2 | 0.35mm |

| 3 | 0.40 mm |

| 6 | 0.50 mm |

| 4 | 0.60 mm |

| 5 | 0.80 mm |

[[[text]]]

About E3D

Questions & Answers about E3D V6 Hardened Steel Nozzle - 1.75 mm

Receive answers from other customers who purchased this product. Please forward any other order-related questions to our Customer Service Team.

Customer Reviews

-

Saket

19 October 2021

Verified purchase

"Verified purchase" means that the rating was submitted by someone who has a customer account and purchased this product directly from our website.

However, anyone with a customer account can rate our products. Close this note

However, anyone with a customer account can rate our products. Close this note

Related products

-

E3D V6 Plated Copper Nozzle - 1.75mm 4 diameters -

E3D V6 Stainless Steel Nozzle - 1.75 mm -

BROZZL Brass Nozzle for E3D V6 Hotends 5 diameters -

BROZZL Copper Plated Nozzle for E3D V6 4 diameters -

BROZZL Hardened Steel Nozzles for E3D V6 4 diameters -

BondTech Brass nozzle for E3D 4 diameters -

BondTech Coated Nozzle for E3D Hotends 4 diameters -

BROZZL Ruby Nozzle for the E3D V6 Hotend 3 diameters -

Micro-Swiss High-speed Hardened Steel Nozzle for E3D V5-V6 3 diameters -

ZODIAC V6 CRB Nozzle 2 diameters -

Micro-Swiss Coated Nozzle for E3D V5-V6 7 diameters -

Micro-Swiss Nozzle - Hardened Steel for E3D V5-V6 3 diameters -

ZODIAC V6 PRO nozzle 2 diameters -

E3D Nozzle Fun Pack -

E3D Nozzle Pro pack

Customers also bought

-

3DJAKE Nozzle Cleaning Set -

3DJAKE Isopropyl Alcohol 1 liter -

E3D V6 Brass Nozzle - 1.75 mm 7 diameters -

Creality Cartridge Heater Kit 3 Model types -

3DJAKE Mini Wire Brush Set 1 set -

3DJAKE PTFE Tube 4 Model types -

BondTech CHT Coated Nozzle M6 x 1.75 mm 7 diameters -

E3D V6 Nozzle X - 1.75 mm 7 diameters -

3DLac Spray Adhesive 400 ml -

Extrudr PLA NX-2 Black 6 Model types -

3DJAKE magicPLA Deep Space 4 Model types -

Creality PEI Flexible Build Plate 18 Model types -

3DJAKE Threaded Inserts (50-piece set) 5 Model types -

E3D V6 Silicone Socks 1 set -

Fiberlogy Nylon PA12 + CF15

Individual cookie settings

-

Marketing

We collect user journey data to show you relevant sponsored content about our products.

For example, we use information from your previous purchases and interactions with the site. We may share this information and a customer identifier, such as device data, with third parties such as Facebook and Google. We use the following services on this site:

For example, we use information from your previous purchases and interactions with the site. We may share this information and a customer identifier, such as device data, with third parties such as Facebook and Google. We use the following services on this site:Facebook Pixel, Google Ads, Google Analytics, Google Analytics 4, Microsoft Bing, Google Surveys, Ads Defender

-

Personalisation

Based on your interactions with the site, your shopping preferences, and the brands you prefer, we can personalise the content that you see. For a personalised shopping experience, we recommend the following services:

AWIN, Omniconvert, RTB House

-

Functional

This data helps us to optimise your shopping experience, eliminate bugs, and test out new features and functions. It also helps us keep the overall focus on user experience on our site as well as analyse our shop for business-related issues. We use the following services:

Google Tag Manager

-

Required

Always active

Essential cookies ensure functions that you need to use our website.

These cookies are only used by us (first party cookies) and cannot be traced back to you. These cookies are used, for example, to keep the products you add to your shopping basket saved in your basket while you're shopping.

These cookies are only used by us (first party cookies) and cannot be traced back to you. These cookies are used, for example, to keep the products you add to your shopping basket saved in your basket while you're shopping.

Expensive nozzle - is there any point?

We want to share our thoughts on the choice and use of nozzles for 3D printers. If the topic is interesting, then welcome under cat.

So let me start with a little background. We have been 3D printing on several completely different 3D printers for quite some time now. More than once we have come across the fact that in Belarus it can be extremely difficult to find one or another engineering material, and it is not easy to find ordinary ABS and PLA of normal quality. I'm not talking about the fact that often plastic is frankly stale (produced 2-3 years ago). Therefore, we decided to open our own online store, thereby providing ourselves and Belarusian 3D printers with high-quality materials.

But this article is not about that. We're talking about 3D printer nozzles. Yes, a lot has already been written and filmed on this topic, but we will share our own opinion on this matter.

Everyone knows that 3D printer nozzles are subject to rather high quality requirements. And it is quite logical that expensive nozzles seem to be better, and cheap nozzles are worse.

And what criteria are indicators of nozzle quality? Everything is pretty simple here. There are three of them:

- the outlet of the nozzle must be located as precisely as possible in the middle

- hole must be round

- hole diameter must match the declared

Compliance with the first two points can be checked with a cheap Chinese microscope, and the third with a feeler gauge.

All sorts of video bloggers add fire to the oil, who categorically insist, citing undeniable arguments that you need to take expensive and high-quality nozzles. That an expensive and high-quality nozzle is a guarantee that even the most budgetary Chinese 3D printer assembled from foil and sticks will print like an expensive ultramaker.

High-quality Chinese brass nozzles don't cost that much anymore - somewhere in the region of $2-$3 bucks apiece. So, in principle, every 3D printer can afford such a nozzle.

And everything would be fine, but every year more and more new composite plastics with carbon or glass filler appear on the market of 3D printed materials. And the prices for them are not so scary. But with these materials, not everything is so simple. Composites cannot be printed with ordinary brass nozzles. Although no, you can print, but brass nozzles (albeit the highest quality ones) wear out from such materials at the speed of light.

And how to be in such a situation? That's right, buy nozzles from more wear-resistant materials - steel, stainless steel, hardened steel, or buy nozzles with corundum inserts - with ruby, sapphire, etc. inserts.

But such nozzles are several times more expensive than even the highest quality brass nozzles. Well, about those nozzles, excuse me, dies that come with corundum inserts, I generally keep quiet, the prices there are just space.

And here again some bloggers jump out of the snuffboxes and start yelling:

“Only hardened steel nozzles should be used for printing with composites!!!! Link in the description!!! Click, go to Ali and buy-buy-buy!!!!!”

And what do seasoned bloggers who improve their skills in printing foxes and cubes advise us to take? Here's what:

We arm ourselves with a curculator and count. Nozzle - 8.76 bucks + shipping 3.04 bucks total 11.8 bucks. How much is it at the exchange rate today, consider for yourself.

What do we get for this money:

We get an excellent quality nozzle.

Everything seems to be fine. And well done bloggers, good advice was given and well done manufacturer. That's just the price...

What about cheap nozzles?

If you approach the issue wisely, then among cheap nozzles you can find worthy options. In the process of finding a supplier, we purchased prototypes and tested them.

This is what a stainless steel nozzle looks like under a microscope:

Similar nozzle, significantly lower price, acceptable quality.

So what's the catch? It's simple, theoretically, the resource of a stainless steel nozzle is lower than that of hardened steel.

It would seem that everything is clear. But it is worth thinking about the actual operation. Some time ago, we needed to print a rather voluminous part made of Total CF-5 plastic from filamentarno.

A carefully stored nozzle from Triangle Lab (the one in the photo) went into action. After 4 hours of printing, something irreparable happened - a clogged nozzle. As a result, an expensive high-quality nozzle, which should have pleased us for many years, fell into disrepair, the part was damaged, a lot of expensive material wasted.

cleaning it was impossible.

It is worth noting that 3D printer nozzles are consumables, regardless of whether they are cheap or expensive. They are equally likely to catch a blockage. But instead of one expensive nozzle, you can buy a bunch of cheap ones, and there will already be a big question of who will live longer than 1 expensive one or a dozen cheap ones.

They are equally likely to catch a blockage. But instead of one expensive nozzle, you can buy a bunch of cheap ones, and there will already be a big question of who will live longer than 1 expensive one or a dozen cheap ones.

For our part, we tried to make the selection of nozzles as convenient as possible for you and supplied each item in the catalog with a photograph from under a microscope.

You can get acquainted with the range of nozzles for 3D printer in our catalog.

Something like this.

Choose expensive or cheap nozzles - it's up to you. The main thing to remember is that the nozzle is a consumable whose life ends in the bin.

Tags: 3D printer, hardened steel, stainless steel, stainless steel, nozzle, die

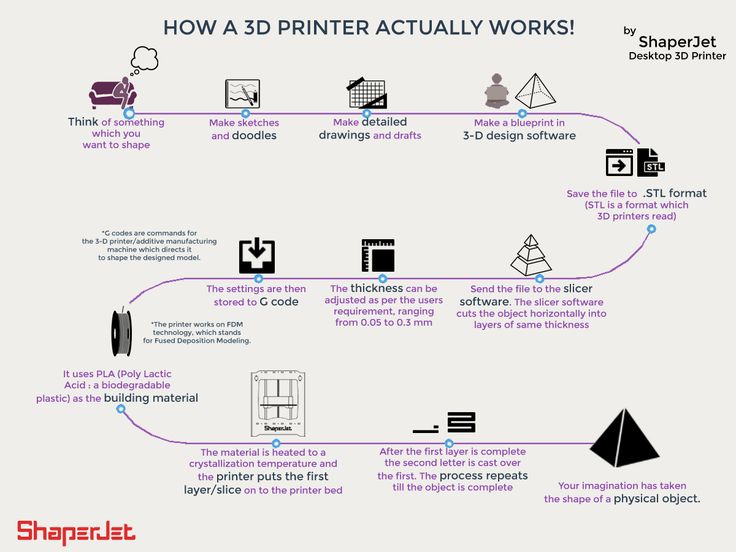

Nozzles for 3D printers - types, differences. Nozzle type

Nozzle is an integral part of any 3D printer, and there are many varieties of this part. Brass products are considered standard nozzles. This type is suitable for printing with conventional types of plastics, but for those that include an abrasive, such as NylonX, is not suitable. Printing with these materials requires higher performance nozzles made from stronger materials. There are also copper nozzles, Clean Tip nozzles - such nozzles are distinguished by the fact that the thread does not stick to them, and they remain clean.

Printing with these materials requires higher performance nozzles made from stronger materials. There are also copper nozzles, Clean Tip nozzles - such nozzles are distinguished by the fact that the thread does not stick to them, and they remain clean.

3D printing allows you to replace nozzles. This allows you to achieve different results and use different materials for printing.

3D printer nozzle: what is it?

The 3D printer nozzle is a special nozzle located in the extruder heater block. It is screwed into place by means of a thread. There is a small chamber inside the nozzle where molten plastic accumulates and is squeezed out through the hole. Moreover, the key parameters of the nozzle will be: the material from which the nozzle is made and the diameter of the hole.

Nozzle material

A standard desktop 3D printer is equipped with a 0.4mm brass nozzle. This is the best option for printing with ABS and PLA plastics. However, such nozzles are not at all suitable for printing with luminescent PLA, carbon fiber and metal enriched filaments. The fact is that plastics, which include solid particles, destroy the nozzle. The internal dimensions of the nozzle are distorted, and this affects the uniformity of the extruded material, which will inevitably affect the quality of 3D printing. For this reason, there are nozzles that are made from harder materials. Consider further the types of nozzles that can be found on the market.

The fact is that plastics, which include solid particles, destroy the nozzle. The internal dimensions of the nozzle are distorted, and this affects the uniformity of the extruded material, which will inevitably affect the quality of 3D printing. For this reason, there are nozzles that are made from harder materials. Consider further the types of nozzles that can be found on the market.

Brass 3D Printer Nozzle

Brass Nozzle is the most popular option used in most desktop 3D printers. Of all the materials used to make nozzles, this one is the softest. But brass nozzles are easy to process, cheap and affordable. Therefore, they are easy and simple to replace.

The main characteristics of brass nozzles:

- corrosion resistance;

- high thermal conductivity;

- relative softness;

- abrasion.

Application: Ideal for printing with "soft" plastics - standard ABS, PLA, PETG, and other plastic filaments that do not contain carbon fiber and metal additives.

Stainless steel or hardened steel nozzle

Steel nozzles are also used for 3D printing. They provide long-term printing with materials that contain solid particles, such as metal, carbon fiber. At the same time, such nozzles are not prone to abrasion and destruction, like softer brass nozzles. That is, you can print for a long time without reducing productivity.

But steel nozzles are not without drawbacks: lower thermal conductivity compared to brass nozzles. This can change the flow, especially when using large nozzles.

The main characteristics of steel nozzles:

- corrosion resistance;

- low thermal conductivity;

- relatively large weight;

- abrasion resistance.

Application: 3D printing with additives (carbon fiber, metal, glass, etc.)

Ruby nozzle

Anders Olsson developed the Olders Ruby nozzle. This is a brass nozzle equipped with a tip made of aluminum oxide, that is, an artificial ruby. This nozzle was originally created for 3D printing by the third heaviest material in the world. The nozzle was the result of an experiment conducted at Uppsala University in Sweden.

This nozzle was originally created for 3D printing by the third heaviest material in the world. The nozzle was the result of an experiment conducted at Uppsala University in Sweden.

Initially standard nozzles made of steel and brass after printing 1kg of plastic wear out and are no longer usable. However, the nozzles have a number of disadvantages. Olson Ruby nozzles combine the high thermal conductivity of brass with the abrasion resistance of ruby. Of course, there are experts who say that the ruby tip has a low thermal conductivity, which negatively affects the printing result, but there is no evidence for this. At least for now.

The main characteristics of Olsson Ruby nozzles are:

- corrosion resistance;

- low thermal conductivity;

- abrasion resistance.

Application: Can be used for highly abrasive threads.

Tungsten Carbide Nozzles

Dyze Design Tungsten Carbide Nozzles are something of a newcomer to the market as they only started production at the end of 2018. Tungsten carbide is hard, wear resistant. It is used for drilling, cutting ceramics and metals. Such nozzles also have disadvantages, but it is too early to talk about them.

Tungsten carbide is hard, wear resistant. It is used for drilling, cutting ceramics and metals. Such nozzles also have disadvantages, but it is too early to talk about them.

Main characteristics of tungsten carbide nozzles:

- abrasion resistance, very high;

- hardness;

- high thermal conductivity;

- corrosion resistance.

Application: This is a universal nozzle that can be added to your nozzle set, and the nozzle is also suitable for printing with highly abrasive filaments.

Nozzle sizes for 3D printer

Nozzles are characterized by the diameter of the hole. This characteristic will affect the degree of print detail. In this case, the influence will be exerted not only on the width of the lines, but also on the height of the layer.

Beginners are advised to use a nozzle with a diameter of 0.15mm. Compared to a standard 0.4mm nozzle, this nozzle allows you to get a higher resolution in the OX and OY axes. Thanks to thin lines, sharper corners can be obtained, but this will only be possible in that case. If your 3D printer is well set up and serviced regularly.

Thanks to thin lines, sharper corners can be obtained, but this will only be possible in that case. If your 3D printer is well set up and serviced regularly.

The choice of nozzle diameter should be determined by the layer height you require. It is necessary to choose a nozzle so that the size of the layer during printing is 25-50% of the nozzle size.

If the device is calibrated correctly, optimum adhesion can be achieved between coats. For example, a standard 0.4mm nozzle allows you to print layers of 0.1-0.2mm. If you want to successfully print ultra-thin layers that are less than 0.05mm high, we recommend using the 0.2mm nozzle.

Small nozzles have one significant drawback. They are more prone to clogging and therefore need to be cleaned regularly. In addition, smaller nozzles significantly increase print time as the print head requires more passes to coat. the larger the nozzle, the less time it will take to print, and the time will be reduced exponentially.