Propeller 3d print

Propeller best STL files for 3D printing・Cults

V-12 Engine, Optional Parts Kit, Engine Mount Frame

Free

propeller launcher

€0.99

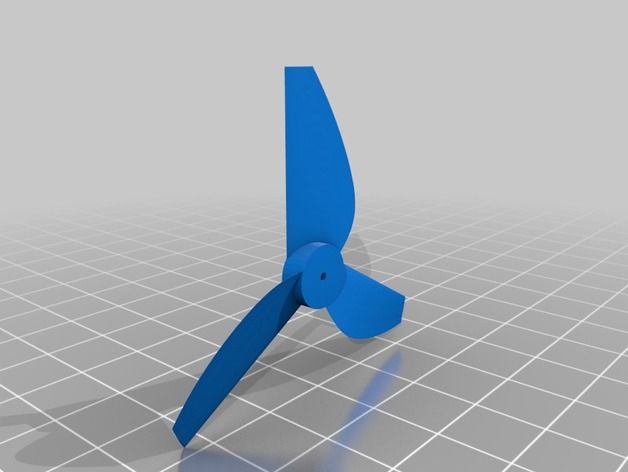

Propeller

Free

PROPELLER LAUNCHER / SPINNERS

€2.94

3 Blades Outboard

€1.02

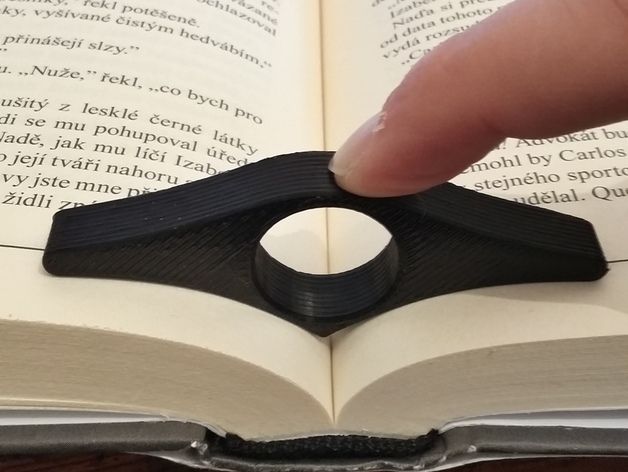

Prop Holder for 5045 Props

Free

Propeller balancer

Free

Squirt prop cutter ! 3,5inch !

Free

Prop guard for 5 inch CineWHOOP Quadcopter

Free

SF-260

€5

V-type 12-Cylinder Engine, Water-Cooled, Cutaway

€57. 64

Outboard Engine GearBox Gear Case

€10.95

LIDL Glider - JMT 1806 spinner

Free

propeller guard improved

Free

Propeller Mushroom Mario Based

€3.83

Propeller Mushroom Mario

€3.83

Propeller Quill Pen

Free

DJI SPARK box Propellers

€1

Radial Engine, 14-Cylinders, Cutaway

€57.64

Flying Peach - Microswift Evolution

Free

Azure Power - Race & Freestyle Propellers 5045 x 3

Free

bladeless drone concept

€17. 63

63

3D Printable Mini Fan

Free

#TrollingBot propeller

Free

impeller for elegoo Mercury plus

€14.41

Drone Propellers CW + CCW 3 Blade 72mm ⌀

Free

Bell 360 Invictus

€9.56

Radial Engine, 7-Cylinder, Optional Parts Kit (3) to 14-Cylinder

€24.02

Flying House

Free

Parametric propeller with hub attack angle

Free

Mavic 2 Propeller Case

Free

1045 Propeller guard

Free

Disk Helicopter 🚁

€2. 17

17

DJI Avata Bumper

€3.50

aircraft propellers

€3.84

Turbine Propeller Fan Generator v2

Free

propsaver for 2212 motor

Free

White Star Line Notice Triple Screw Sign

Free

Flying Drone Sci Fi 3D model Cyber Punk

€3.83

Mavic Air Propellers Case

Free

Miniature RC Drone

€0.50

3 blade spinner + 9,5x7propeller

Free

Best performance propellers for fpv drone

€4.77

#TrollingBot Racing Propeller - Medium size

Free

SF PROPELLER SPINNER V3 5×25 mm

€0. 99

99

SF PROPELLER SPINNER V3 5×35 mm

€0.99

SF PROPELLER SPINNER V3 5×40 mm

€0.99

Zoom copter with pull string parts

Free

Naval Group has 3D printed a one-tonne ship propeller for the French Navy

0Shares

Defense contractor Naval Group has manufactured an entirely 3D printed propeller for a French Navy ship.

The company used its own specially developed DED-based process for the job, which it calls metal wire fusion. Sporting a 2.5-meter span and five individual 200kg blades, the propeller is reportedly the largest thruster of its kind to be 3D printed, and the first to be manufactured using Naval Group’s own process.

Having left the Naval Group site of Nantes-Indret back in October, the propeller was mounted onto the intermediate shaft of the Andromède, a Tripartite-class minehunter, a month later. Then, December saw the successful completion of a series of sea trials with the propeller, cementing its place on all of the ship’s upcoming operational missions.

Then, December saw the successful completion of a series of sea trials with the propeller, cementing its place on all of the ship’s upcoming operational missions.

Meeting defense-grade quality requirements

It’s safe to say military ships operate under some pretty harsh conditions, relating to corrosion, fatigue, and shock resistance to name a few. As such, their production must be held to equally harsh quality requirements. For the SSF (Fleet Support Services) and the DGA (French Defence Procurement Agency) to even authorize the testing of the blades in normal operating conditions, Naval Group had to work very closely with the certification company Bureau Véritas to develop a comprehensive technical justification file.

Emmanuel Chol, Director of the Nantes-Indret site where the propeller was 3D printed, stated, “Obtaining military naval quality requires rigorous development. Nearly three years of R&D – carried out by the Technical and Innovation Department in cooperation with the Ecole Centrale de Nantes within the framework of the LabCom Joint Laboratory of Maritime Technology – went into the development of the deposition process of metal wire fusion. ”

”

The benefits of 3D printing

While the 3D printing of the propeller is a major accomplishment, it is just the first step in a whole new development phase being undertaken by Naval Group. Riding off the back of the successful project, the company is set to focus on redesigning other maritime components that could benefit from 3D printing.

As well as weight savings and significant reductions in lead times, redesigning parts for 3D printing can increase energy and thrust efficiencies, and even improve the acoustic discretion of a component during stealth operations. Furthermore, DED-based technologies like metal wire fusion lend themselves quite well to part repair, alleviating further costs and downtime in the wake of destructive accidents.

Eric Balufin, Director of the Naval Group site of Brest where the blades were mounted, concludes, “The assembly of this 3D printed propeller shows great promise for the future. This new technology will enable us to considerably reduce technical constraints, and therefore allow for new manufacturing solutions for complex geometrical shapes which cannot be produced through conventional processes. It will also enable us to greatly reduce production time and consequently in-service support.”

This new technology will enable us to considerably reduce technical constraints, and therefore allow for new manufacturing solutions for complex geometrical shapes which cannot be produced through conventional processes. It will also enable us to greatly reduce production time and consequently in-service support.”

As Naval Group preaches, 3D printing has excellent potential in the maritime sector – both technologically and logistically. Just last month, digital part storage specialist Ivaldi Group announced that it was taking on the role of project manager in a Phase II Joint Industry Program to advance spare part 3D printing for Singapore’s maritime industry. Citing print speed, part performance, and cost reductions as hurdles to jump, Ivaldi hopes to bring together 14 key industry players to 3D print, certify, and install end-use parts onboard vessels in the region.

Elsewhere, the Indian Navy has previously partnered with 3D printing service provider think3D to help fabricate spare parts on demand for both on and off-shore military components. The collaboration was aimed at remedying the issue of spare part availability, which is reportedly a recurring problem for the Indian armed forces.

The collaboration was aimed at remedying the issue of spare part availability, which is reportedly a recurring problem for the Indian armed forces.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed propeller. Photo via Naval Group.

Tags Bureau Veritas Emmanuel Chol Eric Balufin French Navy Naval Group

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Best STL Files for 3D Printing Propeller・Cults

V-12 engine, accessory kit, engine mount frame

Free

screw launcher

0. 99 €

99 €

Propeller

Free

PROPELLER LAUNCH / SPINNERS

2.94 €

3 blades outboard

1.02 €

Post holder for 5045 posts

Free

Propeller balancer

Free

Squirt cutter! 3.5 inches!

Free

CineWHOOP 9 5" Protective Housing0003

Free

SF-260

5 €

V-12 engine, water-cooled, engine compartment

57.64 €

Outboard gearbox housing

10.95 €

LIDL glider - spinner JMT 1806

Free

improved propeller protection

free

Propeller Mushroom based on Mario

3. 83 €

83 €

Propeller Mushroom Mario

3.83 €

Propeller pen

Free

Propellers DJI SPARK box

1 €

Radial engine, 14-cylinder, bodywork

57.64 €

Flying Peach - Microswift Evolution

Free

Azure Power - Race & Freestyle Propellers 5045 x 3

Free

bladeless drone concept

17.63 €

3D printed mini fan

Free

Propeller #TrollingBot

Free

impeller for elegoo Mercury plus

14.41 €

Propellers for drones CW + CCW 3 blades 72 mm ⌀

Free

Bell 360 Invictus

9. 56 €

56 €

Radial engine, 7-cylinder, additional parts kit (3) up to 14-cylinder

24.02 €

Flying house

Free

Parametric propeller with hub attack angle

Free

Mavic 2 Propeller Case

Free

1045 Propeller guard

Free

Disc helicopter 🚁

2.17 €

Bumper DJI Avata

3,50 €

propellers

3.84 €

Turbine Propeller Fan Generator v2

Free

Propsaver for engine 2212

Free

White Star Line Notice Tri-Screw Sign

Free

Sci Fi flying drone 3D model Cyberpunk

3. 83 €

83 €

Mavic Air Propeller Case

Free

Miniature RC drone

0,50 €

3-blade spinner + 9.5x7 propeller

Free

Best propellers for fpv drone

4.77 €

#TrollingBot Racing Propeller - Medium Size

Free

SF PROPELLER SPINNER V3 5×25 mm

0,99 €

SF PROPELLER SPINNER V3 5×35 mm

0.99 €

SF PROPELLER SPINNER V3 5×40 mm

0,99 €

Zoom quad with extended parts

Free

Hacking 3D printing parts to sabotage the operation of a future device / Sudo Null IT News

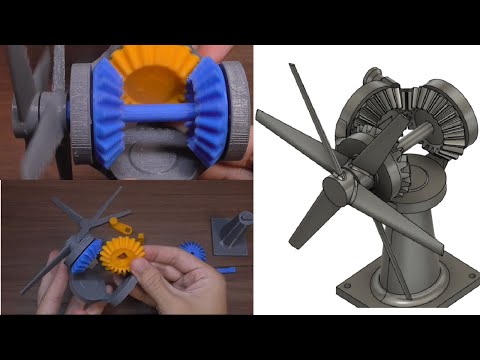

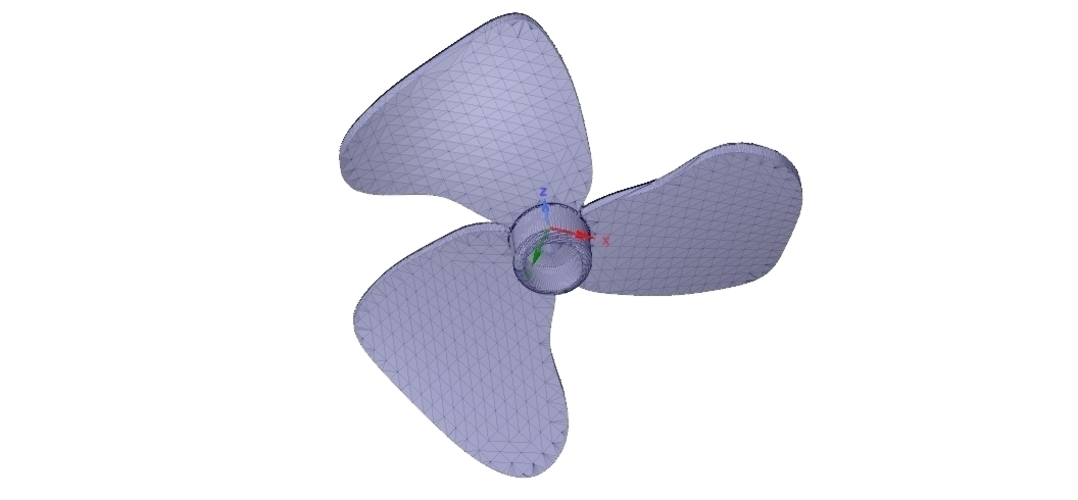

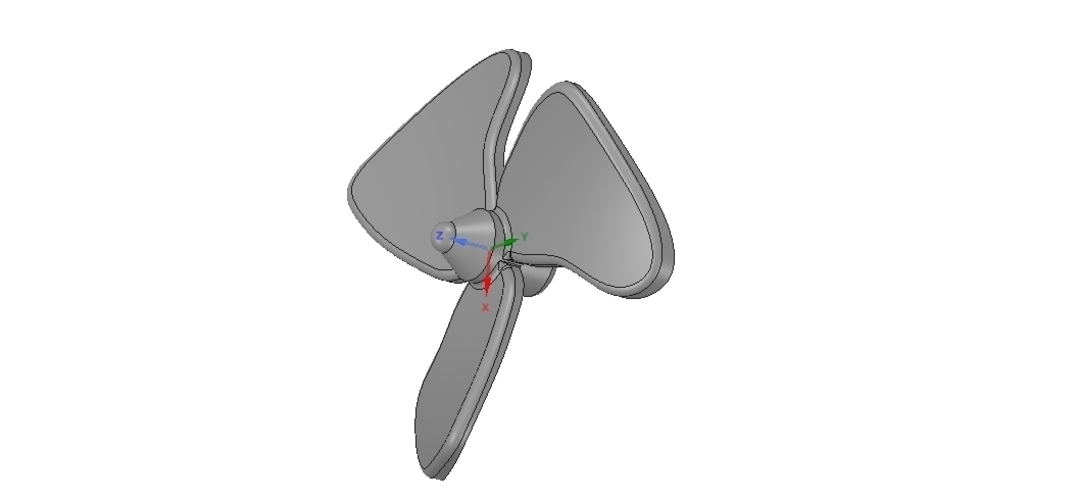

A copter propeller with changes that lead to the destruction of the part during its operation

In 2016, the IoT sphere continues to develop actively. Now literally everything can be connected to the Web, from refrigerators to 3D printers and pacemakers. Not all connected systems are equipped with reliable protection, so hacking most devices is a matter of time. Literally everything can be hacked.

Now literally everything can be connected to the Web, from refrigerators to 3D printers and pacemakers. Not all connected systems are equipped with reliable protection, so hacking most devices is a matter of time. Literally everything can be hacked.

Moreover, hacking is gradually becoming not only a threat to virtual systems, but with the help of cyberattacks it is possible to destroy quite real physical objects. This applies in particular to power plants or other industrial facilities. Crackers have also learned how to drive robo-cars or "digital assistants" in Tesla electric vehicles. The other day there was information about another type of hack: attackers can influence the printing process on a 3D printer in order to start the production of defective components.

Cybersecurity experts from Ben-Gurion University of the Negev, with the help of experts from the University of South Alabama and the Singapore University of Technology and Design, have developed a hacking method for 3D printers that allows you to remotely edit printed parts or influence the printing process directly during the operation of the printer. The edits are almost imperceptible, but they subsequently lead to the destruction of the part itself already in the process of its operation.

The edits are almost imperceptible, but they subsequently lead to the destruction of the part itself already in the process of its operation.

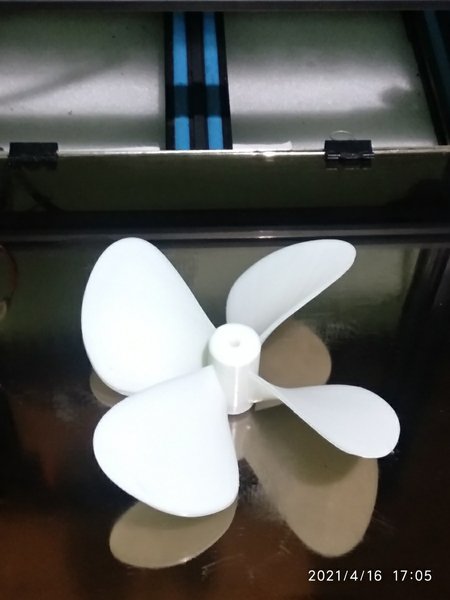

Study named "dr0wned - Cyber-Physical Attack with Additive Manufacturing" . This paper describes the process of hacking a PC with a 3D printer connected to it. During the attack, experts gained access to files of models of drone propeller parts, which were then printed on a 3D printer. And just two minutes later, the quadcopter fell to the ground from a great height as a result of the planned destruction of the propeller blades.

In the experiment, the fall occurred at the moment the drone reached its maximum height. During the fall, the device received significant damage. In particular, one of the motors was damaged, the camera was completely destroyed, the body of the drone was cracked.

To gain access to a computer with a connected 3D printer, the authors of the work used a vulnerability in WinRAR that allows hiding the name and extension of a compressed file. The developers created a malicious executable using the Metassploit framework. The malicious file was disguised as a regular PDF document. The victim received an e-mail message, opened the archive and launched the "document". After launching the file, the Israeli experts gained full access to the “victim's” computer.

The developers created a malicious executable using the Metassploit framework. The malicious file was disguised as a regular PDF document. The victim received an e-mail message, opened the archive and launched the "document". After launching the file, the Israeli experts gained full access to the “victim's” computer.

.STL files were found on the computer, which are ready-made models of copter propellers. One of the copter propeller model files has been modified to make the part more vulnerable to physical impacts. During the experiment, the SolidWork software package was used. After the modification, the modified file was saved on the victim's computer instead of the propeller model file with normal characteristics.

During field testing, researchers found that the propellers can withstand the flight of the copter for several minutes. When the load increases, the modified propeller breaks, which leads to a drone crash.

This problem is more important than it might seem. The fact is that now 3D printing is increasingly used in industry. With the help of such systems, car and aircraft body parts are manufactured at plants and factories. So far, there are only a few such productions, but over time there will be more of them. And industrial sabotage can become much more high-tech than it is now. Moreover, in this case, sabotage does not appear immediately, the consequences of the attack are delayed in time.

The fact is that now 3D printing is increasingly used in industry. With the help of such systems, car and aircraft body parts are manufactured at plants and factories. So far, there are only a few such productions, but over time there will be more of them. And industrial sabotage can become much more high-tech than it is now. Moreover, in this case, sabotage does not appear immediately, the consequences of the attack are delayed in time.

Copter with three normal propellers and one defective

Specialists from David Ben-Gurion University of the Negev demonstrated for the first time an "indirect multi-stage cyber-physical attack." With its help, the authors of the work were able to change the size and position of printed parts. According to these experts, the attack can consist both in changing the specifications of parts, that is, editing files, and in directly changing the production process itself on the fly. Even minor changes can lead to important consequences.