Price of 3d printer material

How much does 3D printing cost?

David Roberson21 September 2021

Guide

Once you understand how 3D printing works, it's important to talk money. A 3D printer should be a long-term asset for your organization that delivers value for years after you buy it. But how much does 3D printing cost?

This return on investment is a benefit that sets 3D printing apart from other solutions like outsourcing. But as with any long-term asset, it pays to be aware of all the associated costs that come with owning a 3D printer, and which expenses – including 3D printer material costs – you need to plan for into the future.

The list below should help you understand the costs involved, how they differ depending on the technology, and which are one-off or repeating. (Prices are indicative and subject to change – so we recommend doing your own research too.)

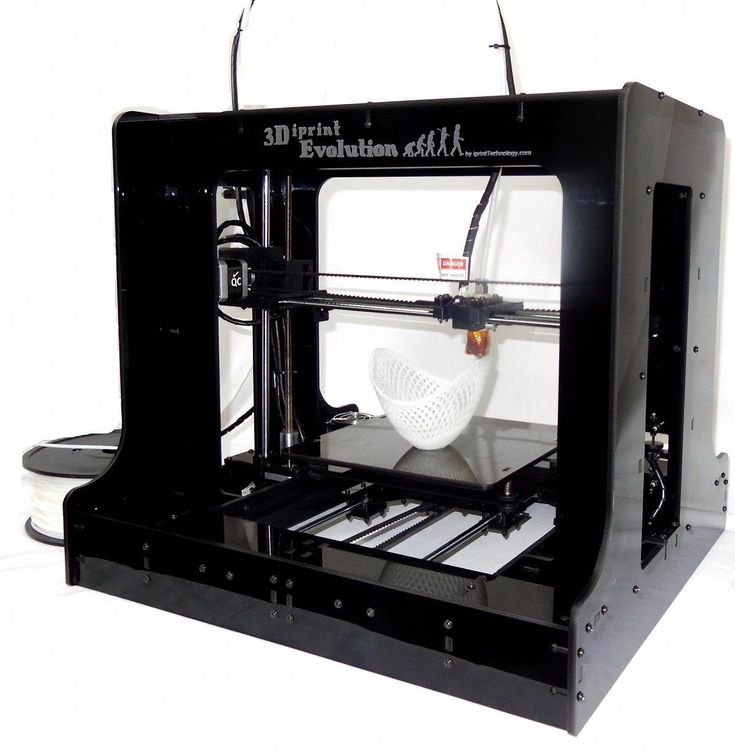

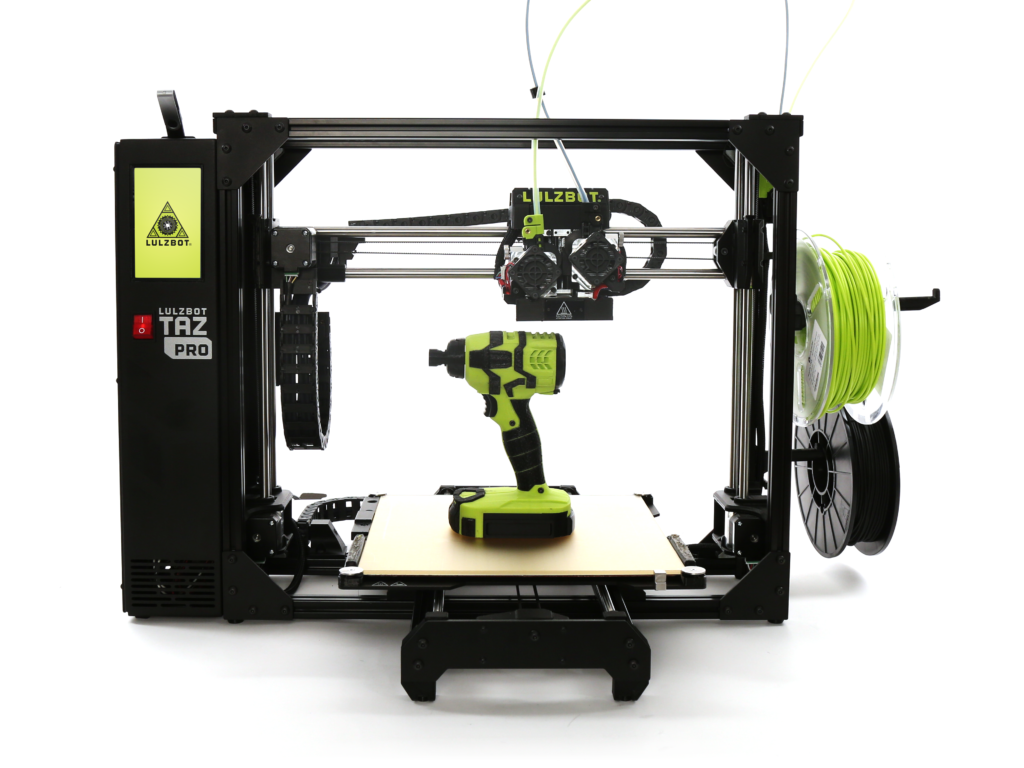

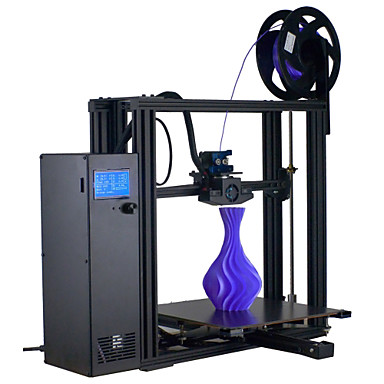

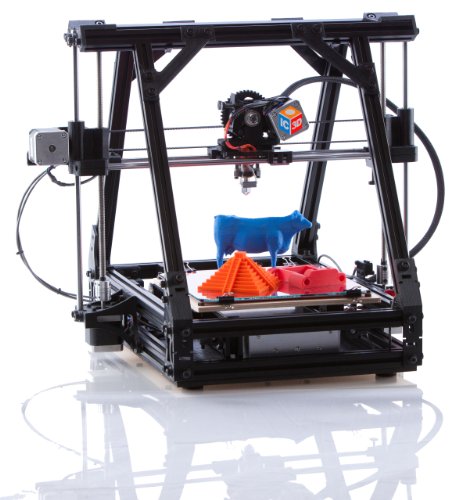

3D printer price

With products on the market for anyone from a home user to the R&D divisions of blue-chip companies, 3D printer prices vary a lot. Typically, FFF offers the greatest variation in price, from hobbyist machines costing a few hundred dollars to higher-performance desktop printers in the $2,000 to $6,000 range. Desktop SLA printers start from around $2,000 to $3,000, while an SLS printer typically costs $10,000 plus. Larger-scale industrial machines of any technology will cost significantly more.

Peripherals

These can add extra functionality, but also add extra expense your 3D printing costs. Post-processing peripherals are almost essential for SLA and SLS printers. For example, SLA prints will otherwise have to be manually washed in isopropyl alcohol and left in the sun to cure – so in practice, these printers often require purchase of post-processing stations unless that appeals to you! For FFF, peripherals can streamline workflows such as material handling, but are up to you depending on your needs.

Maintenance and service

Typically, this should only be the cost of replacing the odd consumable part over time. Check what support your seller includes as part of the price – they may offer installation and maintenance included. Some products also come with extended warranty options or an annual service plan. These plans can add certainty for some customers, but be sure to read the fine print in detail to understand the terms and exactly what support you get if something goes wrong.

Check what support your seller includes as part of the price – they may offer installation and maintenance included. Some products also come with extended warranty options or an annual service plan. These plans can add certainty for some customers, but be sure to read the fine print in detail to understand the terms and exactly what support you get if something goes wrong.

Energy

For regular use for an Ultimaker 3D printer, we calculated this to be around $50 per year. But if you want a more precise figure, check the power consumption specs of a 3D printer and make a calculation based on your likely usage and local energy prices.

Materials

Think of material costs like gas for your car. While not considerable in isolation, over the long-term it will be one of the biggest running costs. For FFF 3D printing, 3D printer filament prices (for an everyday material like PLA or PETG) are around $20 to $50 per kilogram, or $60 to $120 for specialized engineering or support filaments. Entry-level SLA resins cost around $50 per liter, and most professional options cost around $150 to $400. SLS powder can cost around $100 to $200 per kilogram.

Entry-level SLA resins cost around $50 per liter, and most professional options cost around $150 to $400. SLS powder can cost around $100 to $200 per kilogram.

Software

Most professional level 3D printers come with some software included, usually so you can prepare your prints and manage printers. Many cheaper 3D printers don’t come with adequate software, but luckily our Ultimaker Cura software is compatible with hundreds of machines and free to download. And if you really want to scale 3D printing in your business unit or even entire organization, consider an enterprise software plan with added features like direct support, online training courses, and cloud storage for your parts and projects.

You can learn more in our total cost of ownership white paper – available to download for free.

A 3D printer is part of an ecosystem that includes peripherals, materials, and software – either from the manufacturer or third parties

Need more info on 3D printing?

Explore the wider world of this incredible technology by reading our answers to these common questions:

What is 3D printing?

What can you make with a 3D printer?

How to use a 3D printer?

How Much Does a 3D Printer Cost?

In-house 3D printing is a versatile solution for a wide range of applications, from high-resolution models to rapid prototyping, rapid tooling for traditional production processes, manufacturing aids, and even end-use parts in manufacturing.

When you consider investing in a 3D printer, however, viability typically boils down to a simple question: does it make economic sense for your business? How much does a 3D printer cost and how much time and cost can you actually save with it for your business?

3D printer prices range from about $200 to $500,000+ depending on the printing process, materials, and the level of sophistication of the 3D printing solution.

In this guide, we’ll walk you through the 3D printing costs for different technologies, compare outsourcing with in-house production, lay out the various factors you should account for to calculate cost per part, and look at considerations beyond cost when comparing various 3D printing solutions and other production methods.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

The three most established plastic 3D printing processes today are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Each 3D printing technology has its pros and cons—here's an infographic for a quick comparison:

Download the high-resolution version of this infographic here. Would you like to learn more about FDM, SLA, and SLS 3D printing technologies? Check out our in-depth guide.

3D printer prices have dropped significantly in recent years, and today, all three technologies are available in compact, affordable systems.

As a rule of thumb, FDM 3D printers will create the cheapest parts if you’re printing only relatively simple prototypes in limited numbers. SLA resin 3D printers offer higher resolution, better quality, and a wide variety of 3D printing materials at a slight premium, but the difference quickly diminishes when you print complex designs or larger batches due to the less labor-intensive post-processing. Lastly, SLS 3D printing is the most cost-effective process for producing medium to large volumes of high-quality functional parts.

Comparing the overall cost of different 3D printers goes beyond sticker prices -- these won’t tell you the full story of how much a 3D printer costs and how much your printed part will cost. 3D printing material and labor costs have a significant influence on cost per part, depending on the application and your production needs.

3D printing material and labor costs have a significant influence on cost per part, depending on the application and your production needs.

Let’s look at all the different factors and costs for each process.

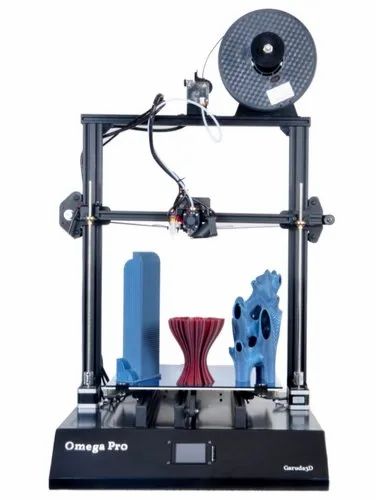

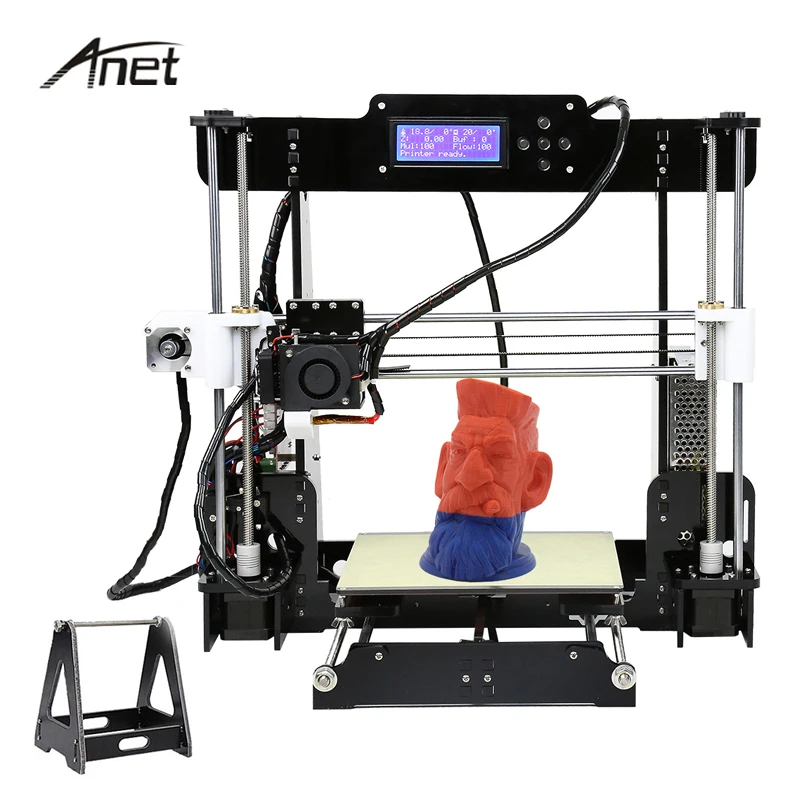

FDM, also known as fused filament fabrication (FFF), is a printing method that builds parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

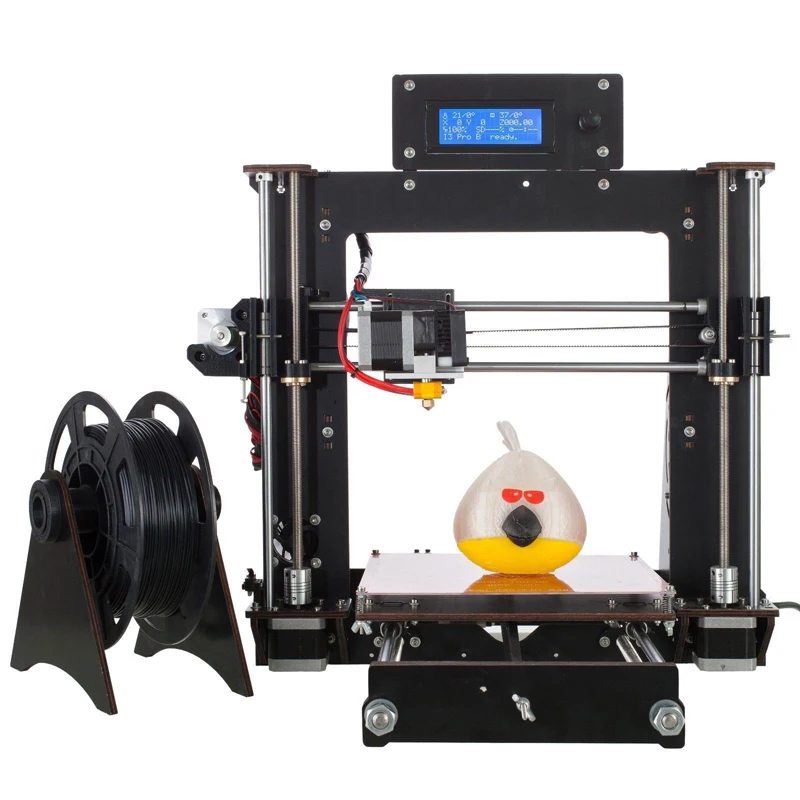

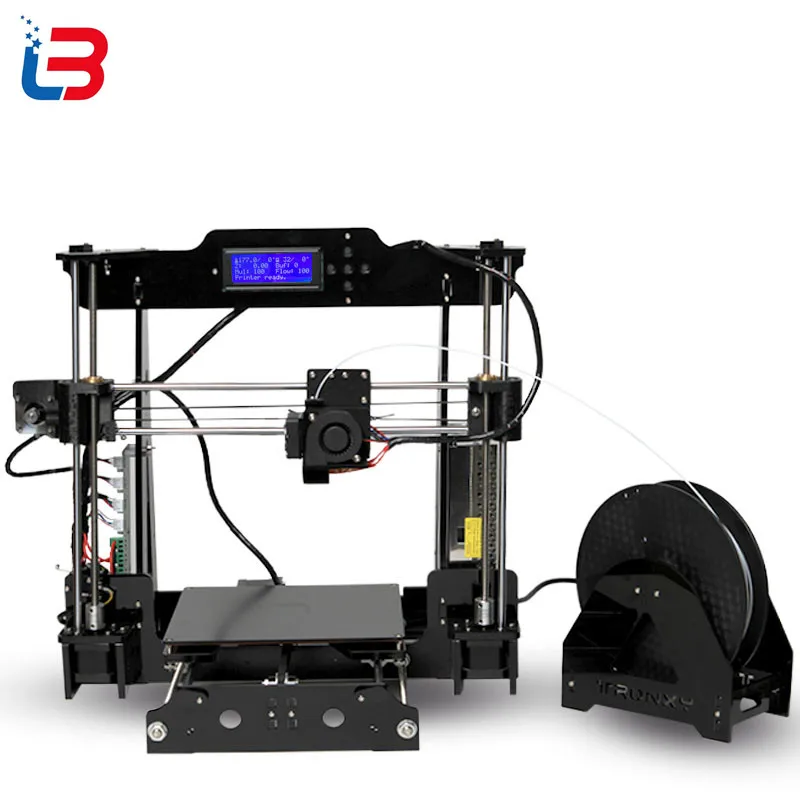

FDM is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. Professional and industrial FDM printers are, however, also popular with professionals.

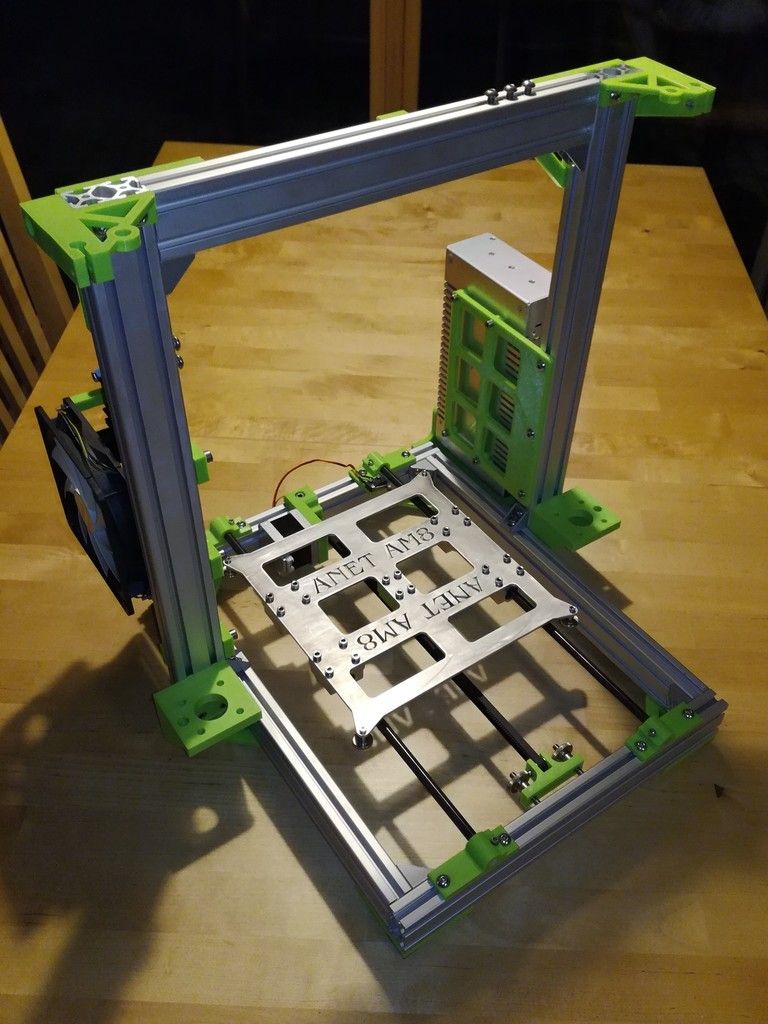

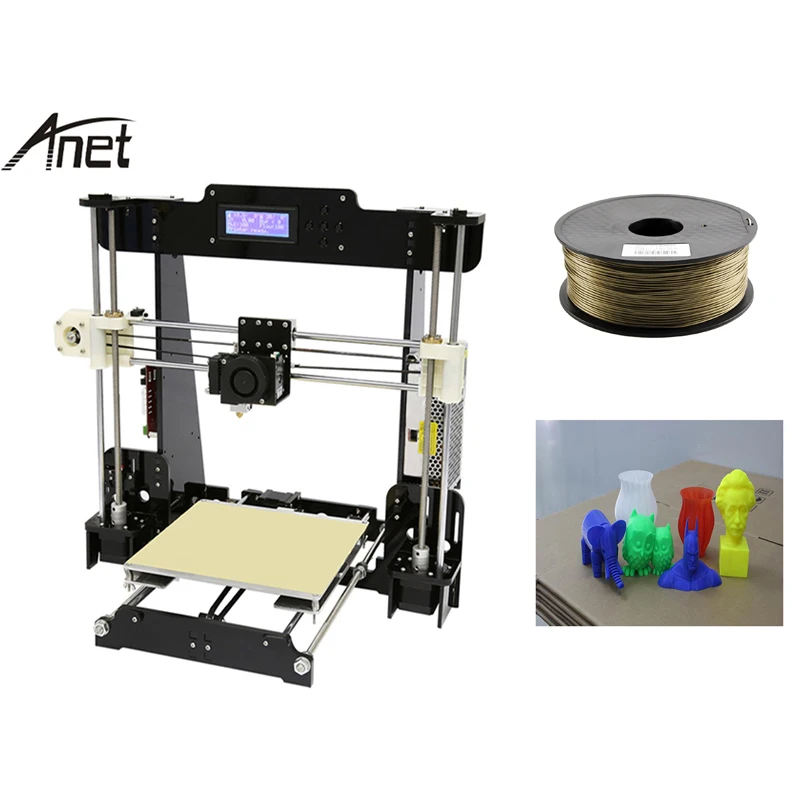

The lowest cost 3D printers are almost exclusively FDM printers. Prices for the cheapest entry-level DIY FDM 3D printer kits start at around $200. However, most of these models are more like toys or DIY projects themselves that require you to spend a considerable amount of time assembling, tweaking, and calibrating the printer. Print quality is highly dependent on the success of these steps and still, these machines will require you to do repairs and regular maintenance to keep them running, so they are only recommended for anyone with an (in progress) engineering degree and lots of time and patience.

Hobbyist FDM 3D printers which cost around $500-$1,500 might come as a kit or assembled, require slightly less tweaking, but they still share much of the same disadvantages as the lowest-cost 3D printers. Some models closer to the top of this range will offer bigger build volumes and also more material options beyond low-temperature materials like PLA.

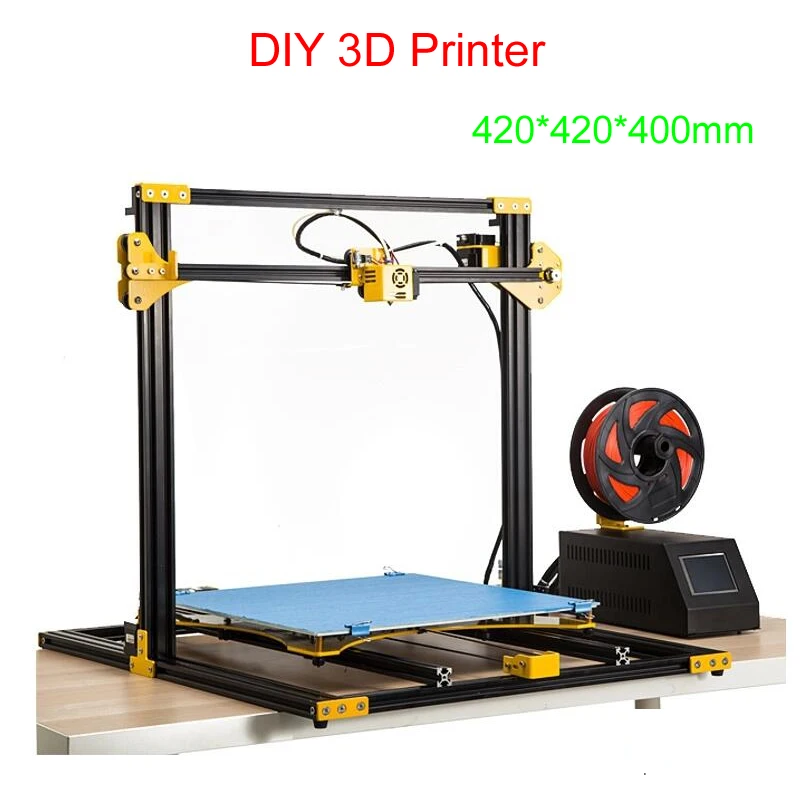

Professional FDM 3D printers start around $2,500, and large-format professional FDM printers start around $4,000, while the most advanced industrial FDM printers can easily cost more than $10,000. Most of these printers will come assembled and calibrated out of the box, or they can auto-calibrate themselves. Printers in this category offer better print quality, a wider range of materials, larger build volumes, better reliability, and are easier to use and maintain. Unlike lower-cost printers, manufacturers of professional 3D printers also offer customer support to troubleshoot issues.

Regarding materials, FDM 3D printing material costs range from around $50 to $150/kg for most standard and engineering filaments and $100-200/kg for support materials. Cheaper alternatives might be available, but once again, with a trade-off in terms of quality.

Cheaper alternatives might be available, but once again, with a trade-off in terms of quality.

Lastly, FDM printing can be highly labor-intensive. Many designs, especially complex models, require support structures for successful printing, which need to be removed manually or by dissolving the structures in case of soluble supports. To obtain a high-quality finish and remove layer lines, parts require lengthy manual post-processing, such as sanding.

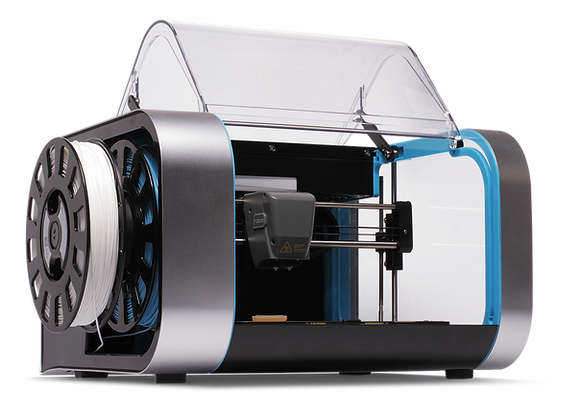

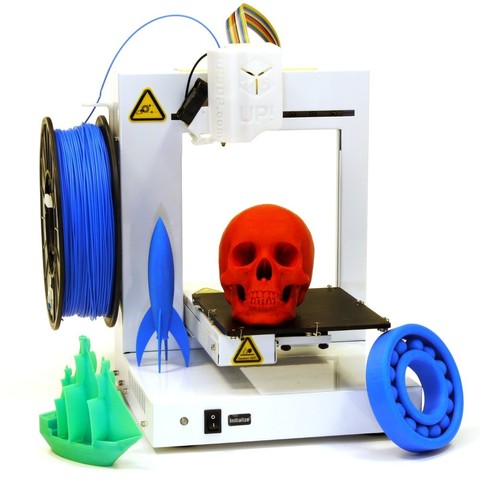

SLA 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization. SLA is one of the most popular processes among professionals due to its high resolution, precision, and material versatility.

SLA parts have the highest accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA 3D printing offers a wide range of materials for a variety of applications.

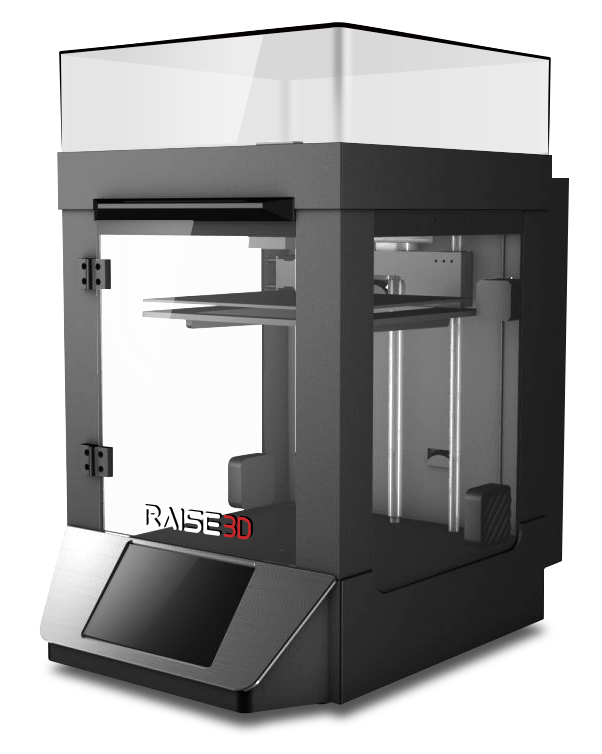

While SLA technology used to be available only in large, complex industrial 3D printers that cost more than $200,000, the process has become much more accessible. With the Formlabs Form 3+ printer, businesses now have access to industrial-quality SLA for just $3,750. Large-format SLA with the Form 3L starts at just $11,000.

SLA 3D printers will come assembled and calibrated out of the box. They’re professional tools that are reliable also for production and require barely any maintenance. Customer support is also readily available to troubleshoot issues in the unlikely event that something goes wrong.

In terms of material costs, SLA resins cost around $149-$200/L for most standard and engineering resins.

SLA printers are easy to use and many steps of the workflow like washing and post-curing can be mostly automated to reduce labor needs. Printed parts have a high-quality finish right off the printer and require only simple post-processing to remove support marks.

White Paper

In this free report, we look at how in-house large-format 3D printing with the Form 3L stacks up against other methods of production, chiefly outsourcing and using FDM printers. We also compare costs between methods, and review when it would be best to bring the Form 3L in-house.

Download Now

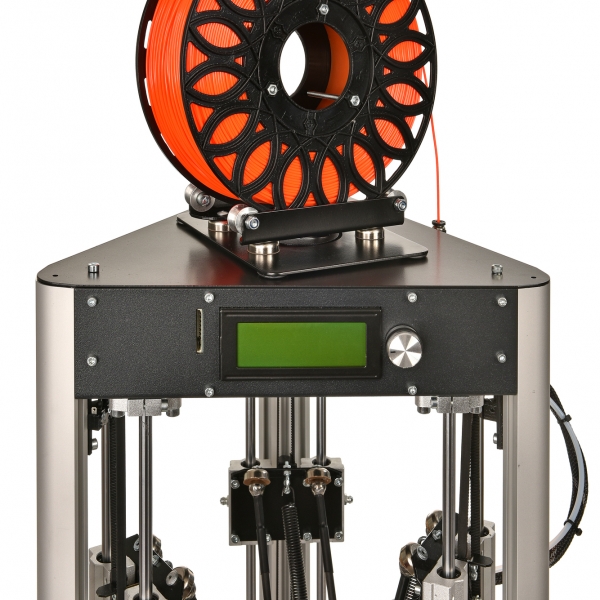

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures, which makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts. As a result, SLS is the most common plastic 3D printing process for industrial applications.

SLS nylon parts are ideal for a range of functional applications, from engineering consumer products to healthcare.

Just like SLA, SLS used to be only available in large-format, complex 3D printing systems starting at about $200,000. With Formlabs’s Fuse 1 SLS printer, businesses can now access industrial SLS starting from $18,500, and $29,743 for a complete setup that includes a post-processing and powder recovery system.

Also similar to SLA printers, SLS printers will come assembled and calibrated out of the box. They are reliable and developed for 24/7 production, and come with advanced training and fast customer support.

Nylon materials for SLS printing cost around $100/kg. SLS requires no support structures, and unfused powder can be reused, which lowers material costs.

SLS is the least labor-intensive plastic 3D printing process in a production setting as parts have great quality right out of the printer and require only simple cleaning to remove excess powder.

Beyond plastics, there are multiple 3D printing processes available for metal 3D printing.

-

Metal FDM

Metal FDM printers work similarly to traditional FDM printers, but extrude metal rods held together by polymer binders. The finished “green” parts are then sintered in a furnace to remove the binder.

The finished “green” parts are then sintered in a furnace to remove the binder.

SLM and DMLS printers work similarly to SLS printers, but fuse metal powder particles together layer by layer using a laser instead of polymers. SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

While metal 3D printer prices have also begun to decrease, with costs ranging from $100,000 to $1 million, these systems are still not accessible to most businesses.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

White Paper

Get design guidelines for creating 3D printed patterns, walk through the step-by-step direct investment casting process, and explore guidelines for indirect investment casting and sand casting.

Download the White Paper

The various plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Here's a quick breakdown.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM | Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) | |

|---|---|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★☆ |

| Throughput | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★☆☆☆☆ |

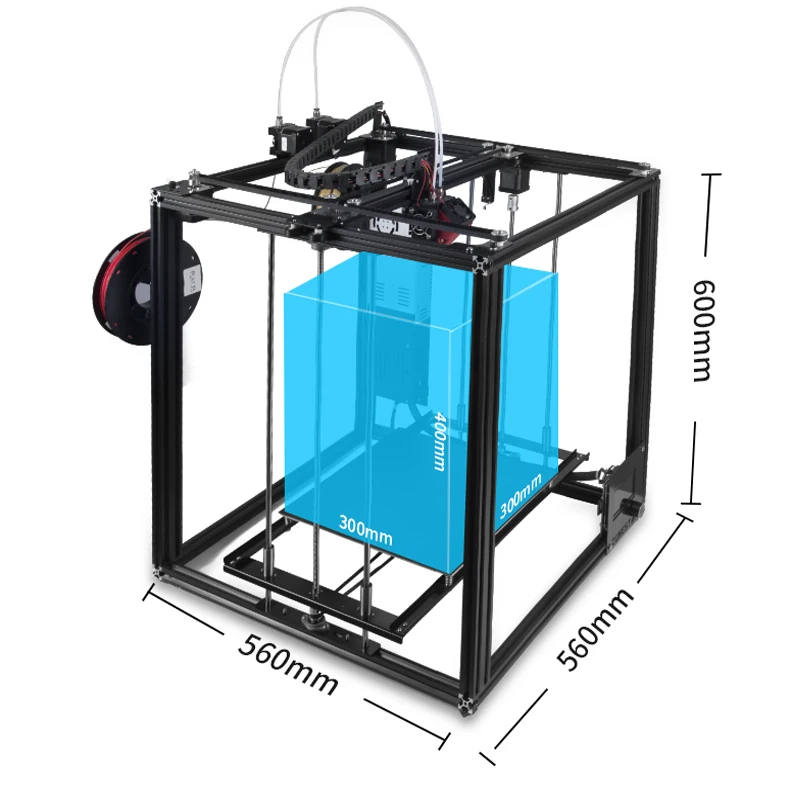

| Build Volume | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) | Up to 300 x 200 x 200mm | Up to 400 x 400 x 400 mm |

| Price Range | DIY printers 3D printer kits start around $200, hobbyist printers range from $500-$1,500. Professional FDM 3D printers start around $2,500, and large-format professional FDM printers start around $4,000. Professional FDM 3D printers start around $2,500, and large-format professional FDM printers start around $4,000. | Professional desktop printers start at $3,750, large-format benchtop printers offer a bigger build volume for $11,000. | Benchtop industrial SLS systems start at $18,500, and traditional industrial printers are available from $100,000. | Metal FDM printers start from $100,000, but the full solution that includes a furnace goes well beyond that. | DMLS/SLM solutions start around $200,000. These printers also come with stringent facility requirements which may increase the costs further. |

| Material Costs | $50-$150/kg for most standard and engineering filaments, and $100-200/kg for support materials. | $149-$200/L for most standard and engineering resins. | $100/kg for nylon. SLS requires no support structures, and unfused powder can be reused, which lowers material costs. | Depends on the material and the technology. Significantly higher than plastics. Significantly higher than plastics. | Depends on the material and the technology. Significantly higher than plastics. |

| Labor Needs | Manual support removal (can be simplified in some cases with soluble supports). Lengthy post-processing is required for a high-quality finish. | Washing and post-curing (both can be mostly automated). Simple post-processing to remove support marks. | Simple cleaning to remove excess powder. | Washing and sintering (both can be mostly automated). Optionally machining and other surface treatments. | Stress relief, support removal, heat treatment, as well as machining, and other surface treatments. |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, silicone-like, flexible, heat-resistant, rigid), castable, dental, and medical (biocompatible). | Engineering thermoplastics, typically nylon and its composites (nylon 12 is biocompatible + compatible with sterilization). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt chrome, copper, aluminum, nickel alloys. |

| Ideal applications | Basic proof-of-concept models, low-cost prototyping of simple parts. | Highly detailed prototypes requiring tight tolerances and smooth surfaces, molds, tooling, patterns, medical models, and functional parts. | Complex geometries, functional prototypes, short-run or bridge manufacturing. | Strong and durable parts, tooling, and manufacturing aids. | Strong, durable parts with complex geometries; ideal for aerospace, automotive, and medical applications. |

Calculating cost per part requires accounting for the costs of equipment ownership, material, and labor. It’s helpful to understand the factors that influence each of these cost components, and the questions to ask to evaluate alternative production methods and uncover hidden costs.

Fixed costs, such as the 3D printer cost, service contracts, installation, and maintenance, together make up the equipment ownership cost. These expenses occur regardless of whether your 3D printer stands idle or produces dozens of parts a week.

Distribute equipment ownership costs over individual parts by adding up all of the forecasted fixed costs over the lifetime of the machine and divide the sum by the number of parts that it is expected to produce. As a rule of thumb, the higher the productivity and utilization of your 3D printer, the lower the equipment ownership cost on a per-part basis.

Desktop 3D printers have achieved tremendous progress in recent years in lowering equipment ownership costs. With a price point 10-100 times lower than traditional industrial 3D printers and the capability to produce thousands of parts over their lifetime, the equipment ownership cost can become negligible.

Questions to ask:

-

Are there installation, training, or further initial expenses beside the cost of the machine?

-

Is there a (mandatory) service contract? What does it include?

-

Beyond the machine, what accessories and tools are required to create final parts?

-

What are the maintenance needs of the machine within the normal range of activity? What’s the expected annual cost of maintenance? How does it change if production levels rise?

Raw 3D printing materials and other consumables required to create parts are variable costs. These costs are highly dependent on the number of parts you’re producing.

These costs are highly dependent on the number of parts you’re producing.

Measure material cost by calculating the amount of 3D printing material that’s required to create a single part, and multiply it by the cost of the material. Calculate in waste and any other consumables that are needed. While equipment ownership costs decrease as production grows, material costs for 3D printing tend to flatten out quickly.

Make sure to clarify what materials you’ll need to create the given parts, as the cost of consumables for 3D printing varies. Also note that some 3D printers only work with proprietary materials, and thus limit your third-party material options.

Questions to ask:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create a given part, including waste?

-

What’s the shelf life of the materials?

-

Are there other consumables required to create the parts?

-

Can the machine work with third-party materials?

While 3D printing can replace the complex workflows of traditional manufacturing methods and lead to substantial time savings, depending on the 3D printing technology, it can still be a fairly labor-intensive process.

Professional desktop 3D printers are generally optimized for ease of use. DIY 3D printers and hobbyist printers often require more tinkering to get the settings dialed in, whereas regular maintenance or changing materials on traditional industrial machines can involve time-consuming tasks that require a skilled operator.

Post-processing workflows vary by 3D printing process, but in most cases include cleaning parts and removing supports or excess material. There are solutions to automate some of these tasks; for example, Formlabs Form Wash and Form Cure simplify the washing and post-curing workflow for Formlabs SLA 3D printers, and Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

To achieve high-quality parts, more advanced processes like SLA and SLS don’t require time-consuming steps, but FDM parts will need lengthy manual post-processing to improve the quality and remove layer lines.

Questions to ask:

-

What is the entire workflow for producing parts? What are the specific steps required to set up a print, change materials, and post-process parts?

-

How much time does it take to post-process a given part?

-

Are there any tools or devices available to automate some of these tasks?

Outsourcing production to service bureaus or labs is recommended when you require 3D printing only occasionally, and for parts that are large or call for non-standard materials. Bureaus generally have several 3D printing processes in-house such as SLA, SLS, FDM, and metal 3D printers. They can also provide advice on various materials and offer value-added services such as design or advanced finishing.

Bureaus generally have several 3D printing processes in-house such as SLA, SLS, FDM, and metal 3D printers. They can also provide advice on various materials and offer value-added services such as design or advanced finishing.

The main downsides of outsourcing are cost and lead time. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing also rapidly becomes expensive.

Desktop 3D printers are great when you need parts quickly. Depending on the number of parts and printing volume, investment into a professional 3D printer can break even within months.With desktop and benchtop machines, you can pay for just as much capacity as your business needs, and scale production by adding extra units as demand grows without making a significant investment in a large-format 3D printer. By using multiple 3D printers, you also get the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Try our interactive 3D printing ROI calculator to see how much time and cost you can save when 3D printing on Formlabs 3D printers compared to outsourcing.

Investment, materials, and labor costs are relatively easy to calculate. But what about indirect costs and factors that are hard to quantify, but still influence your business? Let’s look at some of the key considerations when comparing desktop 3D printing to outsourcing or other production methods.

Time savings: What if you could bring products to market months faster? Or cut the lead time for your products by days or weeks? 3D printing simplifies traditional prototyping and production workflows, helping you to save time and outpace the competition.

Better results: 3D printing allows you to create more iterations, fail faster, and achieve better end products. Finding and fixing design flaws early also helps to avoid costly design revisions and tooling changes in production.

Finding and fixing design flaws early also helps to avoid costly design revisions and tooling changes in production.

Communication: Having high-quality prototypes and parts allows you to better communicate with customers, clients, suppliers, and other stakeholders. Avoid confusion and costly mistakes.

IP protection: Do you work with sensitive information? Creating parts in-house means you won’t have to give away intellectual property (IP) to third parties, reducing the risks of leaks or IP theft.

Calculating cost per part, lead time, and comparing alternatives to figure out if a solution makes sense for your business would normally be the strenuous task of creating an elaborate spreadsheet and trying to gather all of the—often hidden—information from a manufacturer.

To skip this hassle, try our simple, interactive 3D printing cost calculator to calculate 3D printing cost and lead time on Formlabs 3D printers, and to compare time and cost savings to other production methods.

Calculate Cost and Time Savings

How to calculate the cost of printing on a 3D printer

For some ideas, 3D printing is the fastest and easiest solution. In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Despite the fact that it is customary to indicate the price per gram of working material, simply multiplying the weight of the model by the cost of 1 gram will be wrong. In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product.

Each 3D printing technology uses its own consumables. Let's analyze the most popular and affordable of them.

Available technologies and key differences

Currently, a huge number of 3D devices have appeared, from small desktop ones that fit on the desktop to huge industrial machines. Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA).

Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA).

FDM 3D printing

Today, the most affordable 3D printing technology is FDM. A variety of materials and 3D printers allow FDM to be applied to a wide range of applications.

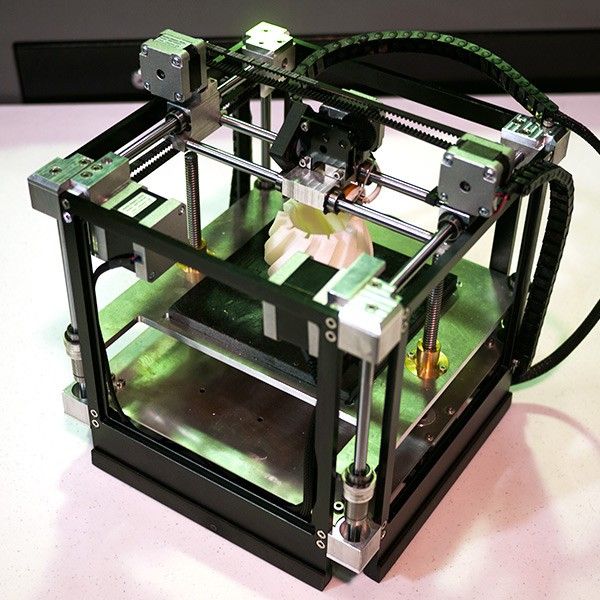

Schematic operation of FDM printer

A large selection makes it easy to choose a 3D printer for a specific task or find a universal device.

The material for printing is a plastic thread - filament. On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc.

Pros:

Cons:

Despite the fact that FDM allows you to print a wide range of plastics with different properties, the technology has some limitations. For example, it is impossible to obtain a perfectly smooth surface, to produce miniature and very thin elements, or to produce parts with very complex internal geometry with high accuracy.

Photopolymer printing

Photopolymer printers can work on one of 3 technologies - SLA, DLP or LCD. These devices will come to the rescue if you need to make a small but very detailed model with many small details.

How photopolymer printers work

As a consumable material, a photopolymer resin hardened by UV radiation is used. Now there is a wide variety of photopolymer resins for every taste. From particularly strong and precise engineering or jewelry resins to soft flexes.

Pros:

-

High print precision

-

Good surface quality

-

A wide variety of printers and consumables

Minuses:

Photopolymer printers have shown themselves well in a variety of industries that require a perfectly smooth surface and high accuracy. They are used in dentistry, the jewelry industry, for making miniature master models for casting, and much more.

Industrial printers

These are already industrial machines, which require a separate room and sometimes certain requirements for ventilation, etc. In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

FDM

In addition to desktop devices using FDM technology, industrial printers that work on the same principle are common.

This category includes devices with a large print area (from 30x30x30 cm and more). For example, Raise Pro2 with a print area of 30x30x30 cm.

Raise Pro2

Or machines designed for printing with refractory materials (eg PEEK). Such 3D printers usually have an active thermal chamber, and the extruder can be heated above 400 degrees.

CreatBot F160-PEEK designed to work with refractory plastics

Photopolymer printers

Industrial photopolymer devices usually have a much larger working area, compared to their "home" brothers. In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model.

In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model.

Prismlab Large Area Industrial Resin Printer Family

3DP

3DP - Three-Dimensional Printing (translated as three-dimensional printing) is a logical continuation of conventional two-dimensional printers. Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored.

Colored plaster model

Since the plaster model is fragile, a similar principle is used for printing with metals. Only the finished product needs to be treated in an oven to remove the binder and improve strength. But despite the processing, such metal prints will still be inferior in strength to cast products.

MJM

This is a proprietary technology of 3D Systems. MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

Models made with MJM technology

Such devices can work with photopolymer resins, wax or thermoplastics. You can combine several materials at once - for example, for complex models, you can use wax as a support.

SLM

SLM is the layer-by-layer sintering of metal powder using a powerful laser. There are several similar technologies - SHS/SLS. The principle of operation is the same, only a thermal print head is used instead of a laser beam.

SLM Turbine

As a material for printing, you can use powders of various metals - gold, stainless steel, aluminum, various alloys, etc.

During printing, the working chamber is filled with an inert gas to prevent oxidation of metals. This allows printing even with titanium powder.

Models made by this method are in no way inferior, and sometimes even superior, to cast products. SLM allows you to produce models with complex internal geometry that cannot be produced by another method (casting or milling).

Cost of 3D printing

The cost of a model usually consists of several factors.

-

Equipment depreciation. The printer, like any machine, requires maintenance and periodic replacement of some parts. During operation, belts gradually stretch, bushings or linear bearings wear out. For example, when bushings or linear bearings are worn; shafts may wear out and need to be replaced.

Cost of materials

The main cost item for a 3D printer is, of course, the printed material.;

FDM (plastic filament)

Since FDM technology is by far the most common, the choice of filaments is very diverse.

-

Engineering plastics are usually nylon with various fillers added to improve the physical characteristics of the finished model. Special cost. plastics starts from 2000r per coil and above. It all depends on the manufacturer and filler (carbon fiber, fiberglass, etc.).

-

Decorative plastics are used to imitate various materials. Plastic can simply be unusually colored (luminous, transparent plastics) or a special filler is added to it (plastics with metal powder). The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

A big advantage of FDM is the diverse choice of materials to work with. This allows, having one printer, to produce almost any product - from a child's toy to a complex engineering prototype.

Photopolymers (resin)

Photopolymer resin printing technology is becoming more and more accessible. There are many different resins.

-

The cost of ordinary colored resin starts from 2500 rubles per 0.5 kg (volume +/- 0.5 l). You can find a smaller volume of resin (250 gr) on sale. You can buy several different resins in small containers and find out in practice which one is best for a particular model.

-

Engineering resins are resins with increased strength. They can be used not only for printing decorative items, but also for making functional prototypes and models. The cost for 0.5 kg starts from 5900r and above.

-

Special resins - burnable, dental, soft flexes, etc. Depending on the resin, the price for 0.5 kg can start from 4800 rubles and more. It all depends on the characteristics of the resin.

Photopolymer resins have not yet reached such a variety as FDM filaments, but they are surely catching up. Although due to the fact that a liter of resin costs significantly more than a spool of filament, the cost of the product is much higher.

Print examples

FDM

Mag Pull (quick release loop) for G3 magazines.

The model was downloaded for free from an open source (the file can be downloaded here). Printing with engineering carbon-filled plastic (price per spool from 4700 rubles). The weight of the model with support is about 25 grams. Post-processing was not needed. The cost of the finished model is 250 rubles.

Plastic fastener

The file was downloaded from an open source (can be downloaded here). Plastic - carbon-filled nylon (price per coil from 4700r). The weight of the finished product is about 20 grams. Print without post-processing. The total cost is 200 rubles.

Model watch

The model is modeled to order (the cost of modeling is from 1000 rubles). The product is printed on an industrial printer using soluble support. Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products).

Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products).

Traction prosthesis

The model is taken from an open source (you can download the modified version of the prosthesis here). The weight of the used material is about 600 gr, printed with ABS plastic (the cost of the coil is from 800 r). After printing, post-processing and assembly took place. The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

Pedal layout

Production of a 3D model according to the drawing (from 1000 r). The weight of the finished model is about 200 gr. The product was printed with engineering carbon-filled plastic (the cost of the coil is from 4700 r). Post-processing was not needed. The cost of the finished product is about 3000 rubles.

Photopolymer printers

Model jaws for crowns

Files for printing were obtained using a 3D scanner and finalized in a 3D editor (the cost of scanning is from 3000 r, the cost of manual revision is from 1000 r). Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Burnout resin rings

The model is made to order. Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product.

Miniatures

The models were bought on the myminifactory website (the cost of the model is from $2). Made with a desktop DLP printer. Post-processing was not required. The cost of the finished figurine is from 70 r per gram.

Custom 3D printing

Many owners of 3D printers are thinking about monetizing their hobby. But you should understand that the price of 3D printing “for yourself” and the price of commercial printing are very different.

When starting to print to order, it is better to have several printers working on different technologies.

Cost of commercial 3D printing

In addition to the cost of the model, to the commercial production of products, you can add:

-

Modeling. Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make.

-

Model post-processing. This can be simply the removal of supports, with cleaning of the place of their contact with the product, or a complete processing cycle (puttying, surface grinding, painting, etc.).

It should be borne in mind that it is not always possible to print the model the first time. Sometimes it may take several attempts. And these are additional costs.

What is unprofitable to print

Despite the wide possibilities of 3D printing, there are models that are unprofitable to make on a 3D printer. For such models, it is better to use other manufacturing methods.

For such models, it is better to use other manufacturing methods.

Commercial print examples

Jewelry for further casting

Manufacture of promotional items and souvenirs

Piece miniatures or master model for further casting

3D printed model

Profitable to print on a 3D printer:

-

If the item is only sold as an assembly. For example, a small gear broke in the mechanism, but the mechanism is sold only “assembly”. It is much cheaper to make the desired gear on a 3D printer than to buy the entire mechanism.

-

A small batch of parts. Small batches, especially models with complex geometry, are more profitable to produce on a 3D printer than by casting or other methods.

Totals

If you need several models or a small project, sometimes it will be more expedient to outsource manufacturing. After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials.

After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials.

Buying a 3D printer for commercial use is justified if you can fully load it with work or then it can be used for other purposes.

To print to order, you need to have several printers working on different technologies. It is better to get several devices with a smaller print area than to buy just one printer, albeit with a large working area.

3D printing cost calculation

Although I posted the link in the discussion of the parallel topic of comrade 3D_MPL (Cost of 3D printing. Calculator for calculating from 3D-MPL), I thought it would be better to make a separate post to get feedback.

So please make constructive (!) suggestions. I will answer any questions on the topic.

.

So.

Again and again the question arises of how to calculate the payment of your labor as correctly as possible. Although some of the details seem simple, they often require a lot of brain effort, which MUST be paid. Well, the time spent too.

Although some of the details seem simple, they often require a lot of brain effort, which MUST be paid. Well, the time spent too.

.

Some people think that it is enough to take into account the weight of the part - I think this method is simply fundamentally wrong, because, for example, printing a vase / box with a 1mm nozzle and a 0.6mm layer will be faster than printing some highly detailed bracket in a car or a souvenir with a 0.2mm nozzle and a 0.05mm layer. So, with the same weight, the time can be many times (tens of times) longer! Yes, and draw a different bracket, you must be able to!

Moreover, we want our many hours of work to be adequately paid.

A typical example from my practice is a kettle handle.

The detail is shapeless, you don't know how to approach it in order to draw it. The result - 7 hours of modeling, 4 hours of printing, an hour of post-processing, 57 (total!) Grams of plastic. And now, imagine, a customer comes to you, 'Why is it so expensive??? It's only 57 grams!!!'. And you lost a whole day (work shift).

And you lost a whole day (work shift).

.

So, I think that the main resource that should be paid for is time!

.

And here is the table itself.

Link to Yandex Disk: https://yadi.sk/i/oy1r3v_dA-8E1w

.

By the way, I update the table from time to time! I recently discovered an inaccuracy in the calculation of the cost of the material, corrected it. So follow the link and check it out.

.

Some characteristics:

Time is written conveniently - in hours and minutes.

Modeling and post-processing cost per hour.

The weight and cost of the coil are written separately - no need to calculate the cost of a kilogram (for lazy people).

The so-called 'difficulty factor' is missing from the table. The complexity itself will be formed from: modeling time (mostly), printing time (necessary detailing), post-processing time (picking out supports from hard-to-reach places, painting, etc. ).

).

Substitute the values that are convenient for you. I don't insist on these. Columns 'Prices' and 'Costs'.

The white numbers in the 'Total' column are reference numbers, just for convenience.

Depreciation is calculated from the time of direct operation of the printer (more work - more wear). I take half a dollar.

The price of the first part differs from the subsequent ones only by taking into account the simulation time.

The maximum printer power is taken - still pennies come out.

Currency - rubles. You can change to yours.

When you write the price for the reel, you must also take into account the cost of delivery! (In our outback, the delivery of one coil is 500 rubles!) I can add the 'delivery' item for convenience, if you want.

.

I advise you not to show this table to the client. Unless if he thinks that it is too expensive, it must be recalled that he would not agree to work for 100 rubles / hour (or how much you put).