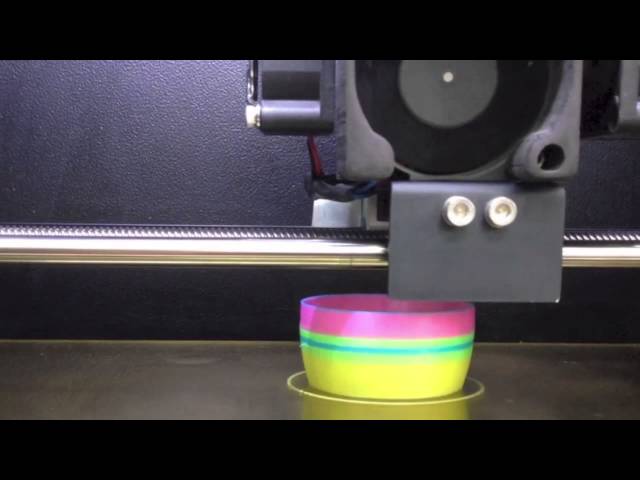

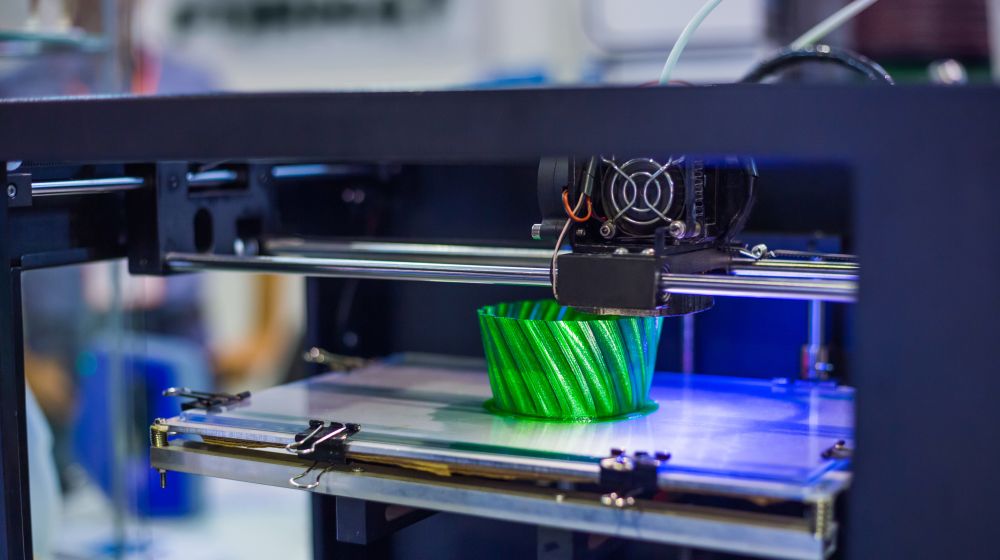

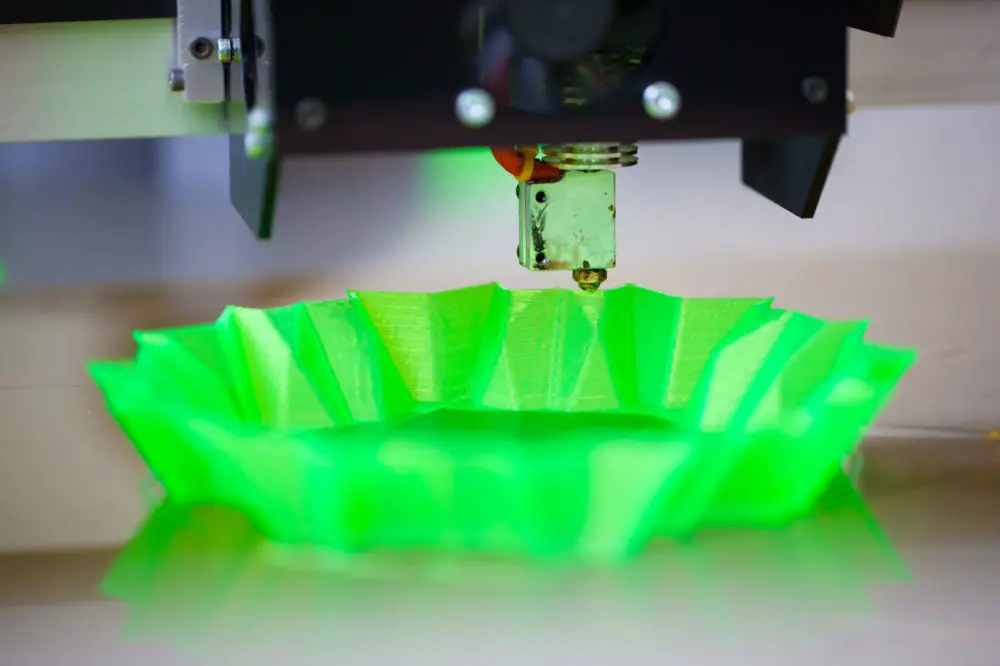

3D printers in action

3D printing gets bigger, faster and stronger

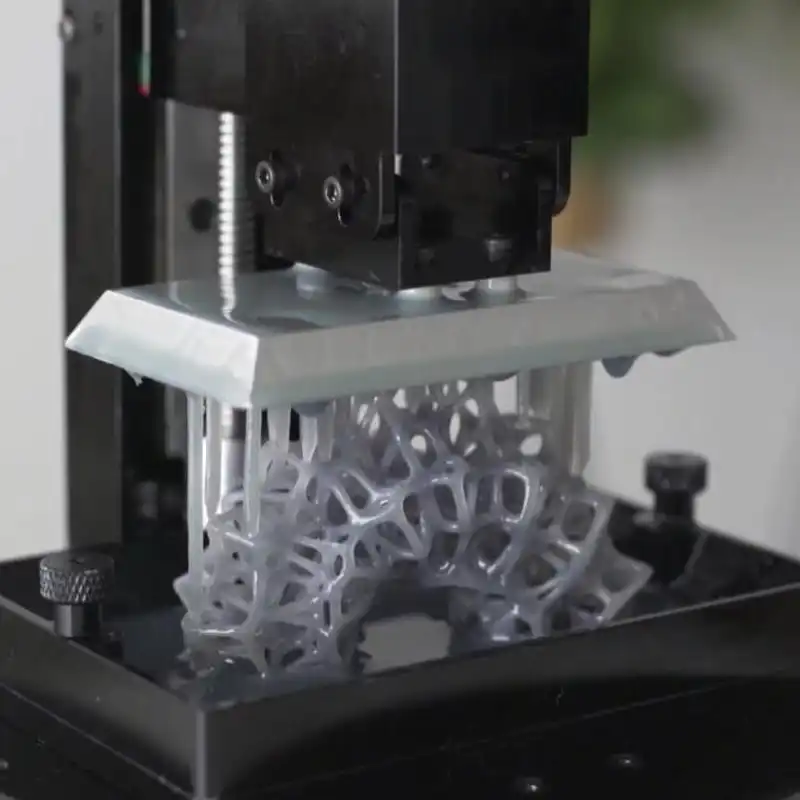

As a metal platform rises from a vat of liquid resin, it pulls an intricate white shape from the liquid — like a waxy creature emerging from a lagoon. This machine is the world’s fastest resin-based 3D printer and it can create a plastic structure as large as a person in a few hours, says Chad Mirkin, a chemist at Northwestern University in Evanston, Illinois. The machine, which Mirkin and his colleagues reported last October1, is one of a slew of research advances in 3D printing that are broadening the prospects of a technology once viewed as useful mainly for making small, low-quality prototype parts. Not only is 3D printing becoming faster and producing larger products, but scientists are coming up with innovative ways to print and are creating stronger materials, sometimes mixing multiple materials in the same product.

Sportswear firms, aviation and aerospace manufacturers and medical-device companies are eager to take advantage. “You’re not going to be sitting in your home, printing out exactly what you want to repair your car any time soon, but major manufacturing companies are really adopting this technology,” says Jennifer Lewis, a materials scientist at Harvard University in Cambridge, Massachusetts.

The latest techniques could be lucrative for researchers, many of whom — Lewis and Mirkin among them — are already commercializing their work. They’re also fundamentally exciting, says Iain Todd, a metallurgist at the University of Sheffield, UK. “We can get performance out of these materials that we didn’t think we could get. That’s what’s really exciting to a materials scientist. This is getting people used to the new weird.”

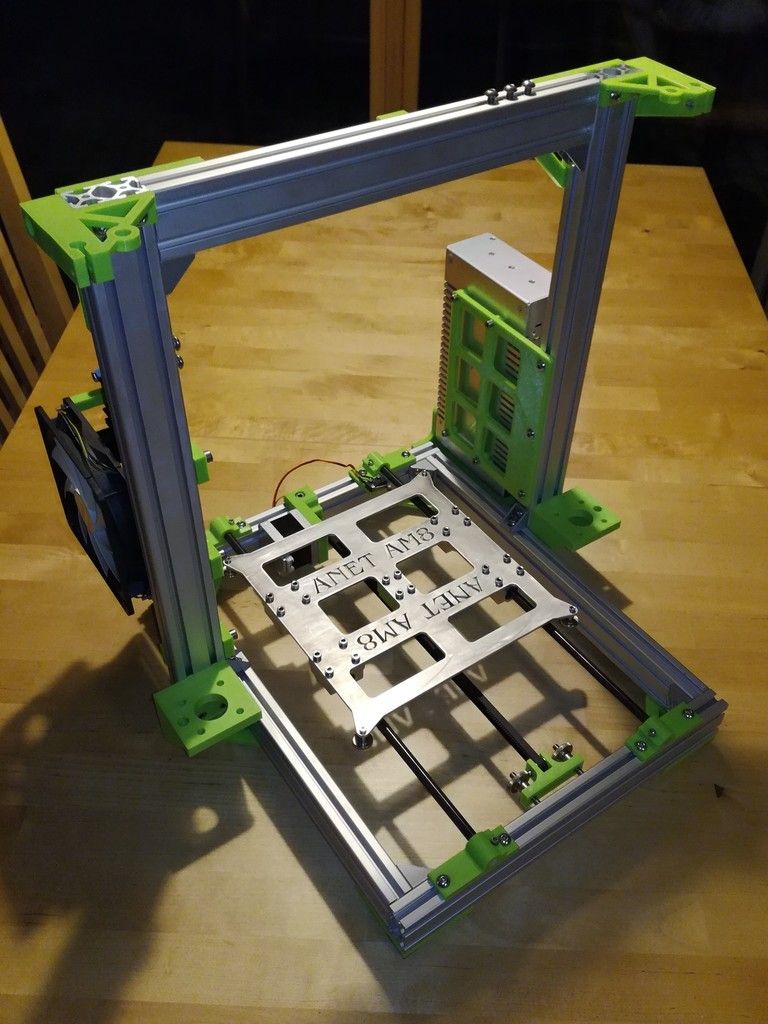

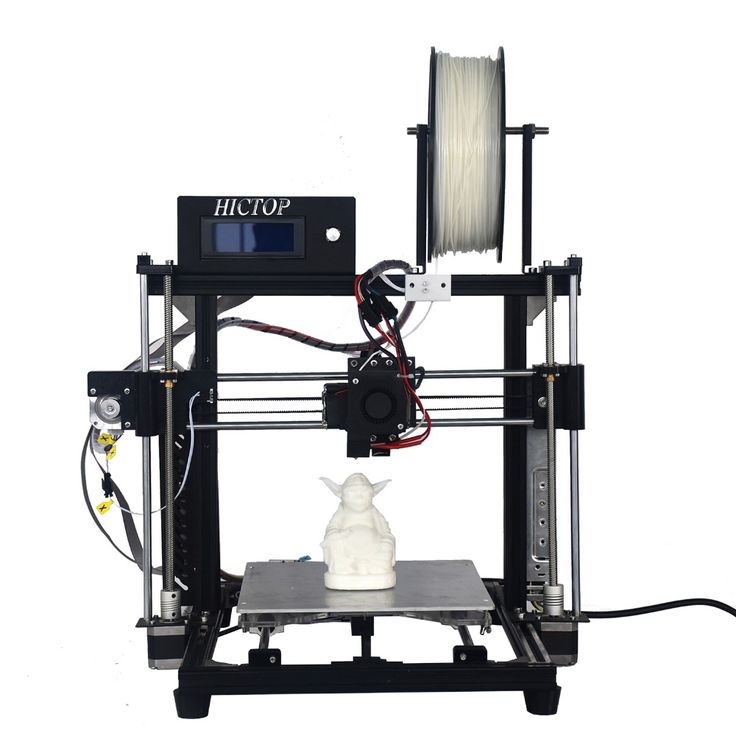

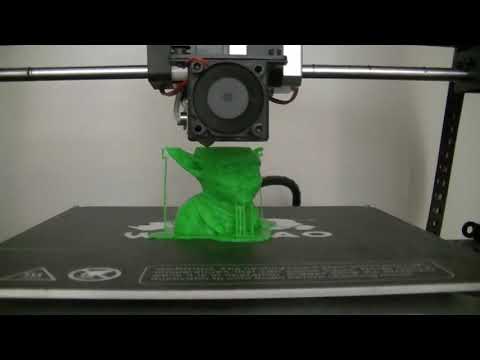

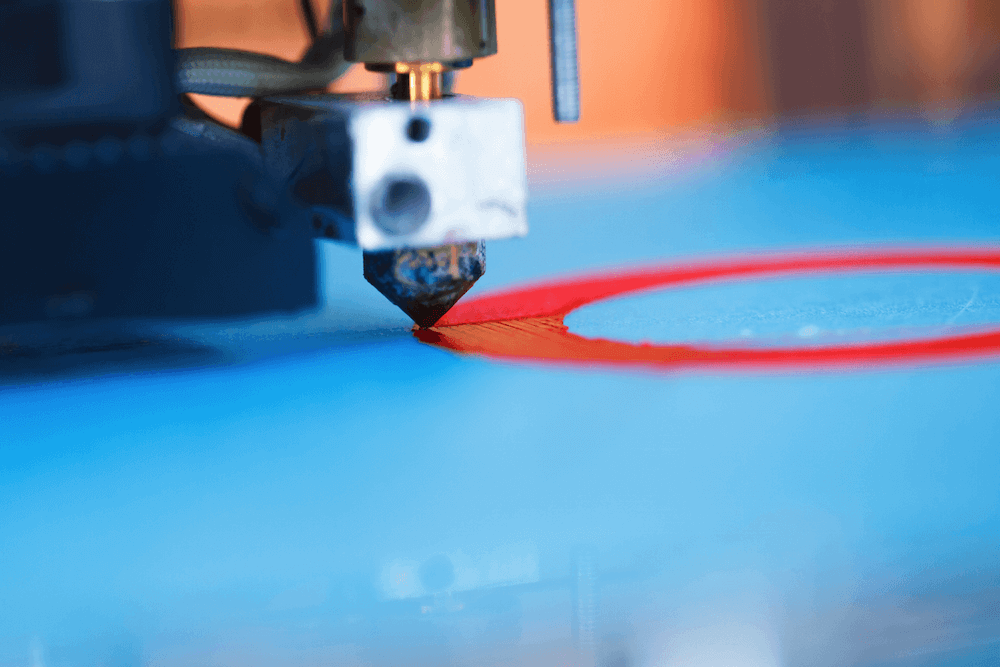

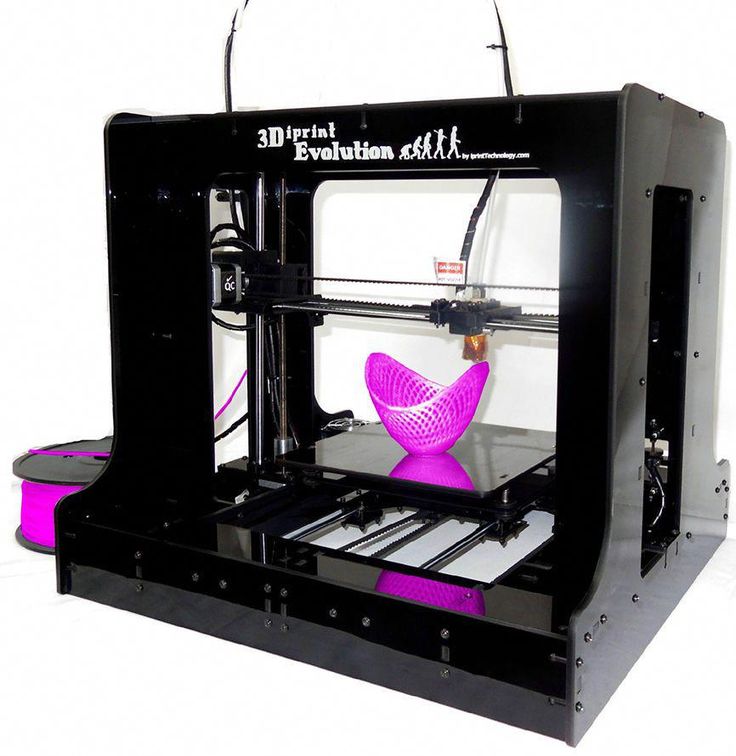

From trinkets to productsThe 3D printing technique is also referred to as ‘additive manufacturing’, because instead of chopping or milling a shape out of a larger block, or casting molten material in a mould, it involves building objects from the bottom up. Its advantages include less waste and an ability to print custom designs, such as intricate lattice structures, that are otherwise hard to create. Low-cost hobbyist machines print by squeezing out thin plastic filaments from heated nozzles, building up a structure layer by layer — a method known as fused deposition modelling (FDM). But the term 3D printing encompasses a much wider range of techniques. One of the oldest uses an ultraviolet laser to scan across and solidify (or ‘cure’) light-sensitive resin, layer by layer. That concept was described as far back as 1984, in a patent filed by Charles Hull2, the founder of a company called 3D Systems in Rock Hill, South Carolina.

Low-cost hobbyist machines print by squeezing out thin plastic filaments from heated nozzles, building up a structure layer by layer — a method known as fused deposition modelling (FDM). But the term 3D printing encompasses a much wider range of techniques. One of the oldest uses an ultraviolet laser to scan across and solidify (or ‘cure’) light-sensitive resin, layer by layer. That concept was described as far back as 1984, in a patent filed by Charles Hull2, the founder of a company called 3D Systems in Rock Hill, South Carolina.

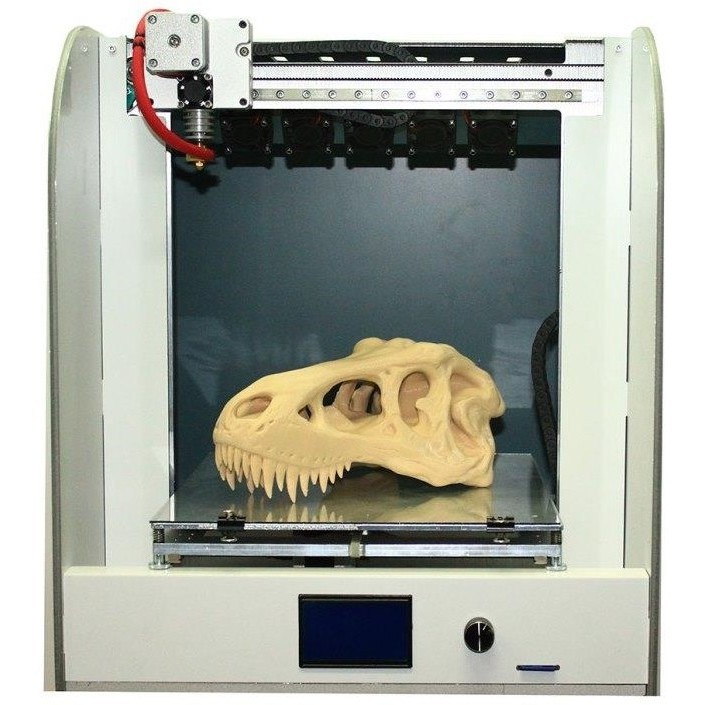

The latest techniques — including Mirkin’s — still use light-sensitive resin, but are faster and larger-scale, following improvements reported in 2015 by a team led by Joseph DeSimone, a chemist and materials scientist at the University of North Carolina at Chapel Hill3. Early printers were slow, small-scale and prone to producing layered, imperfect and weak structures. These found a niche in rapid prototyping, making plastic model parts as mock-ups for later production by conventional methods. As an area of research, this kind of printing wasn’t thrilling, says Timothy Scott, a polymer scientist at Monash University in Melbourne, Australia: “Basically making trinkets and knick-knacks. For a polymer chemist, it was pretty dull.”

As an area of research, this kind of printing wasn’t thrilling, says Timothy Scott, a polymer scientist at Monash University in Melbourne, Australia: “Basically making trinkets and knick-knacks. For a polymer chemist, it was pretty dull.”

In 2015, Joseph DeSimone at the University of North Carolina at Chapel Hill unveiled a technique to speed up 3D printing.Credit: Carbon 3D Inc.

Then DeSimone unveiled a way to print light-sensitive resin up to 100 times faster than conventional printers3. It uses a stage submerged in a vat of resin. A digital projector shines a pre-programmed image up at the stage through a transparent window in the floor of the vat. The light cures an entire resin layer at once. DeSimone’s advance was to make the window permeable to oxygen. This kills the curing reaction and creates a thin buffer layer, or ‘dead zone’, just above the window’s surface so that the resin doesn’t stick to the bottom of the vat each time a layer is printed. The stage rises continually, pulling the completed part up through the liquid as new layers are added at the bottom.

Other labs were working on similar concepts at the time, says Lewis. But perhaps most impressive about DeSimone’s resins was that they could undergo a second reaction in a post-print heat treatment to strengthen the finished product. “It opens up a much broader array of materials,” says Lewis.

Forget everything you know about 3D printing — the ‘replicator’ is here

Many research groups and firms have since built on the work. Mirkin’s printer pumps a layer of clear oil across the bottom of the vat to inhibit the polymer’s reactions. This also acts as a coolant, removing heat that can deform a printed part — and it means that the equipment is not limited to printing with resins that are inhibited by oxygen. He says the printer produces material ten times faster than DeSimone’s. And last January, Scott and his colleague Mark Burns at the University of Michigan in Ann Arbor reported a printer that inhibits the reactions by mixing into the resin a chemical that can be activated by a second lamp emitting a different wavelength of light4. By varying the ratio of the strength of the two light sources, the researchers can control the thickness of the photo-inhibited zone, allowing the creation of more complicated patterns, such as surfaces embossed with seals or logos.

By varying the ratio of the strength of the two light sources, the researchers can control the thickness of the photo-inhibited zone, allowing the creation of more complicated patterns, such as surfaces embossed with seals or logos.

Inventions in 3D printing often have rapid commercial potential: some researchers start forming companies before they publish their advances. On the same day DeSimone’s paper was published, for instance, he showcased it at a TED talk in Vancouver, Canada, and officially launched his start-up firm Carbon 3D in Redwood City, California, although he had quietly registered the company two years earlier. The firm is now one of the biggest start-ups in 3D printing; it has already raised US$680 million in publicly disclosed funding rounds, and is reportedly valued at $2.4 billion. It has high-profile contracts with Adidas to make rubber-like midsoles for athletic shoes, and with sports-gear firm Riddell to manufacture customized helmet padding for American-football players.

Carbon 3D’s technology is used to print Adidas shoes (left) and padding for American football helmets (right).Credit: Carbon 3D Inc.

Mirkin and his colleagues James Hedrick and David Walker have also launched a start-up, Azul 3D in Evanston, Illinois, to commercialize their technique, which they have dubbed HARP (high-area rapid printing). And Scott and Burns are preparing a commercial prototype printer with their Ann Arbor-based start-up Diplodocal, a name derived from the Greek for ‘double beam’.

New resin-printing techniques are still emerging. One begins with a small spinning glass holding liquid resin. As the glass rotates, a projector shines a loop of video onto it that corresponds to 2D slices of the desired object. Within seconds, the final object solidifies inside the liquid resin — no layers necessary5. The method is inspired by X-rays and computed-tomography scans, which image a cross-section of a solid object. This is the inverse: back-projecting cross-sections to form a 3D object.

A projector shines a video loop onto liquid resin, causing an entire object to be created at once, rather than layer by layer.Credit: UC Berkeley

Even in this fast-moving field, the technique turned heads for what Lewis calls “the gee-whiz factor”. It has significant limitations: the resin used must be transparent, and the printed object must be small enough for light to pass through it to cure it. But it also has a potential advantage: it can handle highly viscous resins, which other resin-based printers struggle to suck through the narrow dead zone. That means it could make stronger materials and more accurate prints.

The approach has garnered substantial interest from industry, says Christopher Spadaccini, a materials and manufacturing engineer at Lawrence Livermore National Laboratory (LLNL) in California. Spadaccini was a member of the team that published the work last January5. A group at the Swiss Federal Institute of Technology in Lausanne (EPFL) independently developed the same concept, and has also reported a demonstration of it6. Spadaccini thinks the technology has tremendous commercial potential because it has modest hardware requirements. “In the end, really, what you need is a halfway-decent projector and a rotating stage,” he says.

Spadaccini thinks the technology has tremendous commercial potential because it has modest hardware requirements. “In the end, really, what you need is a halfway-decent projector and a rotating stage,” he says.

While chemists work on smarter ways to 3D-print intricate resins, engineers are pushing boundaries in 3D printing of concrete — using computers and robots to precisely automate the pouring process.

A 3D-printed concrete pedestrian bridge developed by Tsinghua University.Credit: Imaginechina/Shutterstock

The world’s first 3D-printed concrete pedestrian bridge was made by researchers at the Institute for Advanced Architecture of Catalonia in Barcelona, Spain, and installed in a park in Alcobendas, near Madrid, in 2016. Twelve metres long, the bridge features a lattice structure designed with algorithms that maximize strength and reduce the amount of material needed. Other teams have made similar structures, including a 26-metre-long bridge in Shanghai, China, produced by engineers at Tsinghua University in Beijing. And teams and companies in China and the Netherlands have 3D printed demonstration houses.

And teams and companies in China and the Netherlands have 3D printed demonstration houses.

Those structures aren’t constructed in one print job, however: separate segments are printed and then connected. By producing bridges and houses more cheaply and efficiently, 3D printing could reduce concrete’s carbon footprint — but it could also just encourage engineers to build more.

It’s not just concrete that is going big: Amsterdam firm MX3D has printed a bridge from stainless steel. First displayed publicly in 2018, the bridge is now being tested and having sensors installed ahead of a planned installation over an Amsterdam canal.

A view of MX3D’s printer during the process of printing a metal bridge.Credit: Olivier de Gruijter/MX3D

And California start-up firm Relativity Space in Los Angeles says it is constructing a nearly fully 3D-printed rocket. The rocket is designed to lift 1,250 kilograms into low Earth orbit, and its first test launch is slated for 2021. Printed metal doesn’t always have the same heat-dissipating performance as non-printed metal, says Relativity Space’s chief executive, Tim Ellis, but the printing process can add cooling channels in geometries that can’t usually be manufactured. Because rockets are used only once or perhaps a few times, they don’t have to be as strong in the long term as do alloys in aeroplane parts, which must resist failure over tens of thousands of pressure cycles, Ellis says.

Because rockets are used only once or perhaps a few times, they don’t have to be as strong in the long term as do alloys in aeroplane parts, which must resist failure over tens of thousands of pressure cycles, Ellis says.

A metal printer at start-up firm Relativity Space, which aims to test a mostly 3D-printed rocket in 2021.Credit: Relativity Space

These large-scale metal-printed projects are built with robot arms that feed a thin metal wire to a laser that welds the material into place. Other established ways to print metal use a laser or a beam of electrons to melt or fuse a bed of powder into layers of finished product. Another technique binds a bed of powder with liquid glue, then sinters the structure in a furnace. And printers designed in the past few years extrude molten metals through nozzles, in much the same way as in FDM.

Aviation firms such as Boeing, Rolls Royce and Pratt & Whitney are using 3D printing to make metal parts, mainly for jet engines. It can be cheaper than milling metal blocks, and the intricate components often weigh less than their conventionally made counterparts.

It can be cheaper than milling metal blocks, and the intricate components often weigh less than their conventionally made counterparts.

But 3D-printed metals are prone to defects that can weaken the final products. Spadaccini and others are trying to use arrays of sensors and high-speed cameras to watch for irregularities such as hotspots of heat or strain — and then make adjustments in real time, he says.

Five innovative ways to use 3D printing in the laboratory

Many scientists are also hoping to improve the intrinsic strength of printed metals, sometimes by controlling the microstructures of the materials. For instance, in October 2017, a US team reported that the intense heat and rapid cooling used in 3D-printing stainless steel could alter the metal’s microstructure such that the product is stronger than those cast conventionally7. And two months ago, researchers in Australia and the United States reported a titanium–copper alloy with similar strength advantages8. As they solidified, previous 3D-printed titanium alloys tended to form grains that grew in column-like structures. The copper helps to speed up the solidification process, which results in grains that are smaller and sprout in all directions, strengthening the overall structure.

As they solidified, previous 3D-printed titanium alloys tended to form grains that grew in column-like structures. The copper helps to speed up the solidification process, which results in grains that are smaller and sprout in all directions, strengthening the overall structure.

Mark Easton, a materials engineer at RMIT University in Melbourne and one of the leaders of the alloy work, has already had conversations with aerospace companies interested in exploring uses for the material. He says it could also be used in medical implants such as joint replacements.

Many of the printing techniques that work for metals can also be applied to ceramics, with potential applications that include making dental crowns or orthopaedic implants. Moulds for these objects are already made by 3D printing, with the material cast in the conventional way. But 3D-printing the entire object could save time at the dentist or surgeon’s office.

However, it is harder to control the microstructure of 3D-printed ceramics, says Eduardo Saiz, a materials scientist and ceramicist at Imperial College London. And nearly all practical ceramic printing techniques involve extensive post-print sintering that can warp or deform the part. “In my opinion, ceramics is way behind polymers and metals in terms of practical applications,” he says.

And nearly all practical ceramic printing techniques involve extensive post-print sintering that can warp or deform the part. “In my opinion, ceramics is way behind polymers and metals in terms of practical applications,” he says.

The field’s future could also lie in ‘4D printing’ — 3D-printed objects that also have the ability to perform some mechanical action, akin to artificial muscles. Often, these incorporate shape-memory polymers, materials that can react to changes in their environment such as heat or moisture.

In May 2018, researchers at the Swiss Federal Institute of Technology (ETH) in Zurich and the California Institute of Technology in Pasadena reported printing a submarine that propels itself forward using paddles that snap backwards when placed in warm water9. The work could lead to microrobots that can explore the oceans autonomously. But for the moment, the paddles must be reset after each stroke. Such devices could use battery power to reset themselves, but that makes the machine less efficient than one made conventionally, says Geoff Spinks, a materials engineer at the University of Wollongong in Australia. “There are still some big challenges with 4D printing,” he says.

“There are still some big challenges with 4D printing,” he says.

Another approach to 4D-printed devices involves triggering the action with a changing external magnetic field. US researchers have 3D-printed lattice structures filled with a liquid that changes stiffness in response to a magnetic field10 — which could perhaps be used to help car seats stiffen on impact.

A fluid that stiffens in response to a magnetic field is injected into the hollow struts and beams of a 3D-printed lattice. The material can be made stiff or flexible.Credit: Julie Mancini/LLNL

Other, more passive potential 4D printing applications include stents, which could be compressed to be implanted then expanded on reaching the desired site in a blood vessel to prop it open. Last July, researchers in Switzerland and Italy described a 4D-printed stent that is just 50 micrometres wide11, much smaller than conventional ones. The devices are so small, the team says, they could one day be used to treat complications in fetuses, such as strictures in the urinary tract, which can sometimes be fatal.

Perhaps the most ambitious example of 4D printing is matter that not only moves, but is alive. Currently, techniques for such bioprinting can print tissue, such as human skin, that is suitable for lab research, as well as patches of tissue for livers and other organs that have been successfully implanted in rats. But such techniques are still far from ready to integrate into a human body. Researchers dream of printing fully functioning organs that could alleviate long wait lists for organ donors. “I personally feel we’re a decade-plus away from that, at least, if ever,” says Lewis.

All together nowMany inventive ideas about printing matter that moves or changes rely on printing multiple materials together. “That’s absolutely where the field is heading,” says Scott.

Last November, Lewis and her lab described a printer that can rapidly switch between different polymer inks or mix them as it prints a single object12. This means objects can be printed with both flexible and rigid parts. Lewis has spun off previous work on multi-material printers into a firm called Voxel8, a start-up in Somerville, Massachusetts. Her multi-material printer could help with the athletics wear that Voxel8 is developing, says Lewis. Wearable devices need to be flexible around joints while also having rigid parts to house electronics. Saiz calls the printer “beautiful work”, adding wistfully: “There’s nothing like that for ceramics or metal.”

This means objects can be printed with both flexible and rigid parts. Lewis has spun off previous work on multi-material printers into a firm called Voxel8, a start-up in Somerville, Massachusetts. Her multi-material printer could help with the athletics wear that Voxel8 is developing, says Lewis. Wearable devices need to be flexible around joints while also having rigid parts to house electronics. Saiz calls the printer “beautiful work”, adding wistfully: “There’s nothing like that for ceramics or metal.”

And in March 2018, a team led by Jerry Qi, a materials engineer at Georgia Institute of Technology in Atlanta, unveiled a four-in-one printer. This combines a nozzle that extrudes molten polymer with one that prints light-sensitive resin, ready to be cured by ultraviolet lamps or lasers, and two that print wires and circuitry from tiny dots of metal13. The print heads work together to make integrated devices with circuits embedded on a rigid board or inside a flexible polymer enclosure. Qi says his group is now collaborating with electronics companies interested in printing circuit-board prototypes faster than conventional methods.

Qi says his group is now collaborating with electronics companies interested in printing circuit-board prototypes faster than conventional methods.

It wasn’t as simple as bolting four different printers into one platform: the researchers also needed to develop software that would allow each print head to communicate with the others and keep track of the progress.

The field is still far from delivering on early visions of bringing mass manufacturing into people’s homes. For now, sophisticated printers are too expensive to appeal to non-specialists. But 3D printing has come a long way in the past 20 years. Todd remembers people touring his lab in the early 2000s to see his technique to fuse specks of metal dust together to grow parts. Compared with the conventional milling machines and metal-cutting systems in neighbouring labs, his 3D-printing machines struck visitors as a complete oddity. “It was like we were some sort of a dog playing a piano in a bar,” he recalls. Now, for many firms, that trick is standard practice.

3D Printing in Action: Animals Given New Life With 3D-Printed Aid

For many students in STEM, 3D printing can be perceived as being limited to engineering purposes only. This couldn’t be further from the truth! The beauty of additive manufacturing is that its applications are nearly infinite. One compelling and vital way 3D printing is pushing innovation is in wildlife conservation and animal welfare. Animals that before would have suffered or even died are given new life through 3D-printed prosthetics. Habitats that are degrading and vanishing are given a chance for survival with 3D-printed assistance. Conservationists and scientists are using 3D printing to help animals thrive, not just survive.

If you have students interested in a career involving wildlife, this is just one example of how they can combine their classroom knowledge with their passion for animals!

Advances in Animal Prosthetics

The advances in 3D printing technology have aided conservationists by creating substitutes for the parts missing in nature. When an animal is injured or sick in the wild, there’s not much chance for survival. Some of these injuries occur naturally, but most have increased in many species due to habitat loss, animal poaching, and mistreatment from humans. Many animal species are making a comeback thanks to 3D printed prostheses. A tortoise who has lost its shell due to fire, disease, or being hit by a car is given a new protective shell by scanning a healthy tortoise’s shell of the same size and species and fitting it precisely to the injured tortoise. Birds who have lost beaks from hunters are affixed with 3D-printed imitations and are able to live many more years in the wild. Alligators have been given new tails, and ducks have been given new beaks – and none of this would be possible without the precision, accuracy, and flexibility of 3D prints. A toucan, having lost its upper mandible, was given a new one that even matched its original coloring, as an off-color beak would’ve caused the toucan to be shunned in the wild.

When an animal is injured or sick in the wild, there’s not much chance for survival. Some of these injuries occur naturally, but most have increased in many species due to habitat loss, animal poaching, and mistreatment from humans. Many animal species are making a comeback thanks to 3D printed prostheses. A tortoise who has lost its shell due to fire, disease, or being hit by a car is given a new protective shell by scanning a healthy tortoise’s shell of the same size and species and fitting it precisely to the injured tortoise. Birds who have lost beaks from hunters are affixed with 3D-printed imitations and are able to live many more years in the wild. Alligators have been given new tails, and ducks have been given new beaks – and none of this would be possible without the precision, accuracy, and flexibility of 3D prints. A toucan, having lost its upper mandible, was given a new one that even matched its original coloring, as an off-color beak would’ve caused the toucan to be shunned in the wild. And, of course, many cats and dogs are fitted with 3D printed limbs or mobility aids and are able to still have full lives.

And, of course, many cats and dogs are fitted with 3D printed limbs or mobility aids and are able to still have full lives.

See how veterinary students at the University of Florida are using 3D printing to care for large animals!

Preserving Threatened Habitats

Unfortunately, thanks to a combination of pollution, human destruction, and climate change, many delicate ecosystems around the world are in peril. Conservationists have embraced 3D printing as a way to try and support these delicate habitats and give them a chance at survival. Our pollinator populations, especially bees, have been suffering with the loss of habitat and are struggling to find enough nectar to survive. Synthetic flowers, holding a combo of both nectar and pollen, are utilized, as well as a 3D printed honeycomb to provide the bees with a safe home. In another use case, coral reefs are filled with 3D printed coral in an effort to attract live coral polyps and stimulate new growth. The 3D printers are able to use natural materials such as sandstone and limestone, making the prints ocean safe and able to last. The advances in 3D printing technology have made these options feasible for many conservation groups, and the future will certainly hold more applications for 3D printing in animal conservation and welfare.

The advances in 3D printing technology have made these options feasible for many conservation groups, and the future will certainly hold more applications for 3D printing in animal conservation and welfare.

Designs for some 3D printed prostheses are available for free and are an excellent option for animal shelters or low-income pet owners. These designs are able to be printed at a maker lab in your local library or university for only the cost of the filament. For your students, this can be a wonderful way to teach about 3D printing through the challenge of creating a prosthetic while also instilling a sense of gratification and responsibility to give back. There is nothing better than seeing an injured animal able to eat, walk, and move freely again.

Contact us here for more resources about how to connect your students’ passions with STEM learning in the classroom!

Photopolymer 3D printer

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting.

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones.

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

SLA Model

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam.

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation scheme

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Model building animation

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the dimensions of the installation and raise the price to an unacceptable level for most users.

Despite the success of this technology, projected stereolithography is considered to be a more promising, although very similar method.

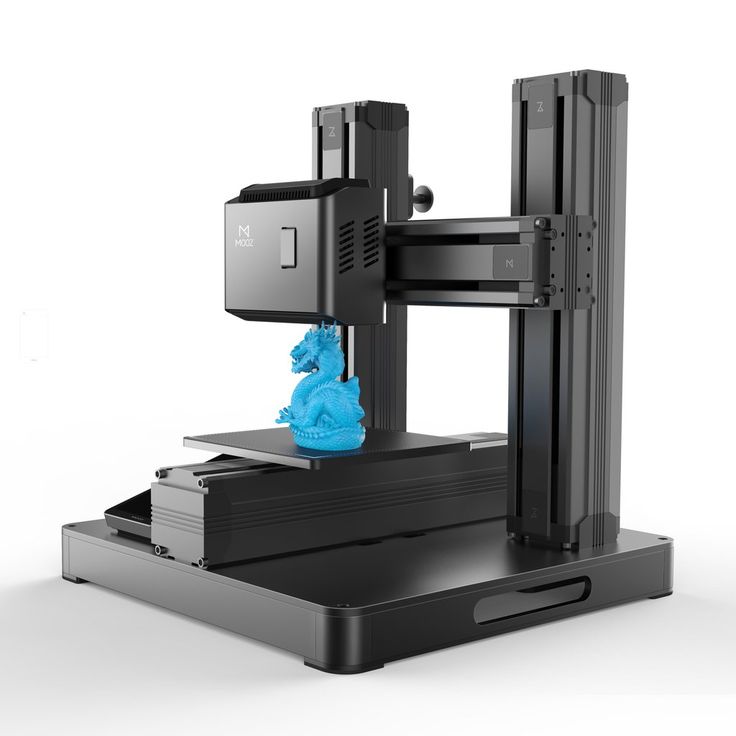

Projector Stereolithography (DLP)

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

Layers are illuminated using a digital projector that highlights patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type plants, but this technology used physical photomasks, making the process costly, time consuming, slow and noisy.

At the moment, the FTI technology continues to exist - the development of SGC, almost indistinguishable from DLP printing, since it also uses digital LED projectors.

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems.

Projection size can be quite significant, reaching the average of popular FDM printers.

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer.

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

3D Systems ProJet 3500HDMax MJM printer

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows to achieve very high printing speed, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use.

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

3D Pens

CreoPop 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld resin printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters.

The pen only extrudes resin through the tip surrounded by LED emitters.

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature - there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy.

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin when used in everyday life.

Additional Lighting

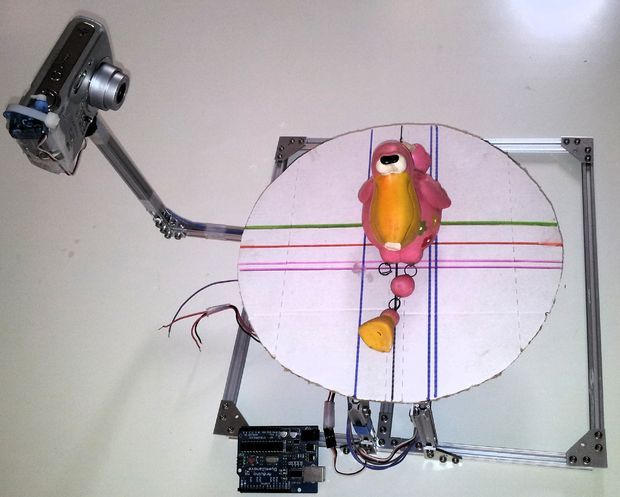

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part.

After production, the models are usually placed in chambers equipped with ultraviolet lamps until fully cured. Of course, if possible, you can simply lay out the models in the sun - the effect will be the same.

Just keep in mind that ordinary glass practically does not transmit ultraviolet light, so exposure to sunlight must be direct.

If desired, a UV-transparent quartz glass container can be used.

Go to the main page of the Encyclopedia of 3D Printing

3d printers. Overview of achievements in 2013 / Sudo Null IT News

Prostheses for humans and animals, 3D printing of space structures, food and shoes, improved printing accuracy, new materials, new software.

A bunch of projects on crowdfunding platforms.

Well, pistols, where would we be without them.

China, Japan, Australia, USA, Netherlands, Africa and Haiti, 3D printing seems to be everywhere in the world.

In 2014, 3D printing will go into space.

(Review of 3D printing achievements 2012 here) We read what we achieved for 2013 under the cut ( 54 photos ).

January

The Chinese printed a 5 meter one-piece aircraft part from titanium

more pictures

This is what a laser 3D printer looks like

Selective laser sintering technology in action

Smaller parts

Here's a plane that uses 3D printed parts

BioCurious hackerspace offers a self-assembly bioprinter based on HP 5150 inkje

9001 (the first inscription where instead of ink - "Escherichia coli")

The European Space Agency is conducting experiments to build a shelter on the moon using a 3D printer

one and a half ton building block

February

A team of scientists from Scotland, for the first time, using a 3D printer, print three-dimensional tissues from stem cells

Article PDF

3D Printed Urbee 2 Is Ready for Production

change the way we make most things. ”

”

In February, the hype started with 3doodler - a 3D pencil that can "draw in the air".

In just a few hours, they raised over a million dollars on Kickstarter.

Articles on Habré about this:

With the 3Doodler pen, you can draw three-dimensional objects directly in the air

Our answer to 3doodler. Assembled in 20 minutes

3Doodler is in a hurry to you! (Bonus: clone review)

In November, the "pencil" was delivered to Russia - the first (and last) review

Scientists print artificial ear

original article

Nike introduced the world's first 3D printed football boot

4D printed. Self-transforming objects

4D printing video at TED

March

The government of Singapore intends to invest $500 million in the development of the 3D printing industry.

3D printing allows the creation of low-cost implants, taking into account the anatomical features of patients0018

April

Oxford University scientists say their 3D printer is capable of creating materials with some of the properties of living tissue

A 3D scanner capable of obtaining images from a distance of 1 km has been created

The Chinese government intends to invest $ 6. 5M in the development of 3D printing technologies

5M in the development of 3D printing technologies

GE prints fuel injectors for aircraft engines

May

Liberator pistol: 100,000 downloads in two days

Printed ear capable of capturing radio frequencies

NASA awarded a $125K grant to develop a 3D food printer for astronauts who will fly into deep space

Saved the life of a child by printing a trachea

NASA plans to send a printer to the ISS August 2014

The Japanese printed a bacteria-sized carbon bunny

The Chinese showed the largest 3D printed part for a combat aircraft0018

June

British government invests £14.7m in 3D printing projects

Polymers create "artificial bone" that is 22 times stronger than its composite component

Microsoft builds 3D printer support into Windows 8.1

Printed foot for a wounded duck

July

MIT develops software that makes it easier to work with composite materials

British children will learn robotics and 3D printing from the age of 5

Telegraph article

August

3D printed rocket engine passes NASA test, setting the stage for many innovations to reduce the cost of manufacturing parts Stem Cell Knee Joint Using a 3D Printer

Scientists at MIT have developed a lightweight structure whose smallest details can be 3D printed and assembled like a Lego set. The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The world's first full-scale architectural installation Echoviren

September

Breakthrough technology - printing with dissimilar materials, both organic and inorganic materials: ceramics, metal, plastic and even biological cells

Developers from Disney introduced software that will allow you create and print mechanical toys on a 3D printer

3D printer for $100 - The Peachy Printer

Scientists from Australia created a model of the Leaning Tower of Pisa using a hand-held 3D scanner

Scientists from the Netherlands created reproductions of paintings by Rembrandt and Van Gogh using a 3D scanner and 3D printer

October

UK provides £500K grant to equip 60 schools with 3D printers

HP plans to enter the 3D printing market in mid-2014

Scientists have discovered that natural components (vitamin B2) can be used in the 3D printing process to create implants

On Haiti 3D printer

Microsoft appeared technology that can turn any smartphone into 3D scanner

November

The program for encryption of 3D-models

Despiode biocratic biocrats for printing organs

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 metal gun printed on a 3D printer

Scientists printed 20 layers of liver tissue that lived for 40 days

article on Habré

Revolution in the textile industry

Desktop metal 3D printer

Progress in the manufacture of lithium-ion batteries using 3D printers.