Xact metal 3d printer

XM200C | Xact Metal | Affordable Metal Powder-Bed Fusion 3D Printing

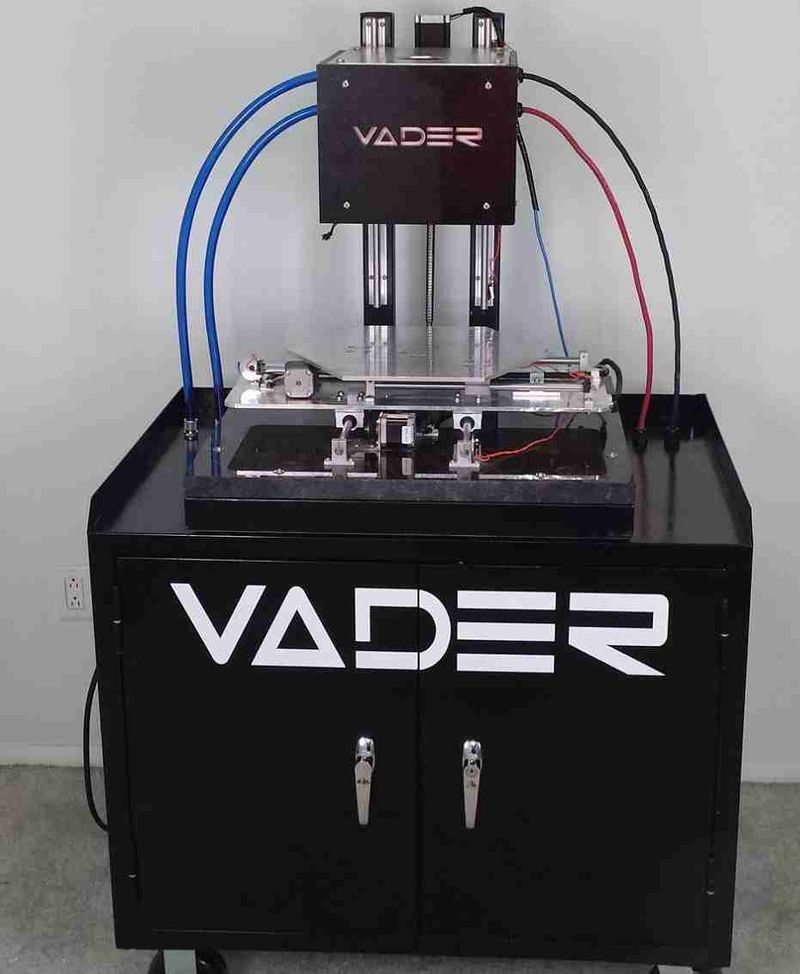

XM200C Printer

Accessible Metal Powder-Bed Fusion 3D Printing

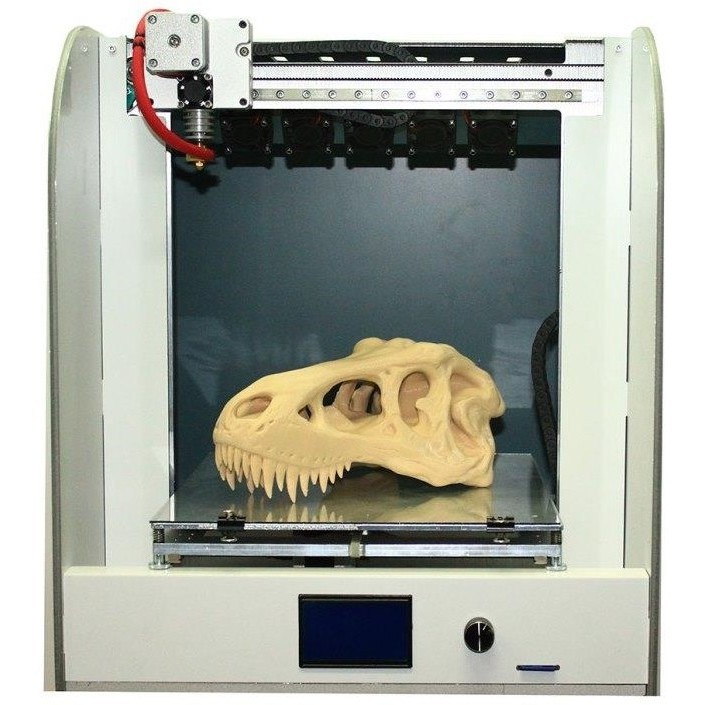

The XM200C 3D metal printer is making waves in the industry, establishing a new level of price and performance. The printer deploys fiber laser-based powder-bed fusion technology by selectively fusing thin layers of metal powder to create parts directly from a 3D-CAD model. Powered by our patented Xact Core™ high-speed gantry system, the XM200C continues to revolutionize metal 3D printing.

XM200C Data

Large Build Volume

125 in³ (5 x 5 x 5 in)

2,048 cc (127 x 127 x 127 mm)

Small Footprint

Approx. 24 x 24 x 51 in³ – W x D x H

(610 x 610 x 1,295 mm³)

Precision Optics*

- 100W Yb fiber laser

- 200W available with optional kit

*Class 1 Laser Product

Scanner

- Orthogonal high-speed scanner

Powder Options

To learn more about Xact Metal powder options, please visit our materials page.

Open Architecture

Allows qualified users the ability to develop their own printing parameters or use their own powder.

Easy Access & Cleaning of Build Area

Top lid opening access build chamber provides quick setup and changeover times.

Modern software architecture

Streamlined, intuitive and functional platform that supports visual workflows.

Cloud connectivity of one or more printers is also available, allowing monitoring of the printing process from anywhere.

Intuitive touchscreen user interface

Leading Technology

Xact Core™

Making quality metal printing accessible requires innovation. Xact Metal’s printing technology is built on the patent-pending Xact Core, a high-speed gantry system platform that allows light, simple mirrors to move quickly and consistently above the powder bed on an X-Y axis.

- Avoids the use of complex rotating galvanometer mirrors and F-theta lenses

- Maintains a constant laser angle across the whole build plate

- A simplified gas flow over the powder bed due to the smaller build chamber

Patent-Pending Recoater

Recoater performance can directly affect the quality of your build. Our patented recoater design offers a variety of benefits.

Our patented recoater design offers a variety of benefits.

- Unique “bulb” shape of the recoating element spreads powder like a blade, yet provides compaction similar to a rolling element

- Compliant design allows the recoater to negotiate out-of-plane growth and continue printing

- Mounting the recoater to the machine lid allows the entire recoating mechanism to be removed from the build chamber

- Easy access to the build chamber allows for simple recoater replacement and adjustments

Intuitive Touchscreen

User Interface

The modern, interactive graphic user interface (GUI) for the Xact Metal printers makes loading files, setting up builds and monitoring the build process quick and easy.

- Home screen displays real-time build monitoring with two cameras

- Chamber setup screen allows customer to optimize print parameters

- Build queue screen provides a description of all builds to be printed

- Monitoring screen shows behavior of important parameters such as bed temperature, chamber temperature and pressure and oxygen percentage

Xact Metal | Materials for Your 3D Printing Needs

Materials

Xact Metal provides a wide range of metal powder materials to be used in powder-bed fusion printing. Optimal print parameters and control processes have been developed to ensure as-printed material performance.

Optimal print parameters and control processes have been developed to ensure as-printed material performance.

Xact Metal partners with industry-leading powder producers, like Praxair Surface Technologies, to offer a wide range of high-quality, certified and proven metal powders. These gas-atomized powders ensure all layers print with consistent density and uniform build rates to deliver mechanical, performance, and final part specifications.

Available Powders

Our high-quality, gas-atomized metal powders are specifically designed for additive manufacturing to support every part you make with capacity, quality, and experience.

Aluminum Metal Powders*

AlSi10Mg

Material Properties

o High strength to weight ratio

o Good thermal properties

o Flexible post-processing

o Good hardness

Applications

o Structural automotive components

o Aerospace applications

o Air ducting systems

o Engine components

Data Sheet

Cobalt Metal Powders

CoCr (Co-538-1)

Material Properties

o Can be polished to a high degree

o Biocompatible

o Excellent wear resistance

o High hardness and corrosion resistance

Applications

o Gas turbine components

o Fuel nozzles

o Dental implants

o Orthopedic implants

Titanium Metal Powders*

Ti-6Al-4V

Material Properties

o High strength to weight ratio

o Excellent corrosion resistance

o Low thermal expansion

o Good fatigue resistance

Applications

o Aerospace components

o Biomedical applications including implants and prostheses

o Marine applications

o Gas turbines

o Racing components

Data Sheet

Copper Metal Powders*

C18150 Copper

Material Properties

o High strength and creep resistance

o Excellent thermal and electrical conductivity

o Reduced sticking during welding

o Wear resistant

Applications

o Back-up electrodes

o Circuit breaker parts

o Electrode holders and adaptors

oTransmission devices

UNS C61800 Bronze

Material Properties

o Good corrosion resistance

o Moderately high heat capacity

o Fairly high tensile strength

o Good weldability

Applications

o Valve and pump components

o High-strength fasteners

o Pole line hardware

o Marine equipment

Nickel Metal Powders

Inconel 625

Material Properties

o High strength and creep resistance

o High corrosion resistance

o High performance at elevated temperatures

o Excellent weldability

Applications

o Aircraft ducting and exhaust systems

o Marine propeller blades and mooring lines

o Chemical processing

o Nuclear applications

Data Sheet

Inconel 718

Material Properties

o High strength and creep resistance

o High corrosion resistance

o High performance at elevated temperatures

o Excellent weldability

Applications

o High temperature bolts and fasteners

o Gas turbine components

o Aircraft engine components

o Cryogenic applications

Data Sheet

Certified BEGO Medical Powders

MEDILOY ® S-CO

BEGO MEDICAL

A type 5 cobalt-based dental alloy for printing dental restorations such as crowns and bridges (including metal ceramic), partial denture frameworks, implant prostheses and other orthodontic applications.

Learn More

WIRONIUM® RP

BEGO MEDICAL

For 3D printing for removable partial dentures. The non-porous microstructure of the component guarantees ideal fatigue strength of the clasps with above-average fit of the partial denture frameworks

Learn More

Iron Metal Powders

316L Stainless Steel

Material Properties

o High hardness and toughness

o High corrosion resistance

o Highly machinable / Can be polished and shot peened

o Good weldability

Applications

o Industrial processing components such as spindles and screws

o Surgical tools

o Maritime components

o Cutlery, kitchenware, and fashion eyewear

Data Sheet

420 Stainless Steel

Material Properties

● High hardness

● Good ductility (annealed)

● Excellent corrosion resistance (polished)

● Must be used below 800 °F (427 °C)

Applications

● Cutlery

● Dental/surgical instruments

● Needle valves

● Shear blades

Data Sheet

M300 Tool Steel

Material Properties

o Very high hardness and strength

o Good corrosion resistance

o Age hardenable

o Good weldability

Applications

o Tool insets for injection moulding and die castings

o High-strength components

o Aircraft landing gear components

Data Sheet

17-4 Stainless Steel

Material Properties

o High toughness and strength

o Good corrosion resistance

o Precipitation hardening

o Versatile in processing

Applications

o Paper mill batch digesters

o Turbine blades

o Food processing equipment

o Marine applications

Data Sheet

15-5 Stainless Steel

Material Properties

o Transverse toughness

o Transverse ductility

o Good strength

o Good corrosion resistance

Applications

o Aircraft components

o Pump parts

o Valves

o Gears

*Only available on XM200G Series

Our Material Partners

Xact Metal partners with industry leading powder producers, like Praxair Surface technologies and Bego Medical, to offer a wide range of high-quality, certified and proven metal powders. These gas-atomized powders ensure all layers print with consistent density and uniform build rates to deliver mechanical, performance, and final part specifications.

These gas-atomized powders ensure all layers print with consistent density and uniform build rates to deliver mechanical, performance, and final part specifications.

Xact Metal has updated the line of budget metal laser 3D printers

News

powders, rolled out a new XM200G additive system, and at the same time dropped the price of the XM200C 3D printer.

Xact Metal can still be considered a start-up, as this enterprise entered the commercial market relatively recently, in 2017. The core is made up of veterans: chief engineer Matt Woods comes from SpaceX, scientific adviser is Pennsylvania State University mechanical engineering professor Tim Simpson, and Juan Gomez, a now thirty-year-old manager who previously worked at General Electric, is leading the parade.

The company specializes in the democratization of laser synthesis technologies, that is, the development of relatively inexpensive 3D printers based on the technology of selective laser sintering of metal powders. In a market where equipment costs run into the hundreds of thousands and often millions of dollars, Xact Metal offers systems starting at $65,000. It is clear that we are not talking about giant machines, but about 3D printers with rather modest working volumes, but often more is not required.

In a market where equipment costs run into the hundreds of thousands and often millions of dollars, Xact Metal offers systems starting at $65,000. It is clear that we are not talking about giant machines, but about 3D printers with rather modest working volumes, but often more is not required.

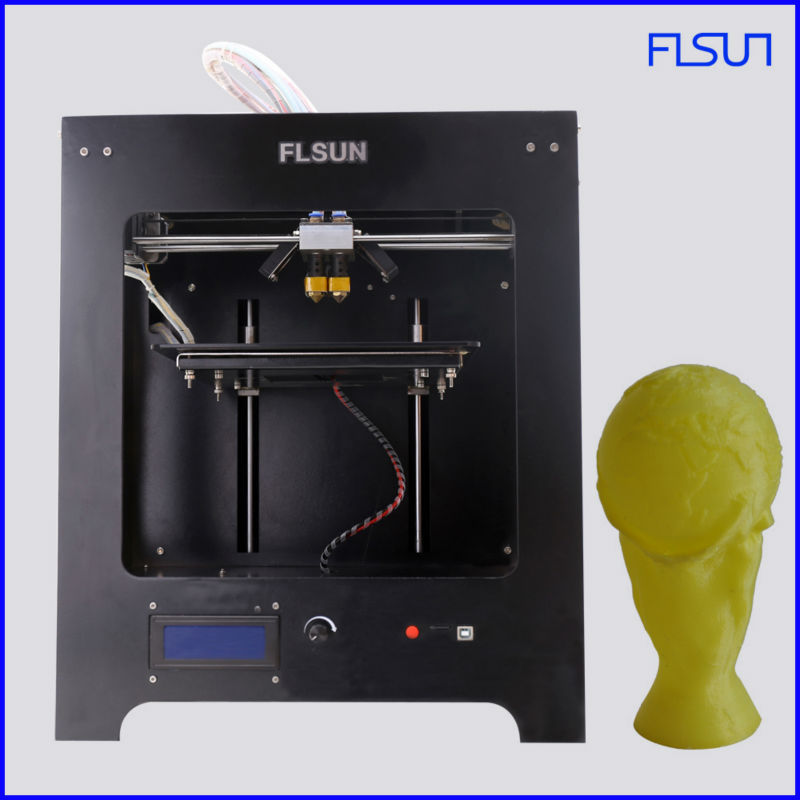

XM200C

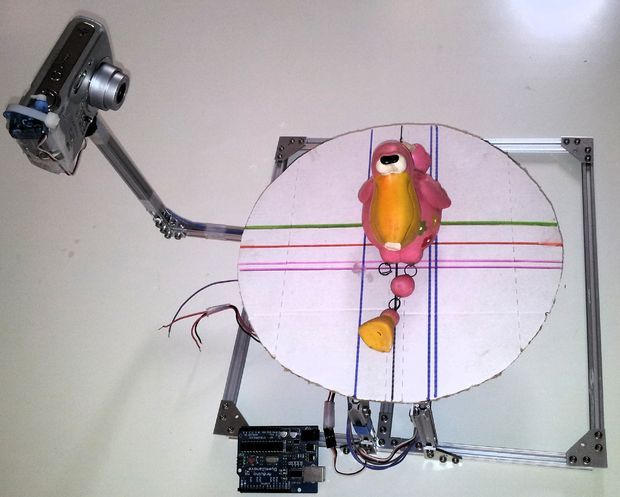

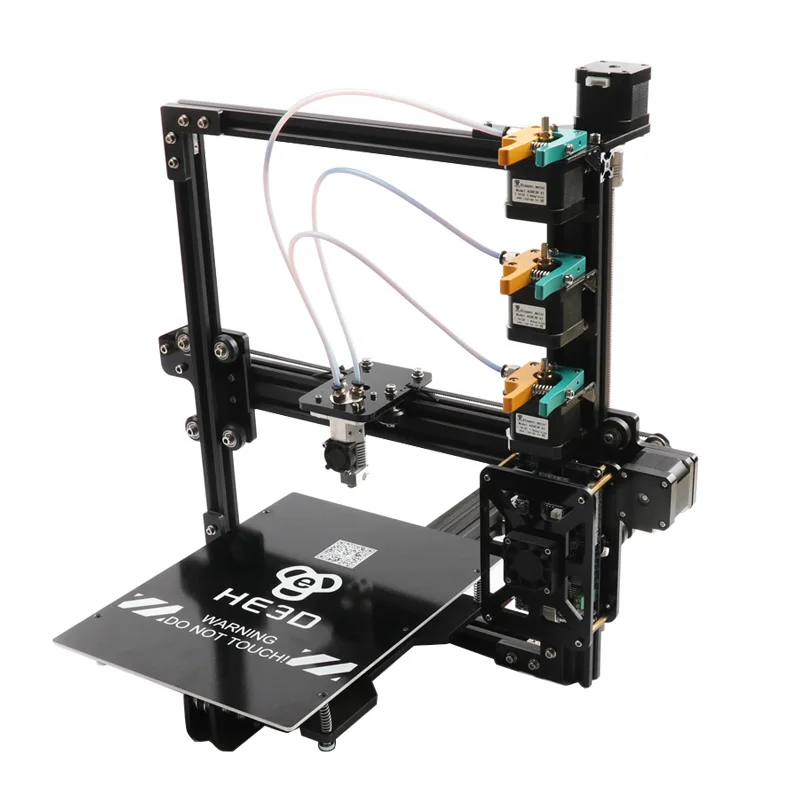

The development of our own line of PBF 3D printers began with the XM200, and then the upgraded version of the XM200C, a rather primitive but fully functional system that relies on mechanical positioning of the laser beam. In other words, the head moves on rails, as in many amateur FDM 3D printers. It is difficult to achieve high hatching speed with such a scheme, but you can save on precision galvanometric scanners used by expensive industrial laser sintering and fusion systems. Following the XM200 and XM200C, larger variants appeared under the designations XM300 and XM300C with two or four lasers and a similar positioning system.

Nevertheless, the guys did not completely abandon galvanometers, and in 2018 they announced the XM200S system - a more expensive, but more accurate and productive version, now with a galvanometric scanning system. Judging by the silence that has reigned since then, the refinement of the new version to the mind was delayed, but now Xact Metal is accepting orders for the XM200G - the same XM200S, but under the new designation, more powerful, with an increased build area and, importantly, at a lower price. 3D printers XM200S were estimated at 120 thousand dollars apiece, while the company is ready to ship the XM200G in the basic configuration for only ninety.

Judging by the silence that has reigned since then, the refinement of the new version to the mind was delayed, but now Xact Metal is accepting orders for the XM200G - the same XM200S, but under the new designation, more powerful, with an increased build area and, importantly, at a lower price. 3D printers XM200S were estimated at 120 thousand dollars apiece, while the company is ready to ship the XM200G in the basic configuration for only ninety.

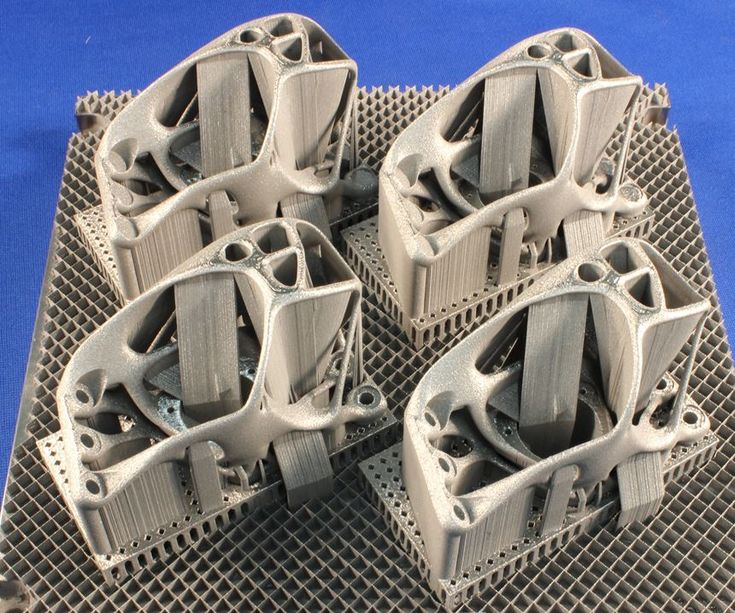

For this money, the buyer will receive a 3D printer capable of working with fine powders of aluminum, titanium, cobalt-chromium and nickel alloys, bronze and copper, as well as various steel grades. The XM200G is available in two versions with one or two lasers. Ytterbium fiber lasers, on the other hand, are available in three versions with powers of 100, 200 or 400 watts. Galvanoscanners are also offered in a couple of options with beam positioning speeds up to 20.7 or 34.6 m/s. The optical system uses F-Theta lenses with a spot diameter of 50 or 100 microns. 93/h The size of the construction area is 150x150x150 mm - you can’t print a hundred-pound weight, but it’s enough for the manufacture of small functional parts and laboratory work with new metal-powder compositions. In addition, the dimensions of the 3D printer itself are as modest as the cost - only 650x780x1930 mm.

93/h The size of the construction area is 150x150x150 mm - you can’t print a hundred-pound weight, but it’s enough for the manufacture of small functional parts and laboratory work with new metal-powder compositions. In addition, the dimensions of the 3D printer itself are as modest as the cost - only 650x780x1930 mm.

Orders for the XM200G are already open with deliveries starting next April. If ninety thousand dollars is too much for you, the company has discounted the XM200C to $65,000. More information is available on the official Xact Metal website.

Dual laser XM200G2 in action:

PBF XM200G XM200C Xact Metal

Follow author

Follow

Don't want

4

More interesting articles

four

Subscribe author

Subscribe

Don't want

Recently, the Traffic Management Bureau of the Ministry of Public Security of the People's Republic of China launched a. ..

..

Read more

four

Subscribe to the author

Subscribe

Don't want

Hello everyone!0003

Read more

sarkazm

Loading

04/01/2016

39827

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing in a short line

FDplast announced the release of a free...

Read more

Xact Metal Announces XM300G Laser Powder 3D Printer

News

Subscribe to the author

Subscribe

Don't want

1

A young American company that started with "budget" 3D printers using Selective Laser Metal Powder Sintering (PBF / DMLS) technology costing from sixty-five thousand dollars, gradually expanding the range towards more capable and expensive additive systems.

Initially, Xact Metal abandoned galvanic scanners in favor of linear mechanical positioning of the laser heads. Such a scheme meant a decrease in speed, but at the same time it made it possible to save on expensive components - an important point for a conditionally budget segment. However, last year Xact Metal returned to galvanometric scanning systems and released the XM200G 3D printer, although it did not completely stop production of early versions - the XM200C and XM200G systems are being produced in parallel.

The main difference between the early XM200C and XM300C (apparently the XM300C has been discontinued) is displacement. The size of the construction area of the base model is 127x127x127 mm, and in the XM300C version it is increased to 254x330x330 mm. After the launch of the XM200G model, it was logical to expect the appearance of a larger version, but this time with a galvanoscanner. This is exactly what the company did: the XM300G is a full-fledged industrial 3D printer with a build area of 300x300x350 mm and the ability to upgrade to 300x300x450 mm versus 150x150x150 mm for the XM200G. It’s already difficult to call this system a budget one: if the XM200C is offered for sixty thousand dollars, and the galvanometric version of the XM200G is for ninety, then the manufacturer asks for the XM300G from $200,000, although for industrial laser powder 3D printers “for metal” this is also not bad.

It’s already difficult to call this system a budget one: if the XM200C is offered for sixty thousand dollars, and the galvanometric version of the XM200G is for ninety, then the manufacturer asks for the XM300G from $200,000, although for industrial laser powder 3D printers “for metal” this is also not bad.

Selling price dependent on equipment: the new 3D printer is available as XM300G, XM300G2 and XM300G4 with one, two and four lasers respectively. The power of ytterbium fiber emitters also varies - either 400 W or 700 W each. The spot diameter is dynamically adjusted within 70-140 mm: as a rule, contours and fine details are lined up with narrowly focused beams, and the filling is hatched with larger diameter spots to increase overall performance. The beam positioning speed reaches 21.26 m/s.

The system can handle aluminum and copper alloys, including bronze, high temperature cobalt-chromium and nickel alloys (Inconel 718, Inconel 625, F75 and Hastelloy X), titanium alloys and various steel grades, including 316L, 17-4 PH, 15-5, 400 and M300.

The Xact Metal XM300G will premiere September 12-17 at the International Manufacturing Technology Show in Chicago. The start of deliveries is scheduled for the third quarter of next year. Additional information is available on the official website of the manufacturer.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

DMLS PBF Xact Metal XM300G

Follow author

Subscribe

Don't want

1

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

A team of scientists from the Perm National Research Polytechnic University has developed.