Polyurethane 3d printing filament

PRO Series TPU (Thermoplastic Polyurethane)

MatterHackers PRO Series TPU 3D printing filament exhibits excellent layer adhesion and strength while being flexible, making it a great solution for parts that require energy return and fatigue resistance. For 3D printed parts that need rubber-like qualities, like custom-fit gaskets or belts, or even prototypes for products like mouth guards and watch straps, PRO Series TPU is a functional material that can handle both intricate and tough print jobs.

Technical Specifications

- Weight: 1lb

- Diameter: 1.75mm or 2.85mm

- Diameter Tolerance: ±0.02mm

- Print Speed: 20-40mm/s

- Print Temperature: 230±10°C

- Download the Technical Data Sheet

PRO Series Filament

PRO Series PLA

PRO Series PLA is intended for producing professional, high quality, 3D printed parts.

PRO Series Tough PLA

Strong like ABS and much easier to use - it's the best material for reliably printing functional prototypes.

PRO Series ABS

A formulation intended to help your prints stand out with a beautiful, glossy, opaque finish.

PRO Series PETG

A strong material combining the ease of PLA printing with the durability of ABS.

PRO Series Nylon

The strength and durability of Nylon now in vibrant colors.

PRO Series Flex

All the benefits of flexible filament together with improved strength over other flexible filaments

PRO Series Ryno

Excellent at bridging and retraction to keep your parts clean with minimal post-processing.

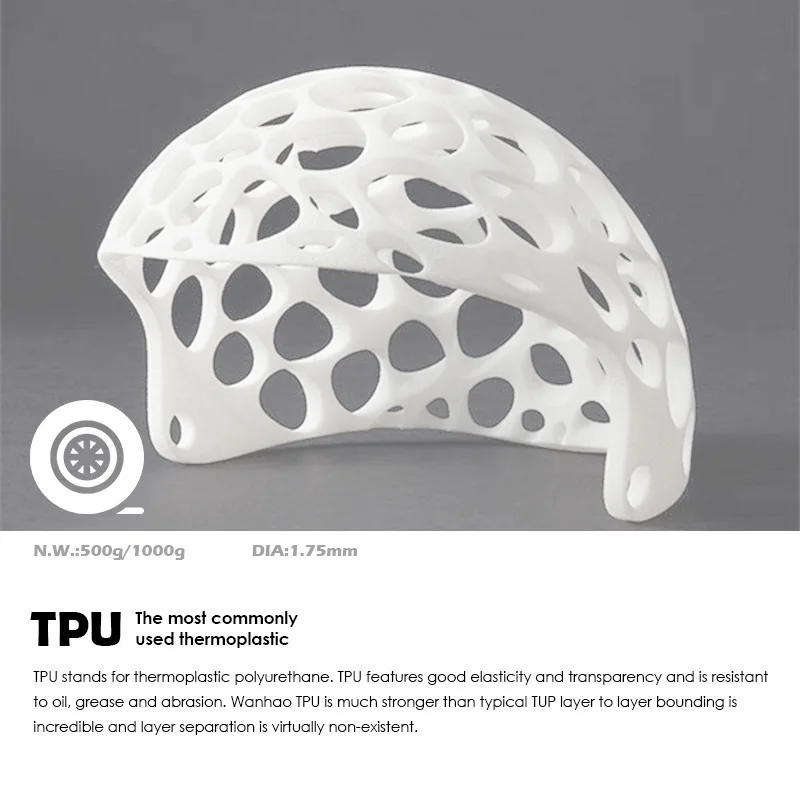

PRO Series TPU

Strong yet bendable filament that has excellent layer to layer bonding.

PRO Series Breakaway Support Material

Provides fast, easy, and clean mechanical breakaway for 3D printed parts.

PRO Series PVA Water-Soluble Support Material

Optimize time, effort, and resources spent on post-processing with water-soluble supports.

Guides & Articles

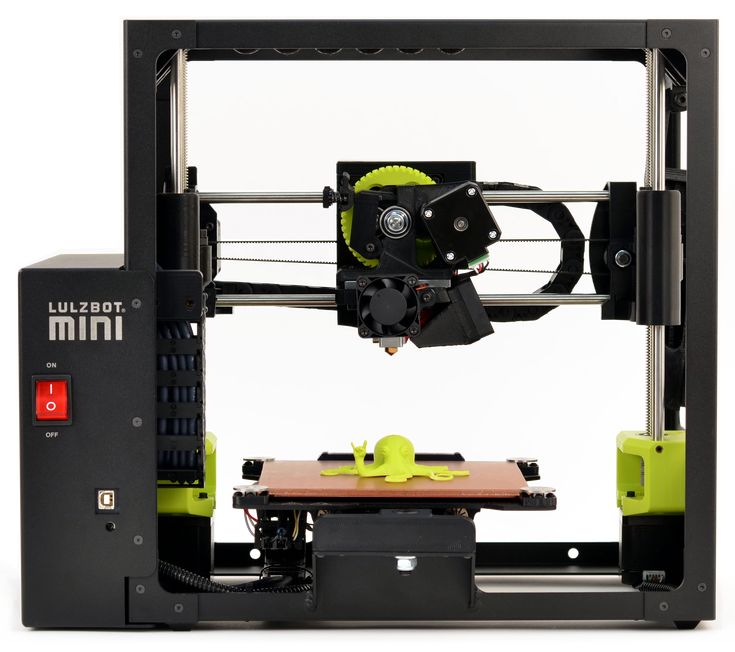

How To Succeed When Printing With Flexible Filament

Let’s take a look at what makes flexible filaments easier to print and how you can add flexible filament to your 3D printing material toolbox.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

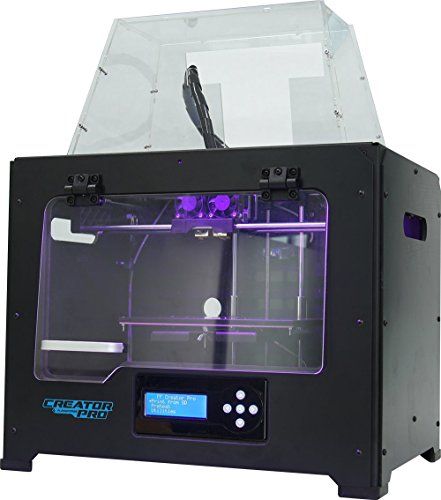

Dual extrusion, cool filaments, and printable upgrades

Are you curious about dual extrusion? Is your printer in need of an upgrade? Interested in practical applications of some new specialty filaments? All of the above? Read on and check out our latest project!

Extruders 101: A crash course on an essential component of your 3D printer

The extruder, a piece that could determine the success or failure of your print. Shoot for success with this simple guide that can improve your print quality.

How To Clear and Prevent Jams on Your 3D Printer

At some point you may encounter a filament jam or a clogged nozzle where your 3D printer is not extruding. This guide is intended to help you prevent such jams, or fix with them as painlessly as possible.

Retraction: Just say "No" to oozing

By understanding a little more about the 3D printing process, and how settings in MatterControl affect extrusion, we can help you reduce and even eliminate oozing and stringing from your 3D prints. This should be a part of the regular maintenance and calibration program for your 3d printer.

Three Reasons to Upgrade to an All-metal Hot End

Desktop 3D printing has come a long way in the past few years. It wasn’t long ago that PLA and ABS were pretty much the only filament options. PEEK-based hot ends – once the industry norm – aren’t able to print all the material options available now. Unleash the potential of your printer by upgrading to an all-metal hot end.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

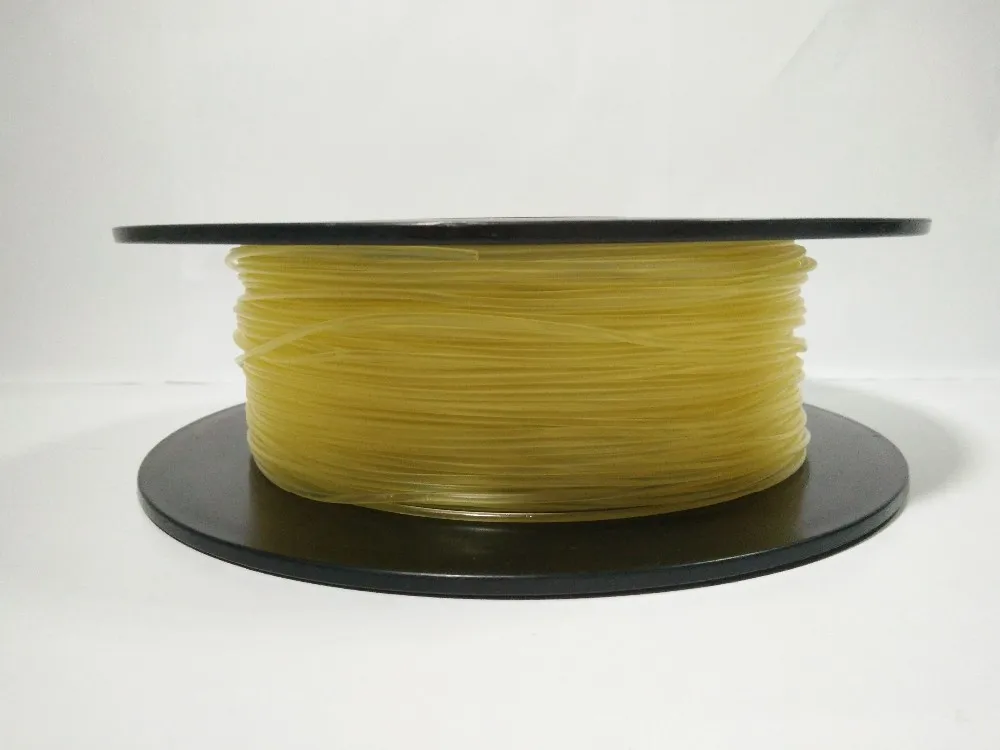

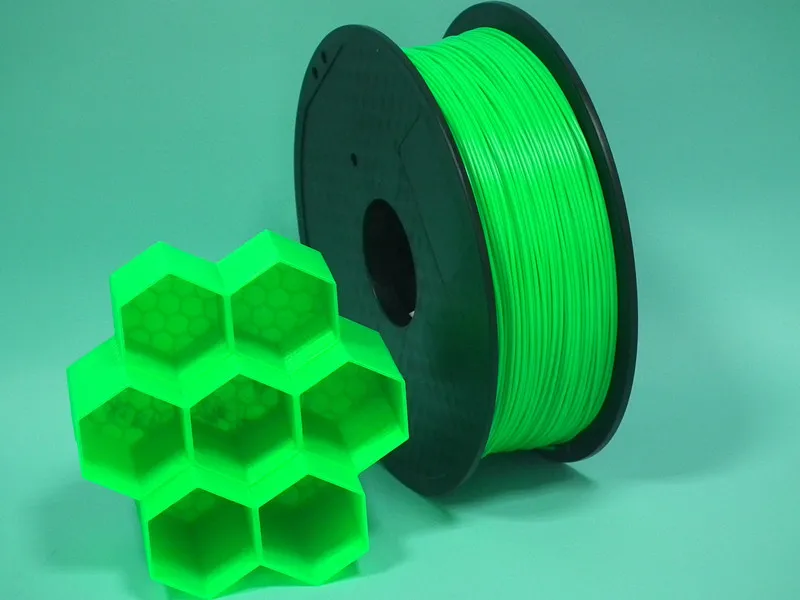

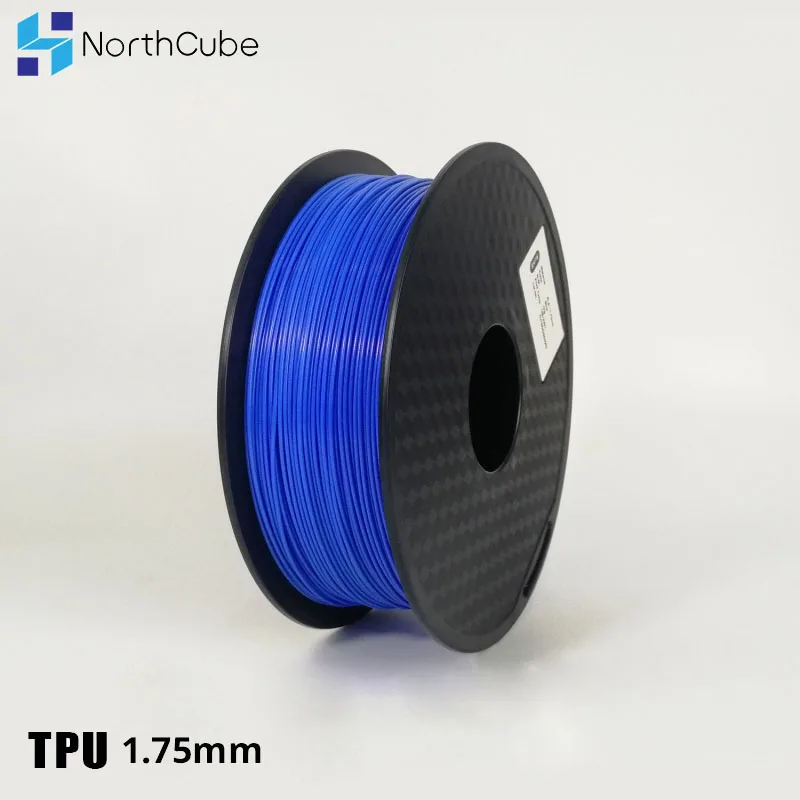

Thermoplastic Polyurethane (TPU), is a flexible filament that is resistant to abrasion, grease and oil. TPU boasts a Shore Hardness of 95 and a clean, easy print experience. If you are looking to print a flexible filament without the hassle, TPU is the filament for you!

TPU is a strong yet bendable filament that has excellent layer to layer bonding that does not allow for any layer separation. This flexible filament is semi-transparent and has some resemblance to rubber. Compared to other elastic filaments, TPU is one of the easiest to print, making it a favorite to novice makers. TPU prints clean up as easy as they print. Simply apply a moderate soap to your piece for a clean finish.

Simply apply a moderate soap to your piece for a clean finish.

PRO Series TPU filament is specially formulated for precision 3D printing and manufactured in the USA.

Black PRO Series TPU (Thermoplastic Polyurethane) - 1.75mm (1lb)

- Home

- Store

- 3D Printer Filament

- PRO Series Filament

- PRO Series TPU

MatterHackers PRO Series TPU 3D printing filament exhibits excellent layer adhesion and strength while being flexible, making it a great solution for parts that require energy return and fatigue resistance. For 3D printed parts that need rubber-like qualities, like custom-fit gaskets or belts, or even prototypes for products like mouth guards and watch straps, PRO Series TPU is a functional material that can handle both intricate and tough print jobs.

Tagged: 1"> and ,

Product No. loading...

loading...

MatterHackers PRO Series filament is all about quality. When the performance of a 3D printed component is the ultimate goal, you need to know you’re printing with a material you can trust. MatterHackers’ PRO Series filament is meticulously refined and continuously tested to provide optimal results for every application. That’s why our material experts have developed a range of responsive high-performance thermoplastics that maintain reliability through your process of rough prototyping to sophisticated, end-use designs. No matter your end goal, PRO Series filament delivers your parts exactly as you intended them.

Function in its Finest FormMatterHackers PRO Series materials are formulated for functional 3D printing. Because of its precisely detailed chemical blueprint, PRO Series 3D printing filament provides the consistency needed for repeatable part-production. Kawasaki’s Supercross Racing Team Engineers use PRO Series materials for both prototyping and end-use parts. Using PRO Series materials for essential components on their teams’ motorcycles has not only helped them fabricate in low volume, but it’s also reduced cost by 95% and time by 86%. They turn to PRO Series because they know it works well.

Because of its precisely detailed chemical blueprint, PRO Series 3D printing filament provides the consistency needed for repeatable part-production. Kawasaki’s Supercross Racing Team Engineers use PRO Series materials for both prototyping and end-use parts. Using PRO Series materials for essential components on their teams’ motorcycles has not only helped them fabricate in low volume, but it’s also reduced cost by 95% and time by 86%. They turn to PRO Series because they know it works well.

PRO Series materials are formulated with zero compromises. The base resin, and all performance-enhancing additives, are carefully sourced to include only those of the highest purity and provenance The consistent colors curated from quality sources combined with the exact manufacturing environment needed to maintain an industry-leading ±0.02mm diameter tolerance create materials you can use confidently. Experience smooth, uniform filament for all your important projects - experience PRO Series.

PRO Series TPU is a great choice for parts that need a high impact resistance

It’s Not Just Filament, It’s a Results-Driven Experience - With OptionsNot only is our PRO Series line of filament carefully crafted, but we have an extensive collection of materials to choose from that fit every need and specific applications. From Tough PLA for serious prototyping to vibrant Nylons for sturdy, lasting products, PRO Series 3D printing materials deliver quality parts, time after time. PRO Series filament is created with end-use results as the main priority, ensuring that your finished 3D printed parts are as clean, sturdy, and functional as possible.

Choose the material developed and guaranteed by the leader in 3D printing materialsMatterHackers PRO Series filament has remained the quintessential choice for anyone that demands exacting results for their business, products, and projects. Our attention to precise filament tolerance, strict coloration guidelines, and definitive chemical patterns are reflected directly in your completed products.

We know that end-use products are only as good as the materials and tools used to create them - that’s why we put our PRO Series filament through rigorous testing before it makes its way to your workshop or manufacturing floor. Having high-quality materials is essential when creating functional or product-ready components, therefore all MatterHackers PRO Series materials are analyzed using in-house testing equipment, including a Universal Testing System and a Melt Flow Indexer. These machines are used specifically to measure tensile and flexural properties, as well as the melt flow index of each material ensuring that all PRO Series filament is dependable and performing at its peak capabilities. MatterHackers PRO Series materials are tested and measured using ASTM 638 and D790 or ISO 527-1, 527-2, and 178.

Quality Assurance: Why Filament Diameter and Ovality MattersWith PRO Series materials, you know you’re getting the most accurate filament diameter and ovality available. Having a consistent diameter of 3D printing filament is very important - it directly impacts the print quality of your designs. The slicing engine calculates the volume of filament that will be deposited on each layer. The critical value that is input into the slicing engine for that volume is the diameter of the material (either 1.75mm or 2.85mm). Therefore, any variation in that diameter can cause the print to over or under extrude. In terms of raw materials - the filament diameter is one that requires a high level of confidence that you KNOW what you’re using.

Having a consistent diameter of 3D printing filament is very important - it directly impacts the print quality of your designs. The slicing engine calculates the volume of filament that will be deposited on each layer. The critical value that is input into the slicing engine for that volume is the diameter of the material (either 1.75mm or 2.85mm). Therefore, any variation in that diameter can cause the print to over or under extrude. In terms of raw materials - the filament diameter is one that requires a high level of confidence that you KNOW what you’re using.

Since we know diameter matters, we obsess over ensuring that PRO Series materials are on the mark so you can create perfectly printed parts. MatterHackers uses two and three-axis laser systems to measure and maintain the accuracy of the filament diameter at 40 hertz (40 times per second) - that way we know the filament diameter is consistent and within our 0. 02mm diameter tolerance guarantee. Not only that, but the data for each production run is recorded and stored so we have traceability on all PRO Series materials to establish further confidence in each batch we produce.

02mm diameter tolerance guarantee. Not only that, but the data for each production run is recorded and stored so we have traceability on all PRO Series materials to establish further confidence in each batch we produce.

Rest assured knowing that MatterHackers controls and actively analyzes the compounding and coloration of each filament batch, ensuring that your projects are the same from spool to spool. Color continuity between batches is controlled and confirmed with a color-analyzing spectrometer running in line during filament production. Your PRO Series filament will always be the same color PRO Series filament.

Technical Specifications

- Print Temperature: 230 ± 10°C

- Bed Temperature: 50 ± 10°C

- Print Speed: 20 - 40mm/s

- Weight: 1lb

- Density: 1.14 g/cm3

- Shore Hardness: 95A/48D

- Diameter: 1.

75mm or 2.85mm

75mm or 2.85mm - Diameter Tolerance: ±0.02mm

- Download the Technical Data Sheet

Ultimaker Thermoplastic polyurethane 3D printing filament Near-field communication, others, miscellaneous, blue png

Ultimaker Thermoplastic polyurethane 3D printing filament Near-field communication, others, miscellaneous, blue pngtags

- miscellaneous,

- blue,

- others,

- material,

- 3D printing,

- thermoplastic,

- thermoplastic polyurethane,

- preform,

- transparency and translucency,

- polyvinyl alcohol,

- seal,

- polylactic acid,

- near field,

- substances,

- hackers,

- hardware,

- extrusion,

- Acrylonitrile butadiene styrene,

- 3D printing on filament,

- ultimaker,

- png,

- transparent png,

- no background,

- free download

31MB )

31MB ) - Image size

- 4256x2832px

- File size

- 7.31MB

- MIME type

- Image/png

resize PNG

width(px)

height(px)

Non-Commercial Use, DMCA Contact Us

- 3D printing Prusa i3 RepRap project 3D Printers, printer, electronics, 3D Printing png 1000x1000px 1.02MB

- 3D printing filament Polymeric acid MakerBot Acrylonitrile butadiene styrene, others, material, material png 1900x860px 1.36MB

- Filament 3D printing Filament Zortrax Z-ABS Z-ABS Filament ABS plastic 3D Printers, printer, electronics, 3D Printing png 900x550px 342.

75KB

75KB - 3D printing filament Polylactic acid Thermoplastic polyurethane, Parts Store, orange, material png 714x687px 494.84KB

- Filament 3D printing Zortrax Acrylonitrile butadiene styrene, printer, electronics, supplies png 1000x612px 1.8MB

- Plastic 3D printing filament Acrylonitrile butadiene styrene, 6 pack, abs, engineering, 3D Printing png 1024x612px 1MB

- 3D printing filament Polyethylene terephthalate glycol Polyethylene terephthalate, others, miscellaneous, 3D Computer Graphics png 752x616px 326.36KB

- 3D printing filament Acrylonitrile butadiene styrene Polymeric acid Extrusion, spool, miscellaneous, white png 1400x1400px 2.

56MB

56MB - Big Sky Franchise Team 3D printing Company Polylactic acid Business, man, miscellaneous, company png 682x1500px 538.8KB

- Polyethylene terephthalate Plastic bottle 3D printing filament PET bottle, recycling, recycling, waste png 1200x800px 891.53KB

- 3D printing filament Ultimaker, printer, blue, electronics png 750x550px 187.35KB

- 3D printing filament colorFabb PLA/PHA Polylactic acid Blue, 1mm fluorescent beads, blue, gray png 1968x2748px 1.59MB

- Polylactic acid 3D printing Filament., miscellaneous, blue png 1800x1310px 636.

84KB

84KB - 3D printing filament Polymeric acid Lyman filament extruder, printer, electronics, 3D Computer Graphics png 600x600px 360.56KB

- Ultimaker 3D printing filament Acrylonitrile butadiene styrene Polylactic acid, 空白乳霜, miscellaneous, monochrome png 1623x1080px 1.22MB

- Filament 3D printing MakerBot Polymeric acid Office Depot, purple filament, miscellaneous, 3D Printing Filament png 1600x957px 2.15MB

- 3D printing filament Polymeric acid Acrylonitrile butadiene styrene, plastic, electronics, material png 1170x779px 170.2KB

- 3D printing filament Polymeric acid Plastic Material, circle, blue, symmetry png 819x822px 108.

85KB

85KB - 3D printing filament Polymeric acid Material, suitable for printing, miscellaneous, 3D Printing png 752x616px 227.16KB

- 3D printing filament Polymeric acid Acrylonitrile butadiene styrene Material, spool, electronics, material png 1400x1400px 2.23MB

- Filament 3D printing Acrylonitrile butadiene styrene Polylactic acid Polyvinyl alcohol, 3dshop 3D Printing Specialist, orange, logo png 1000x1000px 1.12MB

- 3D printing filament material Printer, printer, angle, electronics png 752x616px 164.31KB

- 3D printing filament Polylactic acid Ultimaker, christmas material, blue, electronics png 883x700px 125.

05KB

05KB - 3D printing filament Polymeric acid Acrylonitrile butadiene styrene Material, others, miscellaneous, 3D Printing png 1400x1400px 2.63MB

- 3D printing filament Polylactic acid Acrylonitrile butadiene styrene Cornflower blue, Taobao Blue Copywriter, miscellaneous, blue png 800x800px 569.99KB

- 3D printing filament Extrusion plastic filament Lyman filament, filament, miscellaneous, recycling png 1320x750px 254.9KB

- MakerBot 3D printing Filament polylactic acid, printer, electronics, orange png 880x510px 458.92KB

- 3Doodler 3D printing Pen Polylactic acid, pen, material, industry png 590x590px 271.

17KB

17KB - 3Doodler Plastic 3D printing Pen Computer, pen, 3D Computer Graphics, hand png 599x468px 191.92KB

- plastic 3D printing 3D printers Material 3D computer graphics, routers, 3D Computer Graphics, material png 509x509px 186.94KB

- 3D printing filament Polylactic acid Fused filament fabrication Acrylonitrile butadiene styrene, 3D printing gyroscope, electronics, 3D Computer Graphics png 500x546px 241.83KB

- 3Doodler 3D printing filament Polylactic acid Acrylonitrile butadiene styrene, pen, material, pen png 1408x2362px 320.12KB

- 3D printing filament Polylactic acid material, PLA, material, 3D Printing png 2500x2211px 2.

79MB

79MB - Filament 3D printing Polymeric acid Acrylonitrile butadiene styrene, skydiver, color, 3D Printing Filament png 1024x1024px 1.33MB

- 3D printing filament Carbon fiber Polylactic acid, fibers, angle, fiber png 561x509px 308.79KB

- Filament 3D printing Polymeric acid 3D printers, others, material, material png 1400x1400px 2.16MB

- 3D printing filament Polymeric acid Material, printer, electronics, 3D Computer Graphics png 752x616px 307.64KB

- Ultimaker 3D printing filament Polymeric acid Acrylonitrile butadiene styrene, PLA, steel, material png 2806x3300px 4.

84MB

84MB - Thermoplastic polyurethane 3D printing filament Ultimaker, Prototype material, blue, material png 726x465px 75.01KB

- Filament 3D printing Acrylonitrile butadiene styrene Zortrax, printer, blue, electronics png 600x600px 275.9KB

- Ultimaker 3D printing Building Materials Polyvinyl alcohol, ring material, angle, material png 600x476px 112.16KB

- 3D printing filament Polylactic acid PETG Plastic, Wholesale electronics parts, 3D Printing, tire png 800x800px 350.08KB

- 3D printing filament Polylactic acid filament Innofil 3D PLA filament Acrylonitrile butadiene styrene, purple filament, orange, 3D Printing png 445x664px 123.

98KB

98KB - 3D printing filament Polylactic acid Acrylonitrile butadiene styrene, brown stone, exaggerated uncle, brown, stone png 543x842px 593.62KB

- Ultimaker S5 3D printing Printer, printer, electronics, material png 681x1023px 447.49KB

- Zortrax M200 3D printing Polymeric acid, printer, electronics, 3D Computer Graphics png 825x464px 129.32KB

- 3D printing filament Polymeric acid Acrylonitrile butadiene styrene Thermoplastic elastomer, others, gray, material png 600x600px 356.61KB

- 3D printing Printer Extrusion material, 3d Printers, 3D Computer Graphics, material png 2000x1333px 1.

79MB

79MB - Ultimaker 3D printing filament Polylactic acid Acrylonitrile butadiene styrene, coil, material, material png 2999x1868px 1.89MB

- 3D printing filament Polymeric acid 3D Printers, 3D Printing Filament, angle, material png 752x616px 296.34KB

Consumables

Subscribe to the author

Subscribe

I do not want

4

FORMLABS presented two polyurethane materials for SLAS - PU Rigid 650 Resin and PU Rigid 1000 Resin, which are the strongest and most durable resins.

Printing strong, rigid and durable polyurethane parts on a Formlabs 3D printer is now possible. This will allow designers, engineers and other professionals to break free from the limitations of traditional polyurethane production and find new workflows and applications. Formlabs polyurethane resin lineup now includes:

Formlabs polyurethane resin lineup now includes:

- New photopolymer PU Rigid 650 Resin . Production of durable and pliable polyurethane parts that can withstand extreme impact and harsh environments while maintaining dimensional accuracy under load.

- New photopolymer PU Rigid 1000 Resin . Create semi-rigid, strong and resilient polyurethane parts that can withstand high impact and harsh environments.

- Resin Rebound . Released in 2019Rebound Resin is a ready-to-manufacture, elastic 3D printing material. New Balance used this material to create the TripleCell powered sneaker.

Polyurethane Resins for a Variety of Applications

Polyurethane resins are strong, tough and durable, ideal for printing parts in all phases of prototyping and final production. Traditional SLA resins are made from acrylate polymers, so their durability may decrease over time.

However, polyurethane resins are an unusual material for 3D printing because they require complex chemistry to produce. After years of testing, the Formlabs materials development team settled on hybrid chemistry. The special combination of acrylate and urethane in our polyurethane resins allows them to be used in Formlabs 3D printers, delivering the same standards and quality you expect from our conventional materials. This hybrid chemistry, combined with curing under humidity conditions, brings the printed parts to the state of the finished polyurethane.

After years of testing, the Formlabs materials development team settled on hybrid chemistry. The special combination of acrylate and urethane in our polyurethane resins allows them to be used in Formlabs 3D printers, delivering the same standards and quality you expect from our conventional materials. This hybrid chemistry, combined with curing under humidity conditions, brings the printed parts to the state of the finished polyurethane.

Technical Data - Rigid Polyurethane Resins

PU Rigid 650 Resin Application

The strongest material in the Formlabs line, Rigid 650 PU Resin, is excellent for creating parts that can hold their shape for long periods of time for a long time. This includes shock and shock absorbing parts such as:

- Wheels

- Bumpers

- Grippers and end effectors

- Dampers

- Bushings

Often the best way to build parts for load bearing or permanent functional use is to join two parts together. Because Rigid 650 PU resin retains its shape over long periods of use, it is ideal for creating:

Because Rigid 650 PU resin retains its shape over long periods of use, it is ideal for creating:

- Live Hinges

- Gathered Hinges

- Snaps

PU Rigid Resin Application 1009 90719 9045

Like PU Rigid 650 Resin, PU Rigid 1000 Resin can withstand continuous use without losing its original shape or design. Due to its higher tensile strength, this material can withstand a greater load without breaking. This means Rigid 1000 PU resin is excellent for printing tough and durable end-use parts, such as parts designed to protect vulnerable components. These include:

- Fixings

- Brackets

- Protective structures

- Blooders

- Bumpers

Using the resin of PU Rigid 1000, you can print on other durable materials, for example:

- Circats for bottles

- 9000

- Bicycle pedals

Post-consumption. using polyurethane materials

Polyurethane has a more complex workflow and requires additional equipment and installation costs. Consistent and high quality results require more attention when setting up prints and post-processing details.

The following workflow is similar to printing with other media, but requires additional hardware and post-processing time:

- Create a 3D file. Use PreForm to prepare a custom file to help guide you through the process of adding supports and choosing the correct print orientation.

- Prepare the printer. Formlabs PU Rigid Resins are supplied in an aluminum bottle with funnel and empty cartridge to maintain expiration date. After shaking the bottle to make sure the resin is thoroughly mixed, use a funnel to pour the resin into the empty cartridge. Your printer must be in a dry cabinet to print using any of the rigid polyurethane resins. When the printer is ready, load the resin cartridge, print platform and press the "Print" button!

- Print.

As usual, follow the prompts on the easy-to-use touch screen to start printing.

As usual, follow the prompts on the easy-to-use touch screen to start printing. - Post-processing. Place the Build Platform in a short PGDA rinse, then air dry or use an air compressor. After drying and removal of supports, the parts must be placed in a moisture curing chamber for subsequent curing. Moisture curing completes the reaction of the urethane, turning the part into true polyurethane. This process does not use IPA or traditional flushing solvent. It will take three days to fully cure a 2mm thick piece using PU Rigid 650 or PU Rigid 1000 Resin.

High performance engineering materials for everyone

While some equipment is optional, such as an air compressor to air dry excess PDGA solvent from the surface of the model, other equipment is required. These include a low humidity dry cabinet and a curing chamber. They are necessary to reduce moisture that interferes with end use.

Due to the additional time required for post-processing, polyurethane materials are not ideal for rapid one-day prototyping.