Plan b 3d printer

Plan B 3DP Powder-based Inkjet 3D Printer - Costs Less Than $1300 to Build - 3DPrint.com

Printed on the Plan B 3D Printer

When it comes to 3D printers that people use at home, there are typically two options available. There are Fused Deposition Modeling (FDM) based 3D Printers, which melt spools of plastic filament and subsequently lays this material down, one layer at a time, in order to slowly build up an object. Then there are Stereolithographic (SLA) 3D printers which use either a laser or DLP projector to cure (harden) a liquid resin, also in individual layers. Other than these two technologies, all of the other methods are pretty much only available to large corporations who have the capital to afford machines ranging in price between $50,000 and $2 million+.

A 22-year-old young engineer, named Yvo de Haas has hopes of changing this, with an open source 3D printer that he calls the Plan B. The Plan B is not your typical 3D printer. It utilizes a technology which is quite different than the FDM and SLA based printers that are available to the consumer market today. Instead of melting plastic, or curing a liquid resin, his machine uses a fine powder, which is bound together one layer at a time, using a special binding agent that is fed through an inkjet printer head.

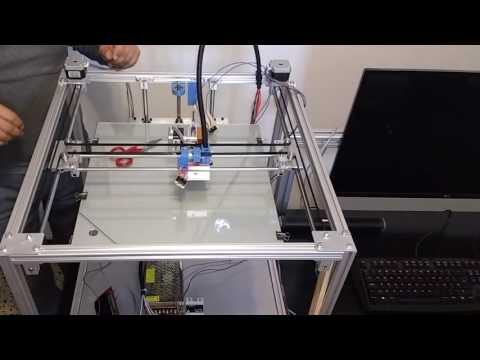

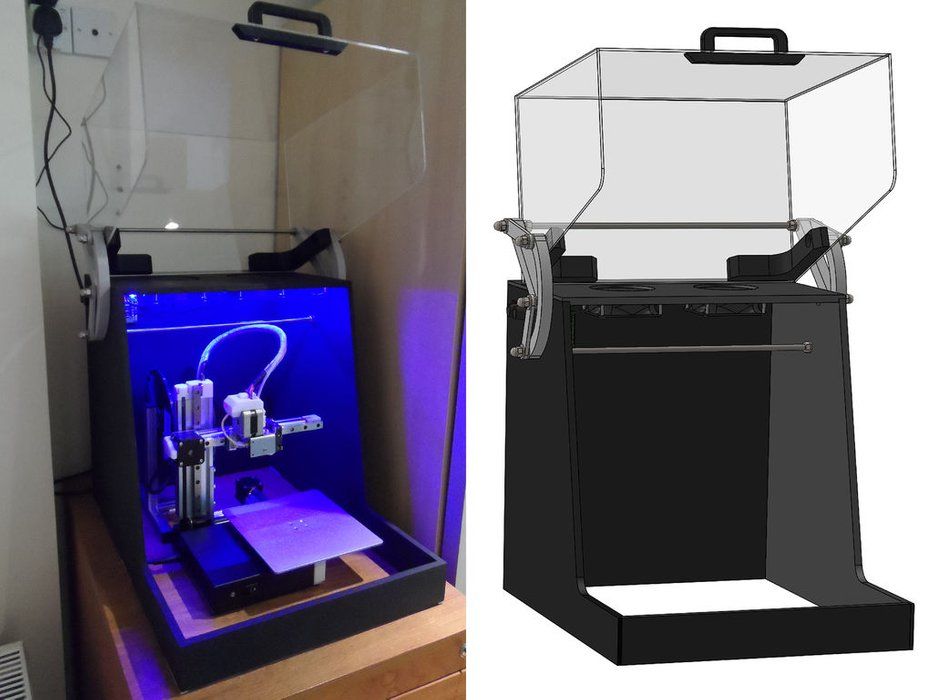

The Plan B 3D Printer

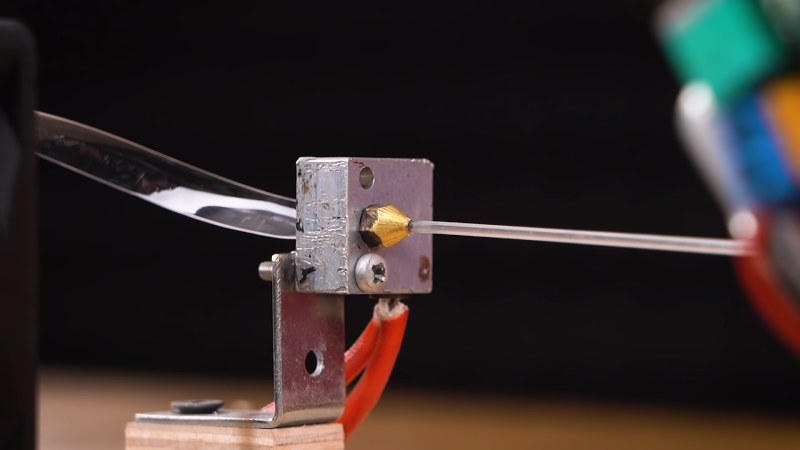

“3DP printing looks a lot like ordinary inkjet printing, the only difference being the third dimension,” Haas explained. “It uses a special powder stored in several hoppers and binder stored in either the cartridge or a separate tank. First the printer adds a thin layer of fresh powder on a special bed (build bed) that can lower. An inkjet head prints thin cross sections of a 3D model in the powder with binder. When a layer is done, the build bed lowers by a fraction and a new layer is deposited. Then the process is repeated until the part is complete.”

Printed on the Plan B

On the surface, this process looks similar to the methods used by industrial level Selective Laser Sintering (SLS) 3D printers, but rather than having a laser bind the powder together, it uses a glue-like binding agent. Because of the way in which it prints, Haas says that it is capable of printing with higher accuracy when compared to FDM based machines. Also, no support material is ever needed when printing obscurely shaped objects, because of the fact that the powder always supports those objects.

Because of the way in which it prints, Haas says that it is capable of printing with higher accuracy when compared to FDM based machines. Also, no support material is ever needed when printing obscurely shaped objects, because of the fact that the powder always supports those objects.

While the Plan B is not actually the fastest 3D printer in the world, Haas says that it has the potential to be faster than FDM machines, because of the simpler movements that the nozzle is required to make, when compared to Cartesian-based FDM printers. While SLA and FDM 3D printers are limited in materials, mostly to plastic based substances, the Plan B is capable of printing in virtually any material that can be turned to a powder. This includes ceramics, stainless steel, graphite, etc.

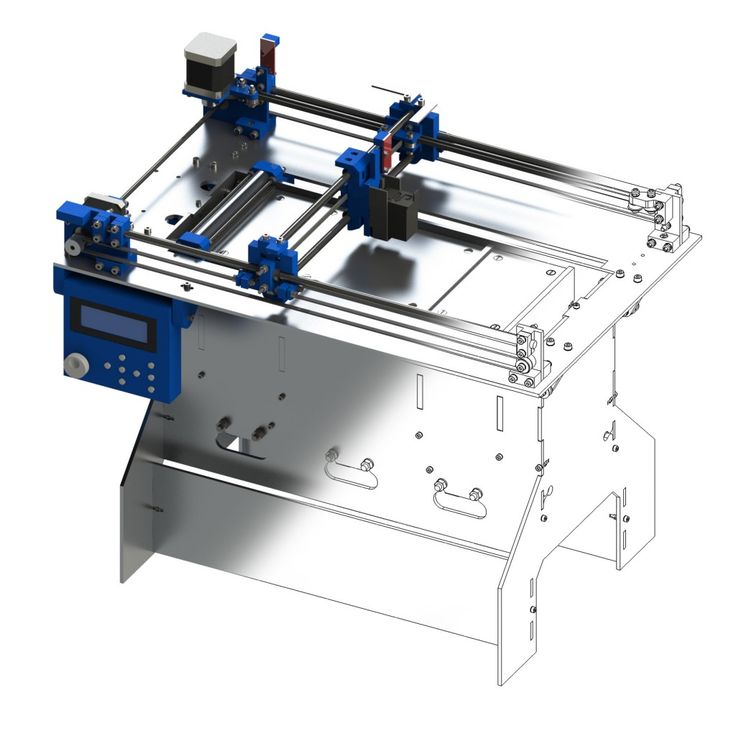

The Plan B in action

Sounds great, doesn’t it? Well there are also some disadvantages to using a printer like the Plan B. For starters, it is quite messy. There is a fine powder that is used, and then must be removed from the print bed, and from the printed object itself. The machine must also remain full of powder at all times in order to function properly. Most annoying of all is the post processing that each individual part requires. Since the binding agent is not very strong, most parts need to be handled very delicately. Powder must be removed, and then the objects typically need to be infused with a CA glue or epoxy in order to provide them with structural strength. Another option to increase the strength is by firing the objects in a kiln, something not available to most people.

The machine must also remain full of powder at all times in order to function properly. Most annoying of all is the post processing that each individual part requires. Since the binding agent is not very strong, most parts need to be handled very delicately. Powder must be removed, and then the objects typically need to be infused with a CA glue or epoxy in order to provide them with structural strength. Another option to increase the strength is by firing the objects in a kiln, something not available to most people.

The printer cost Haas less than 1,000 Euros to construct, and includes the following specifications:

- Buildbox dimensions: 150mmx150mmx100mm (l x w x h)

- Layer thickness: 0.1mm to 0.25mm

- Inkjet resolution: 96DPI (HP C6602)

- Build material: Currently only Zcorp Gypsum and binder without color (this list will expand)

- Step accuracy (X/Y): 0.05mm

- Speed: 60mm/s (higher with future firmware)

- Printing speed: Up to 30mm per hour (higher with future firmware)

- Power consumption: Up to 160W (around 90W average)

- Printer dimensions: 550mmx350mmx450mm (l x w x h)

- Printer weight: 16kg

- Frame material: Aluminum and 3D printed plastic

- Linear guides: LM8UU on 8mm steel rods

- Number of motors: 6x NEMA17 stepper motors

- Features: LCD screen, Keypad with rotary encoder, SD card reader

Loading the printer with powder

If you wish to build your own Plan B 3D printer, Haas has uploaded the instructions on his website. What do you think about the Plan B 3D printer? Is it something you think would be worth creating? Discuss in the Plan B 3D Printer forum thread on 3DPB.com. Check out the video below of the Plan B in action:

What do you think about the Plan B 3D printer? Is it something you think would be worth creating? Discuss in the Plan B 3D Printer forum thread on 3DPB.com. Check out the video below of the Plan B in action:

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3dp • diy • do it yourself • inkjet 3d printer • plan b • powder based 3d printer

Please enable JavaScript to view the comments powered by Disqus.

Build your own Inkjet 3D Printer with Plan B | Atmel

While we have seen plenty of DIY printers (several of which powered by AVR XMEGA and megaAVR MCUs), this one certainly ranks high on the list as most intriguing. In fact, Plan B may have just revolutionized the way we think about the 3D printing process in its entirety.

Designed by 22-year-old engineer Yvo de Haas, Plan B is an open-source platform powered by an ATmega 2560. Unlike other 3D printers on the market, this device works just like a desktop printer. The process is similar to the Selective Laser Sintering (SLS) process, but instead of using a laser to sinter the material, an inkjet printing head deposits a liquid binder onto a layer of gypsum powder.

Unlike other 3D printers on the market, this device works just like a desktop printer. The process is similar to the Selective Laser Sintering (SLS) process, but instead of using a laser to sinter the material, an inkjet printing head deposits a liquid binder onto a layer of gypsum powder.

Then, a thin layer of powder is spread across the surface and the process repeats itself with each layer adhering to the last. Though the “three dimensional printing” method has been in existence for decades, it was typically only seen in industrial uses.

The Plan B printer will aim to bring this method to the masses. The printer is designed to be assembled using only basic tools (e.g. screwdrivers, Allen keys, wrenches, a saw, soldering iron). De Haas’ product can be put together for about $1,300.

This DIY device is capable of printing with a resolution of 0.26mm, and since the 3D models are printed in layers of powder, it requires no additional support material. All excess material can be reused once the model has been removed from it. Currently, the Plan B can only print in gypsum powder; however, the Maker is experimenting with expanding into various types of materials including ceramics, graphite powders and even confectioners sugar.

Currently, the Plan B can only print in gypsum powder; however, the Maker is experimenting with expanding into various types of materials including ceramics, graphite powders and even confectioners sugar.

“The powder material is stored in hoppers on each side of the printing bed. As the inkjet nozzle deposits the pattern on the layer of printing material, the printing bed slightly lowers, causing the powder on the side to rise up slightly above the bed,” 3DPrintingIndustry.com notes.

The printer then levels out each subsequent layer until the design is finished. Once completed, the powder designs are still somewhat fragile. Therefore, a hardening substance must be applied so that they can be handled. De Haas says it depends on what type of material you print with, but in his case, a layer of SuperGlue worked to firm up his final products.

De Haas says it depends on what type of material you print with, but in his case, a layer of SuperGlue worked to firm up his final products.

Plan B is only capable of printing in a single color, but de Haas is planning on updating the printer with multiple inkjet nozzles so multi-color prints will be an option. Currently, printing speed is about 30mm per hour accompanied with a speed of 60mm/s; still Yvo looks to upgrade that frequency in the future. Overall, this is a drastically different take on 3D printing and the sort of thinking we can expect to see a whole lot more of throughout the budding Maker community. The model allows for all excess material to be reused, which can provide an environmentally friendly characteristic that we do not often see in DIY designs.

Interested in learning how to build the Plan B? Check out the Maker’s incredibly detailed guide here.

Like this:

Like Loading...

This entry was posted in 3D Printing, Maker Movement and tagged 3D printer, 3D Printing, DIY 3D Printer, Maker Movement, Plan B 3D Printer on by The Atmel Team. 90,000 collect the jet 3D printer Plan B worth less than 1300 dollars

90,000 collect the jet 3D printer Plan B worth less than 1300 dollars Archive

Subscribe to the author

Subscribe

I do not want

Product, printed on the 3D printer Plan B

, 22-year-old engineer Ivo de Haas developed An open source Plan B 3D printer that's far from ordinary. It uses a technology that is fundamentally different from the method of layered deposition and stereolithography. This printer prints products from fine powder, which sticks together layer by layer under the influence of a special binder. nine0003

Plan B 3D printer

“3D printing differs from conventional inkjet printing only in its three-dimensionality,” explains Haas. – My 3D printer has several powder containers and a binder cartridge. First, he applies a thin layer of powder to the platform. The head sprays the binder, bonding the powder in the right places. When the layer is ready, the platform drops a little lower.This process is repeated until the product is finished.

Plan B 3D printed product

In general, this method is similar to selective laser sintering, but instead of a laser that sinters the powder, it uses a special adhesive that resembles glue. Haas claims that the Plan B prints much more accurately than fused deposition 3D printers. In addition, no support material is required when manufacturing products with a complex design, since the powder itself serves as a support. nine0003

Plan B may not be one of the world's fastest 3D printers, but it prints faster than Cartesian 3D printers because the nozzle doesn't have to move as much as the print head normally does. While stereolithography and fused deposition 3D printers are limited in materials (usually plastic-based substances), Plan B is capable of printing virtually any powder material, including ceramic, stainless steel, graphite, and etc. nine0003

Plan B in action

Sounds great, doesn't it. However, there is a fly in the ointment in every barrel of honey. First of all, it is worth remembering that a very fine powder is used for work, which means that it will contain both the platform and the product itself. Also, the 3D printer's containers must always be filled with powder for it to function properly. But, perhaps, the most unpleasant can be considered the post-processing of products. Printed products are quite fragile, so they should be handled very carefully. First you need to brush off the remnants of the powder from them, then cover them with cyanoacrylic or epoxy glue to give them strength. Another way to fasten the product is to burn it in the oven. Agree, not everyone has a personal kiln at hand. nine0003

However, there is a fly in the ointment in every barrel of honey. First of all, it is worth remembering that a very fine powder is used for work, which means that it will contain both the platform and the product itself. Also, the 3D printer's containers must always be filled with powder for it to function properly. But, perhaps, the most unpleasant can be considered the post-processing of products. Printed products are quite fragile, so they should be handled very carefully. First you need to brush off the remnants of the powder from them, then cover them with cyanoacrylic or epoxy glue to give them strength. Another way to fasten the product is to burn it in the oven. Agree, not everyone has a personal kiln at hand. nine0003

The Plan B 3D printer cost Haas about 1,000 euros to build. Main features:

- Working volume: 150 mm x 150 mm x 100 mm.

- Layer thickness: 0.1-0.25 mm.

- Resolution: 96 dpi (HP C6602).

- Printing material: currently Zcorp gypsum powder and colorless binder (this list will be updated).

- Positioning accuracy (X/Y): 0.05 mm.

- Speed: 60 mm/sec (will be higher with future hardware update). nine0040

- Print speed: up to 30 mm/h (will be faster with a future hardware update).

- Power consumption: up to 160 W (about 90 W on average).

- Printer dimensions: 550 mm x 350 mm x 450 mm.

- Printer weight: 16 kg.

- Frame material: aluminum and plastic.

- Linear guides: LM8UU on steel rods 8 mm thick.

- Number of motors: 6 NEMA17 motors. nine0040

- Extras: LCD screen, rotary keypad, SD card reader.

3D printer loaded with powder

All instructions for building the Plan B 3D printer can be found on the Haas website.

Article prepared for 3DToday.ru

nine0004 the mandalorian razor crest ship

3 €

Captain Harlock Albator Arcadia GX-67

3 €

street hawk mechanical thunder new

3 €

speeder bike star wars the mandalorian

3 €

bmw r18

3 €

nine0004 Captain Harlock Albator battleships death shadow3 €

street hawk motorcycle

2,50 €

motorcycle bobber harley-davidson

2,50 €

The best files for 3D printers in the Tools category

Memory nozzle

Free

nine0004 Slim Arduino Uno CaseFree

EMPTY ROLL IN CABLE ROLL

Free

Dremel forestry sharpening adapter

1,25 €

Writing instrument for children with movement disorders

Free

Tube with filter material

Free

Raspberry Pi 2/Model B Triangular Case

Free

Bestsellers in the Tools category

3D printed wave transmission (harmonic drive)

4. 99 €

99 €

PRECISION CALIPER 3D PRINT DIY

3.12 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

Fire hydrant storage container

1.88 €

Quick print stackable parts containers / storage boxes

2.83 €

Shrek Pooping Toothpaste Topper

2.82 €

Armadillo - flexible wire conduit

€1.67 -10% 1.50 €

'ELEGANCE' Bambu lab set and general 3d printers

5 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2. 81 €

81 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.56 €

Cut-Man - PET bottle cutter with handle!

€3.49

Quick Print Paint Bottle Rack (6 sizes)

2.83 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.74 €

Phone holder

2.43 €

Business card embossing system

3 €

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED REEL

2.12 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.