3D printer pause

Can You Pause a 3D Print Overnight? How Long Can You Pause For? – 3D Printerly

If you wonder whether you can pause a 3D print, you are not alone. 3D prints can last many hours, and even days in some cases, so being able to pause a 3D print would be very important.

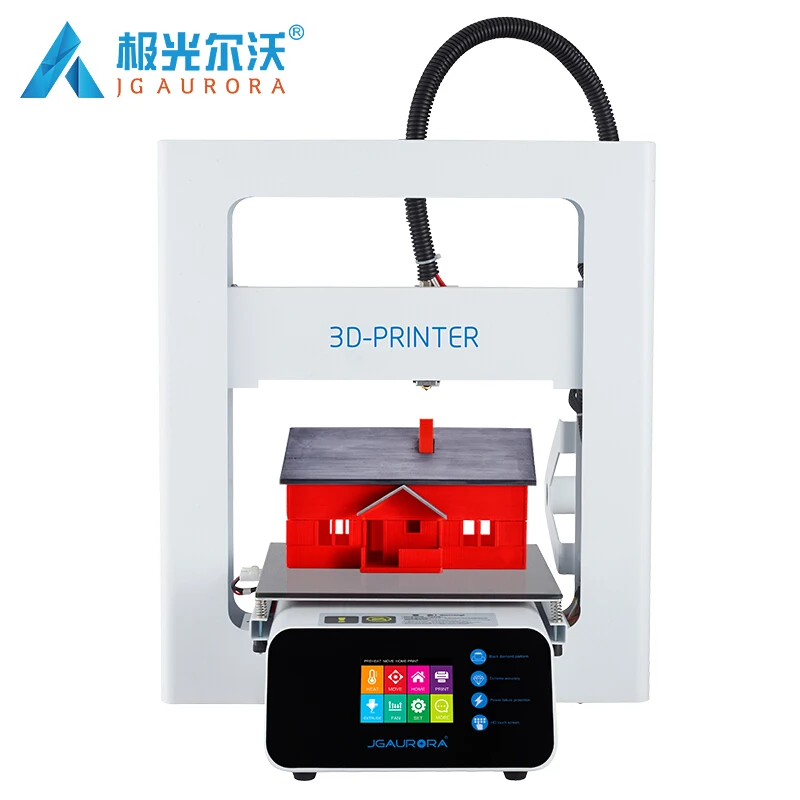

Yes, you can pause a 3D print directly from your 3D printer’s control box. Simply click your 3D printer to bring up your standard options, then select “Pause Print” and it should pause and home the 3D printer head and print bed to the home position. You can simply resume the print by pressing the “Resume Print” button.

Keep on reading for more information about pausing your 3D prints, and how you can use them to your advantage.

Can You Pause a 3D Print?While it is not recommended that you pause prints, it is very possible to pause a 3D print. Even though 3D printers are designed to run for several hours, it may become necessary to pause prints for several reasons.

Some users are not comfortable leaving the printer running unattended for most of the day when they will be at work. Others consider running it overnight to be too loud since it may disturb people’s sleep.

As soon as you are ready to resume your 3D printing, open the UI and initiate resume. This will undo the pause command and return the 3D printer to the printing state.

If you don’t know where the pause print option is on your 3D printer, kindly read the manual.

You’ll notice a pause option on the user interface (UI), and this can be used to do following:

- Disable heating elements

- Changing filaments

- Changing colors after a certain layer

- Embed various objects into a 3D printed object

- Move the printer to a different location

It is possible to pause your 3D printer for as long as you want, as long as the 3D print stays in place and isn’t removed from the bed or jolted. There may be a mismatch on the layer depending on how well the printer resumes. People usually pause a 3D printer for a few minutes to a few hours.

There may be a mismatch on the layer depending on how well the printer resumes. People usually pause a 3D printer for a few minutes to a few hours.

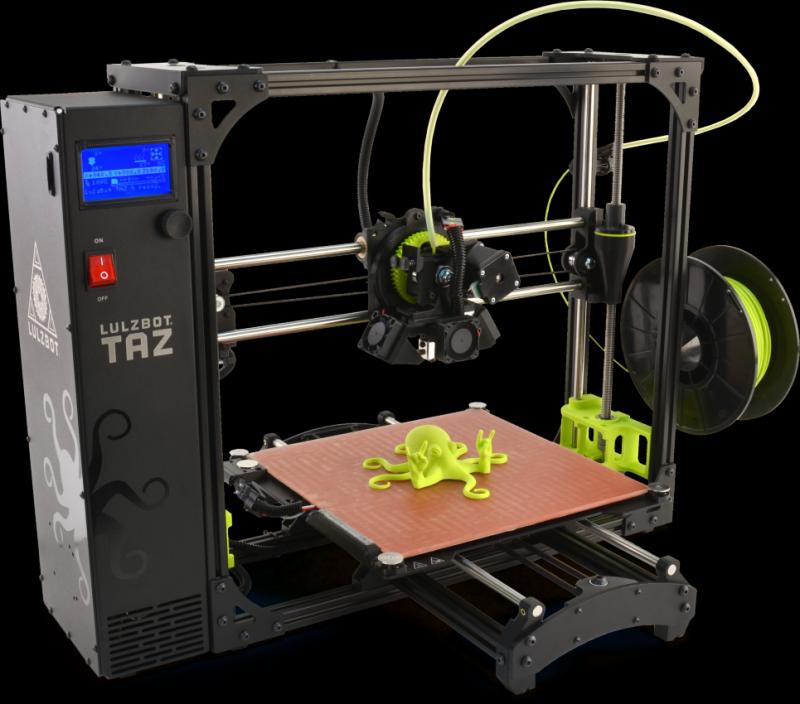

Some 3D printers are going to perform better with pausing, especially if they are proven among 3D printer hobbyists, like the Prusa Mk3S+ or the Ender 3 V2.

The main goal with how long you can pause your 3D printer is being able to keep your 3D print from moving off the print bed.

The main reason why a 3D printer should not be paused for too long is as one user puts it, after leaving the printer to cool down totally, his print lost adhesion and failed.

The longer you leave a 3D printer paused, there is a higher chance of the print falling off.

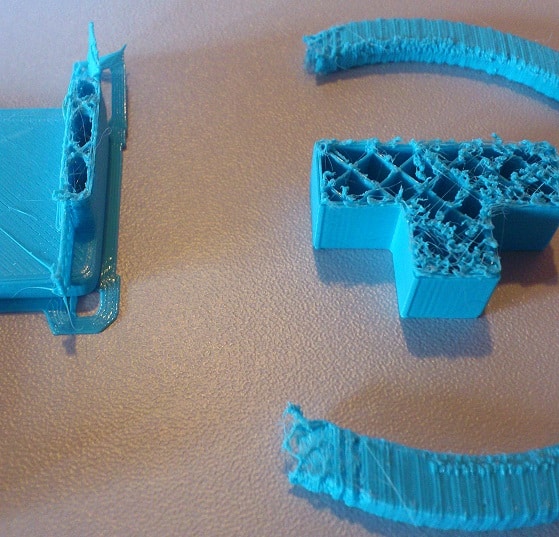

For the most part, failures that happen from pausing a print occurs from warping which is when there are significant temperature changes in the extruded plastic.

For more information on how to pause a 3D print watch this video on pausing an Ender 3. The main thing you want to do is to make sure you initiate the SD card so you get the resume option.

Some people have mentioned that they paused a 3D print overnight. Their recommendation for doing this is that all the parts of the 3D printer must be in good condition.

Upon confirmation, you can turn off the machine, allowing you to take a long pause without any major negative impact.

Some users have paused their 3D prints for several hours and still successfully resumed the print. As long as your print stays in one place, you can pause it for a long time. Using adhesives can make your 3D prints stay in one place better.

To be on the safe side, some users recommend that you pause the print but keep the machine on. This can keep the build surface warm. As long as the build plate is warm, it won’t be too hard for the print to retain its shape.

To slow down the change in temperature, you may use an enclosure or a material that is known not to warp as much. The faster your 3D prints cools down, the more chance it has to warp and change shape. This could eventually lead to losing adhesion from the build plate.

You may also choose to break your 3D prints into smaller parts. This will ensure that you have a hard pause between printing each part without impacting the overall design negatively.

After that, you can simply bond the parts together using superglue or another strong adhesive.

Do 3D Printers Need a Break?A 3D printer doesn’t need a break as long as it is maintained properly and has good quality parts. Many people have printed for 200+ hours without any issues, so if you have a reliable 3D printer, your 3D printer won’t need a break. Make sure your 3D printer is lubricated well and has fresh belts.

3D printers are designed to run for hours and hours at a stretch, with some users confirming that they have kept it running for up to 35 hours. Others have 3D printers that can run for more than 70 hours.

Others have 3D printers that can run for more than 70 hours.

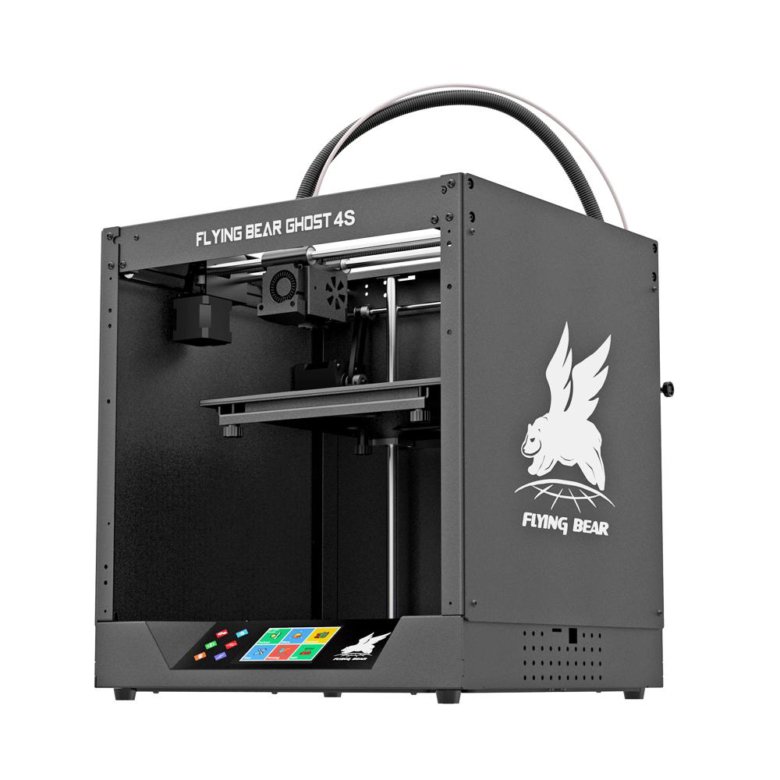

Some 3D printers are better than others at running for longer periods of time. You want to test how your 3D printer runs because some can handle 3D printing for plenty of time while others might not do so well.

If you have a cheaply made 3D printer that isn’t very well known, you might just have a machine that won’t run for so long without needing a break. A popular and reliable 3D printer that has been tried and tested is a lot more likely to not need a break.

These have high quality designs and cooling systems that make sure the 3D printer doesn’t run too hot and can handle constant movement.

As long as everything is fine and no prior faults have been detected, your 3D printer should keep working flawlessly, even for an extended period.

If your 3D printer is not well maintained or has come of age, it may be beneficial if you subject the printer to short breaks at intervals. 3D printers are designed to be long-lasting, but not every part.

Each 3D printer should have Thermal Runaway Protection installed, which is a safety feature designed to protect your printer, your home, and the environment around.

The Thermal Runaway Protection works by checking the readings from the thermistor. If this firmware detects a more-than-required temperature, it automatically stops or pauses the printer until it cools off.

If after an extreme temperature is noticed the printer continues working, it could set the home on fire so having this protection is important, especially when running for long periods of time.

Can I Pause an Ender 3 Printer Overnight?Yes, you can pause an Ender 3 printer overnight by using the “Pause Print” feature within the control box. Make sure not to click “Stop Print” instead because this will end the print altogether. You’ll be able to easily resume the print in the morning.

You can even turn off the whole 3D printer and still resume your 3D print but you have to make sure you initialize your SD card, so your 3D printer recognizes that there is a print to resume.

On confirmation, it brings the nozzle back to temperature and on top of the previously paused 3D print to continue from where it stopped.

7 Important Tips for Pausing a 3D Print Overnight – Printing It 3D

Due to its initial patent holder being an appalling commercial failure, 3D printing is still a fairly new technology over 40 years after it was first invented. And like many technologies, it tends to go wrong the moment you turn your back. So what should you do if you want to pause a 3D print overnight?

Here are 7 important tips for pausing a 3D print overnight:

- Use the pause function.

- Turn the printer off.

- Use glue sticks.

- Minimize dust.

- Leave it alone.

- Keep pets and children away from the printer.

- Preheat the bed.

This article will explore tips for pausing a 3D print overnight. Later it will explore some reasons your printer may stop mid-job and how to restart a 3D print after a loss of power. But first, we will clarify whether or not you can pause a 3D print overnight. Note that some of the advice in this article applies to fused deposition modeling (FDM) 3D printers only.

Later it will explore some reasons your printer may stop mid-job and how to restart a 3D print after a loss of power. But first, we will clarify whether or not you can pause a 3D print overnight. Note that some of the advice in this article applies to fused deposition modeling (FDM) 3D printers only.

Can You Pause a 3D Print Overnight?

While some FDM printer models are better at pausing print jobs than others, most commercially available printers can pause print jobs almost indefinitely.

The user interfaces of most FDM printers have the option to pause a print job. Furthermore, many slicer programs have the option to program pauses into the .stl files they generate.

Unless someone tampers with the printer, the only real problem that might develop is the incomplete printed object detaching from the print bed. You can do a few things to minimize the chance of this happening, which are covered below.

Tips for Pausing a 3D Print Overnight

1.

Use the Pause Function

Use the Pause FunctionAs above, most commercial 3D printers have a “PAUSE” function programmed into their user interface. Your printer’s manual should cover how to pause a print job.

When a pause is initiated, an FDM printer will remember its stage and go into its standby mode. Most printers will keep the heating element under the print bed turned on unless they are turned off.

2. Turn the Printer Off

Once the print job is paused, there is no reason to leave the printer on overnight. A paused printer will still use a considerable amount of power, and there is a small chance that it could overheat and catch on fire.

When you return to your printer, whether it is the next day or several months in the future, the print job can be restarted through the user interface.

3. Use Glue Stick

If you think you might have to pause a print job, it is a good idea to apply an adhesive agent to the print bed before starting. A glue stick will help keep the incomplete print adhered to the print bed.

As the print bed cools, it will contract a bit, and the incomplete object can delaminate from the bed. The glue stick will hold it in place while still being possible to remove from the bed when the job is finished.

If your incomplete object comes unstuck from the print bed overnight, you can secure it with either a glue stick or scotch tape.

4. Minimize Dust

Minimizing dust in the room where you make your 3D prints is a basic best practice, but it is also important when pausing a print job. If dust collects on your incomplete object, specifically the exposed interior, the dust will prevent new plastic from properly adhering when the print job is renewed.

Cover your printer with a cloth or tarp if you are away for more than a few hours. Another good idea is to have an air purifier nearby to remove dust from the air.

5. Leave It Alone

Once your printer is shut down and covered up (if you choose to do so), leave it alone until you are ready to resume the print job. Don’t push around the print bed or do anything to the object. You might dislodge the incomplete object or damage the printer.

Don’t push around the print bed or do anything to the object. You might dislodge the incomplete object or damage the printer.

6. Keep Pets and Children Away From the Printer

Another best practice is to keep your pets and children away from your 3D printer. Children are notoriously skilled at breaking their parents’ things and relationships.

If you are leaving an incomplete print job overnight, it is best to keep it behind a closed door to prevent beings who don’t know better from messing it up.

7. Preheat the Bed

When you are ready to resume your print job, preheat the print bed first. This will preheat the incomplete object, which will help additional plastic adhere to it and improve the structural integrity of the finished object.

Reasons a 3D Printer May Stop Midjob

Even if you don’t want to stop a 3D print part way through, your printer may stop on its own. There are four reasons a 3D printer may stop on its own. Thankfully most of them can be dealt with without much effort.

- Overheating

- Filament problems

- Nozzle clog

- Power failure

Overheating

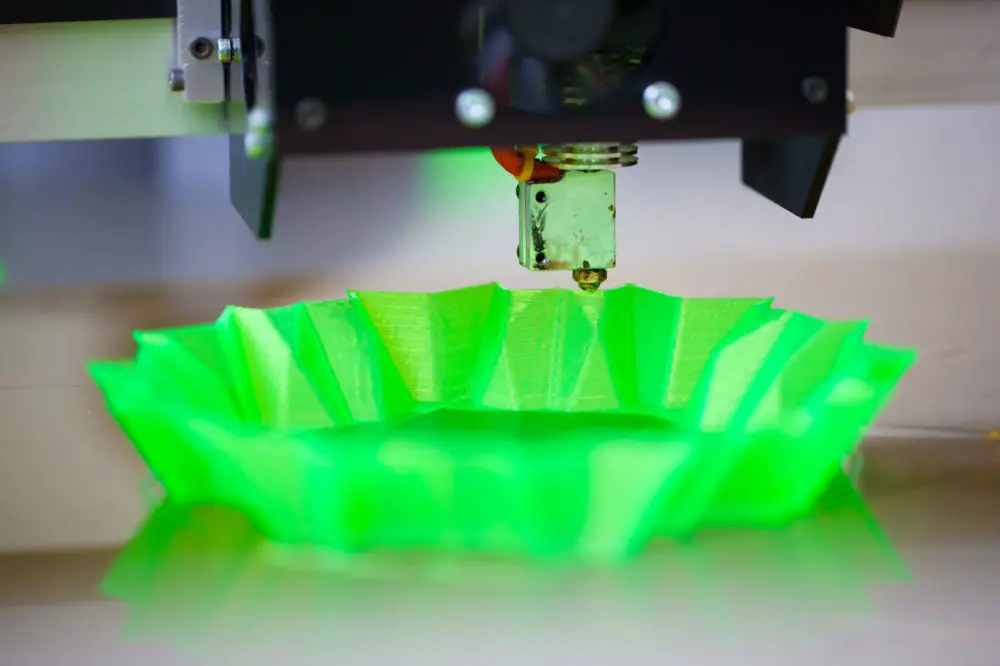

3D printers use heating coils in their extruders and print beds and have other electronic parts which produce their own waste heat. And even with cooling places placed strategically in the extruder, FDM printers can still overheat. If they overheat, 3D printers are designed to shut themselves down to avoid damaging themselves.

Extruder Motor

The most likely part to overheat is the extruder motor. It moves a lot more than the other motors in your printer, and it is near a heating element.

Normally the extruder motor should be kept cool by the extruder cooling fan. But the fan can be clogged up with dust and debris. You can prevent this with proper maintenance.

Part of regular 3D printer maintenance is cleaning out the fans. The most effective way is pressurized air from either a compressor or a can. A cotton swab dipped in rubbing alcohol will do in a pinch.

If you wish to improve your extruder’s cooling, you can add heat sinks to it. Heat sinks are typically sold in batches or as part of kits for around $20 from Amazon or 3D printer manufacturers.

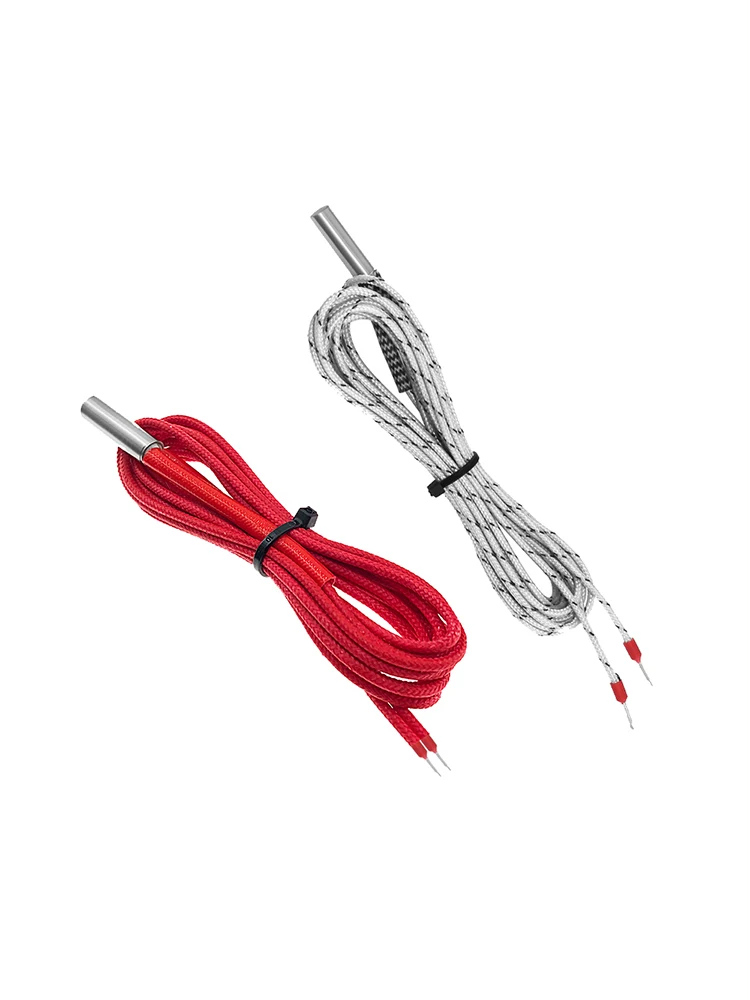

Thermistor Glitch

Another possible cause for a 3D printer thermal shutoff is a faulty thermistor, a variable resistor that adapts to temperature. Your printer’s controller monitors the current in the thermistor circuit, and if it reaches a certain point, it interprets it as an overheat.

Most 3D printers have two thermistors, one in the build plate (assuming it is heated) and one in the hotend. The “hotend” is the part of the extruder that heats up to melt the filament. The firmware of most 3D printers reports a thermistor glitch as a “MINETEMP” error.

The most likely cause of a thermistor issue is a break somewhere in the circuit. Unfortunately, there is not much to prevent this other than being very careful with working around the wires.

If there is a break in the circuit, it can probably be soldered. If the thermistor itself is faulty, it has to be replaced.

Before attempting to solve a thermistor error yourself, please consult with your print’s manual or other literature on the manufacturer’s website.

Filament Problems

It would be best not to leave a 3D printer unattended because something may go wrong with the filament. Your filament could run out, grind against the frame, or snap.

Depleted Filament

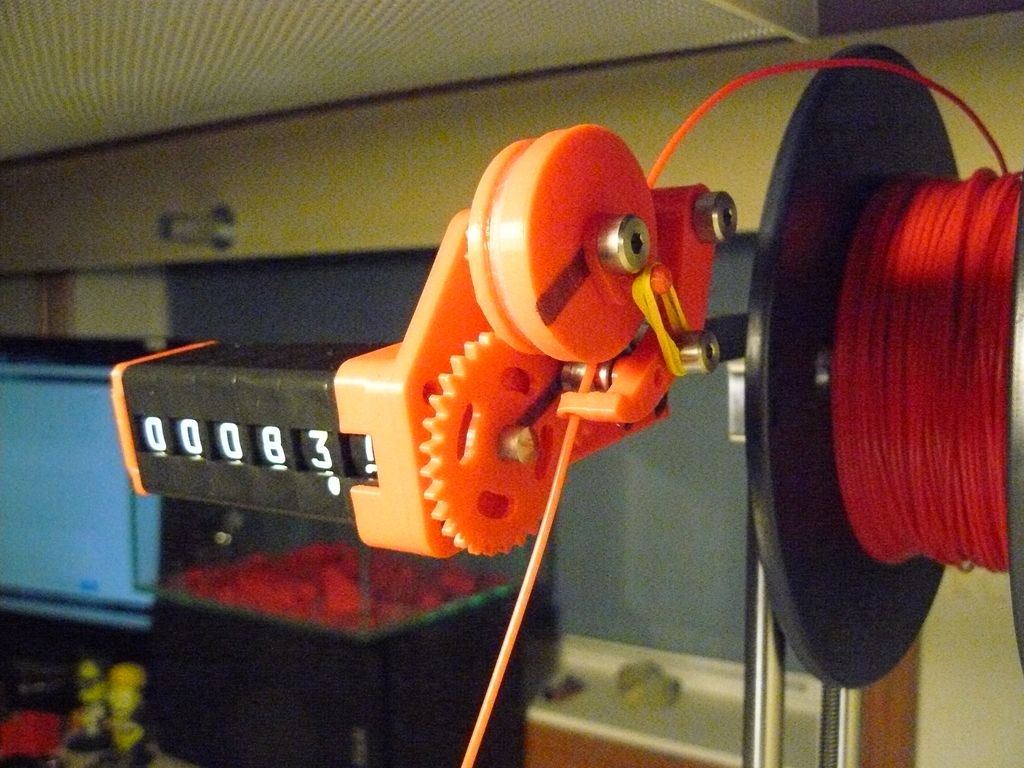

One of the most common issues in 3D printing is running out of filament. It isn’t easy to gauge how much filament is left on the spool. 3D printers are equipped with sensors that will automatically stop a print when the filament is depleted, but most do not.

There is at least a way to tell how much is needed for a particular job. Your slicer program should have a box where it lists the amount of filament required.

Your slicer program should have a box where it lists the amount of filament required.

You can estimate how much filament is left on a spool using a postage scale and some math.

- Weigh a depleted spool.

- Cut off a meter/yard of filament and weigh it.

- Weigh your partial spool

- Subtract the weight of the depleted spool from your partial spool to get the weight of the remaining filament.

- Divide the weight of the remaining filament by the weight of the meter.yard from earlier. The result should approximate the length of filament left on your spool.

Grinding Filament

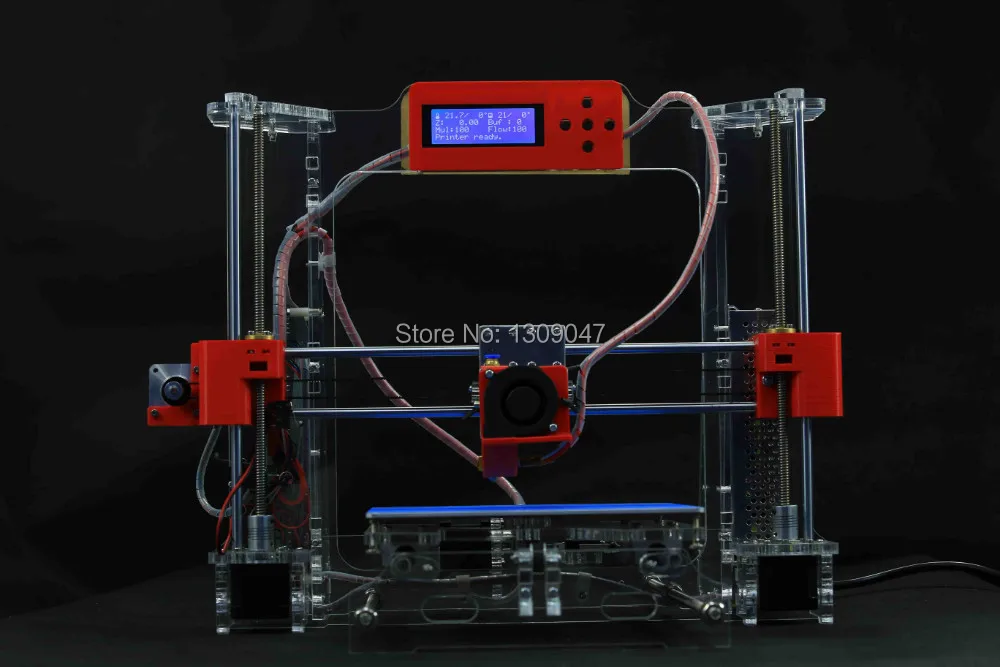

You have to be careful with how you run your filament from the spool to the extruder. If the filament rubs up against the printer’s frame or other parts, it can be gradually damaged. A damaged filament can jam in the extruder and eventually snap.

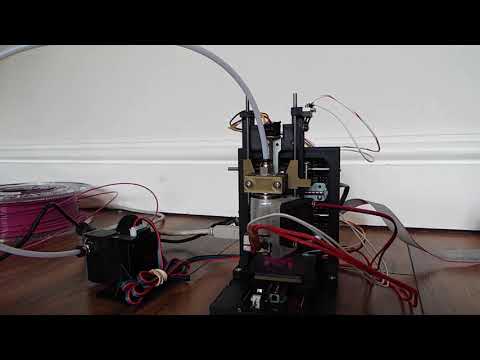

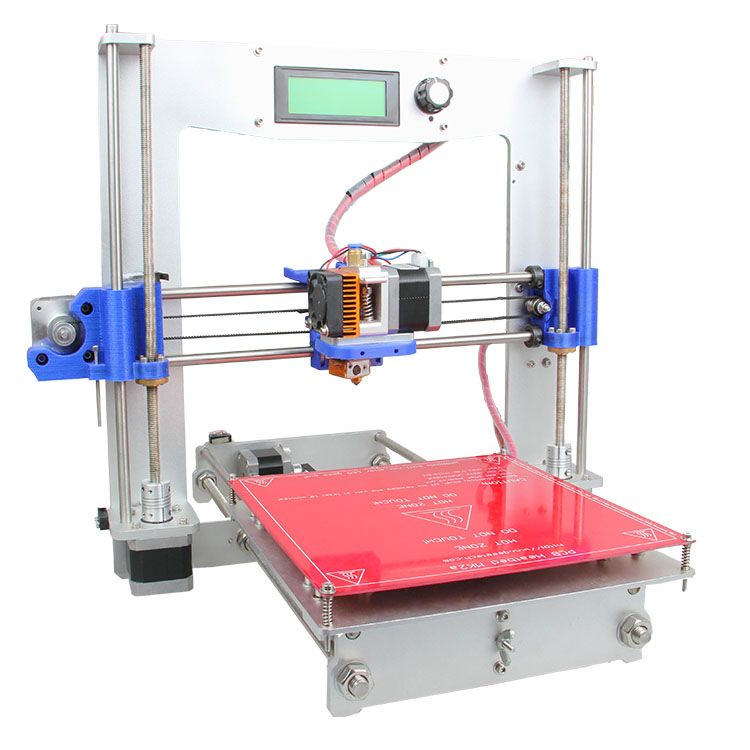

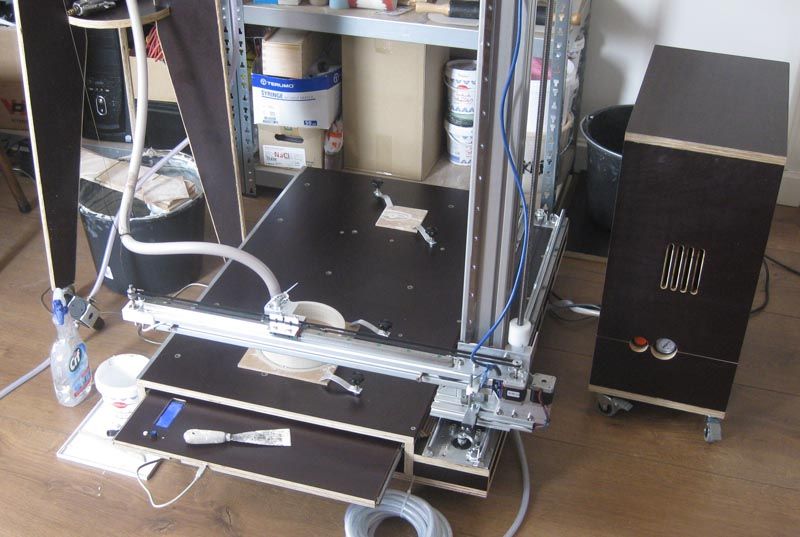

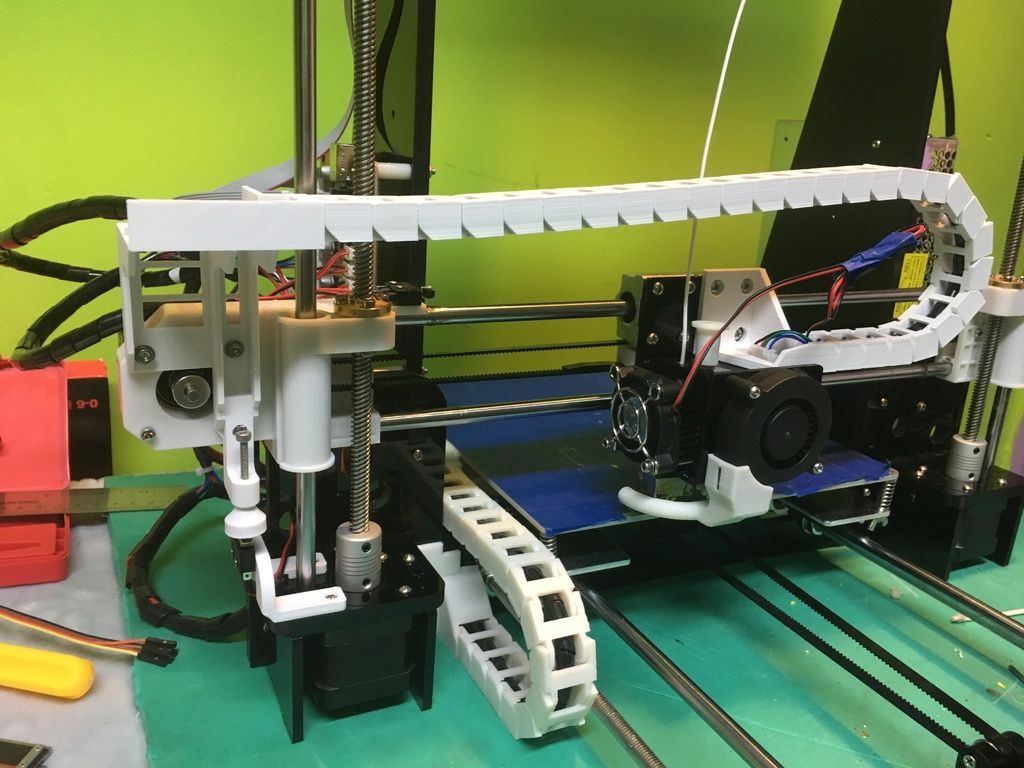

Most commercially available 3D printers mount filament spools so that the filament will not rub against anything. But some build-yourself 3D printer kits might not. If you build your 3D printer, make sure to run the filament to not rub against anything.

But some build-yourself 3D printer kits might not. If you build your 3D printer, make sure to run the filament to not rub against anything.

Snapped Filament

Even if the filament doesn’t grind against anything, it can still snap. Sometimes this will be due to mechanical stress, but usually, it is because of weakness or poor quality.

The key to preserving the strength of 3D printing filament is proper storage. Most filaments are made of mildly hydrophilic (water absorbing) polymers that will gradually absorb ambient moisture from the air. Moist is weaker than properly stored dry filament and is more prone to stringing.

You should store filament in an airtight container with a desiccant (drying) agent inside for the best printing results. A common desiccant is the silica gel packs included in most sealed consumer goods. Such packs are available on Amazon for pennies per gram.

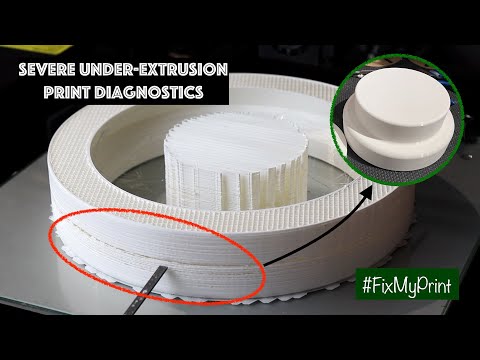

Nozzle Clog

Another reason a 3D printer may stop mid-job is a clogged nozzle. The nozzle is the (usually) metal part of the extruder that places molten plastic.

The nozzle is the (usually) metal part of the extruder that places molten plastic.

A partially clogged nozzle will have an inconsistent flow of molten filament. A clogged nozzle will have no flow of molten filament.

There are five common causes for a clogged nozzle:

- Low hot end temperature setting

- Nozzle sitting too close to the built plate

- Dust or other debris caught in the hot end

- Improperly stored filament swollen with absorbed moisture

- Poor quality filament with an inconsistent diameter

The most common cause of nozzle clogging is debris caught in the hot end. That can be avoided with proper maintenance and cleaning. A low-temperature setting can be avoided by following the manufacturer’s guidelines.

The proper nozzle starting height for your printer will be in its manufacture manual or other literature.

How To Fix a Nozzle Clog

A partially clogged nozzle can be fixed with either the “cold pull method” or cleaning filament. The “cold pull method” is where you feed filament through the extruder at room temperature. It is a “brute force” method of cleaning your printer’s nozzle.

The “cold pull method” is where you feed filament through the extruder at room temperature. It is a “brute force” method of cleaning your printer’s nozzle.

Cleaning filament is a special type made of proprietary uncolored plastic that works to dislodge material stuck in the nozzle. Cleaning filament typically costs around $20 for a few meters of filament.

Totally clogged nozzles typically are not worth repairing. Most nozzles are made of either brass or steel and cost less than $1 to replace.

Power Failure

The local power grid could fail at any time. It is a good idea to run your printer off of a combination surge protector and a backup battery. A good backup should provide enough power to either finish a small print or give you time to pause the job properly.

What if There Is a Power Failure During a 3D Print?

Most 3D printers automatically record their progress print jobs as they go. Once power is restored, the job can be resumed as if it was paused. But if for some reason, your 3D printer fails to do so, you can resume the print job with some additional steps.

But if for some reason, your 3D printer fails to do so, you can resume the print job with some additional steps.

Warning: this procedure requires doing some math!

- Fix the incomplete object in place with tape.

- Measure the height of the incomplete print as precisely as possible.

- Divide the measured height by the layer thickness.

- Edit the part file in your slicer program.

- Restart the print job.

- Post-processing.

Fix the Incomplete Object in Place With Tape.

The incomplete object may delaminate from the print bed. If your 3D printer loses power during a job, you should secure it in place with some tape. We recommend either scotch or painter’s tape, as they are inexpensive and do not leave residue behind.

Be careful not to burn yourself.

Measure the Height of the Incomplete Print

The key to “resuming” your print job is to start a new partial job on top of the incomplete object. Measure the height of the incomplete object from the print bed as precisely as possible. It is best to use a decimal ruler or a pair of calipers.

It is best to use a decimal ruler or a pair of calipers.

Use the same measurement system as your slicer program. If your slicer uses metric, measure the incomplete print in metric.

Divide the Measured Height by the Layer Thickness

Using the black art of math, you have to determine the printer’s layer when the power failed.

In your slicer program, look for layer thickness. Divide the height of the incomplete print by the layer thickness. The result will be the last layer printed.

Use this formula:

HeightLayer Thickness= Last Layer

The result should be a whole number.

If the printer stopped partway through the last layer, you could remove the partial layer with medium-grit sandpaper.

Edit the Part File in Your Slicer Program

Now return to your slicer program. Edit the settings to begin at the layer after the last one printed. If your print stopped at layer 233, tell the slicer to start at layer 234.

Make sure the slicer is set up to print in the same place as the incomplete print and the unfinished object is still correctly aligned. Then generate your g-code and hope for the best.

Then generate your g-code and hope for the best.

“Restart” the Print Job

Enter the g-code for the “resumed” job into your printer, start the printer and cross your fingers.

Post Processing

If everything works out, your printer should print the remainder of your object on top of the incomplete object with no issue. There may be some aesthetic imperfections, stringing, or smudges, which can be removed with basic post-processing.

Pause while printing

It took me recently to pause while printing. SuperSlicer has an option to insert a pause. So for some reason it stopped working for me. That is, once about half a year ago, it definitely worked. I even found the files from which I printed with this pause. Looks the same but doesn't work. I haven’t changed the Marlin version for a long time, I changed the firmware, but I didn’t touch anything potentially related to the pause. So, let’s look - and SS inserts the M601 command as a pause. There is no such command in the documentation. Somewhere I got infa that this is an internal function, an improved version of M0. But it is not clear why, and it is not clear why it is not documented. But the main thing is that now this team slips, as if it does not exist. nine0003

Somewhere I got infa that this is an internal function, an improved version of M0. But it is not clear why, and it is not clear why it is not documented. But the main thing is that now this team slips, as if it does not exist. nine0003

Then got into the dock by G-code. First I found the commands M125 - pause with head parking and M600 - pause to change the filament. The first one just parks the head and returns when you press the button, and the M600 also has parameters for stretching - retracting the filament. Both commands can park their heads if the PARK_HEAD_ON_PAUSE parameter is enabled in the firmware. But only I tried them, it turned out the following

- M125 without parameters - does not work. It parks the head in accordance with the settings in the firmware, immediately returns it back in XY and the printer freezes, only turning off the power works. nine0008

- M125 with parameters works correctly. If the parking position in the firmware is set correctly, then the minimum parameter P1 (M125 P1) must be specified.

- M600 has a bunch of parameters in the firmware and if you didn't set them consciously or don't even know their meaning, then it's not recommended to use them without parameters. At a minimum, it should be tested before actual use. The M600 parameters are described in the documentation, if they are filled in, the command will work correctly.

Both M125 and M600 teams have the same flaw in my opinion. At the end of the pause, the rod is first tightened, then heating is expected. Then they ask if the filament needs to be loaded again, and only after choosing “Continue”, they return the head to the print point and continue printing. The main trouble is that in this version, the plastic has already got into the nozzle, and while you are doing all this and the head is moving across the entire table, snot flows. nine0003

After that, I looked at how the pause is implemented in Cura. There, in the Pause AtHeight plugin, the M0 command is used for this - just a pause without various additional actions and its own settings for these actions - parking zone, retract length, nozzle temperature at pause. Everything is cool, the only thing But is that the plugin uses internal variables and inserts specific values into G-code. Highlighted them in bold in the example.

Everything is cool, the only thing But is that the plugin uses internal variables and inserts specific values into G-code. Highlighted them in bold in the example.

M83; switch to relative E values for any needed retraction

G1 F1500 E-5

G1 F300 Z3 ; move up a millimeter to get out of the way

G1 F9000 X190 Y190

G1 F300 Z15 ; Here it is known at what height the pause is, therefore it raises to the minimum allowed height

M104 S0; standby temperature

M117 It's a Pause

M0 ; Do the actual pause

M109 S250 ; here he knows the print temperature and returns 9 to it0019G1 F1500 E5G1 F199.998 E5G1 F1500 E-5G1 F300 Z3G1 F9000 X125.7 Y99.4 ; Returns to a known XY positionG1 F300 Z2 ; Returns to desired heightG1 F1500 E5G1 F1500 ; restore extrusion feedrateM82 ; switch back to absolute E values G92 E123.08903 ; Returns the position of the extruder, in absolute coordinates

It will not be possible to repeat this without a special API with access to current values, but I tried to do something similar. I found in G-code the ability to save and restore the current position of the head using the G60 / G61 commands. Which, in turn, require that the SAVED_POSITIONS parameter be enabled in the firmware. It is usually disabled to save memory. As a result, we got the following pause script:

G1 F2400 E-10 ; 10mm retract [retract_speed] – removal of plastic from the melting zone so that there is no snot, relative extrusion positioning is enabled in the slicer settings, and in pause you don’t need to bother with absolute values M300 P50 S440; Double signalG4 P200M300 P50 S440G91; Enable relative positioningG0 Z10 F240; Raise by 10MM relative to the current point (here you must be care top of print area)G90 ; return absolute positioningG60 ; Save current positionG0 F9000 X10 Y10 ;Travel to selected parking area XY [travel_speed]M0 Change filament and press button ; Actually pause with message textG61 F9000 XY; restoring XY positionG91 ;use relative coordinatesG0 Z-10 F240 ;Returning in Z, move amount should be set the same as for liftingG90 ;use absolute coordinates; we must additionally enable relative positioning for the extruder, although we did not turn it off.Apparently G91/G90 switch positioning for the extruder

G1 F2400 E10 ; return the plastic to the print area, to the same 10mm [retract_speed]Temperature control and other parameters can be added to taste. There are parameters in square brackets from the settings that could be used in SS, but it turned out that these constants are not available in this place. :(

Color printing on a 3D printer with one extruder

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.00 UAH

-

Thermal mat for 3D printing 200 x 200 mm nine0110

Thermal mat for 3D printing

UAH 150.

00

00 -

Buy epo3d+ 3D printer

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00 nine0003

-

ABS granules

ABS granules for extrusion

400.00 UAH

-

PLA nine0110

PLA environmental plastic from Plexiwire. 100% advance payment....

UAH 375.00

-

Buy ABS plastic (ABS)

ABS plastic from Plexiwire.

100% prepayment. Free shipping...

100% prepayment. Free shipping... UAH 220.00 nine0003

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size is...

UAH 150.00

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends nine0110

Nozzle for 3D printer 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

-

PETG plastic for 3D printer

PETG plastic from Plexiwire. 100% prepayment. Free...

UAH 360.00 nine0003

-

SHF-20 shaft support

SHF-20 shaft support is used for CNC

60.

00 UAH

00 UAH -

A4988 stepper motor driver

35.00 UAH

-

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00 nine0003

All best sellers

Categories

Information

Single extruder 3D printer in color

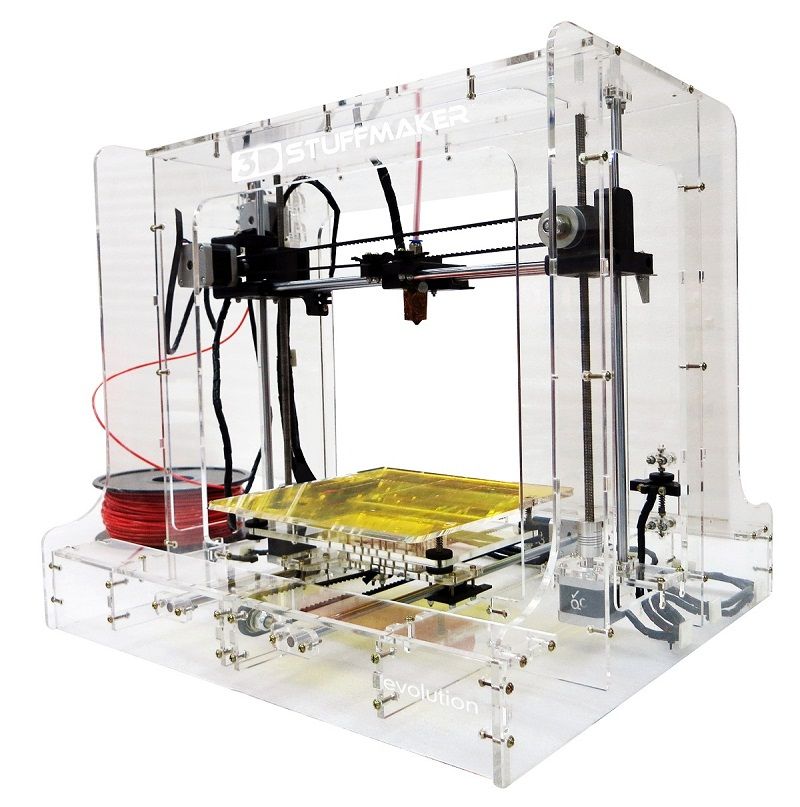

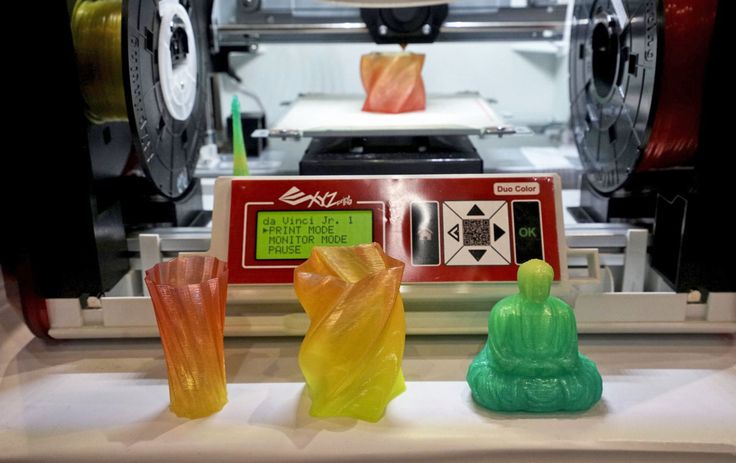

Until recently, 3D printers with multi-color printing were high-end printers, the cost of which was beyond the reach of the average consumer. Now there are various options for creating colorful 3D models.

Let's take a look at direct color 3D printing, where the color comes from multicolored filaments used in a single nozzle FDM printer. nine0217 This article will discuss color printing with a single extruder by assigning multiple tasks to the software. The resulting G-code will give tasks to the printer, start with a single colored thread, and then pause at a certain layer height. At this point, the new filament is replaced and the print job is resumed. This method allows anyone with a standard single extruder printer to create a multicolor object.

nine0217 This article will discuss color printing with a single extruder by assigning multiple tasks to the software. The resulting G-code will give tasks to the printer, start with a single colored thread, and then pause at a certain layer height. At this point, the new filament is replaced and the print job is resumed. This method allows anyone with a standard single extruder printer to create a multicolor object.

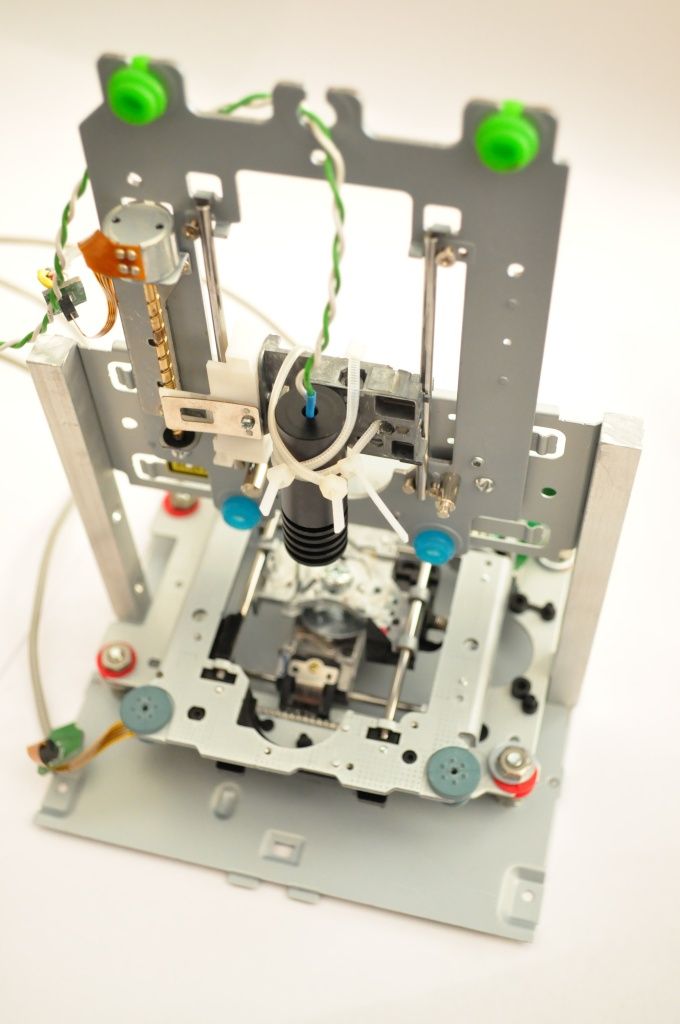

If changing filament while printing seems tedious, you can install an external device Mosiac Manufacturing, Prusa MMU 2.0 or a device with a large print head standing on the Micro, Crane Quad. nine0003

But if you do not have such multi-color devices, but you need to complete the task, you will have to resort to manual color replacement.

3D printing with layering a certain color at a certain height can be used in the production of: logos, board games, patches, badges, key chains, etc.

How to set print pauses in Gcode to replace thread in Simplify3D and CURA

This short guide will help the user without knowing Gcode to easily insert pauses into the code using standard slicers. nine0003

nine0003

Simplify3D

this piece of code will be the one that does all the magic:

G91; Set to relative position

G1 Z20 F5000; Raise the nozzle (lower the table) 20mm along the Z-axis at a speed of 5000mm/min.

G90; Return to absolute position

M0; Pause and wait for user input to continue printing

At this point, change the thread with a different color.

In Simplify3D, we will use the Process > Scripts > Post-Processing setting to inject the above Gcode (no comments) something like this:

{ REPLACE "; layer 3, Z=" " nG91 nG1 Z20 F5000 nG90 nM0 n ; layer 3, Z ="}

Of course, you will need to choose a layer number for the pause (more on that in a moment). Also note that the " n " parts of the code just create a newline in GCode.

Switching to the slicer preview of your model will make this part easier. In Simplify3D, it's a matter of dragging the slider at the bottom of the preview screen (or entering the layer number).

In Simplify3D, it's a matter of dragging the slider at the bottom of the preview screen (or entering the layer number).

CURA

These settings give you complete control over how you pause printing:

• Pause Height / Layer: The height or number of the layer at which you want to pause printing.

• X and Y Parking Printhead: Moves the nozzle to the specified coordinates when printing is paused. nine0217 • Head movement Z : raises the nozzle (lowers the table) during the pause, bringing it to the specified value.

• Retraction: parameters for retraction during the pause period.

• Extrusion amount and speed : amount of material to be extruded when reloading new filament.

• Repeat Layers: You can repeat all previously completed layers to increase adhesion.

• Standby temperature: Nozzle temperature in pause mode.

Slic3r

Locate the Custom G-code section on the Printer Settings tab.

Scroll down to the heading After layer change G-code and paste the following code:

; LAYER: [layer_num], Z HEIGHT: [layer_z]

{if layer_num == 45}M600 ; Color change {endif}

If you want to do more filament changes, just duplicate the last line like this:

{if layer_num == 45}M600 ; Color change 1 {endif}

{if layer_num == 65}M600 ; Color change 2 {endif}

{if layer_num == 85}M600 ; Color change 3 {endif}

Gcode Edits

If you're a bit versed in G-code and you're interested, then this method is for you.

Select the desired saved file with *.gcode extension. Open with a simple text editor - for example Notepad (Notepad) and start editing.

To do this, we determine on which layers it is planned to replace the color or material. Press Ctrl-F (search by text) and enter in the search window “layer 10” where for example the number 10 is the layer where the replacement takes place and click “Find”. After the line “layer 10”, paste the previously copied text with the code. nine0217

After the line “layer 10”, paste the previously copied text with the code. nine0217

G91; Set to relative mode

G1 Z10; Lower table (raise print head) 10 mm

G90; Return to absolute mode

G1 X0 Y0; Zero (Home) X & Y

M0 Click to reset; Pause and wait

G91; Set to relative mode

G1 Z-10; Go back 10 mm

G90; Return to absolute mode

After executing these commands, the 3D printer returns to the last location it was in when the print was saved.

M600 command

This method, like the previous one, allows you to manually insert the M600 command into the G-code.

The advantage over the above is that you insert only one line with the M600 command into the code, and the printer itself rolls back the head to a safe place, ejects the filament and then loads it, and continues printing from the interrupted place.