Monoprice mini 3d printer manual

MONOPRICE SELECT MINI PRO USER MANUAL Pdf Download

Table Of Contents

2-

page of 24

- Contents

- Table of Contents

- Bookmarks

Advertisement

Table of Contents

Table of Contents

Safety Warnings and Guidelines

Introduction

Features

Customer Service

Package Contents

Product Overview

Auto Leveling

Live Leveling

Wi-Fi Setup

Software Installation and Setup

Installing Cura

Repetier-Host

Technical Support

Specifications

Regulatory Compliance

Notice for FCC

EU Declaration of Conformity

WEEE Information

Safety Notice

Select Mini Pro 3D Printer

P/N 33012, 33286, 33287

User's Manual

Table of Contents

Previous Page

Next Page

Table of Contents

Related Manuals for Monoprice Select Mini Pro

- 3D Printers Monoprice Maker Select Plus IIIP User Manual

(38 pages)

- 3D Printers Monoprice MP Cadet User Manual

(39 pages)

- 3D Printers Monoprice extrusion i3 13860 User Manual

(50 pages)

- 3D Printers Monoprice Mini Delta V2 User Manual

(58 pages)

- 3D Printers Monoprice Maker Ultimate 2 User Manual

(43 pages)

- 3D Printers Monoprice 30526 User Manual

Mp education invertor 3d printer (67 pages)

- 3D Printers Monoprice 33820 User Manual

Mp voxel 3d printer (42 pages)

- 3D Printers Monoprice MP Maker Pro Mk.

1 User Manual

(26 pages)

- 3D Printers Monoprice MP10 User Manual

(24 pages)

- 3D Printers Monoprice MP Education Guider II User Manual

(57 pages)

- 3D Printers Monoprice 15710 User Manual

Maker select pro ultimate 3d printer (28 pages)

- 3D Printers Monoprice 35435 User Manual

Mp mini sla lcd high resolution resin 3d printer (28 pages)

- 3D Printers Monoprice Delta Pro User Manual

(16 pages)

Summary of Contents for Monoprice Select Mini Pro

MONOPRICE MINI DELTA V2 USER MANUAL Pdf Download

Table Of Contents

2-

page of 58

- Contents

- Table of Contents

- Bookmarks

Advertisement

Table of Contents

Table of Contents

Safety Warnings and Guidelines

Introduction

Features

Customer Service

Package Contents

Product Overview

Getting Started

Completed Print Removal

Poloprint Pro Wi-Fi Setup

Menu Map

Menu Operation

Main Menu

Print Menu

Printer Maintenance Menu

Filament Operation Screen

Set Target Temperature Screen

Jog Mode Screen

Delta Auto Calibration Screen

Z Offset Setting Screen

Motor off Screen

Printer Setting Menu

Machine Information

Language Setting

WIFI Screen

Post Setting Screen

Powerloss Setting Screen

Diagnosis Screen

Firmware Parameters Screen

Update Screen

Contact Us Screen

Wiibuilder Slicing Software

Installation

Advanced Configuration

Speed Tab

Infill Tab

Support Tab

Build Plate Adhesion Tab

Retraction Tab

Material Tab

Travel Tab

Machine Tab

Line Width Tab

Warping Protection Tab

Seam Tab

Others Tab

Cura Slicing Software

Installation

Care and Maintenance

Cleaning the Nozzle

Clearing a Blocked Nozzle

Replacing the Nozzle

Cleaning the Feed Gear

Technical Support

Specifications

Regulatory Compliance

Notice for FCC

RF Exposure Statement for FCC

Notice for Industry Canada

RF Exposure Statement for Industry Canada

MP Mini Delta V2 3D Printer

P/N 21666

User's Manual

Table of Contents

Previous Page

Next Page

Table of Contents

Related Manuals for Monoprice Mini Delta V2

- 3D Printers Monoprice Mini Delta V2 Quick Start Manual

(4 pages)

- 3D Printers Monoprice MP Mini Delta V2 Quick Start Manual

(3 pages)

- 3D Printers Monoprice MP Mibi Delta User Manual

(22 pages)

- 3D Printers Monoprice MP Cadet User Manual

(39 pages)

- 3D Printers Monoprice extrusion i3 13860 User Manual

(50 pages)

- 3D Printers Monoprice Maker Ultimate 2 User Manual

(43 pages)

- 3D Printers Monoprice Maker Select Plus IIIP User Manual

(38 pages)

- 3D Printers Monoprice 30526 User Manual

Mp education invertor 3d printer (67 pages)

- 3D Printers Monoprice 33820 User Manual

Mp voxel 3d printer (42 pages)

- 3D Printers Monoprice MP Maker Pro Mk.

1 User Manual

1 User Manual (26 pages)

- 3D Printers Monoprice MP10 User Manual

(24 pages)

- 3D Printers Monoprice MP Education Guider II User Manual

(57 pages)

- 3D Printers Monoprice 15710 User Manual

Maker select pro ultimate 3d printer (28 pages)

- 3D Printers Monoprice Select Mini Pro User Manual

(24 pages)

- 3D Printers Monoprice 35435 User Manual

Mp mini sla lcd high resolution resin 3d printer (28 pages)

- 3D Printers Monoprice Delta Pro User Manual

(16 pages)

Summary of Contents for Monoprice Mini Delta V2

This manual is also suitable for:

21666

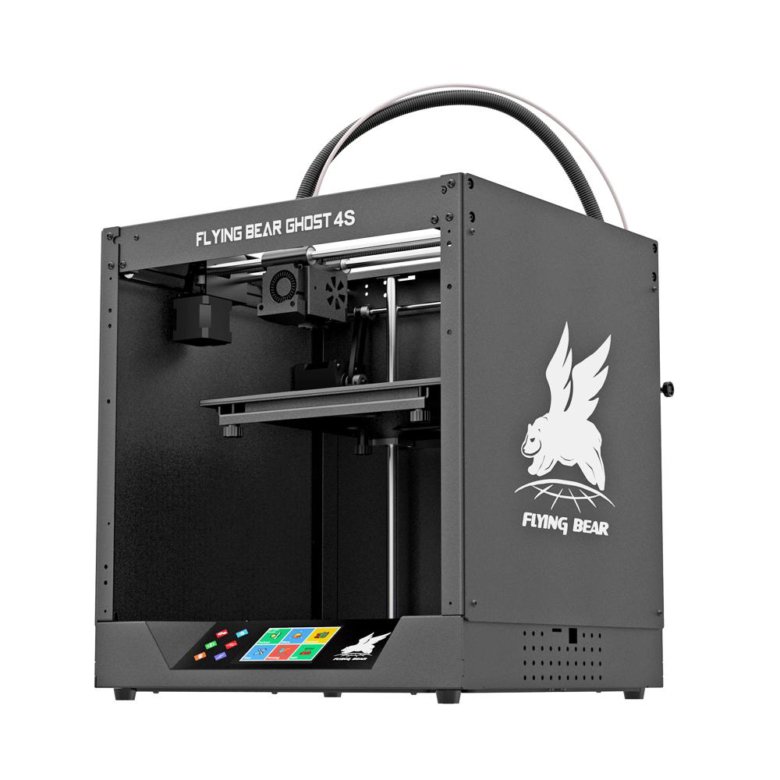

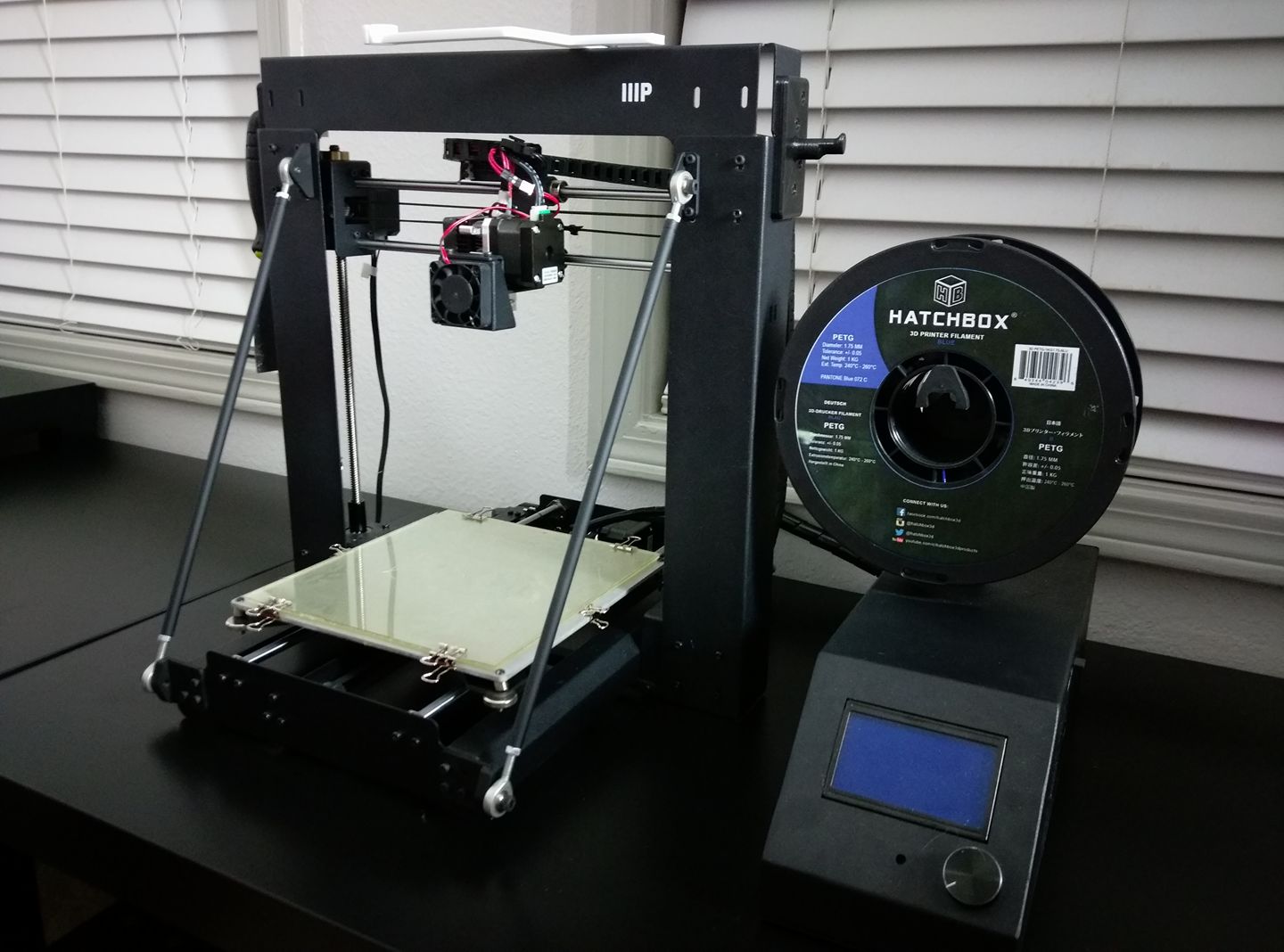

Overview of the budget 3D printer Monoprice Select Mini

3DPrintStory Reviews Overview of the budget 3D printer Monoprice Select Mini

Prices for desktop 3D printers continue to fall. There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini. nine0005

There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini. nine0005

It is worth noting that this inexpensive model breaks established traditions and did not start with Kickstarter, unlike others like M3D Micro, Tiko, OLO / ONO and Trinus, which attracted the attention of consumers and investors thanks to crowdfunding platforms (by the way, this is really an effective development strategy for small startups, but there is often a mismatch between expectations and the final product).

Monoprice is different. This is an American company that did not particularly bother with the development and production of its own 3D printer, but simply imported the Malyan M200 from China, hung its logo on it and put an attractive price of $199. What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

A reasonable question arises: can such a cheap 3D printer compete with Ultimakers or Printrbots? And is it even worth comparing? We will try to answer these and other questions in the review below.

Features Monoprice Select Mini

- Available;

- Robust design;

- Easy to use;

- Predictable 3D printing at low speed; nine0018

- Works with any slicing software and standard 3D printing materials;

- Amenable to improvements and upgrades;

- I think we already mentioned the price?

Disadvantages Monoprice Select Mini

- Difficult to calibrate;

- Prints poorly at high speeds;

- Print table not protected;

- Faulty power supply;

- WiFi module not active;

- Unstable nozzle temperature;

- Strange quirks...

Short Verdict

The Monoprice Select Mini is a great 3D printer for the price. There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

Naturally, there are disadvantages. During operation, the temperature of the nozzle may change, and at high speeds, 3D printing errors occur. The calibration process takes a lot of time and the first time you have to tinker. Well, the most interesting thing is that the power supply burned out after 12 hours. But the latter, incorrect, can be attributed to an accidental marriage. nine0005

Despite all the shortcomings, the Monoprice Select Mini is a wonderful little 3D printer with many great features. In general, it performs in accordance with the information in the technical specifications, and the quality of the 3D printing even exceeded our expectations.

If you are not afraid to take it apart / put it back together, then you can do a few upgrades. The first thing to do is to replace the hotend and update the firmware to activate the WiFi module ( be careful! These upgrades have not been tested as part of this review and may damage your 3D printer! ). You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

Would you recommend the Monoprice Select Mini as your first 3D printer? Yes, definitely.

Specifications and features Monoprice Select Mini

Monoprice Select Mini workspace 120 x 120 x 120 mm. The maximum resolution of 3D printing is 100 microns. Heated table. The 3D printing speed is 55 mm/s. nine0005

You can upload your 3D model via micro SD card or USB. The manual states that compatible slicing programs are Cura, Repetier-Host, ReplicatorG, and Simplify3D. This means that the Monoprice Select Mini recognizes the standard G-code, and this 3D printer is not tied to any particular software. Cura was used during testing for this review.

Monoprice Select Mini doesn't limit your media usage. You can print with any standard 1.75 filament using PLA or ABS thermoplastics. In our case, PLA plastic from ColorFabb was used. nine0005

These two points - the freedom to choose software and filament - are very important in this price range, because manufacturers such as M3D Micro and XYZprinting, which are Monoprice's main competitors in this niche, tend to use proprietary software and their own materials for 3D printing .

Unpacking and installation of the Monoprice Select Mini

Installation of the Monoprice Select Mini is quite simple. You can start typing within 20 minutes.

Inside the box you will find a 3D printer, a power supply, an imbus wrench for calibrating the table, a plastic spatula to scrape off the rest of the material from the table after printing, a 256 MB micro SD card and a micro USB cable.

One piece of paper contains a basic instruction and a link to a website where you can download the full version.

You will also find a rectangular steel sheet, the purpose of which is not clear at first. It turns out that this is a coil holder that is attached to the side of the main unit. nine0005

It is important to note that the Monoprice Select Mini kit does not include media test samples. So stock up on filament with a diameter of 1.75 mm.

You can use the wheel to adjust. The menu is well structured and easy to understand. You can start the calibration process, preheat the extruder and feed the filament.

Calibration can be somewhat difficult. In theory, it should be carried out even before shipment, in production, and you should have a piece of paper between the nozzle and the printing table. If it doesn’t work, then hex keys will come in handy here. It will be necessary to try and tighten the screws at the corners of the table so that the sheet still passes. nine0005

At this stage, the first important shortcoming of this model becomes clear. The printing table is made of aluminum and does not have a special protective film or coating on it. So stock up on blue 3D printing tape or install glass right away. Otherwise, the table will wear out very quickly and you will have to change it.

Well, one more bug that got out in our particular case. The power supply burned out after 12 hours of use. Foaming it was not difficult, but it was very unpleasant. You can probably throw it off for marriage, but in any case, be prepared for a similar turn of events. nine0005

Design and build quality of the Monoprice Select Mini

Very pleased with the build quality of the Monoprice Select Mini. The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

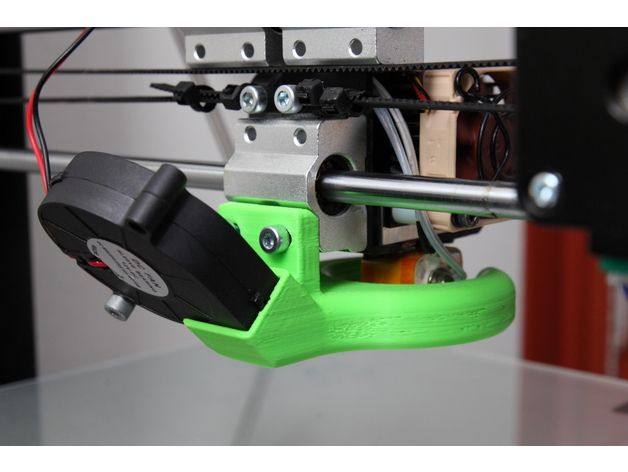

This 3D printer uses deposition modeling technology. The classical Cartesian coordinate system is used. The design is similar to Printrbot Simple. One cooler is used to cool the nozzle. It is likely that problems may arise during 3D printing with unusual materials. nine0005

The extruder has a diameter of 0.4 mm and can be heated up to 230°C. We haven't been able to test how easy it is to change, but in the long run this is an important factor as the nozzle will still need to be changed over time.

Monoprice Select Mini Print Quality

Pre-loaded models will already be on the micro SD card. They are supposed to be optimized for 3D printing on the Monoprice Select Mini. So before uploading our own models, we printed test ones. nine0005

The cat was printed first. The resolution was 200 microns. Everything went well until the last layers. The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

G-code analysis in Simlify3D showed that the table accelerated up to 55 mm/s during the printing of the last layers. That is why the error was repeated. Quite a strange decision of the company - to provide a test model, which a priori will be printed with errors...

The second model that we printed is a test elephant. The resolution was also 200 microns and 10% infill. There were no problems! The result is excellent and you can see it in the photo below. nine0005

Next we moved on to our own models. We used Cura for slicing. This article reveals the excellent Cura settings for 3D printing on the Monoprice Select Mini and we used them.

We printed a classic 3DBenchy and Graphica model: a MEGA Ghost with 200 micron resolution and 10% infill, a V29 whistle with 200 micron resolution and 100% infill, and another 3DBenchy model with 100 micron resolution and 10% infill. nine0005

nine0005

The simple 200 micron models worked well. There are no special problems with small protrusions and holes, although there are sagging. The layers are laid evenly along the X and Y axes.

The V29 whistle sounds as loud as intended, which means the partitions were printed correctly. The Graphica Mega Ghost with its long tongue also printed correctly. The hinge glided smoothly. The

3DBenchy at 100 microns worked well too. When you look at the photo, don't forget that this is a $19 3D printer.9.

We have noticed that most errors in 3D printing occur when the spool of filament clings or there is not enough adhesive coating on the printing table. This cannot be attributed to the shortcomings of the Monoprice Select Mini itself, since this is a global problem for all FFF printers.

During operation, the print table may block access to the control wheel. This point is implemented in the design is not very ergonomic.

Another disadvantage is that the nozzle temperature has an error in the region of 5°C. For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel. nine0005

For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel. nine0005

This does not particularly affect printing with PLA plastics, but may have a negative effect during 3D printing with materials that are more sensitive to temperature changes.

Finally, we printed a Low Poly Moai bust. We scaled the model by 50% and printed with 100 micron settings and 30% infill. It turned out well on the whole, the only small marriage is the influx of material on the chin. By the way, we observed the same effect when printing 3DBenchy with resolution settings of 100 microns. nine0005

Life hacks and upgrades Monoprice Select Mini

A few words about upgrading the Monoprice Select Mini 3D printer. There are no official upgrades! But here are a few options that you can try to implement on your own.

In our opinion, it is necessary to deal with the temperature of the extruder, make it more stable. For example, you can implement a PID temperature controller.

You can activate the WiFi connection by downloading the original Malyan M200 firmware. nine0059 But be careful! This option has not been tested and there is a possibility that you may damage your 3D printer!

Monoprice Select Mini Summary

After testing the Monoprice Select Mini, this is one of the best 3D printers you can buy for $200.

But it's important to realize that the print quality can't be compared to the Original Prusa i3 MK2 or LulzBot Mini. Not to mention the more expensive models.

If you're looking for a small business 3D printer or just high-quality 3D without bugs, then the Monoprice Select Mini is not for you. In addition to the print quality, you will obviously not be satisfied with periodic bugs and a small workspace. nine0005

But if you are just starting to explore the world of 3D printing, then this is a great choice and a good alternative to the Chinese Anet A8 3D printer.

The Monoprice Select Mini has some drawbacks, but it's still a great option for learning and just having fun. It's easy to use and print quality rivals more expensive models.

It's easy to use and print quality rivals more expensive models.

instruction how to work from scratch for beginners and dummies, how

looks likeThree-dimensional printing has become increasingly introduced into our daily lives. Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible. nine0005

What is a 3D printer and how does it work?

The 3D device consists of the printer itself and a computer that controls all processes. The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

- Extruder - the print head through which the thread passes.

The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface. nine0018

The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface. nine0018 - Work surface - a printing platform on which a 3D model is formed.

- Motors - mechanisms responsible for the accuracy of movement and speed of printing.

- Sensors are electronic devices that limit moving parts to specified coordinates.

- The frame is the structure that connects all parts of the printer.

How a 3D printer works: features

Work with the aim of building a three-dimensional model begins with a sketch, which is created in a special program. After that, the software independently generates a plan for the movement of the print head and a print sequence. The 3D model is reproduced by strongly heating the plastic and distributing it evenly. nine0005

3D printers are used in many areas. Let's list some of them:

- Architecture - creation of models of buildings.

- Medicine - dental prosthetics, making models of organs for study.

- Construction - production of houses using 3D printing technology.

- Education - a visual aid for learning 3D printing.

- Automotive - creation of tuning parts, prototype layouts and other products.

This is a small list of industries where 3D printing is actively used. Today, almost every entrepreneur and just an enthusiastic person can afford a printer. nine0005

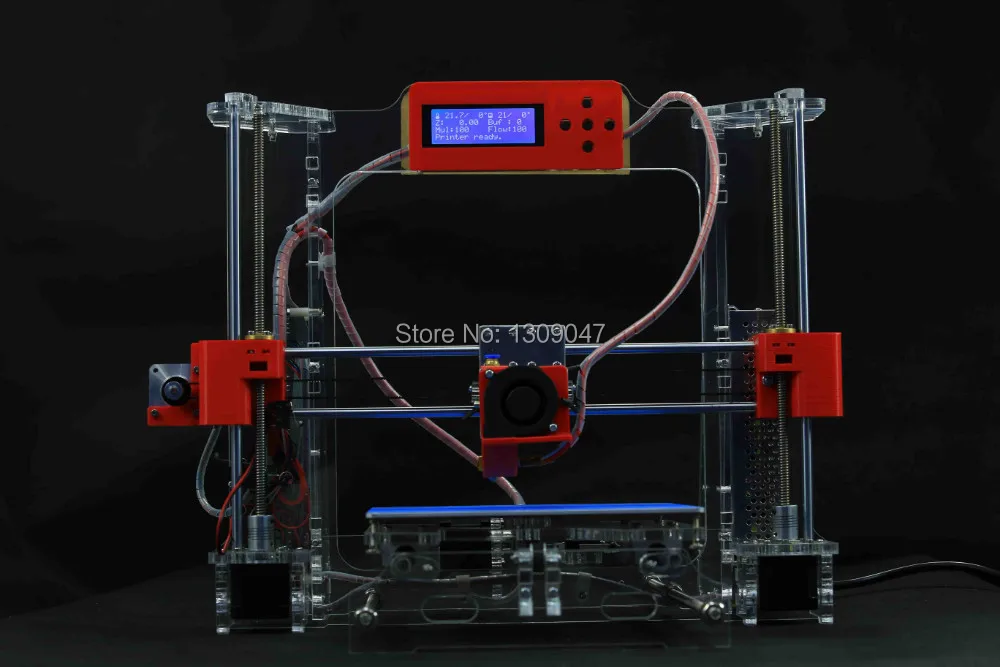

The following printers are distinguished by design features:

- RepRap - self-reproducing printers that can create their own copies.

- DIY-kit - the device comes disassembled with instructions, the assembly of which will take a sufficient amount of time.

- Completed - Models are delivered assembled and ready to use.

- Commercial and industrial - devices capable of printing metal, concrete, polymers and other materials. nine0018

How to use a 3D printer: tips for beginners, where to start

Mastering the technique of 3D printing is not difficult if you follow the recommendations and tips. Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Printer Installation

To begin, you will need to carefully unpack the box and remove any stops. The next step is to install the printer on the surface using the building level. This will allow you to place the device as evenly as possible, which will provide better printing. nine0005

Note. Some 3D printers come with a level for installation.

Next, you will need to connect the printer to your computer and install the necessary drivers. The software disc comes with the 3D device.

Preparing for work

To get started, you need to calibrate the working surface - without this, printing quality products is impossible. This process is carried out automatically or manually. The attached instructions have detailed information on how to perform manual calibration. nine0005

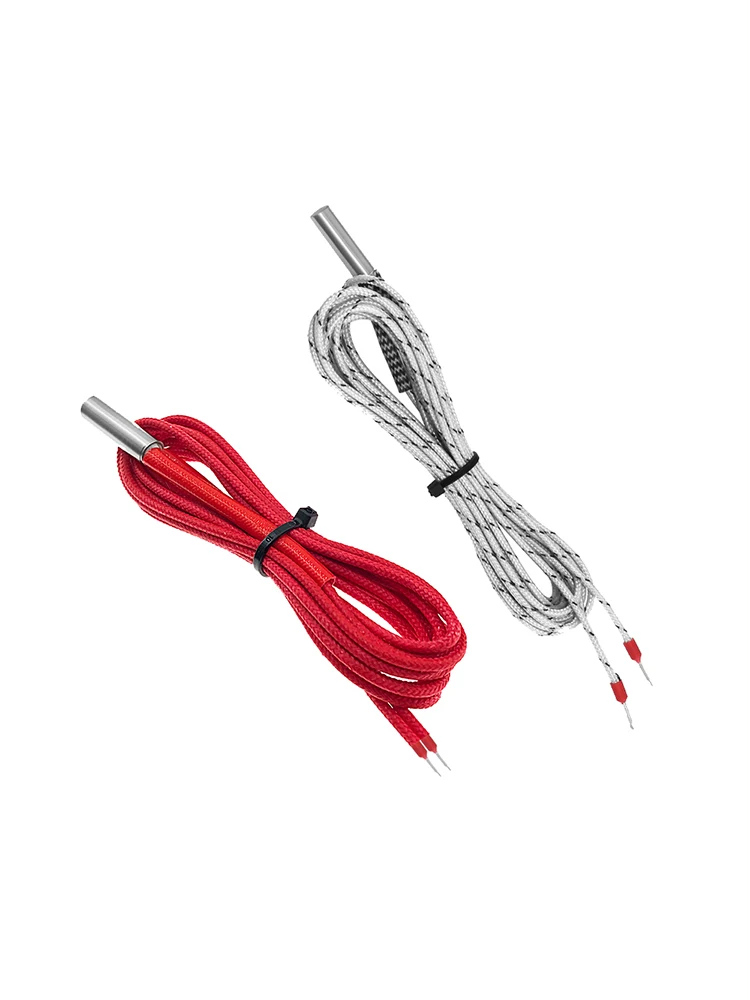

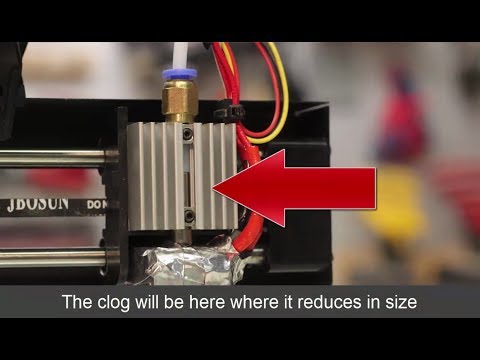

Extruder patency test

The next important step is setting up the extruder. First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refilling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism. nine0005

First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refilling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism. nine0005

Working with models

Models can be created using a variety of 3D modeling programs. The process of manufacturing three-dimensional parts is creative, requiring careful preparation. The better and more detailed the model is drawn, the better the 3D layout will be at the output.

Start printing

After creating the model in the program and preparing the printer for work, you need to send the file for printing and wait for the result. The print speed varies depending on the printer model and specifications, as well as the media used. nine0005

nine0005

Processing the finished product

3D printed products usually do not please the user with an ideal appearance: the parts have an uneven surface. But this is typical for models of 3D printers on FDM, SLA and DLP devices, which are distinguished by higher print quality. Owners of FDM printers should not despair - a simple processing of products will give products an attractive appearance and make the surface smooth.

Several powerful ways to post-process 3D printed parts:

- Mechanical - carried out by sanding the surface with sandpaper or a special sponge for grinding.

- Chemical - Surface treatment with aggressive solvents such as acetone and dichloroethane.

- Mixed - In this case, the above two processing methods are used.

What are the possible errors and how to avoid them?

3D printing technology can be mastered even by a beginner, but despite this, the production of the first products causes excitement for the user. Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

- Calibrate and test the 3D printer before starting work.

- Be sure to use the correct file extension for quality printing.

- Do not remove the finished product from the printer immediately after processing, as this may damage the part and cause defects.

- If you encounter errors during the 3D printing process, try restarting the device - this usually helps.

- If restarting the printer still does not help, try changing the settings or re-entering the model. nine0018

- When assembling the 3D printing devices, follow the enclosed instructions carefully.

- Use only the correct materials for your 3D printer.

- Subscribe to useful 3D printing channels and read articles.

Following the tips above will allow you to set up your 3D printer, get it ready to run and, most importantly, print your first 3D products.