Peachy 3d printer kickstarter

Peachy Printer Collapses After Embezzlement of $320K Kickstarter Funds to Build Co-Founder's New House - 3DPrint.com

When the Peachy Printer was launched on Kickstarter back in September 2013 it seemed almost too good to be true. Creator Rylan Grayston had designed and created a working prototype of a stereolithography 3D printer that would only cost $100. But unlike a lot of the many, many crowdfunded 3D printers that sounded fishy, the Peachy Printer actually worked, and had a remarkably clever design that was just as innovative as it was inexpensive. While Grayston and his business partner David Boe were initially only seeking about $50,000 to fund its continued development, the campaign eventually netted over $650,000, at the time making it one of the most successful 3D printer Kickstarter campaigns ever.

The Peachy Printer

Once the campaign ended, Grayston said that he would begin development on a production version of the Peachy Printer right away, and at first his updates came regularly and showed significant progress. But eventually the updates started to come at a trickle, and time marched on. While Grayston was still publicly very optimistic about the eventual release of the Peachy Printer, many of the backers started to be concerned for the future of the project. However Grayston seemed like a nice, personable guy, and he had deep roots in his local maker community, so no one ever really questioned him about the ongoing delays. Unfortunately, it turns out that behind the scenes the only thing that the Peachy Printer was able to make was a brand new house for co-owner Boe.

David Boe

In a shocking update on Kickstarter today, as well as recently released two videos, Grayston finally came clean about his partner’s embezzlement of more than $320,000 of the Kickstarter funds. The problem, as seems typical with almost all of the successfully funded campaigns that end up collapsing, was an astonishing lack of, well, common sense. Rather than setting up a business bank account, all of the Kickstarter funds — $587,435. 73 worth — were sent directly to Boe’s personal bank account. When the corporate business bank account had finally been opened Boe immediately transferred $200,000 over to it, leaving the remaining funds in his own accounts. Unfortunately, at the time Boe was in the process of building a new home, and decided to start dipping into Peachy Printer funds to help complete it.

73 worth — were sent directly to Boe’s personal bank account. When the corporate business bank account had finally been opened Boe immediately transferred $200,000 over to it, leaving the remaining funds in his own accounts. Unfortunately, at the time Boe was in the process of building a new home, and decided to start dipping into Peachy Printer funds to help complete it.

“I ran a campaign in Canada for The Peachy Printer – a 3D printer project that raised over half a million in just 30 days – but now I’m in a very tough position. My business partner and the Financial Manager of Peachy Printer, David Boe, has stolen a large portion of the crowd sourced money. Crowdfunding empowered me, and now crime has brought me to a halt. My backers are mad, and so am I. When I talk to the police about this, I have to explain what crowd funding is, and how I think this problem should be approached. This is very understandable because crowdfunding is so new to Canada,” Grayston wrote in an open letter on the Peachy Printer website.

The flow of Peachy Printer Kickstarter funds.

Within a month of the Kickstarter funds being transferred to him, Boe had spent more than $165,000 on his new home; within three months almost all of it was gone. According to statements made by Boe, the intention was always to pay the money back as soon as he started receiving mortgage funds from his bank. Throughout 2014, Grayston claims that he repeatedly asked Boe to transfer the remainder of the Kickstarter funds into the corporate account only to have Boe respond with excuses for being unable to do so. But as the business funds started to dry up, Grayston said that he became more insistent, and when Boe was only able to transfer $30,000, he said that he finally knew that something was wrong. It would take another month before Grayston was able to get Boe to admit what he had done.

The distribution of the Peachy Printer Kickstarter funds.

Grayston immediately removed Boe from all company accounts, accepted his resignation and after discussing the issue with lawyers redistributed Boe’s shares back into the company. In an effort to complete the project, the pair made a deal to continue with Boe’s plan of paying back the money when his mortgage funding was released. Grayston said that he agreed to not tell backers provided the repayments were made. In the meantime, he pursued additional funding, including a $50,000 personal loan from a family member and some grant money from the Canadian government. Over the next few months Boe paid back about $100,000 of what he owed Peachy Printer; however his last repayment was on March 2, 2015.

In an effort to complete the project, the pair made a deal to continue with Boe’s plan of paying back the money when his mortgage funding was released. Grayston said that he agreed to not tell backers provided the repayments were made. In the meantime, he pursued additional funding, including a $50,000 personal loan from a family member and some grant money from the Canadian government. Over the next few months Boe paid back about $100,000 of what he owed Peachy Printer; however his last repayment was on March 2, 2015.

At this point relations between the two former friends and business partners became strained, and Peachy Printer has gone completely broke. The last ditch plan for the company was to start selling retail units of the Peachy Printer before backers were able to get theirs, a wholly unpopular action that was certain to upset the campaign’s backers. According to Grayston, the plan was to sell retail units and begin sending out backer units as the money from the retail units started to come in. Sadly, the process of certifying the laser in the Peachy Printer cost more, and was taking longer, than anticipated, which resulted in the company going completely into the red. With no options available to him, Grayston finally came clean in a pair of, frankly, rather bizarre videos.

Sadly, the process of certifying the laser in the Peachy Printer cost more, and was taking longer, than anticipated, which resulted in the company going completely into the red. With no options available to him, Grayston finally came clean in a pair of, frankly, rather bizarre videos.

Peachy Printer account balance timeline.

The first video consists of Grayston explaining the chain of events, and showing a taped video of Boe admitting to the embezzling that he made as part of his agreement to repay the Kickstarter funds and avoid involving the police. The video is kind of uncomfortable to watch, especially watching Boe squirm on camera, but it begins to turn surreal as Grayston includes some elaborately animated charts and the melodramatic musical score (yes, it has background music) starts to kick in. It is a really strange video:

The second video shows Grayston inviting three of his local Kickstarter backers to the Peachy House, where the printer was being developed, to give them the bad news. The backers were presumably not told before the cameras began rolling, which seems like more of a reality show than real life. I don’t even know how to describe how awkward the eleven-minute video is, it just needs to be seen for yourself:

The backers were presumably not told before the cameras began rolling, which seems like more of a reality show than real life. I don’t even know how to describe how awkward the eleven-minute video is, it just needs to be seen for yourself:

So here we are, yet another 3D printing Kickstarter collapses due to human failure and absurdly poor planning. How Kickstarter doesn’t have a prerequisite of potential crowdfunders at the very minimum having an independent business bank account before any funding is disbursed is beyond me. But what makes this truly tragic is the fact that by all accounts the Peachy Printer actually works and would have done what it said it would do. Not only had the technology been dramatically improved since the initial prototype was created by Grayston, which would have made his backers happy, but it also looks like it could have been an incredibly successful retail product.

Rylan Grayston.

It’s easy, I suppose, to absolve Grayston of most of the wrongdoing here and place it all at Boe’s feet. Part of the success of the campaign was due to Grayston’s passion for the project and the fact that he just comes off as a genuinely nice guy. But while Boe clearly deserves the lion’s share of the blame, Grayston was incredibly irresponsible from almost the beginning. And at this point, despite his claims of having consulted a lawyer, I find it hard to believe that by not reporting the embezzlement for nearly a year Grayston isn’t in some way partially guilty of the same laws broken by Boe. The strange videos, that seem to bend over backwards to absolve him of any crimes, don’t really make it seem as if he’s entirely on the up and up either, if i’m being honest.

For what it is worth, Grayston has pledged to continue to do whatever he can to complete the Peachy Printer and fulfill the rewards for his backers. Short of Boe coming through with the final repayments, which seems unlikely, or securing some outside funding to continue the work, which seems even more unlikely, I’m not exactly sure how exactly Grayston would be able to deliver. It looks like, once again, Kickstarter backers are going to be let down, and out the money that they paid for a product. But considering Boe’s new home, with two fireplaces, was built using Peachy Printer’s money, maybe everyone could work out a timeshare deal to pay off the outstanding debt. The house sounds pretty nice, so maybe if you find yourself up in Canada look it up and get a good look at what you paid for.

It looks like, once again, Kickstarter backers are going to be let down, and out the money that they paid for a product. But considering Boe’s new home, with two fireplaces, was built using Peachy Printer’s money, maybe everyone could work out a timeshare deal to pay off the outstanding debt. The house sounds pretty nice, so maybe if you find yourself up in Canada look it up and get a good look at what you paid for.

The house that the Peachy Printer built.

You can read Grayston’s entire message on Kickstarter here. And you can read the entire timeline of events, see all of the original documents and evidence of the embezzlement on an Executive Summary that Grayston posted over on Peachy Printer here. And if you would like to file a complaint with the Saskatoon Police Department, you can find out how here.

Do you find this story to be a bit of a shock? Discuss in the Peachy Printer Kickstarter Funds Embezzled forum over at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printer kickstarter • 3D printer theft • 3d printers on Kickstarter • crowdfunding • David Boe • kickstarter • Kickstarter failure • kickstarter fraud • money • peachy printer • peachy printer embezzlement • peachyprinter • Rylan Grayston

Please enable JavaScript to view the comments powered by Disqus.

Kickstarter Offers Up a Real Peach of a 3D Printer

At this point in the evolution of the additive manufacturing (AM) market the challenge isn’t finding a 3D printer to buy, it’s finding a worthwhile printer to buy. With AM systems popping up on Amazon, and with brick-and-mortar stores the likes of Staples putting 3D printers on the shelves, buying an AM system isn’t much more difficult than purchasing any other electronic doodad.

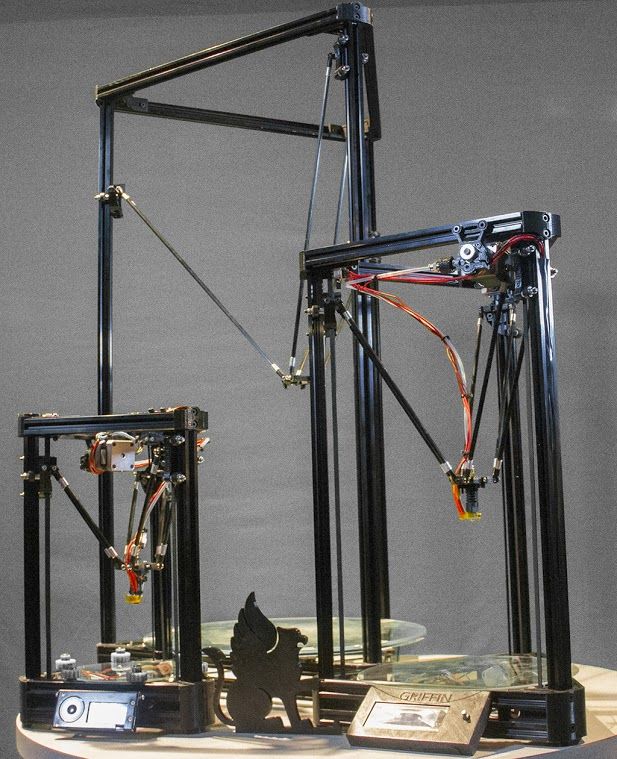

Most of the 3D printers within the price range of individual consumers are material extrusion systems that build up objects in layers using PLA or ABS plastic. A notable exception is Formlabs, which offers stereolithography with its desktop FORM 1. Now a new system named the Peachy Printer has arrived on Kickstarter and Indiegogo, and offers photolithography builds at an astonishingly low price.

A notable exception is Formlabs, which offers stereolithography with its desktop FORM 1. Now a new system named the Peachy Printer has arrived on Kickstarter and Indiegogo, and offers photolithography builds at an astonishingly low price.

Let’s start by getting the price out of the way. For $100 you get a Peachy Printer kit, including 100 ml of resin. That sounds crazy, right? You have to be wondering if this thing is made out of paper mâché and chewed bubble gum to be that affordable. Some people spend near that much for a single tank of gas.

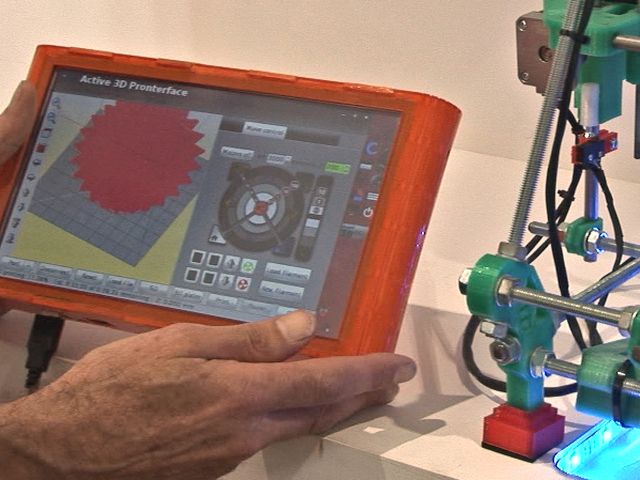

Rylan Grayston, inventor of the Peachy Printer, is a clever man. His decision to use photolithography is actually what makes the low price point possible. Grayston designed and developed his own parts, including what is essentially the print head. In place of a bunch of moving parts, the Peach Printer uses electromagnetic mirrors to bounce a laser beam to the appropriate part of the resin tub to build 3D objects.

The laser itself is directed by sound. Grayston wrote an add-on for Blender that translates a 3D object into sound waves. The sound waves are translated into X, Y coordinates by the laser and mirrors, projecting the image of the 3D object into the resin. The Z axis is controlled by the level of the resin in the reservoir. In the case of the Peachy Printer, the resin floats atop saltwater. As the build progresses, the amount of the salt water in the reservoir is increased to raise the level of the resin.

Solid details on specs for the Peachy Printer are a little sketchy yet. Grayston is willing to commit to a minimum wall thickness of 0.2 mm, but that’s about all. As far as build envelope is concerned, according to the inventor, the size of build is only limited by the size of the resin reservoir. The laser beam that directs builds will become more diffuse as it travels longer distances, but Grayston mentions a canoe as a potential build candidate.

Although I’m not fond of it coming as a kit, with a little more development time, the Peachy Printer may well prove itself as a viable contender for desktop AM. The sample prints look to have a fair amount of strata, but no more than what you’d expect from a low-cost material extrusion printer. Resin has also come down in price, making it a viable alternative to plastic filament.

The sample prints look to have a fair amount of strata, but no more than what you’d expect from a low-cost material extrusion printer. Resin has also come down in price, making it a viable alternative to plastic filament.

Below you’ll find a couple videos about the Peachy Printer.

Sources: Kickstarter, Peachy Printer

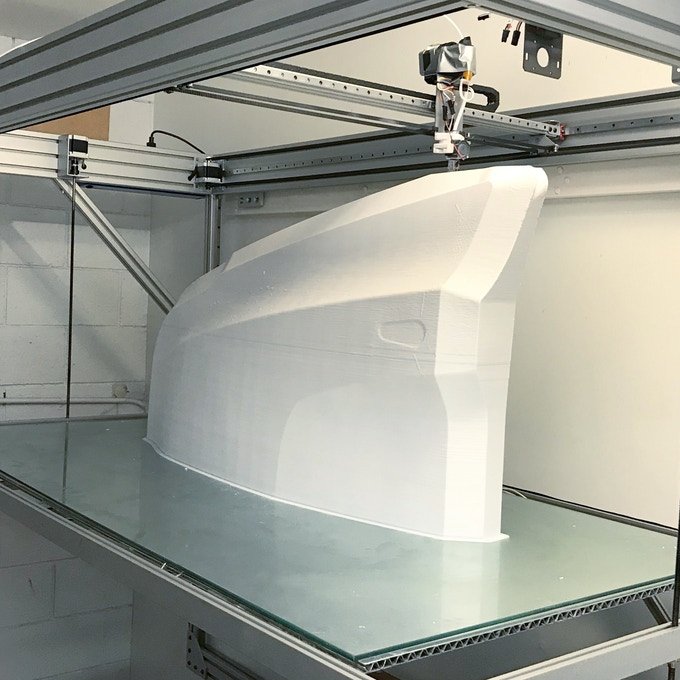

90,000 conveyor 3D printer from Creality enters the KickstarterNews

Subscribe to

Subscribe

Z. The desktop additive system can be used for both oversized 3D printing and small-scale additive manufacturing.

This 3D printer has already been featured in several reviews under the designation CR-30. In the additive community, the idea of conveyor 3D printers has been floating around for a long time, at least twelve years, but commercial versions have only recently begun to appear: Blackbelt in 2017, Powerbelt Zero in 2019, from the open source versions, the White Knight project can be mentioned. Another promising option called Printrbelt was never brought to market due to the untimely demise of Printrbot.

Another promising option called Printrbelt was never brought to market due to the untimely demise of Printrbot.

It was only a matter of time before an analogue appeared in the assortment of leading Chinese manufacturers of 3D printers, and already on November 18, everyone will be able to apply for Creality's system, called 3DPrintMill. The development of our own version of a conveyor 3D printer was promoted by Naomi Wu (a.k.a. SexyCyborg), a DIYer familiar to our community members, who has been collaborating with Creality for a long time. Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538.

As you can see in the illustrations, the distinguishing features of these 3D printers are the guides mounted at an angle of 45 ° to the surface along the X and Y axes, as well as the conveyor belt. You can get confused with the coordinate system, but imagine that a slightly skewed 3D printer is lying on its back - then the CoreXY kinematics are mounted on the portal with the appropriate coordinates, and the belt moves along the Z axis. The tilt of the portal, coupled with the translational movement of the belt, provides the ability to build parts in height without the need to rollback the entire model. In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window.

You can get confused with the coordinate system, but imagine that a slightly skewed 3D printer is lying on its back - then the CoreXY kinematics are mounted on the portal with the appropriate coordinates, and the belt moves along the Z axis. The tilt of the portal, coupled with the translational movement of the belt, provides the ability to build parts in height without the need to rollback the entire model. In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window.

Alternatively, this 3D printer can be used for in-line production, printing one part after another and allowing the models to separate themselves from the tape at the end and fall into a container. From an economic point of view, serial 3D printing will be justified as long as we are talking about relatively small batches of products, measured in hundreds or thousands of pieces.

Polylactide, PET-G, and TPU are listed as consumables, but there is a heated platform in the work area under the belt. The wear-resistant conveyor belt is made on a nylon base, apparently with the addition of carbon fibers. The system is calibrated at the factory, equipped with quiet drivers, a massive airflow with three fans is installed on the head. Additional features include a filament sensor, save and resume function, plus a card capture reader for offline operation. Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt.

The wear-resistant conveyor belt is made on a nylon base, apparently with the addition of carbon fibers. The system is calibrated at the factory, equipped with quiet drivers, a massive airflow with three fans is installed on the head. Additional features include a filament sensor, save and resume function, plus a card capture reader for offline operation. Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt.

Specifications of 3DPrintMill 3D Printer (CR-30):

- Print technology: FDM

- Number of extruders: 1

- Construction area size: 200x170x∞ mm

- Printing accuracy: ±0.1 mm

- Nozzle diameter: 0.4 mm

- Layer thickness: 0.1-0.4 mm

- Hot end temperature: ≤240°C

- Heating temperature: ≤100°C

- Power consumption: 350W

- Power supply: AC 100-120V / 200-240V, DC 24V

- Consumables: PLA, PET-G, TPU

- Filament diameter: 1.

75 mm

75 mm - Interface language: English

- Data transfer: USB, SD card

- Software: CrealityBelt Slicer

- Dimensions: 535x656x410 mm

- Weight: 16.5 kg (net), 20.5 kg (gross)

The start of accepting orders is scheduled for November 18, 19:00 Moscow time.

You can subscribe to the notification about the start of the campaign here.

FFF fdm CREALITY 3DPrintMill CR-30 conveyor

Follow author

Follow

Don't want

11

More interesting articles

ten

Subscribe to the author

Subscribe to the author

Don't want to

The project is experimental and symbolic: the structure was erected by 3D4Art to celebrate. ..

..

Read more

7

Follow the author

Subscribe

Don't want

A team of scientists from the Perm National Research Polytechnic University has developed...

Read more

59

Subscribe to the author

Subscribe to the author

Subscribe

Don't want to

The 3Dtoday portal, supported by Creality and Bestfilament, invites everyone to participate in...

Read more0001

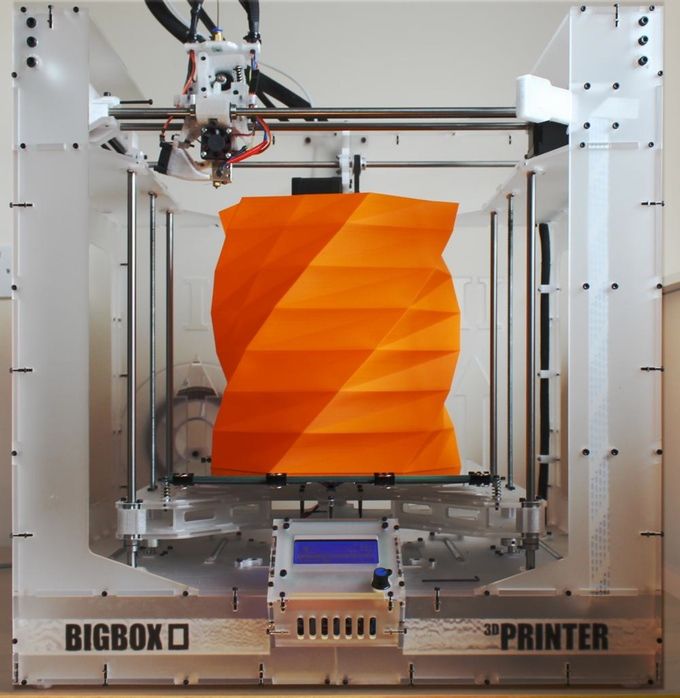

I could not pass by an interesting project to raise funds for the production of a Longer photopolymer 3D printer on the Kickstarter site.

The model is called Orange 30. This photopolymer 3D printer (SLA UV) is a simple and reliable desktop model that is accessible to everyone. A big plus of the Orange 30 is that it doesn't require much skill for basic printing. Manufacturer Longer has several videos that teach the basics of 3D printing. The printer is quiet, there are no exposed moving or hot parts, and it is practically safe to use at home or in the office.

A big plus of the Orange 30 is that it doesn't require much skill for basic printing. Manufacturer Longer has several videos that teach the basics of 3D printing. The printer is quiet, there are no exposed moving or hot parts, and it is practically safe to use at home or in the office.

→ Longer Project: Reliable & Most Affordable Desktop SLA 3D Printer on Kickstarter

→ Official store Longer3d.com

The Longer Orange 30 photopolymer printer is a “tower” with dimensions of 20 x 20 x 39 cm, a massive metal base, a light-protective cap on top. The cap, by the way, is needed not so much to protect the user as to protect the photopolymer from parasitic light from outside. Under the hood is a tray for photopolymer and a Z-axis drive that raises the print table gradually upwards as the model is created. At the base there is a control board with a touch screen, a UV matrix for illuminating the photopolymer, and a 2K display (LCD display with a resolution of 2560 x 1440 pixels). The size of the bath is 120 x 68 mm, the maximum working stroke along the Z axis is 170 mm. This is more than the popular budget Sparkmaker SLA 3D printer.

The size of the bath is 120 x 68 mm, the maximum working stroke along the Z axis is 170 mm. This is more than the popular budget Sparkmaker SLA 3D printer.

Features

Brand: Longer

Model: Orange 30

Type: SLA UV 3D printer

Print area size: 120 x 68 x 170 mm

Print layer thickness: 0.02...0.1 mm

Print speed: 30 mm/h (at 0.1 mm layer).

Display: yes, touch, 2.8"

Illumination type: UV LED matrix 405 nm

Consumable type: 405 nm photopolymer resin (UV Resin)

If you decide to become a baker, please be aware that the current rate available is $229 (Orange 30 printer + bottle of photopolymer). Shipping cost to Russia $110. They promise to start sending samples in August 2019.

This is one of the most budget options. You can wait and take this printer for sale. But the price may rise (on Kickstarter, the "crossed out" price is $450). Maybe not get up. OEM clones of previous Longer models are freely sold in Chinese stores (FDM printers from $150 and up, SLA from $250).

The design is simple but effective: a single Z-axis is fitted with an MGN12 rail guide. Not crooked shafts, but a normal (Chinese) rail. A bath for a photopolymer is used metal. Yes, it is simple, on tacks, stamped, but it is not plastic. The table for forming the model is also metal. The printer developers have provided a mechanism for leveling the table. There is a corresponding operation in the printer menu for this.

Bold plus of this model is the presence of a touch screen with printer control, printing and model preview. I have never seen a built-in file viewer before. In my opinion, this is a killer feature in a budget model.

Why do you need a photopolymer printer - to print accurate models (copies) with high detail (20...50 microns). Similar printers are used in dentistry, jewelry, modeling, etc. There are special photopolymers, for example, castable, which allows casting on 3D models.

Longer3D and before that flashed, as a manufacturer of OEM models, which then appear under other brands, such as Alfawise.