Pcl 3d printing

Facilan™ PCL 100 Filament | 3D4Makers

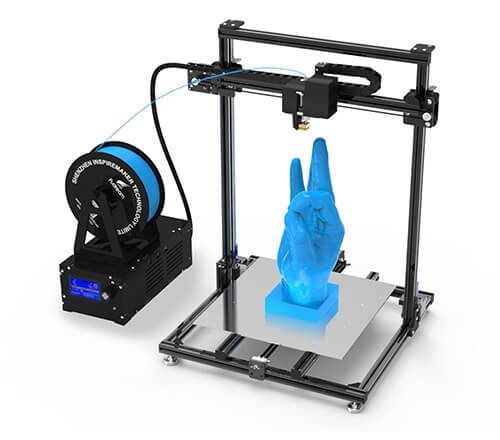

Roll over image to zoom in Click on image to zoom

Save €-105.00

Facilan™SKU: FPCL1-0000-175-750-3D4M

3 reviews

Color: Natural

Natural

Diameter: 1.75mm

1.75mm

2.85mm

Weight: 750 gram

750 gram

2300 gram

Variant

Natural / 1.75mm / 750 gram - €105.00Natural / 1.75mm / 2300 gram - €289.95Natural / 2.85mm / 750 gram - €105.00Natural / 2.85mm / 2300 gram - €289.95

Facilan™ PCL 100 (Polycaprolactone) Filament

- Facilan™ PCL 100 it is perfect for high-value applications such as medical research.

- Our customers use our PCL for research into artificial trachea, smart materials, scaffolds for tissue engineering, bioabsorbable implants, drug-loaded implants and other cutting-edge applications.

- Facilan™ PCL 100 is used by many leading universities and research centers worldwide for bleeding edge work in bioprinting and patient specific medical research.

- Facilan™ PCL 100 is very flexible and tough with a glass transition temperature of -60 °C and a print temperature of around 120°C.

- Facilan™ PCL100 is polycaprolactone homopolymer with a molecular weight of 50000 g/mol.

- Facilan™ PCL100 is a semi-crystalline aliphatic biodegradable polyester with white final appearance.

- Filament produced by 3D4Makers is based on raw material produced in compliance with the European regulations EC No. 1935/2004 and EC No. 10/2011 concerning plastic materials and articles coming into contact with food.

- The material has an amazing adhesion between layers which results in great improvement of the impact resistance, strength, durability, and printability.

- Due to the low melting point, of Facilan™ PCL100 it can be reshaped after 3D printing in water with a temperature of 55 °C.

Recommended restrictions

Do not use in medical applications involving permanent implantation in the human body.

3D4Makers Polycaprolactone Facilan™ PCL 100 is one of the most extensively used bioprinting and medical 3D printing research materials worldwide.

Facilan™ PCL100 Material Properties

- Density: 1.1 g/cm³

- Tensile Strength: 45 MPa

- Elongation at Yield: 15 %

- Tensile Modulus: 350 MPa

- IZOD Impact Strength (notched): 8 kJ/m2

- Shore D Hardness: 46

- Heat Deflection Temperature (0,45 MPa): 57 °C

Print Settings

- Print Temperature: 130°C (130 to 170°C)

- Bed Temperature: 30-45°C

- Adhesion: Ultimaker Adhesion sheets, Avery Mailing labels L7567-25, PEI Sheets

- Print Speed: 10mm/s (10 - 30 mm/s)

- Mass flow: 120%

- Fan Speed: 100%

- Note: Add M302 S120 into the beginning of the g-code to allow cold extrusion, below 170°C

- Extra: Minimum Layer Time considerably +/- 60 sec minimum, highly dependent of model size and complexity and enabled Lift Head.

- Support: If PVA or breakaway Support = enabled; Support overhang angle = 0°; Enable Prime Tower = Enabled. Support with Facilan Ortho onto itself: not recommended

TDS

You can download the Technical Data Sheet for Facilan™ PCL 100 here.

MSDS

You can download the Material Safety Data Sheets for Facilan™ PCL100 here:

English

Spanish

French

Italian

German

Dutch

*The previous name of this product was PCL100

AmazonAmerican ExpressApple PayDiners ClubGiropayGoogle PayiDEALJCBMaestroMastercardPayPalPaySafeCardShop PaySOFORTVisa

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Country

NetherlandsGermanyItalyUnited States---AfghanistanÅland IslandsAlbaniaAlgeriaAndorraAngolaAnguillaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong Kong SARHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SARMadagascarMalawiMalaysiaMaldivesMaliMaltaMartiniqueMauritaniaMauritiusMayotteMexicoMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorwayOmanPakistanPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalQatarRéunionRomaniaRussiaRwandaSamoaSan MarinoSão Tomé & PríncipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaSt. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

Zip code

Returns

Our policy lasts 30 days. If 30 days have gone by since your purchase, unfortunately we can’t offer you a refund or exchange.

To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging.

To complete your return, we require a receipt or proof of purchase.

Any item not in it's original condition, is damaged or missing parts for reasons not due to our error.

Any item that is returned more than 30 days after delivery

Refunds

Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

If you are approved, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within 14 days.

Late or missing refunds

If you haven’t received a refund yet, first check your bank account again.

Then contact your credit card company, it may take some time before your refund is officially posted.

Next contact your bank. There is often some processing time before a refund is posted.

If you’ve done all of this and you still have not received your refund yet, please contact us at [email protected].

Sale items

Only regular priced items may be refunded, unfortunately sale items cannot be refunded.

Exchanges

We only replace items if they are defective or damaged. If you need to exchange it for the same item, send us an email at [email protected] and send your item to: Oudeweg 91-95 Haarlem NL 2031CC.

If you need to exchange it for the same item, send us an email at [email protected] and send your item to: Oudeweg 91-95 Haarlem NL 2031CC.

Gifts

If the item was marked as a gift when purchased and shipped directly to you, you’ll receive a gift credit for the value of your return. Once the returned item is received, a gift certificate will be mailed to you.

If the item wasn’t marked as a gift when purchased, or the gift giver had the order shipped to themselves to give to you later, we will send a refund to the gift giver and he will find out about your return.

Shipping

To return your product, you should mail your product to: Waarderweg 56 Haarlem NL 2031BP

You will be responsible for paying for your own shipping costs for returning your item. Shipping costs are non-refundable. If you receive a refund, the cost of return shipping will be deducted from your refund.

Depending on where you live, the time it may take for your exchanged product to reach you, may vary.

If you are shipping an item over €75, you should consider using a trackable shipping service or purchasing shipping insurance. We don’t guarantee that we will receive your returned item.

PCL Low Temperature Filament - Natural - 1.75mm - 1 KG

€21,95 Save €-21,95

SKU: 12-D4-3647 Filaments.ca

Sold Out

Description

Low Price Guarantee

Shipping Policy

Returns & Exchange

Our PCL (Polycaprolactone) 3D filament is a very unique material that can well suited for many unusual applications.

PCL is also a safe & biodegradable plastic!

The main feature of PCL is that it has a very low melting temperature compared to usual 3D printing materials such as PLA, ABS etc.

Main Features of our PCL filament:

- PCL has a melting temperature of only 58°C ~ 60°C.

- It can be 3D printed at much lower and safer temperatures (70°C to 140°C) and does not require a heated bed.

- Objects can be re-shaped after printing to fit specific application by simply softening it in warm 60°C water (Example: re-shaping a river to fit through a whole).

- Once cooled, PCL is a very tough and impact resistant plastic.

- PCL has a glass transition temperature of -60°C which makes it tough, flexible and durable.

- Can be easily colored

- Great inter-layer adhesion

NET WEIGHT: 1 KG (2. 2 LB) 2 LB) |

PrintingTemperature: | Notes: |

| 70°C - 140°C |

|

We want to make sure that your shopping experience is truly worry-free, that's why we guarantee our everyday competitive prices & won't be beat on price!

We will beat any advertised price on identical or comparable products!

If you find an identical or comparable item currently offered for less at a local competitor's store or website (including shipping, handling and fees, if applicable) before you buy or within 30 days of your purchase we’ll beat that price by 10% of the difference. In addition, should our own price be reduced after your purchase, present us with your original receipt within 30 days of purchase and we will match the price and refund you the difference.

How to make a request:

Simply contact us by phone, email or live chat and show us confirmation of the price that you have found for less from a local competitor via a complete URL (web address) of the product page on the competitor's website or via flyer/print-out (including shipping, handling and other fees, if applicable).

The product you’re comparing must:

- Be priced in Canadian Dollars and include all fees, shipping costs, and other charges.

- Be sold and shipped by a retailer AND authorized dealer located within Canada.

- Be in stock, available for sale, and cannot be a limited time offer or available only in limited quantity.

- Not be lower priced due to an advertising error, misprint, or special sale price

Special sale prices are excluded from this offer, these include but not limited to the following:

VIP SALE, Black Friday, Friends and Family, Cyber Monday, Boxing Day/Week, special educational prices, restricted offers, mail order offers, rebates, coupons, premiums, free or bonus offers, Original Equipment Manufacturer (OEM) prices, open box products, close-outs, liquidations, discontinued, clearances, demos, refurbished items, open box items, financing offers and errors or misprints.

Also excluded are marketplace sellers on websites such as Amazon.ca or resellers such as eBay.ca as well as any sellers whose products are refurbished or liquidated.

Canada & International Shipping:

We ship Canada wide as well as internationally. We use Canada Post, UPS, Purolator, Canpar & FedEx for our shipping solutions. Large shipments, 50kg or more may be shipped by freight. Shipping costs are automatically calculated by the carrier during the checkout process. Any additional shipping charges incurred as a result of incorrect or incomplete address information as well as delivery refusal will be at the customer's expense.

All orders are shipped "Signature not required" unless otherwise requested (additional charges may apply).

All orders are shipped directly from our Mississauga, Ontario warehouse.

Please note that international shipments may incur additional charges such as brokerage, duties, taxes or other cross border related fees. These fees are NOT calculated during the checkout process, are NOT charged by Filaments.ca and are completely out of our control. It is important to note that Filaments.ca does NOT charge any additional fees beyond what is stated on the order invoice. Any cross-border related fees are the sole responsibility of the purchaser and are handled between the purchaser and the country the good being imported into, including any related agencies and/or customs brokerage companies.

These fees are NOT calculated during the checkout process, are NOT charged by Filaments.ca and are completely out of our control. It is important to note that Filaments.ca does NOT charge any additional fees beyond what is stated on the order invoice. Any cross-border related fees are the sole responsibility of the purchaser and are handled between the purchaser and the country the good being imported into, including any related agencies and/or customs brokerage companies.

Free Shipping:

We offer free shipping within Canada for orders totaling CAD$125 or more before tax. We also offer free shipping within the 48 contiguous United States for orders totaling CAD$200 or more before tax. To take advantage of this offer, please choose the free shipping option during the checkout process.

We reserve the right to choose the most economical shipping method. The shipping fee coverage for the free shipping option is limited to shipping services with charges up to CAD$50.

Free shipping does not apply to bulk or custom orders with discounted pricing.

FedEx Overnight:

Please note that our cut-off time for shipping overnight is 03:00 PM (Eastern Time). This means that if you choose FedEx Overnight as your shipping option, the order must be placed by 03:00 PM (Eastern Time) in order to get the order the next business day (FedEx overnight orders placed on a Friday will be delivered the following business day / Monday). It is important to follow this cut-off time in order to allow our warehouse time to prepare your order and still hand it over to FedEx on time for their overnight service.

Same Day Local Delivery:

Local delivery is available in the Greater Toronto Area. Please click here for more information.

Tracking Numbers:

As soon as your order is fulfilled, you will receive an email confirmation including your tracking number. Some shipping options such as envelopes or local deliveries may not have a tracking number.

Failed Deliveries:

Please note that in case of a refused delivery or if a shipment fails to be delivered to you because no one is home or available to receive the package, the courier WILL send the package back to us at OUR expense. When this happens, we will try to contact you and make further arrangements. These additional shipping charges incurred as well as charges to re-ship the package, will be forwarded to you, the customer. Therefore, please ensure that someone is always available to receive the package or pick it up from your local post office/courier facility before the courier ships it back to us.

Processing Time:

We strive to ship out orders as soon as same day for all orders placed by 2pm EST. Although depending on order specifications, it can take between 24 to 48 hours. Unexpected issues may further delay this process and will be communicated accordingly.

Out of Stock & "Sold Out" Products:

The inventory in our online store and the inventory in our warehouse are synced. When you purchase a product on our online store it means the product is already in stock and ready to ship. But on very rare occasions, technical issues might cause this sync to fail, and one or more of the products purchased might be out of stock. IF this happens, we will offer an alternative product or refund you for the out of stock item/s. Your order may be marked as "partially fulfilled", meaning we will immediately ship the items that are in stock and the rest will be shipped as soon as the item/s are back in stock.

When you purchase a product on our online store it means the product is already in stock and ready to ship. But on very rare occasions, technical issues might cause this sync to fail, and one or more of the products purchased might be out of stock. IF this happens, we will offer an alternative product or refund you for the out of stock item/s. Your order may be marked as "partially fulfilled", meaning we will immediately ship the items that are in stock and the rest will be shipped as soon as the item/s are back in stock.

Products marked as "Sold Out" or "Unavailable" are normally available again within 1-4 weeks. Feel free to check back or contact us for information about availability of specific products.

Order Pick Ups:

Customers in the Greater Toronto area are welcome to pickup orders at our Customer Pickup location in Mississauga. Please note that we require at least 1 business day notice for pickup orders. When placing an order online, simply choose the "PICKUP" option on the checkout page. After we process your order we will send you an additional email with details about the date and time your order will be ready to be picked up.

After we process your order we will send you an additional email with details about the date and time your order will be ready to be picked up.

Pickup Address:

7355 Torbram Rd.

Unit 15

Mississauga ON

L4T 3W3

Please have your ID ready to pick up your package.

Buy in Store:

Products can also be purchased directly at our Mississauga pickup location using credit, debit or cash.

Check our returns & exchange policy for information.

3D printing with low-temperature plastic

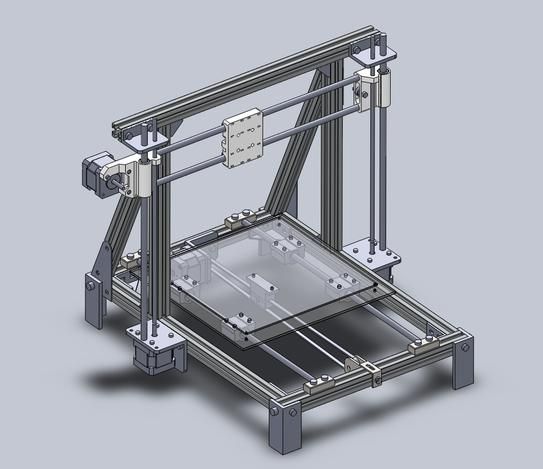

Material extrusion (FDM, FFF, etc.) is a popular technology in additive manufacturing for the manufacture of products from general-purpose thermoplastic materials, as well as engineering and special-purpose plastics, including composite ones. The formalized model of the technological process of extrusion printing is presented in fig. 1 .

At the design stage, a list of requirements is formed that the product must meet during operation. When developing the technological process of extrusion 3D printing, the temperature interval for processing the selected material used for the manufacture of the product is taken into account. nine0005

When developing the technological process of extrusion 3D printing, the temperature interval for processing the selected material used for the manufacture of the product is taken into account. nine0005

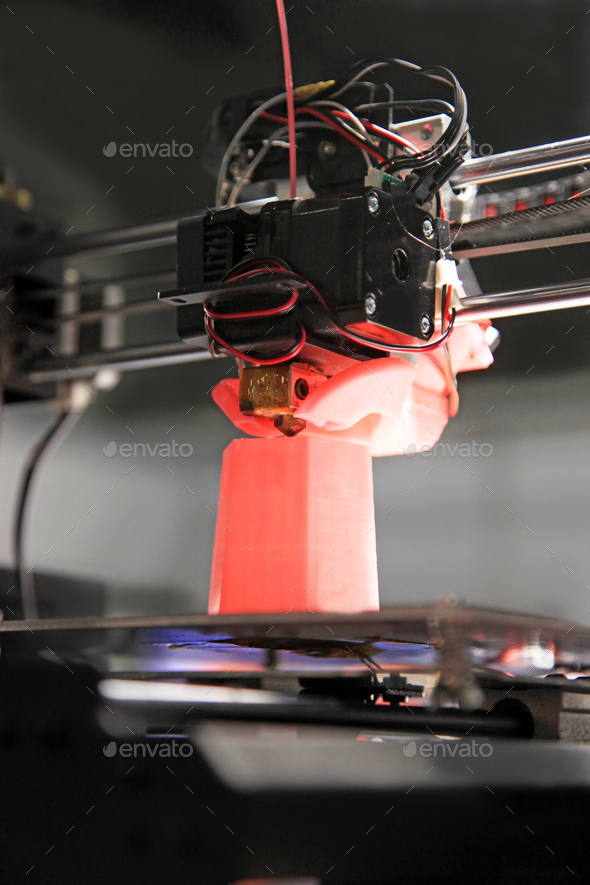

When performing a 3D printing operation ( fig. 1 ), physical processes occur in the processed material, the control of which allows obtaining a defect-free product that meets the requirements formulated by the designer.

Fig. 1. Extrusion 3D printing technology model

The purpose of this article is to determine the temperature range of extrusion 3D printing of low-temperature thermoplastic materials based on the analysis of their thermal properties. Thermograms obtained by differential scanning calorimetry (DSC) on Mettler Toledo equipment, which can be used to select the temperature range of 3D printing, are considered using the example of thermoplastic materials, Wax3D wax and TPU plastics. An example of a product made from thermoplastic wax is shown in fig. 2 . This is a master model for the subsequent production of a one-time shell mold using investment casting technology.

2 . This is a master model for the subsequent production of a one-time shell mold using investment casting technology.

Fig. 2. An example of a master model made of thermoplastic wax

Under "low temperature" is considered a thermoplastic material processed using extrusion 3D printing technology in the temperature range from 50 to 190 (200) ° C in equipment with an active or passive thermal chamber. Under these conditions, materials such as thermoplastic waxes (for example, Wax3D) [1], polycaprolactone (PCL), low-pressure polyethylene (PND, with a lower processing temperature limit of 190°C), polyurethane (TPU, with a lower temperature limit of 190°C), polyacetal (POM, with a lower temperature limit of 170°C).

Thermoplastic material PCL is described in sufficient detail in [2–4]. It is noted that biodegradable low-temperature plastic developed in the 1930s, characterized by a relatively low melting point (59–64°C), gained popularity again by the early 2000s, including due to the emergence of additive technologies.

A few words about the physical processes occurring in a thermoplastic polymer material during extrusion 3D printing and the parameters that determine them. In [5, 6], a rather in-depth analysis of the physical processes and parameters ( fig. 3 and 4 ) was carried out, which determine them and are associated with extrusion in 3D printing.

Fig. 3. Physical processes during extrusion 3D printing [5]

Fig. Fig. 4. Key parameters affecting the result of extrusion 3D printing [6]

4 shows the external parameters that affect the course of the extrusion process. At the same time, thermophysical transformations take place in the material itself, leading to a change in the physical state of the polymer material. Extrusion 3D printing, as well as traditional methods of processing polymer materials, is based on the transfer of a polymer material into a viscous state (melt). nine0005

nine0005

One of the key parameters of extrusion 3D printing is temperature: printing (heating block) temperature, working platform temperature, ambient temperature. The conditions of extrusion 3D printing are not isothermal even if the 3D printer has a passive or active thermal chamber. In [7], the temperature distribution in the 3D printing area was experimentally measured, showing its non-uniformity ( Fig. 5 ).

a) b)

Fig. 5. Temperature distribution during extrusion 3D printing [7]:

b) temperature distribution during extrusion, measured using

IR thermal cameras

, glassy, viscoelastic. One of the methods for analyzing thermophysical properties is differential scanning calorimetry (DSC; GOST R 55134–2012 (ISO 11357–1:2009), which consists in determining the difference in heat fluxes as a function of temperature and/or time in the process of exposure to the test and reference samples by a controlled temperature program. Heat fluxes are supplied to the crucible, inside which the test and reference samples are located. DSC analysis makes it possible to investigate physical transformations (glass transition, melting, crystallization, polymorphic transformations), in particular, in thermoplastic materials.

Heat fluxes are supplied to the crucible, inside which the test and reference samples are located. DSC analysis makes it possible to investigate physical transformations (glass transition, melting, crystallization, polymorphic transformations), in particular, in thermoplastic materials.

For thermoplastic wax, an example of a thermogram obtained as a result of DSC analysis is shown in fig. 6; for plastic type TPU with a hardness of 55D - at fig. 7.

Fig. Fig. 6. Thermogram of thermoplastic wax

Fig. 7. Thermogram of thermoplastic TPU type plastic with a hardness of Shore 55D

at a temperature above the glass transition temperature and up to a temperature of ~120.0°C, the thermoplastic material gradually passes into the melt state. nine0005

The temperature maxima on the thermogram are associated with the melting of crystallites of different sizes. The temperature range of 3D printing is selected from the range of values from 90 to 115°C, which is due to the completion of the transition of the polymer material to the melt state. The boundary (minimum and maximum temperatures) is selected depending on the material properties of the product, for example, the mechanical properties that must be formed as a result of processing. Verification of mechanical properties can be performed on the basis of a tensile test of standard samples (GOST 11262–2017 and GOST 33693–2015 (ISO 20753:2008)).

The boundary (minimum and maximum temperatures) is selected depending on the material properties of the product, for example, the mechanical properties that must be formed as a result of processing. Verification of mechanical properties can be performed on the basis of a tensile test of standard samples (GOST 11262–2017 and GOST 33693–2015 (ISO 20753:2008)).

From the thermogram of plastic type TPU ( fig. 7 ) the glass transition temperature (according to the second heating; Tst) is determined - 18.97°C. The temperature range of 3D printing is selected from the range of values from 190 to 205°C, which is due to the completion of the transition of the polymer material to the melt state. The boundary (minimum and maximum temperatures) is chosen in the same way as in the case of thermoplastic wax, depending on the material properties of the product, for example, mechanical properties that need to be formed as a result of 3D printing. nine0005

Conclusions and forecast

The performed analysis of the literature, conducted full-scale experiments allow us to formulate recommendations on the choice of temperature range for extrusion 3D printing of some low-temperature thermoplastic plastics: mechanical), which must be formed in the material as a result of processing; nine0005

- a preliminary selection of the temperature range can be predicted from the results of DSC analysis - a thermogram; clarification of the temperature range - based on the results of a study of the achieved level of physical and mechanical properties required in accordance with the operational requirements for the product;

— Extrusion 3D printing temperature calculated from thermogram requires additional verification (confirmation) from test results, such as tensile testing. ■

■

References

Affordable wax mold printing // Additive technologies. 2019. No. 4. P. 30–33. [electronic edition] URL: https://additiv-tech.ru/publications/dostupnaya-pechat-voskovyh-form-dlya-litya.html (date of access: 01/10/2022).

Van Natta FJ, Hill JW, Carruthers WH. Polymerization and ring formation, caprolactone and its polymers. J Am Chem Soc 1934;56:455–9.

Maria Ann Woodruff, Dietmar Werner Hutmacher. The return of a forgotten polymer - Polycaprolactone in the 21st century. Progress in Polymer Science. Volume 35. Issue 10. 2010. P. 1217–1256. nine0005

US8859691B2 Zhang, Zhongqun. (2014). Low temperature thermoplastic material and preparing method thereof.

Bastian Brenken, Eduardo Barocio, Anthony Favaloro, Vlastimil Kunc, R. Byron Pipes. Fused filament fabrication of fiber-reinforced polymers: a review. Additive manufacturing. Volume 21. 2018. P. 1–16.

L. G. Blok, M. L. Longana, H. Yu, B.K.S. woods. An investigation into 3D printing of fiber reinforced thermoplastic composites. additive manufacturing. Volume 22. 2018. P. 176–186. nine0005

additive manufacturing. Volume 22. 2018. P. 176–186. nine0005

D. Pollard et al. Filament Temperature Dynamics in Fused Deposition Modeling and Outlook for Control / Procedia Manufacturing. 11 (2017). 536–544.

Authors: P.A. Petrov, M.S. Bronin, B.Yu. Saprykin, M.S. Dolgov

Moscow Polytechnic University, Department of Machining of Materials by Pressure and additive technologies, [email protected]

Source journal "Additive Technologies" № 1-2022

Tags:

, journal "Additive Technologies" No. 1-2022

Polycaprolactone (PCL). Monofilament launches PCL monofilament for 3D printing

Currently, there is a growing interest in the production of biocompatible plastics for the creation of long-acting implants using additive technologies. Implant sizes are always different for different human vessels or bones and require a custom design. It is difficult for traditional processing methods such as injection molding or injection molding to compete with additive technologies due to their long production cycles and the high cost of molding tooling for product development. nine0005

It is difficult for traditional processing methods such as injection molding or injection molding to compete with additive technologies due to their long production cycles and the high cost of molding tooling for product development. nine0005

Fig. 1. Polycaprolactone implants

A number of materials have been identified that have the ability to be biocompatible, such as polylactic acid, polyvinyl alcohol and polycaprolactone (PCL, Polymorphus), but have different properties and behavior. The last of these, PCL, is a semi-crystalline and hydrophobic biopolymer that prevents accidental hydrolytic cleavage of the ester chain and, as a result, degrades over a relatively long period compared to other bioresorbable polymers. This is of great interest for 3D printing of biocompatible elements and products with a long service life, especially where structural support is required for many weeks. nine0005

PCL also decomposes under physiological conditions at certain times (depending on the molecular weight of PCL) into components that are safe for the human body, which was the main reason for using it as an implantable biomaterial. PCL is used as a suture and implantable biomaterial, as a capsule shell for drugs, and in cosmetology as a filler for local injections.

PCL is used as a suture and implantable biomaterial, as a capsule shell for drugs, and in cosmetology as a filler for local injections.

PCL has also been widely used in the manufacture of clothing and footwear, various layouts and food containers because this material has good elasticity and high strength. When used in modeling, it easily takes the desired shape, and can be molded from it as if from plasticine. PCL is often used as a material for making crafts, custom fasteners, or other parts. But it is not suitable for creating functional mechanical models. nine0005

Polycaprolactone is a quality, biocompatible and biodegradable polyester plastic derived from petrochemical raw materials. Has a low melting point 59-64 0 C.

2. Structural formula PCL Softens in warm water, after which it becomes transparent and plastic. Rice. 3. Polycaprolactone granule and its softened appearance in warm water

The biodegradability of this plastic lies in the fact that under the influence of environmental factors (ultraviolet radiation, exposure to microorganisms, high temperatures and radiation), the material is completely decomposed into carbon dioxide and water , with partial - to the formation of methane, hydrocarbons, carbohydrates or inorganic mixtures, as well as intermediate metabolic products in living cells.