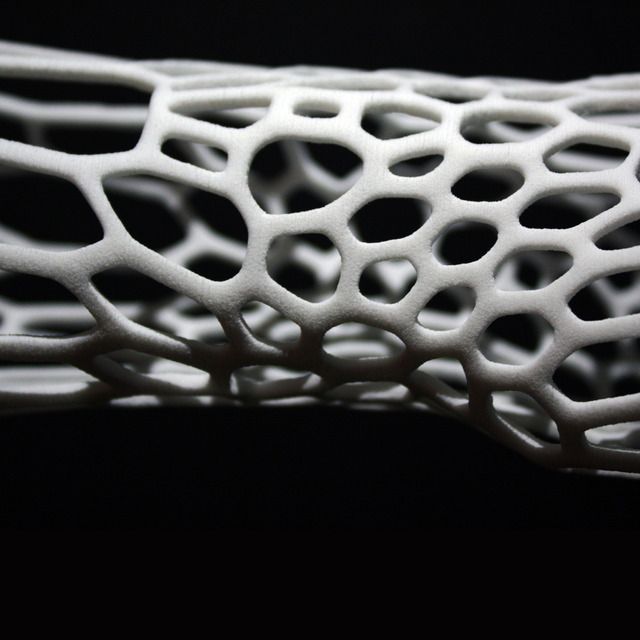

Osteoid 3d printed cast

|

||||||||

| A' Design Award and Competition aims to highlight the excellent qualifications of best designs, design concepts and design oriented products worldwide in all creative disciplines and industries. | ||||||||

|

|

||||||||

The primary aim of the award is to create publicity, PR push and advertisement opportunities for design award winners while supporting the global design culture, creating incentives for entrants to come up with superior designs for a better future. A' Design Awards is a premier annual juried design competition that honors the best designers, architects, engineers, design studios, brands and design oriented companies worldwide to provide them publicity, fame and recognition. A' Design Award and Competitions are organized and awarded annually and internationally in a wide range of categories.

Every year, projects that focus on innovation, technology, design and creativity are awarded with the A' Award. The A' Design Award and Competition has a very well developed methodology for choosing the best designs using rigorous evaluative criteria, blind judging processes, score normalization, cross matching and more, to reward only the best designers and firms that truly deserve special recognition. The Jury of the A' Design award is composed of Academics, Professionals, Enterprise and Focus Group members and follow strict guidelines to provide a fair and ethical evaluation. The A' Design Award & Competition logo, awarded by international experts, is trusted worldwide and denotes solidly proven design quality. Companies and design studios use their A' Design Award victory as a visible symbol in their communication. Participating in the A' Design Award & Competition demonstrates the will to innovate, redesign, rethink and the courage to compare yourself to others in competition. The purpose of A' Design Award is to highlight, advertise & advocate good design, and to provide its' winners extensive and intensive publicity, fame and prestige.

|

||||||||

|

|

||||||||

|

||||||||

Osteoid Medical cast, attachable bone stimulator

Osteoid Medical cast, attachable bone stimulator - Designers. org

org 3D Printing Design Award Winner.

Awarded for Good 3D Printed Forms and Products Design.

Osteoid Medical cast, attachable bone stimulator

by Deniz Karasahin

- Awarded April 15, 2014

- CLIENT: Dk Desıgn Studio

- 69.591

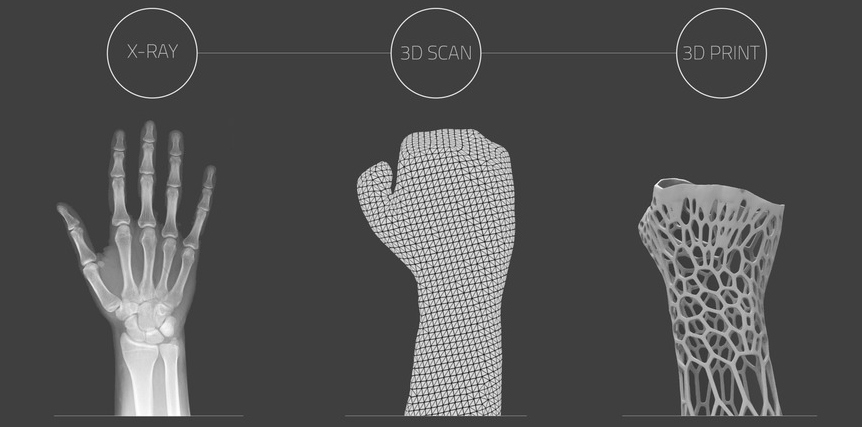

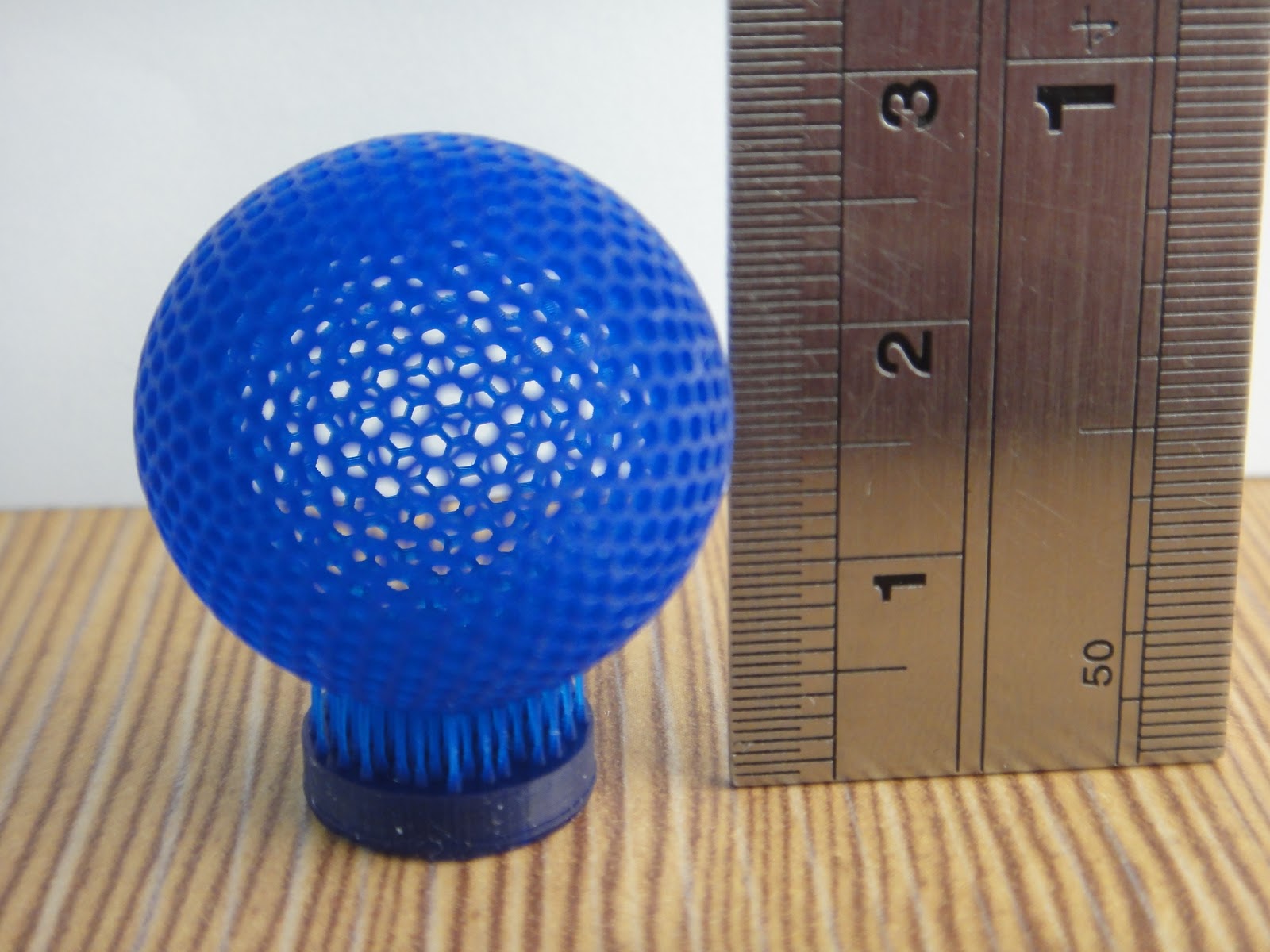

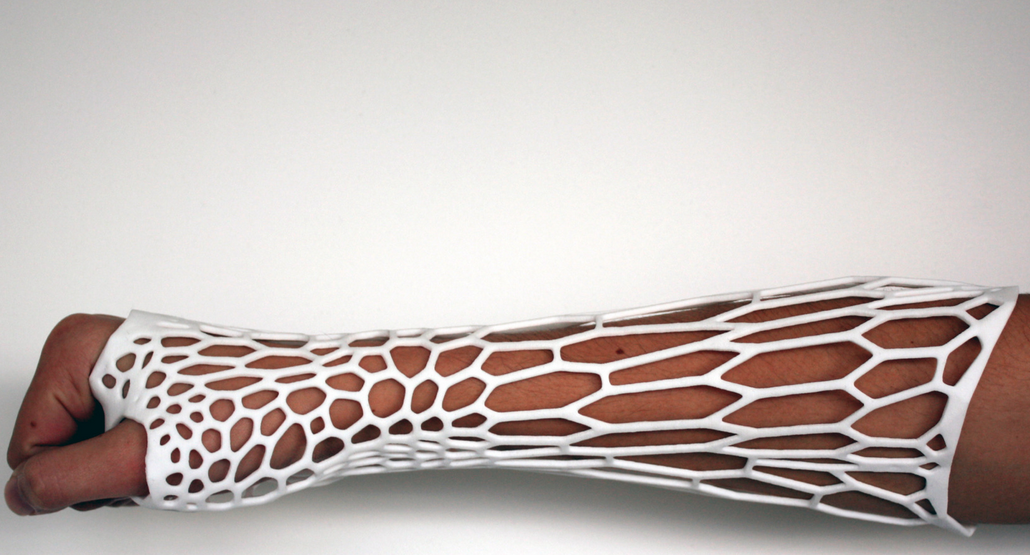

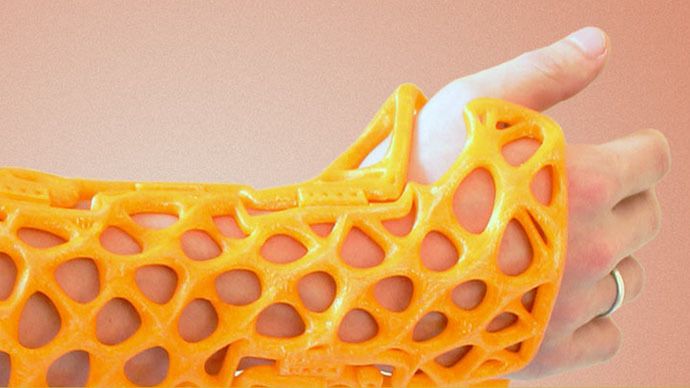

The goal of this project is to improve the overall healing experience for broken or fractured limbs by focusing on the patient’s comfort and healing time. Osteoid cast offers a new way of tackling these problems by introducing new technologies which enables us to make custom fitted, durable 3D printed medical casts that doesn't itch or smell. The end products are slimmer, lighter, doesn't affect from water and environmentally friendly. This cast can also be combined with, a low intensity pulsed ultrasound (LIPUS) bone stimulator resulting in faster recovery.

Learn More

Osteoid Medical cast, attachable bone stimulator

Good Design

Osteoid Medical cast, attachable bone stimulator

Great Design by Shunji Yamanaka & fuRo

Osteoid Medical cast, attachable bone stimulator

Inspirational Mobility Robot Design

Osteoid Medical cast, attachable bone stimulator

CanguRo Mobility Robot Image

Osteoid Medical cast, attachable bone stimulator

Deniz Karasahin

Designer of Osteoid Medical cast, attachable bone stimulator

Good Design Deserves Great Recognition

Discover A' Design Award, World's Largest Design Accolade.

Learn More

Stay Updated with Latest Design News

Your Name, Surname, Email and Country

First Name (Required)

Last Name (Required)

E-mail (Required)

Country (Required) Afghanistan (AF)Albania (AL)Algeria (DZ)Andorra (AD)Angola (AO)Antigua and Barbuda (AG)Argentina (AR)Armenia (AM)Australia (AU)Austria (AT)Azerbaijan (AZ)Bahamas (BS)Bahrain (BH)Bangladesh (BD)Barbados (BB)Belarus (BY)Belgium (BE)Belize (BZ)Benin (BJ)Bhutan (BT)Bolivia (BO)Bosnia and Herzegovina (BA)Botswana (BW)Brazil (BR)Brunei Darussalam (BN)Bulgaria (BG)Burkina Faso (BF)Burundi (BI)Cambodia (KH)Cameroon (CM)Canada (CA)Cape Verde (CV)Central African Republic (CF)Chad (TD)Chile (CL)China (CN)Cocos (Keeling) Islands (CC)Colombia (CO)Comoros (KM)Congo (CD)Costa Rica (CR)Croatia (HR)Cuba (CU)Curacao (CW)Cyprus (CY)Czech Republic (CZ)Côte d'Ivoire (CI)Democratic People's Republic of Korea (KP)Democratic Republic of the Congo (CG)Denmark (DK)Djibouti (DJ)Dominica (DM)Dominican Republic (DO)Ecuador (EC)Egypt (EG)El Salvador (SV)Equatorial Guinea (GQ)Eritrea (ER)Estonia (EE)Ethiopia (ET)Faroe Islands (FO)Fiji (FJ)Finland (FI)France (FR)Gabon (GA)Gambia (GM)Georgia (GE)Germany (DE)Ghana (GH)Great Britain (GB)Greece (GR)Grenada (GD)Guatemala (GT)Guinea (GN)Guinea-Bissau (GW)Guyana (GY)Haiti (HT)Honduras (HN)Hong Kong (HK)Hungary (HU)Iceland (IS)India (IN)Indonesia (ID)Iran (IR)Iraq (IQ)Ireland (IE)Israel (IL)Italy (IT)Jamaica (JM)Japan (JP)Jordan (JO)Kazakhstan (KZ)Kenya (KE)Kiribati (KI)Kosovo (XK)Kuwait (KW)Kyrgyzstan (KG)Lao People's Democratic Republic (LA)Latvia (LV)Lebanon (LB)Lesotho (LS)Liberia (LR)Libya (LY)Liechtenstein (LI)Lithuania (LT)Luxembourg (LU)Macedonia (MK)Madagascar (MG)Malawi (MW)Malaysia (MY)Maldives (MV)Mali (ML)Malta (MT)Marshall Islands (MH)Martinique (MQ)Mauritius (MU)Mexico (MX)Micronesia (FM)Moldova (MD)Monaco (MC)Mongolia (MN)Montenegro (ME)Morocco (MA)Mozambique (MZ)Myanmar (MM)Namibia (NA)Nauru (NR)Nepal (NP)Netherlands (NL)New Zealand (NZ)Nicaragua (NI)Niger (NE)Nigeria (NG)Norway (NO)Oman (OM)Pakistan (PK)Palau (PW)Palestine (PS)Panama (PA)Papua New Guinea (PG)Paraguay (PY)Peru (PE)Philippines (PH)Poland (PL)Portugal (PT)Puerto Rico (PR)Qatar (QA)Republic of Korea (KR)Romania (RO)Russian Federation (RU)Rwanda (RW)Saint Kitts and Nevis (KN)Saint Lucia (LC)Saint Vincent and the Grenadines (VC)Samoa (WS)San Marino (SM)Sao Tome and Principe (ST)Saudi Arabia (SA)Senegal (SN)Serbia (RS)Seychelles (SC)Sierra Leone (SL)Singapore (SG)Slovakia (SK)Slovenia (SI)Solomon Islands (SB)Somalia (SO)South Africa (ZA)Spain (ES)Sri Lanka (LK)Sudan (SD)Suriname (SR)Swaziland (SZ)Sweden (SE)Switzerland (CH)Syrian Arab Republic (SY)Taiwan (TW)Tajikistan (TJ)Tanzania (TZ)Thailand (TH)Timor-Leste (TL)Togo (TG)Tonga (TO)Trinidad and Tobago (TT)Tunisia (TN)Turkey (TR)Turkmenistan (TM)Tuvalu (TV)Uganda (UG)Ukraine (UA)United Arab Emirates (AE)United States of America (US)Uruguay (UY)Uzbekistan (UZ)Vanuatu (VU)Venezuela (VE)Viet Nam (VN)Wallis and Futuna (WF)Yemen (YE)Zambia (ZM)Zimbabwe (ZW)

By clicking Sign-Up, you are opting to receive promotional emails from A' Design Awards, World Design Rankings, World Design Consortium and Designers. Org You can update your preferences or unsubscribe any time.

Org You can update your preferences or unsubscribe any time.

You are now at the right step

Join Designers.org & Start Promoting Your Design Worldwide.

Create an Account

Digital 3D printer in Orthodontics Restom

The key to the success of any medical procedure is a correct diagnosis and competent treatment planning, and modern technologies give doctors great opportunities for this and are good helpers, one of which is digital 3D printing. Dentistry is closely intertwined with innovative diagnostic methods, and three-dimensional printing fits perfectly into high-tech techniques that are actively being introduced into all aspects of dental services.

The Restom clinic complies with all modern standards of dental treatment and offers its patients treatment and diagnostic methods using modern technologies and equipment. One of such equipment is the NextDent 5100 high-precision 3D printer.

A digital printer is equipment with which our specialists can print surgical templates and accurately plan operations, create aligners for orthodontic treatment, print templates and jaw models for diagnostics and orthodontic treatment planning, print temporary orthopedic structures, print unloading mouth guards, etc.

With the advent of modern 3D printing technology, there is no longer a need to hand-make bite impressions or dental templates and then send the blanks to a laboratory where custom fixtures will be made. All manipulations carried out using a 3D printer take several hours, do not cause discomfort, and save time for both the doctor and the patient.

Equipment operation principle

There are several ways to print, we use the method of digital LED projection - DLP. DLP stands for Digital Light Processing and is one of the fastest and most accurate digital printing methods. It is based on the use of a special mirror matrix, where each of its individual elements is a microscopic mirror. The difference from other methods: in DLP printing, the layer of the working material is not drawn by rays, but is entirely projected onto a photopolymer, which makes the technology similar to stamping. Due to this, the method made it possible to maintain the high accuracy of laser technology, significantly speeding up the operation of the device.

The difference from other methods: in DLP printing, the layer of the working material is not drawn by rays, but is entirely projected onto a photopolymer, which makes the technology similar to stamping. Due to this, the method made it possible to maintain the high accuracy of laser technology, significantly speeding up the operation of the device.

Benefits of using 3D printer

- The main advantage of digital data acquisition is patient comfort. Modern equipment reduces the time from diagnosis to prescription of therapy. Virtual imaging allows Restom doctors to use a smaller number of invasive procedures, to make prostheses with high accuracy.

- Digital dentistry speeds up the treatment process, the patient will no longer have to visit the doctor multiple times, which means he will save both time and money.

- The high precision of the equipment allows to produce the most comfortable prostheses. Modern technologies will allow you to forget about repeated visits to correct prostheses, crowns, implants and other dental appliances.

Clinic "Restom" takes care of each patient, offering the most modern methods of diagnosis and treatment. Strong, healthy teeth, a snow-white smile - this is what we are fighting for in each case. And in this, Restom doctors are assisted by high-tech equipment - a 3D printer, with which we can quickly produce the necessary models, templates and designs that help make the reception better and more productive.

3D printers in dentistry

3D printers are becoming increasingly important in the work of any dental clinic, dental laboratory, research centers. With their help, dentists not only improve the quality of their products and services, but also save significant money. In addition, 3D printers in dentistry guarantee accelerated production volumes and incredible accuracy of finished products.

- How to improve your business

- Benefits of 3D printing

- How it works

- Select 3D printer

- How to improve business

- Advantages 3D prints

- How it works

- selection

as 3D-approval.

business

business 3D printers save dentists from a very complex and time-consuming process in their work - manual modeling of prostheses, crowns and other products. Clients no longer need to wait and go through the entire complex process from the first visit to the installation of the final structure, passing through a series of fittings and improvements. Now they just need to do a mouth scan - and soon get a great result.

Dental technicians usually rely on a steady hand and good eyesight, and their work is very labor intensive and takes a long time to get an acceptable result. 3D printing brings the dental business to production capacity and ensures consistent accuracy. Now you can use oral imaging and scanning to quickly design CAD/CAM and 3D print crowns, bridges, plaster models and unique orthodontic instruments.

Each client's unique tooth shape is incredibly difficult to capture with hand or milling. However, dental 3D printers make complicated and outdated manufacturing methods unnecessary. Thanks to the latest technologies and the most modern materials, you get finished products several times faster than before. But the main thing is that dental models printed on a 3D printer exactly repeat all the nuances of the original sample.

Thanks to the latest technologies and the most modern materials, you get finished products several times faster than before. But the main thing is that dental models printed on a 3D printer exactly repeat all the nuances of the original sample.

How 3D printers are improving the dental business

3D printers relieve dentists of a very complex and time-consuming process in their work - manual modeling of prostheses, crowns and other products. Clients no longer need to wait and go through the entire complex process from the first visit to the installation of the final structure, passing through a series of fittings and improvements. Now they just need to do a mouth scan - and soon get a great result.

Dental technicians usually rely on firm hands and good eyesight, and their work is very laborious and time consuming to get an acceptable result. 3D printing brings the dental business to production capacity and ensures consistent accuracy. Now you can use oral imaging and scanning to quickly design CAD/CAM and 3D print crowns, bridges, plaster models and unique orthodontic instruments.

Each client's unique tooth shape is incredibly difficult to capture with hand or milling. However, dental 3D printers make complicated and outdated manufacturing methods unnecessary. Thanks to the latest technologies and the most modern materials, you get finished products several times faster than before. But the main thing is that dental models printed on a 3D printer exactly repeat all the nuances of the original sample.

Cobalt Chromium bridge blank printed on 3DLAM Mini 9 3D printer0003

Biocompatible Resin Surgical Guide

3DLAM Mini Cobalt Chromium Bridge Blank

Biocompatible Resin Surgical Guide

Benefits of 3D Printing for Dentists

- 90 patient data in digital form, no more impressions and samples - just print the desired model on a 3D printer.

- Significantly speed up the production of the desired items.

- Fully automatic printing process that eliminates the human factor.

- Increasing production without additional staff - your customers no longer have to wait weeks for a master to become available.

/cdn.vox-cdn.com/uploads/chorus_asset/file/14690726/osteoid.0.1409422739.jpg)

- Incredible manufacturing precision - no more mistakes and no need to make new samples.

- The use of the most advanced technologies will have a positive effect on the image of your company.

Benefits of 3D printing for dentists

- You can store all patient anatomy data digitally, no more impressions and specimens – just 3D print the model you need.

- Significantly speed up the production of the desired items.

- Fully automatic printing process that eliminates the human factor.

- Increasing production without additional staff - your customers no longer have to wait weeks for a master to become available.

- Incredible manufacturing precision - no more mistakes and no need to make new samples.

- The use of the most advanced technologies will have a positive effect on the image of your company.

How it works: Using a 3D printer to make a denture

How it works: Using a 3D printer to make a denture

1.

While realized projects find opportunities to get published, reach new markets and meet a wide range of buyers for their existing products, the organization also helps the creative minds and startups to meet with the business people to realize their product ideas.

While realized projects find opportunities to get published, reach new markets and meet a wide range of buyers for their existing products, the organization also helps the creative minds and startups to meet with the business people to realize their product ideas.  For potential clients, the A' Design Award winner logo is a guideline for finding the best designs and creative services within the marketplace. Learn about the benefits here.

For potential clients, the A' Design Award winner logo is a guideline for finding the best designs and creative services within the marketplace. Learn about the benefits here.