3D printing signage

3d Printed Signs - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D Printing in Signage and Retail

3D Printing in Signage and Retail - 3D printed signsThe next generation of technology is transforming marketing and the way advertising & themed environments are created. 3D printing in signage and retail will change the whole market. With large format 3D printers super-sized objects for retail, staging, display, events and architectural design can be produced. Objects can be fabricated in any size and shape without the restrictions of traditional methods. Above all 3D printing in signage and retail provides the opportunity to create stunning eye-catchers.

Requirements of 3D Printing in signage and retail

Strength

With a single 3D printed object, greater strength can be accomplished. This is due to the perimeters encapsulating the entire object and passing loads throughout without disruptions in the path. The Infill that is inside also assists in taking the load and spreading it through the entire print and thus reducing stress concentrations. This enables prints to be exceptionally strong in compression, and to a lesser degree, tension. Depending on the infill rates used on a print, the forces necessary to cause damage might be well in excess of what an average adult could exert.

No Assembly Required

When talking abou 3D Printing in signage and retail, there are numerous instances where 3D printed objects are glued, melted, or mechanically held together to form bigger pieces. One of the qualities of being able to print in a seriously large format is that pre- and post-processes can be eliminated. When printing smaller pieces for an item that will be assembled, there may need to be design work to add pegs and keys assist pieces in locking together. On the other hand, utilizing glues and other methods are time consuming and not always simple. The ability to fabricate a big object in one go helps to simplify the manufacturing process and save time.

Life size

We’ve seen 3D printers make everything from toys to jewelery to food, but the signage and retail industry needs bigger. So big, in fact, that this industry demands 3D printers that can print entire pieces of furniture and sculptures. In addition channel letters, tables, lamps, action figures and mannequins all fit into the idea of life size 3D printing in signage and retail.

Practical Functionality

In addition to the life size benefit of large format 3D printing in signage and retail, practical functionality is also a key perspective. For instance, to scale models of hand-held gadgets, toys, newly designed point of purchase displays, and many more items are useful for sales and visualization purposes.

Expanded creativity and capability

Many more details can be expressed or replicated in a piece that is large. For instance, there have been several artists who have made pieces over 20 feet long by incorporating 3D printing into their skillset. Sculptures of dinosaurs with fantastic skin detail have been cast by a lost wax process after using 3D printed pieces as the base of the work. Full size busts of persons have been printed as well as spaceship simulators and functional robots. The possibilities for creating new items is endless!

- ✓ Real large volume

- ✓ Unique designs

- ✓ Endless creativity

Common applications of 3D Printing in signage and retail

Soft Signage – frames

Soft signage, digital textile printing, is a fabric graphic inserted into a frame. Traditionally these frames are created out of aluminum, wood, acrylic, and steel. With today’s technologies, why not 3D printed? After 3D printing the frame you can finish it with lighting to make it stand out even more. When you have a LARGE VOLUME series 3D printer which is able to create huge designs, this opens up a world of possibilities.

Traditionally these frames are created out of aluminum, wood, acrylic, and steel. With today’s technologies, why not 3D printed? After 3D printing the frame you can finish it with lighting to make it stand out even more. When you have a LARGE VOLUME series 3D printer which is able to create huge designs, this opens up a world of possibilities.

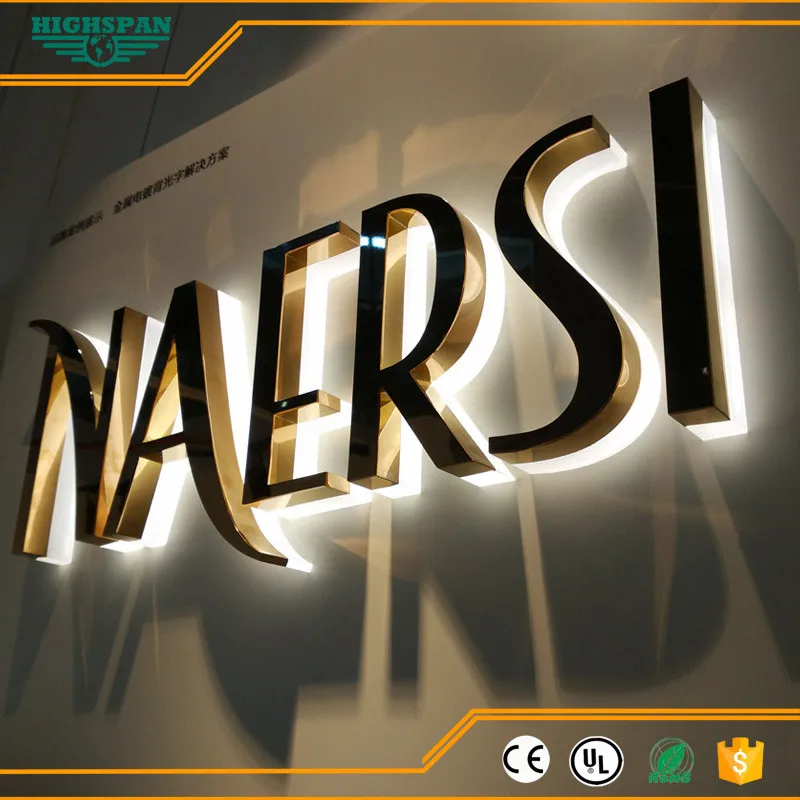

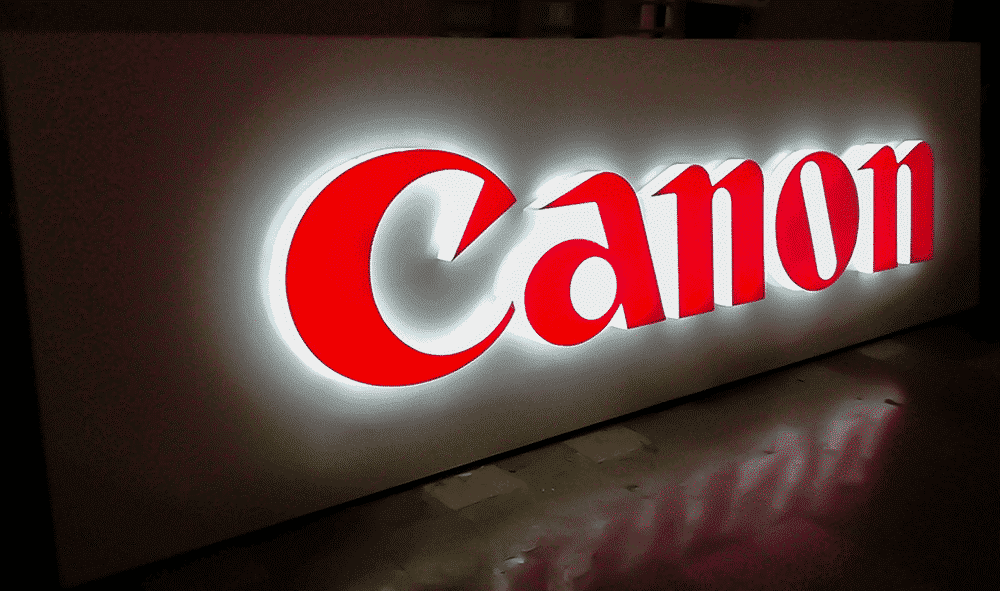

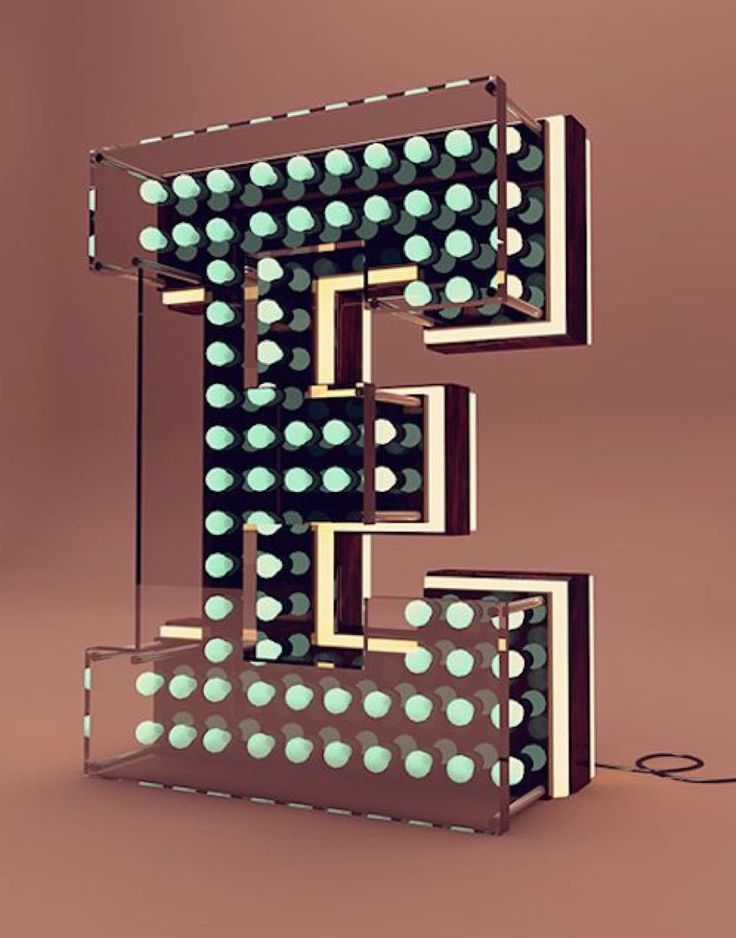

Branding with channel Letters

Channel letters are the number one choice in exterior signage on public and commercial buildings. It can also be used to attract customers to an exhibition stand or decorate the interior of a store. These custom-made letters are made out of metal or plastic and often internally illuminated. 3D printing channel letters on demand with a large format printer will save a lot of time and money compared to traditional methods.

Read up on our case of Styles Werbetechnik, who specializes in channel letters

Ornaments and Architecture

Through the introduction of large volume 3D printing, the architecture industry has changed. The ability to create large objects using 3D printing will simplify construction and renovation projects. They can take on a completely new identity thanks to the ability to 3D print large structures, for example ornaments. Ornaments no longer have to be handcrafted, significantly reducing labor costs as well as material costs (since it is made of plastic).

The ability to create large objects using 3D printing will simplify construction and renovation projects. They can take on a completely new identity thanks to the ability to 3D print large structures, for example ornaments. Ornaments no longer have to be handcrafted, significantly reducing labor costs as well as material costs (since it is made of plastic).

Interior Decor

A large volume 3D printer enables people to 3D print lamps, tables, chairs, etc. Designers now have the ability to create interior decor on the spot. First they will make a digital design of the decor and after that they can make it reality by 3D printing it.

Custom Sculptures of Mannequins for Retail

People are no problem to 3D print. Celebrities, football players, catwalk models, you name it, can be printed. Large volume 3D printing allows for entirely customized campaigns. One of our clients is 3D printing entire fashion mannequins for their retail customers.

Light your world

You can print entire lamps in one piece with a large format 3D printer. Tractus3D printers in combination with the 3D printing software Simplify3D enables you to print a hollow object to fit the light bulb without any problems.

Tractus3D printers in combination with the 3D printing software Simplify3D enables you to print a hollow object to fit the light bulb without any problems.

Point of Purchase Displays

3D printers are used in retail to manufacture point-of-purchase stands like exhibition kiosks and displays. This is down to the flexibility of 3D printing and the wide range of colors of the printable materials (filaments).

Exhibition Designs

When organizing special events you can distinguish yourself with a large format 3D printer. They are ideal to produce parts of exhibition designs or props to impress visitors. For example create your own 3D printed guest in a life-size sculpture or action figure like Batman, to amaze everybody.

As you can imagin, these new ways of 3D Printing in signage and retail, will change everything.

3D printers used in signage and retail

T3500SE

T3000SE

Copyright 2020 Terms of agreement Privacy statement

Printing advertising signs on a 3D printer.

Order 3D printing

Order 3D printing Now it is difficult to surprise someone with a bright unusual sign, and thereby attract the attention of buyers. In Russian cities, flashy banners are everywhere, inviting potential customers to purchase goods here. Ordinary posters, even large ones, may simply not be noticed in this ubiquitous cycle of advertising.

3D printing of advertising signs - a solution

In order to increase sales, I thought about creating an unusual sign. I wanted to see aesthetic, but at the same time eye-catching advertising on the building of my store.

The decision came unexpectedly. I was visiting my friend and saw how his son was drawing some figure with a 3D pen. The baby, of course, did not look like a dinosaur. At first I did not even understand what he was trying to portray. But still, printing with 3D pens is an interesting and fun thing for a child.

And at that moment it dawned on me - I need to contact a 3D printing services company. I used to hear that absolutely everything is printed on a 3D printer - from towel hooks to real houses. But I had never been able to use 3D printing before, so at first I didn’t even expect high results.

But I had never been able to use 3D printing before, so at first I didn’t even expect high results.

How the letters were printed

In a short period of time, my order was executed just fine. Printing was carried out with consumables of different colors, so it turned out very beautiful and creative. The shape of the letters turned out exactly according to my wishes, and the decor exceeded all expectations. According to my idea, the letters should have been framed by curved lines with a fancy pattern.

The employees of the company allowed me to be present at the creation of my sign. We agreed on the design, letter size and additional elements. First, the specialists brought all these parameters to a computer, created a three-dimensional model in digital format. Then, according to the specified conditions for the operation of a 3D printer, the equipment gradually recreates a real object.

The guys did a great job - it turned out the perfect sign for my store. I was pleased with the result. Looking ahead, I can say with confidence that three-dimensional letters stand out perfectly from the rest of the advertisement.

I was pleased with the result. Looking ahead, I can say with confidence that three-dimensional letters stand out perfectly from the rest of the advertisement.

Now I always use 3DMall if I need some kind of promotion. In particular, I order logos, notify with the help of signs printed on a printer about ongoing promotions, discounts, and the arrival of new goods. And people really began to come more often.

Over time, I decided to modernize the "face" of my store. I ordered volumetric luminous letters. I attached the name of my outlet to a light box with a wave shape and a day-night film. It turned out to be an unreal spectacular spectacle. Now on the busiest street, my sign stands in stark contrast to the rest of the store ads. As a result, there are more and more buyers, sales are growing, profits are increasing.

My conclusion after using 3D printing services: 3D printed advertising signs are the best solution to make your business stand out among thousands of others. There are many options for printing outdoor advertising. On a 3D printer, you can print signs in any format and design.

There are many options for printing outdoor advertising. On a 3D printer, you can print signs in any format and design.

The advantages of 3D printed 3D outdoor advertising also include low price. Specialists offer a huge selection of consumables from which a sign is made: plastic, gypsum, polymers, etc. An unusual approach using a three-dimensional printer allows not only to convey the shape of future objects, but also to present them in a more favorable light, endow them with brightness and individuality.

You can send a request for the calculation of the cost of printing letters in the 3D printing section - GO

Large 3D letters and signs on a small 3D printer "RUSSIA" - 2 meters!

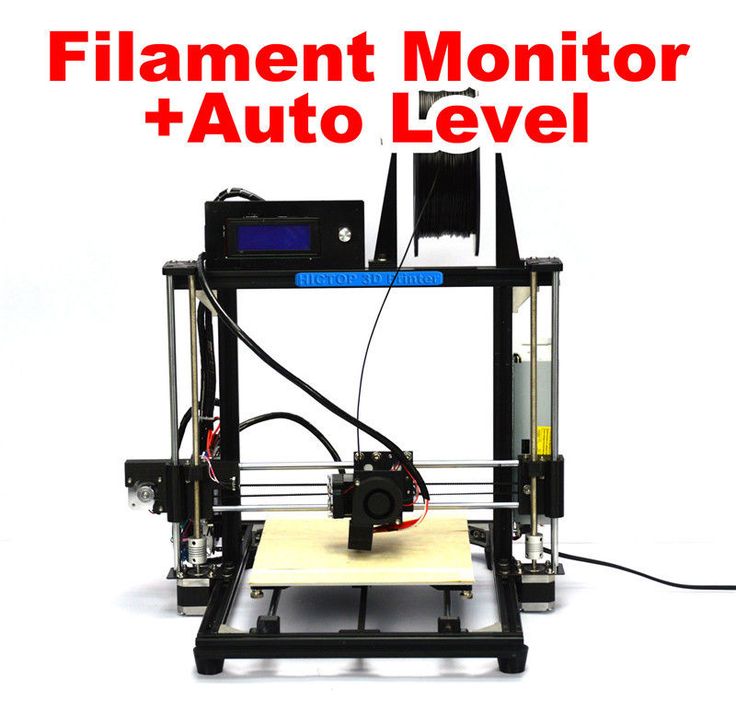

It's no secret that if a printed 3D model is larger than the printer desktop, then this model is divided into parts, printed in separate elements and glued together. At the same time, seams are visible on the final glued model, which have to be further processed, and possibly putty and painted - all this is a rather laborious, complex and dirty process, where post-processing experience is important. In this regard, printing models that are much larger than the working area of the printer on a commercial basis is quite a risky business, with no guarantee that time, effort and material will not be wasted. In fact, prototyping and manufacturing of broken plastic parts of mechanisms (gears, various latches) remain the most common sources of income on a 3D printer - something that usually does not exceed the size of a 3D printer table in its dimensions.

In this regard, printing models that are much larger than the working area of the printer on a commercial basis is quite a risky business, with no guarantee that time, effort and material will not be wasted. In fact, prototyping and manufacturing of broken plastic parts of mechanisms (gears, various latches) remain the most common sources of income on a 3D printer - something that usually does not exceed the size of a 3D printer table in its dimensions.

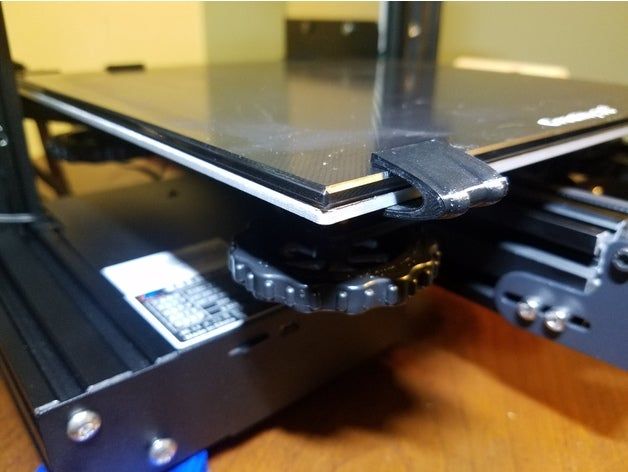

In fact, there is a simple way to avoid the steps of mechanical finishing of the seam, putty and painting, and get printed parts from under the printer, in which the seam will not be visible after gluing. And all that needs to be done is to mask the seam in a certain way at the design stage of the 3D model.

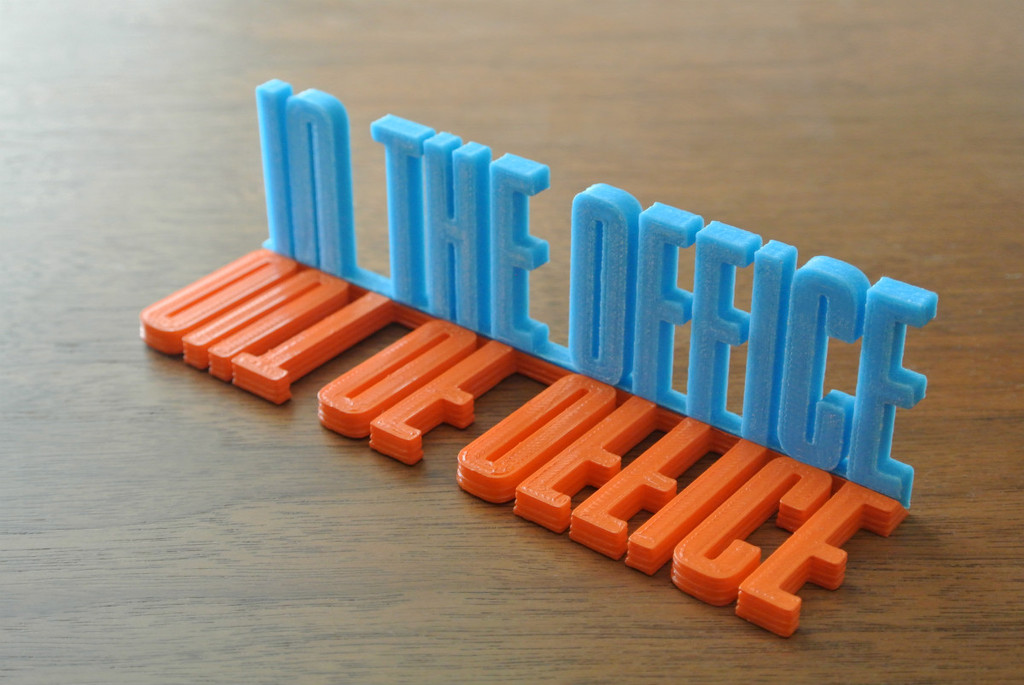

To demonstrate the method, I designed two signs that I printed with Pet-g ABS Maker plastic. "REMIX" signboard - small, total length 70 centimeters, and "RUSSIA" signboard - total length of composition 2 meters.

On the example of the REMIX sign, it is very easy to understand how this is done and how it looks when finished.

When designing "REMIX", the black and red letters fit into the size of the 3D printer's table (20x20cm). The red stripes inside the "M", as well as between the "I" and "X" were easily placed in their entirety. The red shelf under "RE" goes beyond the printable area and had to be split into two elements (pictured below). And in order to hide the seam, false decorative repeating elements were made during modeling, and in one of them the model was divided into two parts. An important feature of the decorative elements-cutouts (1) is that when modeling, they must be lowered by at least 2 mm in order to form a shadow that masks the cut of the model. Also, an important condition is the cutout on the visible end (2) of the model.

After printing, if you fold the entire shelf, the seam is completely invisible.

Signboard "RUSSIA" - harder. In it, each letter is a unique pattern and a way to hide a seam, from simple to more complex. This is a great example for demonstrating to customers various options for making 3D letters on a 3D printer. The size of the letters is approximately 25X25 cm, which, for a better demonstration of the technique, I divided into 4 parts. The height of the letters is 4 cm.

So, in order.

Letter "P" (total plastic weight 412 g). Developed a design in such a way that where we need to cut the letter, a small striped pattern is superimposed, not entirely on the entire letter, but only in the seam area. As in the example with "REMIX", simple front (1) and end (2) cutouts are used here, with which everything is perfectly masked.

Letter "O" (total plastic weight 378 g). In this case, I put a large geometric pattern on the entire letter and extruded different sections at different levels. The geometric shapes of the pattern are also separated by grooves that extrude below all shapes. And all this is accompanied by end cutouts.

The geometric shapes of the pattern are also separated by grooves that extrude below all shapes. And all this is accompanied by end cutouts.

The first letter "C" (total plastic weight 473 g). It is made with the design of separate strips, along the edges of which the model is separated.

Second letter "C" (total plastic weight 273 g) . More difficult option. This letter is formed by two geometric patterns superimposed on top and bottom. Further, these drawings randomly flow into one another (in separate areas), and in the middle of the letter a common body is formed. At the same time, in order to build up the body of the letter, many such overflows are needed. For example, several lower ones flow into one upper triangle. The photo also shows pseudo stripes between the triangles, in some of them the separation of the model is carried out. It is worth noting that such a model cannot be made in any way other than 3D printing, and I assume that this is the main competitive advantage of printing signs on a 3D printer.

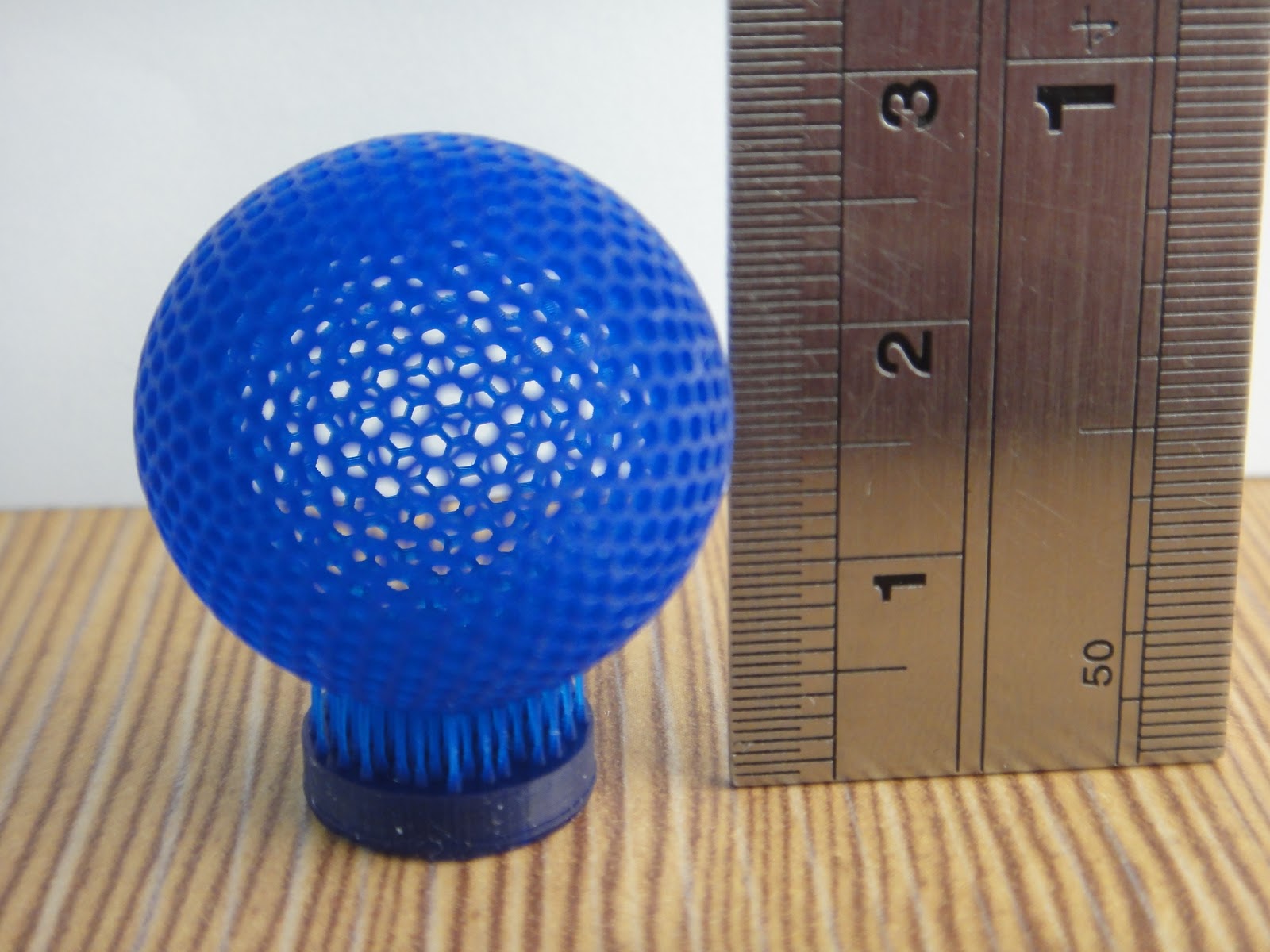

Letter “I” (total plastic weight 517 g). Its production, as well as the second letter "C", is possible only with the help of 3D printing. Designed it in the following way. I applied the same geometric “honeycomb” pattern above and below, then in a chaotic manner one lower “honeycomb” flows into one upper one. In some places these columns intersect and merge. Since the columns are made in a separate figure, this letter is very easy to cut anywhere.

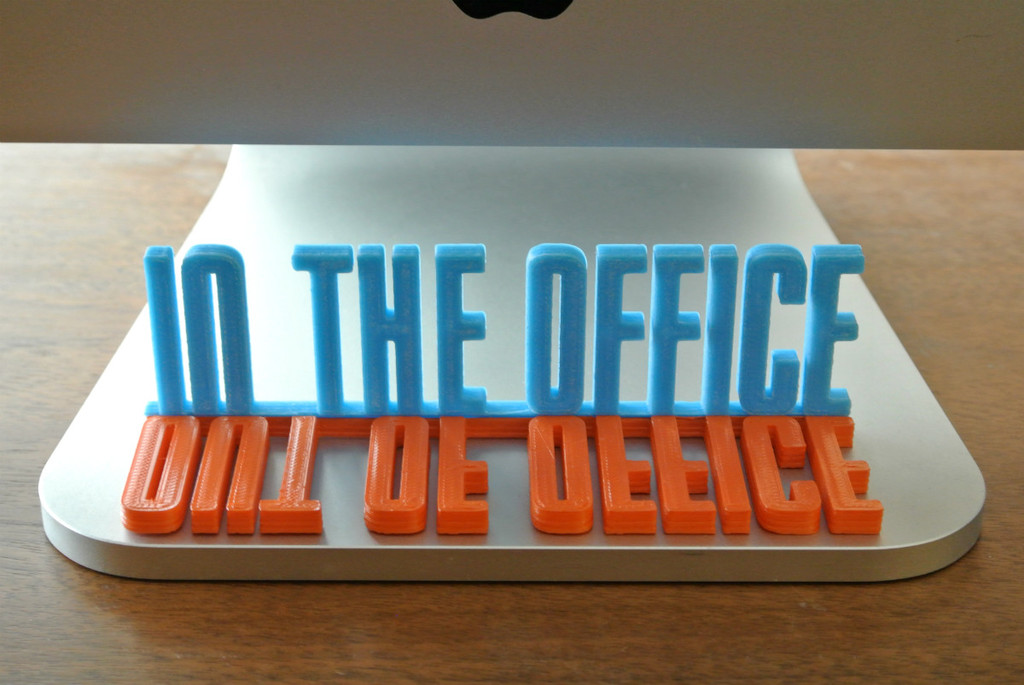

Letter "I" (total weight of plastic 375 g). In this letter, the division into parts is masked by the printing of these parts from plastic of different colors. Visually, the cut within the boundaries of the color change does not focus attention, and in general, everything looks the same. Additionally, on one of the blue parts of the letter, there is a simple decorative embossed design, just for beauty.

3D Flag (total plastic weight 822 g). Divided into six parts. The separation is implemented in two ways - by color and by a decorative pattern, as in the "REMIX" sign.

Divided into six parts. The separation is implemented in two ways - by color and by a decorative pattern, as in the "REMIX" sign.

Of course, not everything turned out so easy and simple the first time, a lot of plastic went to waste - a common thing in samples and experiments ...

But, having collected everything in a single composition, certain thoughts appeared regarding the work done. Making signs and volumetric letters of any size and shape using 3D printing is not difficult. Added to this is the predictable production time and the lack of post-processing, which, in principle, makes sign printing commercially viable. And in view of the fact that with the help of 3D printing it is possible to realize large three-dimensional compositions with interesting three-dimensional shapes, then their competitive advantages appear.

In general, it is worth paying attention to the standard technologies for manufacturing letters and signs. They are usually made with a milled acrylic top and PVC sidewalls. The whole thing is glued together. Additionally, surfaces can be pasted over with a colored film. There is also another technology, when the sidewalls are assembled from a specialized flexible profile. Therefore, in my examples, I tried to make letters different from the typical ones that advertising agencies offer on the market. And of course, it didn’t make it too complicated so that it would be easy to repeat them on the most common printer with a print area of 200x200X200mm.

They are usually made with a milled acrylic top and PVC sidewalls. The whole thing is glued together. Additionally, surfaces can be pasted over with a colored film. There is also another technology, when the sidewalls are assembled from a specialized flexible profile. Therefore, in my examples, I tried to make letters different from the typical ones that advertising agencies offer on the market. And of course, it didn’t make it too complicated so that it would be easy to repeat them on the most common printer with a print area of 200x200X200mm.

Pet-g plastic showed excellent shrinkage performance. All models were designed without additional allowances and gaps. All components connected without problems. Given the heat resistance and excellent interlayer adhesion. The letters printed with Pet-g are stronger than those printed with the conventional method. But are such strong letters necessary? You have to think…

The cost of equipment - 10 printers cost about the same as a cheap portal mill. On 10 3D printers, you can quickly produce signs without any labor costs. As an example: each letter from the "RUSSIA" signboard was made in approximately 24 hours, that is, on 10 printers in one day you can get the entire signboard, glue it in 15 minutes - and the order is ready for shipment. This is quite productive and quite competitive in comparison with the technology of milling, manual assembly and pasting with a film.

On 10 3D printers, you can quickly produce signs without any labor costs. As an example: each letter from the "RUSSIA" signboard was made in approximately 24 hours, that is, on 10 printers in one day you can get the entire signboard, glue it in 15 minutes - and the order is ready for shipment. This is quite productive and quite competitive in comparison with the technology of milling, manual assembly and pasting with a film.

In addition, with this technique, it is possible to easily implement letters with different backlighting options, for example, by combining 3D printing technology and milling acrylic for LED backlighting.

By also using the interchange printing method, 3D printed letters can gain even more competitive advantage.

Additional information:

PS: I will upload the files to my profile, the link will be in the comments to the article. The archive contains the letters of the composition "RUSSIA" not only in STL format, but also in STEP format, all the geometric drawings that I used when designing letters in the CDR format of version 12 of CorelDRAW.