Learn about 3d printers

What is 3D printing? How does a 3D printer work? Learn 3D printing

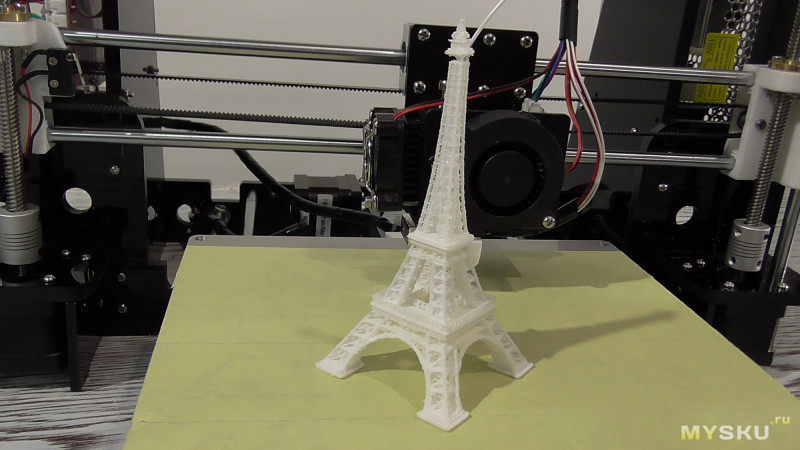

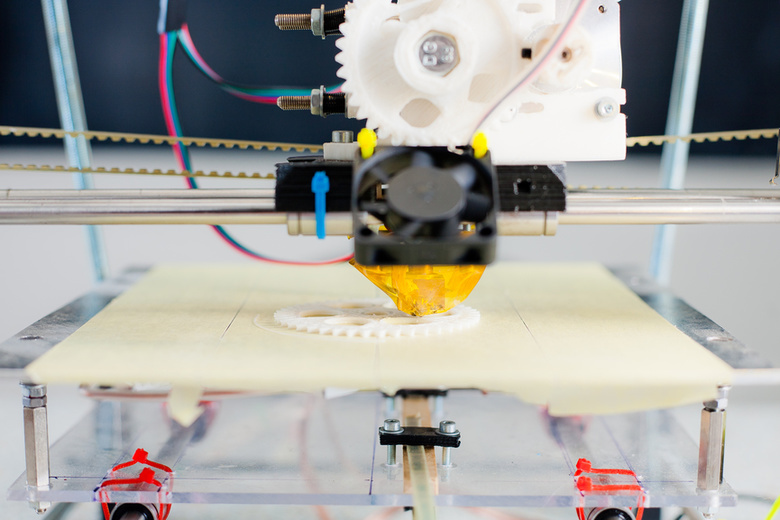

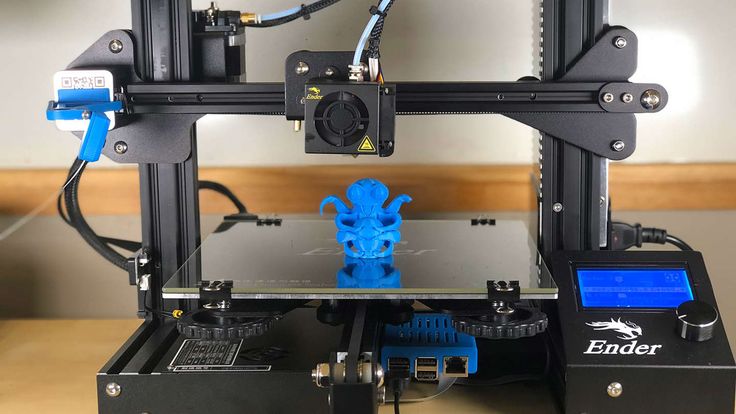

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

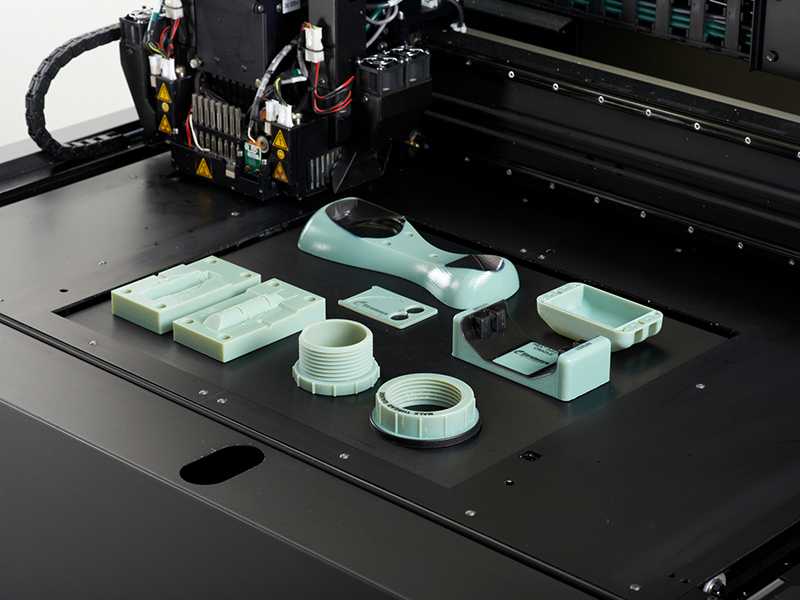

Rapid Prototyping & Rapid Manufacturing

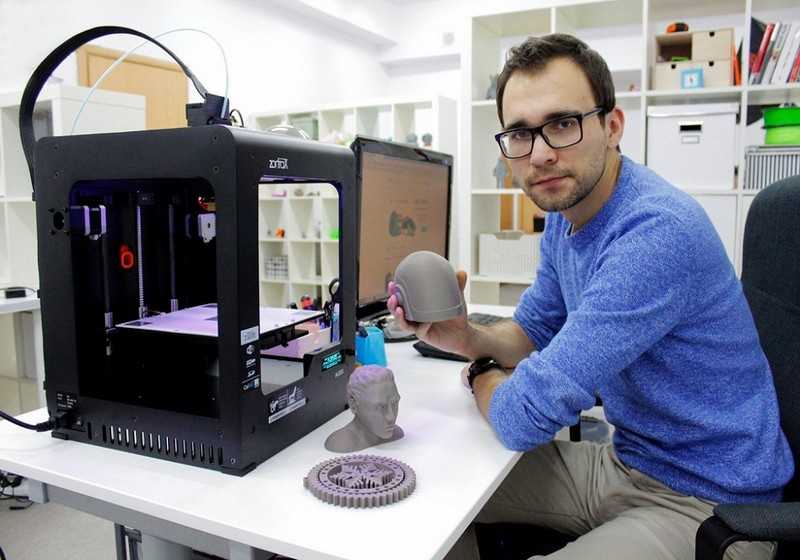

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

Aviation loves additive manufacturing, largely due to the promise of lightweight and stronger structures offered by 3D printing. We’ve seen a whole bunch of innovations in the domain of aviation lately, with the appearance of more critical parts being printed.

Turbine Center Frame

One such large component printed this year was the turbine center frame which was printed by GE as part of the EU Clean Sky 2 initiative.

The Advanced Additive Integrated Turbine Centre Frame (TCF) is a 1 meter diameter part printed in nickel alloy 718 by GE and a consortium from Hamburg University of Technology (TUHH), TU Dresden (TUD) and Autodesk. It is one of the largest single metal parts printed for aviation.

Big turbine center frame. (Image credit: GE AAT Munich)Typically components like this are manufactured using casting, and consist of multiple parts. In the case of the 3D printed version, it was reduced from an assembly of 150 parts down to just 1 single piece. The printed version also benefits from a reduction of both cost and mass by 30%, and a reduction in lead time from 9 months to just 10 weeks.

In the case of the 3D printed version, it was reduced from an assembly of 150 parts down to just 1 single piece. The printed version also benefits from a reduction of both cost and mass by 30%, and a reduction in lead time from 9 months to just 10 weeks.

Metal Parts Certified by EASA

Back in June 2022 it was reported that Lufthansa Technik and Premium AEROTEC had created the first load-bearing metal part that had been approved for use in aviation.

The new A-link was produced using LPBF and had demonstrated higher tensile strength compared to the traditionally-forged version.

The part was made at Premium AEROTEC’s facility in Varel, Germany, and a large number of test parts were printed and tested to ensure quality and repeatability for certification.

Printed titanium A-links (Image credit: Lufthansa Technik)Printing the part represented a cost saving for the component and set the stage for using this manufacturing method for creating structurally important metal parts in the future. It was also used to test the process and to demonstrate the certification process of load-bearing AM parts.

It was also used to test the process and to demonstrate the certification process of load-bearing AM parts.

Hypersonic Fuel Injector

This next printed item was never destined to be fitted to an aircraft, but rather it was designed to be installed in a facility for testing flow conditions at hypersonic speeds.

When flying in the hypersonic flight regime above (Mach 5), the air passing around the vehicle becomes incredibly hot, and the pressure increases significantly. These conditions can cause the air itself to become chemically reactive, which causes issues for fuel burning vehicles.

Simulating flow conditions with CFD is computationally expensive (if not impossible), and so to replicate the flow conditions, researchers at Purdue fabricated a giant burner to recreate the hot, fast, high pressure experienced in hypersonic flight. In short, they basically built a rocket nozzle and they placed the test components in the exhaust plume to see how they performed.

The injectors that they printed feed fuel and air into the combustion chamber to create specific turbulent flow fields and a stable flame.

The injectors were printed with Hastelloy X, which is a superalloy with superior temperature resistance. The team printed multiple different injectors in rapid time, and tested them all in the burner to see which performed the best.

Now they are able to replicate the hypersonic conditions for flight on Earth at a fraction of the cost (and risk) associated with doing it miles above the Earth’s surface. This can benefit fast aircraft such as scramjet powered vehicles as well as space vehicles.

Relativity Space

We have covered US-based rocket printing company Relativity Space quite a lot on this website.

From their super large metal printer the “Stargate” to the rocket themselves, this company has been doing big things with both printing and rockets. The 4th gen Stargate 3D printer is capable of printing objects measuring 120ft long and 24ft in diameter, and 12x faster than their previous printers.

The 4th gen Stargate 3D printer is capable of printing objects measuring 120ft long and 24ft in diameter, and 12x faster than their previous printers.

The new AI-assisted robotic printer has been able to achieve faster printing speeds thanks to its innovative multi-wire print head. This print head allows for multiple metal feedstock wires to be fed into it at the same time, resulting in higher deposition rates.

The company is scheduled to make their first LEO test flight of the printed Terran-1 rocket this month of January 2023, so we just thought we would give them an honorable mention in this article as a reminder.

You can see the Terran-1 undergoing a hot fire test in the video below.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

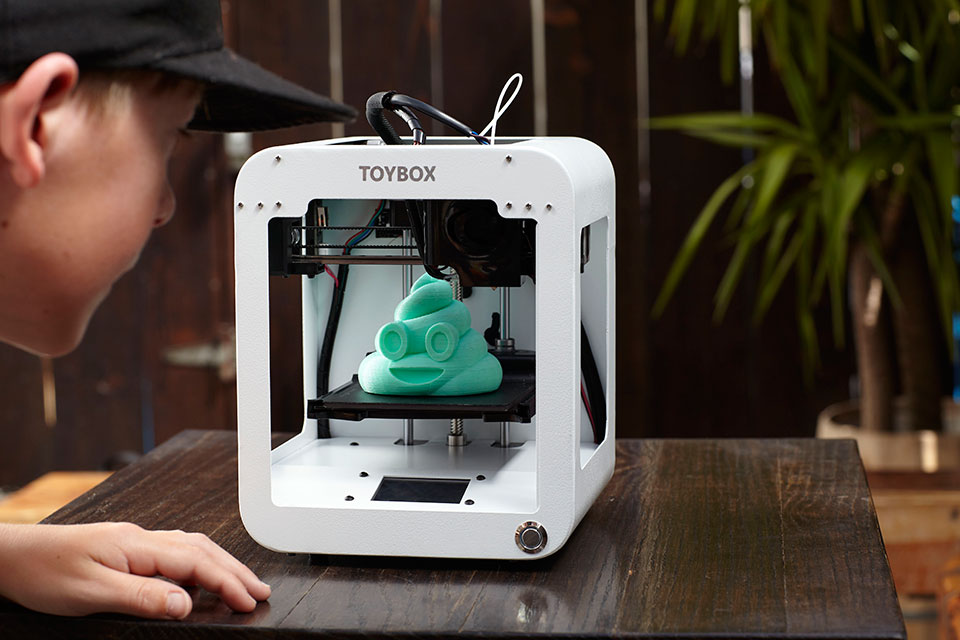

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

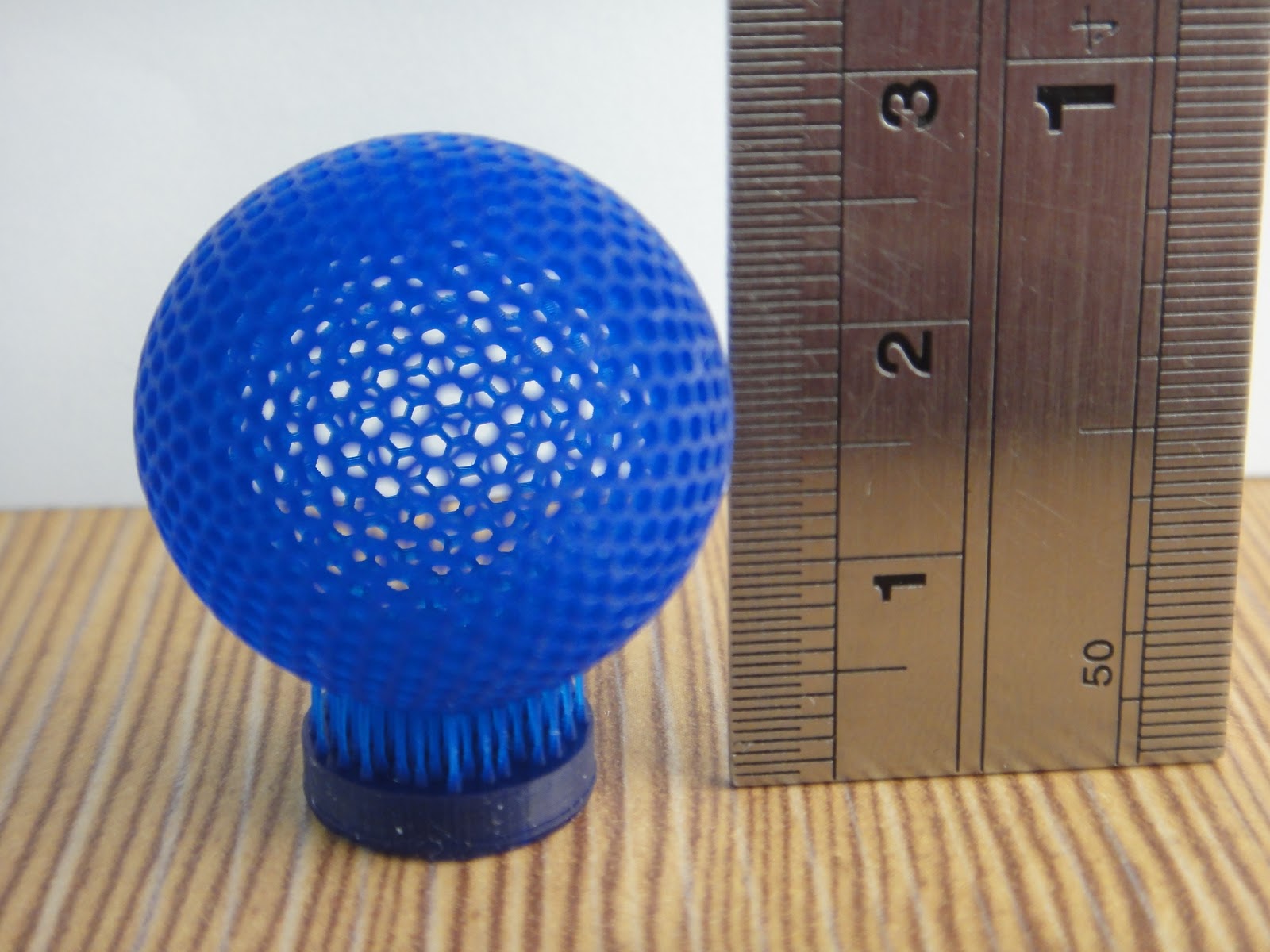

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. It is estimated that 99% of hearing aids manufactured are made with the use of additive manufacturing, and it’s clear to see why.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

Crowns and dentures are already directly 3D printed, along with surgical guides.

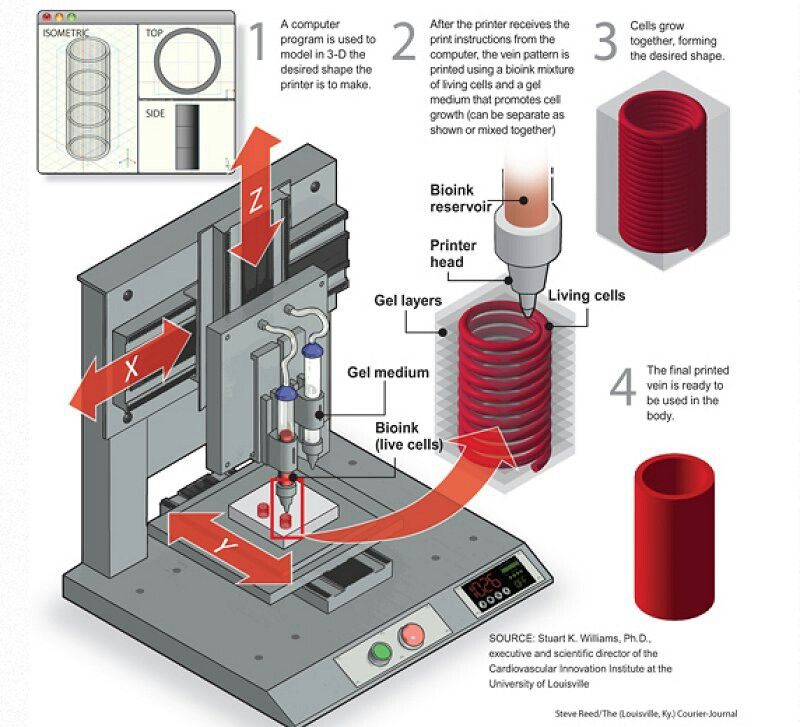

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

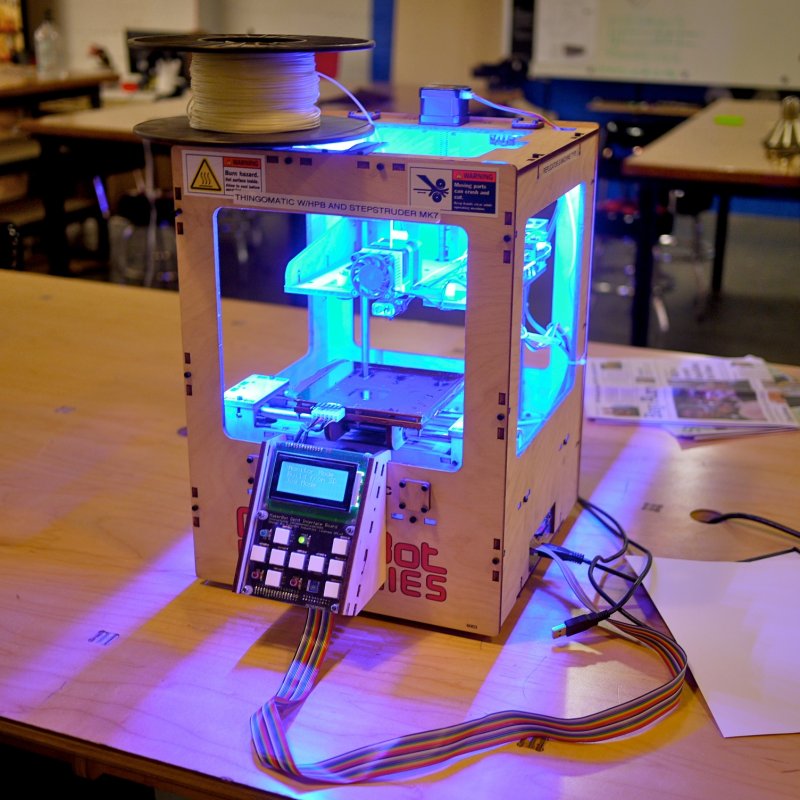

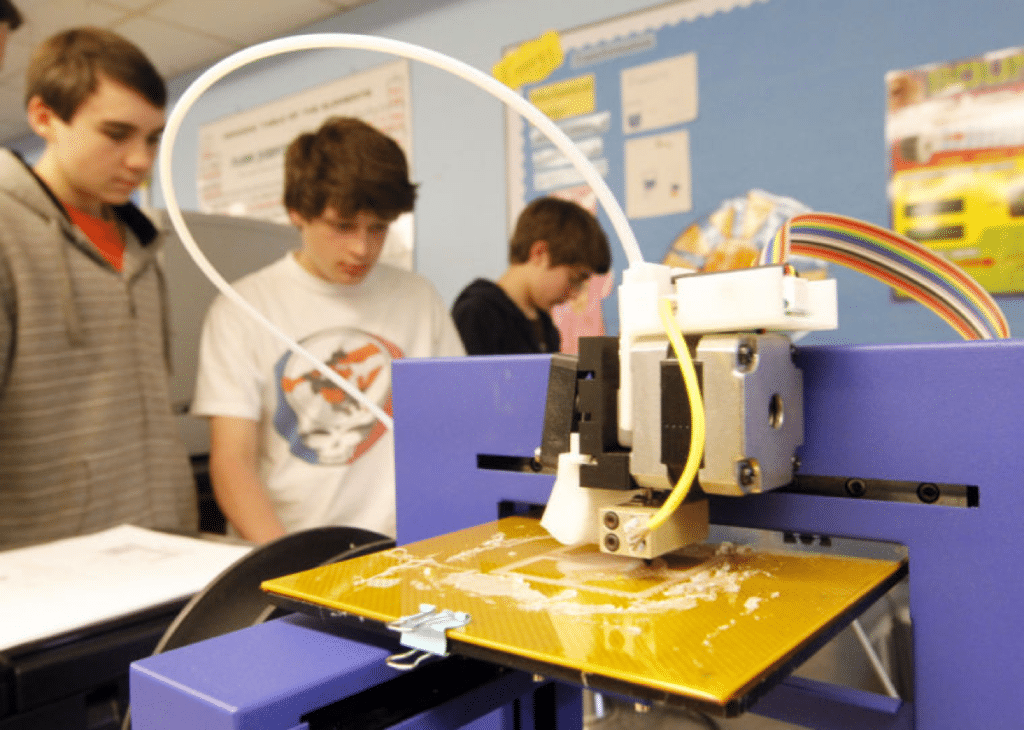

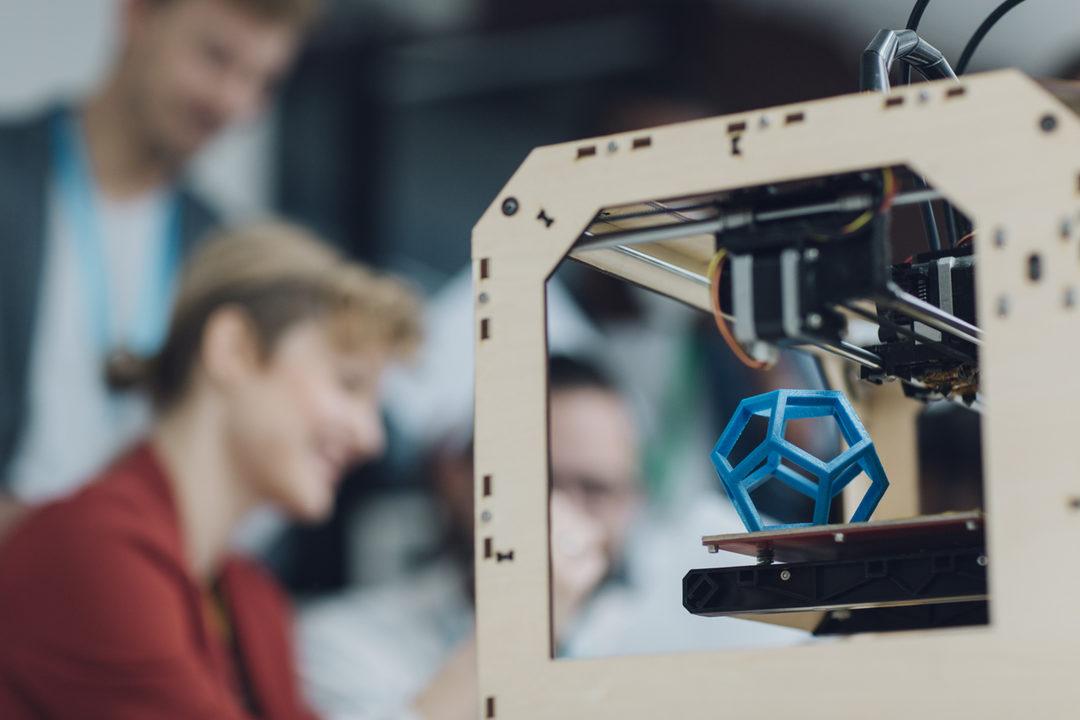

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

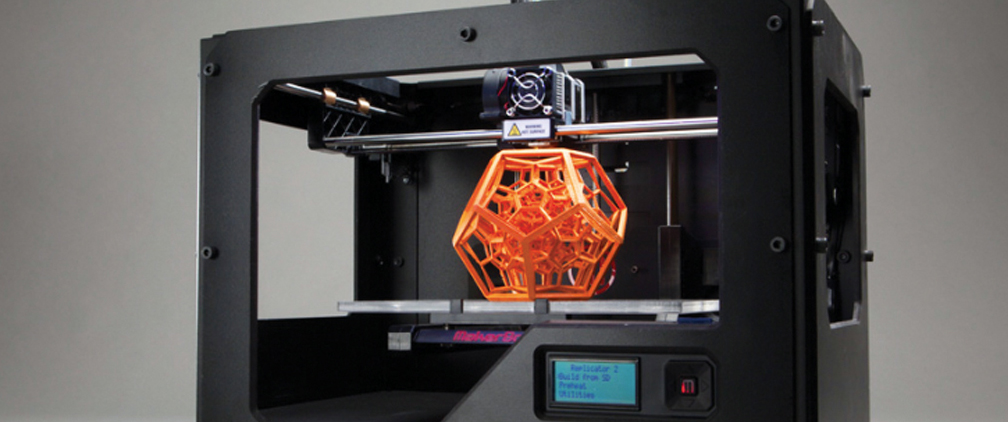

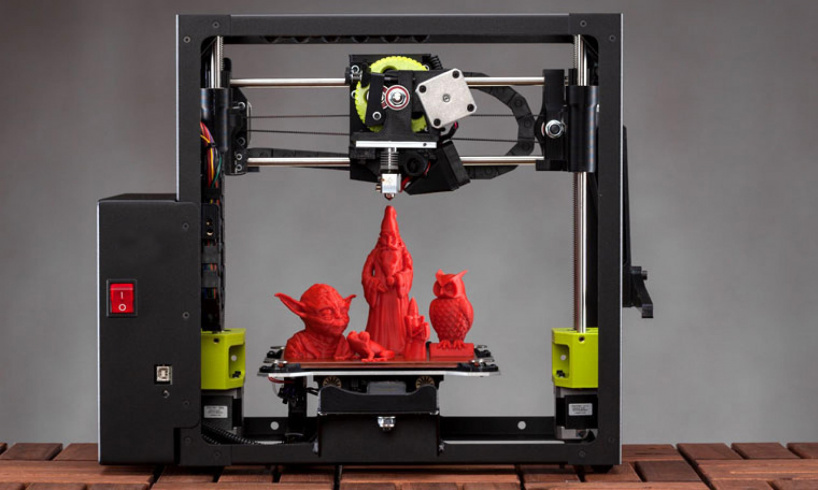

Fused Deposition Modeling (FDM)

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

The 10 Best Blogs and Websites to Learn 3D Printing

3D printing is a fascinating technology that has exploded in popularity over the years. As people read more about 3D printing, they tend to become more interested in making their own 3D printed products.

But where can you go for information about 3D printing? Well, many great blogs and websites can teach you everything you need to know. Here, we will list some of the best resources to learn 3D printing all by yourself. So, let's get started.

So, let's get started.

All3DP is a website that provides information and resources on 3D printing. The site includes articles, tutorials, and a reviews section where they review 3D printers and 3D modeling software. The company was founded in 2014 in Germany. Since then, All3DP has become one of the leading websites for 3D printing information and resources.

The website has a "Basics" section where you can learn the fundamentals of 3D printing and a "Pro" section where you can dive into more advanced topics. The site also allows users to read their content in five different languages: English, Dutch, French, Spanish, and Portuguese.

All3DP also includes its own online 3D printing service, CraftCloud, where one can request custom parts wherever you are. Whether you are designing strong 3D models or just simple ones, and you want to 3D print but don't have a 3D printer, you can simply use CraftCloud. The company will deliver your design to your doorstep.

In addition to articles and tutorials, All3DP offers reviews of 3D printers and software and a buyer's guide to help users find the best 3D printer for their needs. Overall, the site is an essential resource for anyone interested in learning about or getting started with 3D printing.

Overall, the site is an essential resource for anyone interested in learning about or getting started with 3D printing.

Sculpteo is a 3D printing service that offers businesses and individuals an easy and affordable way to create custom 3D-printed products. Sculpteo also offers a wide range of finishing options, such as painting, plating, and anodizing, that can help to develop unique 3D-printed products.

In addition to being a 3D printing service provider, Sculpteo is an excellent resource for learning 3D printing. The site has a "Material Guide" section where users can learn about 3D printer filaments and the various 3D printing technologies available.

Sculpteo also has a "Resources" section, a blog category where they publish helpful content on 3D printing. Additionally, you can also download 3D printing ebooks for product development, general 3d printing knowledge, the material selection guide, and a complete surface finish guide.

Ultimaker is an excellent resource for those looking to get the most out of their 3D printer. The blog covers many articles, from beginner tips to advanced techniques. Whether you want to learn about the different types of filaments available or how to troubleshoot common printing problems, the Ultimaker blog has you covered.

The blog covers many articles, from beginner tips to advanced techniques. Whether you want to learn about the different types of filaments available or how to troubleshoot common printing problems, the Ultimaker blog has you covered.

The website has a "Learn" section where you can read about customers' success stories in 3D printing and get some inspiration. You can also watch free webinars for 3D printing and improve your knowledge.

Ultimaker also offers online courses via its 3D Printing Academy, where you can enroll and learn the essentials of Ultimaker printers, materials for 3D printing, firmware, and slicers like Cura. You can also subscribe to the podcast on their website and learn how far additive manufacturing has reached and its impact.

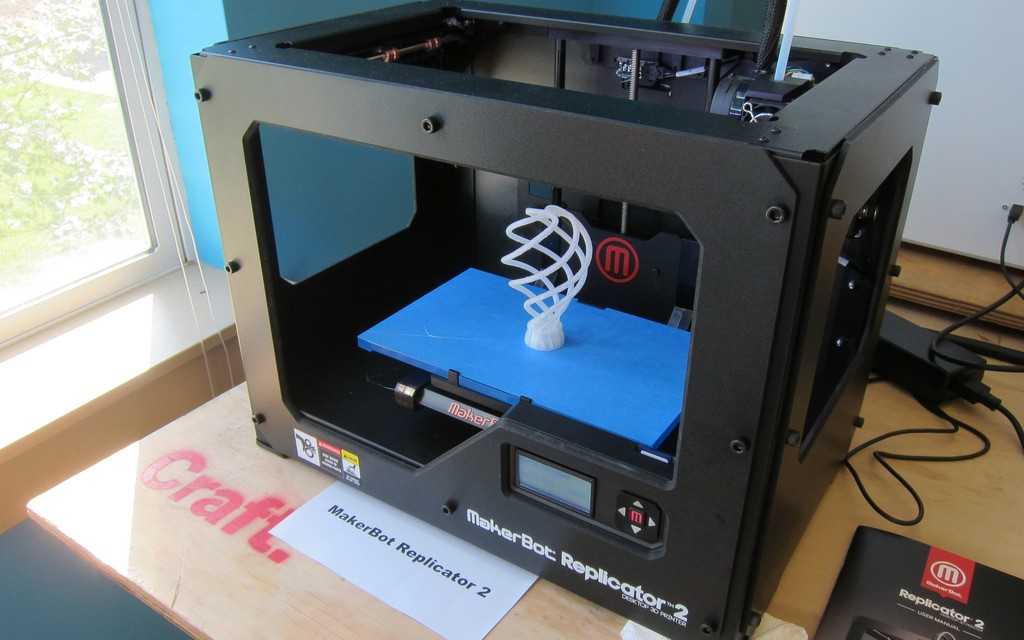

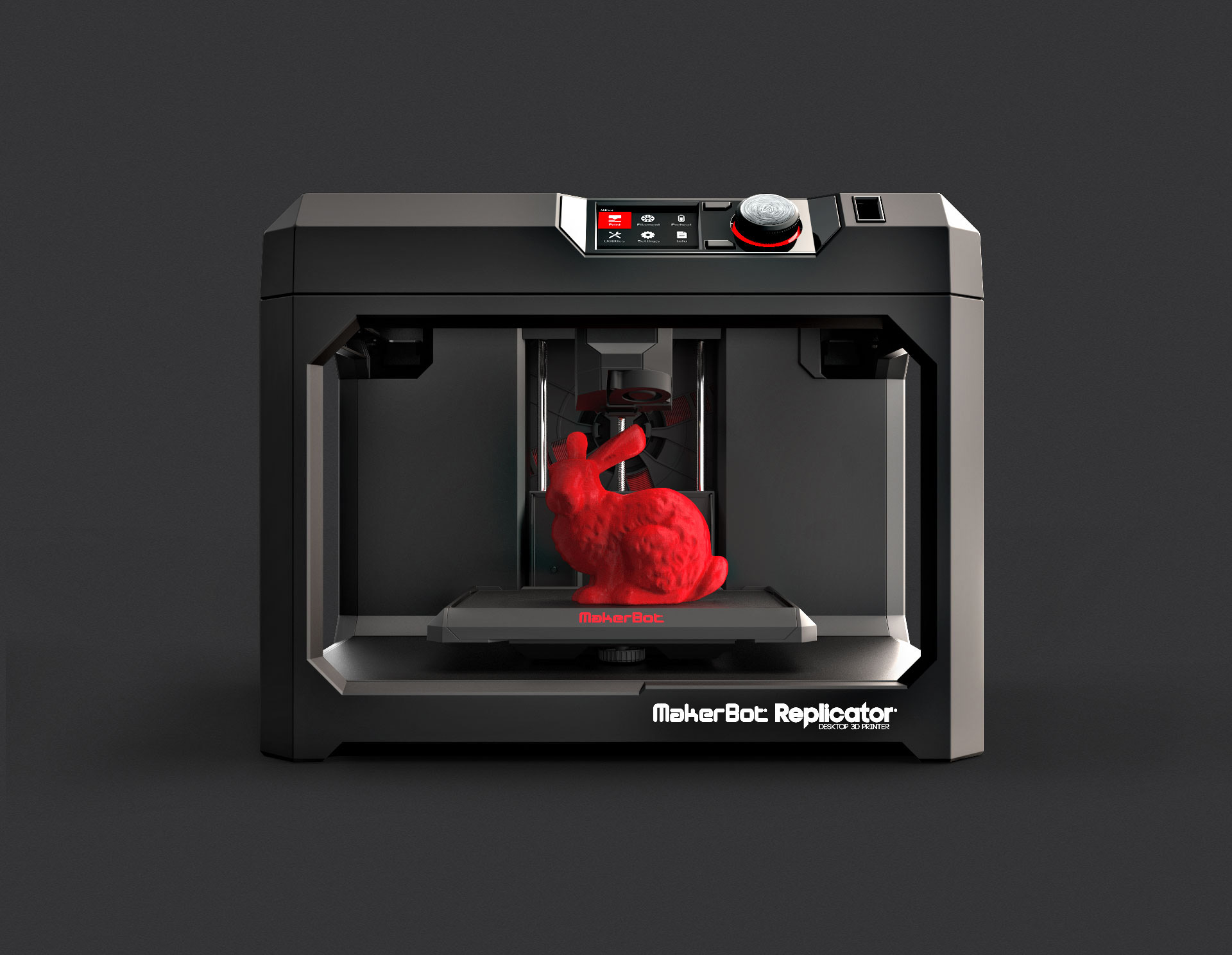

MakerBot is a 3D printer company that manufactures desktop 3D printers for home, office, and classroom use. In addition to manufacturing 3D printers, the site also has a "Resources" section where you can learn about the materials for 3D printing. You can also learn about the various uses of a 3D printer in different industries, like the automotive industry.

You can also learn about the various uses of a 3D printer in different industries, like the automotive industry.

The Educational Resources section offers resources to help those interested in 3D printing in the education industry. The Resources section also houses a "Post Processing" category where users can learn how to finish their designs after 3D printing.

3DPrinting.com is a website that provides an online learning resource for 3D printing. The website offers a variety of tutorials and articles that cover topics such as the basics of 3D printing, how to design 3D models, and how to troubleshoot common problems.

The site's blog section houses a "Use Cases" category where users can learn how 3D printing is used in various industries and how each 3D printing material is used. The "Reviews" category also contains in-depth product reviews of different 3D printers to help readers decide before purchasing a 3D printer.

Whether you are just getting started with 3D printing or you are looking for ways to improve your skills, 3DPrinting. com is an excellent resource.

com is an excellent resource.

Clever Creations is a website that provides users with everything they need to know about 3D printing. The site's 3D Printing section contains a wealth of articles from experts on topics such as choosing the right 3D printer, understanding file formats, and troubleshooting common problems.

Clever Creations acknowledges that not everyone is an expert in 3D printers, and that's why the site has a "Buyer's Guides" section where you'll find detailed reviews of 3D printers based on hands-on experience. These unbiased guides help one make the right decision when buying their 3D printer so users can get the best results for their needs.

i.materialise is a 3D printing service that allows customers to get their parts 3D printed. The website provides a simple interface that allows users to upload their designs.

In addition, the site can also help you understand the basics of 3D printing. Head over to the 3D Printing section, where you can learn how 3D printing works, the various 3D printing technologies, and 3D printer materials.

The website's blog section keeps users updated on the new 3D printing technologies, best 3D modeling tutorials, and attractive 3D designs.

Formlabs is a 3D printing company that produces desktop 3D printers and filaments. Founded in 2011 by MIT graduates Max Lobovsky, Natan Lohr, and David Cranor, Formlabs has become one of the leading manufacturers of 3D printers.

The website has a wealth of resources for those interested in 3D printing. For instance, the "Learn" section includes a blog with articles on various aspects of 3D printing and in-depth webinars from experts in the field.

You can also interact with the community and gather tips from experts in the field by heading over to the forums. Formlabs also offers a variety of software tools to help users get the most out of their 3D printers.

TCT Magazine is one of the world's leading additive manufacturing and 3D printing magazine. The site is packed with the latest news, emerging technologies, products, projects, and interviews with the top personalities in the industry.

TCT Magazine is an essential read for anyone involved in additive manufacturing or 3D printing, whether you are an engineer, designer, manufacturer, or service provider. With a global readership and an unrivaled team of expert writers and editors, TCT Magazine is the go-to source for everything additive manufacturing.

3D Insider is another website that provides comprehensive information on all things 3D printing. Readers can learn about the history of 3D printing, how it works, and the different types of filaments used to create 3D printed objects.

The site also covers more advanced topics such as 3D printed drones and provides detailed instructions on how to build them. Whether a complete novice or an experienced maker, 3D Insider has something to offer for everyone interested in learning about this fascinating technology.

Start Your 3D Printing Journey With These Sites

Although it may seem daunting, learning 3D printing all by yourself is possible with the right resources. Many websites offer helpful information on 3D printing. However, some are more useful than others.

Many websites offer helpful information on 3D printing. However, some are more useful than others.

All the blogs and websites we've listed are excellent places to start. You can visit any of these sites to kickstart your 3D printing journey today, but don't be afraid to explore other options. Over time and with adequate patience, you can become a 3D printing expert and possibly even look into starting a career in 3D printing.

8 nuances worth paying attention to / Sudo Null IT News

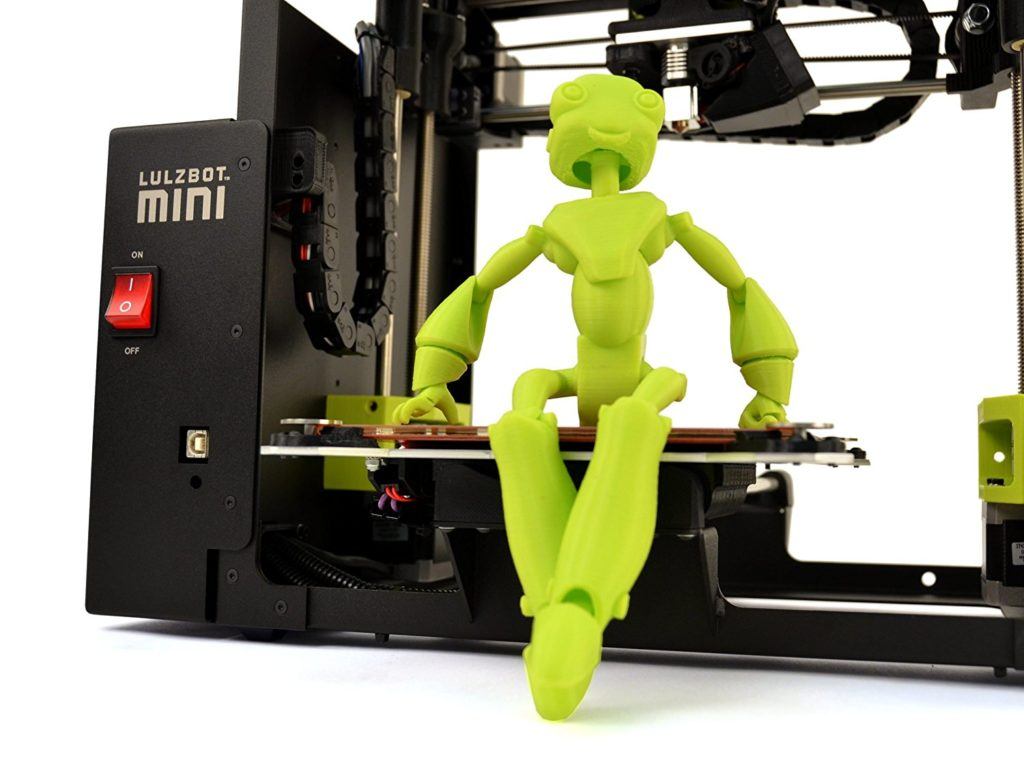

Sooner or later, everyone learns about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible.

What to pay attention to and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer.

You need to decide for yourself what tasks you will use this technique for? What capabilities should a 3D printer have to solve your problems?

Point 1: Decide on a 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here.

If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models.

Prominent representatives of this segment: Form 2 3D printer or B9Creator 3D printer

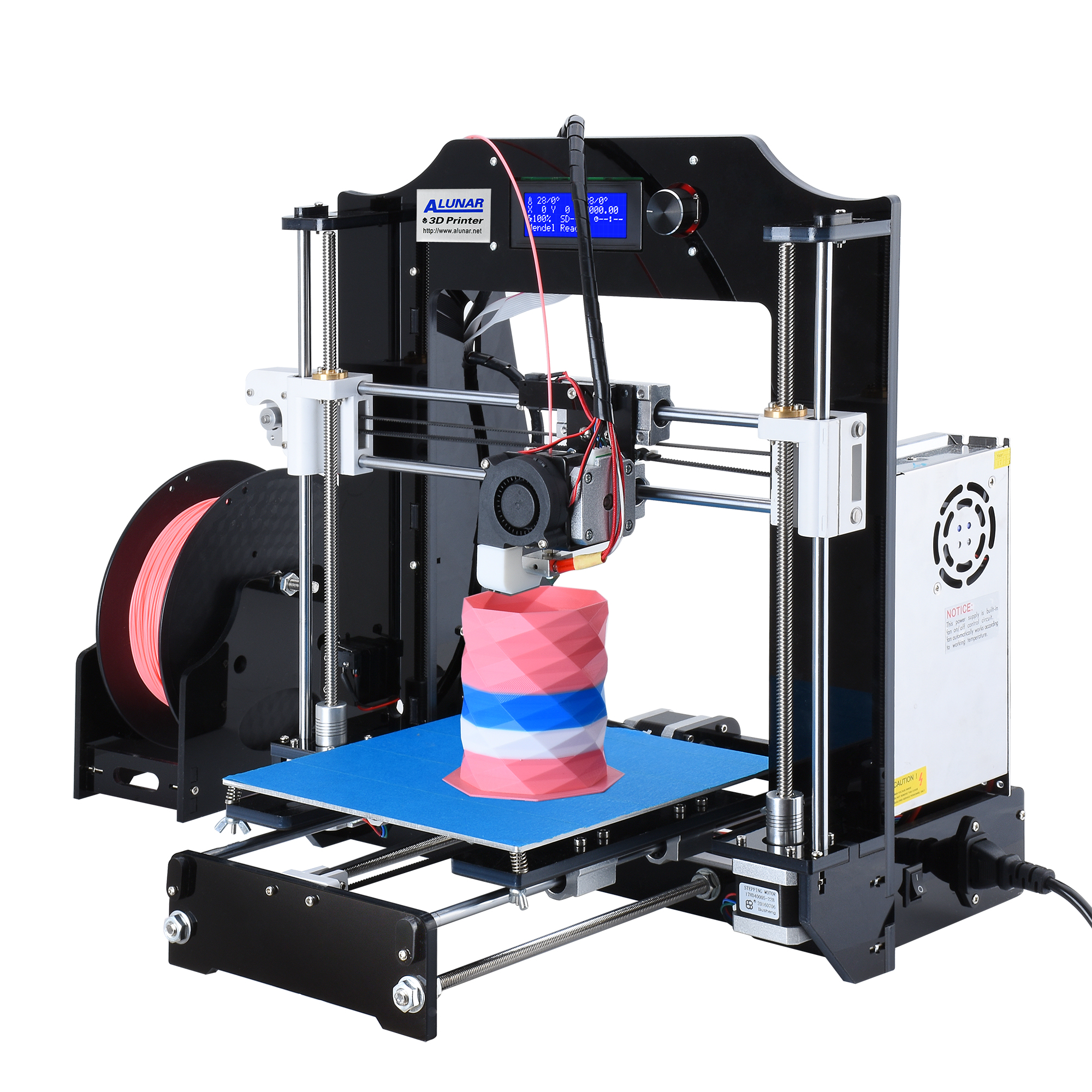

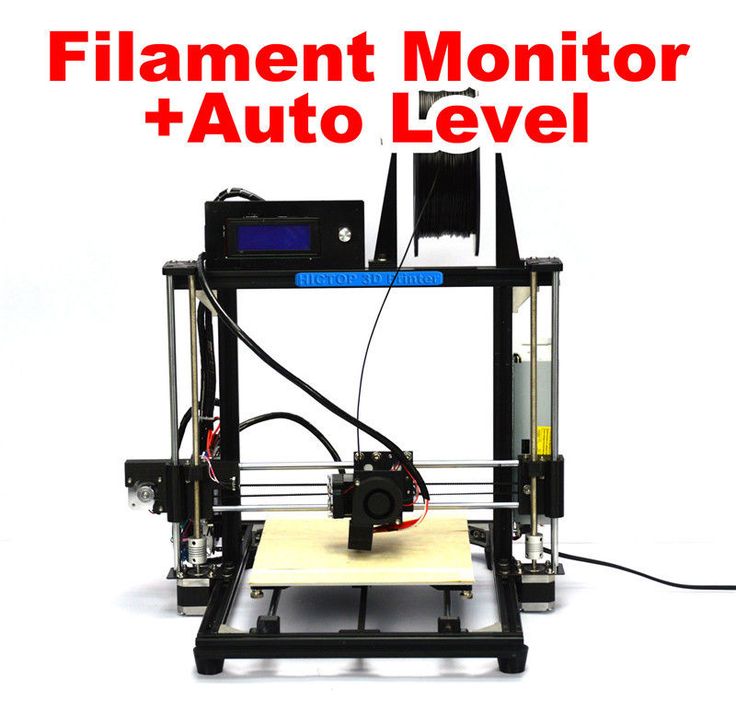

If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic.

3D printing on this equipment involves layer-by-layer melting of plastic.

If everything is clear according to SLA printers. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs soberly

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems?

What can be an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks.

This volume is enough to solve 95% of any tasks.

But options are possible...

If you plan to make small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area.

In other cases, the size of the printable area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

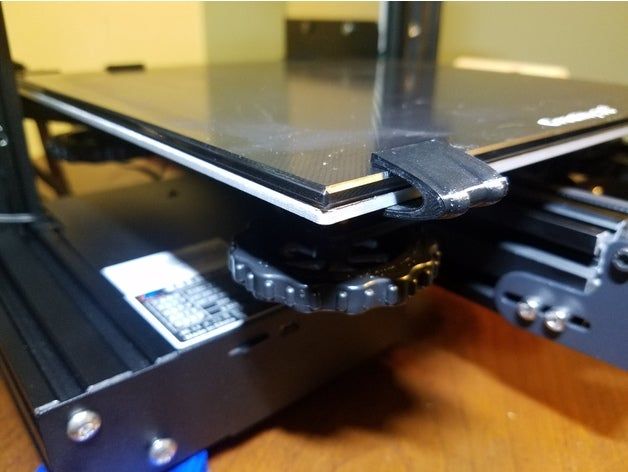

Point 3: Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles greater than 30 degrees.

If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles greater than 30 degrees.

Tip 4: Decide on a list of materials to use.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model.

If you plan to print with PLA only. You don't need a heated table.

You don't need a heated table.

But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform a full range of tasks facing a 3D printer.

One more thing. Possibility of printing with flexible materials.

Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common.

Usually, for most people, this happens like this:

A couple of models are printed, the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

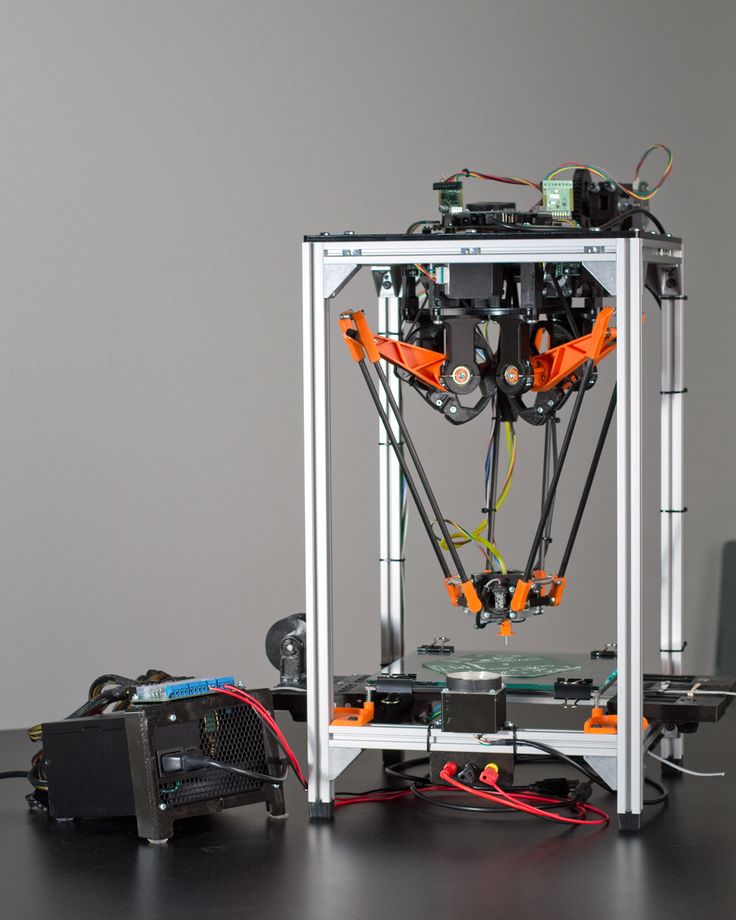

Point 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say?

Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say?

Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble.

Also, the lack of a closed housing can cause print quality problems with high shrink plastics (ABS, Nylon).

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the scheme with a lifting table. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage.

And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage.

Closed case printers are more rigid. This results in better quality printing.

Kinematics for moving the print head, available in various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Point 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer.

Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary.

If you do not plan to do this, then this opportunity is not so necessary.

What do we mean by specific tasks?

This is especially true for large prints where it is important to reduce print times. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity.

So, just like with the heated table, the ability to change nozzles is a nice bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Detail 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Point 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube.

What are the advantages and disadvantages of each type of extruder?

Bowden extruder, due to the absence of a motor on the print head, has a lower weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually quite difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex.

But it has one drawback. It is usually quite difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex.

This extruder reveals all its positive features when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm.

Direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy.

Which do you prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely.

And will save you time and money when choosing a 3D printer.

3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) Business 3D printers

3) Large area 3D printers

4) SLA and DLP 3D printers

Still have questions? Call by phone: +7 (499) 992-72-23 (Moscow) and 8 (800) 775-86-69 (free of charge within the Russian Federation) or write to the mail: [email protected] and our employees will be happy to give you a detailed consultation on any topic of interest.

Myths about 3D printing and 3D printers: common misconceptions

Myths about 3D printing

As you know, what people are not very good at, eventually acquires a lot of myths and erroneous judgments. 3D printing technology is no exception. Unfortunately, in Ukraine there is an extremely low percentage of awareness about 3D technologies, which does not favor the opinion about innovative methods. Myths about 3D printing are very different, and are built on the basis of what a person has already heard about the technology. Printing on a 3D printer is a very unusual process. But most do not bother to gain deeper knowledge and are content with meager explanations about how the technology works. This is how 3D printing myths are born.

3D printing technology is no exception. Unfortunately, in Ukraine there is an extremely low percentage of awareness about 3D technologies, which does not favor the opinion about innovative methods. Myths about 3D printing are very different, and are built on the basis of what a person has already heard about the technology. Printing on a 3D printer is a very unusual process. But most do not bother to gain deeper knowledge and are content with meager explanations about how the technology works. This is how 3D printing myths are born.

In this article we will try to bring the most common myths about 3D printing and dispel them with reasoned facts. We hope this section will help you learn more about 3D technologies and better understand the process of printing with a 3D printer.

The most common myths about 3D printing

Let's start this section with some of the most common myths and misconceptions about 3D printing. So, what people often think about printing on a 3D printer:

1.

It's expensive

It's expensive Myths about 3D printing are proudly led by the opinion about its cost, and this is not accidental. People are convinced that 3D printing is very expensive and out of reach for the average user. This myth is only half true. Prices for industrial installations for 3D printing are really very high. But that's why it is professional equipment used in production. The cost of desktop 3D printers is much lower and continues to decline as technology advances. The prices of consumables are also falling. Already, this makes 3D printing very accessible, and in the future, a 3D printer will become part of almost every home.

2. It's professional

Many people think that 3D printing is only suitable for a narrow range of specialized tasks or industrial applications. We can assure you that this is not the case. Of course, the prospects for 3D printing in the industry are extremely promising, but for home use, a 3D printer can be no less useful.

3. Can only be printed with plastic

Now this is a completely absurd opinion. 3D printing technology is steadily moving towards the fact that anything can be used as a material. Already today there are food 3D printers, 3D bioprinters that print with living cells, devices that print with metal, wood, silicone, rubber, clay and even glass. The method of contour construction is also actively developing, that is, 3D printing of houses. As you can see, you can print anything, almost anything.

3D printing technology is steadily moving towards the fact that anything can be used as a material. Already today there are food 3D printers, 3D bioprinters that print with living cells, devices that print with metal, wood, silicone, rubber, clay and even glass. The method of contour construction is also actively developing, that is, 3D printing of houses. As you can see, you can print anything, almost anything.

4. 3D printing is only good for making trinkets

Contrary to the opinion about the professional use of 3D printers, there are thoughts that 3D printing is not suitable for creating serious things. A variety of functional models and final parts made on 3D printers will help to convince skeptics. Many large aerospace and automotive companies use 3D printing in their practice. For example, Airbus launched a plant that uses only additive techniques. And the creation of cars using a 3D printer has become a very common practice.

Don't miss it, you'll love:

Myths about 3D printers

After listing the common myths about 3D printing, let's move on to the myths about 3D printers. Some exaggerate the capabilities of these devices, some downplay. But there are myths about 3D printers, and it's up to us to dispel or confirm them. So, what do ordinary people think about 3D printers?

Some exaggerate the capabilities of these devices, some downplay. But there are myths about 3D printers, and it's up to us to dispel or confirm them. So, what do ordinary people think about 3D printers?

1. This is a complex device

On the one hand, you can't argue with that. The device is really not easy, but the developers care about the maximum ease of managing 3D printers. Desktop devices are aimed at comfortable and simple work. For example, on Kickstarter, the project of the simplest 3D printer was considered. Moreover, you can assemble some printer models yourself. And if you do everything right, they will work well. Therefore, everything is not as difficult as it seems.

2. Products do not require post-processing

This is perhaps the biggest misconception. No matter how much you want, but just take it and print it will not work. Objects should definitely go through a minimal post-processing process, especially if they were printed with supports.

3. Print in any color

Unfortunately, modern desktop 3D printers are not yet able to print full color samples. There are models with multiple extruders, but the maximum possible is two or three colors. On industrial printers, it is quite possible to print products in full color. However, developers are actively working to eliminate this limitation and are making significant progress. Relatively compact full color printers already exist. It remains to wait for their mass entry into the market and lower prices.

This concludes the myths about 3D printing. We hope the article was informative. And if you know even more myths and misconceptions about 3D printers and 3D printing that we have not touched on, write to us by e-mail and we, if necessary, will add them! Best regards, 3DDevice team.

Also visit our online store and choose 3D scanners, 3D printers, 3D pens, 3D plastic and accessories. In addition, we provide 3D printing, 3D modeling and 3D scanning services.