Open source resin 3d printer

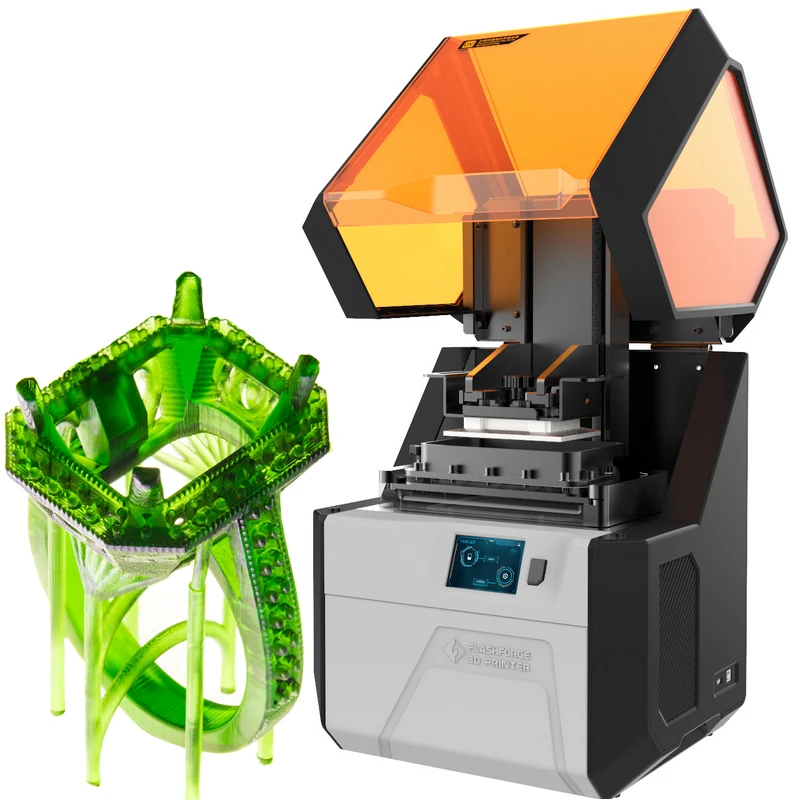

Introducing Original Prusa SL1 - Open Source SLA 3D Printer by Josef Prusa

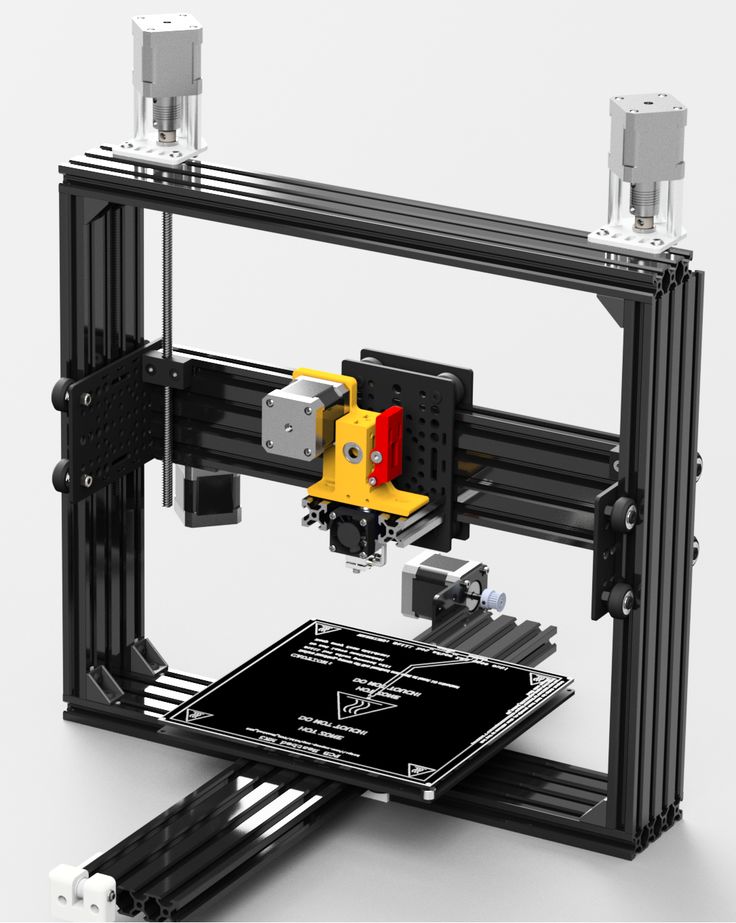

I am in the FFF filament based printers industry for quite some time, almost 10 years since I started to play with RepRaps and later joined the project as a core developer. That is more than ⅓ of my life and if I think about it like this I get butterflies in my stomach. Over that time I gained an incredible amount of experience and built a huge team of 320 people working with me in Prusa Research. With this in mind, I got an itch last year: it would be a shame not to use our experience in additional projects. First was the filament. Oh… sorry, Prusament 😉 which we launched just two days ago to an incredible response. Quite frankly, I will have to start looking for second building just for extra filament lines pretty soon. 😀 And today, I will show you our second project that came out of that itch, a new resin-based printer Original Prusa SL1!

To help us with this huge undertaking, earlier this year I acquired a Czech company Futur3D specializing in resin printing – and their exceptional team joined us at Prusa HQ, bringing over 5 years of experience in this field with them, so we can make the SL1 really awesome right from the start. It is also great news for the 3D printing world, because with this acquisition we will be open-sourcing all the designs starting with SL1! Resin 3D printing was always done at premium prices and by big corporations. We may not wear suits, but we have an incredible amount of new ideas and we are willing to work our asses off, which is something corporations usually lack.

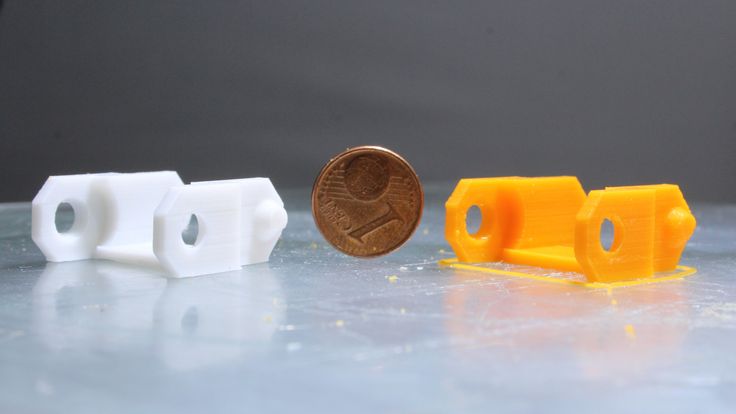

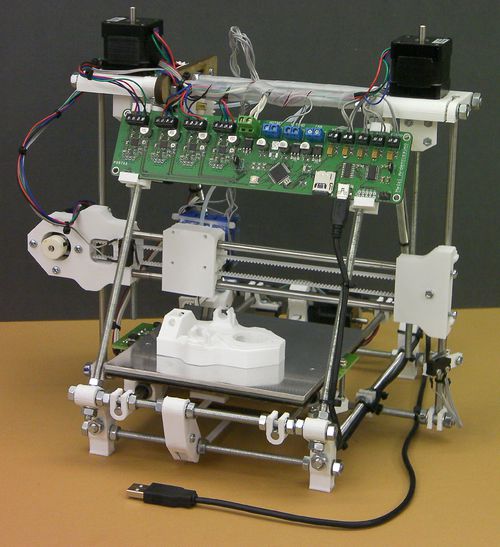

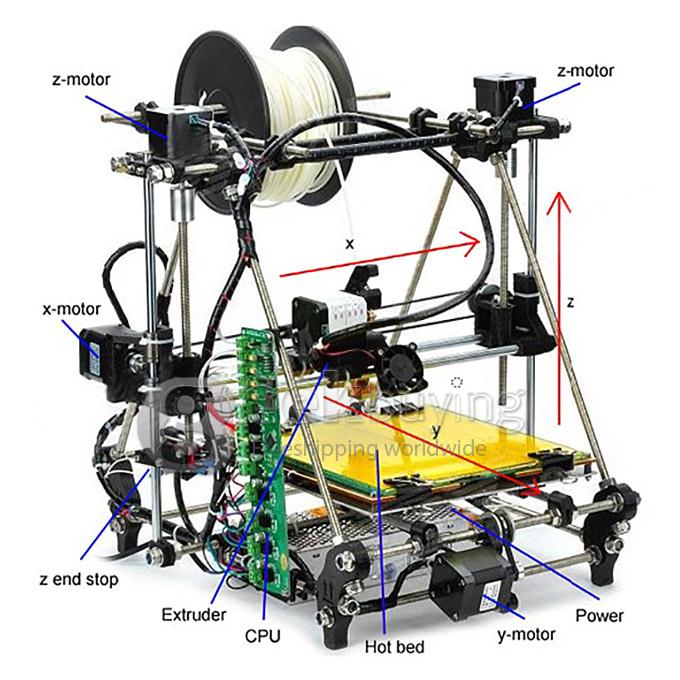

But before we start talking about SL1, let’s take a brief look at the difference between FFF/FDM and SLA printers. FFF/FDM technology is based on extruding melted thermoplastics – you know them as ‘filaments’. SLA, on the other hand, is based on curing photosensitive resin into thin layers using an LCD screen and a light source. And it can reach the insane layer height of just 0.01 mm! However, the recommended values are between 0.025 and 0.1 mm.

FFF/FDM technology is based on extruding melted thermoplastics – you know them as ‘filaments’. SLA, on the other hand, is based on curing photosensitive resin into thin layers using an LCD screen and a light source. And it can reach the insane layer height of just 0.01 mm! However, the recommended values are between 0.025 and 0.1 mm.

The SL1 isn’t trying to compete with the flimsy Photon or with the ultra-pricey Form but instead I want it to be the MK3 of the resin world – have the best print quality, convenient design and features, ease of use and other things, while keep a price accessible for an everyday hobby maker.

SLA technology explained

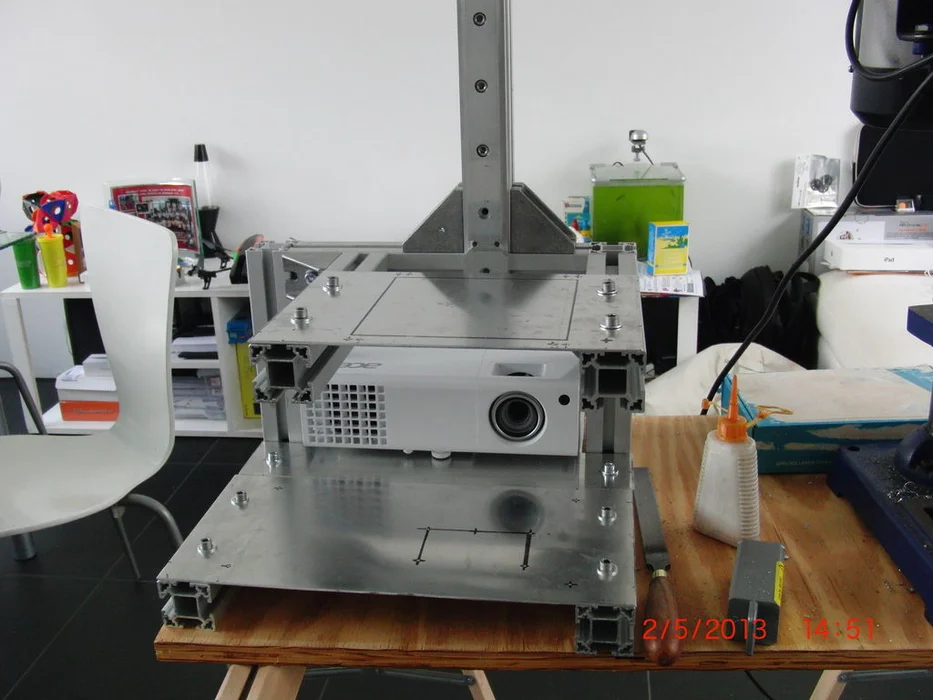

There are three main categories of SLA processes: laser-based stereolithography (laser SLA), digital light processing stereolithography (DLP-SLA), and masked SLA (MSLA). For all these processes, a tank of photo-reactive liquid resin is selectively exposed to light in order to form very thin solid layers that stack up to create one solid object. Even though laser-based SLA, DLP-SLA, and MSLA are all types of stereolithography and utilize similar technology, they can produce significantly different outputs.

Even though laser-based SLA, DLP-SLA, and MSLA are all types of stereolithography and utilize similar technology, they can produce significantly different outputs.

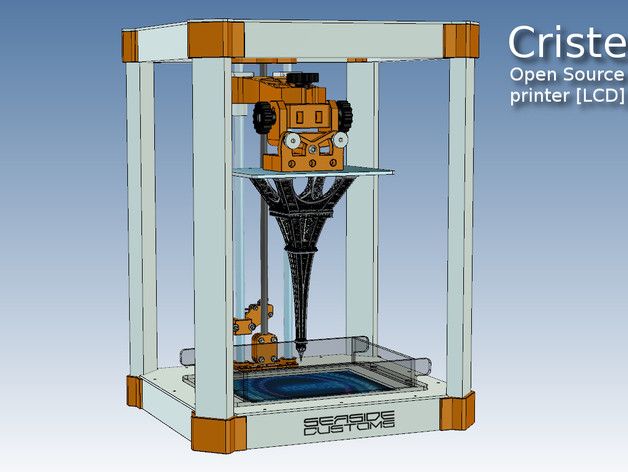

Original Prusa SL1 uses MSLA, which means that there is an LED array as it’s light source in combination with an LCD photomask to shape the light image. Like with DLP printers, the LCD photomask is digitally displayed and it is composed of square pixels. The pixel size varies based on how the LCD photomask is manufactured, and individual pixels are deactivated on the LCD to allow the LED light to pass through to form the resulting layer. Thus, the XY accuracy is fixed (it’s the physical resolution of the LCD) and it does not depend on how well you can zoom/scale the lens as is the case with DLP. And that’s the reason why MSLA is more accurate.

In the other words, let’s say that the LCD displays layer shapes as transparent images and the rest of the image (beyond the outlines of the layer) is black, so the light passes only through the transparent layer shape 🙂

Original Prusa SL1 Tech Specs

Alright, that was the boring part – now for some cool hardware specifications! The SL1 is using a 5. 5’’ high-resolution LCD display with the physical resolution of 2560×1440p, resulting in 0.047mm per pixel, that’s the fixed XY resolution. A high-performance UV light will cure one layer at a time, which takes about 6 seconds and then the printing platform is lifted, so the printer can start creating another layer. This configuration gives us a maximum print area size of 120 × 68 × 150 mm (or 4.7 × 2.6 × 5.9 in.).

5’’ high-resolution LCD display with the physical resolution of 2560×1440p, resulting in 0.047mm per pixel, that’s the fixed XY resolution. A high-performance UV light will cure one layer at a time, which takes about 6 seconds and then the printing platform is lifted, so the printer can start creating another layer. This configuration gives us a maximum print area size of 120 × 68 × 150 mm (or 4.7 × 2.6 × 5.9 in.).

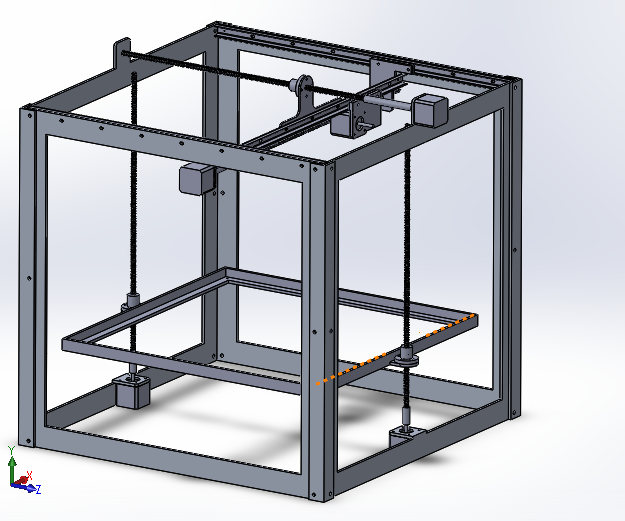

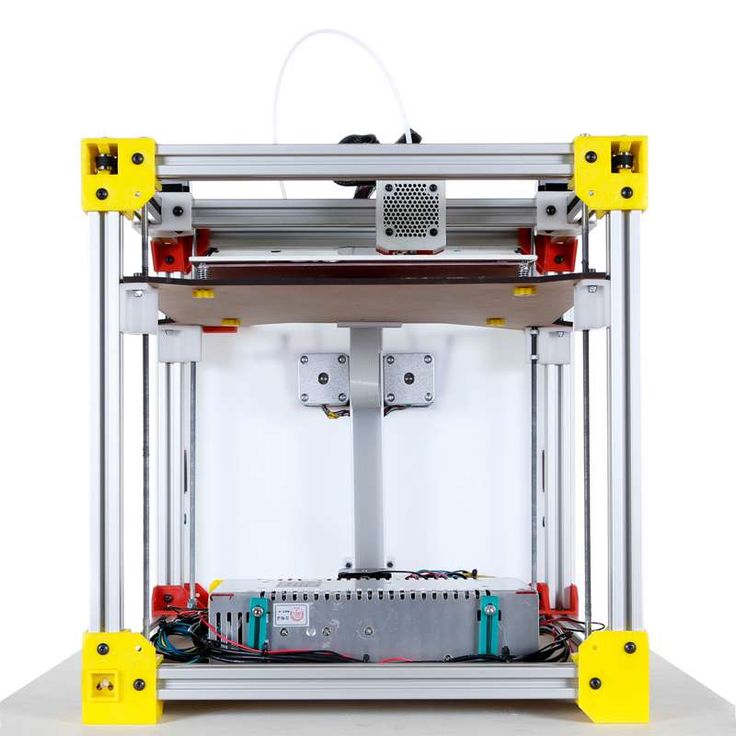

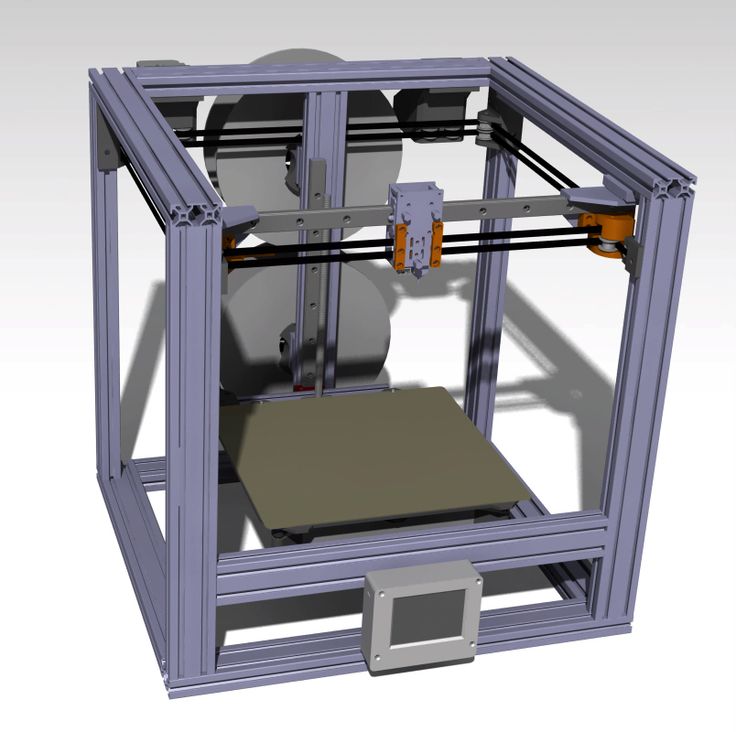

By the way, we are using a pretty smart design for the printer: its core is a rigid dural frame with a separate body, which greatly improves stability and reliability. To put it simply, it’s not another wobbly plastic thing. This thing is HEAVY! 🙂

As already mentioned, thanks to Trinamic drivers and rigid dural frame, the SL1 can reach a layer height of just 0.01 mm. But most users should stay within the recommended range of 0.025 – 0.1 mm per layer. And yes, we will also give you the option to enable variable layer height. And rest assured that our printer is open to third-party resins.

And rest assured that our printer is open to third-party resins.

Original Prusa i3 MK3 was a major step forward in terms of reliability and ease of use thanks to its many sensors and smart features. I actually said that MK3 is ‘bloody smart’. And SL1 will be no different. You can expect smart features, safety mechanisms, detailed manuals and handbooks, 24/7 live support, perfectly described functions, easy maintenance and cheap spare parts… things that are usually not found in cheap Chinese 3D printers.

Tilt bed and resin level sensor

SL1 features a unique resin level sensor, which is located in the resin bed (also called ‘tank’). It helps you to pour the optimal amount of polymer into the tank and it also notifies you when the resin is running low and needs a refill This prevents the situation when you would run out of resin mid-print. Also, even in case you decide to ignore the sensor and pour too much liquid into the tank, there is a special membrane protecting the electronics, so the insides of your printer will stay safe. This is a pretty unique feature which will save you a lot of prints and makes resin printing sooo much easier!

This is a pretty unique feature which will save you a lot of prints and makes resin printing sooo much easier!

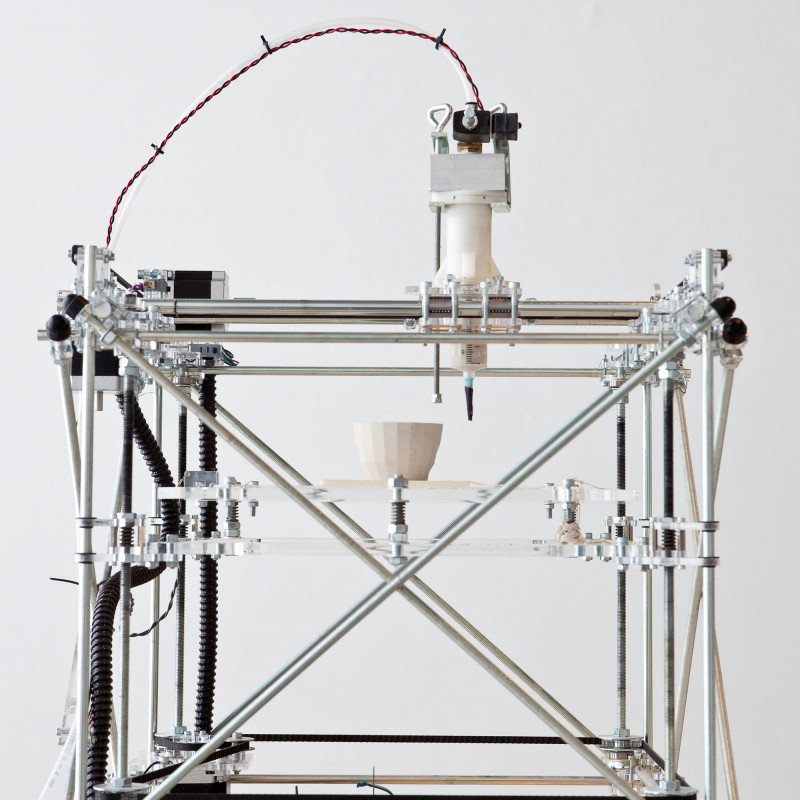

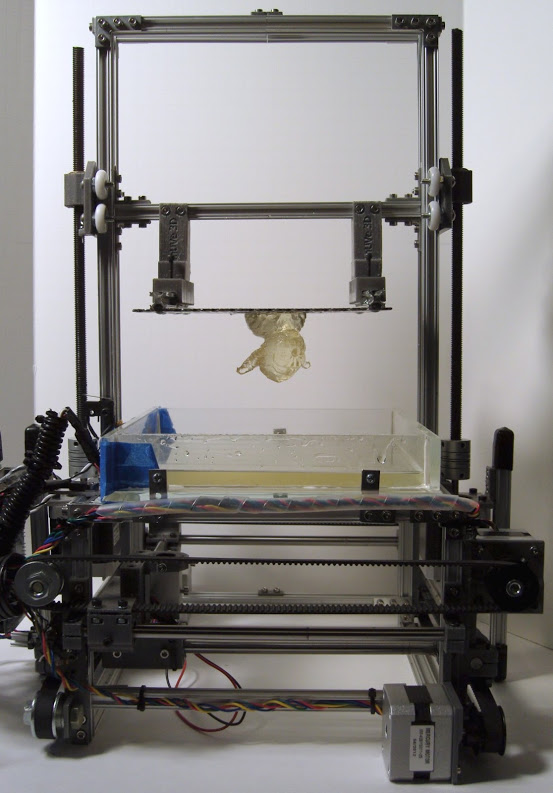

Speaking of the resin tank, it’s another major feature of this printer. What we have here is a removable tank with a flexible transparent FEP film on the bottom. Right underneath it is the LCD display (cooled to improve its lifetime) and the UV light. So, first of all, the resin tank has a motorized tilt function, which means that after curing a single layer, the print is not lifted vertically from the bottom of the tank. Instead, the tank tilts – This is huge, it drastically improves the surface finish of the models and reduces the stress on the model which is less likely to detach from the base. We can do this thanks to our extremely rigid aluminum build of the printer. If the core would be cheap and flimsy, this would just flex the whole printer frame.

Next, by tilting the tank, we also stir the resin – which has a noticeable impact on print quality. And also, it makes printing faster, allowing us to reach around 6 seconds per layer because with MSLA it doesn’t matter how many objects are placed on the print platform.

And also, it makes printing faster, allowing us to reach around 6 seconds per layer because with MSLA it doesn’t matter how many objects are placed on the print platform.

Sounds complicated? It’s actually the opposite! FEP material is cheap and we will have spare parts available through our e-shop. In case you scratch or damage the FEP film in any way, the replacement is actually pretty easy – just unscrew a couple of screws, remove the damaged film and insert a new one. It will automatically stretch as you tighten the screws again.

To compare, Form 2 is using resin tanks with silicone instead of FEP and even the resin tank for “high volume” printing “may last 2 liters+” at a price of $99. You have to bin the whole tank after it stops working.

Automatic calibration

We have put a lot of thought into creating a simple and reliable printing platform, that doesn’t need to be calibrated after every print.

Since we have a great experience with the Trinamic drivers in our MK3, we use them here as well. Trinamic drivers ensure silent printing and also enable an automatic calibration. How does it work? The printing platform is connected to the main arm by a ball joint so if you loosen it and start the automatic calibration, the Z-axis will lower the printing platform until it gently hits the bottom of the resin tank. Once it’s there, it’s perfectly level, so just tighten the ball joint and move the platform up. From that moment, the printer is perfectly calibrated and allows you to remove only the printing platform using a quick-release mechanism without affecting the calibration.

Trinamic drivers ensure silent printing and also enable an automatic calibration. How does it work? The printing platform is connected to the main arm by a ball joint so if you loosen it and start the automatic calibration, the Z-axis will lower the printing platform until it gently hits the bottom of the resin tank. Once it’s there, it’s perfectly level, so just tighten the ball joint and move the platform up. From that moment, the printer is perfectly calibrated and allows you to remove only the printing platform using a quick-release mechanism without affecting the calibration.

Connectivity options and smart functions

We will offer a wide range of connectivity options for the SL1. The whole device is controlled by a full-color LCD touchscreen and the print files can be uploaded via a USB flashdrive. However, there is also LAN and Wi-fi connectivity, which allows us to do some cool things apart from uploading print files – like enabling you to control the printer via a web browser.

Everything is, of course, connected. Which means, that if the resin level sensor detects that you are running out of ‘fuel’, it will send a notification to your phone.

Another function that was inspired by the MK3 is the Power Panic mode. In short: in case of a power outage, the printer can save the last known position of the printing platform and once the power is restored, the machine can continue with the print job.

Vapor extraction

This may be a minor function for some users, but it’s important to mention it nevertheless: SL1 features a sophisticated cooling system and also a vapor extraction system. If you didn’t know, printing with SLA produces various fumes, so that’s also why the printer has a lid. However, a good airflow is also important, so the printer has a fan with a high-quality filter at the back of the machine.

Actually, the part with the fan is removable, so you can e.g. mount a hose onto the printer to push the fumes out of a window.

Slice and dice!

There are many different slicing software solutions out there, some even go as far as being only cloud-based. That’s not our case! Our goal is to deliver an open-source printer, and that’s what we’re going to do! 🙂 We will expand the features of our current Slic3r PE and integrate SLA slicing directly into the existing software.

This brings a number of advantages, one of them is the simple fact that Slic3r PE has an incredible amount of features and new ones are appearing quite often, plus we have big plans how to improve and redesign our Slic3rPE.

Curing and washing machine

And we’re not done yet! There will be an optional accessory for the SL1. Basically, when you print something from resin, it is incredibly messy, because you have to rinse the model with isopropyl alcohol and ideally finish the curing. You can wear gloves and make a mess in your sink and then place the model outside in the sun to finish the curing.

Or better, you can get our 2-in-1 curing and washing machine (or CurWa, if you want ;-). Insert a tank with isopropyl alcohol, put a 3D printed object inside and the magnet-driven propeller will stir the IPA and wash the printed object. It uses standard food prep containers, so you can easily switch them out or replace. Once you remove the tank and place only the printed object inside the machine, it will start curing it with UV light.

BTW we are open for better naming suggestions before the machine goes on sale 😉

Availability and shipping

And that’s it! I hope that you learned everything you wanted to know about our new SLA 3D printer and I hope you like it. For us, it’s an expansion to a brand new territory and it’s very, very exciting! But I should once again point out that we don’t have to learn things from scratch! The team behind SL1 has over 5 years of experience in resin printer design and manufacturing, so we know what we’re doing! 🙂

We are launching pre-orders right now, and we’re throwing in a special discounted price for early adopters. You can pre-order a pre-assembled SL1 3D printer from our e-shop for 1.599 USD / 1.599 EUR (VAT incl.) and these printers will start shipping in December this year. Another option is to pre-order the kit (assembly required), which is priced at 1.299 USD /1.299 EUR (VAT incl.) and it will start shipping in January 2019. There are also special bundles of both printer variations with Curing and Washing Machine. You will save $200 / 200 € (VAT incl.) when you buy these bundles (assembled printer bundle or kit bundle) instead of buying both items separately.

You can pre-order a pre-assembled SL1 3D printer from our e-shop for 1.599 USD / 1.599 EUR (VAT incl.) and these printers will start shipping in December this year. Another option is to pre-order the kit (assembly required), which is priced at 1.299 USD /1.299 EUR (VAT incl.) and it will start shipping in January 2019. There are also special bundles of both printer variations with Curing and Washing Machine. You will save $200 / 200 € (VAT incl.) when you buy these bundles (assembled printer bundle or kit bundle) instead of buying both items separately.

We will, of course, also start selling resins, spare parts, FEP films, and other accessories later.

If you want to learn more about the SL1, check out the product page, our e-shop or ask us directly via e-mail. And you can also visit our booths at the World Maker Faire in New York (September, 22-23) and TCT Show in Birmingham (September, 25-27) – we have the SL1 with us. 🙂

🙂

Happy printing!

Jo Prusa

Lite3DP 3D Printer | Crowd Supply

Lite3DP 3D Printer | Crowd Supply3D Printing

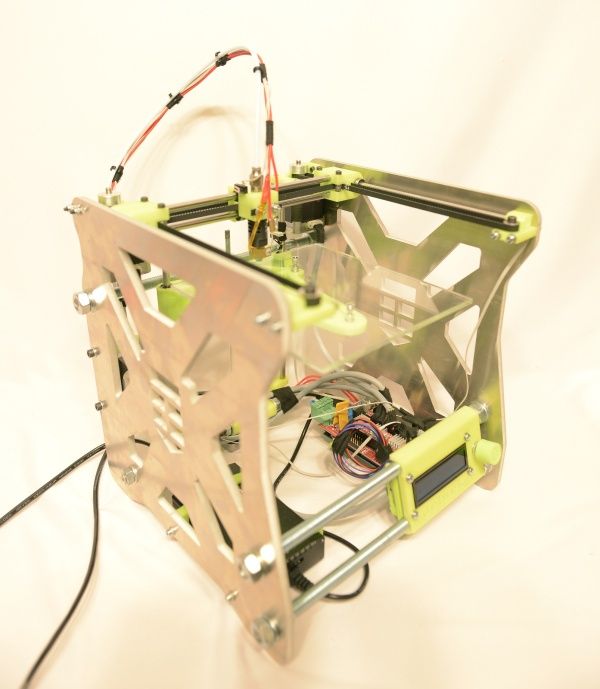

An Arduino-based, open source MSLA / LCD-SLA resin micro 3D printer kit

Recent Updates

- Aug 03, 2021 Kitting News, Shipping Address Changes

- Jul 08, 2021 Shipping News

- May 27, 2021 Manufacturing News

- Mar 16, 2021 A Comprehensive Schematic, Additional Capabilities, and Optimized Firmware

View all project updates

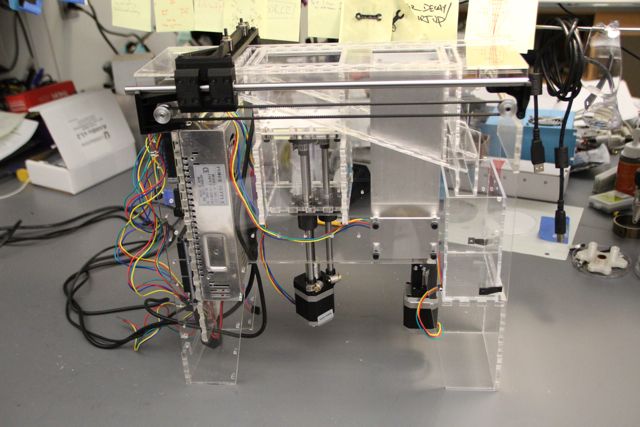

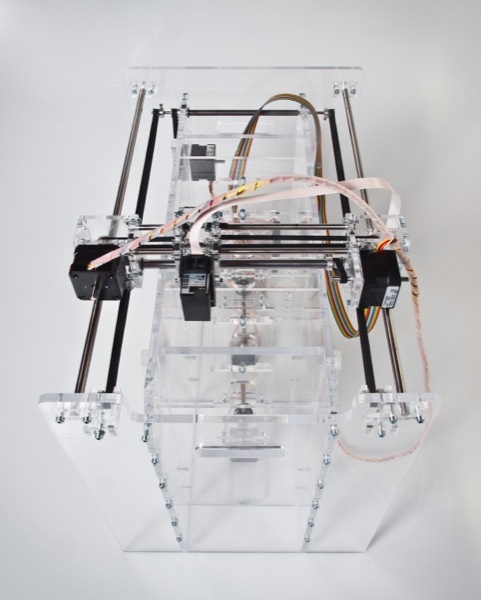

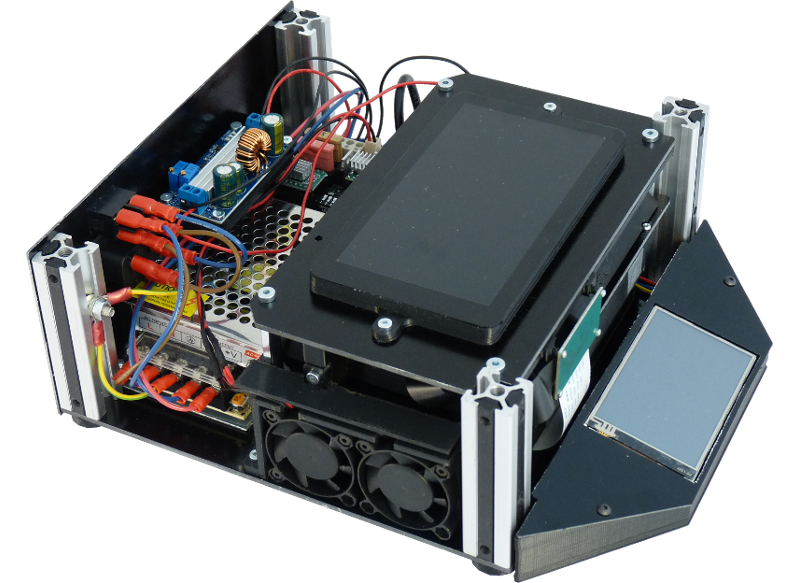

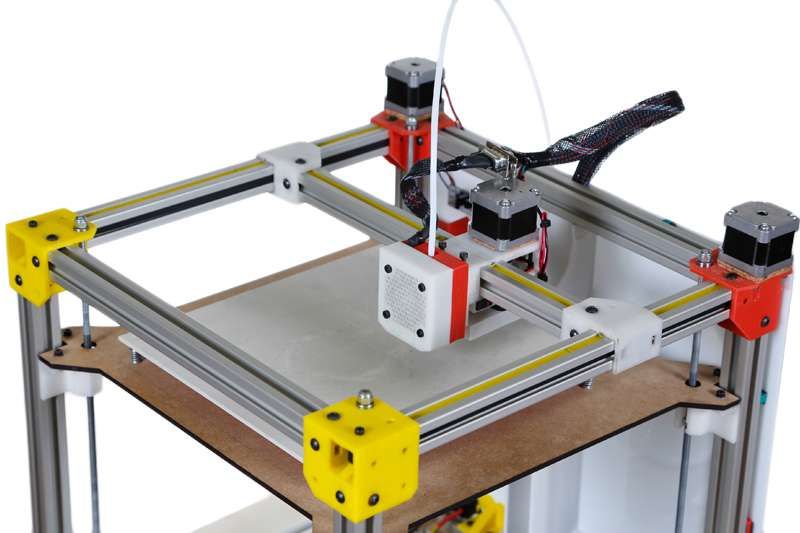

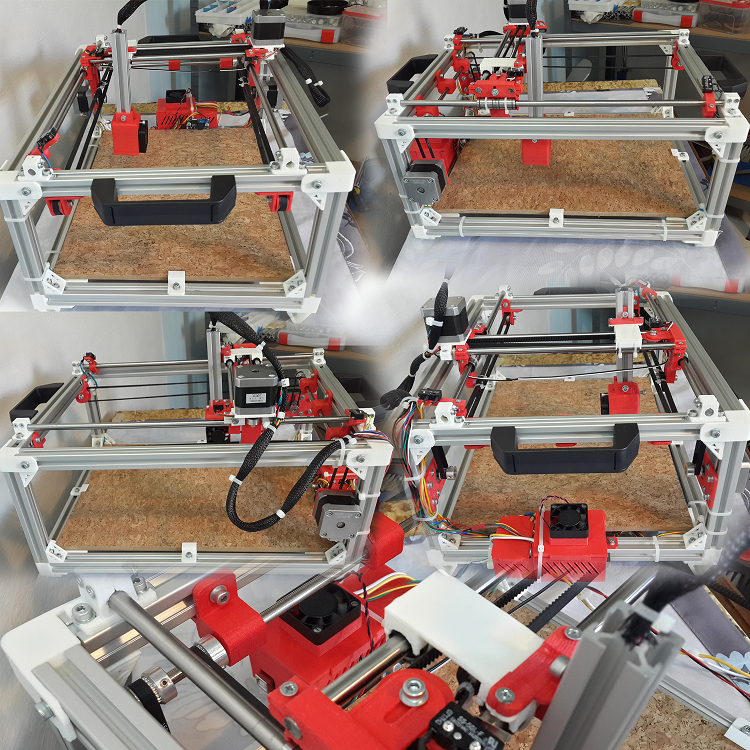

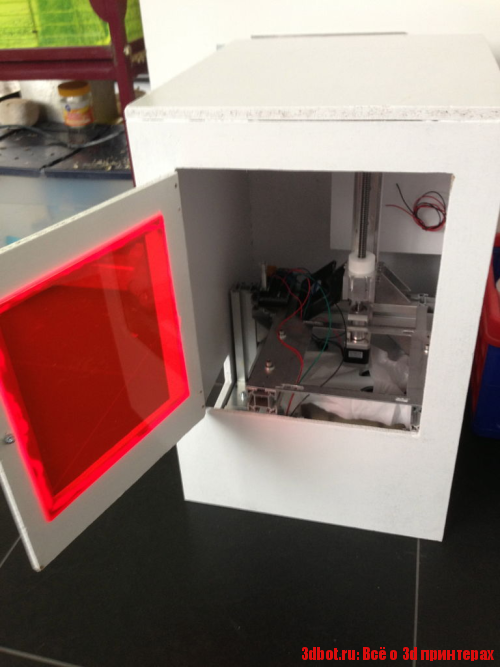

You'll be notified about news and stock updates for this project.Lite3DP is a micro 3D printer that utilizes high-print-quality, virtually-silent MSLA technology. It’s the first of its kind to be based entirely on Arduino, is open source, and comes in an easy-to-assemble kit format. It’s a simple machine that is designed for experimentation and allows for a deep and complete understanding of its operation. And it can fit on just about any desk or in any workshop.

It’s a simple machine that is designed for experimentation and allows for a deep and complete understanding of its operation. And it can fit on just about any desk or in any workshop.

MSLA resin 3D printing technology can achieve stunning detail levels and surface finishes, far superior to what filament 3D printers can reach - essentially by curing resin using a screen such as the LCD on Lite3DP. Although 3D printers with MSLA technology are already offered at prices similar to those of filament printers, they are closed source projects, skirting one of the most precious characteristics of modern 3D printing - accessibility.

Features

- Manufactures plastic parts by solidification, layer by layer, of a liquid photosensitive resin

- Prints with an extraordinary level of detail and surface finish, far superior to what filament 3D printers can reach

- Fits in the palm of your hand

- Works with any brand of 405 nm UV resins

- Utilizes a precision linear guide

- Features a magnetic attachment system on the tray and platform (a single manual knob for its preparation)

- Works autonomously with a microSD card

- Is well-documented and open source

Using the Printer

File Preparation

Once you’ve designed your model, it can be prepared for printing using the CHITUBOX utility. CHITUBOX slices your model into separate images for each print layer, which are then formatted to be read by the machine and uploaded to a microSD card by the Lite3DP Converter application.

CHITUBOX slices your model into separate images for each print layer, which are then formatted to be read by the machine and uploaded to a microSD card by the Lite3DP Converter application.

Printer Setup

Once the machine is powered up, and your prepared microSD card has been inserted, all you have to do is:

- Place the magnetic printing platform

- Prepare the printing platform

- Select the file to print on the machine's screen

- Select the printing parameters: layer resolution and exposure settings

- Place the magnetic tray and add resin

- Hit print

It’s that simple. During 3D printing, images corresponding to each slice of the model will be drawn on the screen and thus cured into the resin.

Can’t wait to have the Lite3DP in your hands? You can start using our online simulator right now!

Time-lapse of a Lite3DP Print

Preparing the Printing Platform

Preparation of the printing platform is done before each print. When setting this, the magnetic printing platform will automatically lower towards the screen and all you need to do is adjust a single knob to lock it.

When setting this, the magnetic printing platform will automatically lower towards the screen and all you need to do is adjust a single knob to lock it.

The height of the automatic approach of the printing platform is set the first time the machine is used and is then permanently saved in the Arduino memory.

Lite3DP Components

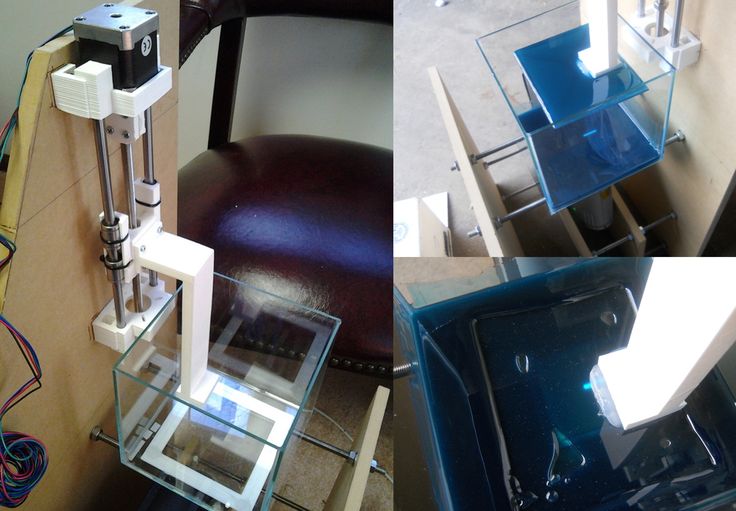

Lite3DP features an all-in-one PCB that includes an Arduino Pro Mini, the driver for the stepper motor, a module for a microSD card, and a screen with dual-functionality: to provide the masking for 3D printing and to allow selection of printing parameters. The PCB also has a structural function, since the motor and the other parts of the machine are attached to it.

The base is made up of 2 mm aluminum plates, which reinforce the structure and allows passive dissipation of the heat from the UV LED, avoiding the need for noisy fans. During operation of the 3D printer, only a soft sounds of the stepper motor are heard intermittently, which is activated for a few seconds at the end of each layer.

Like all MSLA 3D printers, Lite3DP has a single axis of movement, consisting of a stepper motor with metal gear reduction, a precision linear guide, a square thread screw and POM nut.

All kits will include an injected-molded plastic tray, developed to avoid any breakage or leakage problems. Trays will also offered separately for those who might need more than one, or for those who make their own machine from scratch and want to ensure good performance.

Specifications

- Machine size: 100 x 100 x 150 mm

- Technology: MSLA // LCD-SLA

- XY resolution: 0.14 mm

- Z resolution: 0.05 and 0.1 mm

- Build volume (W x L x H): 45.1 x 33.8 x 70 mm

- Tray volume: 50 cm³ (1.7 fl oz)

- Compatible resins: All UV 405 nm resins (standard, industrial, flexible, castable, dental, etc.)

- Data input: micro SD card autonomous operation

- Power consumption: less than 4 W

- Weight: less than 350 g (12.

3 oz) - perhaps the lightest printer in the world

3 oz) - perhaps the lightest printer in the world

Proudly Open Source

This project is fully open source and the software, Arduino firmware, hardware, 3D printing files, and user guide are available on the Lite3DP website for you to understand and/or modify. You can also follow progress on Instagram.

Comparisons

| Lite3DP | Phrozen Sonic Mini | Longer Orange 30 | |

|---|---|---|---|

| Open source | YES: FW + HW + SW | NO | NO |

| Build experience | Easy-to-assemble DIY kit | Assembled machine | Assembled machine |

| Weight | 0.35 kg | 4.30 kg | 8.00 kg |

| Printer size | 100 x 100 x 150 mm | 250 x 250 x 328 mm | 200 x 200 x 390 mm |

| Cooling | Passive | Active = continuous noise | Active = continuous noise |

| Repairability | Easy and inexpensive | Complex and expensive | Complex and expensive |

| Resin-compatibility | All 405 nm | All 405 nm | All 405 nm |

| Z resolution | 0. 1 and 0.05 mm 1 and 0.05 mm | 0.3 - 0.01 mm | 0.1 - 0.01 mm |

| XY resolution | 0.14 mm | 0.06 mm | 0.05 mm |

| Build volume | 45.1 x 33,8 x 70 mm | 120.0 x 66.0 x 129.5 mm | 120.0 x 68.0 x 170.0 mm |

| Electronics | All-in-one PCB, Arduino-based | Mini PC + microcontroller board + video board | Mini PC + microcontroller board + video board |

| One-time slicing | YES: 1 file = all resins and layer heights | NO | NO |

| Touchscreen | NO | YES | YES |

| Magnetic attachments | YES | NO | NO |

| Autonomous operation | YES: Micro SD card | YES: USB drive | YES: USB drive |

| Price | USD 89 | USD 239 | USD 239 |

Fulfillment & Logistics

Once all kits and trays have been manufactured, verified, and packaged, the entire batch will be shipped to the US for distribution to backers via Crowd Supply’s fulfillment service. For more information about shipping, please see Crowd Supply’s Ordering, Paying, and Shipping guide and the international shipping section of their Fulfillment & Logistics guide.

For more information about shipping, please see Crowd Supply’s Ordering, Paying, and Shipping guide and the international shipping section of their Fulfillment & Logistics guide.

Manufacturing Plan

To achieve the desired high standards of quality, manufacturing will be performed at our own facilities, where we can take care of every detail personally. Of course, the standard components will be ordered from Chinese factories. As soon as the campaign is over, a first order of PCBs (possibly from JLCPCB) and all the electronic components will be placed. In this way we can quickly begin to assemble. At the same time, the injection of the trays and the 3D printing of the rest of the plastic parts will begin. The laser-cut metal parts will be manufactured at a prestigious local company. When the second shipment of mechanical components arrives, they will be carefully inspected and will be packed together with the rest of the manufactured components.

Risks & Challenges

Three years of continuous development and hundreds of hours of testing allow us to believe that both software and hardware have stable operation. It is, of course, an experimental machine, and we expect you to do all sorts of crazy tests, improvements, and modifications. But that’s at your own risk! We are hopeful that the COVID-19 pandemic will not cause us significant delays, but any delays that do occur will be promptly communicated in project updates.

It is, of course, an experimental machine, and we expect you to do all sorts of crazy tests, improvements, and modifications. But that’s at your own risk! We are hopeful that the COVID-19 pandemic will not cause us significant delays, but any delays that do occur will be promptly communicated in project updates.

3D Natives

"It can be held in the palm of your hand. Unlike other 3D printers, the Lite3DP S1 is really adapted to any kind of office or work space."

Hackster News

"If you care about detail more than size, the Lite3DP S1 could still be a viable option for you. It’s open source and the controller is based on an Arduino Pro Mini. "

Ask Crowd Supply about an order

Ask Lite3DP a technical question

Submit a field report about how you used this project

Produced by Lite3DP in Buenos Aires, Argentina.

Sold and shipped by Crowd Supply.

Complete Kit

All the parts you need to build a Lite3DP. MicroSD card and 405 nm resin not included.

$89 $8 US Shipping / $18 Worldwide

Power Supply Plug Type US EU

289 claimedLite3DP 3D Printer Kit

All the parts you need to build a Lite3DP. MicroSD card and 405 nm resin not included. Power supply sold separately.

$99 $8 US Shipping / $18 Worldwide

110 claimedExtra Tray

One tray, ready to be assembled - includes: an injected plastic tray, steel frame, 4 screws, and FEP film. A second tray is great to have if you want to keep different resins separate for cleaning purposes.

$14 $8 US Shipping / $18 Worldwide

165 claimed12 VDC 18 W International Wall Mount AC Adapter

From the Crowd Supply Basics project.

A 12 V, 1.5 A (18 W) AC adapter with interchangeable plugs provided for the US, EU, AU, UK, plus a CCC-compliant plug - connecting via a 2.1 mm center-positive barrel jack.

$16 $8 US Shipping / $18 Worldwide

In Stock

Lite3DP

Buenos Aires, Argentina · lite3dp.com

Alfredo Bonini, Argentine mechanical engineer, 32 years old, great 3d printing enthusiast.

Alfredo Bonini

Lite3DPPrinty

Fully open-source SLA 3D printer kit

JuicyBoard

An open source, modular, robotic control system for building 3D printers, CNC routers, and other robotics applications

8-MOSFET

A stackable, DIN-rail mountable, solid-state power driver for Raspberry Pi and other SBC & MCU platforms

Subscribe to the Crowd Supply newsletter, highlighting the latest creators and projects

Future: Science and technology: Lenta.

ru

ru Frame: Formlabs / YouTube

1

Bird's beak printed using biocompatible resin in the USA

Scientists from the University of South Florida (USA) and Formlabs specialists performed a successful operation on replacement of part of the diseased beak of a rare bird. Doctors operated on a hornbill that lives in the Tampa City Zoo, Florida. The animal suffered from skin cancer, which is fatal to this type of bird; as a result of cancer, the part of the beak that covers the nasal sinuses was damaged. Specialists scanned the skull of the animal, made a prosthesis based on a special resin and installed it in place.

According to doctors, after the operation the bird quickly recovered, the surgical intervention did not affect her appetite and habits. After some time, the protective mask printed on a 3D printer acquired the color of a beak, which became possible due to the secretions of special glands produced by the body of hornbills. The inventors of a medical 3D printer and a biocompatible resin said that in the future it is possible to use prostheses and artificial organs created individually for each patient with a specific disease.

The inventors of a medical 3D printer and a biocompatible resin said that in the future it is possible to use prostheses and artificial organs created individually for each patient with a specific disease.

3D printed hornbill implant

Photo: ZooTampa at Lowry Park

2

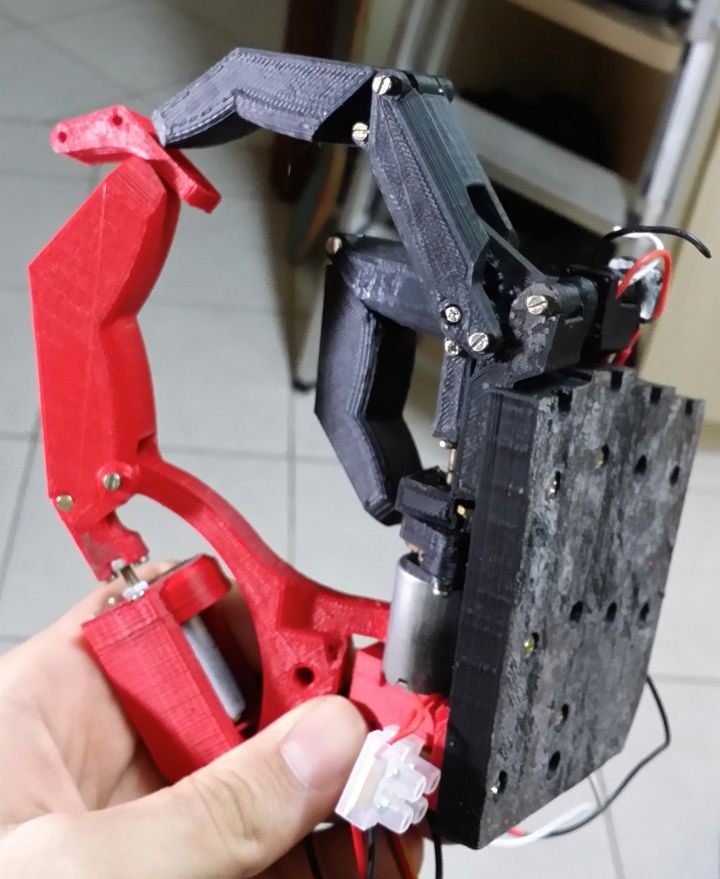

3D printing solves the problem of creating high-quality and affordable prostheses

Experts estimate that hundreds of thousands of people lose limbs and become waiting for a prosthesis. Mass-market prostheses are only available in a few sizes, so wearers have to adapt to the features of the medical equipment. In addition, they are short-lived and expensive to manufacture. 3D printing allows you to create an almost perfect prosthesis according to individual drawings. In this case, he can successfully replace the lost arm or leg.

Prosthetic services are also commonly available to patients in the developed world with good medical insurance. Formlabs experts note that the problem lies in the lack of manufacturing processes that allow the production of non-standard parts at an affordable price. 3D printing could make prosthetics more affordable. For example, the non-profit initiative e-NABLE offers free blueprints, mockups, and open source programs to create medical devices using printers. In this case, the cost of one custom-made prosthesis can be only about $50.

3D printing could make prosthetics more affordable. For example, the non-profit initiative e-NABLE offers free blueprints, mockups, and open source programs to create medical devices using printers. In this case, the cost of one custom-made prosthesis can be only about $50.

3

Medical 3D printing requires a special resin that is compatible with living organisms

Modern 3D printers print blanks based on photopolymer resin, a special liquid substance that hardens when exposed to light. In medical printing, everything is much more serious, since it is believed that a person will be in direct contact with an object created using a 3D printer for quite a long time. Scientists explain that printed prostheses must have an ideal shape, taking into account the structural features of the body, and also consist of safe materials that will not cause an allergic reaction or rejection.

“The importance of 3D printing in healthcare cannot be overestimated,” says Gaurav Manchanda, director of medical market development at Formlabs. For example, medical "live" resin essentially resembles the material for printing conventional 3D blanks, but differs in detail from them. Firstly, it allows you to print more accurate objects - about a hundred microns in size. Secondly, it is designed for prolonged contact with the skin or mucous membranes. Thirdly, the resin can be given absolutely any shade, which is especially important in dentistry. For example, Formlabs has BioMed Clear Resin, which has a high degree of transparency, which may be required to produce parts that show internal anatomy.

For example, medical "live" resin essentially resembles the material for printing conventional 3D blanks, but differs in detail from them. Firstly, it allows you to print more accurate objects - about a hundred microns in size. Secondly, it is designed for prolonged contact with the skin or mucous membranes. Thirdly, the resin can be given absolutely any shade, which is especially important in dentistry. For example, Formlabs has BioMed Clear Resin, which has a high degree of transparency, which may be required to produce parts that show internal anatomy.

4

3D printing will eliminate organ transplants

When organ transplants are needed, patients may face the same problem as when creating a prosthesis: the supply of suitable biomaterials is extremely limited, and the cost of transplantation is very high. In addition, the body may not accept a new organ, in which case the efforts to find a donor and prepare the patient for surgery will go down the drain. Theoretical medicine proposes to create the necessary organs on order, literally printing them on the basis of the patient's biomaterial.

Theoretical medicine proposes to create the necessary organs on order, literally printing them on the basis of the patient's biomaterial.

Experts describe the use of bio-ink, a special material and a kind of raw material for medical 3D printers. Bio-ink is created using tissue engineering techniques based on samples received from the patient. Doctors take a part of the patient's tissue and place it in a bioreactor, where, with the help of nutrients, the material acquires the mechanical and biological properties of organic tissue. Bioengineers can direct cell growth in such a way that the desired tissue or organ type is obtained as a result. The probability that the resulting organ will take root in the patient's body is extremely high. Also, scientists from around the world offer to grow organs in the body of animals. According to Genotek CEO Valery Ilyinsky, such technologies will become a reality in five to ten years. However, the production of individual kidneys, liver or heart based on the patient's biomaterial still seems to be a more reliable way to replace a damaged organ - due to the maximum compatibility of the printed organ and the patient's body. In this case, resorting to exotic methods of solving the problem - such as transplanting a pig's heart to a person - will not be required.

In this case, resorting to exotic methods of solving the problem - such as transplanting a pig's heart to a person - will not be required.

At the moment, doctors can grow primitive parts of the tissues of the human body, and the technology for creating complex internal organs is still in the field of futurology. At the same time, scientists look much further - in the future, printing not only the heart, but also blood vessels. Experts remind that diseases of the cardiovascular system are now the number one cause of death in the world. “Creating blood vessels with 3D printing opens up the possibility of creating a ‘design’ of blood vessels that fits the patient,” says Dr Sam Pashneh-Tala from the University of Sheffield.

3D printed artificial heart prototype by Israeli experts

Frame: ColdFusion / YouTube

20 best and free 3D printing software and 3D printer software

Looking for a 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

Most slicers are free.

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Which slicer should I choose? In this article, we will tell you which slicer is the best choice for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source.

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

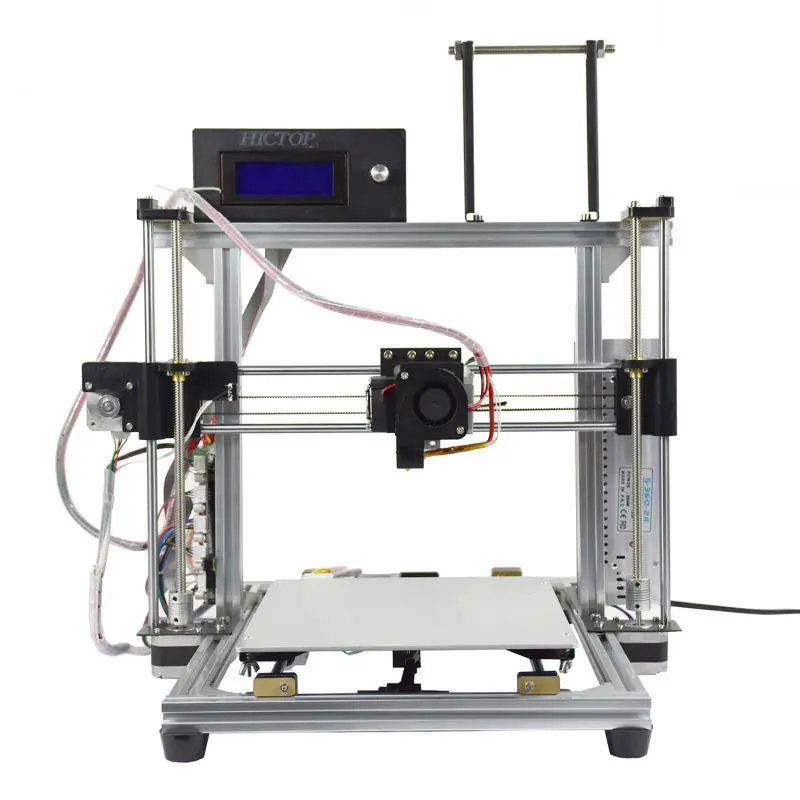

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode.

If finer control is required, switch to Expert mode.

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers.

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur.

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of the object from different angles - the more the better - after which they will be compiled into a 3D model.

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills.

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D.

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, browser

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time.

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

another easy and intuitive online tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled.

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe.

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer.

Don't let the 'Basic' in the name fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb.de

Price: Free

Systems: PC, Mac, Linux

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community. Today the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone.

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and - the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i. e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will have everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers.

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and check STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it.

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools in existence. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

No.18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically.