Cocoon 3d printer review

Cocoon Create 3D Printer Touch review - an affordable 3D printer that's ideal for beginners

Many people interested in purchasing a 3D printer have been put off by the high prices but now there’s an affordable product available from Aldi priced at under $500 that can open up a whole new world of creation.

The Cocoon Create 3D Printer Touch is priced at $499 (we’ve seen it’s been reduced even further to $449) and Tech Guide put it through its paces.

We’ve never used a 3D printer before and we imagine the more expensive models can print larger objects.

When 3D printers were brand-new, like any new technology, they were quite expensive.

But now, years later, there are a lot more affordable as we can see from the Cocoon Create 3D Printer Touch.

What’s the use of having a 3D printer, a lot of people ask.

For a start, it’s a lot of fun making objects.

You can create all kinds of things including desk organisers, decorative objects and even jewellery.

It won’t be long before instead of buying parts for our household products and appliances, will be able to print them out ourselves.

The Cocoon Create 3D Printer Touch is priced like a beginner’s machine but can a beginner use it? We decided to find out.

But before we get into our review you have to understand how 3D printing works.

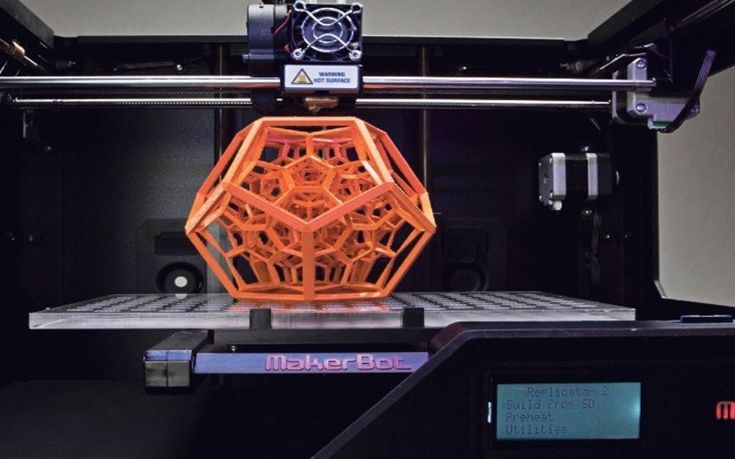

A 3D printer produces three-dimensional objects unlike your regular printer that can put writing or pictures on a piece of paper.

To do this it requires plastic filament which is fed into an extruder.

Like a regular printer, a 3D printer also requires a file.

In this case that file is a three-dimensional construction of an object which the printer can follow and create layer by layer.

Each layer is about a millimetre high with some objects taking several hours to produce.

The 3D printer creates these layers by heating up the plastic filaments and depositing that melted material to lay them in a certain order until the object is complete.

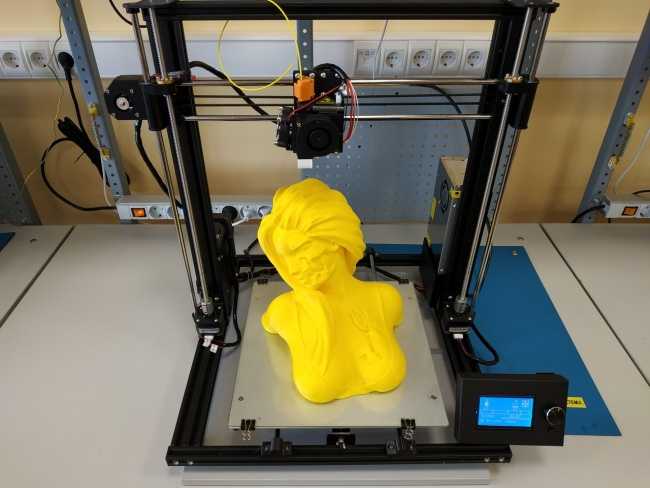

Have a guess what we’re printing with the Cocoon Create 3D Printer Touch from @aldiaustralia. Find out in our review at techguide.com.au #3dprinter #filament #aldi #tech #review

A post shared by TechGuide (@techguideau) on

OK, now you know the basics of 3D printing, let’s turn our attention to the Cocoon Create 3D Printer Touch.

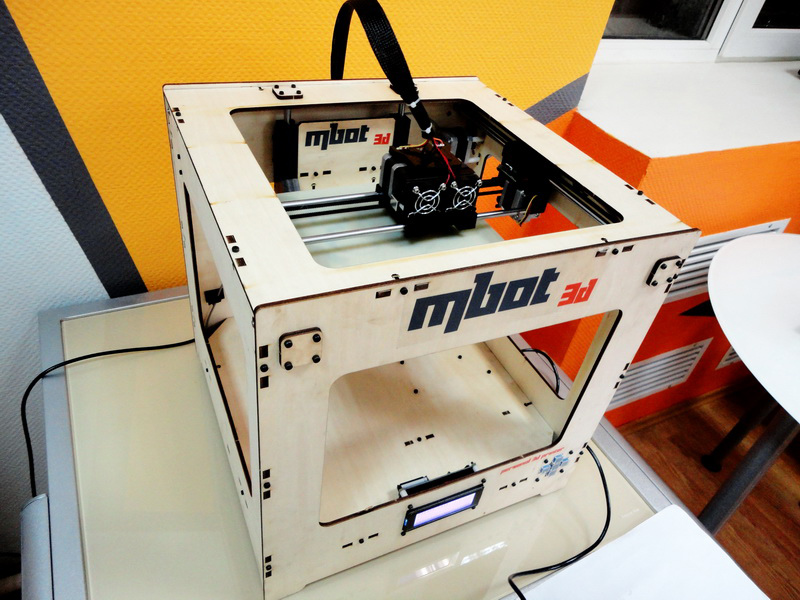

The device comes in a pretty large box and after you unpack all the pieces, you need to put it together.

The 3D printer needs a bit of room and has about the same footprint as a multifunction printer.

The difference here is it also needs a fair bit of height, so you can fit the filament roll and give it space to produce objects.

To get started we had to place the printer’s base through the tower frame and screw it all together.

Part of the base is the print bed where the object is printed layer by layer. On the front is a touchscreen to control the device.

The tower frame includes the extruder and the belt drive.

And plugging all the parts together was really simple thanks to the clear labelling – A plugs into A etc.

The filament rollIt wasn’t long before we were all set up, all plugged in and ready to go.

Included with the printer are some filament samples in various colours so you can print out a few small objects.

For serious printing, you will need to purchase larger filament rolls which cost about $40 each and are available in various colours.

But there was enough filament to get started printing small objects.

Setting up Cocoon Create 3D Printer Touch serves two purposes. It gets the printer ready for your first print but also teaches you the basics of 3D printing.

First thing we had to do, was make sure the print bed was level. Each corner of the bed has an adjustment screw as the extruder moves to each corner.

A small card that comes with the printer is used to test the gap between the extruder and the print bed.

To increase or reduce the gap between the bed and the extruder, you adjust the screw to raise or lower the bed.

After levelling the bed, the next step is to feed in the filament.

The filament rests on the spool holder at the top of the frame and can be fed in to the top of the extruder through a small hole.

A small lever allows access to pass the filament down into this gap. It was here where the instructions weren’t too clear.

We had to look up a video on YouTube to give us a better direction on how to set it up.

Another thing we learned was that a 3D printer needs to operate at high temperatures.

The printer bed is heated to a certain level – usually about 70 degrees – while the extruder, so It can draw down the filament and melted to mould into the object, can be as hot as 240 degrees.

So a tip for young players, keep your hand away from the bed and the extruder while the printer is working.

The Cocoon Create 3D Printer Touch uses gcode files to print objects.

There are some examples on the included SD card which slots into the side of the machine.

There is a cable to connect it directly to your computer, but that isn’t necessary. You can print directly from the SD card if you prefer.

Also included on the SD card is the Cura software which is a free open source slicer, available for Windows and Mac computers which allows users to convert 3D files into the gcode format.

The touchscreen makes it easy to navigate the menus with the main tasks being adding filament and choosing the object you want to print.

The printer is bed level and the filament has been fed into the extruder and is starting to feed out of the bottom.

This is when you know you’re ready to go.

First up we chose something simple to print – a seven-pointed star. This only took about 20 minutes and we were surprised with the quality.

And the fact that we created something from nothing – three-dimensional object we could hold our hands – was fascinating.

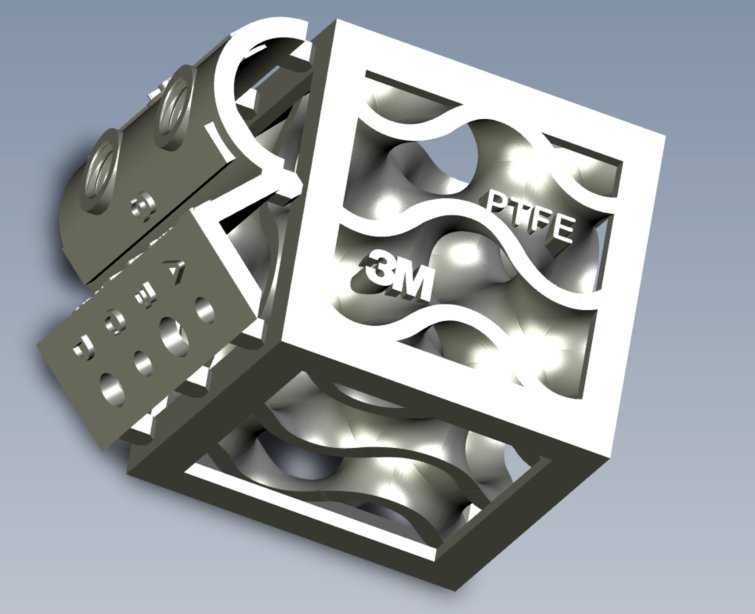

We got braver and more confident and started printing other objects including a unicorn, a dice, more stars, a moon and an NFL ball.

We were really impressed with the level of detail the printer can produce right down to the finest points and sharpest corners.

The smoothness and consistency of the surfaces was also surprisingly high quality.

But this process also had some hiccups. There were times when the object we were printing wouldn’t stick to the print bed and we had to stop everything and start again.

There were also other issues we had where we needed to call technical support to help us through.

The issue we had was while we were trying to change the filament and it just wasn’t going through.

We were advised to take apart the extruder cooling fan and assembly – there were only two screws involved – and we found a piece of filament had broken off inside the extruder which explains why the new filament wasn’t passing through.

We removed the excess filament with a pair of tweezers and put everything back together again and we were good to go.

We added a full roll of filament so we can print out some larger objects.

One was a rocket that had to be printed in three separate pieces before fitting neatly together.

As we are writing this review, we are halfway through printing a small replica of the Eiffel Tower.

Users have to understand, some prints can take quite a long time, were talking up to ten hours in some cases.

But it is fascinating to watch as the object is being built and how, layer by layer, we eventually see the finished product.

The Cocoon Create 3D Printer Touch certainly punches above its weight in terms of ease of use and the quality it can produce for the price.

The documentation and setup instructions could have been a bit more detailed and without the assumption the user knows anything about 3D printing to begin with.

This is important as a first time 3D printer buyer would naturally choose a product like this to get started rather than spending thousands of dollars on a more advanced unit.

As beginners ourselves we were a great example of that, and now we’re hooked.

Cocoon Create 3D Printer Touch

Price: $499 (seen for $449) available now from Aldi.

VERDICT

The Cocoon Create 3D Printer Touch is an affordable device that can produce surprisingly good results. It is a fine introduction to the amazing world of 3D printing.

ALDI Cocoon Creator 3D Printer

ALDI Cocoon Creator 3D Printer has been discontinued. See all ALDI Products.

1 photo

3.5 from

4

reviews · View Statistics

Write a reviewAsk a question

‹ See all Products- Reviews (4)

- Q&A (3)

- Details

- Compare

Write a reviewAsk a question

See the Best Products in 2022 as rated by Australians on ProductReview. com.au.

com.au.

Listing monitored by ALDI

Reviewer Photos & Videos

Your trust is our top concern. Companies can't alter or remove reviews from ProductReview.com.au.

Craig T.Perth, WA

Awesome little printer

published

It works well but takes a bit of effort like any 3d printer. Small build size though but a very good cheap reliable starter printer. See the photo for an example print.

Purchased in at ALDI for $399.

- Incentivised Review No

Share

More

Similar opinion? Write a review on ProductReview.com.au!

Kevin K.

You get what you pay for.

published

This is a pretty cheap printer and as a result the prints you get won't be the best going around. Having said that, if you manage to find a use for it, (I did but it took a while) it is very handy and gives good results. However, if you are wanting to go with a "wow" factor to your mates, be prepared for the "wow" to be muted.

Having said that, if you manage to find a use for it, (I did but it took a while) it is very handy and gives good results. However, if you are wanting to go with a "wow" factor to your mates, be prepared for the "wow" to be muted.

Share

More

Similar opinion? Write a review on ProductReview.com.au!

Darren GPerth, WA

- 3 reviews

Extremely disappointing.

published

Four 1 kg rolls of filament and no successful prints, endless adhesion problems, manual was from another printer, although the same machine. Thermistor wire failure and the machine was a paper for two weeks, even with $8 for shipping. Could not find settings in slicer program.Turns out its under another name, not noted in the manual. Although cocoon were contactable, best wishes ans sadness for my disappointment didn't fix anything. If it wasn't for a Facebook group, whom had battled with the same issues, it would have been returned inside the six week period. Now its mine for keeps.

If it wasn't for a Facebook group, whom had battled with the same issues, it would have been returned inside the six week period. Now its mine for keeps.

Share

More

Similar opinion? Write a review on ProductReview.com.au!

Mark KuzmaSouth East Queensland, QLD

- 10 reviews

- 6 likes

- Verified

Manufacture cares more for the Customer than Aldi

published

As an Aldi promotional special the Cocoon Creator ModelMaker 3D printer is a top buy at a top price. It is very rare that a problem will arise with this great starter to learn more about 3D printing. I did however run into a mechanical error 1 week and 1 day after purchase with a part failing. I contacted Aldi with regard to the problem and was informed that it was the manufacturer I needed to speak to, although, my understanding with consumer law makes Aldi just as responsible, but Aldi did put me through to the manufacturer on the Friday morn. ..

..

Read moreing who was able to offer some assistance and suggested that I contact Aldi and exchange the machine. I did contact Aldi back and they informed me that they were all sold out except for stores a minimum of 3 hours each way drive away from me and again informed me that it was not their responsibility. I called the manufacturer, Winplus, back and they asked me to email photos of the part in question to them and that they would send me a replacement part. Photos were sent by mid afternoon Friday, and the part was delivered to me on the Gold Coast from Melbourne at 8:00am Monday morning. Fantastic customer service.

The machine is for the best part unbreakable and idiot proof, and at the Aldi price is a product that I would recommend to anyone - a superb 3d printer for a superb price.

Aldi on the other hand, I have since found multiple units in each of the 5 closest to me stores, so Aldi, you need a little more honesty in your customer service area, and a little more understanding of Australian consumer law. All that aside, anyone looking for a 3d printer, this is a great unit to get

All that aside, anyone looking for a 3d printer, this is a great unit to get

Share

More

Similar opinion? Write a review on ProductReview.com.au!

Find out how ALDI Cocoon Creator 3D Printer compares to other Products

Know better, choose better.

Compare all

Questions & Answers

Mark W.asked

Why doesn’t the cocoon 3D printed use the whole bed for printing

Share

More

3

answers

Darren G

It’s a setting in the slicer program. If the printer is listed on the slicer’s settings you can generally change the print area,but, as I found out at the time, it wasn’t, I used another printer setting

Report

Mark W.

Thank you

Report

Craig T.

It's a limitation of the printer and a lot of earlier printers the axis belts can only move so far. It's a bit misleading of the manufacturer to make such a big bed on a small build volume. Possibly it is due to the type of bed it uses.

Report

rap attackasked

Has anyone changed a nozzle with this printer as mine is clogged. I tried to unclog but unsuccessful

Share

More

6

answers

Mark Kuzma

Search Wanhao Mini i3 on youtube to learn how to do most with your Cocoon creator. When it comes to unclogging your nozzle it is generally best to un-assemble your complete hot end with the exception ...

Read moreof removing your heater and thermistor from the block. Once you have the unit apart and your hot end nozzle in your hand, using a pair of pliers and a small gas torch (refillable ones are available at Bunnings quite cheap), and a toothpick, hold your brass nozzle with the pliers whilst heating it with the torch, once hot push the toothpick in carefully to push the blockage out and clean some of the excess filament from the nozzle. DO NOT attempt to push the toothpick through the small hole. To do the final clearing of the hole, and I do this on both my printers (my other is an ender3) I visited a local acupuncturist and purchase a few needles from him as they seem to be the right size for final clearing. Remember to heat the nozzle the same as before prior to using the needle to finally clean the tip. I always double-check that I can see light through the nozzle before re-assembly. Make sure also that you have removed all filament from the surface around where it enters the nozzle. Re-assembly needs to be done carefully also. While the block has only the heater and thermistor connected to it screw the nozzle back into the block all the way (don't tighten yet) and once it is all the way in, back it off 1/4 of a turn.

Once you have the unit apart and your hot end nozzle in your hand, using a pair of pliers and a small gas torch (refillable ones are available at Bunnings quite cheap), and a toothpick, hold your brass nozzle with the pliers whilst heating it with the torch, once hot push the toothpick in carefully to push the blockage out and clean some of the excess filament from the nozzle. DO NOT attempt to push the toothpick through the small hole. To do the final clearing of the hole, and I do this on both my printers (my other is an ender3) I visited a local acupuncturist and purchase a few needles from him as they seem to be the right size for final clearing. Remember to heat the nozzle the same as before prior to using the needle to finally clean the tip. I always double-check that I can see light through the nozzle before re-assembly. Make sure also that you have removed all filament from the surface around where it enters the nozzle. Re-assembly needs to be done carefully also. While the block has only the heater and thermistor connected to it screw the nozzle back into the block all the way (don't tighten yet) and once it is all the way in, back it off 1/4 of a turn. Now screw the throat back into the other side by hand until it is tight against the nozzle. Making sure now that you are holding the block firmly from the 2 sides adjacent to the thermistor and heater, (I use vice grips) tighten the nozzle, not too tight as you can snap them, but quite tight as this will form the joint between the throat and the nozzle and prevent seepage from the joint which can make a real mess. This is why it is important to ensure that you have also cleaned filament from all external surfaces of your nozzle. This connection is very important and in the event of buying a new hot-end at any time always check this before installation. Take good care of your M12 nozzle as this type seems to be the most expensive of all the nozzle types to purchase. Also, check out Facebook groups for 3d printing as many of them have very experienced members and generally they are more than happy to help out with little problems like this.

Report

rap attack

oh thanks I have no experience with the heated thing so would rather replace the nozzle. I am too anxious to do things like that especially because I haven't before. Will check out what you said thoug...

Read moreh and read this again when I get home. appreciate your help

Report

Mark Kuzma

To replace your nozzle, or even your whole hot-end you will still have to follow the same process with the only missing part being the cleaning, which is not a hard thing to do

Report

Amanda Ngasked

How long does it take to print a basic item eg.5cm (L)x5cmx(B)3cm (thickness)? Thanks!

Share

More

3

answers

Mark Kuzma

As with all 3d printers the time taken will depend on your settings. For example if your fill setting is 20% it will print much quicker than it your setting is 30% or even higher. If your layer height...

For example if your fill setting is 20% it will print much quicker than it your setting is 30% or even higher. If your layer height...

Read more is 0.2 it will print faster than if your layer height is at 0.1, likewise 70mm per second print speed will take less time than 50mm per second. Every setting change alters the time taken to print your item and the quality of your print, although for the most part the quality difference is not always that noticeable. The instruction book with this printer is very informative and will guide you through the learning process. The manufacturer/supply company (winplus) whose contact you will also find within the book are also very helpful. You might like to check their website (winplus.com.au) for more information with regard to your new, or proposed new printer. Once you place your design into the software to recode it for printing, the software will give you a print time estimate. Sorry I am not prepared to offer you even an estimate of time for this print as there are far too many variables

Report

Amanda Ng

Hi

I understand it varies with size and structure. Thus I gave an example of say 50mm x 50mm x 3mm (height).. and maybe on an average setting of say maybe 50mm per second? If someone can give an esti...

Read moremate of if this was the size, how long would it roughly take to print. Am not asking for 'guaranteed' numbers. Just so to know what to expect.

Report

Priscilla

My first try and the item being printed slid off the magnet mat… would you please advise as to reason and remedy. I just don’t wish to waste any filament. Thank you

Report

Get an answer from our members and ALDI representatives

Ask your question

Details

| Category | Products |

|---|---|

| Release date | |

| Discontinuation date |

Extra Information

ProductReview. com.au has affiliate partnerships. These do not influence our content moderation policies in any way, though ProductReview.com.au may earn commissions for products/services purchased via affiliate links.

com.au has affiliate partnerships. These do not influence our content moderation policies in any way, though ProductReview.com.au may earn commissions for products/services purchased via affiliate links.

Review of 3D printer Anycubic Photon M3 • A guide to the photopolymer world

Again Anycubic and again Photon, but with the subtitle M3 - what will surprise the initial device in the new line? And will it surprise you at all? Find out in our review!

The devices from Anycubic in the review are always a small celebration for us, such a cozy friendly gathering where we can calmly talk about the pros and cons without fear of being disappointed in the end, because Anycubic hold the bar.

You are on the official LIDER-3D website and reading a review of the Anycubic Photon M3 3D printer!

Content:

- On company

- Assembly, appearance and equipment

- Technical characteristics

- Data transfer and management

- Software

- Video

- Where to buy?

- Company business card LIDER-3D

About the company

If you see a yellow protective cap, a nice streamlined design, a resin bath and a happy person who works with this device - most likely this is a 3D printer from Anycubic.

The Chinese company already has a bunch of good photopolymer printers in its arsenal, and Anycubic is definitely not going to stop there.

The best part is that the Chinese do not break the prices of their devices, so devices from Anycubic can be seen both in the hands of beginners and in the hands of professionals in the field of 3D printing.

Appearance and Package Contents

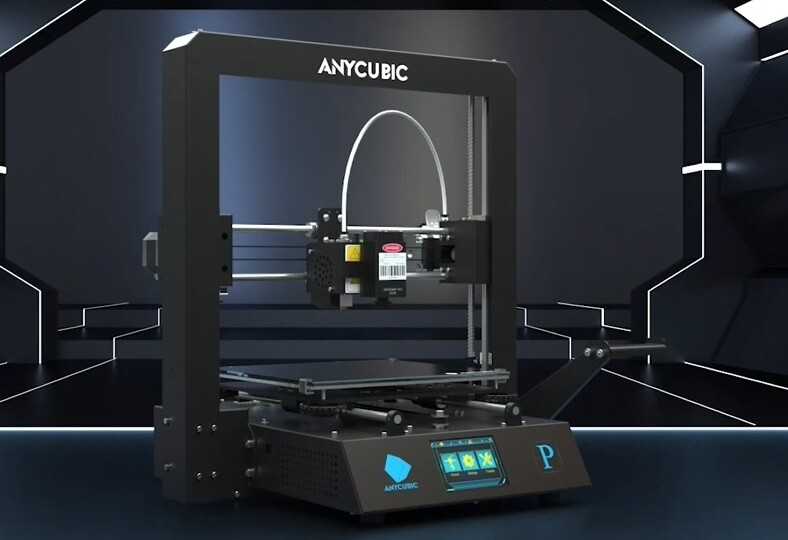

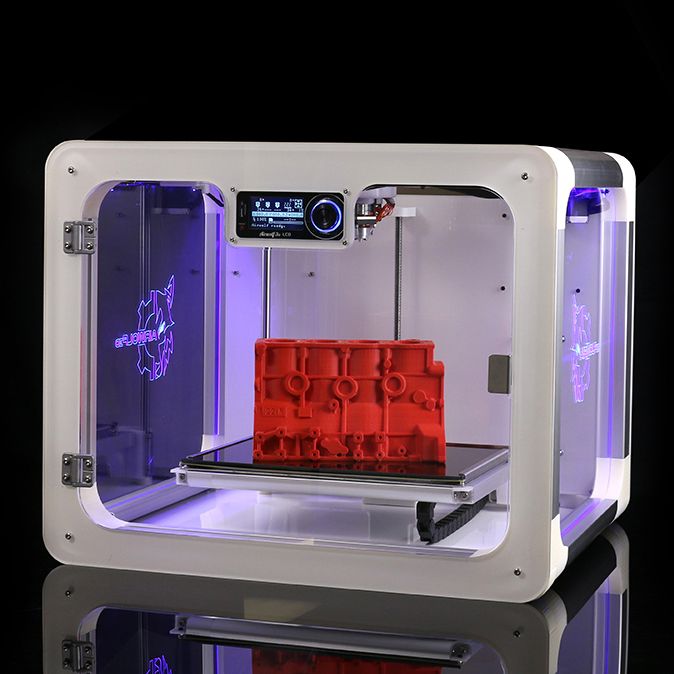

The Anycubic Photon M3 is the third generation of Anycubic photopolymer 3D printers. It's a compact printer with a recognizable Anycubic design and attractive price tag, which is tacitly positioned as the "entry level" device in the new M3 line, which also includes much larger and more expensive devices.

The Photon M3 is not a big step forward in technology compared to previous devices from Anycubic. Nothing really exciting or revolutionary. The only thing this printer tries to be is a solid platform on which to build your hobby and produce high quality print results.

This can be seen both in design and in characteristics (more on that later).

For now, let's talk about the configuration, although “talk” is a strong word. The package bundle of Anycubic is almost the same from device to device.

Specifications

Compared to the Photon Mono 4K, Anycubic's latest device in this price range, the Photon M3 has approximately 72% larger build volume, namely 163x102x180mm.

More print is nice, but what about resolution? The

Photon Mono 4K had a resolution of 35 microns, while the new Anycubic Photon M3 had a resolution of 40. In reality, this means very, very little. 5 microns is actually five thousandths of a millimeter. Unless you have absolutely perfect vision, you won't be able to detect such a small difference.

The Photon M3 matrix is monochrome, with a size of 7.6 inches and a resolution of 4096x2560 pixels, 4K is obtained. The screen is made of tempered glass with a layer of optical glue applied.

Plus, the Photon M3 features a new LED lamp with a 400:1 contrast ratio, which theoretically means sharper edges and a better surface finish.

Maximum Z-axis speed 10mm/s. By reducing the speed as you get closer to the screen, the layers light up better and the chance of print failures is greatly reduced. This, by the way, is a specific feature of Anycubic.

ThePhoton M3 features a new laser engraved platform to ensure excellent print adhesion.

It's hard to say if the laser engraving improved the print quality, but we can say that the prints adhered well to the platform and were also easy to remove.

A selection of articles from the "Knowledge Base" section from the LIDER-3D website: 1) How to choose a good portable 3D scanner • 2) 3D printing in jewelry: how does it work? • 3) Post-processing of models after 3D printing

Control screen and data transfer

Touch screens do not give the user much choice, they are either bad or good. The Anycubic Photon M3 has a 2.8-inch color touch screen, which was used in previous models from Anycubic. It is responsive and fast, but quite small in size.

The Anycubic Photon M3 has a 2.8-inch color touch screen, which was used in previous models from Anycubic. It is responsive and fast, but quite small in size.

You can transfer files via a USB stick or USB cable.

Software

Works Photon M3 with Lechee slicer or Anycubic Workshop proprietary slicer - which, by the way, is quite good and constantly improving.

Examples

Video review

And to carefully consider the Anycubic Photon M3 and take part in the prize draw, follow our video in order!

Total

The Anycubic Photon M3 is a great starter device if you want to dive into the world of resin 3D printing. This is not a printer that is trying to do something new, unusual or exciting. The Anycubic Photon M3 is simply a reliable resin 3D printer.

The improvements made by Anycubic to the Photon M3 are not very noticeable and therefore unlikely to appeal to those who already have, for example, Photon Mono 4K. However, people who are just getting started with photopolymer 3D printing are a completely different matter, and we can say with confidence that they will like this device.

However, people who are just getting started with photopolymer 3D printing are a completely different matter, and we can say with confidence that they will like this device.

Minor drawbacks - such as a small control interface - are really minor, and do not spoil the impression of the Photon M3. It feels like Anycubic could have tried a little more, and they did, with other devices in the M3 line that we'll cover in the future.

In the meantime, we leave you alone with a good photopolymer 3D printer for beginners who are going to print at home or for professionals who are going to teach beginners.

Thank you all, the material was prepared by a team of LIDER-3D specialists, we will be glad to hear your questions in the comments.

If you are interested in the Anycubic Photon M3 3D printer, you can get detailed expert advice by contacting us at LIDER-3D, as well as purchase this equipment on our website.

Follow us on social networks: Telegram, VKontakte, Ya.Zen, RuTube, YouTube, TikTok, My World, Odnoklassniki to be the first to receive the most interesting materials!

3d printers. Review of achievements for 2013 / Sudo Null IT News

Prostheses for humans and animals, 3D printing of space structures, food and shoes, improved printing accuracy, new materials, new software.

A bunch of projects on crowdfunding platforms.

Well, pistols, where would we be without them.

China, Japan, Australia, USA, Netherlands, Africa and Haiti, 3D printing seems to be everywhere in the world.

In 2014, 3D printing will go into space.

(Review of the achievements of 3D printing 2012 here)

We read what we achieved for 2013 under the cut ( 54 photos ).

January

The Chinese printed a 5 meter one-piece aircraft part from titanium

0003

Here is an aircraft that uses 3D printed parts

Hackerspace BioCurious offers a self-assembly bioprinter based on HP 5150 inkje

(the first inscription where instead of ink - "Escherichia coli")

The European Space Agency is conducting experiments to build a shelter on the moon using a 3D printer

1. 5 ton building block

5 ton building block

February

A team of scientists from Scotland, for the first time, using a 3D printer, print three-dimensional tissue from stem cells

Article PDF

3D Printed Urbee 2 Machine Ready for Production

change the way we make most things”

In February, there was a buzz with 3doodler, a 3D pencil that can “draw in the air”.

In just a few hours, they raised over a million dollars on Kickstarter.

Articles on Habré about this:

With the 3Doodler pen, you can draw three-dimensional objects directly in the air

Our answer is 3doodler. Assembled in 20 minutes

3Doodler is in a hurry to you! (Bonus: clone review)

In November, the "pencil" was delivered to Russia - the first (and last) review

Scientists printed an artificial ear

original article

Nike presented the world's first cleats printed on a 3D printer

4D printing. Self-transforming objects

Self-transforming objects

4D printing video at TED

March

The government of Singapore intends to invest $500 million in the development of the 3D printing industry.

3D printing makes it possible to create low-cost implants taking into account the anatomical features of patients

83-year-old inventor won $40,000 in a competition for his DIY extruder

April

Oxford University scientists say their 3D printer is capable of creating materials with some of the properties of living tissue0003

Created a 3D scanner capable of obtaining images from a distance of 1 km

The Chinese government intends to invest $6.5M in the development of 3D printing technologies

GE prints fuel injectors for aircraft engines

in two days

Printed ear capable of capturing radio frequencies

NASA awarded a $125K grant to develop a 3D food printer for astronauts who will fly into deep space

Saved life to the child, printing the trachea

NASA plans to send a 3D printer for the ISS in August 2014

The Japanese printed a carbon bunny the size of a bacterium

The Chinese showed the largest detail for a combat aircraft, printed on 3D Printing Printing Printers

June

UK government invests £14. 7m in 3D printing projects

7m in 3D printing projects

Polymers create 'artificial bone' that is 22 times stronger than the composite component

Microsoft built support for 3D printers in Windows 8.1

A foot was printed for a wounded duck

July

MIT develops software that makes it easier to work with composite materials

British children will learn robotics and 3D printing from the age of 5

Telegraph article

August

3D printed rocket engine passes NASA test, which was the starting point for many innovations to reduce the cost of spare parts production

Melbourne scientists have proposed a technology that allows you to grow your own cartilage for the knee joint from stem cells using a 3D printer

MIT scientists have developed a lightweight structure, the smallest details of which can be 3D printed and assembled like a Lego constructor. The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The world's first full-scale architectural installation Echoviren

September

Breakthrough technology - printing with dissimilar materials, both organic and inorganic materials: ceramics, metal, plastic and even biological cells

Developers from Disney introduced software that will allow you to create and print mechanical toys on a 3D printer

$100 3D printer - The Peachy Printer0135

Scientists from the Netherlands using a 3D scanner and 3D printer created reproductions of paintings by Rembrandt and Van Gogh

October

UK provides £500K grant to equip 60 schools with 3D printers

HP plans to enter the 3D printing market in mid-2014

Scientists have discovered that natural components (vitamin B2) can be used in the 3D printing process to create implants

Haiti has a 3D printer 9

November

Encryption software for 3D models released

Gelatin bio-ink for printing organs

Scientists printed 20 layers of liver tissue that lived for 40 days0135

Desktop metal 3D printer

Progress in the manufacture of lithium-ion batteries using 3D printers.