Online 3d printing service india

3D Printing Services in Bangalore

1. What is 3D printing and how does it work?

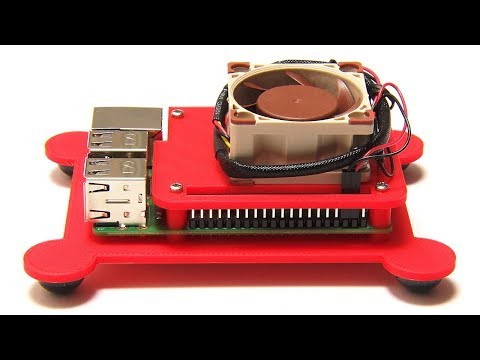

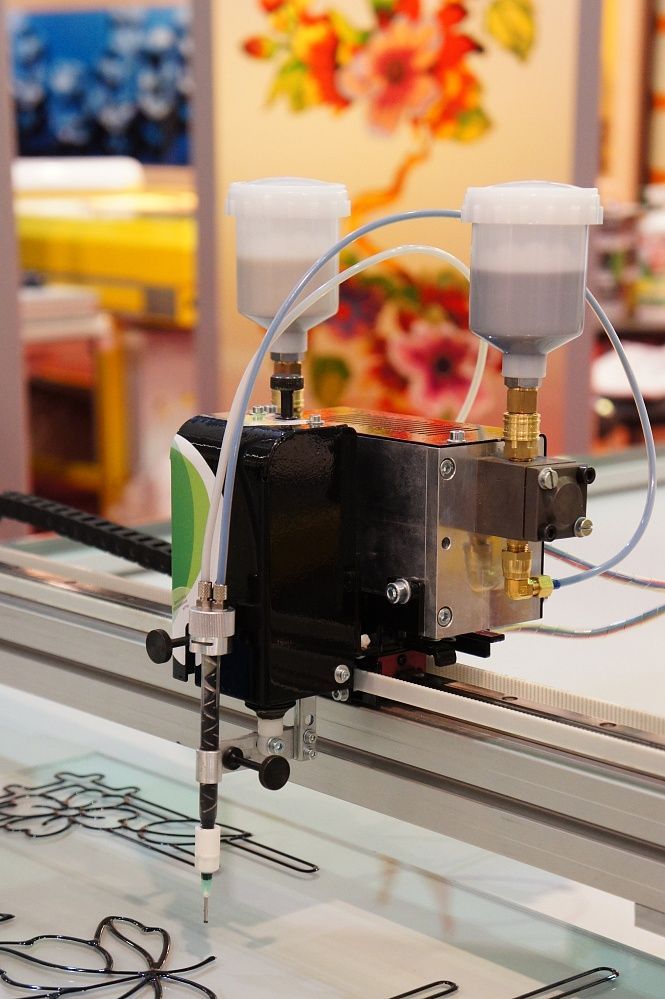

3D printing Bangalore is the process of creating a three-dimensional, physical object from a digital model. 3D printing service is sometimes referred to as “additive manufacturing,” although this term is used more frequently within the manufacturing industry to describe online 3D printing’s role in the industrial process.

3D printing in Bangalore begins with a 3D CAD model that is sliced into fine layers. The software turns these layers into instructions for your 3D printer, which deposits material layer by layer until the model is replicated. Excess material is removed post-process, leaving the user with a complete physical object. The software and materials that are used vary depending on the user’s intended application for the product.

2. What materials can be used in 3d printing?

Below are the materials used for 3D Printing in Bangalore:

ABS

ABS is a low-cost material, great for printing tough and durable parts that can withstand high temperatures while 3D Printing online.

Flexible

Flexible filaments, commonly referred to as TPE or TPU, are known for their elasticity allowing the material to easily stretch and bend for 3D Printing in Bangalore.

PLA

PLA is the go-to material for most users due to its ease-of-use, dimensional accuracy, and low cost.

HIPS

HIPS is a lightweight material most commonly used as a dissolvable support structure for ABS models in online 3D Printing India.

PETG

PET and PETG filaments are known for their ease of printability, smooth surface finish, and water resistance.

Nylon

Nylon is a tough and semi-flexible material that offers high impact and abrasion resistance. It is an ideal choice for printing durable parts.

Carbon Fiber Filled

Carbon fiber filaments contain short fibers that are infused into a PLA or ABS base material to help increase strength and stiffness.

ASA

ASA is a common alternative to ABS and is great for outdoor applications due to its high UV, temperature, and impact resistance for 3D Printing in India.

Polycarbonate

Polycarbonate is known for its strength and durability. It has very high heat and impact resistance making it an ideal choice for tough environments.

Polypropylene

Polypropylene is great for high-cycle, low strength applications due to its fatigue resistance, semi-flexible, and lightweight characteristics.

Metal Filled

Metal filled filaments are made by mixing a fine metal powder into a base material, providing a unique metallic finish, and added weight.

Wood Filled

Wood filaments combine a PLA base material with cork, wood dust, or other derivatives, giving the models a real wooden look and feel.

PVA

PVA is commonly known for its ability to be dissolved in water and is often used as a support material for complex prints in 3D Printing Bangalore.

3. Is 3D printing the future?

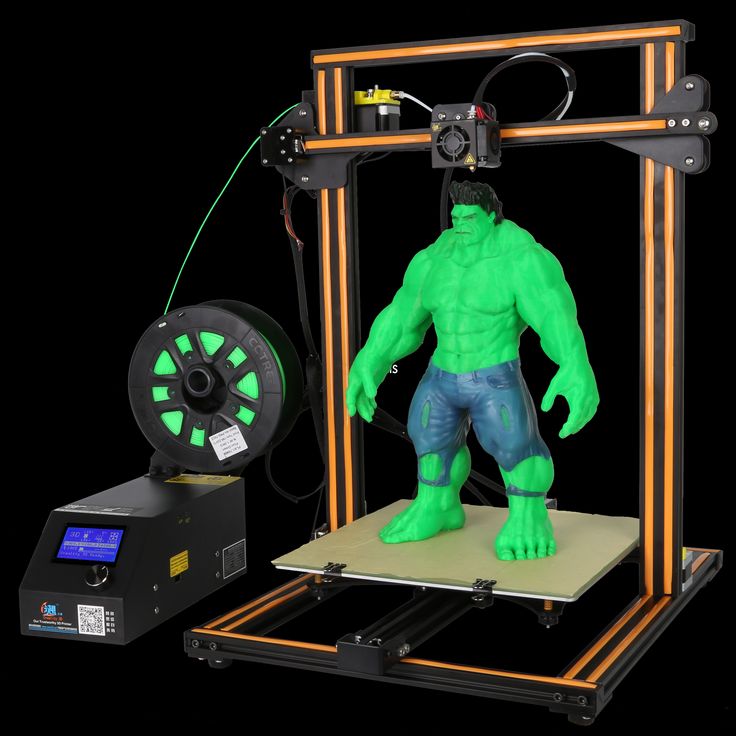

In short, Yes. 3D printing in Bangalore provides the design freedom to experiment with more effective and efficient part shapes, with fewer potential points of failure improving the management of a sensitive thermal environment. As product development cycles shrink across every industry, these capabilities give manufacturers a level of design, production, and supply chain flexibility previously unobtainable.

4. Why is 3D printing not popular?

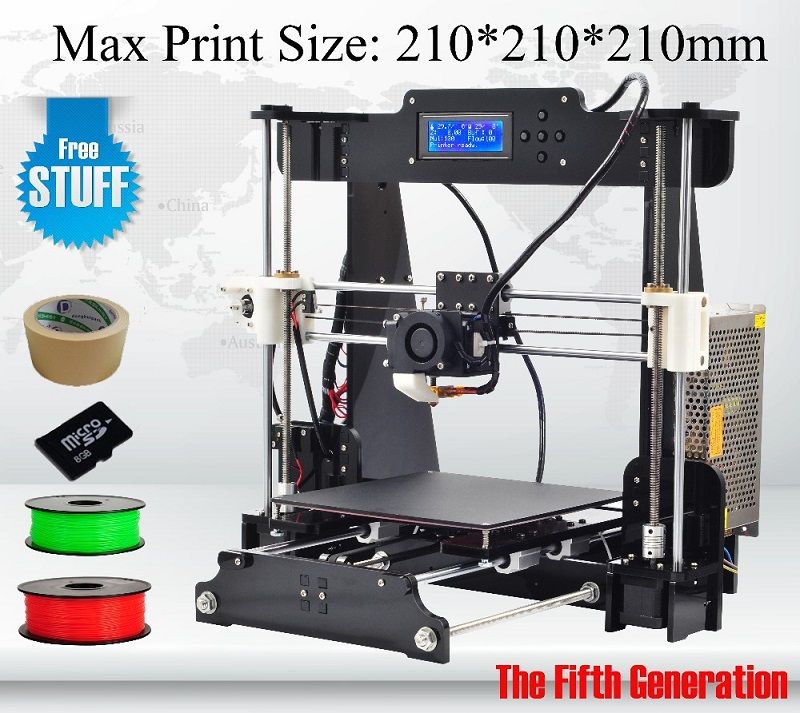

3D printing Bangalore is an upcoming technology, and it is already a part of INDUSTRY 4.0 . But on par we have to accept the fact that it is not commonly used except for the industrialists down the lane. According to us, a few reasons for its reduced popularity:

- 3D printers are costly ones but a one time investment.

- Basic CAD knowledge is necessary for working with 3D printing in Bangalore.

- Above all there are no predetermined properties for the printer materials i.

e., we do not know the performance of 3D printed materials

e., we do not know the performance of 3D printed materials - Any breakage caused by the whole component has to be replaced . It cannot be repaired unlike steel components.

5. Limited raw materials, not all material can be 3d printed with 3D Printing Bangalore.

5. Is 3D printing time consuming?

The quantity of parts being produced also has an impact on the amount of time it takes to complete a 3D printing Bangalore job. However, the reduction in print time is not as greatly reduced for more complex parts with short layers as the actual printing process is still fairly time-consuming.

6. How popular is 3D printing in Bangalore?

With the help of 3D Printing Bangalore, you can print anything from electronics to jewellery just sitting at home. Yes, that is what 3d printing service does! It has been in use in the industrial setting for almost 30 years and now it is advancing towards consumer as well as small scale-oriented businesses in Bangalore.

7. What can 3D printers make?

There’s much more on the list of applications for 3D printing in Bangalore, all happening now in myriad industries using a variety of innovative technologies and materials. Think dentistry, eyewear, prosthetics, furniture design, archaeology, palaeontology, and forensic sciences, to name just a few. And you can be sure that the creative and diverse uses for 3D printing Bangalore will continue to grow — and continue to improve the way we live and work.

8. Is nylon good for 3D printing?

Yes. When it comes to 3D printing materials, Nylon has to be mentioned as one of the most popular materials for professional users. This can be attributed in large part to its popularity outside of 3D printing Bangalore. Nylon has a wide range of applications thanks to its unique properties and the benefits of 3D printing in Bangalore mean that parts can be made on the fly easily and inexpensively.

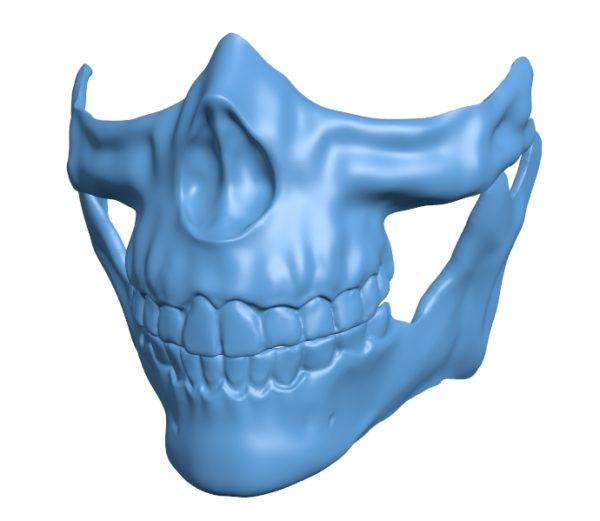

9. Is there a Limitation to what shapes you can 3D print?

No limits in terms of shapes, but no information on manufacturability. One of the principal advantages of 3D Printing Bangalore is that it is possible to imagine all shapes without the limits of the constraints of the plastics industry, such as undercuts, hollowness, respect for thicknesses, etc.

One of the principal advantages of 3D Printing Bangalore is that it is possible to imagine all shapes without the limits of the constraints of the plastics industry, such as undercuts, hollowness, respect for thicknesses, etc.

10. How can Makenica help me?

Makenica offers 3D Printing services in India with which it is possible to print complex geometric shapes and interlocking parts that require no assembly. It is also possible to produce single objects, in small quantities, at low cost and fast delivery. This technology of 3D Printing Bangalore at Makenica also helps in the reduction of production-related material loss.

11. Why to Choose Our 3D Printing Service in Bangalore?

Here are the reasons why 3D Printing Bangalore with Makenica is popular:

- Flexible Design

- Rapid Prototyping

- Print on Demand

- Strong and Lightweight Parts

- Fast Design and Production

- Minimising Waste

- Cost Effective

- Ease of Access

- Environmentally Friendly

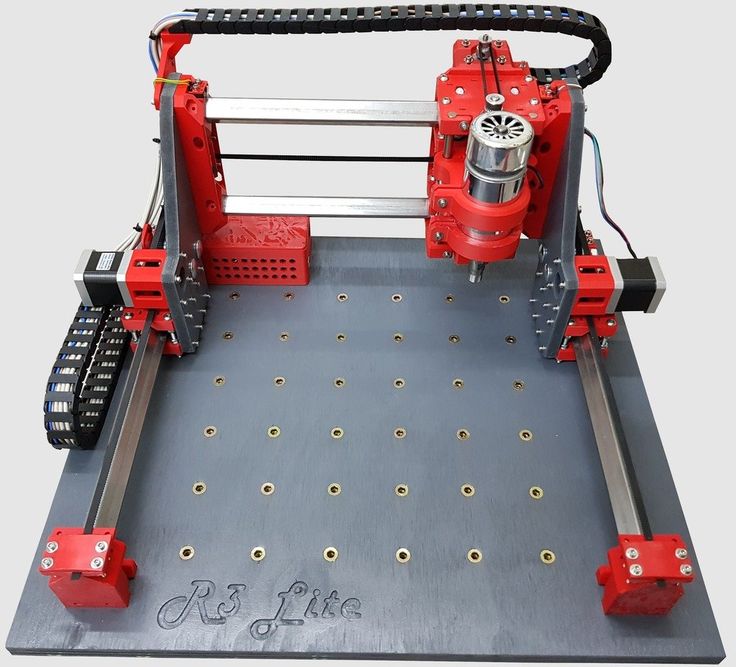

- Advanced Equipment

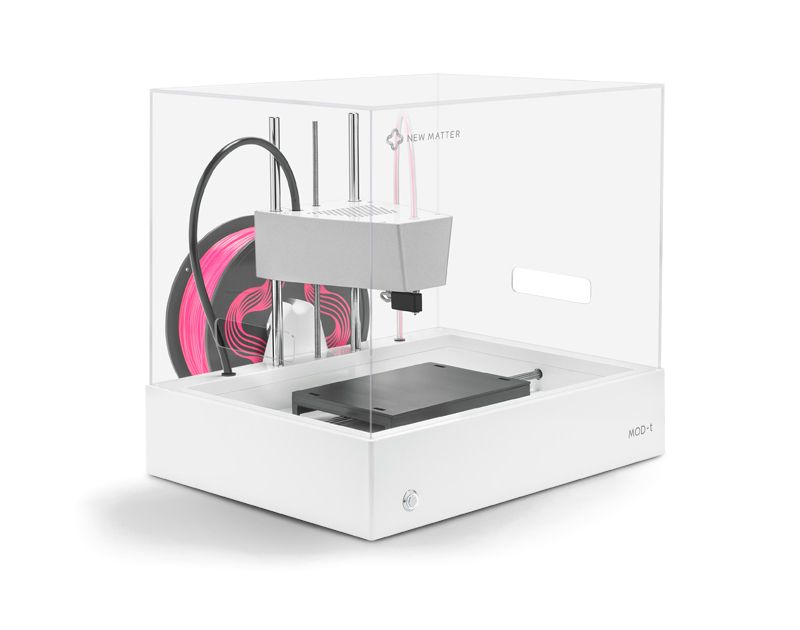

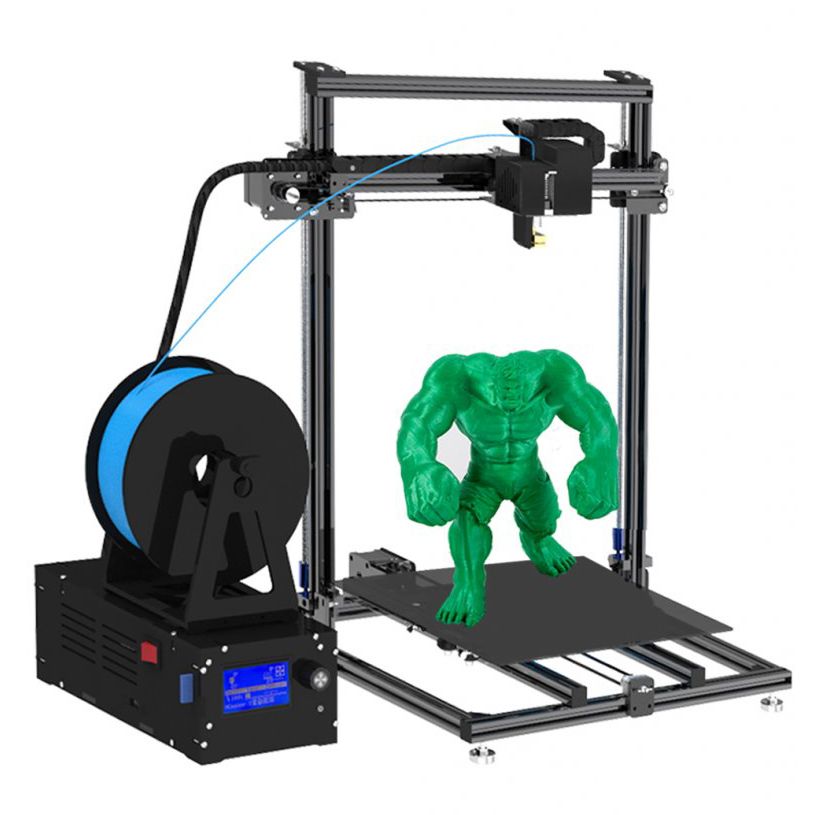

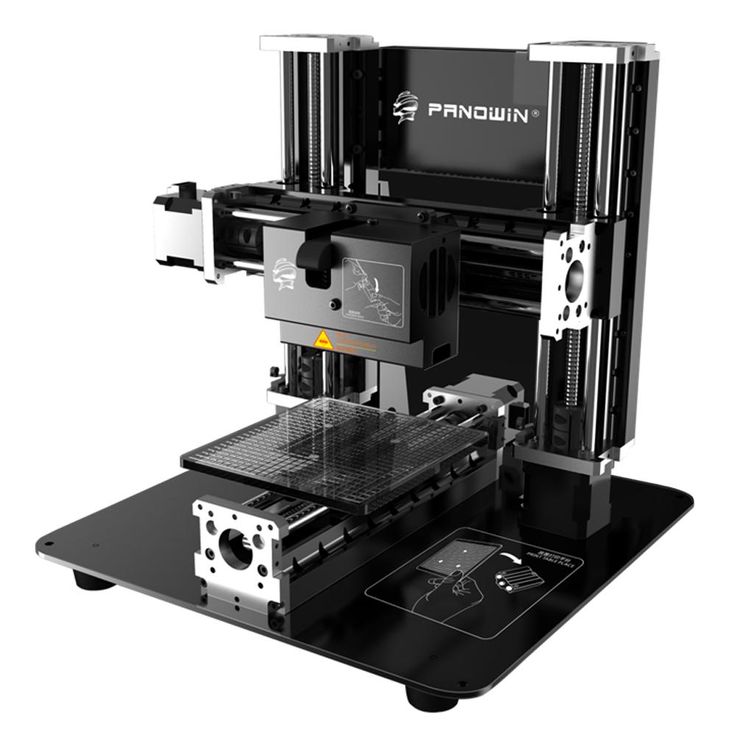

12. What types of 3D printers are there?

What types of 3D printers are there?

The seven different types of 3D printers used for 3D Printing in Bangalore are:

Fused deposition modelling (FDM)

Stereolithography(SLA)

Digital Light Processing(DLP)

Selective Laser Sintering (SLS)

Selective laser melting (SLM)

Laminated object manufacturing (LOM)

Digital Beam Melting (EBM)

13. Which Cities Makenica Service in India ?

Makenica, with a significant presence, is the country's greatest pool of 3D Printing expertise, with competent professionals. Makenica has five facilities in Bangalore, with headquarters in the United States. This broad reach has enabled us to provide excellent service to a large customer base. The online 3D Printing services available at Makenica range from personalised to one-of-a-kind bespoke solutions. Each customer is guided on their route to quality production by our team of specialists.

Vacuum Casting Service Online - Rated 4.9/5 by more than 307 Clients in 2020

LEARN MORE

1. What is Vacuum Casting Service?

What is Vacuum Casting Service?

Vacuum Casting is used for the production of low volume production (<200 nos) of functional plastic parts. This is achieved using two-component polyurethanes and silicone molds, Vacuum Casting is known for its fast production of high-quality prototypes or end-use products while being highly affordable.

The vacuum casting process is a casting process which is used for the manufacturing of small numbers of highly accurate polyurethane prototype parts of functional materials usually plastic, rubber and metals.

with characteristics and quality comparable to the final product.

This is a slower process than SLA as it requires the additional steps involved in the process, some of which are intensive.

2. Why should you opt for Vacuum Casting or Urethane Casting Service?

Vacuum Casting also known as Silicone molding produces high-quality parts comparable to injection-molded components. This makes vacuum casted models especially suitable for fit and function testing, showcase materials, marketing purposes, or a series of end-use parts in limited quantities (< 200 nos). Vacuum Casting offers a variety of finishing degrees, and we can even match the finish you need for your parts.

Vacuum Casting offers a variety of finishing degrees, and we can even match the finish you need for your parts.

3. What is Silicone Molding?

Vacuum Casting is also known as Silicone Molding and is referred to as Silicone Molding since it uses Silicone as the primary material for mold making.

4. What is Urethane Casting?

Urethane is the scientific name for Silicone Resin using which the main mold is created. In some industries, vacuum casting or silicone molding is referred to as Urethane Casting Process.

5. How does Vacuum Casting/Urethane Casting works?

While Urethane Casting seems easy, it carries many nuances that make or break your end-parts finish. Here is an overview of the process:

- Step 1: Getting the 3D Design Ready

- Making a product design that confirms with the tolerances will reduce costs as well as time.

- Step 2: High-Quality Master Model

- We fabricate an ultra-realistic model of your design using SLA Process or Polyjet FDM 3D Printing.

- We double-check the dimensions and looks of the Master Model as per the end results we wish to achieve.

- We fabricate an ultra-realistic model of your design using SLA Process or Polyjet FDM 3D Printing.

- Step 3: Making the Mold Cavity

- The master is immersed in silicone to form the master mold

- The mold is cured under high temperatures to ensure that silicone toughens.

- Then the mold is cut open into two parts which can be stick together again. This is used to strengthen the mold and make it more durable.

- Step 4: Producing Parts from the Mold Cavity

- We fill the opening of the Mold Cavity with the desired materials and let the resin material cure itself into the shape as per the specs of Master Pattern.

- After a few hours, we open the mold and repeat the above steps.

- Step 5: Discarding the master mold

- It is advised to discard the master mold after 15-20 runs per mold.

- We re-make the master mold using the Master Pattern until the Master Pattern can withstand extreme temperatures of the Silicone without losing its dimensional accuracy.

That's it. In order to get a quick quotation for Vacuum Casting Service, click here

The process is carried out in steps: -

- Have A High-Quality Master Model

The first step in Vacuum Casting is to generate a high-quality surface finish master model, either using Stereolithography or Laser Sintering.

Followed by casting silicone around the master copy, partially under vacuum to avoid air bubbles.

The master model being used is made with utmost attention in dimensions and looks to make sure that no flaws are transferred to the model prototype after finishing the process.

- Cure Process

In Next step, the master model is enclosed into a two-part silicone rubber mold.

The mold is then cured under high temperatures to ensure that the two parts stick together.

After this, the silicone mold is cut according to pre-defined parting planes and the master is removed, leaving a cavity to make copies.

After the mold is cut into two, it is kept in the vacuum chamber.

- Filling the resin

In this step, fill the mold with the designated material.

The resin material is sometimes mixed with metallic powder or any coloring pigment to achieve aesthetic or specific functional properties.

Later it is placed in the vacuum chamber to ensure that there are no air bubbles in the mold.

- Final cured process

In the final stage, the resin is kept in the oven.

The mold is cured in high temperatures to ensure that the material is strong and durable.

Silicon is removed from the mold so that it can be used in making more prototypes.

At last the prototype is removed from mould and painted and decorated.

The painting and designs are used to ensure that the product has a gorgeous final look.

6. What are the Vacuum Casting Service tolerances?

Here are some of the Vacuum Casting or Urethane Casting Service tolerances:

| Distance Dimensions | +/- 0. 010” or +/- 0.003” per inch, whichever is larger, is typical. 010” or +/- 0.003” per inch, whichever is larger, is typical. |

| Shrink Mitigation | A shrinkage rate of +/-0.15% can be expected due to thermal expansion of the liquid, and the response of the flexible mold. |

| Surface Quality | The surface finish is externally smoothed to a glossy, satin, or matte surface. |

| Feature Definition | Extreme sharp corners and small text may appear slightly rounded. |

| Size Recommendation | Parts can be as large as 500mm on any one side. |

7. What is the minimum order quantity for Vacuum Casting Service?

The minimum order quantity for Urethane Casting Service is as follows:

- One Master SLA Part

- One Master Mold Cavity

- One Run of Mold Cavity

8. What are the size limitations for Vacuum Casting Service?

| Maximal part size | 500 mm (40in) |

| Minimal part size | 1. 0 mm (0.04 in) 0 mm (0.04 in) |

| Minimal diameter | 0.6 mm (0.02 in) |

9. What is the assurance on the output quality of the Vacuum Casting Parts?

Every Vacuum Casting service order includes our standard inspection file that includes reports and certifications such as:

- Critical dimensions

- Quantity of parts

- Removal of sharp edges and burrs

- Number of parts inspected

- Surface finish

- Threads and tolerances

- Full dimensional inspection report

- Resin material test report

- ISO9001, ISO14001, ISO27001, and IATF 16949 certifications

10. How many outputs can you get from one Vacuum Casting Mold?

Every Master Pattern can make up to 3 Mold Cavity and each Mold Cavity can produce 15 to 25 parts based on the product design.

In one total run, you can expect between 45-75 parts from one Master Pattern.

11. Which plastics are supported for Vacuum Casting Service?

Vacuum Casting offers a variety of industrial-grade materials to suit your end-part needs. Some of those are as follows:

Some of those are as follows:

| Nylon-6 (Cast) |

| PP-Like |

| PC-Like (Clear) |

| Acrylic (PMMA) |

| Flame retardant (8263) |

| Nylon-12 (PA 2200) |

| High Temperature |

| Teflon (PTFE) |

| Elastomers |

| ABS-Like |

| PP (Machining) |

| ABS (Basic) |

| ABS |

| PC-ABS (8051) |

| Rubber (VC 3300) |

| Ultra Detail (Vero) |

| ABS Transparent (8095) |

| Nylon (VC 3365) |

| Tough Resin |

| POM (Delrin) |

| ABS Black (PX-223HT) |

| ABS Food Grade (9012) |

| Rubber-Like (Tango) |

| GF Nylon-12 (PA 3200) |

| PLA (Basic) |

| Polypropylene (8045) |

| High Temperature (8060) |

12. Which material finishes are available with Urethane Casting Process?

Sadly, vacuum casting doesn't allow much choice when it comes to surface finishes. You can post-process the end-parts to make them look appealing in either Matte Finish or Glossy Finish.

You can post-process the end-parts to make them look appealing in either Matte Finish or Glossy Finish.

13. Which industries use Silicone Molding Services?

Silicone Molding is a process that every manufacturing company deploys before going into the Injection Molding Process. Here are some of the industries which use Silicone Molding extensively:

- Automotive Mould

- Aircraft Parts

- Home Appliance Mould

- Household Plastic Mould

- Connector Mould

- Crate Mould

- Package Mould

- Cooking Utensils

- Medical Devices

• This method can be opted for producing cost-effective low volume production.

• It can be used to build models and prototypes of any size.

• Pre-launch product testing

• Small series of housings and covers

• Concept models

• Food and Beverages

The food and drinks industry use this product for packaging of their final products.

• Commercial Products

Commercial products include sunglasses, mobile cases, food and drinks packaging, and pens.

• Household Products

Products like washing detergents, food processing, and cosmetics are manufactured using this process.

14. What are the benefits of using Vacuum Casting Service?

While there are many benefits to Vacuum Casting Service, we have summed up a few that are highly critical:

- Access to industrial-grade materials

- 80% Injection Molding Quality of the end-part

- Best suited for low volume production

- Low investment in tooling and preparation costs

- Economical and Fastest turnaround time

The vacuum casting process results in high-quality products as compared to injection molded components.

Fine detail to the finished product

High precision in producing exact replicas of a prototype on a large scale.

Every attention to detail is considered and taken into account no matter how complex.

Vacuum casted models are usually used for functioning testing and marketing purposes. The end product has such good finishing that this technique has attracted a large set of the audience towards it.

The end product has such good finishing that this technique has attracted a large set of the audience towards it.

High quality of the product

resin allows you to choose the right material to be used in making of the final product.

This allows you to have a wider choice of flexibility, hardness and rigidity expected in products.

All this leads to a higher quality of products.

Lowers the production costs

Vacuum casting process is more economical manufacturing method than others as Silicone is affordable as compared to aluminum or steel.

Hence it becomes more cost-effective process as compared to the use of 3D printing.

Ideally one silicone mold can produce up to 20 good replicas but again the capability may vary as per the design complexity & quality acceptance.

A great method when you want to meet a deadline

Vacuum casting is a fast method for low volume production. It usually takes up to seven to ten days to make around 50 functioning prototype parts.

It usually takes up to seven to ten days to make around 50 functioning prototype parts.

Heat resistance

- Colours and tints

- Fire retardance

- Flexibility and rigidity

- UV stability

15. Is there a difference between Urethane Casting and Silicone Molding?

Nope. They are the same and sometimes used interchangeably with Vacuum Casting Services.

16. What is the cost comparison between various manufacturing processes?

For a standard part that we checked on our in-house Vacuum Casting Setup, costs for various processes are as follows:

- 3D Printing -> INR 4500 for 1 part

- CNC machining -> INR 7000 for 1 part

- Urethane Casting -> INR 4000 for 1 part

- Injection Molding -> INR 60 for 1 part with the cost of mold starting at INR 70,000

17. How to reduce Vacuum Casting ServiceCost?

Here are some ways to reduce the overall cost of your vacuum casting process:

- Remove Unnecessary Rounded Internal Corners

- Limit the Depth of Cavities

- Limit Use of Tight Tolerances

- Avoid Flashy Surface Finishes

- Remove Small Text & Lettering

- Avoid Small Features with High Aspect Ratio

- Use Widely Used Materials

- Increase the Thickness of Thin Walls

- Choose Quantity and Turnaround Time Tradeoffs

18. How to choose material for Vacuum Casting Services?

How to choose material for Vacuum Casting Services?

While there are various methods of choosing the material, the end choice depends on the use case of your product. Nonetheless, here are some metrics which will help you choose the right material:

- Physical appearance quality

- Surface texture/finish

- Transparency/translucence

- Rigidity

- Flexibility

- Strength

- Hardness

- Temperature resistance

- UV stability

- Colour

19. What are the technical specifications for Vacuum Casting?

Vacuum Casting Technical Specifications

Typical lead time | Up to 20 parts in 15 days or less, depends on the part specification and volumes. |

Accurate | ± 0.3% (with lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

Minimum wall thickness | To ensure that the mold is filled properly, a wall thickness of at least 0. |

Maximum part dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

Typical quantities | Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

Color & Finishing | Pigment is added to the liquid polyurethane prior to casting, custom painting and texture. |

20. Which cities do we provide Vacuum Casting Services in?

Makenica provides the vacuum casting services in all tier-1,2 & 3 cities.

TIER-1 CITIES:

Bangalore

Chennai

Delhi

Hyderabad

Kolkata

Mumbai

Ahmedabad

Pune

TIER-2 CITIES:

Agra

Ajmer

Aligarh

Amravati

Amritsar

Asansol

Aurangabad

Bareilly

Belgaum

Bhavnagar

Bhiwandi

Bhopal

Bhubaneswar

Bikaner

Bilaspur

Bokaro Steel City

Chandigarh

Coimbatore

Cuttack

Dehradun

Dhanbad

Bhilai

Durgapur

Erode

Faridabad

Firozabad

Ghaziabad

Gorakhpur

Gulbarga

Guntur

Gwalior

Gurgaon

Guwahati

Hamirpur

Hubli–Dharwad

Indore

Jabalpur

Jaipur

Jalandhar

Jammu

Jamnagar

Jamshedpur

Jhansi

Jodhpur

Kakinada

Kannur

Kanpur

Kochi

Kolhapur

Kollam

Kozhikode

Kurnool

Ludhiana

Lucknow

Madurai

Malappuram

Mathura

Goa

Mangalore

Meerut

Moradabad

Mysore

Nagpur

Nanded

Nashik

Nellore

Noida

Patna

Pondicherry

Purulia Prayagraj

Raipur

Rajkot

Rajahmundry

Ranchi

Rourkela

Salem

Sangli

Shimla

Siliguri

Solapur

Srinagar

Surat

Thiruvananthapuram

Thrissur

Tiruchirappalli

Tiruppur

Ujjain

Bijapur

Vadodara

Varanasi

Vasai-Virar City

Vijayawada

Visakhapatnam

Vellore

Warangal

five services for working with 3D-graphics in the browser / Software

When the first three-dimensional animated pictures and new games with a 3D environment began to appear on the screens, users showed great interest in this area of computer graphics. Shrek, Toy Story, Monsters Inc. and other 3D films seemed at first to be something very unusual. After viewing such brilliant works, many had a desire to figure out how all this is created. But over time, the excitement around three-dimensional graphics has cooled down, and the release of the next Shrek series today does not arouse its former interest.

Shrek, Toy Story, Monsters Inc. and other 3D films seemed at first to be something very unusual. After viewing such brilliant works, many had a desire to figure out how all this is created. But over time, the excitement around three-dimensional graphics has cooled down, and the release of the next Shrek series today does not arouse its former interest.

Computer "3D" has become better, and designers have stopped using 3D where it is not needed. A clear example of this misplaced use of 3D is the game Worms, which lost its appeal as soon as they tried to create a three-dimensional arcade game from it.

And yet today we again see a growing interest in 3D, only its cause is completely different - it no longer lies in the banal question "How is it done?". Now that the Internet has reached a certain level of development, users have the opportunity to use three-dimensional technologies right in the browser window. And the prospects for this direction are obvious - from interactive games to completely new unusual web applications and services. Both those who directly create 3D graphics and those who are just discovering this most interesting world can appreciate the potential of the "three-dimensional" Internet.

Both those who directly create 3D graphics and those who are just discovering this most interesting world can appreciate the potential of the "three-dimensional" Internet.

3D web services use WebGL technology. It allows you to create any 3D content using a web browser as a platform. In other words, you don't need to install any additional software to work with 3D graphics in the browser. WebGL supports hardware acceleration, so not only the resources of the central processor, but also the capabilities of the video card can be used to render 3D animation. Using WebGL, you can create games in the browser, but the presence of many services for working with 3D confirms that the technology is already actively used not only for entertainment, but also for quite serious tasks.

However, keep in mind that services running on WebGL require the presence of Google Chrome or Firefox browsers (in Opera, technology support has not been finalized - it remains a test function). Judging by our experience, it is still better to give preference to Chrome - in many cases, 3D is not displayed in Firefox, although its support is officially announced.

⇡#Viewing 3D models in a browser

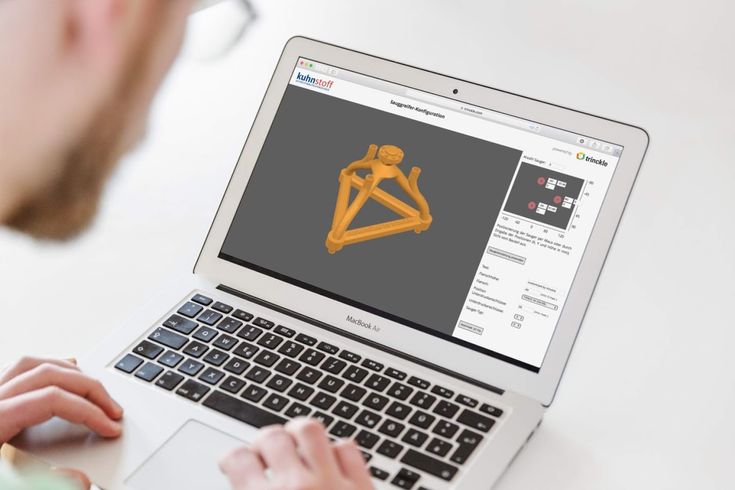

One of the uses of WebGL technology is to display 3D models. Let's suppose that the created model needs to be shown to a client who does not understand anything in 3D and who does not have any applications for working with 3D graphics installed on his computer. You can take a screenshot or several visualizations, but any model looks much more impressive if it is viewed in 3D. Services for viewing models in a browser make it possible to demonstrate your work on any computer that has a modern browser.

Some of these services can even be used as an online portfolio. To show off their skills, a 3D modeler used to have to spend time rendering models from different angles and with different presentation options (mesh, smoothed, etc.), creating a showreel based on them in a video editor, uploading it to the Internet, etc. With services for viewing 3D models in the browser, everything is much simpler.

P3d.in

The P3d. in service allows you to upload models in OBJ format to the site and share them. After downloading, a link like http://p3d.in/BIcqM is generated. If you go along it, you can view the model from all sides, rotate it, zoom in. It is very convenient that different representations can be used for viewing: grid, solid color, grid on a smooth surface, and so on.

in service allows you to upload models in OBJ format to the site and share them. After downloading, a link like http://p3d.in/BIcqM is generated. If you go along it, you can view the model from all sides, rotate it, zoom in. It is very convenient that different representations can be used for viewing: grid, solid color, grid on a smooth surface, and so on.

The account owner can work with their models in the web gallery, sort them using tags, add descriptions, manage the initial view of the camera. Basic material customization is also possible: you can control the color and presence of texture for the Diffuse and Specularity parameters, as well as the placement of the texture on the object. When switching to a paid account, the ability to manage materials is added: additional types of maps appear (Bump, Ambient Occlusion), the maximum allowable texture resolution increases, and it becomes possible to upload pictures in PNG. So far, Pro-accounts are only being tested, so you can take advantage of all their benefits completely free of charge.

Sketchfab

Sketchfab can be seen as a more advanced version of P3d.in. If the previous site is a good fit for those who need to showcase individual 3D models to clients from time to time, Sketchfab is the place to build a real online portfolio.

For $7/month Sketchfab hosts a complete portfolio site like myname.sketchfab.me where you can post your details and upload all your models (just models, not images that often take a long time to render). watch). A potential employer will be able to see all the models in 3D and view them from all sides.

However, the site can be used for free. In this case, a page like sketchfab.com/3dnews is created, which is similar to a thematic social network profile. On it you can see all the models uploaded by the user and the number of their views. Other Sketchfab users can comment on the model, like it, and subscribe to updates.

It's worth keeping in mind that with a free account it's not possible to make models public only for private access, so you need to remember: the content that is uploaded to the service becomes visible to everyone.

However, the developers of Sketchfab made sure that users can present their models in the best possible way. You can choose to display with or without shaders and mesh, control many material parameters, add one of four solid background options, or place the model against an image background (starry sky, winter forest, and so on - more than 10 options in total).

Screen Space Ambient Occlusion (SSAO) can also be used to display the model better. In edit mode, useful information about the model is available: the number of triangles and vertices. Sketchfab supports many formats, including OBJ, 3ds, blend, DAE.

Verold Studio is the youngest member of our review. The project, launched only last summer, was created already when Sketchfab and P3d.in existed on the market, so its developers tried to offer something that competitors do not have. The first is more opportunities for working with materials. Verold Studio has a built-in miniature material editor, so there are many more opportunities to make the model beautiful. You can add reflections, highlights, and so on.

You can add reflections, highlights, and so on.

A variety of lighting options are also available, with backlight, fill light, backlight separately controlled. Just like Sketchfab, this site allows you to use background images and flexibly customize the background. But there are many more options for presenting the model. You can, for example, turn on the normal or UV rendering mode. Another nice feature of Verold Studio is that you can load models with a simple drag and drop from the file manager.

Verold Studio also focuses on project collaboration. The service offers many social features, in particular, real-time multi-user discussion of projects. Like Sketchfab, there is an option to subscribe to new user models. True, in terms of user pages, Verold Studio is clearly lagging behind - a profile page with an address like studio.verold.com/users/519dd09d6e7eb82000000a2 clearly loses to the simple address that Sketchfab users receive. Yes, and the Sketchfab model editor seemed clearer to us, so the young Verold Studio project still has work to do.

⇡#3D graphics in the browser - for 3D printing

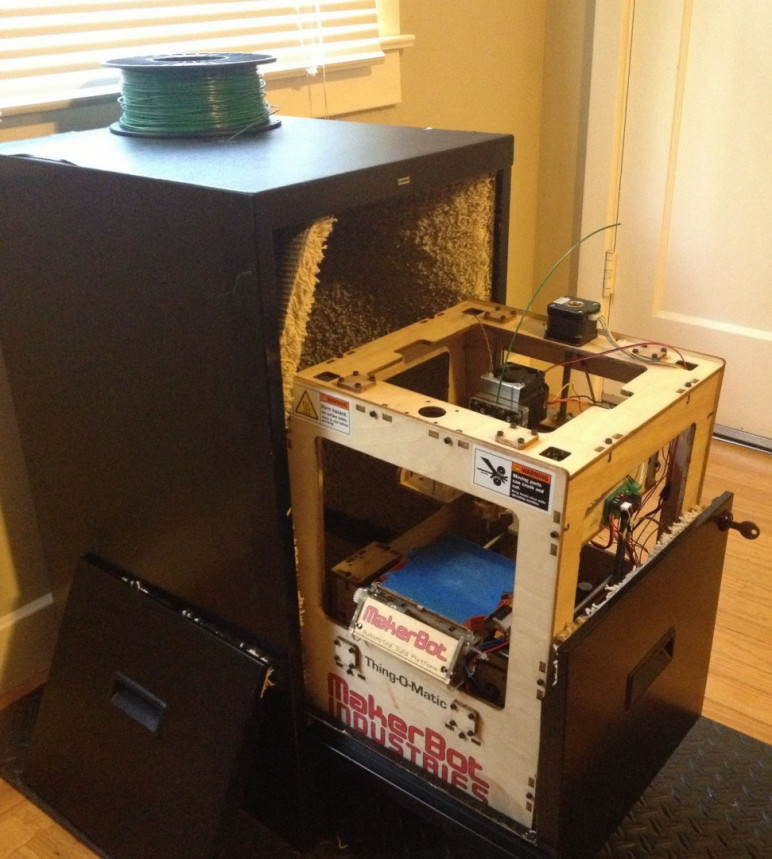

3D printing has given a new impetus to the study of three-dimensional graphics. For many, this direction is still a novelty, but it is already becoming clear that three-dimensional printers will gradually become completely “home” peripherals over time.

The development of 3D printing technology has made the impossible possible. From now on, with the help of a three-dimensional printer, you can create things in minutes that would have taken weeks to produce. The only thing required to create an item, other than equipment, is a 3D model.

Of course, you can make them in traditional programs for working with three-dimensional graphics, but learning all kinds of 3D studios at a professional level takes a lot of time. The process of creating a completed project in a 3D editor involves several stages, each of which requires skills in a certain area - in texturing, setting rendering parameters, preparing animation, and so on. However, for 3D printing, only one stage of development is most important - 3D modeling. And it is quite possible to cope with it using web applications for working with three-dimensional graphics.

However, for 3D printing, only one stage of development is most important - 3D modeling. And it is quite possible to cope with it using web applications for working with three-dimensional graphics.

3DTin is an online 3D editor created by a small group of enthusiasts from Mumbai, India in 2010. In a relatively short period of time, the service has gained a large number of users. In May of this year, the number of registered users exceeded 100 thousand people. Such popularity is natural - a few years ago a three-dimensional editor in the browser seemed impossible.

3DTin has only a basic set of functions for 3D modeling (primitive 3D shapes, transformation tools, 3D text), but even this minimal set of tools is enough to build 3D scenes. The web app even has the ability to create animations!

If you have never worked in 3D before, it will be very easy to learn the functions of 3DTin. Firstly, you can select the Russian language in the interface settings, and secondly, you can learn the online editor using video tutorials integrated into the web application's help system.

Models created in the web application can be sent to popular 3D printing services or exported to STL, OBJ, DAE. All data is stored in the cloud, so you don't have to worry about the safety of your work. After completing the simulation on one computer, you can continue working on another after some time.

Tinkercad was the first 3D CAD editor to run in the browser. Its main purpose is to create models for 3D printing. The editor's interface is very similar to SketchUP - it's just as easy to add and manipulate 3D objects. Resizing, moving and rotating are performed by moving the handles that surround the object. When resizing, you can immediately see the size of the model in millimeters or inches - at the user's choice. There are also tools for alignment and mirroring. Tinkercad has a lot of ready-made models. These are not only geometric objects, but also all letters of the English alphabet, numbers, punctuation marks, and other popular symbols (heart, asterisk). You can also quickly create chicken paws, an egg and rabbit ears.

Finished projects can be saved in STL, OBJ, VRML, X3D and SVG formats. If desired, the user can not bother with formats, but simply immediately send the project to one of the four supported 3D printing services. The file will be uploaded to the service, which will automatically determine the cost of printing.

In March of this year, Tinkercad almost shut down. Its creators decided to focus on the new Airstone project, closed the registration of free accounts and announced the complete cessation of the service in mid-summer 2014. Fortunately, Autodesk, which has been actively developing not only software for working with 3D and CAD, but also thematic web services and mobile applications, has become interested in an interesting project. A week ago, a Canadian company bought Tinkercad, reopening registrations and giving free account users more options. For freeware accounts, all the possibilities of importing and exporting projects now work, restrictions on the number of created designs have been lifted. You can also use Shape Scripts as part of a regular account, creating your own 3D objects using a scripting language.

You can also use Shape Scripts as part of a regular account, creating your own 3D objects using a scripting language.

⇡#Conclusion

WebGl technology destroys the stereotype that the browser is an informational application suitable only for viewing graphics, video and text. Now its possibilities are much wider, and even working with 3D does not seem to be something particularly unusual. And this is just the beginning. The most interesting will begin when online web applications can compete with desktop programs. And judging by the capabilities of the services presented in the review, it will be very soon.

List of 3d printing services / Sudo Null IT News

AndreyPanov

3D printers

Good afternoon everyone!

On Habré, you can relatively often see articles on 3d printers, comparing their prices and ordering opportunities with us.

And what about the finished 3D models?

What if I don’t want to buy a printer yet, but it would be interesting to “feel” the printed model. And it is advisable to choose from a catalog of ready-made models, and not draw it yourself.

Are there many resources where they can be downloaded, bought or printed from the catalog?

Answering these questions, I decided to make a small list of resources with the ability to select ready-made models and order printing.

Foreign services:

- www.thingiverse.com is probably the most well-known one in existence. The service was created for the free exchange of models under the GNU General Public License. The service has been operating since 2008. Owned by MakerBot Industries, USA.

- www.shapeways.com - custom printing. The service has been operating since 2011. Production (printing) is located in the Netherlands and the USA. You can add your own, you can even create your own store.

Due to the extensive fleet of 3d printers, they provide a large selection of materials, including ceramics and steel. They deliver to Russia.

Due to the extensive fleet of 3d printers, they provide a large selection of materials, including ceramics and steel. They deliver to Russia. - i.materialise.com/gallery - Print models from the catalog. The company has been operating since 1990 and is located in Belgium.

- It is also possible to evaluate your model and choose a material

- www.sculpteo.com/en/gallery/today - print 3d models and sell your own. There are quite complex and expensive models.

- www.kraftwurx.com - a platform for creating 3d models and selling them.

- www.turbosquid.com — database of 3d models for game designers, architects, etc. Many models were not created for the purpose of 3d printing, you can find something.

Russian services:

- 3dmarket.org is a service that allows you to download and upload models, as well as select an artist for printing.

If the list is not complete, please add in the comments, I will update the post.

75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm

75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm