3D printed diamond ring

$100 3D Printed Engagement Ring

Conventional wisdom says to spend one to three month's salary on your engagement ring. My fiancée and I are ardent Mustachians, and found this figure to be both ludicrously large (we'd much rather max out our Roth IRA's with that kind of money) and rather impersonal.

With this in mind, we decided to forgo a diamond (Have you ever tried to sell a diamond?) with an identical looking cubic zirconia stone purchased on ebay for about 1/1000th of what a similar sized diamond costs. The trouble then was finding a good setting.

Classical ring 1 from pinterestClassical ring 2 from pinterestElisa had, conveniently, already been hard at work researching styles of rings she liked. She favored a classical look, but try as I might, I couldn't find the original source of the rings she'd found, only rings that were similar, but not perfect. Through lots of google image reverse image searching and random combinations of keywords, I stumbled on this ring pretty close to the ones Elisa liked that actually was for sale:

3-Stone Vine Engagement Ring from http://rosestonejewelry.This ring came with an accompanying blog post that showed exactly how it was custom made. From the original sketches:

original sketches of 3-Stone Vine Engagement Ringto the 3D sketch:

3D sketch of 3-Stone Vine Engagement Ringthen 3D printed in wax:

wax mold of 3-Stone Vine Engagement Ringthen put in a lost wax casting plaster mold, filled with molten gold, and then dunked in a bucket of water so the plaster dissolves away:

gold filling of 3-Stone Vine Engagement Ringtaken out of the mold in a gold tree:

gold tree of 3-Stone Vine Engagement Ringcleaned:

raw 3-Stone Vine Engagement Ringthen polished:

polished 3-Stone Vine Engagement Ringfinal 3-Stone Vine Engagement RingThe post went on to describe an additional 12 hours of detailing (chasing and engraving) that was done on this particular ring before setting the gem - a very expensive and labor intensive process that added some detail, but Elisa and I actually preferred the smoother non-engraved look.

This blew me away - I had no idea you could just make a ring by 3D printing it. I thought they were hand engraved by people with really tiny hands or something, but apparently this is now a common practice in jewelry making. Here's an excellent video on the entire process:

I contacted the designer of this ring, Jeshua Rosestone, and asked for a quote for a ring without the blue side stones (neither Elisa or I liked them) resized for her finger. He promptly emailed back and explained that that ring was a custom order for $2,600, but that he could make the alterations and deliver a similar ring for us for $1,890.

This was still considerably more than I would have liked to spend on a ring (less money available to invest for retirement), so I asked how much a ring would be without the detailing. He emailed back understandably perturbed, but offered $250 for the raw 3D design and $200 for the gold casting, or $450 total.

He emailed back understandably perturbed, but offered $250 for the raw 3D design and $200 for the gold casting, or $450 total.

This was considerably better, but I got a strong feeling that he wouldn't be too happy about this deal (it would be an order of magnitude lower than his typical jobs) and may be difficult to work with if we wanted to go through a few iterations. With this in mind, I ventured off to get quotes from other 3D modelers that I could work closer with, with plans of trying to learn the lost wax casting and metal molding myself (knowing that wax models could be 3D printed online).

I went through the top three 3D printing online services (i.materialise, shapeways, and sculpteo) and tried to find designers that had made rings before that may be open to contract work. I found a great forum page on i.materialise of designer profiles and emailed every single one asking if they'd be interested.

Dani Epstein's detailed work.I got a lot of rejects, and quotes all over the map: $200 to $600 (and remember, this is just for the design). I settled on moving forward with a designer named Dani Epstein, who had a very impressive portfolio including a piece of jewelry that had a lot of classical detail work.

I settled on moving forward with a designer named Dani Epstein, who had a very impressive portfolio including a piece of jewelry that had a lot of classical detail work.

He was also one of the lowest bids: he only charged £20 GBP (~$40 USD) per hour, and gave an initial quote of 4 hours (£80 GBP, or $160). Through our email correspondence, I felt he was a guy that I could work back and forth with for tweaking.

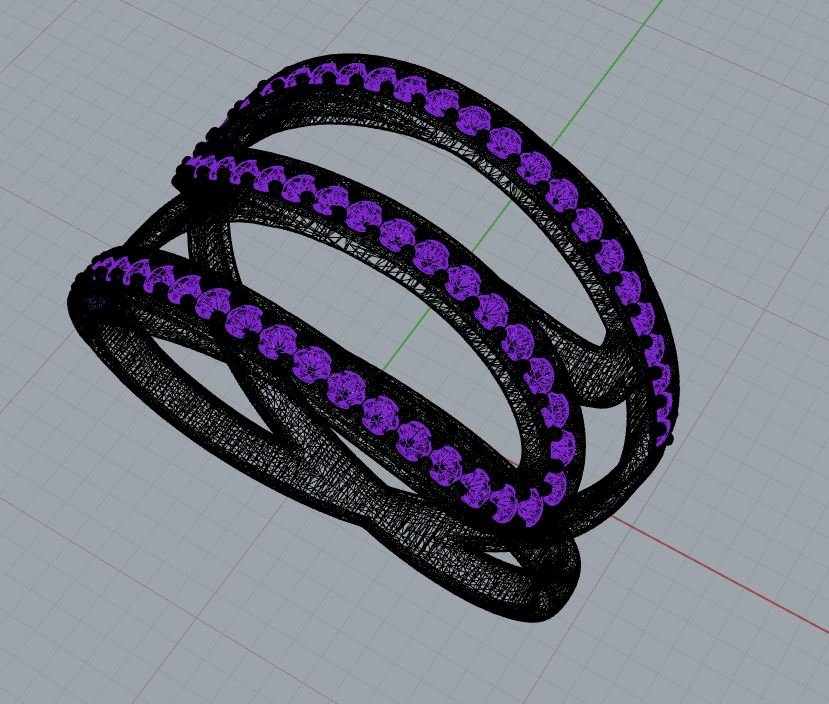

I sent him images of all of the rings we liked and tried to sketch out what I wanted the end result to look like. After only two hours, he came back with this:

first draftI was blown away, and made a mental note to get really good at 3D modeling one day (I asked him for some resources to get started and he recommended the free Blender program).

Dani came back the next day with a design that was exactly what I'd sketched out:

second draft3D file is too thin in some placesWhen seeing it all together, I didn't love the detail on the shoulders of the ring - the leafs were a little too much visually. Additionally, the 3D file had some trouble being printed (shapeways and i.materialise said a lot of areas were too thin).

Additionally, the 3D file had some trouble being printed (shapeways and i.materialise said a lot of areas were too thin).

We went back and forth a few times on various design changes and errors in the print process. The most embarrassing of which was that the ring was initially created with a 15.53mm radius instead of diameter. When this was fixed, the 6.5mm space for the stone was also shrunk by half, which we didn't discover until ordering a test print in plastic:

test print in plasticThis was especially evident when compared with a 1 carat ring I bought on ebay for $12:

diamond size is too smallA quick edit later and this too was fixed:

diamond resizedTotal, Dani charged £170 GBP, or about $290 USD. For all the customizing we did, and the willingness and help Dani gave through the process, I'm incredibly happy with how much I spent and how it turned out.

silver 3D print arrived!With this small change, I crossed my fingers and ordered the ring to be printed in silver (turns out the 3D printing companies will do the lost wax casting and polishing for you). The day this arrived I was elated.

The day this arrived I was elated.

The level of detail was much better than in the plastic prints, likely from the polishing process. It looked like a real ring! The last step was figuring out how to get the cubic zirconia on there.

I searched on youtube to see if it was something I could just do. Some videos made it look pretty easy, but for the quality and style of this ring it looked pretty complicated. I opted to have it professionally done at a local jewelry store.

They initially quoted $45, but Sophia (my sister) and I talked them down to $35.

Two days later and the finished ring was in my hands! A short while later, after engagement preparations had been made (parents' permission asked, time and place arranged, trying to hide everything from Elisa until the final moment, etc.) and it was finally on her finger:

if you like it then you should put a ring on itHere's a blurry closeup:

blurry closeupTotal cost:

- 1 carat CZ wedding ring (for emergency backup): $13.

41

41 - Handful of Cubic Zirconia stones in different sizes: $41.76

- Design by Dani Epstein: $290

- Handful of 3D printed rings to test different materials and size: $34.30

- Test print in plastic: $28.05

- Silver Print: $66.25

- Ring mounting: $35

- Total: $508.77

However, if we wanted to print an identical copy, the marginal cost would only be:

- 1 carat CZ stone: $5

- Silver Print: $66.25

- Ring mounting: $35

- Total for another ring: $106.25

the happy engaged couple

It was a lot of back and forth through uncharted territory, and a lot of unnecessary expenses, but I'm incredibly glad I went this route. The final ring - even with the extra overhead of learning the process as I went - was a fraction of the cost it would have been the traditional route, and feels like a much more personal token. At the same time, if the ring were ever lost, stolen, or damaged, we could sleep easily knowing we could have an identical copy made - perhaps even in a different material or with a different sized stone - in about two weeks for a hundred bucks.

Plus, now I have a perfect 3D model of Elisa's ring if we ever wanted to do something clever like make a chocolate mold out of it for wedding party favors or something.

tl;dr: 3D printed an engagement ring because we're living in the future. A++ would print again.

Update: I also 3D printed my own wedding ring as a plain wedding band, modeled in OpenSCAD. Here's what it looks like:

my 3D printed plain wedding band2019-06-14 Update: wow! I've had so many people reach out to me asking about this process. Several have 3D printed rings of their own. If you've 3D printed your ring from the advice in this article, send me a picture and I'll add it below!

3D printed ring from Sam O.Buy 3D Printed Engagement Ring Online I LACE Wedding Ring Collection – LACE by JennyWu

Buy 3D Printed Engagement Ring Online I LACE Wedding Ring Collection – LACE by JennyWu Skip to contentThis site has limited support for your browser. We recommend switching to Edge, Chrome, Safari, or Firefox.

We recommend switching to Edge, Chrome, Safari, or Firefox.

Congratulations! Your order qualifies for free shipping Spend $100 more for free US shipping.

Carbon Collection Available now here!

the LACE Sampling Program Available now here!

A departure from tradition, the LACE by Jenny Wu wedding collection reinvents the classic symbol of timeless love.

View collection

Introducing

An innovative approach to your wedding rings, from design to finish.

The LACE Wedding Collection embraces a bold, elevated take on the traditional wedding ring. Each engagement ring and wedding band is designed as the perfect set, to stack seamlessly on your hand. Our digitally crafted pieces are made to order and never mass produced. Each ring carries the detail and precision that only 3D printing technology can accomplish, and finished off by our master craftsmen in Downtown Los Angeles.

SHOP NOW

LACE Engagement Rings

Our 4 Signature Sets - Your ring should reflect who you are.

We designed 4 unique rings, each with a distinct personality. Learn more about each ring, and find the perfect one for you.

Statement - RHEA AND HERA SET

Statement - RHEA AND HERA SET

Quiet Luxury - Iris and Agnes set

Quiet Luxury - Iris and Agnes set

New Classic - CLIO AND LYRA SET

New Classic - CLIO AND LYRA SET

Bold - Amare and sera set

Bold - Amare and sera set

I fell in love with the Amare engagement ring and ended up buying an entire set for my husband and I.

Thank you for creating such unique, beautiful designs. I feel special every day wearing them.

Valerie Victoria Customer

These jewelry pieces are like no other. They're stunning in their geometry and form, fascinating in production and material - all rendering something very thoughtful and special.

Shelley Tupac customer

Love the art of each piece. A true unique collection in the way it’s made - an innovative staple in your jewelry wardrobe.

Rachel Flanagan customer

Have questions?

Contact our team to find the perfect ring, get help with sizing, styling, or just to chat!

Message us here!

Cart

Congratulations! Your order qualifies for free shipping Spend $100 for free shipping

No more products available for purchase

Your cart is currently empty.

Pair With

Add Order Notes

Leave a note about your order

Estimate Shipping

First Name

Last Name

Company

Address1

Address2

City

Country

Province

Postal/Zip Code

Phone

Items $0.00

Subtotal $0.00

Shipping, taxes, and discount codes are calculated at checkout

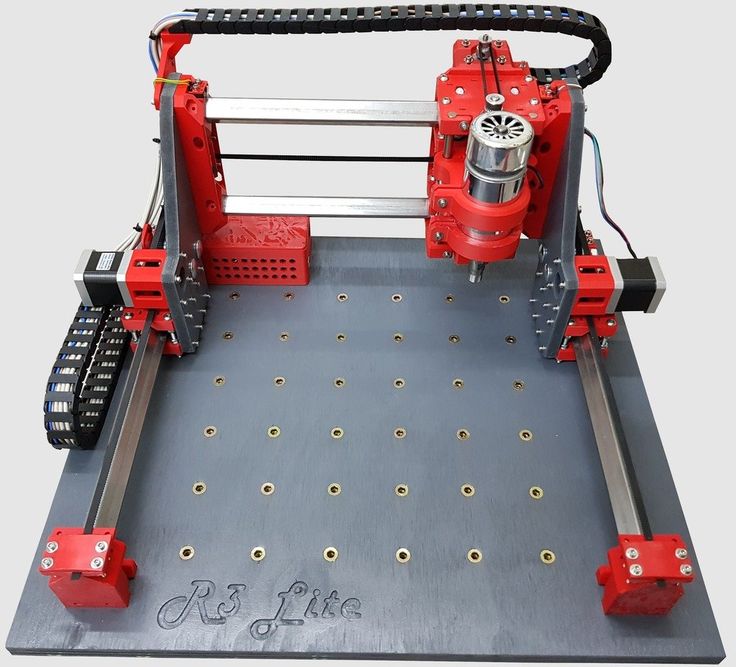

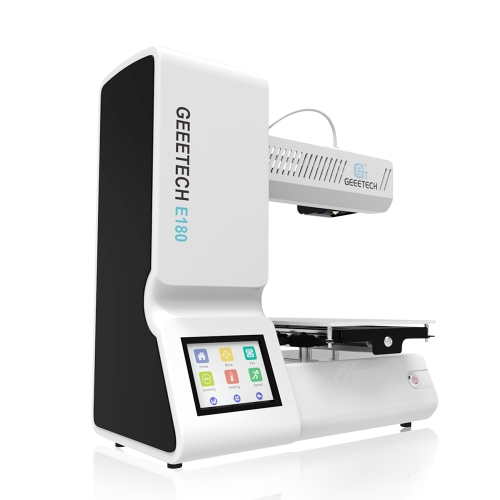

Printing jewelry on a 3D printer - an overview of the most interesting models

The times when 3D printing of jewelry seemed like something fantastic is over. Today, more and more designers are using 3D equipment to bring their ideas to life. Some printers work with filament, others use powder, and still others print with liquid resin or wax. 3D printed jewelry looks and feels exactly like traditionally molded pieces.

3D printed jewelry looks and feels exactly like traditionally molded pieces.

White and black Gemino & Orbis Nylon earrings printed with SLS nylon resin. The material has a very light weight, which makes the jewelry comfortable, ideal for everyday wear. An interesting design will organically fit into both a classic and a shocking image.

3D printed wedding rings. Original custom-made symbols of eternal love accurately convey the details that are important for the newlyweds. With a unique asymmetrical line and elegant twists, Ray's ring will appeal to fans of the original designs. For lovers of clean, minimalist silhouettes, the Clio is the way to go. For connoisseurs of unconventional solutions, the Amar diamond ring will suit, the design of which forms a loose knot of two lines that merge, symbolizing an unbreakable union.

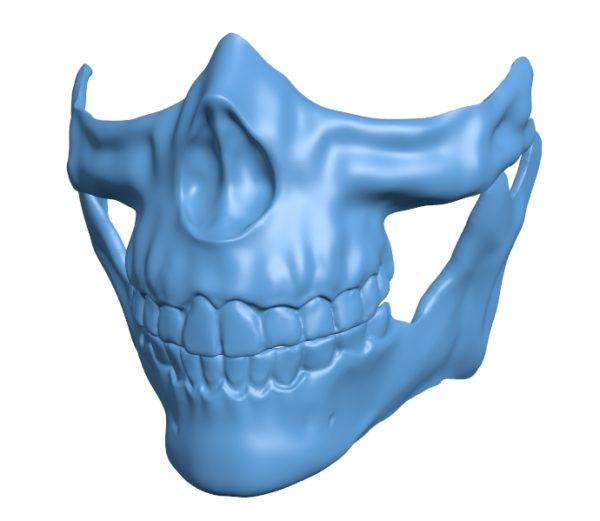

Gorgeous 3D printed face jewelry by Iris van Herpen. Cellchemy 3D printed jewelry designs look like a mask and the way it sits on the face of the wearer looks like something otherworldly. The wire masks are printed with a high resolution multi-material printer. Each part of the mask, custom-designed for a specific runway model, was created using a generative design process after a 3D scan of her face.

The wire masks are printed with a high resolution multi-material printer. Each part of the mask, custom-designed for a specific runway model, was created using a generative design process after a 3D scan of her face.

Guinness World Record-listed diamond ring. India's major 3D printing service provider Imaginarium helped Kotti Shrikant win the Guinness World Record for having the most diamonds set in a single ring. The process of developing a masterpiece called "Divine - 7801 Brahma Vajra Kamalam" went through several iterations. The design team chose the Himalayan camellia flower, which strikes the perfect balance between traditional and contemporary forms. Computer-aided design (CAD) was then used to calculate the number of diamonds. Imaginarium managed to make petals of gold and helped to set the intended number of stones.

18K Gold Charm 3D print by Elizabeth Landis. The spectacular pendant reminds of natural harmony and succinctly complements the luxurious look. Honeycombs are formed into an openwork pattern, and the figure of a bee symbolizes wisdom, diligence, purity.

Frog Ring 3D Gold Plated Brass Object by Peter Donders. The designer rejects classical forms and traditional solutions. He uses 3D printing to revolutionize the jewelry industry, be it in the areas of jewelry making or designing finishes. The frog ring emphasizes the grace, sense of humor of the fair sex.

A charming decoration that can effectively complement a creative look.

"Opposites" collection by Francesca Paolin "spring-summer 2015", printed in polyamide. The MA in Fashion Design from Domus Academy channeled her creativity into creating body jewelry from alternative materials using 3D technology. The author drew inspiration for the development of the collection from ancient history and culture.

The author drew inspiration for the development of the collection from ancient history and culture.

Solar nylon bracelet. The Septem brand offers unique fashion items from designers around the world. All products are made on 3D printers. The customer can choose their favorite materials, colors, sizes from the list. The original bracelet attracts with its futuristic design and adds creativity to the image.

N-E-R-V-O-U-S necklace is a 3D printed necklace made up of 175 unique pieces. It is a 21st century piece of jewelry designed and manufactured using methods that did not exist until recently. The necklace is built in layers of durable yet flexible nylon using selective laser sintering technology. The design comes out of the printer fully assembled. The necklace attaches simply and securely with a hidden magnetic clasp.

Plumeria Nylon Earrings have a matte texture, ideal for original, bold looks. You can choose any color from 12 possible. Earrings with a floral pattern will appeal not only to young fashionistas, but also to elegant ladies.

Earrings with a floral pattern will appeal not only to young fashionistas, but also to elegant ladies.

Ide Bag Nylon is a stylish element of the look. A model that imitates openwork knitting will add charm to the ensemble, plus it will allow you to create a harmonious, feminine, exclusive look.

The Orbits Bracelet Nylon is your own galaxy on your wrist. 3D printed space-inspired jewelry is the choice of daring experimenters who are not afraid to try on new looks. Unusual material plus an innovative manufacturing method add enchantment and extravagance to the little thing.

Jewelry designers are constantly testing new materials and experimenting with different design approaches. Printing jewelry on a 3D printer has already become a popular production method. The technology allows you to implement bold ideas, make adjustments and see the results within a few hours.

3D printed jewelry is a Hollywood trend

3D printing has long been used as an auxiliary technique in architecture or design. And finally, a small revolution happened: 3D-printed products, including jewelry, became an independent phenomenon. And - began to rapidly become fashionable. At least, this is what happens in the West - and perhaps at some point this trend will come to us.

And finally, a small revolution happened: 3D-printed products, including jewelry, became an independent phenomenon. And - began to rapidly become fashionable. At least, this is what happens in the West - and perhaps at some point this trend will come to us.

Refinery29, an independent American fashion and style portal, published an interview with the founder of the LACE jewelry brand, Jenny Wu, a designer who introduced spectacular 3D jewelry into fashion, which caused a noticeable interest in this technology. We share with you the materials of this article.

Today, everyone can purchase designer works printed on a 3D printer. And it all happened, in large part thanks to one particular initiator - the founder of the Los Angeles company for 3D printing jewelry Jenny Wu.

Jenny Wu moved to the jewelry industry from architecture, where she first got to know 3D printing techniques. In 2004, she co-founded Oyler Wu Collaborative , an architecture firm known for its impressive projects such as Hollywood's Culinary Lab, or the Cube, a four-story steel and rope installation displayed outside the Olympic Stadium at the Beijing Biennale. -2013".

-2013".

Now Jenny Wu manages to do architectural projects and - her jewelry company LACE , which produces surreal and futuristic necklaces and rings. And her jewelry has already conquered the sphere of contemporary art. They can be seen both on Hollywood stars (Carrie Underwood and Ingrid Nielsen) and at various festivals (for example, Burning Man).

Prices for LACE products range from $50 to $1200, and the jewelry itself is made in a wide variety of materials, including atypical ones for jewelry: nylon, stainless steel, and of course traditional premium materials, silver and rose gold.

Jenny Wu

What is 3D printing? How is this technique used to create jewelry?

3D printing is a manufacturing process based on the principle of “adding”. A 3D printer “grows” a piece of jewelry by applying layer upon layer of a powdered material such as nylon, metal or wax. As soon as the next layer of material is “printed”, it is covered with a reinforcing agent that binds the layers together. After the last layer has been printed and the product has reached its final shape, a special cleaning program is started, which removes excess powder and material overlaps not planned by the design.

After the last layer has been printed and the product has reached its final shape, a special cleaning program is started, which removes excess powder and material overlaps not planned by the design.

What does the whole process look like?

My product design process starts with sketching by hand. Then my colleagues help visualize the drawing in a 3D computer model. We are making several variants of decoration, trying to see how this design will look in all three planes, and how the decoration will “sit down” on a person.

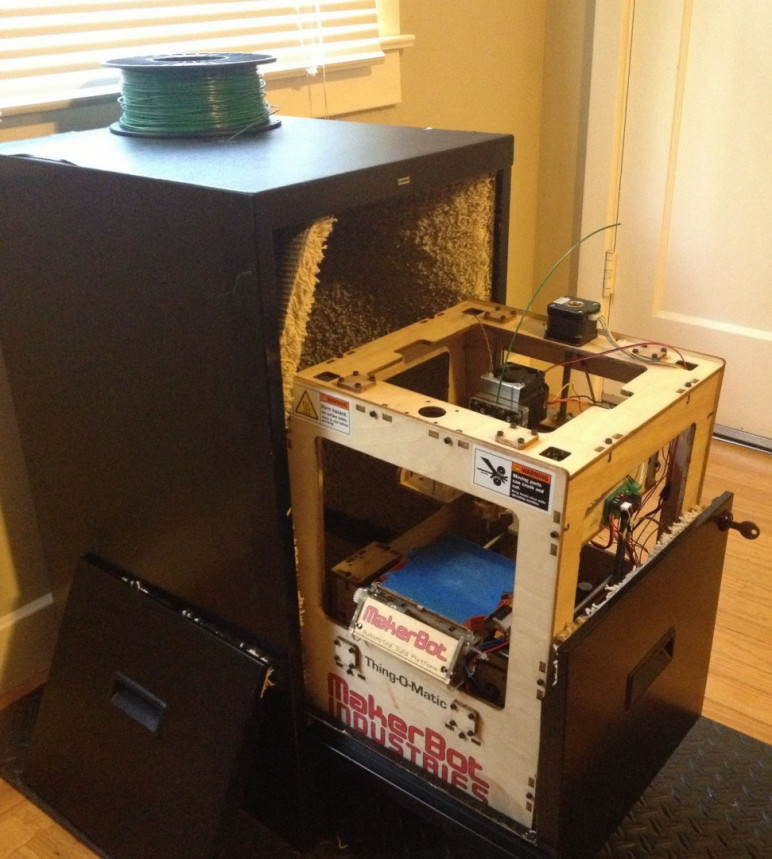

Once our digital jewelry model is ready and we are satisfied, we start printing a prototype of the jewelry on our own 3D printer in our office (FDM - Fused Deposition Modeling is the most popular 3D printer that everyone can buy for themselves today) . Prototyping is the most cost effective and fastest way to test how a particular design will look and wear.

Once we are completely satisfied with the design, we send the file to a 3D printing service bureau, where the final product is produced.

Can a 3D printed jewelry be worn right away?

There is a misconception that a piece of jewelry just out of print is immediately ready to be shipped to the customer. In fact, there are additional processes, for example, grinding, painting, and so on - different ways to bring the product to its perfect form.

How did you get started in 3D printing jewelry? Is this a difficult thing?

I first started using a 3D printer while at Harvard to create architectural models. However, I only started experimenting with printing other objects, such as the design of things and jewelry, about five years ago.

The hardest part of the whole 3D printing process is getting my sketches right into a 3D digital model on the computer. We use the most advanced 3D modeling software commonly used for animation (cartoon production and similar).

How did you decide to start the LACE jewelry brand?

A couple of years ago I came up with the idea to create a necklace with a high collar. And I remembered my architectural background and experience with a 3D printer, thinking - why not apply it and see how this form will look on me?

And I remembered my architectural background and experience with a 3D printer, thinking - why not apply it and see how this form will look on me?

As a result, I printed this necklace for myself and went to the exhibition-show dedicated to contemporary art - Miami Art Basel. And there, at parties, everyone suddenly started to stop me and ask - where did I buy it, and who is the author of the necklace? After such a rush of attention to jewelry, one could only ask oneself the question: why not start a company producing such things?

I spent the next year figuring out how to make 3D printed things to wear on the body and how I could turn it into a business—which eventually resulted in the founding of LACE.

What is the fundamental difference between 3D printed jewelry and traditional ones? What is their advantage?

3D printing essentially "speeds up" the manufacturing process. For example, my chain necklaces are made from woven links. And instead of making each link separately, then fastening, welding, or fixing the smallest parts together, I just get the whole chain as a whole - as a single product, at one time.

And instead of making each link separately, then fastening, welding, or fixing the smallest parts together, I just get the whole chain as a whole - as a single product, at one time.

Another advantage is that it's more like a business plan. The fact is that the cost of production using 3D printing of one (conditionally) ring is exactly the same as the cost of printing hundreds of rings. And because it's so easy to take and print as much as you need, when you need it, there's no need to stock up.

Finally, 3D printing offers great customization options. I can make each copy to order, and deliver it within 2-3 weeks.

What advice would you give to someone who wants to start their own 3D project?

3D printing is a great way for design enthusiasts and professionals alike to test their ideas. Technology is becoming more and more accessible. For example, there are now many basic 3D software options available, such as Google SketchUp, that you can quickly learn with little or no modeling experience.