Olo 3d printer ship date

ONO: How the alleged "Biggest 3D Printing Scam" of All Time Unfolded

Following on from the 2013 to 2014 boom, optimism in the 3D printing industry in early 2016 was rife, and backers were clamoring to support Kickstarter projects claiming to revolutionize the sector. Many fledgling Kickstarter projects became extraordinarily successful. Formlabs even went unicorn.

This article is an opinion piece and reflects our own research into, and thoughts on, the ONO project. Under legal threats by the ONO team in July 2021 we would like to clarify that this article is an opinion piece — and in discussing the word “scam” we are not proposing this as objective fact, but merely quoting what backers of the project have voiced.

But some projects bordered into naïve, buoyed by fashionable buzzwords and heavily padded announcement videos. Several projects raised over a million dollars, sometimes based only on ambitious – perhaps far-fetched – targets and little evidence of feasibility, and as the months drew on, never even produced a final product for backers to be disappointed with.

One project however stands head and shoulders above others for its disaster: in magnitude of failure; amount of money lost; and emotional turmoil. It has been called the “biggest 3D printing scam” of all time, taking $2.3 million from 16,180 backers. For the next four years, they relentlessly teased supporters that they were days from receiving their printer, just to let them down again.

Here’s how it unfolded. This is the story of the ONO.

OLO: The first days

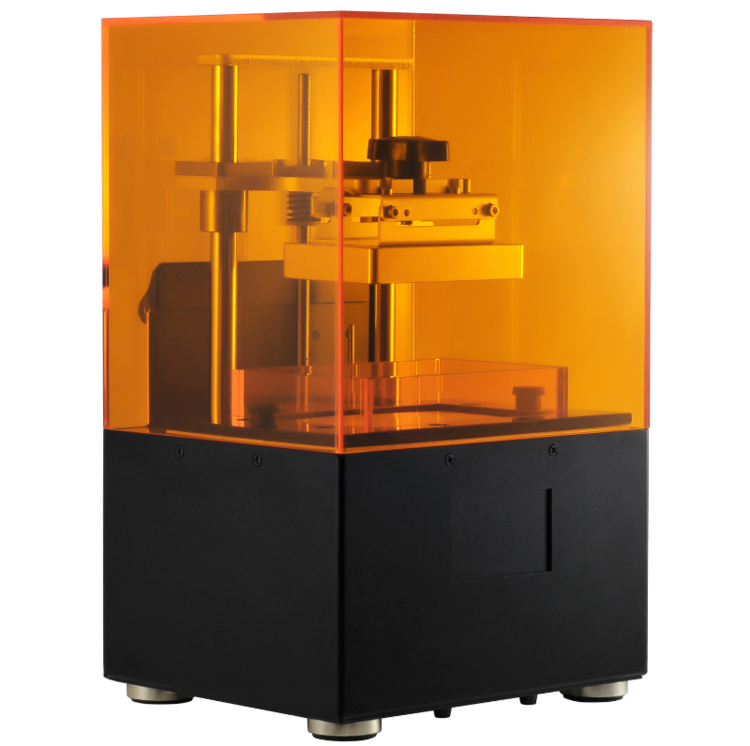

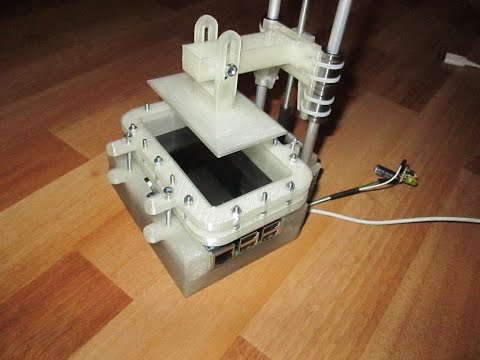

The OLO 3D printer campaign went live on Kickstarter on March 21st, 2016, promising a $99 resin 3D printer that used your smartphone screen’s light to solidify resin and create a finished model. Back in 2016 resin 3D printers started at a few thousand dollars, and even in the present day $99 is absurdly cheap – but OLO said they could do it for less than $100.

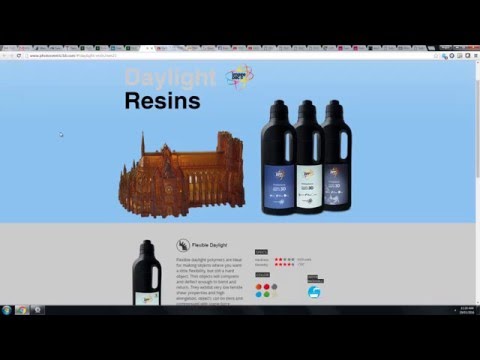

Normal resin printers use a powerful light source to cure and solidify resin. Instead of using standard UV resins, OLO’s phone printer system used a daylight-sensitive resin that your phone screen’s comparatively weak light source could still polymerize. The tech made sense in theory, and if perfected anyone with a smartphone could 3D print. OLO made 3D printing accessible, and at the lowest prices the world had ever seen.

The tech made sense in theory, and if perfected anyone with a smartphone could 3D print. OLO made 3D printing accessible, and at the lowest prices the world had ever seen.

The world noticed. OLO targeted $80,000 to make the project a reality and deliver the technology to market. Kickstarter campaigns run for 30 days, OLO hit their target in 33 minutes. The project was a roaring success.

The First Cracks

Some were still sceptical amidst the hype and optimism. Angus Deveson, better known as Maker’s Muse, was unconvinced. As the campaign hit $1M in funding, he posted a video outlining his concerns about the project’s feasibility.

Firstly, the resins. Low cost resin printers at the time often used DLP technology – Digital Light Processing – a technology also used in cinema projectors. The light source used is immensely powerful as to cure photo-sensitive resin, and exponentially more powerful than a smartphone’s screen.

Using your smartphone’s comparatively weak light source, prints could take a whole day – possibly longer than your phone’s battery life. This is time where you cannot even look at your phone, never mind use it. Could people handle that level of inconvenience?

This is time where you cannot even look at your phone, never mind use it. Could people handle that level of inconvenience?

Additionally, the OLO Kickstarter video and photos shows clear resin bottles for their daylight-sensitive resins, which would cause the resin to instantly cure and harden in the bottle far before you could print with it. Resins are always packed into matte black containers to avoid this.

OLO original Kickstarter image, with clear resin bottles.Most dangerously, Maker’s Muse highlighted the blatant safety errors in the video: resins are harmful and should not be handled without gloves and goggles, and not just washed in water as the video demonstrated.

In a grimly prophetic statement in his 27th March 2016 video discussing the project, Angus surmised that he felt OLO was a world away from being production ready: ‘You may be waiting a very long time to get this project.’ The campaign was only six days old.

Fake it till you make it?

It is unofficially accepted that for many technology campaigns on Kickstarter, creative liberties are taken to show supposed market-ready prototypes. This is not necessarily bad, executing a precocious vision is requisite for greatness, and it is difficult to get people excited about a project if you do not have the funds to create said exciting project. Therefore, companies seeking investment tell white lies, show what the product will look like post-investment, rather than how it is now.

This is not necessarily bad, executing a precocious vision is requisite for greatness, and it is difficult to get people excited about a project if you do not have the funds to create said exciting project. Therefore, companies seeking investment tell white lies, show what the product will look like post-investment, rather than how it is now.

Many of the 16,000 backers were aware they were bridging the gap between vision and reality with their support. So, when Maker’s Muse pointed out that many of the objects shown in their campaign were clearly laser cut rather than printed on their machines, it did not cause the outrage that perhaps it should have. Slick marketing blurred the lines between fantasy and falsity, between hype and fraud.

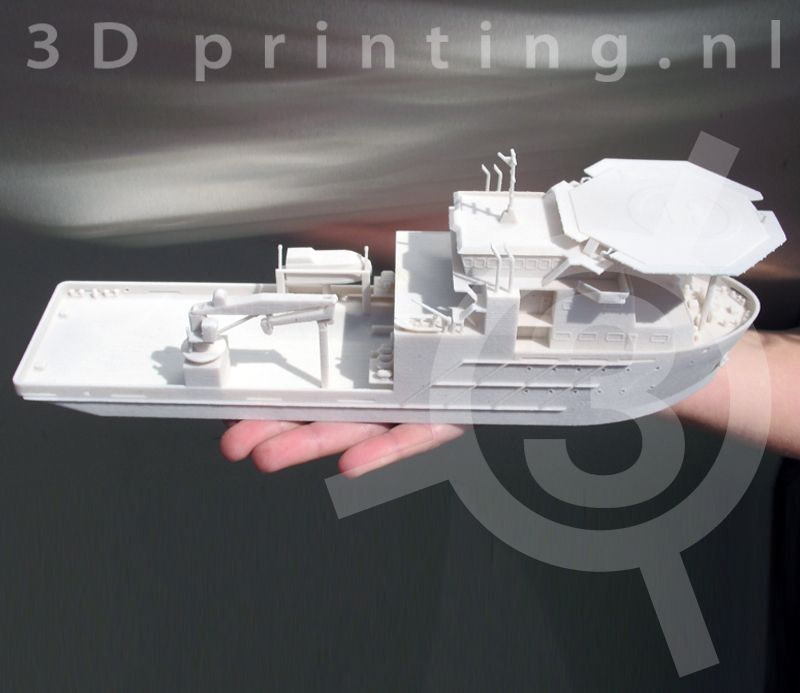

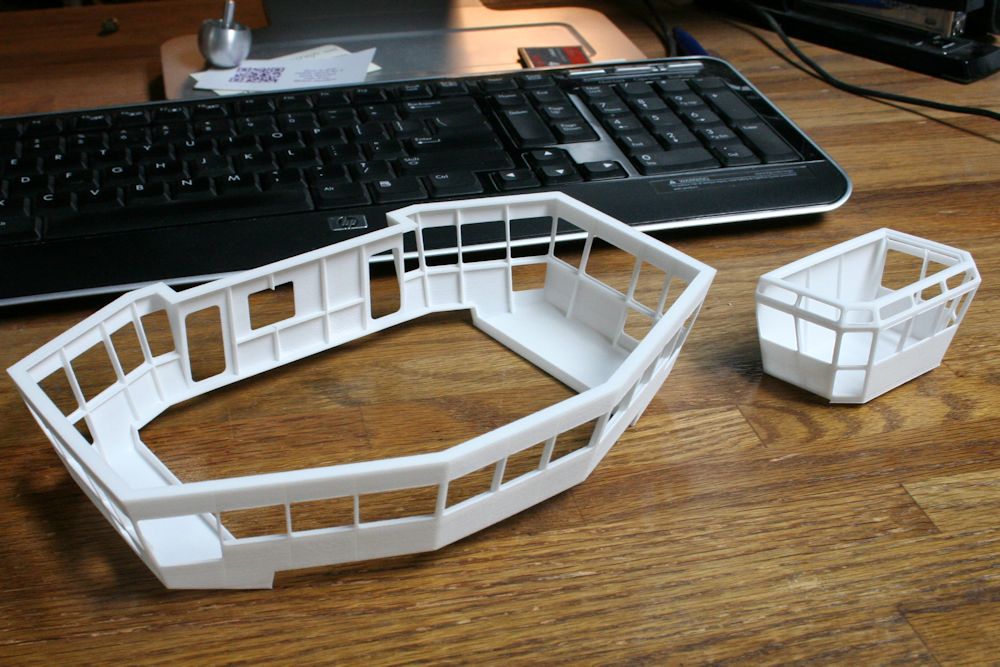

One thing deducible from the laser cut parts was that OLO was not a working prototype. The parts the OLO team said their machines had printed were assuredly not printed by those machines. The question was not whether they did print those models, but whether they ever could. This part looks laser cut rather than 3D printed, as echoed by Maker’s Muse.

This part looks laser cut rather than 3D printed, as echoed by Maker’s Muse.

Though in the Kickstarter campaign it was claimed to be a San Francisco-based project, OLO’s founders are in fact Italian. The two founders, Filippo Moroni and Pietro Gabriele, claim to have 15 years’ experience in the 3D printing industry in a company called Solido3D, as well as founding a 3D printing network called Fonderie Digitali. While on face value this adds prestige, further research unveils red flags.

From OLO to ONO to Oh No

Following the successful campaign, patrons waited excitedly for their OLO printers, having been promised delivery within a few short months. A few months later, on August 29th, 2016, OLO posted an update detailing how a similar-named company had contacted them with their grievances, and that therefore they were changing their name from OLO to ONO. This was perhaps symbolic for the four following years.

Resin 3D printers use a print bed which, upon finishing each solidified layer of resin, descends a small amount so that the next layer of liquid resin can be solidified. OLO’s original design controlled the print bed by plugging into your smartphone’s headphone jack and sending audio signals that act as directions, communicating when to move the print bed as each layer finishes. Many felt this was unnecessarily complicated and they should just use a Bluetooth method, but they pressed on with the headphone jack plan. It had already delayed the printer’s release due to issues with some phones having headphone jacks on top, while some had them on the bottom.

OLO’s original design controlled the print bed by plugging into your smartphone’s headphone jack and sending audio signals that act as directions, communicating when to move the print bed as each layer finishes. Many felt this was unnecessarily complicated and they should just use a Bluetooth method, but they pressed on with the headphone jack plan. It had already delayed the printer’s release due to issues with some phones having headphone jacks on top, while some had them on the bottom.

However, as they scrambled to fix these issues, phones were beginning to cut the headphone jack out entirely. The iPhone 7 released in September 2016, the highest profile of early phones to ditch the headphone jack. Suddenly all ONO’s planning was obsolete. A Bluetooth device was eventually decided on.

On March 22nd 2017, almost nine months after the original shipping date, ONO announced they would start shipping units the following day, on the 23rd. However, after going silent they eventually posted an update on April 10th discussing a last-minute issue with their electrical boards. The ordeal meant that a year after their promised delivery date, no printers were arriving on any backers’ doorsteps.To reassure backers, pictures such as this one were posted showing their production facility in China, producing units.

The ordeal meant that a year after their promised delivery date, no printers were arriving on any backers’ doorsteps.To reassure backers, pictures such as this one were posted showing their production facility in China, producing units.

Take a deeper dive into the OLO team’s claims and some interesting information arises. Regarding the claim that the founders have 15 years’ experience in 3D printing, in another interview Filippo says he himself has 15 years, while Pietro was new to the 3D printing industry, his previous business experience concerns running a jazz club.

On further inspection of Fonderie Digitali, most of the companies the team claimed to comprise the Fonderie Digitali in their email sent to Maker’s Muse network are now defunct, and were already defunct in 2016 when they sent the email. On visiting the website now, none of these other companies are mentioned, only Solido3D and ONO. It does not appear to be a network, but an extra brand name to promote the team’s existing enterprises. The only legitimate, active company claimed in the 2016 email to comprise Fonderie Digitali was WASP, known for making delta 3D printers that print extraordinarily fast, as well as for ceramic 3D printing. WASP no longer feature in any part of the Fonderie Digitali website or contacts list.

The only legitimate, active company claimed in the 2016 email to comprise Fonderie Digitali was WASP, known for making delta 3D printers that print extraordinarily fast, as well as for ceramic 3D printing. WASP no longer feature in any part of the Fonderie Digitali website or contacts list.

On ONO Founder Filippo Moroni’s LinkedIn page, Solido3D and Fonderie Digitali are absent. In fact, despite claiming to have 15 years’ experience 3D printing, his LinkedIn employment history is non-existent between graduating from the Politecnico di Milano in 2002 and founding OLO in 2015. It is therefore impossible to verify any job history or experience when, according to his LinkedIn, he has never worked.

Joel Telling - 3D Printing Nerd

@joeltelling

It's me, @makersmuse, and a real @ono3d #3dprinter! https://t.co/On5zHL4fBK

9:06 PM · May 19, 2017

Suddenly, at New York Maker Faire 2017, 3D printing YouTuber Joel Telling – also known as 3D Printing Nerd – posted a video on October 1st titled “ONO Resin 3D Printer – Working!” with a member of ONO’s team, exclaiming he had seen a working prototype. Joel Telling’s reputation for honesty and reluctance to promote anything sub-par to his fanbase made this all the more reassuring.

Joel Telling’s reputation for honesty and reluctance to promote anything sub-par to his fanbase made this all the more reassuring.

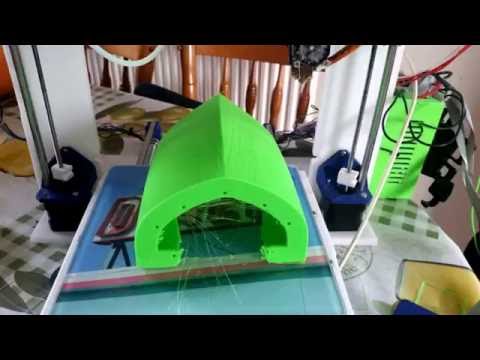

ONO cut a hole in the side of one of their printers to show footage of the actual printing process during the vlog. The time lapse showed the print process in detail — they appeared to have a working prototype. Backers were happy. Such a powerful co-sign, as well as demonstrating proof of concept, meant surely it was just a matter of time until their ONO arrived.

But then another year passed, and now two years after the original delivery date, nobody had received a printer. The controller board issues were still blamed, but even beyond this, months of updates concerned various difficulties involved in gaining the requisite certifications to ship the printers. Surely, if everything was safe and above board, this should not have taken so long.

StartEngine

Despite claiming they were readying to ship, an ONO campaign suddenly appeared on fundraising platform StartEngine in 2018. The campaign aimed to raise up to $1.07 million, offering Series B shares for $10 each. In the campaign, ONO declared that when you invest in them, you are betting that the company’s share value will exceed $30 million. They were yet to ship a printer. Perhaps most interestingly, they claimed to have 20,000 printers in their Shenzhen factory ready to ship, enough to deliver to all their backers with almost 4,000 spares to sell through retail.

The campaign aimed to raise up to $1.07 million, offering Series B shares for $10 each. In the campaign, ONO declared that when you invest in them, you are betting that the company’s share value will exceed $30 million. They were yet to ship a printer. Perhaps most interestingly, they claimed to have 20,000 printers in their Shenzhen factory ready to ship, enough to deliver to all their backers with almost 4,000 spares to sell through retail.

Backers who invested $500 earned the first reward: an ONO t-shirt. Invest $2,500 and you earned a $99 ONO printer. Perhaps the wiser move was saving $2,000 and going for the t-shirt – you might have actually received that. Still, the campaign raised $42,825.

Many will question why a company that raised so much capital would return to any kind of fundraising institution. This usually happens when a company has run out of money. We can only guess where over $2 million went, and question strongly whether the money was spent creating 20,000 supposed ONO units, as none were being sent to those who invested their hard-earned savings in good faith.

Dig deeper into Solido3D, the founders’ supposed previous venture, and perhaps the strangest discovery is that this is not the only Solido3D. Another Solido3D, a 3D printer manufacturer, exists. This other Solido3D’s explosive existence included releasing the SD300Pro 3D printer back in 2009, riding high on $11 million in funding by 2010, and becoming insolvent in 2011, laying off all their employees. Their website has since recently been hijacked by gambling sites, but as of 2016 when ONO’s Kickstarter was in full swing, was alive and appeared respectable. Most would assume these two companies are the same company operating in two different geographies, and Maker’s Muse’s video about OLO displays the other Solido3D’s website, assuming that this company is the founding team’s previous venture, an easy mistake to make.

In fact, they appear to be different companies operating under the same name. Any would-be backer doing their due diligence on the founding team’s history that found the multi-million-dollar-backed, 3D-printer-releasing Solido3D, could easily mistakenly assume this was ONO’s previous venture, trusting the team based on a venture they were not involved in. If they named the company deliberately to create confusion with the 3D-printer-manufacturing Solido3D, this could be deduced as deceitful.

If they named the company deliberately to create confusion with the 3D-printer-manufacturing Solido3D, this could be deduced as deceitful.

The Italian Solido3D claims to offer 3D file and 3D printing services. 3D printing services only require the possession of a 3D printer, which are no longer massive investments; offering a 3D printing service does not make you a high-flying manufacturing aficionado. ONO were contacted to comment on a variety of questions including whether the names were deliberately similar, but did not respond.

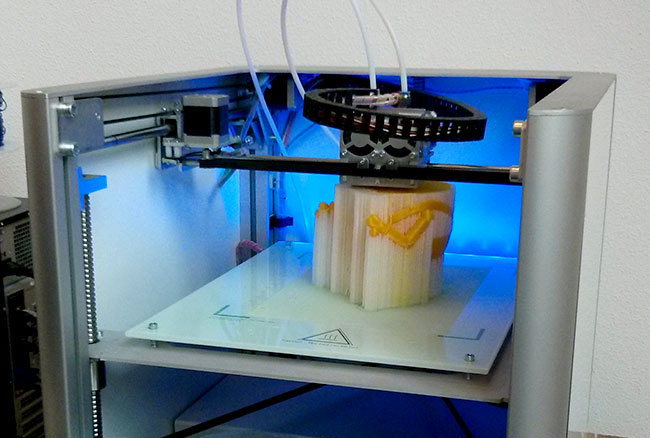

On the 25th of July 2018, two years after they were supposed to ship, ONO proved they could indeed print, and streamed a three-hour octopus model print live. At the same time, a supposed nine ONO printers were sent to beta testers. One beta tester, Chris Northwood, posted several videos detailing the printing on his ONO printer. A video uploaded on the 20th August 2018 showed that ONO did work, but the prints were of worse quality than even the cheapest FDM 3D printers, despite being far slower and using expensive resins. The printers were certainly not the finished article.

The printers were certainly not the finished article.

ONO eventually fell silent on StartEngine. Backers waved their e-pitchforks and filled the publicly available comments with demands for refunds. But ONO were nowhere to be seen.

Photo from ONO’s alleged China production line.Final Update

Fast forward to March 2nd 2019, ONO’s final update on Kickstarter (as of June 2020). The title featured an ancient Chinese proverb which loosely translates to “Wading across the river by feeling for stones” and claimed they were “advancing carefully”, and “step by step”. It was introduced as a romantic and nostalgic look back at the last few years, like a now-old rockstar reminiscing about the drug-addled debauchery on tour in his youth. The only difference was there was no success to look back on, just 16,000 backers out of pocket and over $2 million squandered. Even then, they maintained they were making 100 units a day and that they would eventually deliver, and included photos of several dozen units in what appeared to be a factory. Producing 100 units per day, they could have fulfilled every patron’s order within six months. There is no evidence that anyone except the beta testers ever received a printer.

Producing 100 units per day, they could have fulfilled every patron’s order within six months. There is no evidence that anyone except the beta testers ever received a printer.

Beyond this, silence. In the absence of any admission, we are left to infer ourselves what really occurred. What follows is my personal take on what happened behind closed doors.

What could have really happened

There are some key events that portray a genuine attempt to deliver a product. Although not to be blindly trusted, Founder Filippo Moroni said several times in updates that he could deliver the printers, but that they would not be completely ready. He constantly said things like “I don’t want to send you a brick.” He seemed genuinely concerned with meeting backers’ high expectations. It is hardly a Peachy – a 3D printer Kickstarter project that raised over CA$600K before abruptly announcing that the game was up. The reason: one of the founders had embezzled over $300,000 to build himself a mansion. The similarities are there – Peachy was also a resin 3D printer, and cost $100 – but ONO just does not feel like an intentional scam, just naïve and incompetent leadership.

The similarities are there – Peachy was also a resin 3D printer, and cost $100 – but ONO just does not feel like an intentional scam, just naïve and incompetent leadership.

The pressure to deliver perfection could explain why delivery was constantly delayed, spliced between app releases and other fluff. The polar opposite to a minimum viable product (MVP) in start-up terms, refusing to release the printer until it was absolutely perfect meant it never released at all. I can understand how anxious it must feel having thousands demanding you to ship something that consumed so many years, yet still was not ready. But, if I were a backer, I could not forgive this as a reason for not delivering. Perfectionism is not an excuse here.

The working prototype in September 2017’s New York Maker Faire and live stream in 2018 proved the technology existed. ONO could print. But there were clear underlying issues – if it printed consistently, it would have shipped. The error rate in manufacturing is briefly mentioned in several updates, so there appeared to be some reliability issues, and beta tester videos show an unfinished product with low print quality. And the fact they had to launch a second fundraiser suggests that these faulty printers drained them dry, leaving them unable to finish the project and deliver serviceable 3D printers. Perhaps he was projecting his frustrations when he stated he did not want to send 16,000 people a “brick”. 16,000 bricks could build a house, but $2.3 million could build a whole neighborhood.

And the fact they had to launch a second fundraiser suggests that these faulty printers drained them dry, leaving them unable to finish the project and deliver serviceable 3D printers. Perhaps he was projecting his frustrations when he stated he did not want to send 16,000 people a “brick”. 16,000 bricks could build a house, but $2.3 million could build a whole neighborhood.

View this post on Instagram

Delivering. #ono3d

A post shared by filippo_moroni (@filippo_moroni) on

For the record, I believe ONO have a moral duty to ship whatever they currently have in stock, even if it is just a brick with some added sentimental value. But I also do not believe that backers will ever receive their printer. ONO’s updates include photos of packaged units as well as boxes of unassembled ONO parts, therefore at least around fifty ONO printers exist, possibly far more. Every printer they have produced should be sent out, no matter its functionality. Too much time has passed to allow time extensions to get it right, just send the bricks.

Every printer they have produced should be sent out, no matter its functionality. Too much time has passed to allow time extensions to get it right, just send the bricks.

To conclude in one sentence: naive, overambitious and excitable team, unexpected (yet standard in a start-up) problems, and splurging money until it was all gone. The result: 16,180 rightly angry backers who have lost sizable investments.

But does it even matter now?

Since the campaign launched four years ago, 3D printing technologies have advanced tremendously, especially in resin 3D printing. If ONO were to ship now, the technology would no longer be standout, but mediocre. Current LCD 3D printers starting at $200 far outperform ONO, and it will be infuriating to give up your printer for 8+ hours as your peers create better quality models effortlessly and in a third of the time.

The blame sits squarely on the shoulders of the founders, who gladly took life-changing amounts of money without the expertise to deliver. But backers also only saw what they wanted to see, and we all know what they say about things that seem too good to be true. In their excitement and haste, many glazed over glaring red flags: the clear resin bottles; opaque walls so you could not monitor your print; and safety errors in the launch videos portraying a lack of knowledge about 3D printing. Maker’s Muse pointed out all these flaws in his early video, but the campaign continued to garner support. It is a painful and expensive lesson in due diligence.

But backers also only saw what they wanted to see, and we all know what they say about things that seem too good to be true. In their excitement and haste, many glazed over glaring red flags: the clear resin bottles; opaque walls so you could not monitor your print; and safety errors in the launch videos portraying a lack of knowledge about 3D printing. Maker’s Muse pointed out all these flaws in his early video, but the campaign continued to garner support. It is a painful and expensive lesson in due diligence.

Four years on, the continuing vague hope of receiving an ONO printer makes the whole ordeal even more traumatic. ONO has been the worst kind of abusive partner to over 16,000 people all over the world, an abuser that shows the occasional glimmer that they can be the person the victim felt they knew originally, preventing the complete loss of hope that would finally let them move on. The extremely slim yet non-zero chance of receiving a printer maintains ONO’s unwanted occupancy in the untranquil gardens of aggrieved backers’ minds. Screenshot of comments on the OLO Kickstarter. One backer claims that one of ONO’s original Co-Founders has distanced himself from the project.

Screenshot of comments on the OLO Kickstarter. One backer claims that one of ONO’s original Co-Founders has distanced himself from the project.

But it persists, in four years of excuses and uncertainty following on from one month’s slick marketing. There are talks of lawsuits, and some have complained about ONO to the Better Business Bureau. One Kickstarter backer claims to have spoken to Pietro, the Co-Founder, and claims he said he distanced himself from the project two years ago, and no longer speaks to Filippo. Filippo Moroni himself still posts ONO-related content on his Instagram page (@Filippo_Moroni), though he conveniently does not reply to any ONO-related negative comments on his posts. The OLO Kickstarter now has over 11,000 comments, many containing expressions we cannot post here.

Perhaps ONO’s refusal to give up is the most unforgivable part. If they announced they were done, insolvent and penniless, I suspect the reaction would be one of relief, not just of anger. Finally, we can just forget about this and get on with our lives. Hope can be damaging in that regard. Let the project die so that people can grieve their monetary loss, reach stoic acceptance, and move on, free from any thought or hope for the project. Let the people give up hope.

Finally, we can just forget about this and get on with our lives. Hope can be damaging in that regard. Let the project die so that people can grieve their monetary loss, reach stoic acceptance, and move on, free from any thought or hope for the project. Let the people give up hope.

ONO pulls plug on smartphone 3D printer leaving backers empty-handed

0Shares

Kickstarter-funded company ONO has finally pulled the plug on its smartphone-powered resin 3D printer, leaving thousands of backers out of pocket and without the goods they invested in.

As is the nature of a Kickstarter project, backers haven’t directly bought goods from ONO but have instead invested in the project with the reward of an ONO 3D printer and related technology if the project proved successful. Despite this, backers are clearly unhappy with the way the project has unfolded, with some going so far as to call it a “scam”.

Having made its debut in 2016, the ONO 3D printer raised north of $2. 3 million from backers on Kickstarter, yet reportedly only a handful of supporters have received their machine to date. The most recent update from the company, and supposedly the first in more than two years, confirmed “the end” of the ill-fated 3D printing campaign, citing financial and legal reasons as the final nails in the coffin.

3 million from backers on Kickstarter, yet reportedly only a handful of supporters have received their machine to date. The most recent update from the company, and supposedly the first in more than two years, confirmed “the end” of the ill-fated 3D printing campaign, citing financial and legal reasons as the final nails in the coffin.

ONO’s promising start

3D Printing Industry has followed ONO since its early days, or OLO as the company was originally known. The firm debuted what was deemed to be the first smartphone 3D printer on Kickstarter in March 2016 and after raising more than $2.3 million in a month became the fifth most funded 3D printer ever, at the time.

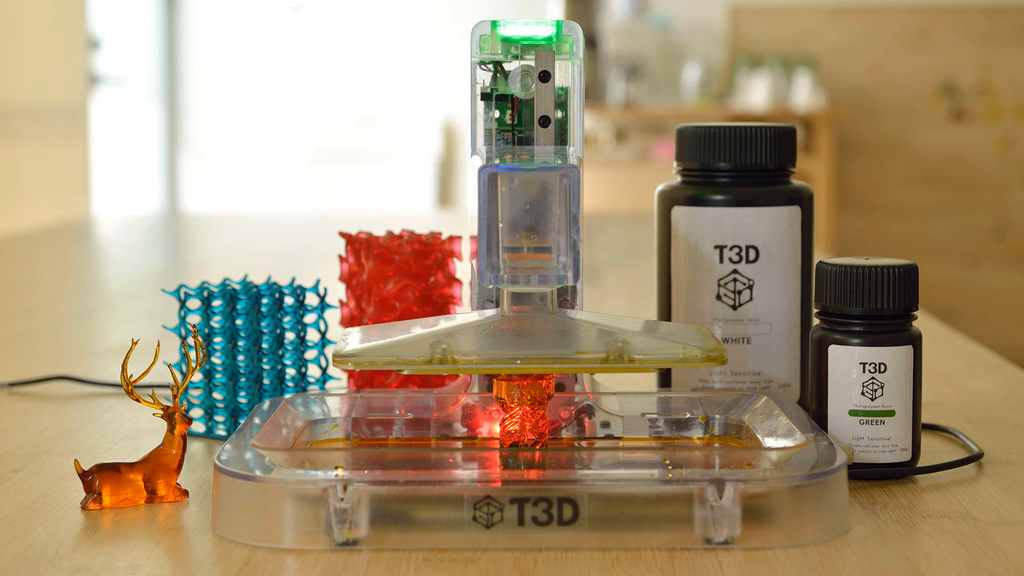

The concept behind the ONO 3D printer was to enable users to 3D print objects directly from their smartphone via an app. Masks of light are projected from the phone onto the printer’s resin tray, hardening each layer of an object as the ONO 3D printer lifts it out of the vat layer by layer. OLO relies on specialty resins that can be cured by ordinary white light, called daylight-reactive materials, as opposed to UV resins which require lasers or digital UV projectors.

Masks of light are projected from the phone onto the printer’s resin tray, hardening each layer of an object as the ONO 3D printer lifts it out of the vat layer by layer. OLO relies on specialty resins that can be cured by ordinary white light, called daylight-reactive materials, as opposed to UV resins which require lasers or digital UV projectors.

The printer has a build volume of 3 x 5 x 2 inches and can reportedly achieve layer thicknesses as fine as 36 microns with a resolution of 42 microns.

Gearing up to the project’s launch, there was significant hype around the printer’s capabilities, exemplified by ONO winning the Editor’s Choice Award at Maker Faire New York. Claiming to transform any smartphone into a 3D printer, the technology undoubtedly appeared promising to backers, so what went wrong?

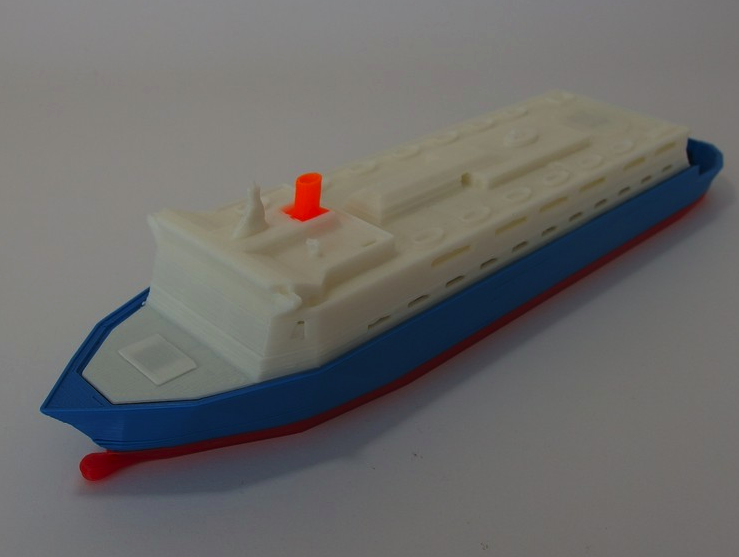

ONO 3D printer and resins. Photo via ONO.ONO to oh no…the demise

ONO originally announced a shipping date of September 2016, however by February the following year backers were still waiting for their printers to arrive. The company announced then that “every backer will have their printer(s) in hand by the end of March”, however four years on and only a handful of printers have been shipped.

The company announced then that “every backer will have their printer(s) in hand by the end of March”, however four years on and only a handful of printers have been shipped.

On July 4th 2021, the company sent a final update to its backers announcing the project’s end, with CEO Filippo Moroni admitting the company had faced “unexpected complexities, unfaithful suppliers, consultants who took advantage of it…and obviously made several mistakes, like so many other projects.”

In the statement, Moroni also revealed he had made “the biggest mistake giving the management and control of the US funds to the wrong person”, but that he and another in the company used their own resources to “avoid disaster, saving peoples’ jobs and recover from this nightmare.”

Moroni claims that after a long absence and silence due to legal issues, he “got rid” of the CEO and partner at fault, taking back 100 percent of his shares of the company and closing pending orders with suppliers using almost $600,000 of his own money. He also says he has “saved several jobs, paid off tax debts, and secured all of the merchandise.”

He also says he has “saved several jobs, paid off tax debts, and secured all of the merchandise.”

Now, ONO is a “bankruptcy safe but resourceless company” that supposedly has a warehouse in China full of components, some 5,000 ready-made printers, and monthly server and warehouse costs that the firm can no longer afford. It is unclear what will happen to this stock, or whether these printers will ever reach their backers.

Moroni ended the statement with the announcement that he has decided to open up the ONO project and its related patents to open-source, however thus far there has been no hint of a GitHub link or other sourcing for the released materials. 3D Printing Industry has contacted ONO to gain clarity on this development.

Unsurprisingly, backers of the project have been vocal in their disappointment regarding the project’s failure, with some questioning the validity of the project and whether there was any intention to ship the printers in the first place. Some have gone as far as to call the project a “scam”, and many have invoked their rights under Kickstarter’s Terms of Use for a refund of their pledged amount.

3D Printing Industry has contacted ONO for a comment in response to these allegations, however as yet we have not received a response from the company.

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows ONO 3D printer and resins. Photo via ONO.

Tags Filippo Moroni Kickstarter Maker Faire New York ONO ONO smartphone 3D printer

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Welcome to the iCover blog! San Francisco-based startup OLO launched its crowdfunding campaign on March 21, 2016, with a preliminary goal of $80,000,000. As of this writing, on March 27, over 8,000 Kickstarter backers have donated $1,135,401. With 23 days to go until the end of OLO's introduction, this startup advertising the cheapest 3D printer has every chance of becoming one of the most successful in the platform's history. About what, besides the price of $99 managed to attract the attention of so many backers the OLO baby printer and what the developers promise us for this money, we will tell in this article.

OLO is truly unique in its kind, as it is the world's first resin 3D printer that can be fully controlled by a smartphone app during the printing phase. There are no components traditional for such devices that monitor the correctness of the movement of the print heads here. Moreover, there are no printheads themselves. The material for the production of the required 3D printed objects are liquid polymers that solidify under the influence of light in accordance with the space-time sequence specified by the software algorithm. The screen of a smartphone acts as a source of a controlled light flux, and a special photopolymer resin, created by the authors of the technology for this purpose, acts as a material that hardens under the influence of white light. nine0003

There are no components traditional for such devices that monitor the correctness of the movement of the print heads here. Moreover, there are no printheads themselves. The material for the production of the required 3D printed objects are liquid polymers that solidify under the influence of light in accordance with the space-time sequence specified by the software algorithm. The screen of a smartphone acts as a source of a controlled light flux, and a special photopolymer resin, created by the authors of the technology for this purpose, acts as a material that hardens under the influence of white light. nine0003

As you can see, the idea is really simple: the smartphone is installed in the base of the printer and, using the application, is synchronized with a movable carriage that holds the object in the required position.

The OLO is simple as it consists of only seven plastic parts, two of which are identical, one chip and one motor. According to the authors of the invention, the device was not originally developed for mass production, but, inspired by the results obtained, they decided not to stop there and make 3D printing technology available to everyone. This became the main stimulus for the further development of the project. nine0003

According to the authors of the invention, the device was not originally developed for mass production, but, inspired by the results obtained, they decided not to stop there and make 3D printing technology available to everyone. This became the main stimulus for the further development of the project. nine0003

Are you a jeweler? Designer? Engineer? Architect? Manufacturer of seals and stamps? Dentist? Student? Teacher? Teapot? A man with an unbridled imagination, obsessed with the idea of translating content into form? Then OLO is for you! — Declared by its creators. The first significant step towards the user is the idea of using a smartphone that is already in his pocket as half of the hardware. Taking into account the fact that the number of smartphone owners (without reference to technical characteristics) is estimated at a figure close to 2.2. billion, the availability of technology in the future, even for some users, looks more than attractive. nine0003

nine0003

The work on the project, including the improvement of the mechanical part, the reengineering of microchips, the creation of a fundamentally new line of materials called “Daylight Resins”, took up to 2 years in total. The current version of the prototype works with smartphones of almost any size or brand, turning them into a 3D printer. However, the quality (accuracy) of printing directly depends on the resolution of the smartphone.

The authors of the project managed to make OLO "multi-platform". All it takes to reach the end goal is a flat touch screen smartphone running iOS, Android or Windows. OLO supports smartphones with overall dimensions up to 162mm x 82mm x 10mm and is able to form an object up to 128mm x 76mm x 52mm. nine0003

All you have to do is select the object to print, pour the right amount of resin into a transparent container and start the program, after doing your own business - OLO will do the rest on its own.

OLO rear cameras are designed to prevent light from entering. This allows you to maximize the intensity of white light emitted from your smartphone's display and speed up the printing process. So far, the print speed is not too high, which is largely due to the existing limitations of the technology: using the iPhone 6, you can print 1 cm in about 46 minutes (or 1 inch in about 1 hour and 55 minutes). The application allows you to create your own or use 3D layouts created with any 3D scanning software, including Autodesk 123D Catch, etc.

This allows you to maximize the intensity of white light emitted from your smartphone's display and speed up the printing process. So far, the print speed is not too high, which is largely due to the existing limitations of the technology: using the iPhone 6, you can print 1 cm in about 46 minutes (or 1 inch in about 1 hour and 55 minutes). The application allows you to create your own or use 3D layouts created with any 3D scanning software, including Autodesk 123D Catch, etc.

Mixes of 8 colors (White, Red, Black, Gold, Grey, Cyan, Yellow, Blue) are available for printing. The cost of a bottle (excluding local fees and all other expenses) will be $15 in the future. And it is very possible that it is the patented consumables, and not the device itself, that will become the main source of income for OLO 3D Inc., especially in the future if the company manages to offer an alternative for tablets as well.

The device is powered by standard AA batteries

OLO is powered only by built-in batteries. The charge level is controlled automatically. The application determines if it is sufficient to complete the full print cycle of a particular object. If the charge is not enough, the user will receive a notification before printing. At the same time, it is always possible to connect the charger to the smartphone placed inside. Kickstarter, as the developers explain, is only the first step towards the deployment of a global project, and feedback from users will be very important, thanks to which further improvement of the product will become possible. At the same time, tremendous work has been done for the subsequent successful promotion of OLO to the market: a patent application has been filed and legal protection of the technology has been provided, project partners have been identified - manufacturers, distributors, logistics and major resellers. What makes OLO so good, according to the inventors themselves: — Modern, laconic design: elegant and seamless lines. It is not allowed to mix resins of different colors with each other, but work in this direction is underway. Since resins of all colors will be supplied in black bottles, there are no special conditions for lighting during storage, a dry and cool room is quite enough. nine0003 To make sure that everything that the authors of OLO say is true, we will have the opportunity at the end of the coming summer, when the first users receive the promised kits and form the first opinions and reviews. And we wish the team good luck and the implementation of their current and future plans. Project page Dear readers, we are always happy to meet and wait for you on the pages of our blog. We are ready to continue to share with you the latest news, review materials and other publications, and will try our best to make your time with us useful. HP started shipping its Jet Fusion 3D 4200 Printer 3D printers to customers. The first to receive the devices are the company's partners who supported the development of the novelty - Jabil, Materialise and Shapeways. Jet Fusion 4200 operates on the basis of “HP Multi Jet Fusion technology”, which is a modified SLS (Selective Laser Sintering): layers of special powder are poured layer by layer, the desired areas of the layer are selectively sintered under special lighting. The printing process is as follows: the model file and powder are loaded into the Processing Station, which prepares the printing process in the ”Build Unit”. Next, the Build Unit is removed from the station and installed in the printer itself, and printing starts. Main specifications of the Jet Fusion 3D 4200 Printer (without Processing Station): Processing Station weighs from 450 kg and measures from 1926 x 1245 x 2400 mm to 3121 x 1571 x 2400 mm (with rapid cooling system installed). Read more about HP Jet Fusion 3D printers here. The Jet Fusion 4200 is currently printing with HP's proprietary 3D High Reusability PA12 resin (with the ability to reuse “excess” powder). The device will also support materials from alternative manufacturers (the concept of Open Platform). For example, Evonik recently announced the release of its plastic. Printing materials will also be supplied by BASF, Arkema and Lehmann and Voss. nine0003 Ramon Pastor, Vice President of HP, commented: “6 months ago we released information about our Jet Fusion 3D and a list of forward-thinking companies looking to join HP on the path to the industrial revolution. We hope that this cooperation will lead to a joint development, as a result of which we will achieve unparalleled quality and print economy.” Also soon, HP plans to release a more budget solution with limited speed and layer height HP Jet Fusion 3D 3200 with a price of 130 thousand dollars. With Processing Station - $155,000.

correct dosage in each case? In order to rationalize the use of resin, the process of calculating the required amount for printing a specific object is carried out automatically: the amount of resin will be indicated by the printer itself after the object to be printed is loaded into the application. To prevent software failures during the printing process, the smartphone is switched to the “Flight” mode, Wi-Fi is turned off. nine0003

To prevent software failures during the printing process, the smartphone is switched to the “Flight” mode, Wi-Fi is turned off. nine0003  nine0003

nine0003

— High-quality software that provides simple and easy access to information, the use of cloud technologies

— Possibility of use by the most complete “dummies” in 3D printing technologies.

- Print accuracy: X-Y resolution: up to 0.042 mm (DEP quality) and Z-axis resolution: up to 0.036 mm (0.12 mm fast). nine0005 - Ease of maintenance. No special chemicals are required to clean the working surfaces of the device - just a clean paper towel and alcohol at the final stage.

— Portability + Ultra light: fits easily into a compact bag.

- Automatic leveling: there is no need for manual leveling and calibration.

No Noise: The quietest 3D printer ever made.

- Autonomy: The 3D printer runs on batteries. nine0005 — Maintenance: durable drives that do not require systematic lubrication.

- Durability: made of simple and strong technopolymers.

- The application for OLO will be open for further improvement by third-party developers.

And, of course, do not forget to subscribe to our rubrics. nine0005 Our other articles and events

And, of course, do not forget to subscribe to our rubrics. nine0005 Our other articles and events

HP started shipping Jet Fusion 3D 4200 Printer 3D printers « 3D « Knowledge base MnogoChernil.ru

Powder from unused areas can sometimes be reused. HP claims that its devices are more reliable, print faster (advantage up to x10) and better, and the infrastructure being created in the form of professional software and the market for materials will make their use as convenient as possible. nine0003

Powder from unused areas can sometimes be reused. HP claims that its devices are more reliable, print faster (advantage up to x10) and better, and the infrastructure being created in the form of professional software and the market for materials will make their use as convenient as possible. nine0003

Learn more