How does a 3d printer work wiki

3D printing - Wiki | Golden

3D printing, also known as additive manufacturing or additive layer manufacturing, is the construction of a three-dimensional object from a digital 3D model. The name additive manufacturing comes from the differentiation of 3D printing, which adds material layers upon each other to build an object, from the more traditional process of subtractive manufacturing, which removes material through milling, machining, carving, and shaping to create an object.

Traditionally, subtractive manufacturing has been used for high production volume manufacturing, while additive manufacturing has been reserved for prototyping and rapid tooling. However, the increased cost-effectiveness of additive manufacturing, the reduction of material waste, and the increased mainstream adoption of 3D printing systems has increased the use of additive manufacturing systems. These, along with the increased precision, repeatability, and material range of 3D printing, have increased the use of the technology for higher volume production.

In the case of most 3D printers, a user creates a design using computer aided design software or by scanning an object to print. Software translates the design into the printed layers and framework for the machine to follow. The plan is sent to the printer, which begins creating the object. The materials capable of being printed include polymers, metals, ceramics, foams, gels, and biomaterials.

Processes

Material extrusion

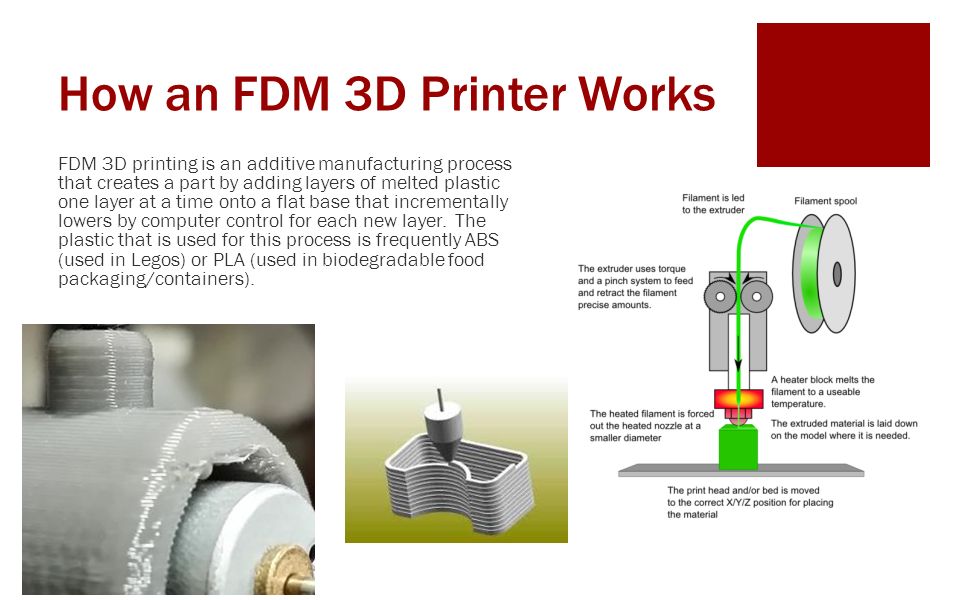

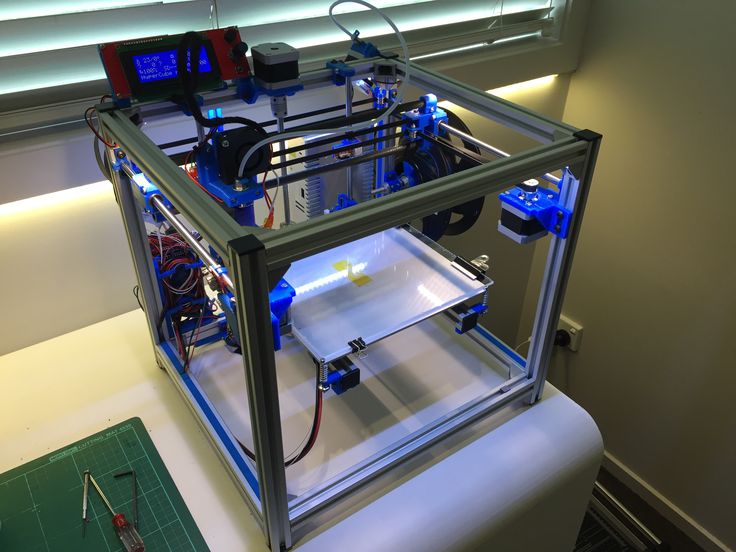

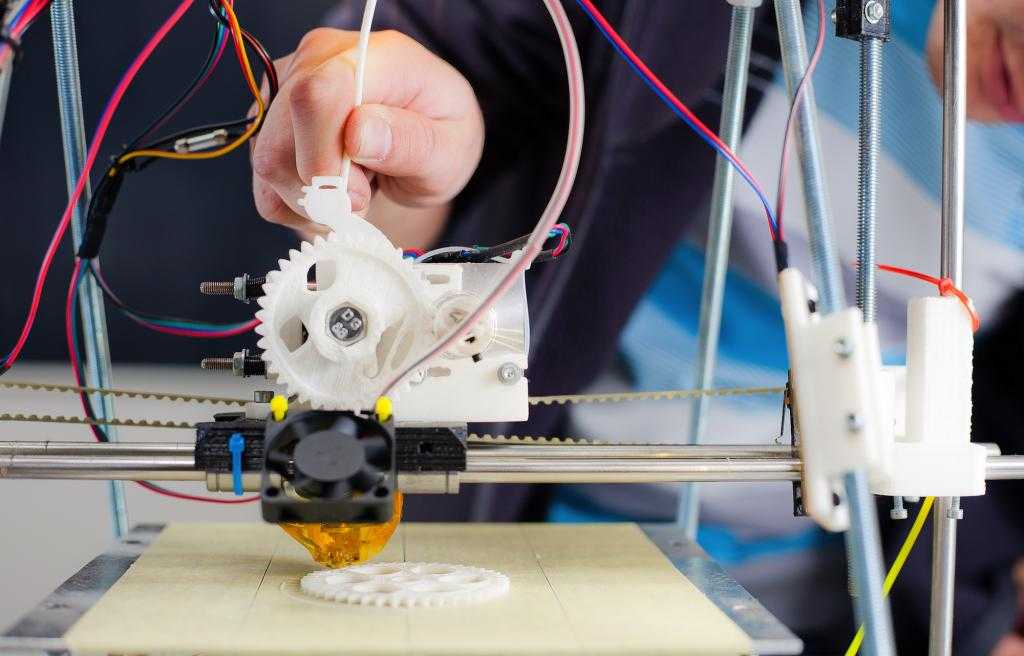

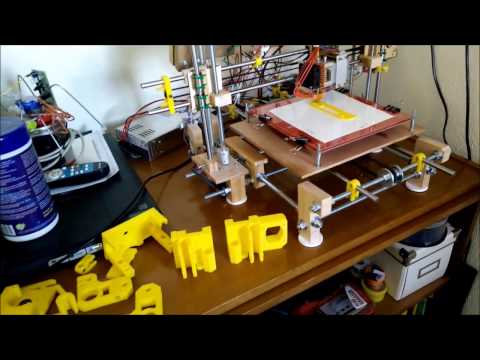

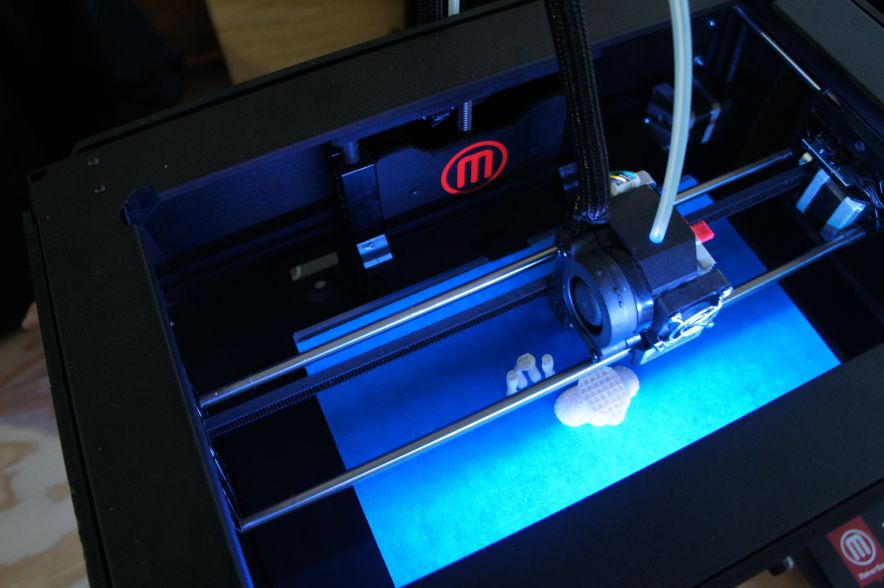

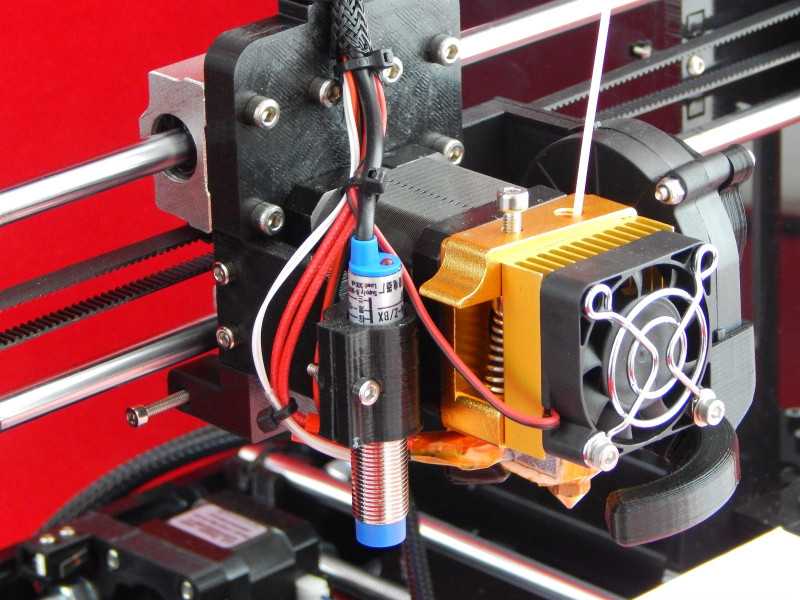

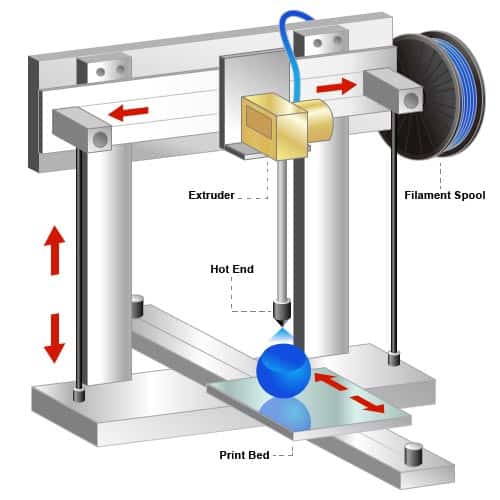

Material extrusion printing, or fused filament fabrication, also known by the trademarked term "fused deposition modeling," is a 3D printing process using a continuous filament of a thermoplastic material. Through this method, filament is fed through a moving, heated printer extruder head and deposited on a growing work. Printers using this method use a computer to control the printed shape. And printers of this type layer the printed object one horizontal layer at a time before making a small vertical move to start the next layer. The extruder head speed can be controlled to start and stop deposition in order to form an interrupted plane without stringing or dribbling between sections. Fused filament fabrication is the more popular printing process (by number of machines) for hobbyist-grade 3D printing.

The extruder head speed can be controlled to start and stop deposition in order to form an interrupted plane without stringing or dribbling between sections. Fused filament fabrication is the more popular printing process (by number of machines) for hobbyist-grade 3D printing.

The fused deposition modeling technique was developed by S. Scott Crump, the co-founder of Stratasys, in 1988. The patent on the technology expired in 2009 and presented the beginning of people using the type of printing without paying rights to Stratasys. This allowed commercial, hobbyist, and open-source 3D printer applications to grow.

The materials capable of being extruded by fused filament fabrication machines include thermoplastics, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high-impact polystyrene (HIPS), thermoplastic polyurethane (TPU), and aliphatic polyamides (nylon).

Stereolithography (SLA)

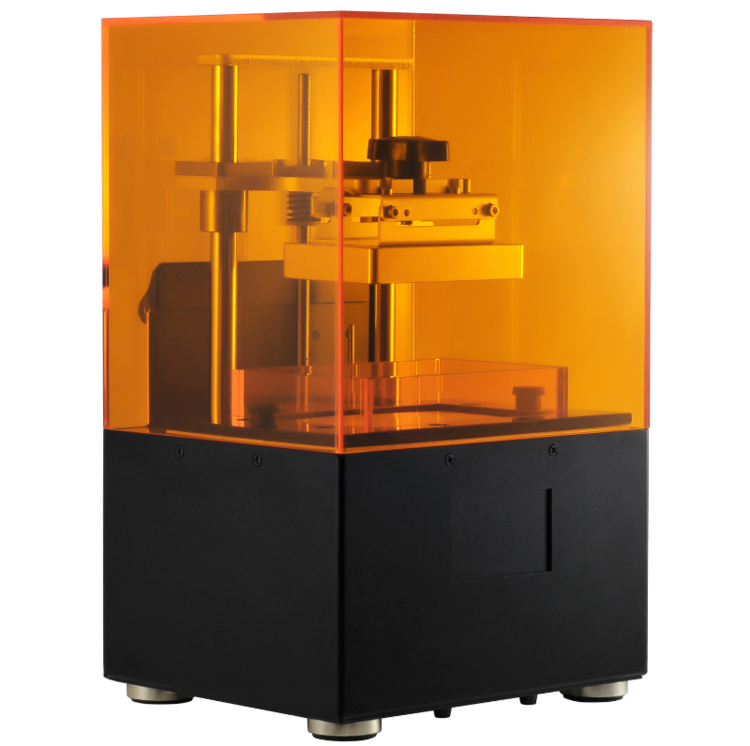

Stereolithography (SLA), also known as optical fabrication, photo-solidification, VAT photopolymerisation, or resin printing, is a 3D printing technology that prints parts in a layer-by-layer fashion using photochemical processes. SLA uses light to cause chemical monomers and oligomers to cross-link and form polymers that, in turn, make the body of a three-dimensional solid. The process is fast and can produce almost any design, but can be cost prohibitive. The main fields of application include products in development, medical models, and computer hardware.

SLA uses light to cause chemical monomers and oligomers to cross-link and form polymers that, in turn, make the body of a three-dimensional solid. The process is fast and can produce almost any design, but can be cost prohibitive. The main fields of application include products in development, medical models, and computer hardware.

The materials used in SLA printing are referred to as resins and are thermoset polymers. These resin materials can be soft or hard, filled with secondary materials such as glass and ceramic, or imbued with mechanical properties such as heat deflection or impact resistance. In the post-process of SLA manufacturing, parts need to be removed from a support structure, and alcohol and water rinses are used to remove excess resin. At times, post processing can include scrubbing to remove additional material, and some processes use ultraviolet light for a post-cure process.

Stereolithography was first developed in the early 1980s by Hideo Kodama, who used ultraviolet light to cure photosensitive polymers. French inventors Alain Le Mehaute, Oliver de Witte, and Jean Claude Andre filed an early patent for technology that was later abandoned. The final patent, which gave the process the name "stereolithography," was filed by Chuck Hull in 1984 and granted in 1986. Chuck Hull later founded 3D Systems to commercialize the patented technology.

French inventors Alain Le Mehaute, Oliver de Witte, and Jean Claude Andre filed an early patent for technology that was later abandoned. The final patent, which gave the process the name "stereolithography," was filed by Chuck Hull in 1984 and granted in 1986. Chuck Hull later founded 3D Systems to commercialize the patented technology.

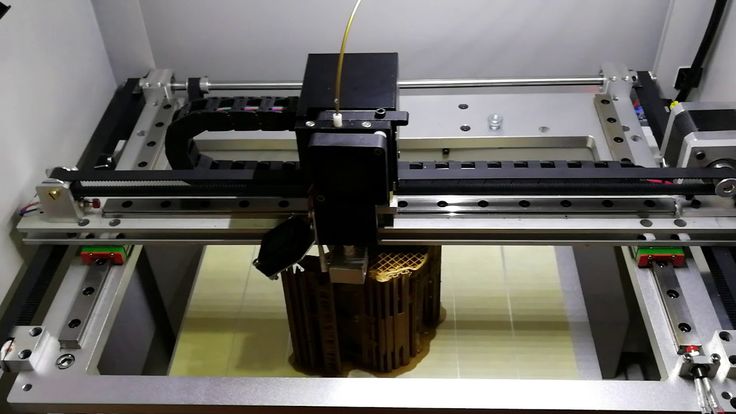

Powder bed fusion

The powder bed fusion manufacturing process includes the printing techniques of direct metal laser sintering, electron beam melting, selective heat sintering (SLS), selective heat sintering, and selective laser melting (SLM). All methods use either a laser or an electron beam to melt and fuse material powder together. The methods involve spreading the powder material over previous layers, using either a roller or a blade while a hopper or reservoir provides fresh material supply. In all methods, a layer, typically 0.1 millimeters thick, of material is built over the platform and the laser or electron beam fuses new material in layers or cross-sections. Materials capable of being used in powder bed fusion manufacturing processes include nylon, stainless steel, titanium, aluminum, cobalt chrome, steel, and copper.

Materials capable of being used in powder bed fusion manufacturing processes include nylon, stainless steel, titanium, aluminum, cobalt chrome, steel, and copper.

In direct metal laser sintering, metal powders are sintered layer by layer with a range of metals available.

In electron beam melting (EBM), layers are fused using an electron beam to melt metal powders. In the EBM process, a vacuum is required with a pressure of 1×10-5 mba, and electromagnetic coils are used to control the beam. The EBM process also produces better strength properties due to even temperature during fusion. These strength properties with the high quality and finish of the product suits it to manufacturing of parts for aerospace and medical applications.

In selective laser sintering (SLS), machines are made up of three components: a heat source, a method to control the heat source, and a mechanism to add new layers of materials. The SLS process requires no additional support structure for the product being printed. In the SLS chamber, nitrogen is often used to maximize the oxidation and end quality of the model. A cool-down period is also required to ensure high tolerance and quality of fusion. Some SLS machines monitor the temperatures layer by layer and adapt the power to improve quality. SLS processes use plastic powders, rather than metal powders used in direct metal laser sintering.

The SLS process requires no additional support structure for the product being printed. In the SLS chamber, nitrogen is often used to maximize the oxidation and end quality of the model. A cool-down period is also required to ensure high tolerance and quality of fusion. Some SLS machines monitor the temperatures layer by layer and adapt the power to improve quality. SLS processes use plastic powders, rather than metal powders used in direct metal laser sintering.

Selective heat sintering uses a heated thermal printhead to fuse powder material. Layers are added with a roller between fusion of layers. The use of a thermal printhead reduces the heat and power levels required for printing. Selective heat sintering systems use thermoplastic powders and require support materials in the process of printing. The process is often used to create concepts prototypes rather than structural components.

Selective laser melting (SLM) is similar to selective laser sintering, except it is faster while requiring the use of an inert gas and requiring higher energy use with poor overall energy efficiency. Through the process, a roller or blade is used to spread new layers of powder over previous layers. In cases when a blade is used, the blade is often vibrated to encourage a more even distribution of powder.

Through the process, a roller or blade is used to spread new layers of powder over previous layers. In cases when a blade is used, the blade is often vibrated to encourage a more even distribution of powder.

Material jetting

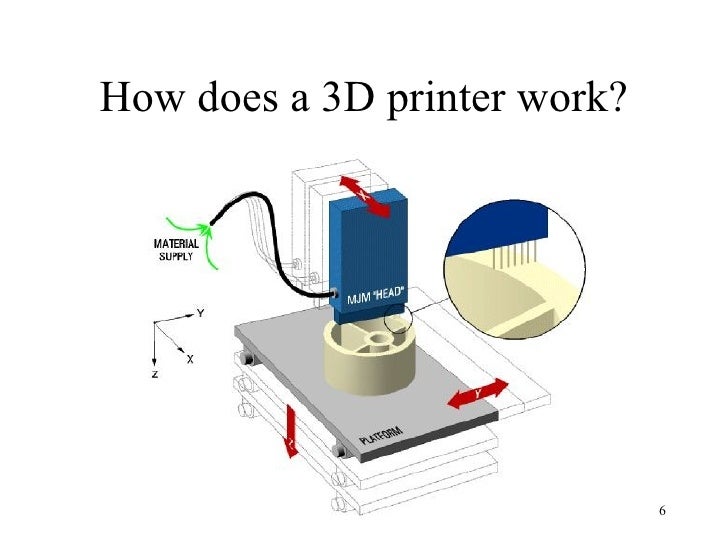

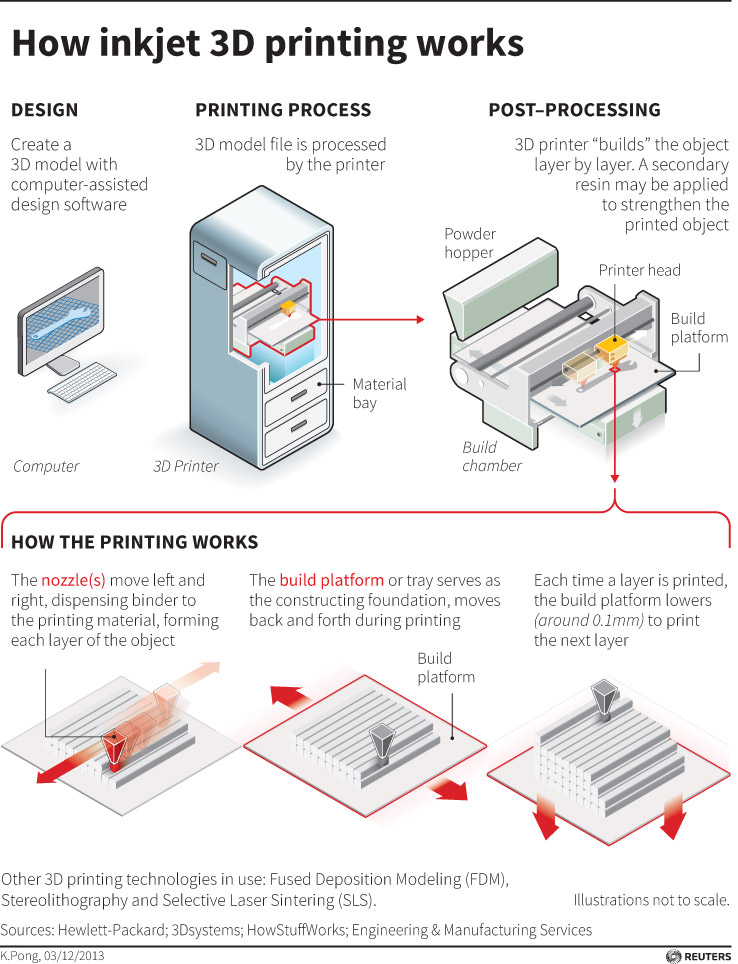

Material jetting, also known as multi-jet modeling, creates objects in a similar method to an inkjet printer. The process uses droplets to build a material on a support structure, while ultraviolight light or heat cures the droplets to create a 3D object. In the technique, droplets are selectively deposited on an X, Y, and Z axis controlled by computer and based on computer-aided designs. Common materials used in material jetting machines include polymers and waxes, due to their viscous nature that can form droplets. Overall, the materials suitable for use in material jetting machines are limited. And the parts printed through material jetting printers are mainly suitable for non-functional prototypes, as the printed parts often have poor mechanical properties.

The types of material jetting technologies include PolyJet technology, NanoParticle Jetting, and Drop On Demand. PolyJet technology jets thin layers of photopolymer material onto a build tray, in which each layer is cured by ultraviolet light. PolyJet technology was the first material jetting technology introduced. The PolyJet process was developed by Object and was later bought by Stratasys.

NanoParticle jetting technology was developed by XJet and uses a dispersion methodology to deposit solid nanopoarticles suspended in a liquid and jetted onto the build tray. In the system, two printheads and thousands of nozzles spray ultrafine drops that both build and support materials onto the build trays, while high temperature in the build area evaporates the liquid jacket around the nanoparticles. The remaining nanoparticles are sintered and the support material is removed, with a thin and smooth surfaced product capable of fine details remaining.

Drop on demand (DOD) technology is a process typically used for viscous materials, and consists of deposits tiny dots of material instead of continuous lines. The printers consist of two heads for each build and support material and are often used for make wax patterns for investment casting. In the printing process, wax material is printed in layers with the support material automatically laid down and eliminating the need for designers to create support structures. The finished part is placed in a liquid bath which dissolves the support material away.

Binder Jetting

Binder jetting is a manufacturing technique in which a binding liquid is selectively deposited to join powder material to form a 3D part. The process does not require heat during the printing process. Exon, an early developer of the binder jetting technique, uses furan binder, silicate binder, phenolic binder, and aqueous-based binder for their binder jetting printers. Regardless of binder, the process of a binder jetting printer sees the application of a layer of material powder, followed by a printhead depositing the binder adhesive on the powder where required until a 3D model is finished. The unbound powder remains until it is removed.

Regardless of binder, the process of a binder jetting printer sees the application of a layer of material powder, followed by a printhead depositing the binder adhesive on the powder where required until a 3D model is finished. The unbound powder remains until it is removed.

Binder jetting processes can manufacture in a range of different colors and in a range of metal, polymers, and ceramics. The two-material process allows for many different binder-powder combinations with various mechanical properties. However, often, through the use of specific binder materials, binder jetting printed materials are not always suitable for use as structural parts.

Sheet Lamination

Sheet lamination is a process of building a 3D object by stacking and laminating thin sheets of material. The lamination method can be bonding, ultrasonic welding, or brazing while a final shape is achieved through laser cutting or CNC machining. Sheet lamination produces parts with the least additive resolution compared to other additive manufacturing processes; however, it is a low cost and offers fast manufacturing times from easily available low-cost material.

The materials involved in sheet lamination include paper, plastic, metal, and woven fiber composites. Forming methods include CNC milling, laser cutting, and aqua blasting. And the lamination techniques include adhesive bonding, thermal bonding, and ultrasonic welding. The process either follows a form then bond process, in which sheet material is cut into shape and then bonded layer on layer to create a 3D object. Or it follows a bond then form process, in which the material layers are bonded and then cut into the desired shape. Sheet lamination types, each offering some kind of variation of the above methods, can be categorized into seven types:

- Laminated object manufacturing (LOM)

- Selective lamination composite object manufacturing (SLCOM)

- Plastic sheet lamination (PSL)

- Computer-aided manufacturing of laminated engineering materials (CAM-LEM)

- Selective deposition lamination (SDL)

- Composite based additive manufacturing (CBAM)

- Ultrasonic additive manufacturing (UAM)

Directed Energy Deposition

Directed energy deposition is an additive manufacturing process that forms 3D objects by melting material as it is deposited using focused thermal energy such as laser, electron beam, or plasma. Both energy source and the material feed nozzle are manipulated using a gantry system or robotic arm. Due to the nature of direct energy deposition, even though it is possible to create 3D objects from scratch, the process is generally used for adding to an existing part or repairing existing parts. Direct energy deposition systems are used in hybrid manufacturing, in which a substrate bed is moved to create complex shapes.

Both energy source and the material feed nozzle are manipulated using a gantry system or robotic arm. Due to the nature of direct energy deposition, even though it is possible to create 3D objects from scratch, the process is generally used for adding to an existing part or repairing existing parts. Direct energy deposition systems are used in hybrid manufacturing, in which a substrate bed is moved to create complex shapes.

Direct energy deposition systems can be used to make metal, ceramic, and polymer parts, although they are primarily used to make metal parts. The types of systems include laser-based systems, such as Optomec's laser engineering net shape system, which uses a laser as the main energy source. An electron beam based system, such as Sciaky's electron beam additive manufacturing system, uses electron beams to melt the powdered material feedstock. And the plasma or electric arc based system, such as Wire's arc additive manufacturing process use electric arcs to melt wire.

The suitable materials for direct energy deposition systems include niobium, titanium and titanium alloys, inconel, stainless steels, hastelloy, aluminum alloy, tantalum, zinc alloy, tungsten, and copper-nickel alloys. Direct energy deposition systems are used in industries such as aerospace, defense, oil and gas, and the marine industry.

Applications

The applications for 3D printing are various across industries and for hobbyist uses with the introduction of lower cost printing technology.

Housing

3D printing is being explored as a construction method that reduces the costs of on-site construction and time-to-build of a home. The application of 3D printing in home construction has been explored as an affordable housing solution for urban areas.

3D printing companies in housing industry

Aerospace

Additive manufacturing systems are capable of producing lightweight parts with complex geometric designs useful for the aerospace industry. In 2013, NASA tested SLM-printed rocket injector during a hot fire test generating 20,000 pounds of thrust. In 2015, the FAA cleared 3D-printed parts for use in commercial jet engines. In the 2017 Paris Air Show, the Boeing 787 displayed FAA-certified structural parts fabricated from 3D printing of titanium wire.

In 2013, NASA tested SLM-printed rocket injector during a hot fire test generating 20,000 pounds of thrust. In 2015, the FAA cleared 3D-printed parts for use in commercial jet engines. In the 2017 Paris Air Show, the Boeing 787 displayed FAA-certified structural parts fabricated from 3D printing of titanium wire.

3D printing companies in aerospace industry

Automotive

The automotive industry has used 3D printing processes for rapid prototyping. As manufacturing techniques have advanced, 3D printing has been used for developing automotive parts. This includes the McLaren Formula 1 racing team using 3D printed parts in their race cars, including a rear wing replacement that took ten days to produce using 3D printers, instead of the five weeks subtractive manufacturing can take. In 2014, Koenigsegg, Swedish supercar manufacturer, used 3D printing for many components. Most of the manufacturing processes extend to the bodywork and related elements, but do not extend to the powertrain.

Healthcare

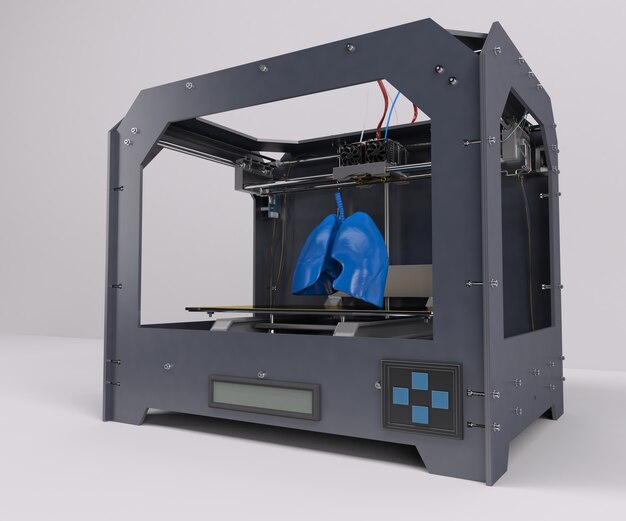

Additive manufacturing has been used in the healthcare industry to produce medical items and prosthetics. This has included medical device manufacturing company Stryker using additive manufacturing technology to create surgical implants for patients suffering from bone cancer. A clinical study done by the New York University School of Medicine is looking into the use of patient-specific, multi-colored kidney cancer models and whether they can effectively assist surgeons with pre-operative assessments.

There have been studies into the viability of 3D bio-printing for use in tissue engineering applications, including the printing of organs and body parts. In the process, layers of living cells are deposited onto a gel medium or sugar matrix to build a three-dimensional structure, including vascular systems. In May 2018, a 3D printing system was used for a kidney transplant to save a three-year-old boy.

In the pharmaceutical industry, 3D printing systems are being used by researchers as a new way to develop formulations of materials and compounds not possible with conventional techniques such as tableting or cast-molding. One of the possible uses of 3D printing in pharmaceuticals is to print personalized dosages to better target patient needs.

One of the possible uses of 3D printing in pharmaceuticals is to print personalized dosages to better target patient needs.

3D printing companies in healthcare industry

Clothing

In the clothing and fashion industry, designers and manufacturers have experimented with 3D printed clothing items, including Nike using 3D printing to prototype and manufacture their 2012 Vapor Laser Talon football shoes and New Balance 3D manufacturing custom-fit shoes for athletes.

Shoes

In 3D printing for shoes, the additive manufacturing techniques offers a chance for creators and designers in the fashion industry to create designs and collections with shapes or designs that could be otherwise unable to create in subtractive manufacturing methods. As well, there are many projects launching to develop new speakers, futuristic lightweight footwear, and customer printed shoes for specific athletes.

Food

Additive manufacturing systems, or analogues, are also being used in the manufacturing of food. The foods printed have included chocolate, candy, crackers, pasta, and pizza. NASA has pursued research into the technology to reduce food waste and design foods to fit astronauts' dietary needs. And in 2018, Giuseppe Scionti developed technology to generate fibrous plant-based meat analogues using a custom-built 3D bioprinter.

The foods printed have included chocolate, candy, crackers, pasta, and pizza. NASA has pursued research into the technology to reduce food waste and design foods to fit astronauts' dietary needs. And in 2018, Giuseppe Scionti developed technology to generate fibrous plant-based meat analogues using a custom-built 3D bioprinter.

Often 3D printing in foods describes an additive manufacturing process, such as an automated pizza vending machine that is capable of extruding dough, topping the dough with tomato sauce and cheese, and sending that to an oven. Food can, especially in the case of viscous foods, be printed fairly easily. 3D printing has been used for decorating and deserts where the accuracy of the printer can create complex designs. However, in the case of other types of food, 3D printing can be more restrictive. As well, in the case of 3D printing new or novel foods, the technology is further behind its peers, as the technology can be prohibitively expensive and often is not scalable.

Firearms

Additive manufacturing has been used in the firearms industry to offer a new manufacturing method for established companies, and has produced possibilities for the do-it-yourself manufacturing of firearms.

All 3D printing companies

What is 3D printing? How does a 3D printer work? Learn 3D printing

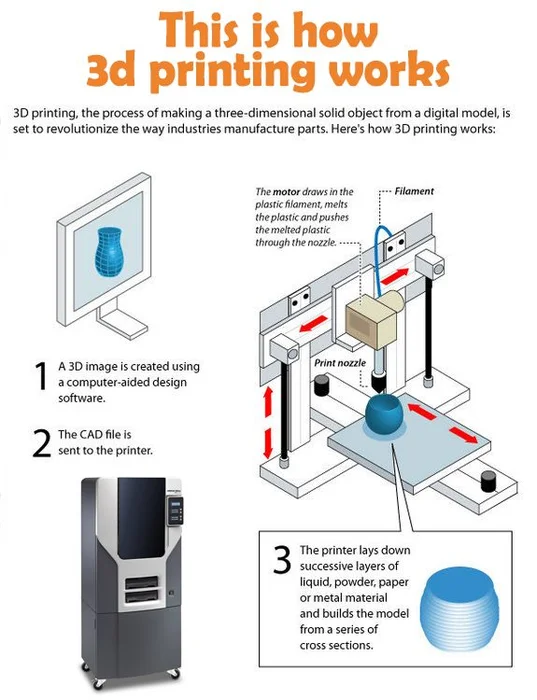

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

The aviation industry uses 3D printing in many different ways. The following example marks a significant 3D printing manufacturing milestone: GE Aviation has 3D printed 30,000 Cobalt-chrome fuel nozzles for its LEAP aircraft engines. They achieved that milestone in October of 2018, and considering that they produce 600 per week on forty 3D printers, it’s likely much higher than that now.

Around twenty individual parts that previously had to be welded together were consolidated into one 3D printed component that weighs 25% less and is five times stronger. The LEAP engine is the best selling engine in the aerospace industry due to its high level of efficiency and GE saves $3 million per aircraft by 3D printing the fuel nozzles, so this single 3D printed part generates hundreds of millions of dollars of financial benefit.

GE’s fuel nozzles also made their way into the Boeing 787 Dreamliner, but it’s not the only 3D printed part in the 787. The 33-centimeter-long structural fittings that hold the aft kitchen galley to the airframe are 3D printed by a company called Norsk Titanium. Norsk chose to specialize in titanium because it has a very high strength-to-weight ratio and is rather expensive, meaning the reduction in waste enabled by 3D printing has a more significant financial impact than compared to cheaper metals where the costs of material waste are easier to absorb. Rather than sintering metal powder with a laser like most metal 3D printers, the Norsk Merke 4 uses a plasma arc to melt a metal wire in a process called Rapid Plasma Deposition (a form of Directed Energy Deposition) that can deposit up to 10kg of titanium per hour. A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. Nearly every hearing aid in the last 17 years has been 3D printed thanks to a collaboration between Materialise and Phonak. Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

Fused Deposition Modeling (FDM)

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing? nine0012

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer—that is, it builds or grows. nine0005

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0005

The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0005

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that converts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print. nine0005

Simply save the file to the included SD card and insert it into your 3D printer and hit print. nine0005

The whole process can take several hours and sometimes even days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

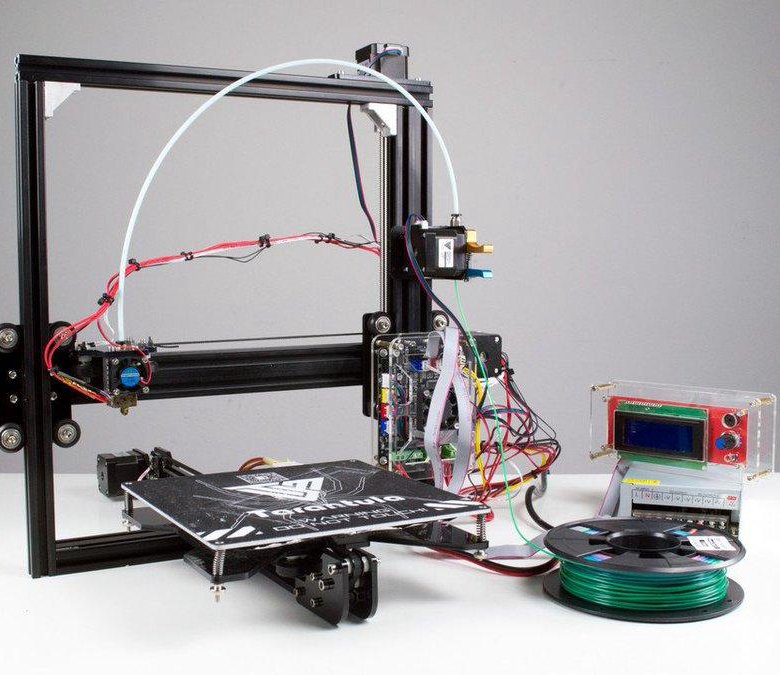

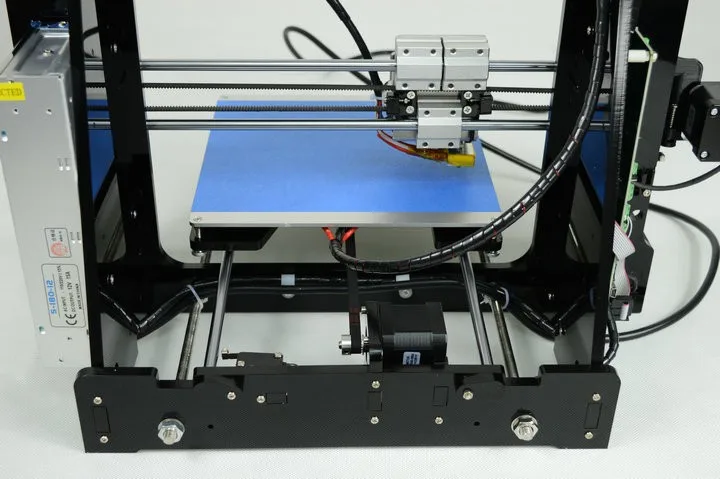

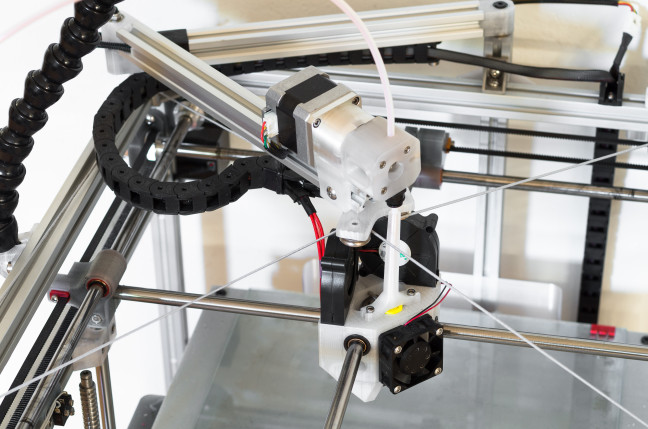

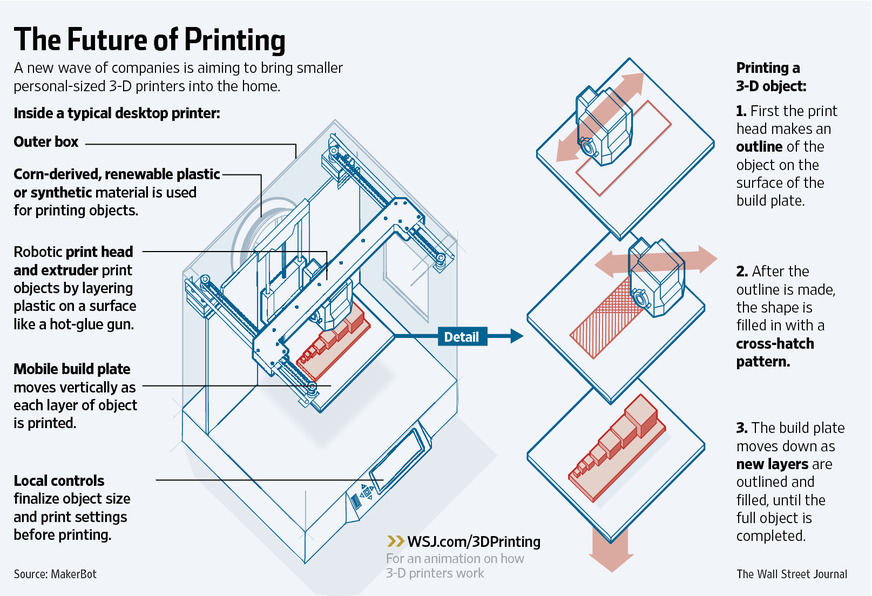

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts in the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed? nine0021

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical usage examples:

Custom Models

Create custom products that perfectly match your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.

Cost reduction

The cost of 3D printing end-use parts and prototypes is low due to the materials and technology used. Reduced production time and material consumption as you can print models multiple times using only the material you need. nine0005

Reduced production time and material consumption as you can print models multiple times using only the material you need. nine0005

How to choose and buy a 3D printer? →

How does a 3d printer work?

In this article, we would like to briefly outline the principle of operation of a 3D printer.

You can read more about the principles of operation of each specific technology here, about how they appeared here, in this article we will briefly describe the principles of operation that unite all the main 3d printing technologies.

3D printing technology is classified as Additive manufacturing, which means production by adding material. However, 3D printing also refers to such a "direction" as digital manufacturing (digital manufacturing), that is, the basis for production is a computer code, in this case acting as a digital 3D model created in one of the programs for 3D modeling. nine0005

A 3d model is a key element in the 3D printing process and the quality of 3D printing, the strength of the model and the cost (cost) of the process itself depend on its shape, parameters and correct preparation. The model must be exported to one of the formats, for example, we accept: STL (main format), STP, IGS, OBJ. Each specific material has its own requirements and limitations for 3D models, however, they will be common to all: volume closed on all sides (no holes, "slits", etc.), minimum wall thickness (at least 1.2 mm for basic materials) , as well as sufficient quality of the surface (to avoid "faceting" of all non-straight sections of the model). nine0005

The model must be exported to one of the formats, for example, we accept: STL (main format), STP, IGS, OBJ. Each specific material has its own requirements and limitations for 3D models, however, they will be common to all: volume closed on all sides (no holes, "slits", etc.), minimum wall thickness (at least 1.2 mm for basic materials) , as well as sufficient quality of the surface (to avoid "faceting" of all non-straight sections of the model). nine0005

Read more about the requirements for preparing a model for 3D printing (including for various materials) here, how to export to STL format - here.

A correctly prepared 3D model is loaded into the 3D printer software, where it (or they) are placed on the platform (for some technologies this is a very important point, for example for plastics), settings are selected for it (for example, layer height) and a task is prepared for printing (the same digital code). The task is transferred to the printer, where, after preparation, 3D printing begins directly. nine0005

nine0005

Above, we wrote that 3D printing refers to the production by adding material. After preparation, the 3d printer starts adding material (or curing it) by moving the print head (or laser beam) along 2 coordinate axes, in accordance with the coordinates that are in the previously prepared 3d print job. Upon completion of the contour, there is a movement along the 3rd axis, by moving the platform to the height of the layer, after which, the creation of a contour along 2nd axes on a new layer begins. When printing is completed, the model is removed from the chamber (most often together with the platform) and is cleaned of supports (more on this below) and / or material residues. nine0005

A 3D model, or rather parts of it, cannot be printed (under certain conditions) without supporting structures. The angle of inclination of the model, limiting the supporting structures, can be set (sometimes), but on average, it is not recommended to print products with an angle of more (or less, as you see) 45 degrees, otherwise there is a risk of marriage.