Office works 3d printing

Australian Office Supply Store Officeworks is Introducing In-Store 3D Printing Services - 3DPrint.com

Remember a few years ago when tech writers were tripping over themselves to call 3D printing nothing more than a fad? Contrarianism for contrarianisms sake is nothing new, especially in the technology journalism world. Nearly every leap forward is often met with a chorus of naysayers dooming technology before it even leaves the starting gates. From the television to the internet, there has always been a healthy dose of skepticism based not on evidence or facts but rather a profound dislike based on personal preference.

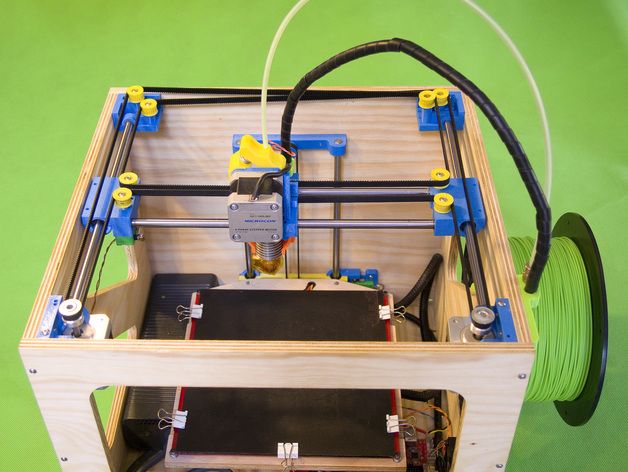

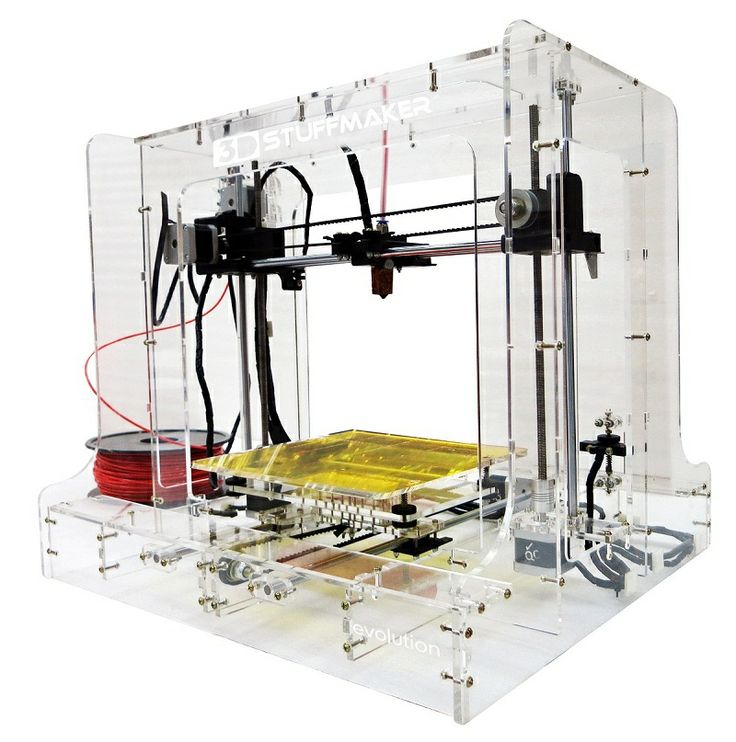

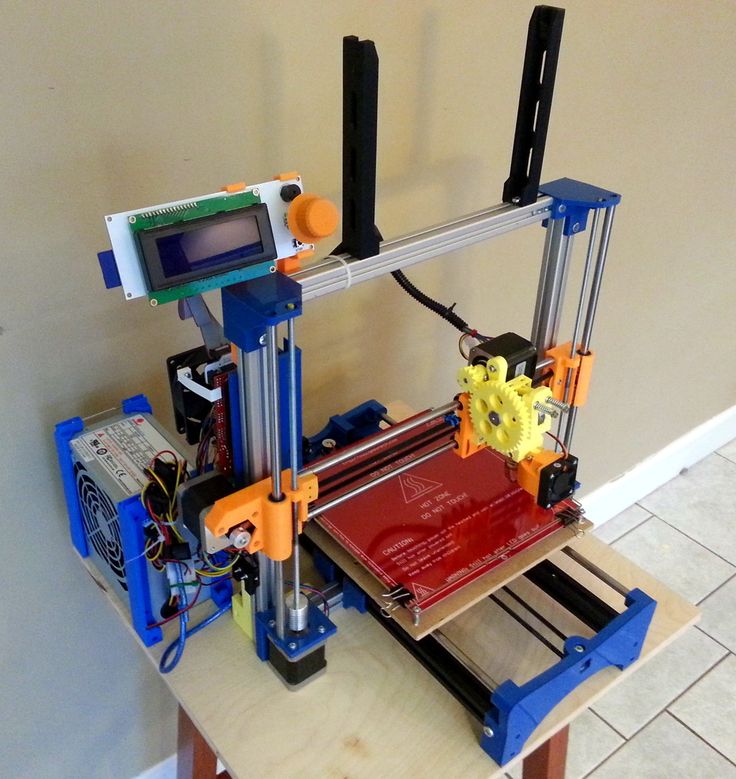

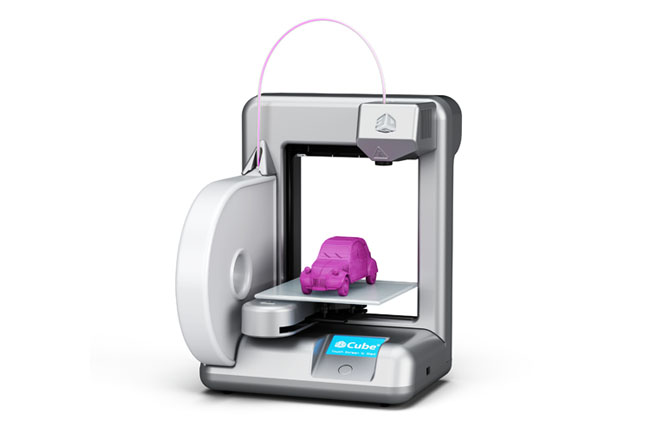

3D Systems Cube was the first model of 3D printer sold by an Australian retailer.

Not that skepticism is bad or unhealthy of course, many terrible products have been uncovered by technology journalists who saw through some shoddy vaporware and called it out. And there are plenty of examples of 3D printing marketing not accurately representing what was really being sold. But the suggestion, even six years ago when the first MakerBot burst onto the scene, that there was no future for 3D printing was just an exercise in empty, uninformed opinion. While desktop 3D printing may have been new, industrial 3D printers were already in use throughout a wide range of industries. 3D printing wasn’t invented by MakerBot or the Reprap community, it was simply popularized and miniaturized.

With news coming out that one of Australia’s largest office supply store chains will begin offering in-store 3D printing services, hopefully the last nail will be beat into the notion that 3D printing is a fad. Officeworks will be the first large Australian chain store to offer these services, and this comes after they were the first retailer in the country to sell 3D printers in their brick and mortar locations. They join North American based companies like The UPS Stores, Staples and even Home Depot in offering in-store 3D printing, who treat the service with just as much seriousness and commitment as all of their other offered services. 3D printing isn’t a fad to these stores, it is a viable revenue stream that they are all beginning to heavily invest in.

3D printing isn’t a fad to these stores, it is a viable revenue stream that they are all beginning to heavily invest in.

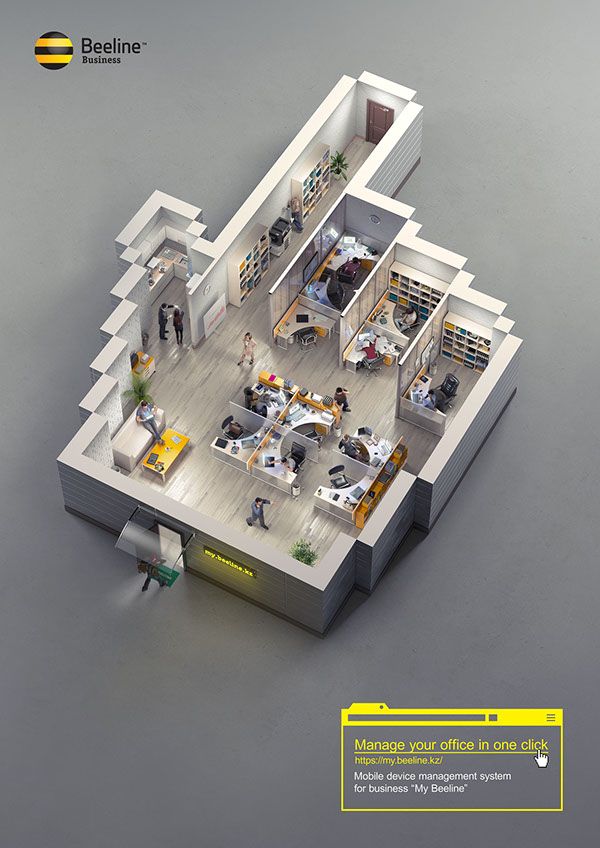

Officeworks is set to open it’s very first 3D Experience Centre in their Russell Street, Melbourne location on June 15th. The 3D printing center will offer a full selection of 3D printing materials, colors and object sizes that can all be selected in store and professionally printed by a trained technician. Customers will simply need to bring in their 3D file on a memory stick and they can either have the completed print delivered to them, or they can pick it up in store.

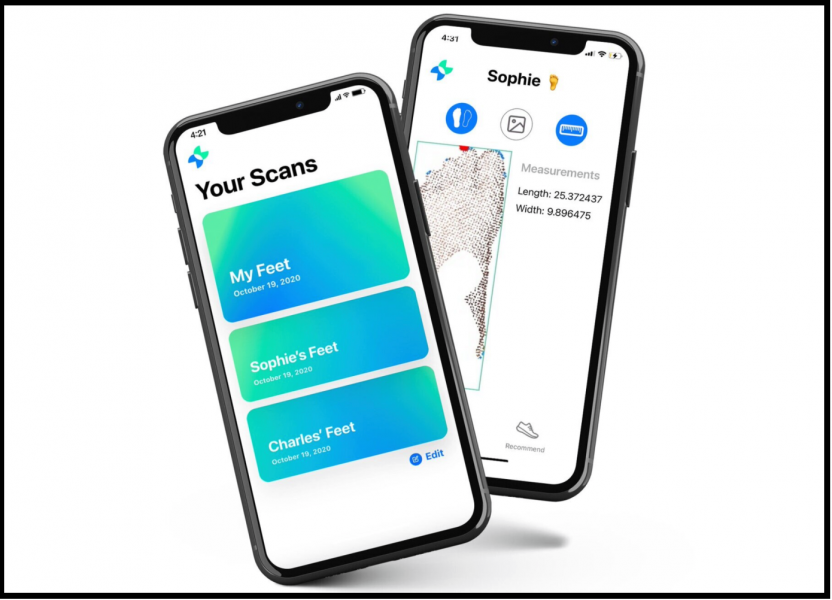

The Officeworks 3D Printing center will also be installing a full-sized 3D scanning both that will use top of the line 3D scanning technology fitted with 160 individual cameras. Customers will be able to have a replica of themselves or any large object scanned and 3D printed. To start, most of the backend support for the new 3D printing services will be handled by an Australian 3D printing company called Keech 3D, however if the new services prove successful I’d imagine Officeworks would begin training their own staff the same way that The UPS Stores and Staples have done.

While the utopian goal of a 3D printer in every home is probably many years off, a greater access to 3D printing is only going to hasten the eventuality. I always thought that 3D printing was interesting and cool, but it wasn’t until I was able to 3D print something myself and watch it happen that I jumped on board. The same psychology behind stores putting computers, cameras and tablets on display for people to hold and use is at play here. Reading a story about 3D printing or seeing pictures of something that was printed is one thing, but the experience of seeing something that you created or downloaded from the internet made tangible is a completely different experience.

I’m hardly in a position to declare a debate over, and this being the internet and all it is bound to continue, but I think it is time to stop acting like 3D printing isn’t going to be a reality. It is time to start taking it seriously and help find it’s proper place in our society. What do you think about the future of 3D printing? Talk to us in the Officeworks is Introducing In-Store 3D Printing Services forum at 3DPB. com.

com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing services • 3d scanning services • 3d systems • australia • cube 3d printer • in store 3d printing services • officeworks • retail 3d printing

Please enable JavaScript to view the comments powered by Disqus.

How To Make 3D Printed Stuff Without Owning A 3D Printer

Eric Ravenscraft

Published 7 years ago: March 18, 2016 at 7:30 am -

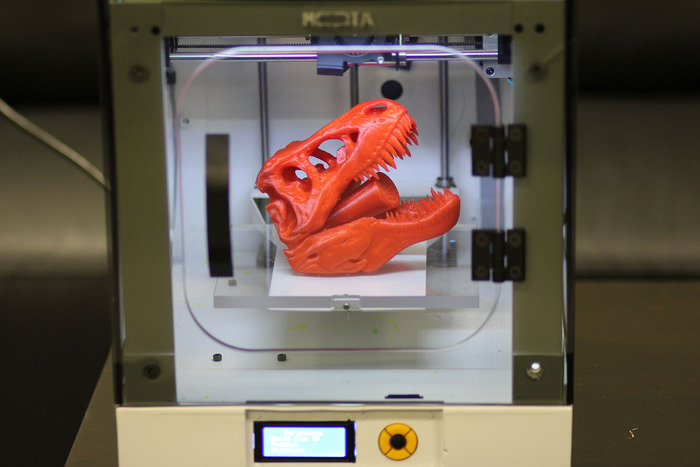

3D printing is really friggin’ cool, but promises that we’d all have one in our homes by now have turned out to be less than true. Fortunately, you don’t need one of your own to bring your imaginary creations to life. Photos by Creative Tools and Karen Blakeman.

You may still be wondering why you should care about 3D printing to begin with. It’s a fair question! While 3D printer prices haven’t plummeted like some expected, the community around them has grown considerably. Sites like Thingiverse have huge libraries of ready-to-print models. You can download everything from cool stuff like a miniature Millennium Falcon (a neat gift idea!), to useful things like phone stands or cord protectors. There are a ton of things that you can print that are absolutely worth what they cost to make. They just might not be worth thousands of dollars for the printer, as well. If your hang-up is the hardware, here are some places that will let you print out objects without buying a mini factory.

It’s a fair question! While 3D printer prices haven’t plummeted like some expected, the community around them has grown considerably. Sites like Thingiverse have huge libraries of ready-to-print models. You can download everything from cool stuff like a miniature Millennium Falcon (a neat gift idea!), to useful things like phone stands or cord protectors. There are a ton of things that you can print that are absolutely worth what they cost to make. They just might not be worth thousands of dollars for the printer, as well. If your hang-up is the hardware, here are some places that will let you print out objects without buying a mini factory.

Things to Consider Before You Print

Before you pick a place that’s going to make your 3D object, you need a 3D model to actually print. There are a few things you need to consider when you’re looking for something to make. Contrary to early adopter opinion, 3D printing isn’t the best solution for everything. When you’re getting started, ask yourself a few questions:

- Does what I want already exist somewhere else? When I was browsing 3D printed objects, I found a potentially useful bag carrier that would make bringing in groceries easier.

Then I found this thing on Amazon for $US6. 3D printing is cool, but it’s not always necessary. Before you order something, see if a regular mass-produced version exists.

Then I found this thing on Amazon for $US6. 3D printing is cool, but it’s not always necessary. Before you order something, see if a regular mass-produced version exists. - Does the model have any flaws? In case you’ve never worked with 3D models before, let me give you a tip: they’re hard to get right. Before you spend money on an object, read reviews where available, or look for pictures of an item after it’s been printed, rather than just the renders of what an object “should” look like.

- Do I need to alter or tweak this model? While you can technically change any 3D model using modelling software, some objects are easier to tweak than others. Thingiverse has an entire collection of customisable items with specific aspects you can tweak to fit your needs, like a Christmas tree stand with an adjustable diameter, so you can make it fit your tree. Before you download and print a model, make sure you check out all the possible ways to customise it that are available.

- What materials will this be made of? Wait, aren’t all 3D printed objects just coloured plastic? Nope. You can get 3D printed objects in wax, sandstone, porcelain and even precious metals like gold and silver. That’s super awesome, but it’s also another thing that can affect your object. If you’re going to make something other than plastic, check out material sample kits so you can see how durable your object might be, or how intricately it can be printed.

Even if you do your due diligence, keep in mind that printing isn’t always perfect. You may get an object that you need to sand down to make it look just right, or you may have an intricate object that doesn’t quite line up. Be prepared for the possibility that something might not come out exactly the way you envisioned it.

Option One: Order Through Online Services

Several 3D printing services have popped up in the last few years that allow you to upload your own models and get them printed in whatever material you want. One of our favourites is Shapeways. This site lets you upload your own designs and get an immediate quote on how much a particular object will cost in a variety of materials. You can explore the object in a 3D model viewer.

One of our favourites is Shapeways. This site lets you upload your own designs and get an immediate quote on how much a particular object will cost in a variety of materials. You can explore the object in a 3D model viewer.

If you don’t have a ready-made 3D model to work with, services like You3Dit will pair you with designers who can help you create what you want, then print it for you. This can be a little more expensive than just uploading a model and ordering a print, but it also reduces the likelihood that you’re going to get a botched product. Not to mention, most 3D printing services will use industrial-grade equipment that can get a lot more detail than the typical consumer models that you’re used to seeing in stores.

Option Two: Get a Quick Print at Local Stores

I have a confession: I don’t own a printer. And not the 3D kind: I don’t own a regular, 2D paper printer either. I just have so few instances where I need to print something, and unused printers break so much, that it just makes more sense to go down to the local library and print something when I need it. Unsurprisingly, some stores have decided that this concept works just as well for 3D printing and now offer in-store printing of your own models.

Unsurprisingly, some stores have decided that this concept works just as well for 3D printing and now offer in-store printing of your own models.

This is more common in the US than in Australia, however the Russell St Officeworks in Melbourne is equipped with 3D printers. A quick google search also reveals a few speciality 3D printing stores. They may not be nearby for everyone, but if you do happen to live near one, it’s probably easier to drive to a store for a bit, instead of buying a hulking machine just to make a cool figurine.

Option Three: Check Your Local Library

When you get to your local library, among the many other cool things they have, you may find a 3D printer. That’s right, libraries are cool. You heard it here first. If your library has a 3D printer, you may be able to use it for free (though you may have to buy or bring your own materials).

If you want to really get your hands dirty learning how to 3D print objects, this is one of your two best bets. Most libraries won’t have a clerk behind a desk who takes a USB stick and gives you a printed object. They will let you get hands-on with the software and learn how it works. Not every library will have staff that are experts in 3D modelling, but you can experiment on your own and learn how to do it yourself. Learning in a library. Imagine that.

Most libraries won’t have a clerk behind a desk who takes a USB stick and gives you a printed object. They will let you get hands-on with the software and learn how it works. Not every library will have staff that are experts in 3D modelling, but you can experiment on your own and learn how to do it yourself. Learning in a library. Imagine that.

Option Four: Join a Makerspace Community

So far this year, I’ve visited three different Makerspace communities in Atlanta, and every single one has had at least one 3D printer. If you can find a Maker Faire in your town, or a local maker community, and you’re even slightly interested in 3D printing, take a day and visit. If you’re actually looking to learn how 3D printing works, this will be the most educational and likely the most rewarding.

Not only will most makerspaces have shared resources (like 3D printers!), they also have people who are experienced in using them on site. You probably won’t be able to walk in the front door, ask for a print job, and walk out. Instead, you can join classes, or work directly with someone who knows what they’re doing.

Instead, you can join classes, or work directly with someone who knows what they’re doing.

In my experience, this was the best way to get started with 3D printing, as you learn some of the intricacies of what you’re doing, not to mention the problems that can arise. Despite cool demo videos, prints can become improperly aligned, nozzles can get clogged or material can come out unevenly. All of these can quickly ruin a project, especially if you don’t know how to fix your printer.

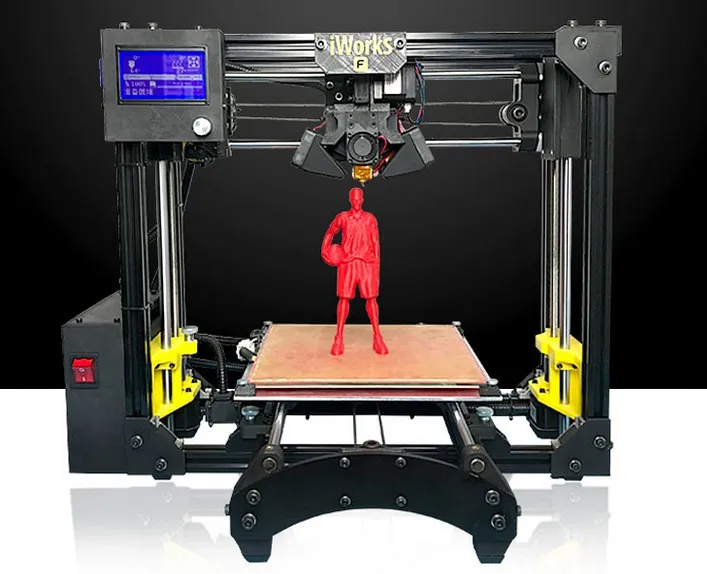

Owning a 3D Printer Probably Isn’t a Good Idea to Begin With

With all of these options on the table, you might reasonably start to wonder, “Is it ever going to be worth owning a 3D printer?” And the truth is… probably not? It’s easy to imagine a wonderful world where anything you can imagine, you can build. The reality is that 3D printers are still printers. They get clogged, jammed and misaligned, and they can ruin your day when they don’t work right.

3D printing services, on the other hand, are much more consumer friendly. You can use models you find online (or make yourself) and get someone else who knows what they’re doing to make the product itself. If you really want to get one to learn how to make your own stuff, libraries and makerspaces are going to be way better for you than just buying a 3D printer for your house and fiddling with it until something good comes out. For enthusiasts and regular makers, owning a 3D printer might be a great idea, but for the rest of us, contracting that work is likely going to be the best bet for a long time to come.

You can use models you find online (or make yourself) and get someone else who knows what they’re doing to make the product itself. If you really want to get one to learn how to make your own stuff, libraries and makerspaces are going to be way better for you than just buying a 3D printer for your house and fiddling with it until something good comes out. For enthusiasts and regular makers, owning a 3D printer might be a great idea, but for the rest of us, contracting that work is likely going to be the best bet for a long time to come.

More From Lifehacker Australia

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution for building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- 3D printing in civil engineering

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How can 3D printing be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

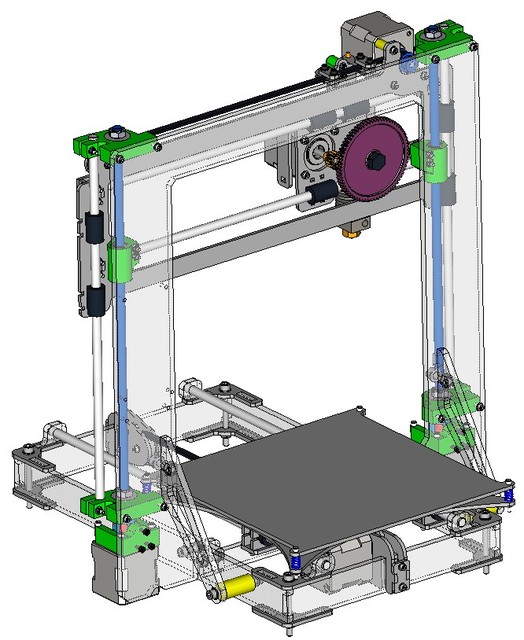

3D printing for construction uses both a 3D printer that has a robotic “crane-arm” that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it has only been in the last decade that this technology has been improved enough (and the cost has been reduced significantly) that it has become a real mainstream.

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of different materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine starts layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

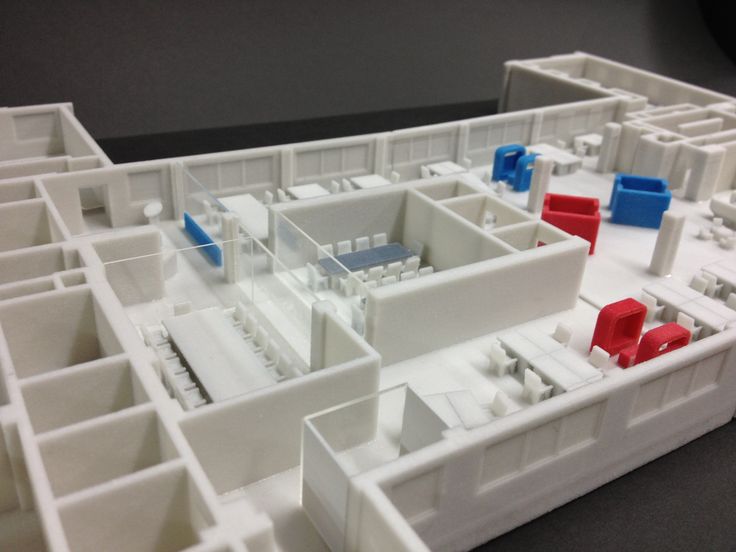

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed license plate at Lewis Grand Hotel, Philippines

3D printed license plate at Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs be useful for construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry.![]() According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the entire design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future, more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future some time ago, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Skilled labor shortage

With the current problem of a shortage of skilled labor in the construction sector as a whole, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and most likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.

ABOUT PLANRADAR

PlanRadar was founded in 2013 and provides an innovative mobile software solution for construction and real estate. Our app is available on all iOS, Android and Windows devices and has already helped over 13,000 customers digitize their workflow in over 55 countries. Find out more about the app here.

Vacancies

Home

Vacancies

Your job in the largest digital production integrator

Send resume

By clicking the button, you agree to the processing of personal data.

Find out more about us

www.top3dshop.ru

How our

works the company from the inside

www.habr.com

How the company was created - an unusual story

www.rbc.ru

Millions in 3D: Who and how makes money on 3D printing

Video about us

Our certificates and references

We sell

Why you will like it here

The Top 3D Shop team brought together people with experience in large international companies who understand how to make a quality product. A feature of our corporate culture is a high degree of openness and trust within the team, the ability to value ideas based on their usefulness, and not the age and status of the person who proposes them.

A feature of our corporate culture is a high degree of openness and trust within the team, the ability to value ideas based on their usefulness, and not the age and status of the person who proposes them.

The company grows because the team solves the most ambitious tasks and is not afraid to take on difficult challenges. For its part, Top 3D Shop offers the best conditions on the market, including opportunities for rapid career growth and decent wages.

Our conditions

Best training programs

High level corporate training: online and offline trainings on leadership, corporate culture, products and business processes.

Close-knit team

No random people - only professionals. Plus - a community where you can always get support.

Participation in conferences

Russian and international exhibitions, conferences and seminars are open to you. Extensive opportunities for the exchange of experience and access to technological innovations and up-to-date knowledge of the industry.

The widest product portfolio

We work with customers from such areas as automotive, medicine, design and advertising, dentistry, construction, aerospace, military and food industries.

Comfortable office

Cozy offices in Moscow (5 minutes from Alekseevskaya metro station) and St. Petersburg (5 minutes from Frunzenskaya metro station).

Comfortable workplace

Modern technology and everything you need for successful work is already waiting for you in Top 3D Shop.

Food and recreation

You can have a snack in a separate kitchen, where there is always tea and fruit, and have lunch in an inexpensive canteen on the territory of the office.

Free English

For experienced employees.

Corporate events and sports

We communicate informally and have fun at boring corporate parties, we hold team competitions in football, volleyball and basketball.

Decent pay

Everyone answers the question where he wants to be in a year and goes to this goal together with the team. Payments without delay. Interesting bonuses.

Payments without delay. Interesting bonuses.

Rapid professional growth

Gaining new knowledge and competencies opens up opportunities for rapid career growth for any team member.

VHI after probation

Including dental services and sick pay.

Social responsibility

Financial assistance, gift certificate for the birth of a child, travel allowance.

Loan from the company

On favorable terms for employees with experience

Don't take our word for it, look at the company through the eyes of the team

Vyacheslav Nigamedzyanov

Dealer Relations Manager

Good, clean office. Friendly colleagues, good management. The pay system is clear.

Malakhovsky Evgeny

Sales manager prof. equipment

Interesting work in a friendly team. Continuous development of your skills and knowledge. Decent pay.

Larionov Alexander

Service engineer of the service department

Young and close-knit team, excellent communication between departments. Completely satisfied!

Completely satisfied!

Be part of a big story

Custom projects

Professionals

Outstanding results

Vacancies

If you are close to responsibility, diligence, adequacy and thirst for new knowledge - we will be happy to consider your candidacy for one of the open vacancies below.

- Service engineer (3D printers, CNC)

- Account Manager

- Warehouse picker

- Public Procurement/Tender Manager (3D printers, 3D scanners, Machine tools)

- Online store manager

- CNC Machine Sales Manager

- CNC Sales Manager

- Sales manager for robotics and automation projects

How to become our employee

- Contact our HR department.

- Submit a test for the position.

- Go to the office for an interview and tell us about yourself.

Or respond via the feedback form:

Reply

How to find us

Our address: Saint-Petersburg , BC Kyiv, st.